Flanging riveting equipment based on engine intake manifold

A technology for intake manifolds and engines, which is applied in the field of riveting equipment for plastic shells and intercoolers, can solve the problems of difficult troubleshooting of intercoolers and large plastic shells, and reduce the time required for the process. The effect of fast and convenient loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In the following description, for purposes of explanation, numerous specific details are set forth in order to provide a thorough understanding of one or more embodiments. It may be evident, however, that these embodiments may be practiced without these specific details. In other instances, well-known structures and devices are shown in block diagram form in order to facilitate describing one or more embodiments.

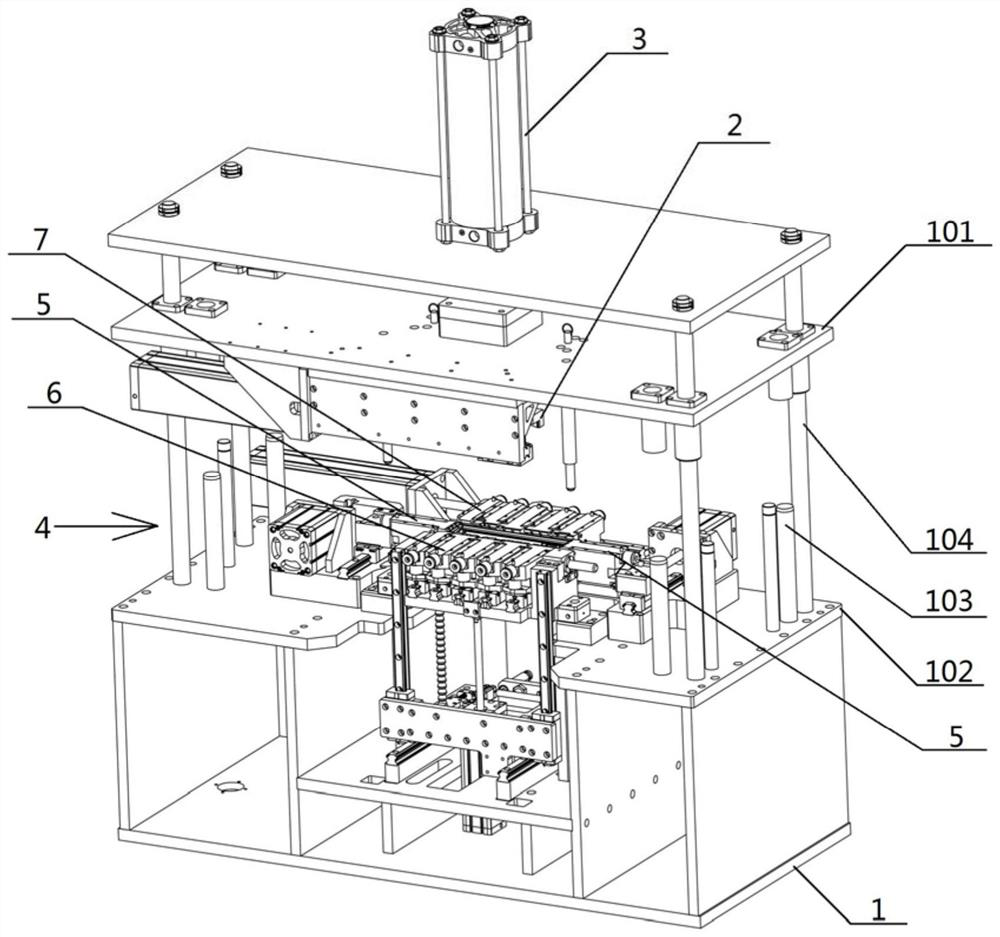

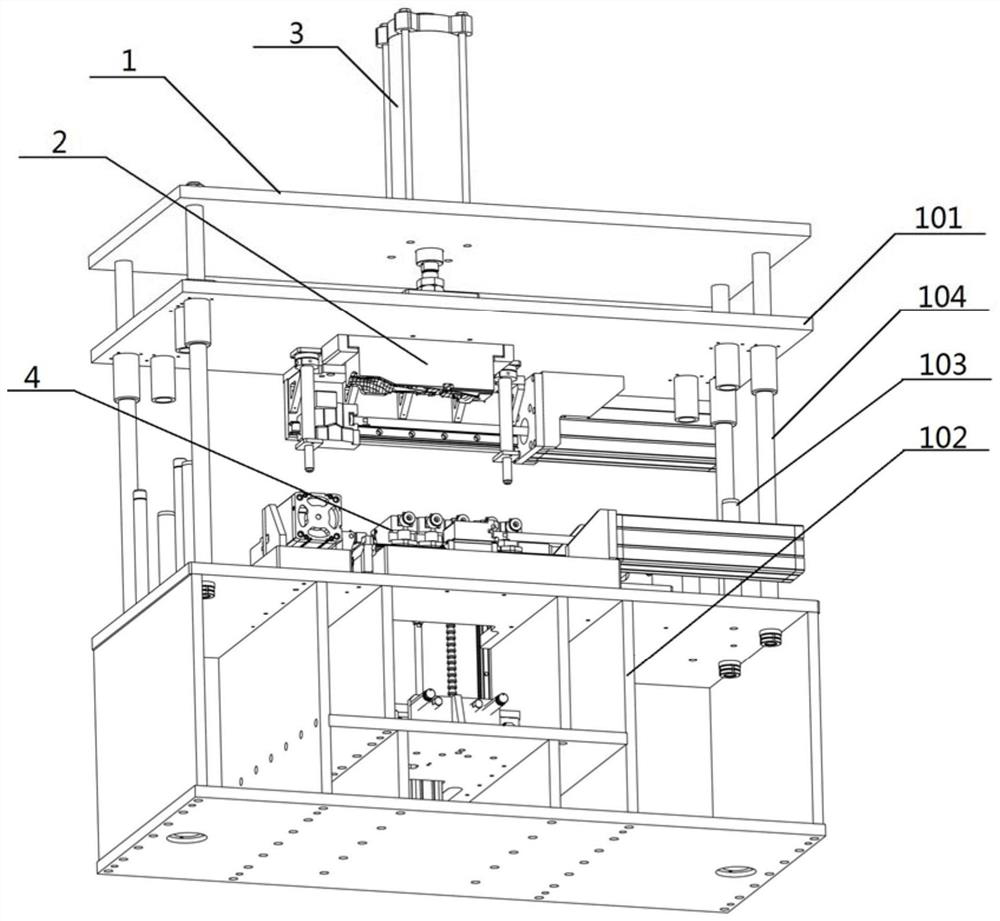

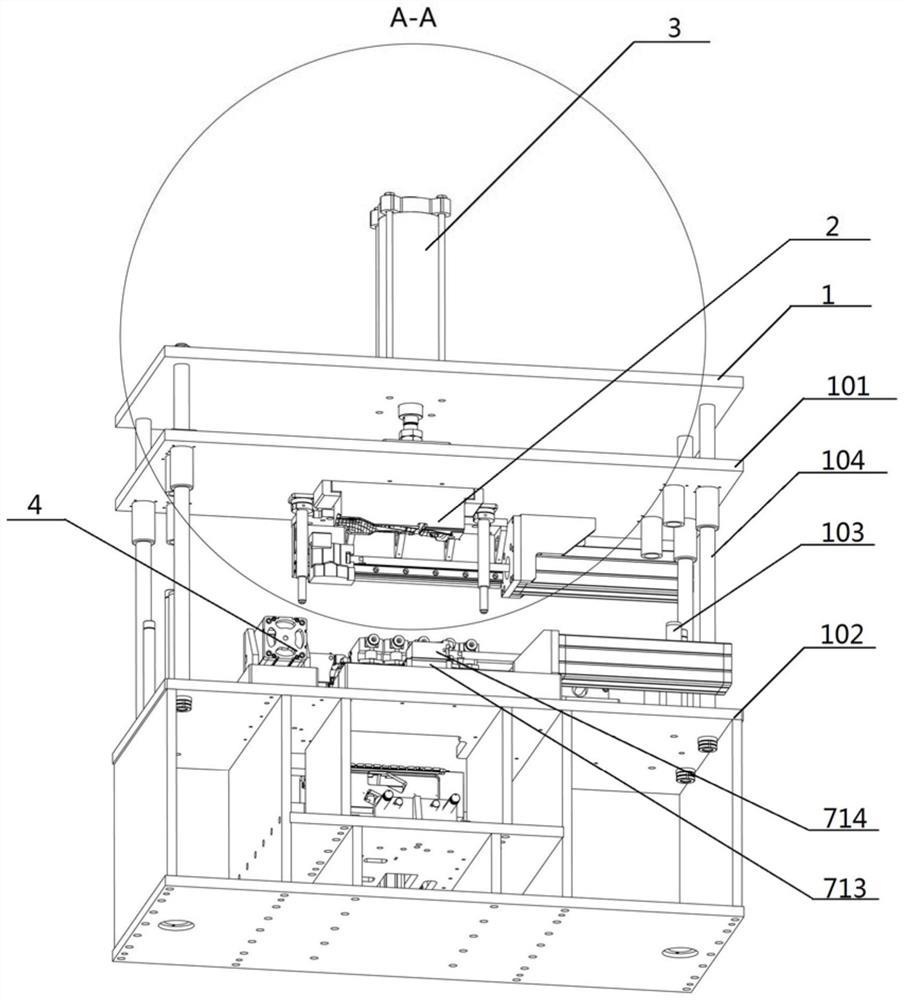

[0040] Figure 1-14 A schematic diagram of the overall structure according to an embodiment of the present invention is shown.

[0041] Such as Figure 1-14 As shown, the flanging riveting equipment based on the engine intake manifold provided by the embodiment of the present invention includes: a frame 1, a profiling tire mold 2 installed on the upper mold platform 101 of the frame 1, and a profiled tire mold 2 installed on the frame 1. And drive the upper mold driving cylinder 3 of the profiling tire mold 2, the flanging riveting device 4 installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com