Patents

Literature

253results about How to "Strong pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

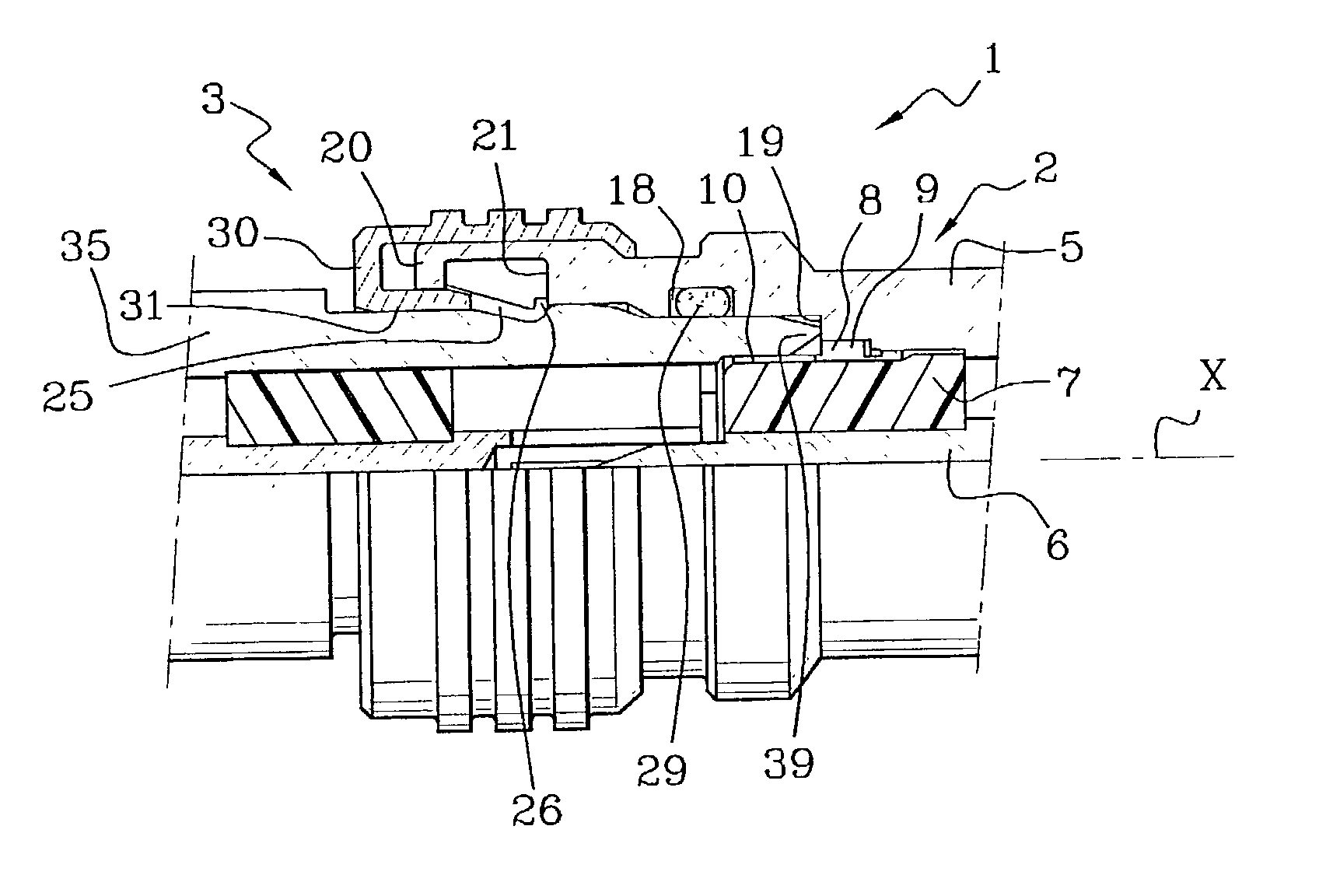

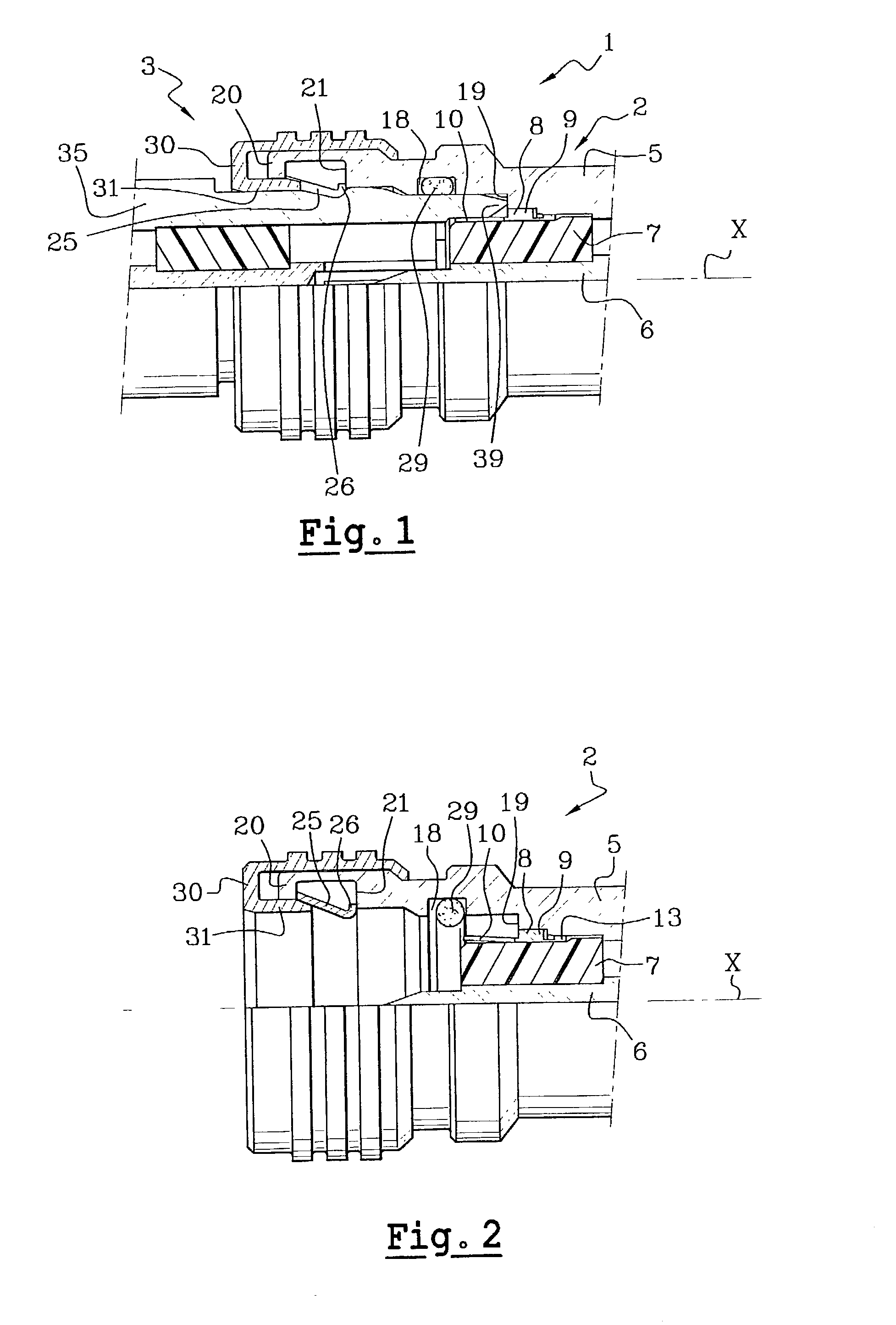

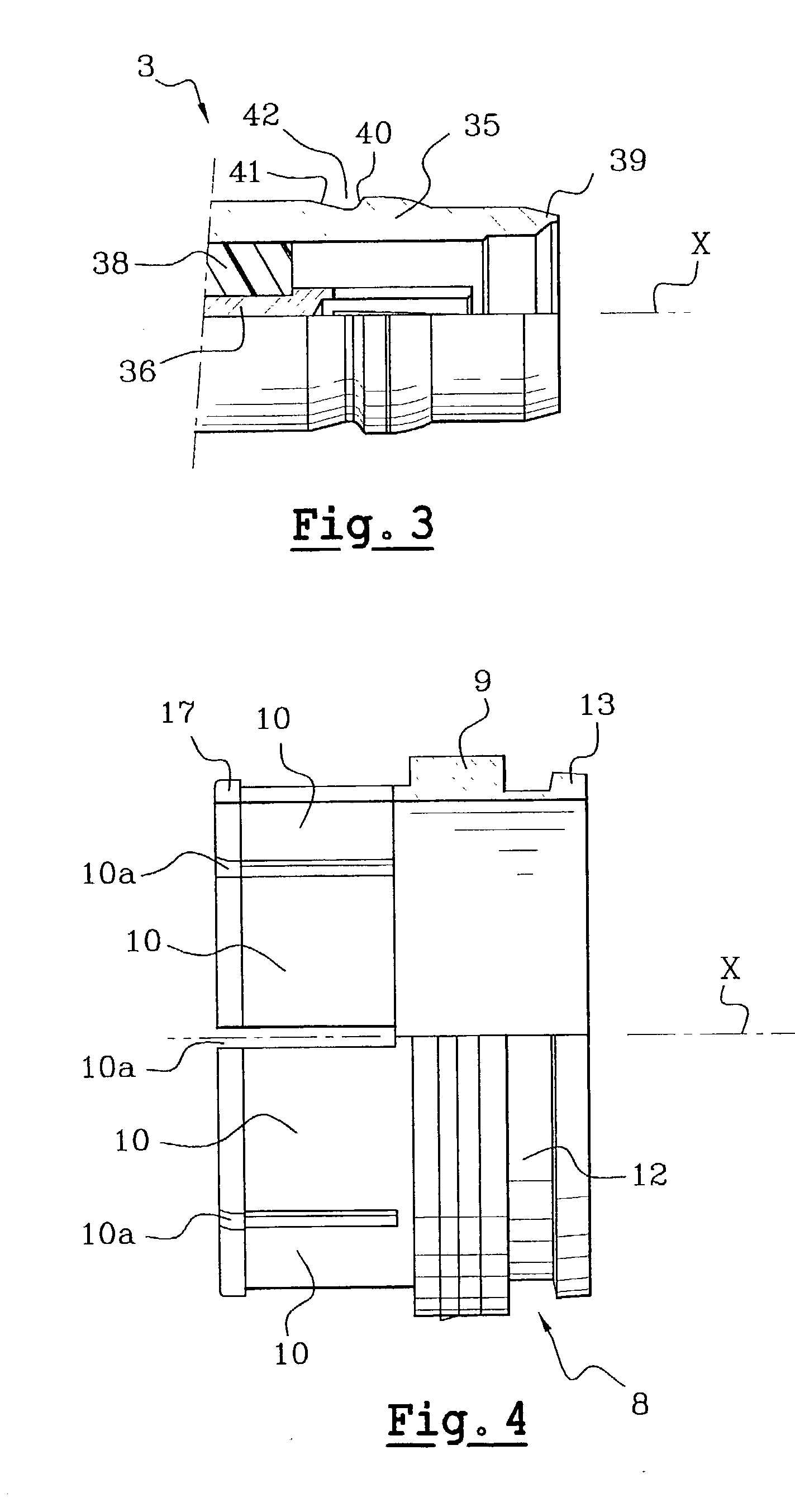

Coaxial connection with locking by snap-fastening

InactiveUS6645011B2Improve the level ofImprove intermodulationTwo pole connectionsTwo-part coupling devicesGround contactContact pressure

