Vibrating rivet tool for pressing and fixing rivets in component holes and method for the use thereof

A technology for riveting tools and rivets, applied in the field of vibration riveting tools, to achieve the effect of simpler structure, reduced pressure and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

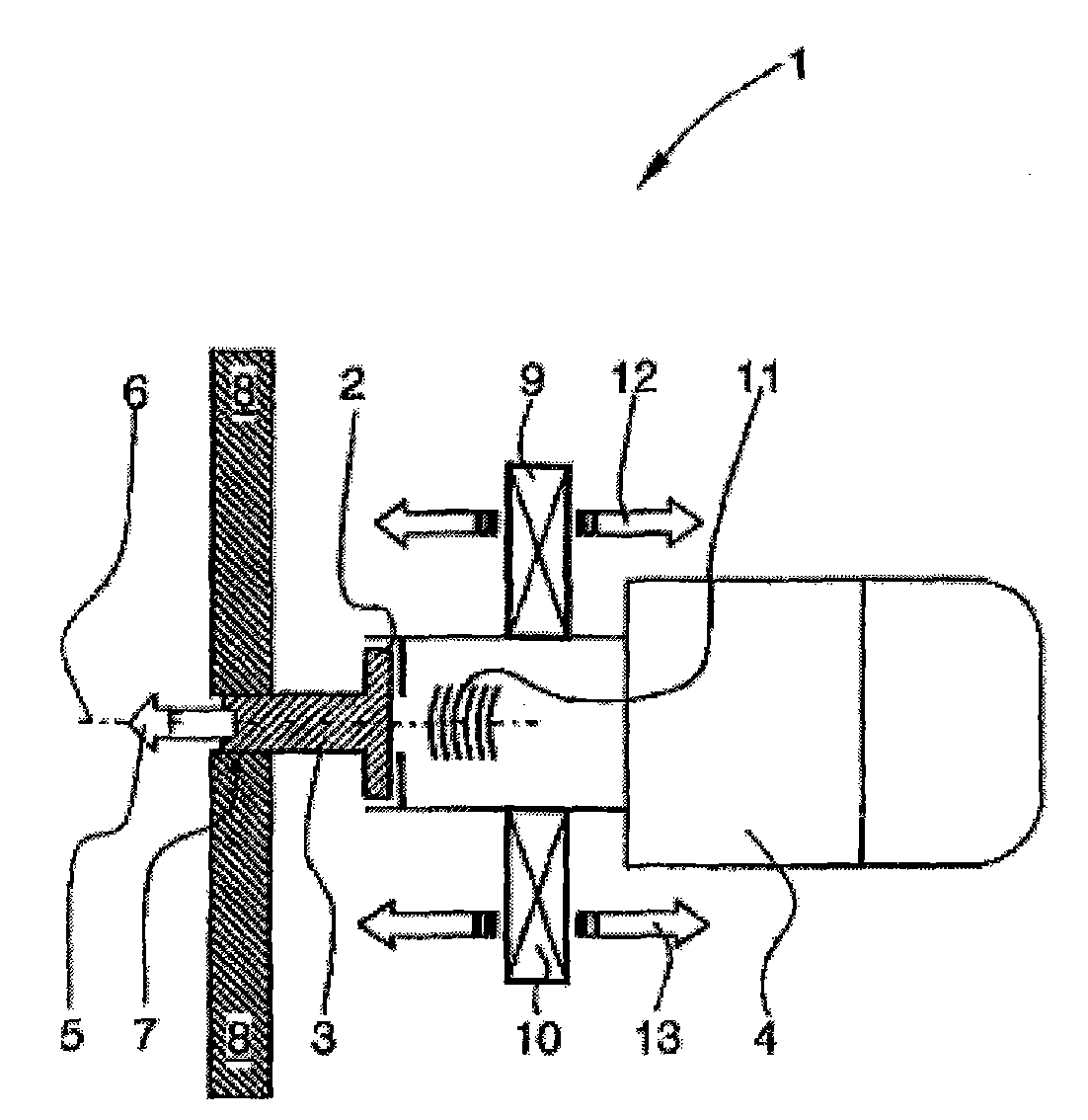

[0021] figure 1 A first variant of a vibratory riveting tool is shown.

[0022] Wherein, the vibration riveting tool 1 includes: a rivet container 2 for accommodating a rivet 3 and a driving unit 4 . The drive unit 4 generates a considerable purely mechanical static pressure 5 which acts substantially parallel to the longitudinal axis 6 of the rivet. In order to facilitate the process of pressing the rivet 3 into the component hole 7 in the component 8, vibration generators 9, 10 for generating mechanical vibrations 11 are arranged in the area of the rivet container 2, the amplitude of which vibration is equal to the static pressure 5 overlay. exist figure 1 In the exemplary embodiment shown, the vibration generators 9 , 10 are arranged diametrically opposite one another in the region of the rivet container 2 . In principle, it is also possible to arrange the vibration generator 9 or the vibration generator 10 only on one side of the rivet container 2 . Furthermore, mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com