Aluminum-plastic cover film easy to position and cut for blister packaging and preparation method of aluminum-plastic cover film

A technology of blister packaging and aluminum-plastic cover, which is applied in packaging, household packaging, packaged food, etc., can solve problems such as unfavorable cutting, easy rupture, and potential safety hazards, so as to facilitate positioning and cutting, ensure stability, The effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

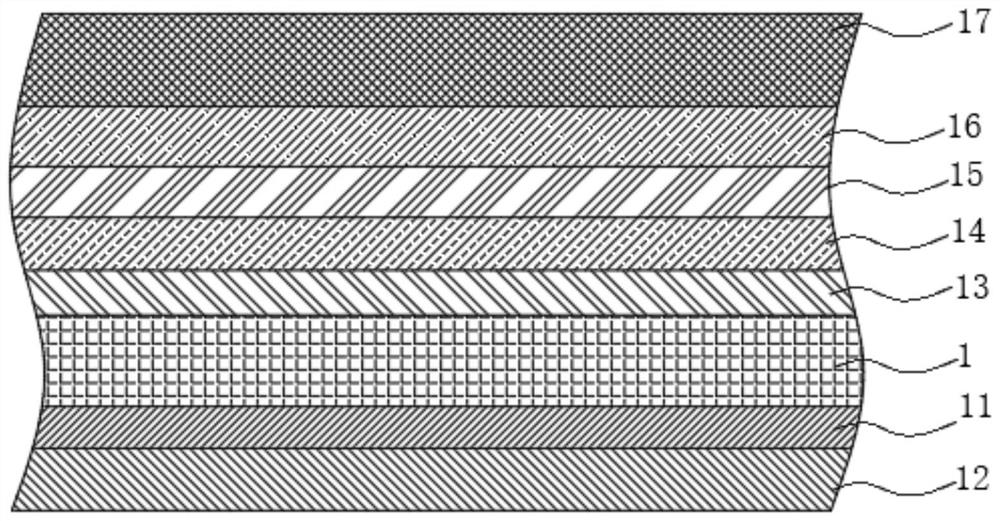

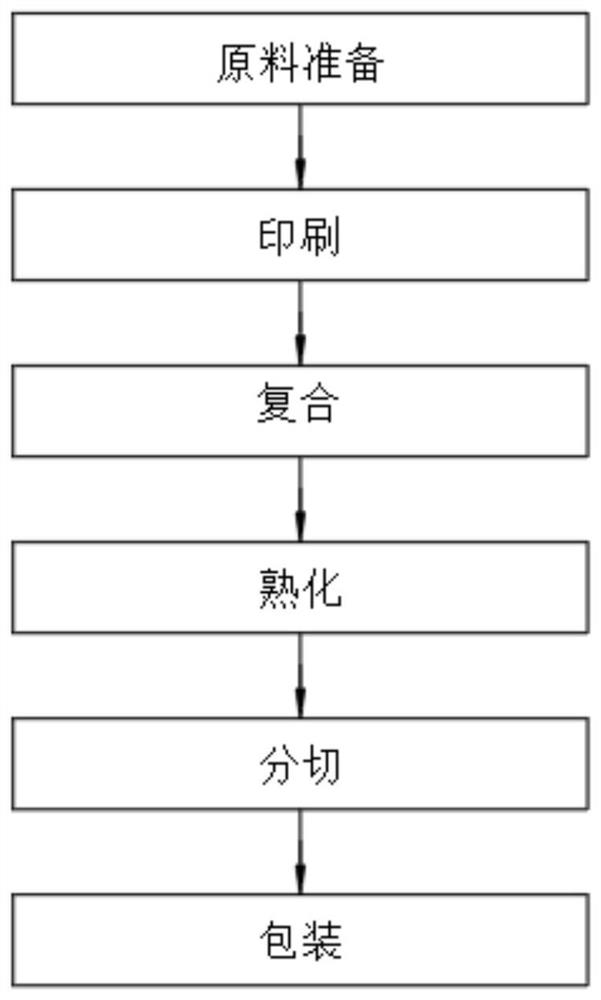

[0022] Example 1: Using aluminum foil as the main raw material, first, adding reinforcing material, heat sealing material, adhesive, polyester film and ink material in sequence to form the corresponding aluminum foil layer, reinforcing layer, heat sealing layer, first adhesive layer agent layer, polyester film layer, second adhesive layer and ink printing layer, then the ink printing layer is sent to a gravure printing machine for printing, a printing layer is formed on its surface, and then the printing layer is coated Varnish, after drying to form a varnish layer, the printing speed is not more than 200m / min, the drying temperature after printing is 50-80 ℃, and then the two sides of the polyester film layer are coated with adhesive respectively, so as not to exceed The speed of 200m / min passes through two groups of drying boxes in sequence, and the temperature in the drying box is set to 55-65°C and 75°C-85°C, respectively. After drying, the second adhesive layer of the firs...

Embodiment 2

[0023] Example 2: Using aluminum foil as the main raw material, first, adding reinforcing material, heat sealing material, adhesive, polyester film and ink material in sequence to form the corresponding aluminum foil layer, reinforcing layer, heat sealing layer, first adhesive layer agent layer, polyester film layer, second adhesive layer and ink printing layer, then the ink printing layer is sent to a gravure printing machine for printing, a printing layer is formed on its surface, and then the printing layer is coated Varnish, after drying to form a varnish layer, the printing speed is not more than 300m / min, the drying temperature after printing is 50-80 ℃, and then the two sides of the polyester film layer are coated with adhesive respectively, so as not to exceed The speed of 300m / min passes through two groups of drying boxes in sequence, and the temperature in the drying box is set to two intervals of 70-80°C and 80°C-90°C, respectively. After drying, the second adhesive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com