Owner:RADIALL SA +1

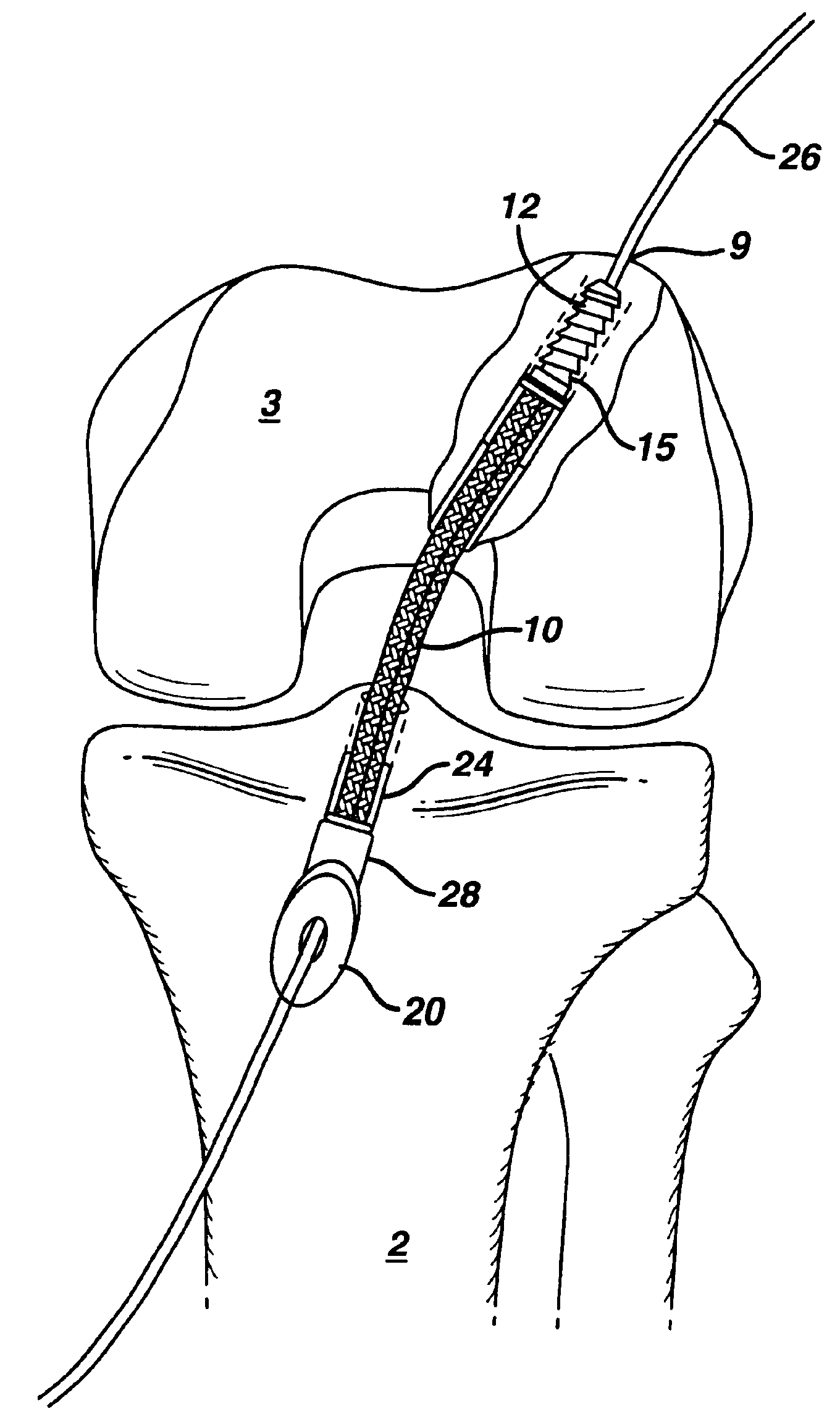

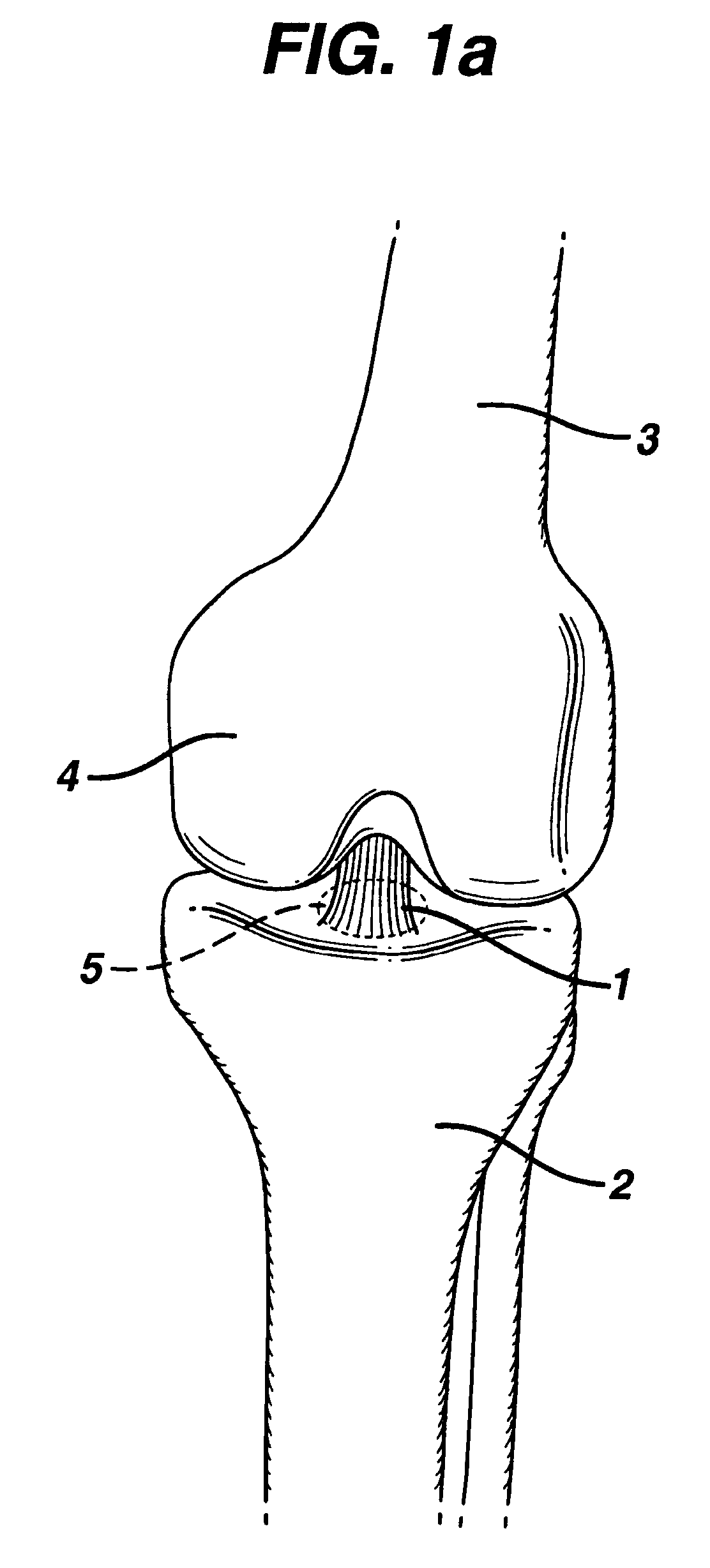

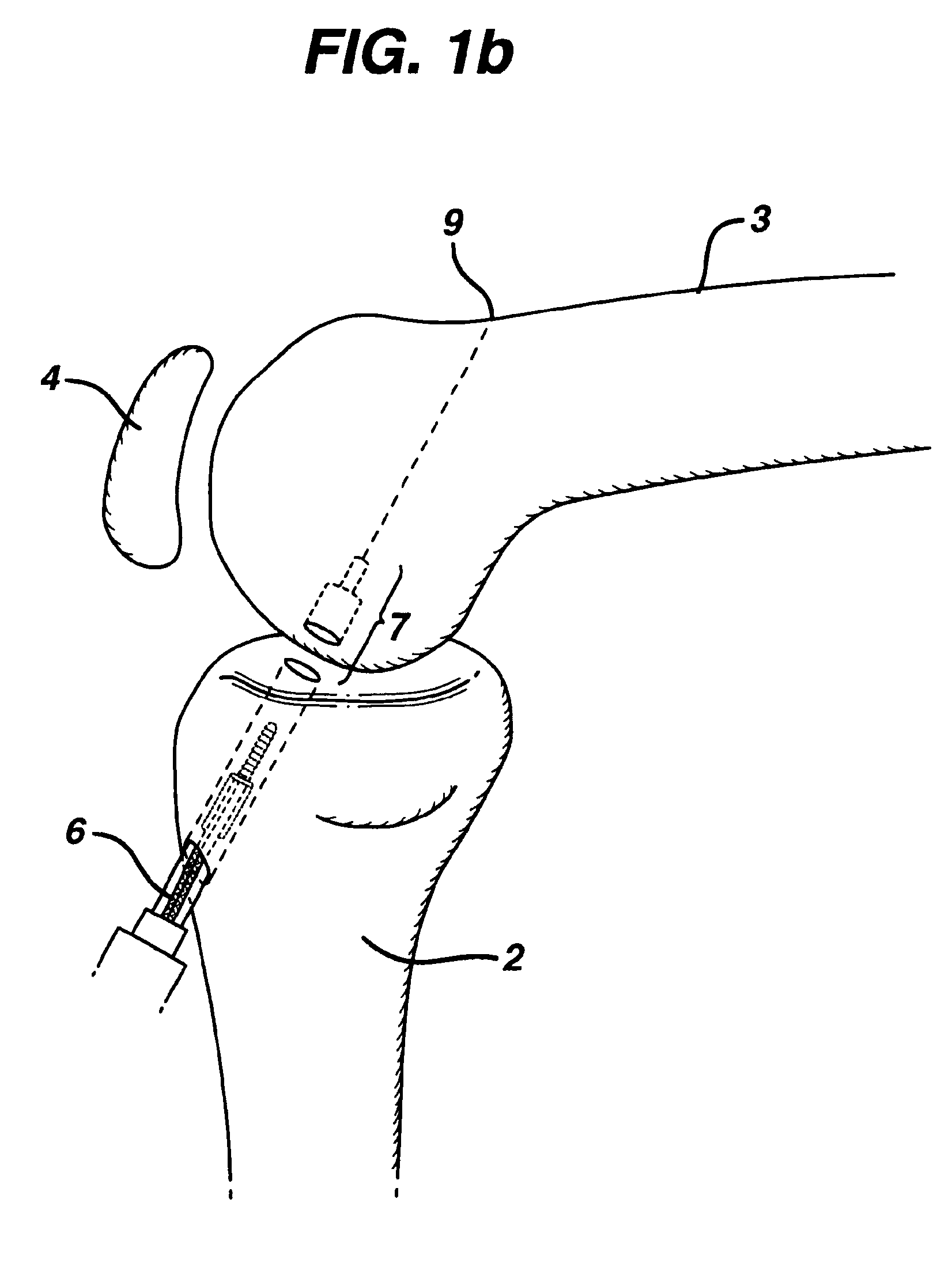

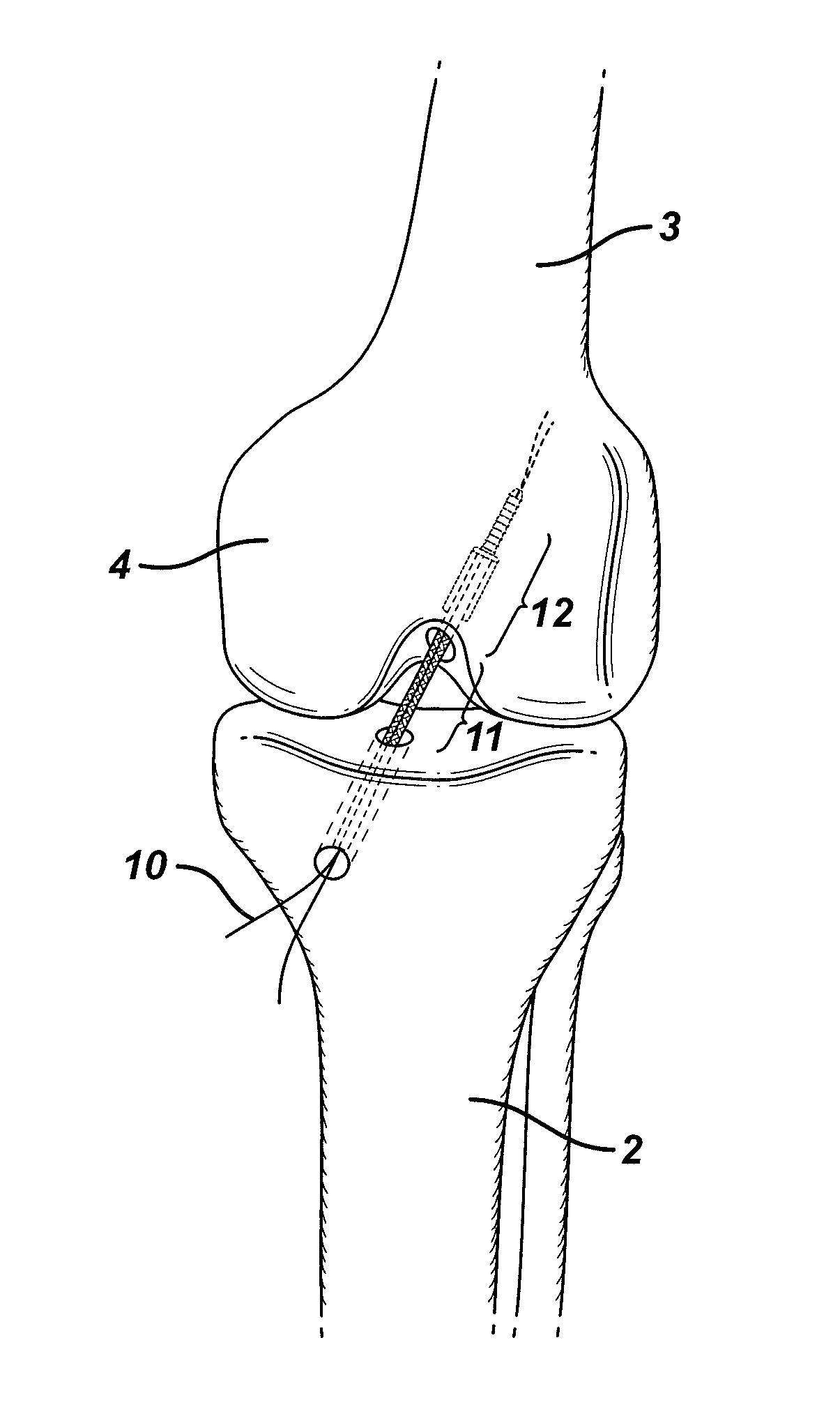

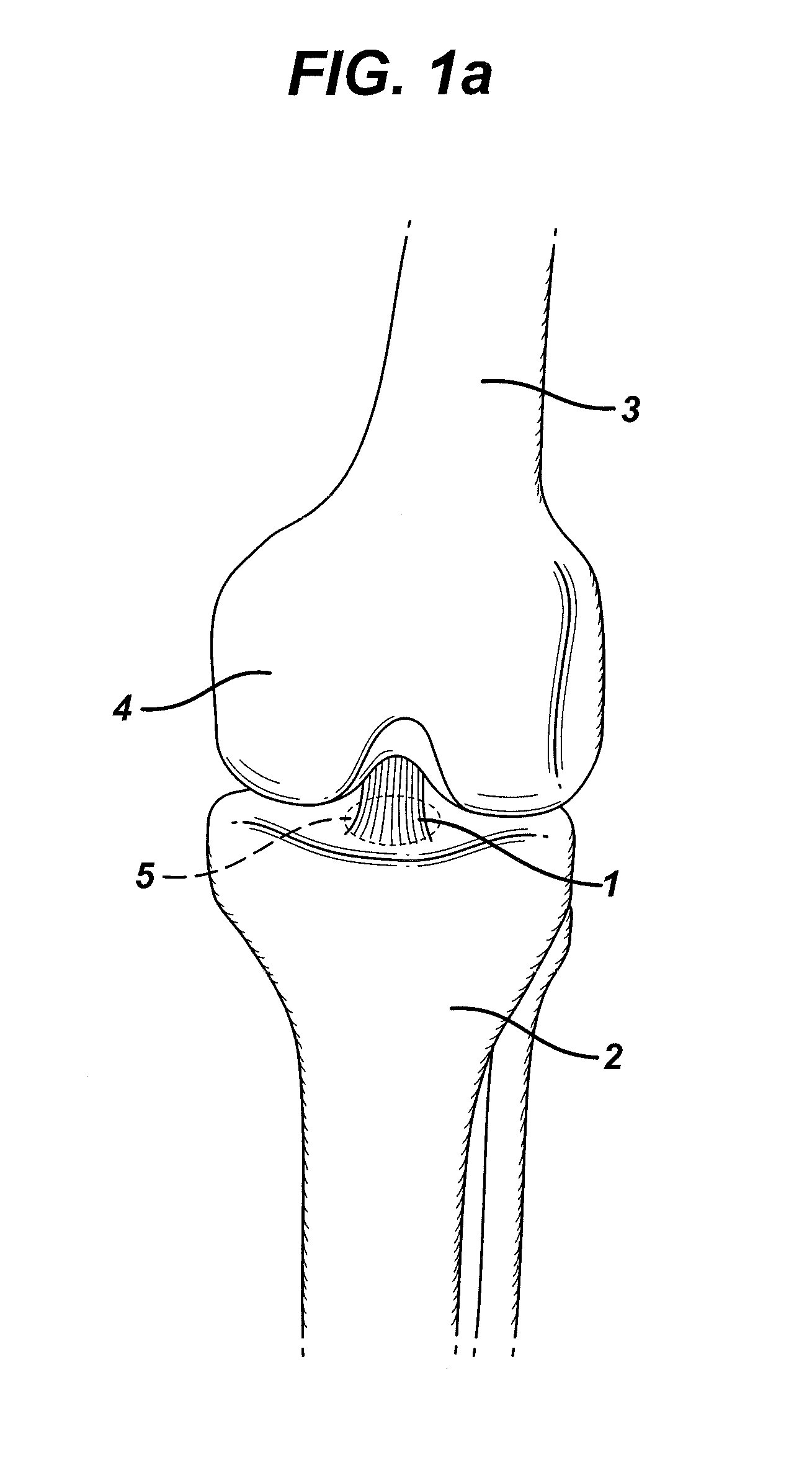

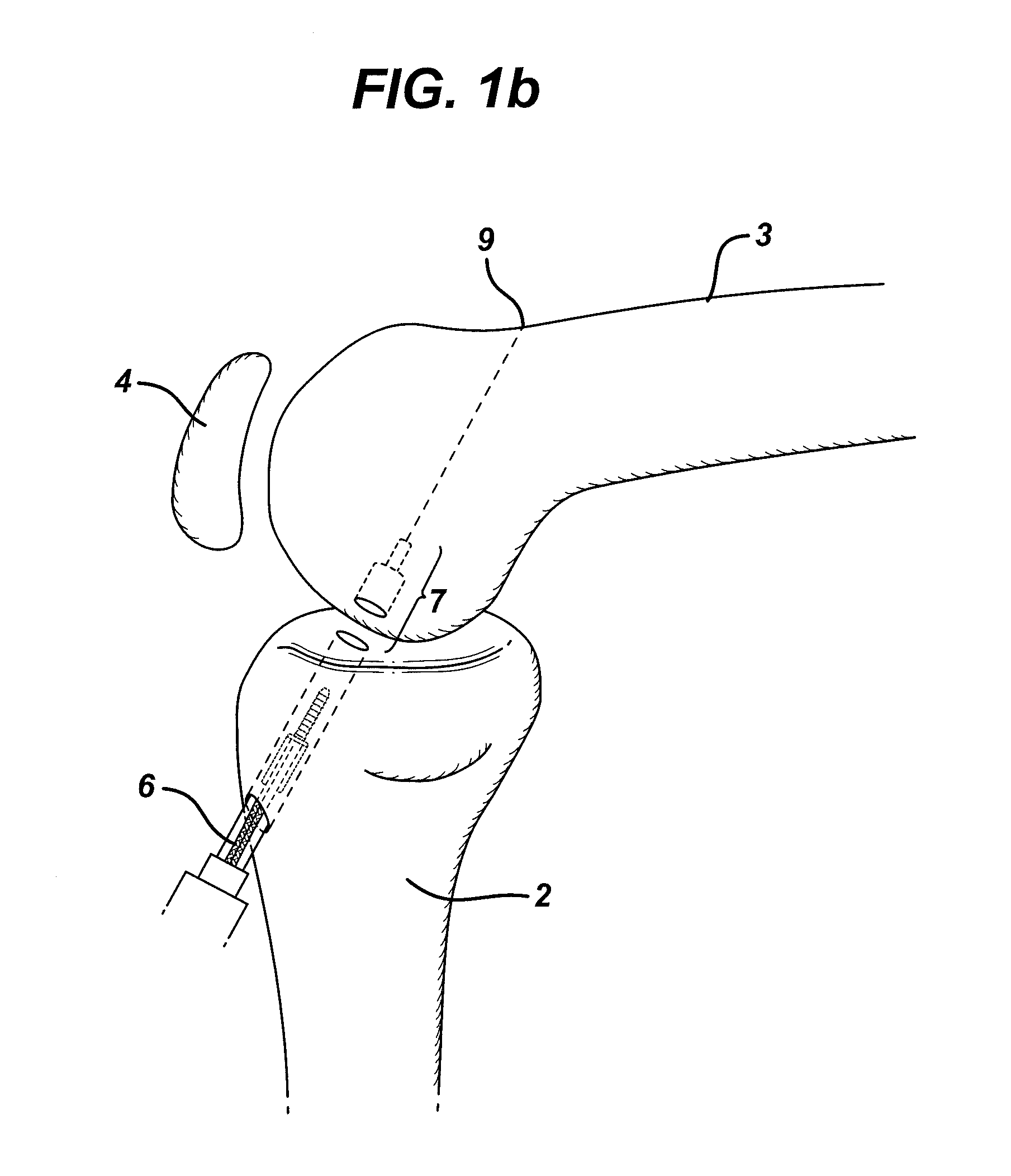

Method for anchoring autologous or artificial tendon grafts in bone

InactiveUS7637949B2Strong pressure fitAdverse reactionSuture equipmentsInternal osteosythesisTendon graftBiomedical engineering

A method for anchoring autologous or artificial tendon grafts in bone is provided. In one embodiment, the method includes affixing a stabilizing element in bone; and placing the stem of an insertion element therein. A tendon graft may be secured to the insertion element either before or after its placement in the stabilizing element. Two such anchors may be linked with one or multiple grafts, in either a two-ply or four-ply arrangement.

Owner:INNOVASIVE DEVICES

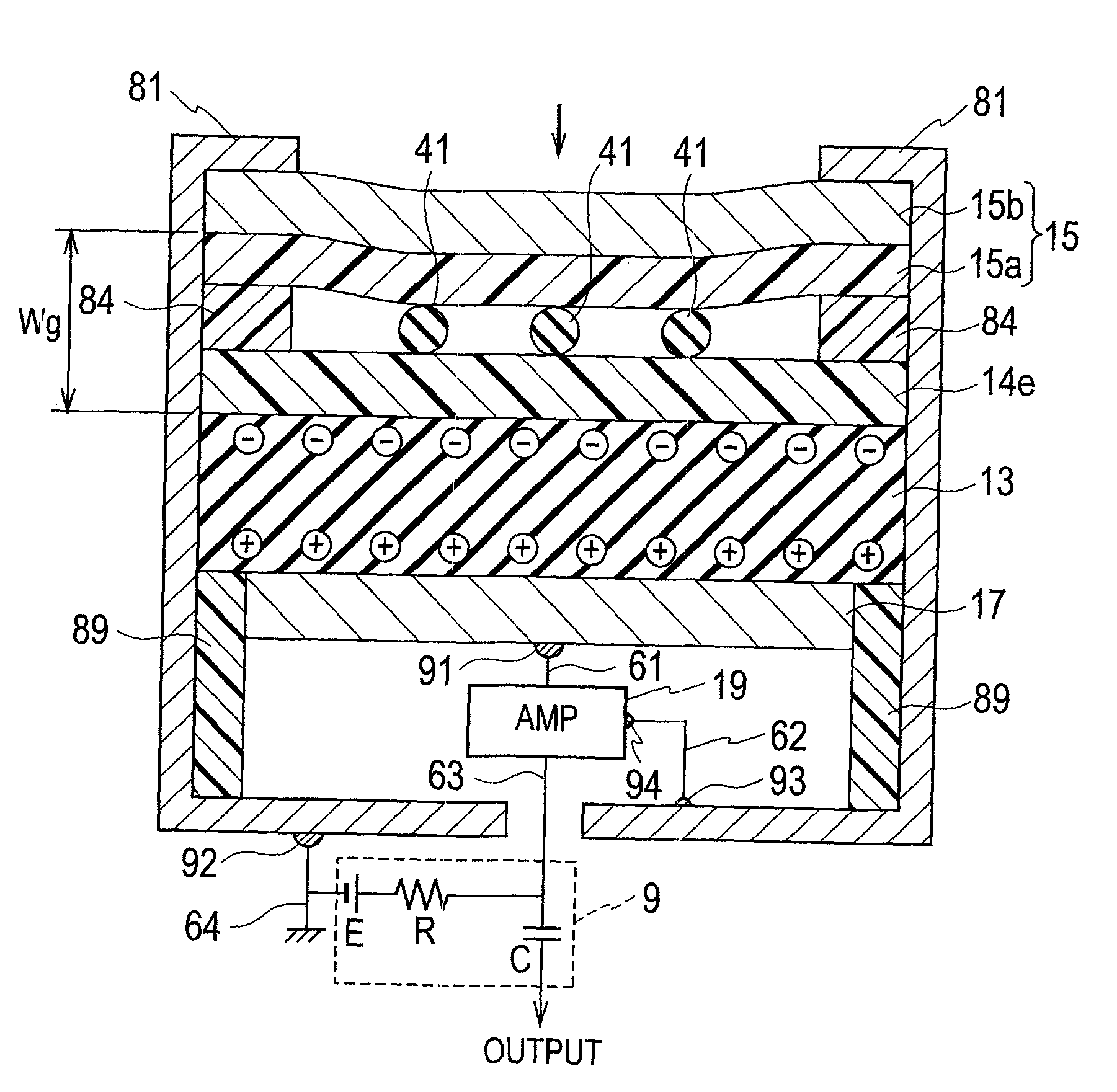

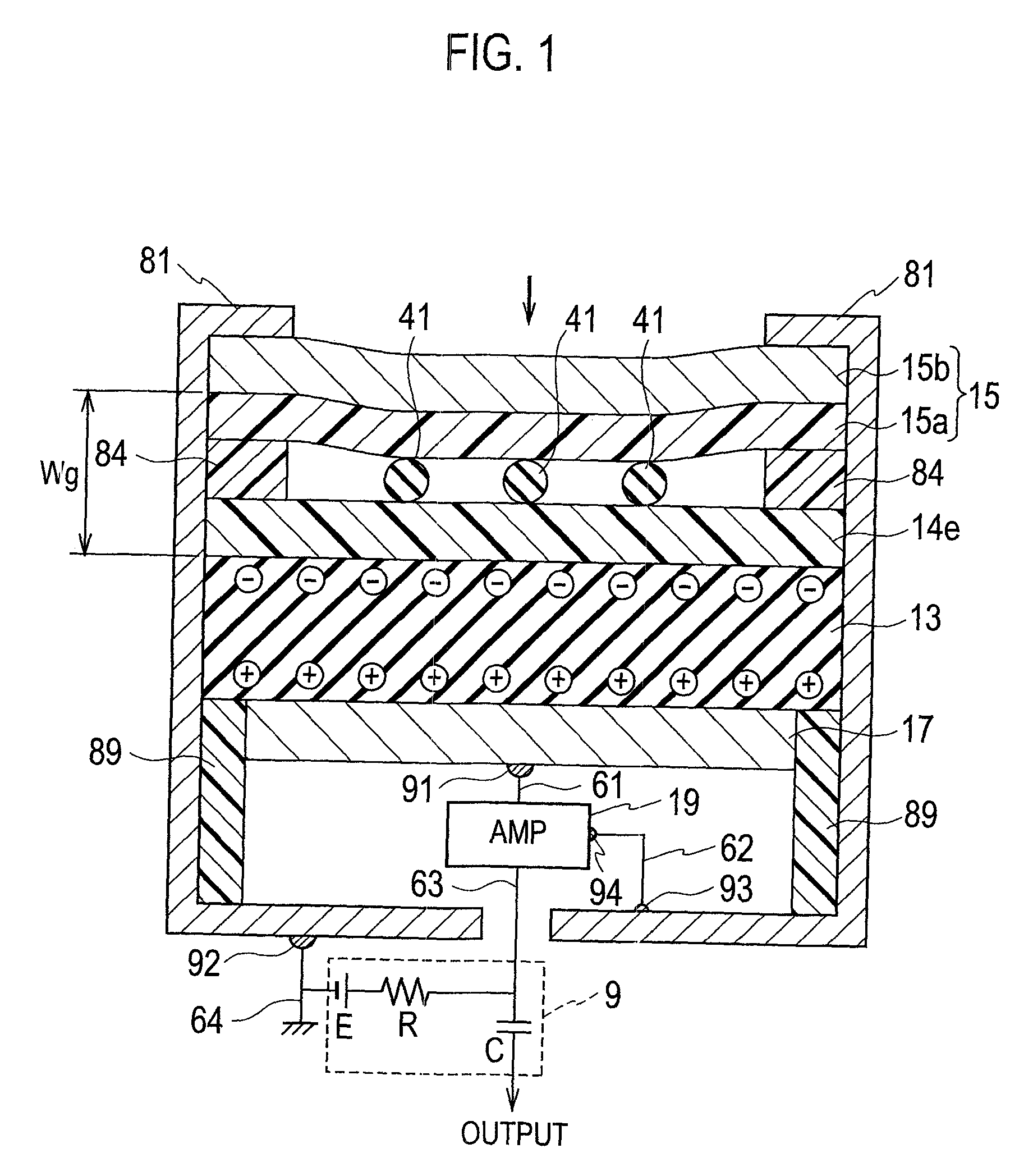

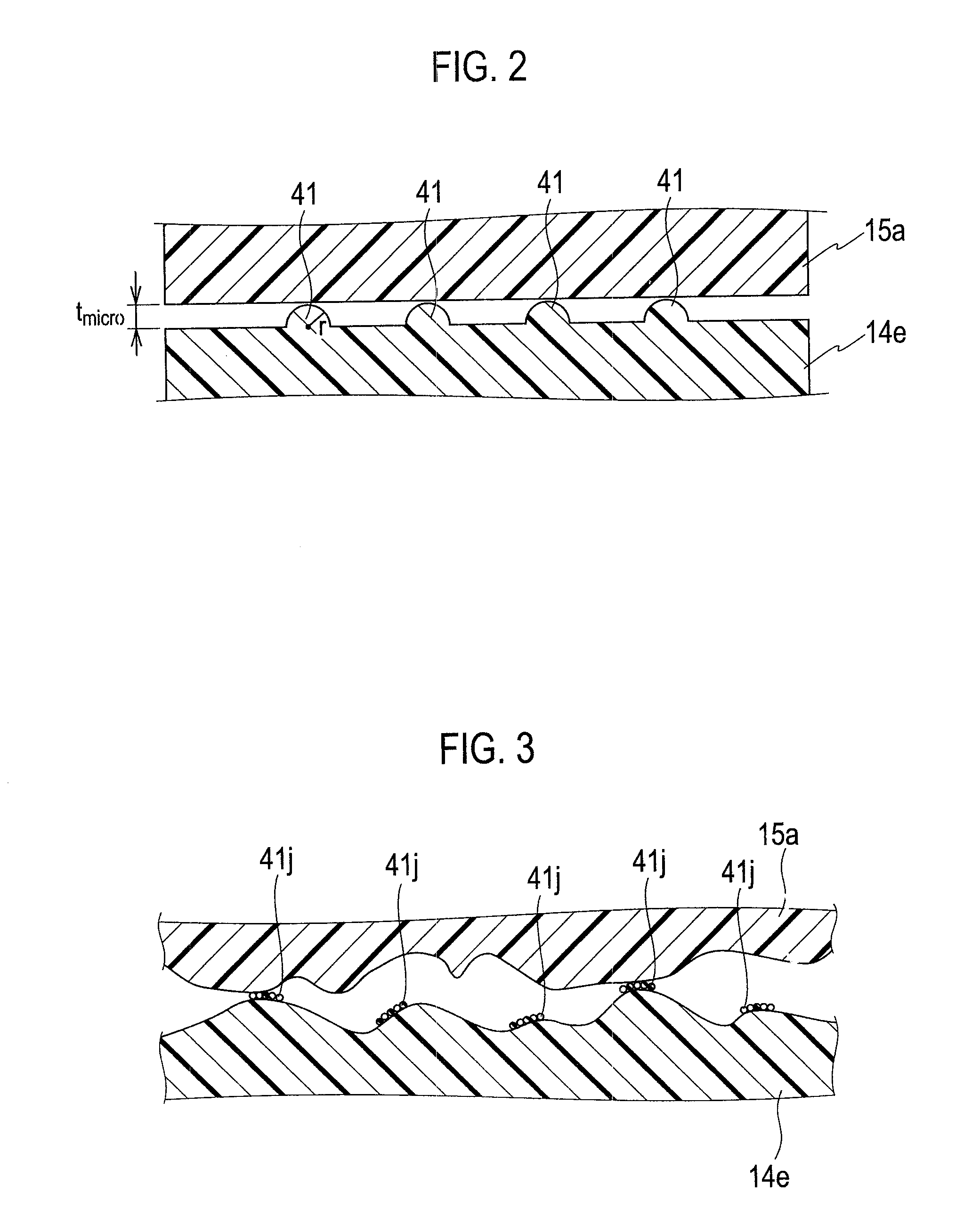

Electro-mechanical transducer, an electro-mechanical converter, and manufacturing methods of the same

InactiveUS20110108838A1Increase freedomStrong sound pressurePiezoelectric/electrostrictive microphonesSemiconductor electrostatic transducersMicrometerTransducer

An electro-mechanical transducer contains a vibrating electrode (15b), a vibrating-electrode-insulating film (15a) disposed at a bottom surface of the vibrating electrode (15b), an electret layer (13) facing to the vibrating electrode (15b), an electret-insulating layer (14e) joined to a top surface of the electret layer (13), and a back electrode 17 in contact with a bottom surface of the electret layer (13). A microgap between ten nanometers and 100 micrometers is established between the vibrating-electrode-insulating film (15a) and electret-insulating layer (14e). A central line average roughness Ra of the vibrating electrode (15b), including a bending, is 1 / 10 or less of a gap width measured between the bottom surface of the vibrating electrode (15b) and the top surface of the electret layer (13).

Owner:SAITAMA UNIVERSITY

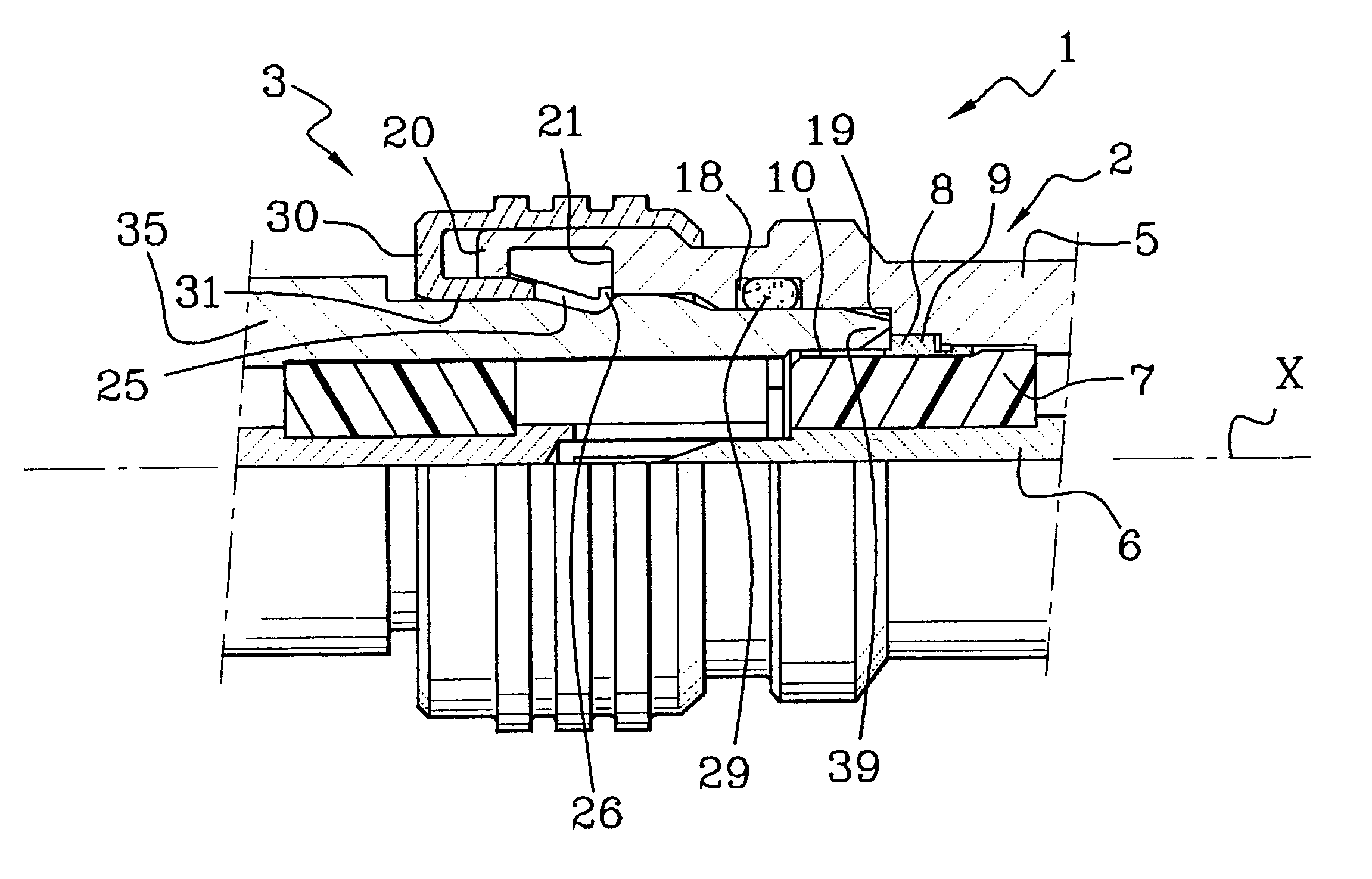

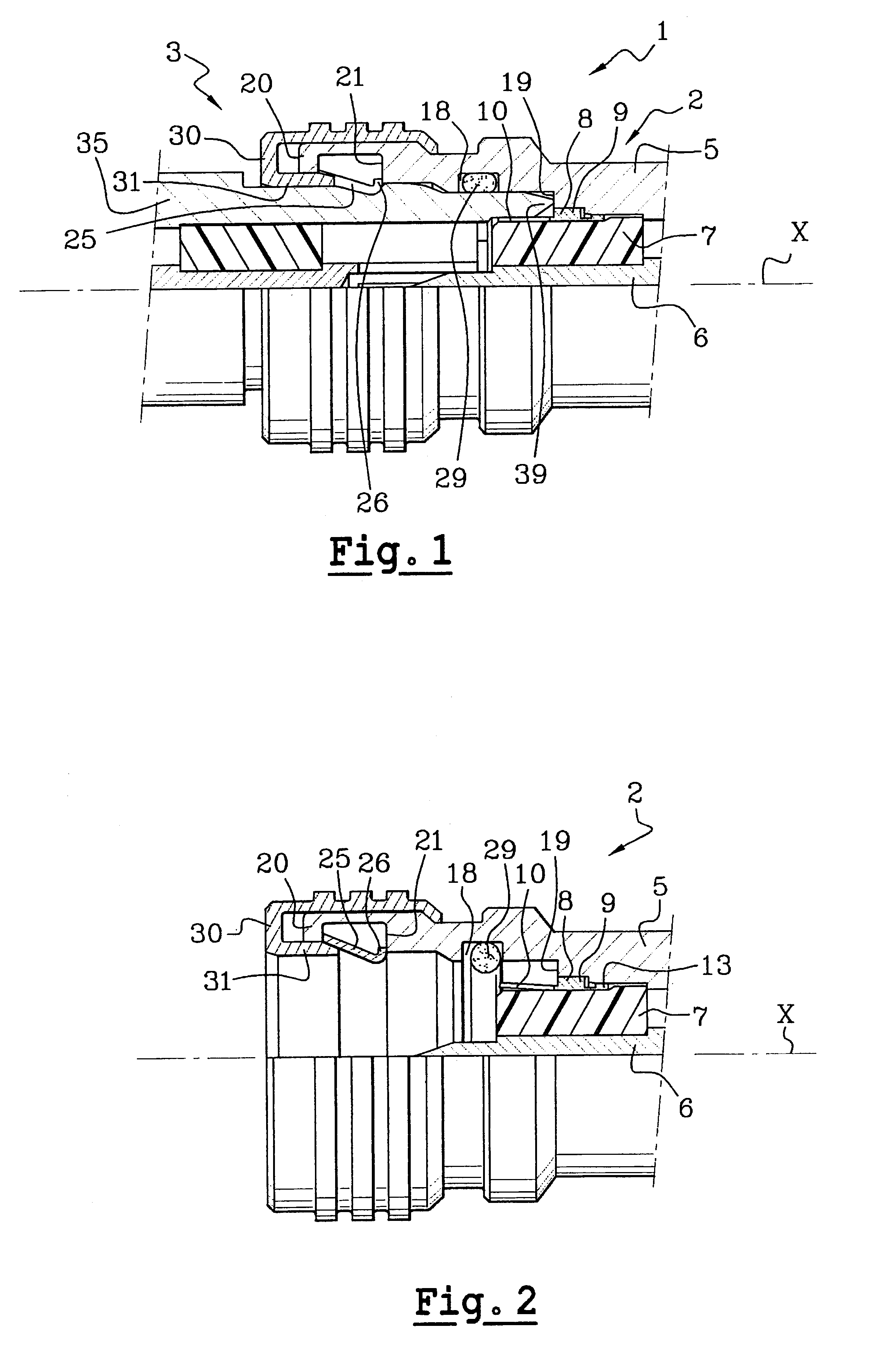

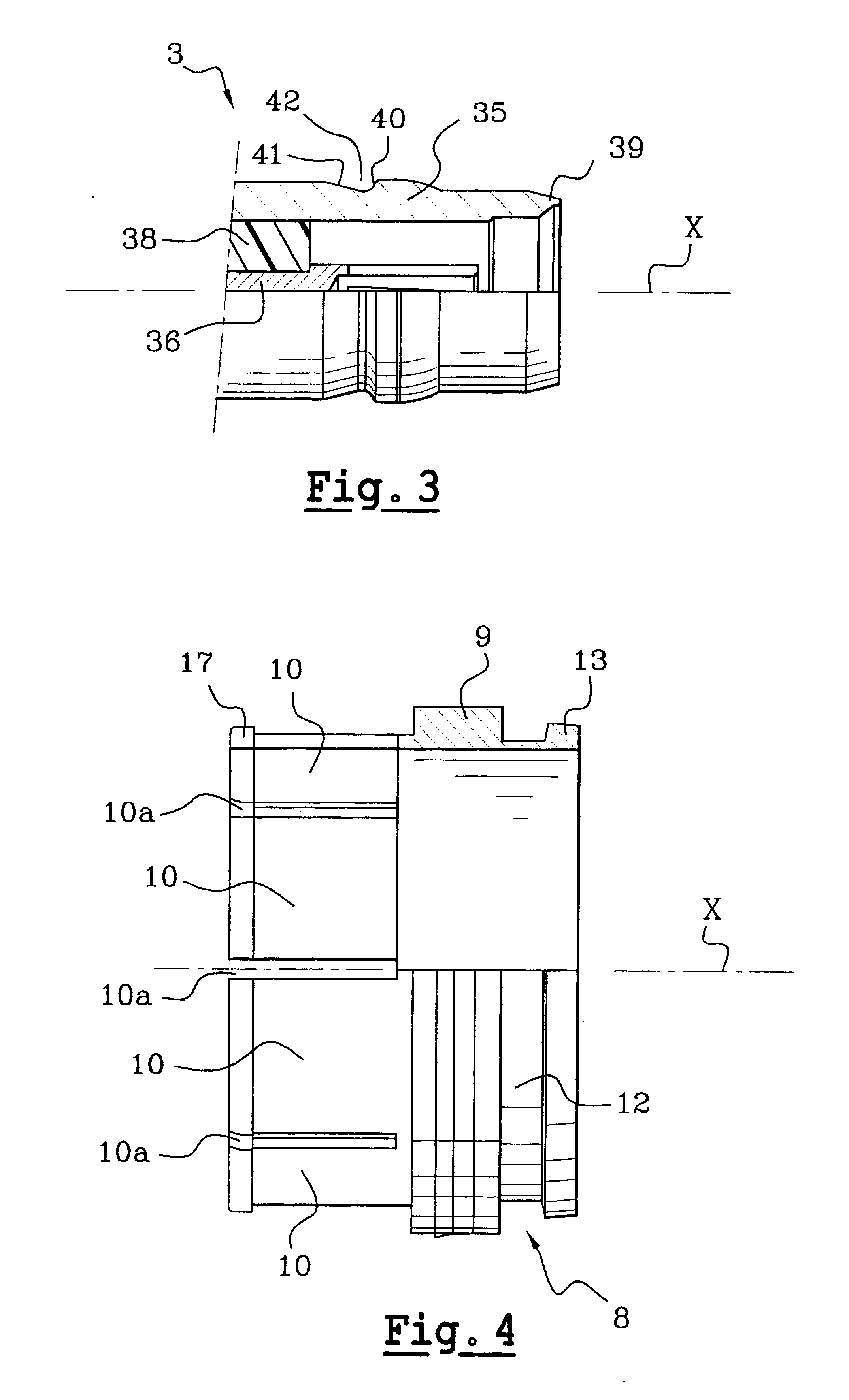

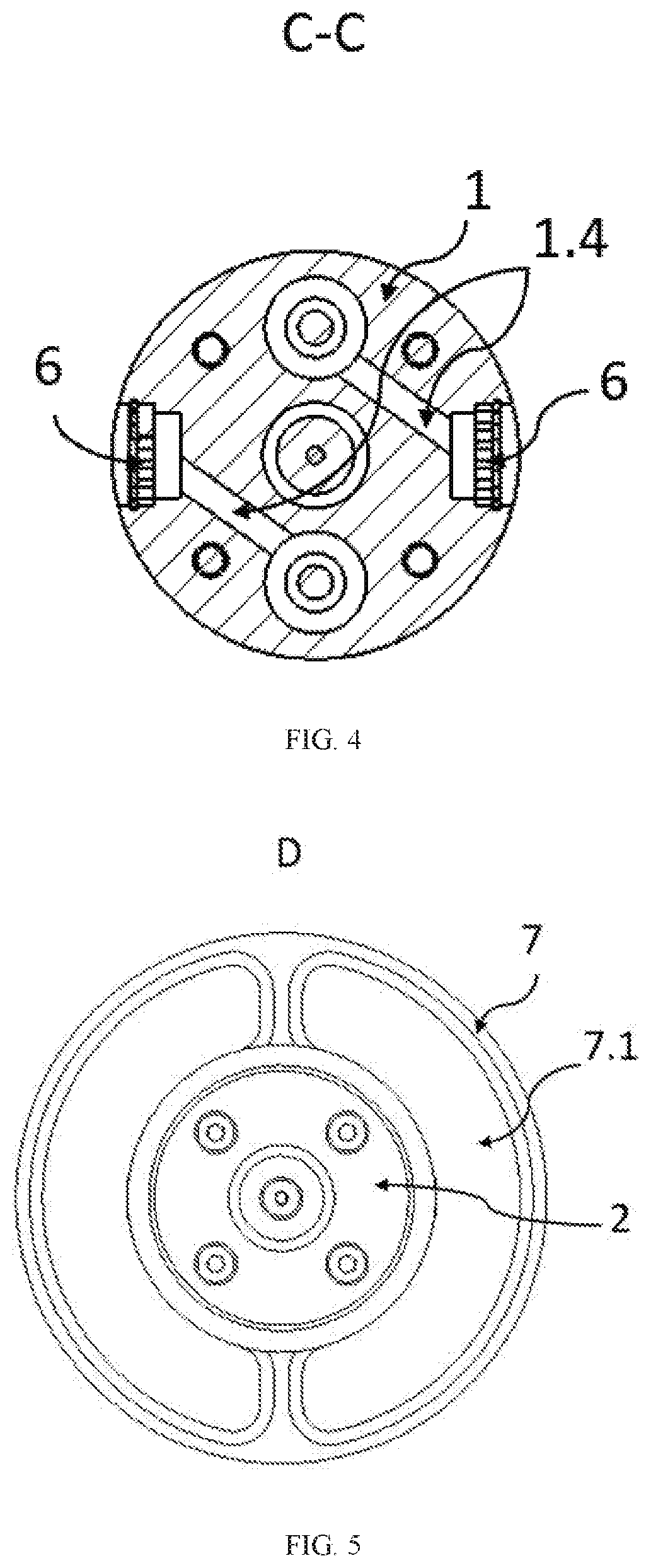

Coaxial connection with locking by snap-fastening

InactiveUS20030027435A1Improve the level ofImprove featuresTwo pole connectionsTwo-part coupling devicesGround contactContact pressure

A coaxial connector with locking by snap-fastening, the connector comprising two complementary connector elements each comprising a tubular body forming a ground contact and containing a central contact, which central contact is male in one of the bodies and female in the other and is held in the corresponding body by means of insulation, wherein a first one of the connector elements has a retaining member suitable for exerting a radial force on the second connection element which is arranged in such a manner that said radial force generates an axial force on the second connector element tending to press it axially against a bearing surface of the first connector element, and wherein the body of one of the connector elements has a member inserted therein that forms an internal ground contact and that is suitable for coming into contact with an inner wall of the body of the other connector element while exerting relatively strong contact pressure thereagainst.

Owner:RADIALL SA +1

Method of anchoring autologous or artificial tendon grafts in bone

InactiveUS20120078369A1Strong pressure fitAdverse reactionInternal osteosythesisLigamentsTendon graftTendon grafting

An anchor assembly for autologous or artificial tendon grafts comprises an insertion element and a stabilizing element. The insertion element has a stem and a head containing an aperture large enough to receive a graft. The stabilizing element is adapted to be embedded in bone, and comprises a sleeve with a cavity arranged to receive and hold the insertion element stem. In use, the stabilizing element is affixed in the bone, and the stem of the insertion element is placed therein. A tendon graft may be secured to the insertion element either before or after its placement in the stabilizing element. Two such anchors may be linked with one or multiple grafts, in either a two-ply or four-ply arrangement.

Owner:DEPUY MITEK INC

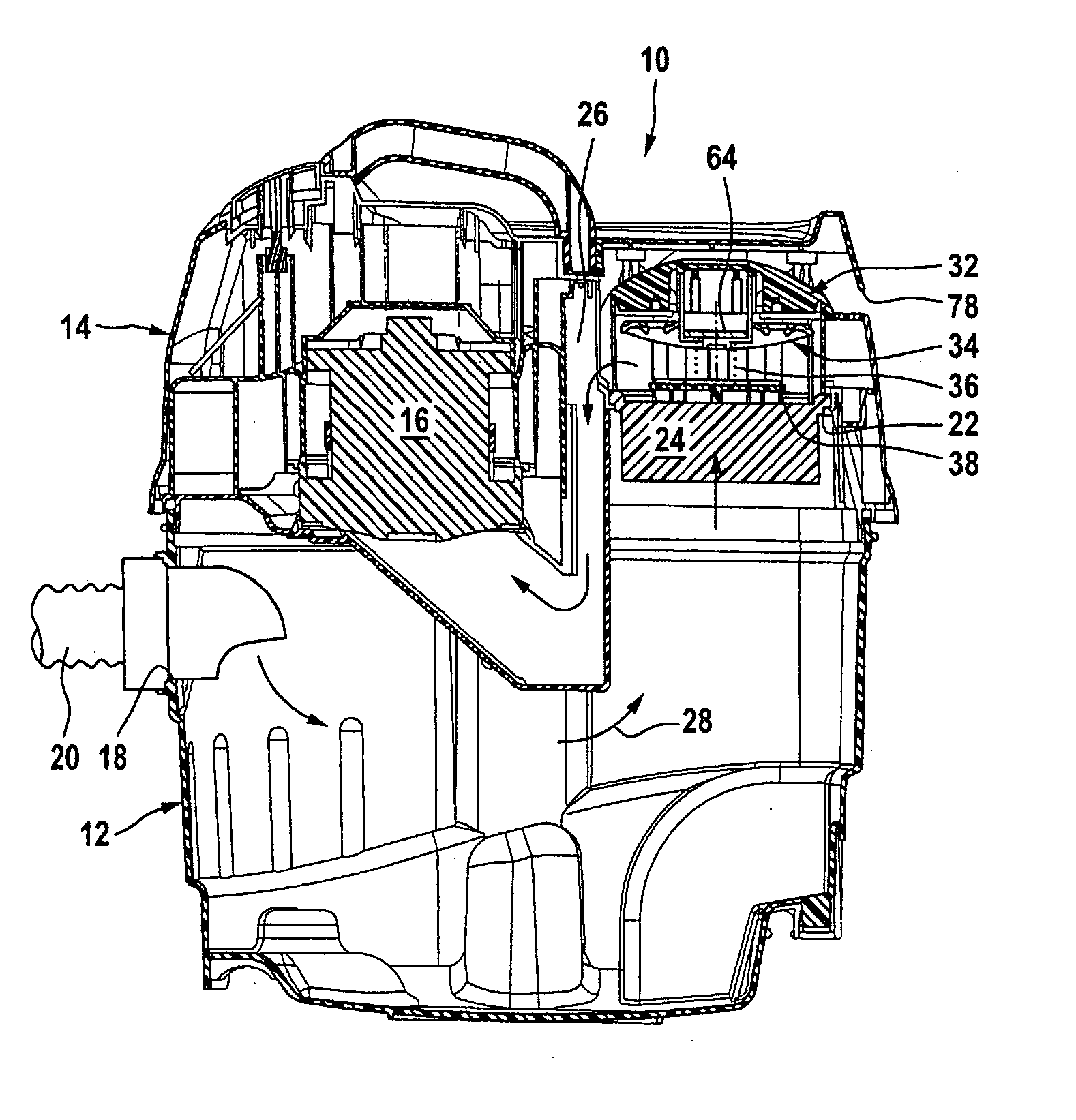

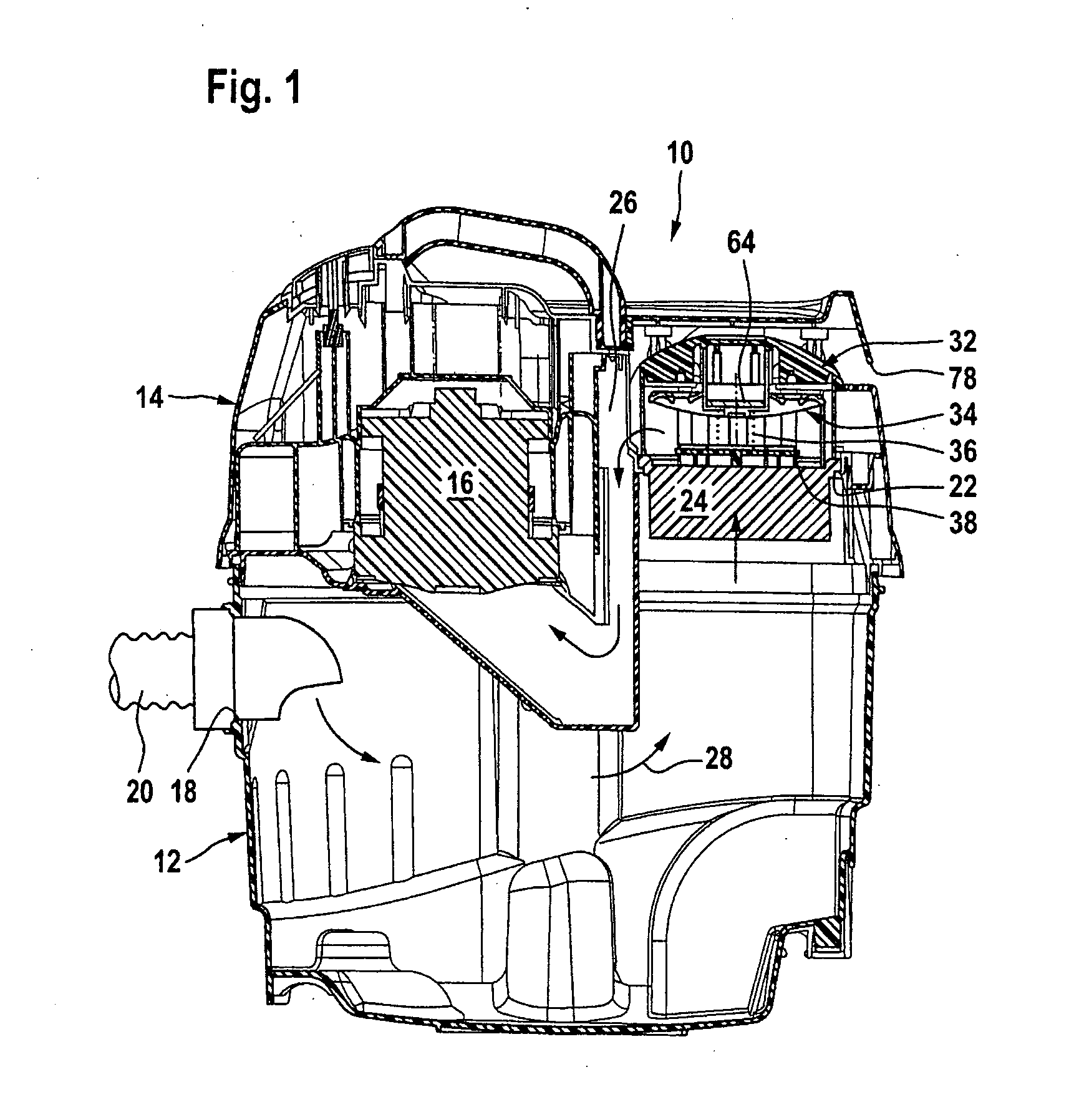

Method for cleaning the filters of a vacuum Cleaner and vacuum cleaner for carrying out said method

ActiveUS20080092498A1Low remanenceEasy to cleanCleaning filter meansCombination devicesEngineeringVacuum cleaner

The invention relates to a method for cleaning the filter of a vacuum cleaner which has a dirt collecting container with a suction inlet, to which a suction tube is connected, the dirt collecting container being connected to at least one suction unit via at least one filter and at least one suction line, and at least one closing valve closing an external air inlet, via which the suction line is connected to an external air supply, in which method, for cleaning the filter, the closing valve is opened and the side of the filter that is oriented away from the dirt collecting container is impinged upon by external air. To develop the method further in such a way that all the filters present can be flowed through by suction air during suction operation, but suction operation does not have to be noticeably interrupted for filter cleaning, it is proposed according to the invention that, by opening the closing valve, the negative pressure that forms within the suction tube at a distance of 3 cm from the suction inlet, on connecting a standard suction tube, is lowered for at least 10 ms and at most 150 ms to values of less than 40% of the value forming when the closing valves are closed. The invention also relates to a vacuum cleaner for carrying out the method.

Owner:ALFRED KARCHER GMBH & CO KG

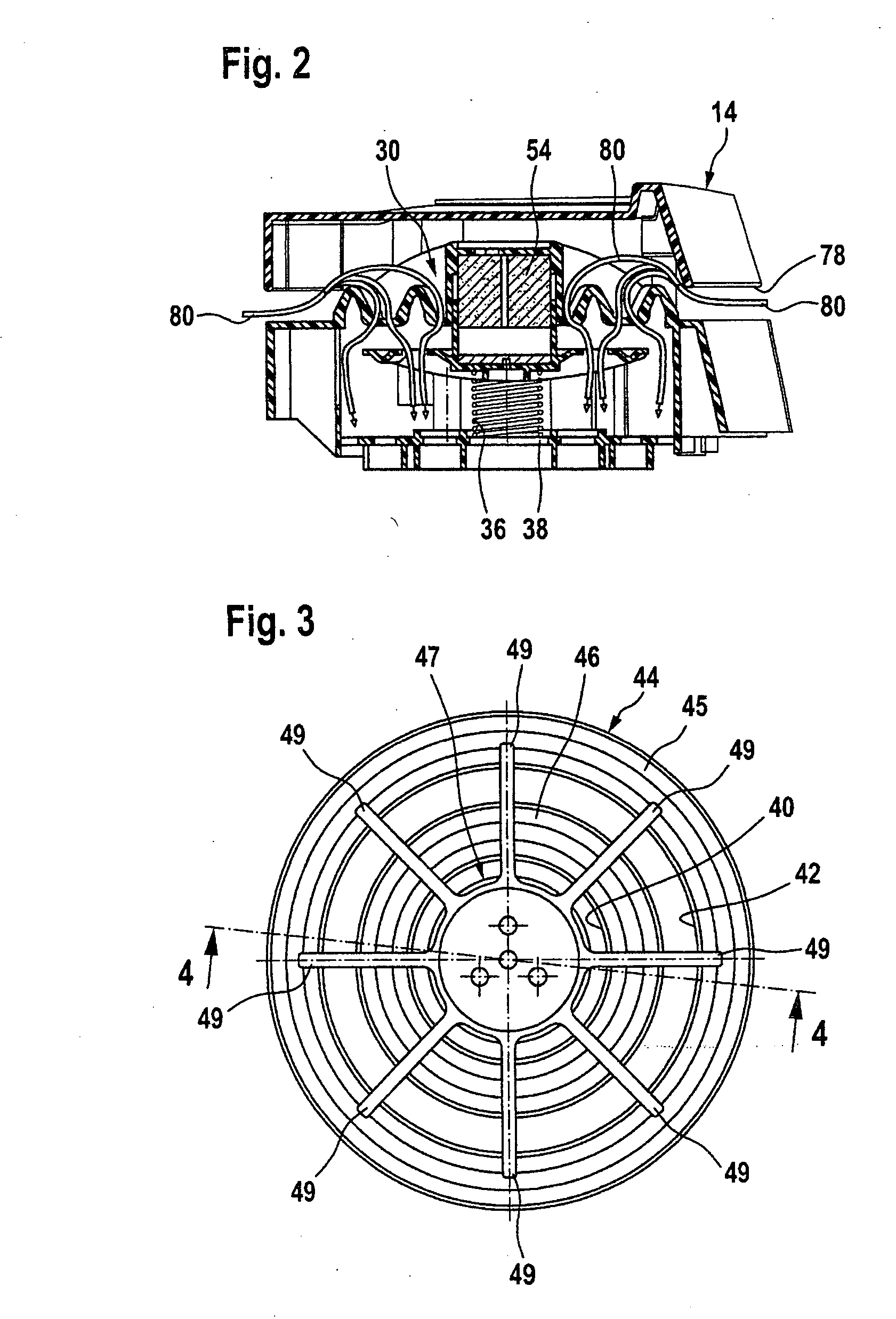

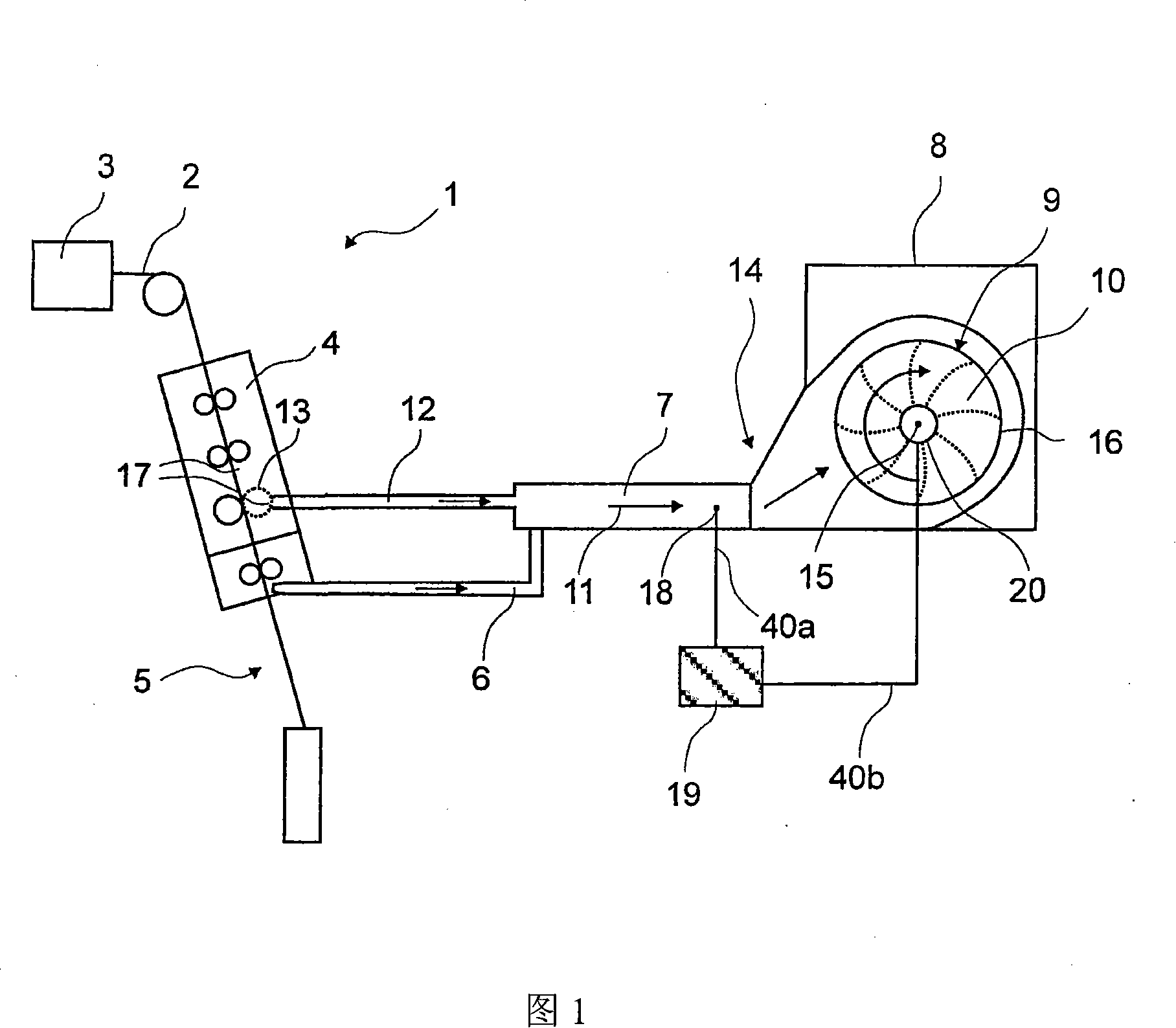

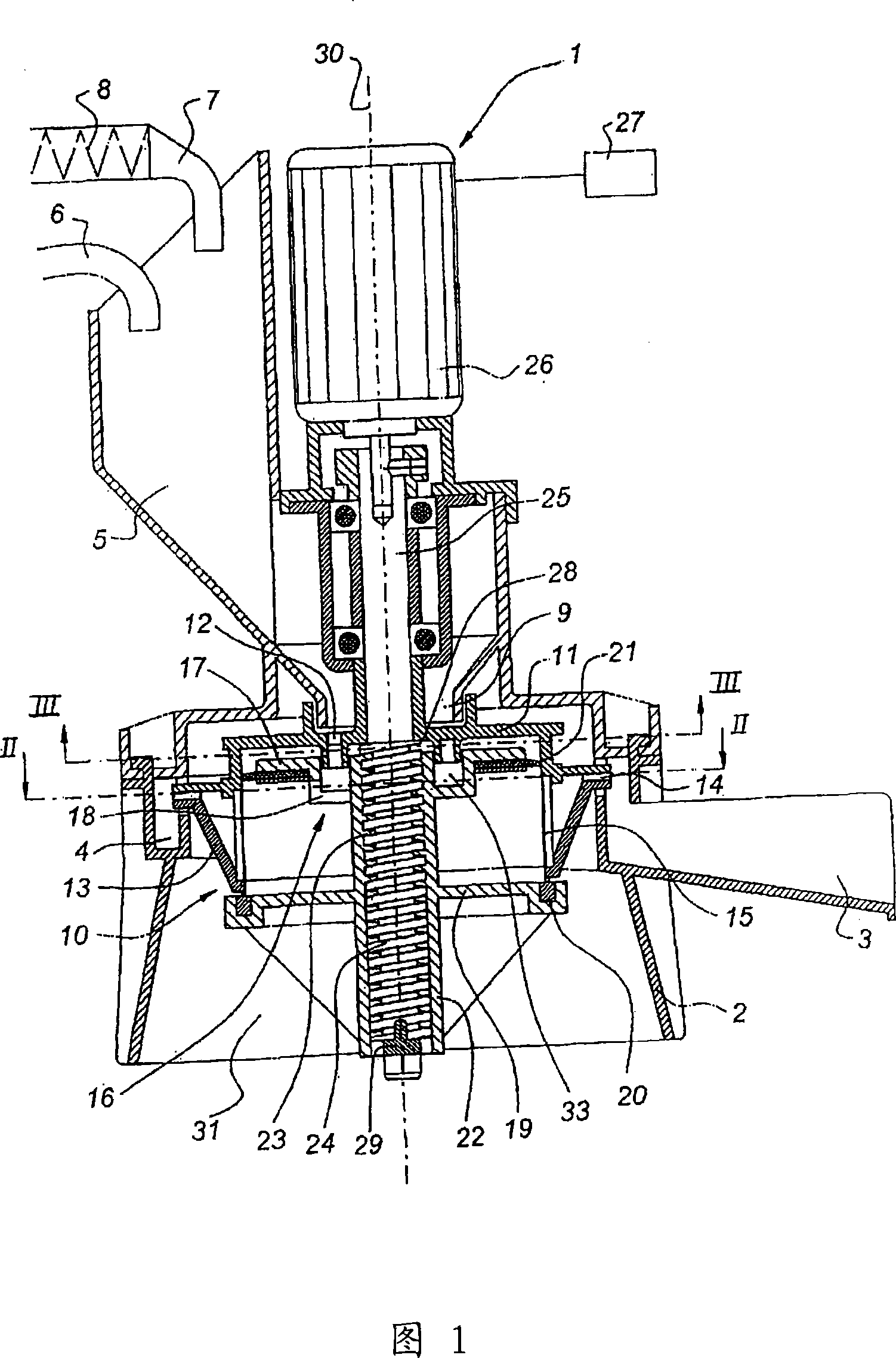

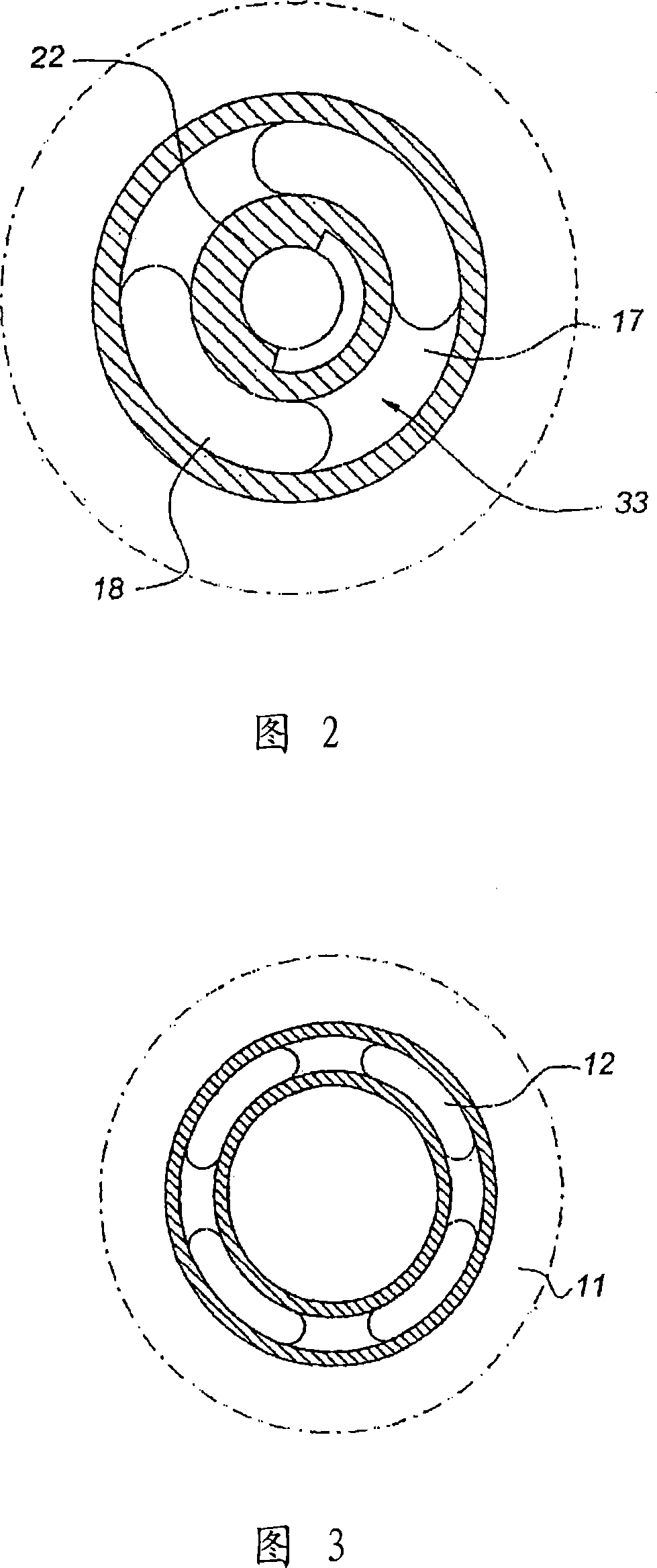

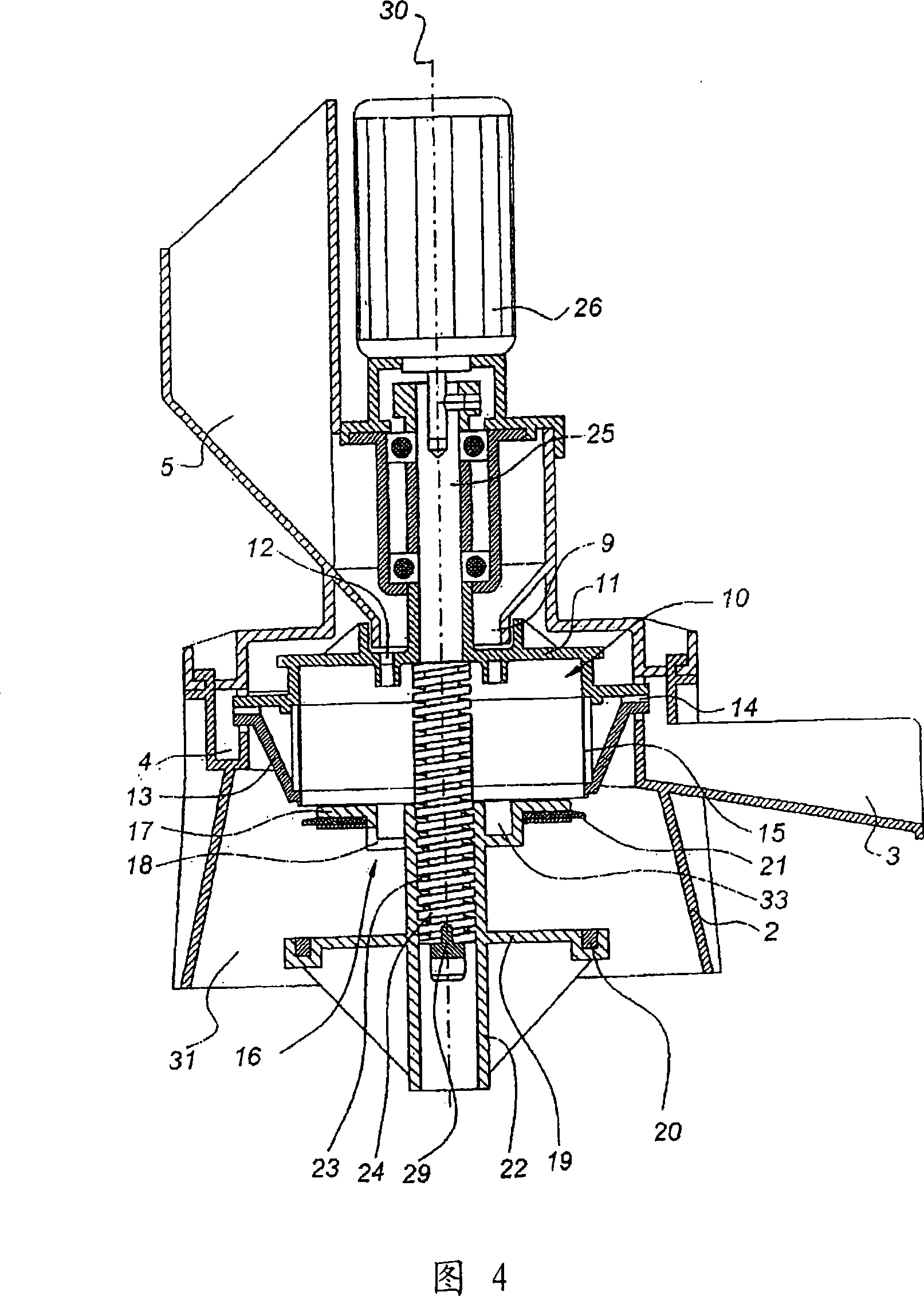

Device and method for pumping and filtering air containing dust and/or fibre on the spinning machine

InactiveCN101113537AEasy to storeEffectively fixedDispersed particle filtrationTransportation and packagingFiberMotor drive

The device for the suction and filtration of dust- and / or fiber loaded air on spinning machines (1), comprises working places consisting of a suction channel (7), a filtering device (8) with a filter forming a filtering surface (16), a system for removing the filter outflow from the filtering surface, a vacuum source (10) for generating an induced draft, an operating means for carrying out a filter cleaning process using a removal system, and a vacuum sensor arranged in the main suction channel for measuring the vacuum in a vacuum zone before and / or after the filtering. The device for the suction and filtration of dust- and / or fiber loaded air on spinning machines (1), comprises working places consisting of a suction channel (7), a filtering device (8) with a filter forming a filtering surface (16), a system for removing the filter outflow from the filtering surface, a vacuum source (10) for generating an induced draft, an operating means for carrying out a filter cleaning process by a removal system, and a vacuum sensor arranged in the main suction channel for measuring the vacuum in a vacuum zone before and / or after the filtering. The device contains a controller or regulator for vacuum in the vacuum zone before and / or after the filtering surface based on the vacuum values, vacuum target values or vacuum target value areas, which are measured by the vacuum sensor. The controller or regulator is connected with a driving mechanism for filter cleaning. The controlling or regulating of the vacuum takes places by the operation of the driving mechanism. The spinning place contains suction places (17), over which polluted air is sucked out and supplied over a central suction channel or -channel of the filter arrangement. The vacuum source contains an axial- or radial ventilator. The filter outflow is liftable or removable from the filtering surface using removal- or a lifting device and is fed to a collecting- or disposing device. The controller contains a signal converter and a control device, by which the measured values received by the vacuum sensor in the form of vacuum values are compared with the vacuum target values and vacuum target value areas. Controlling or regulating signals are generated for correcting the variation of actual value from the target value for operating on an actuator and / or a final control element containing driving means. The filtering device contains a filter drum with a cylinder shaped, fixed or flexible filter surface, which is arranged on the removal system. The driving mechanism comprises a drive system for turning the filter drum around the drum axis. The filter cleaning is carried out by a continuous or sequential turning of the filter drum, by which the filter surface is directed to the removal device and the filter outflow is removed. The driving mechanism contains a hydraulic or pneumatic piston drive, and a linear motor or electric cylinder, which is connected with a gear between the driving mechanism and the filter. A control is intended for thread count and / or equipment parameters of the pressure ratio in the channels and / or pipes are adjustable. The control consists of a means for changing the vacuum over the filter device and / or over the ventilator output. The filter device contains a continuous filter band forming a space, and electro motor driving mechanism for a circulatory movement of the filter band, which forms a layered filter surface. Independent claims are included for: (1) a spinning machine; and (2) a method for the suction and filtration of dust- and / or fiber loaded air on spinning machines.

Owner:MASCHINENFABRIK RIETER AG

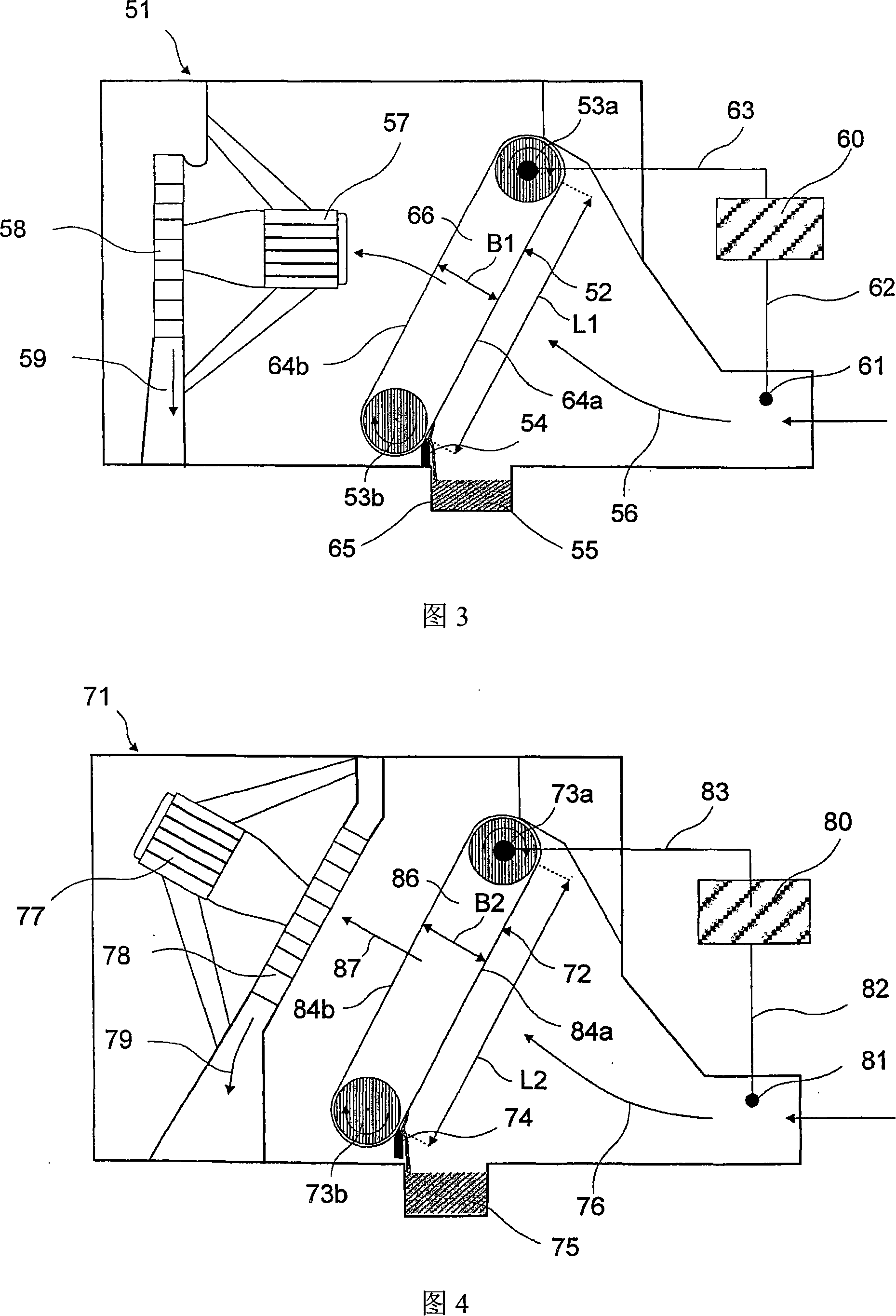

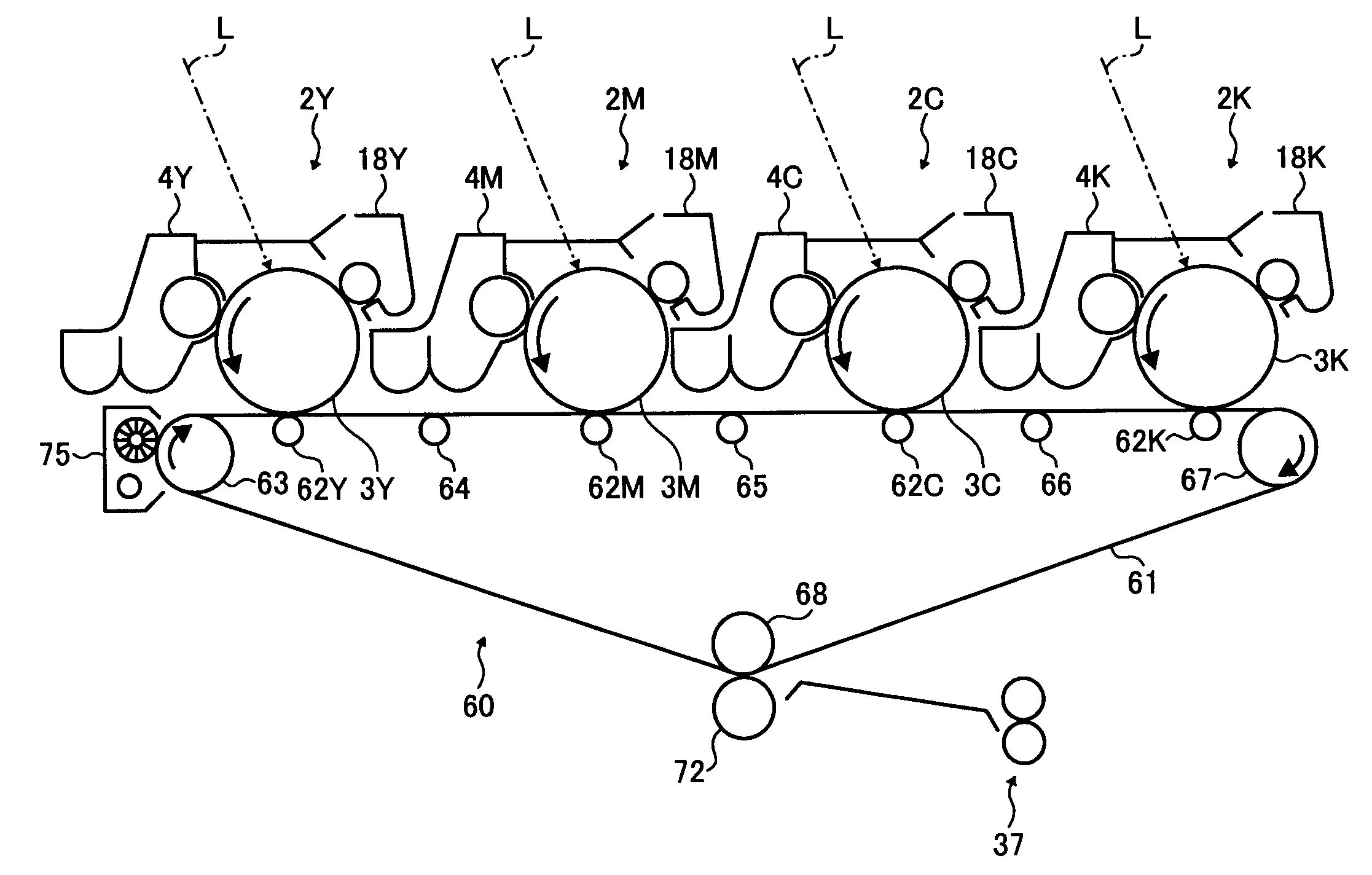

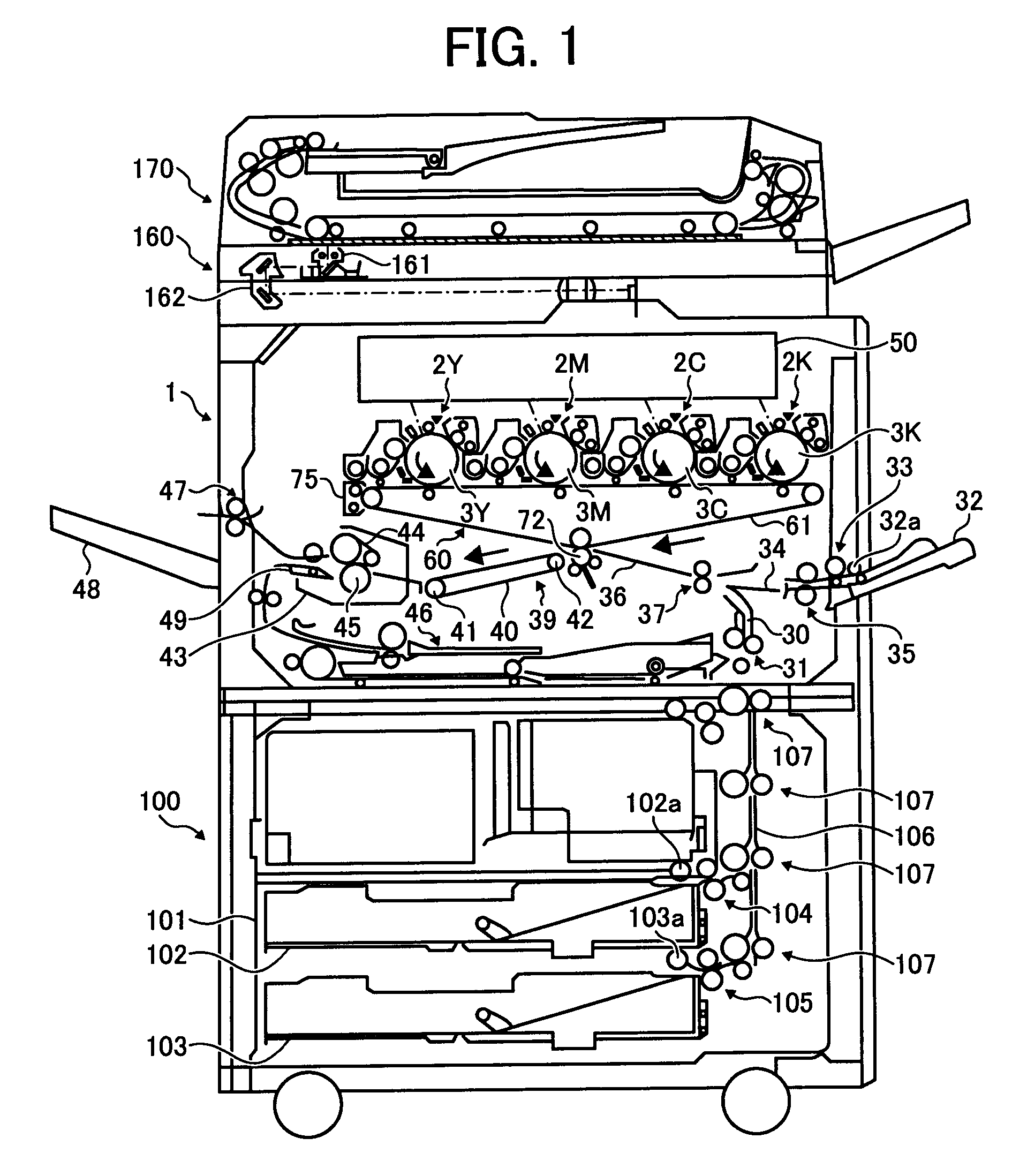

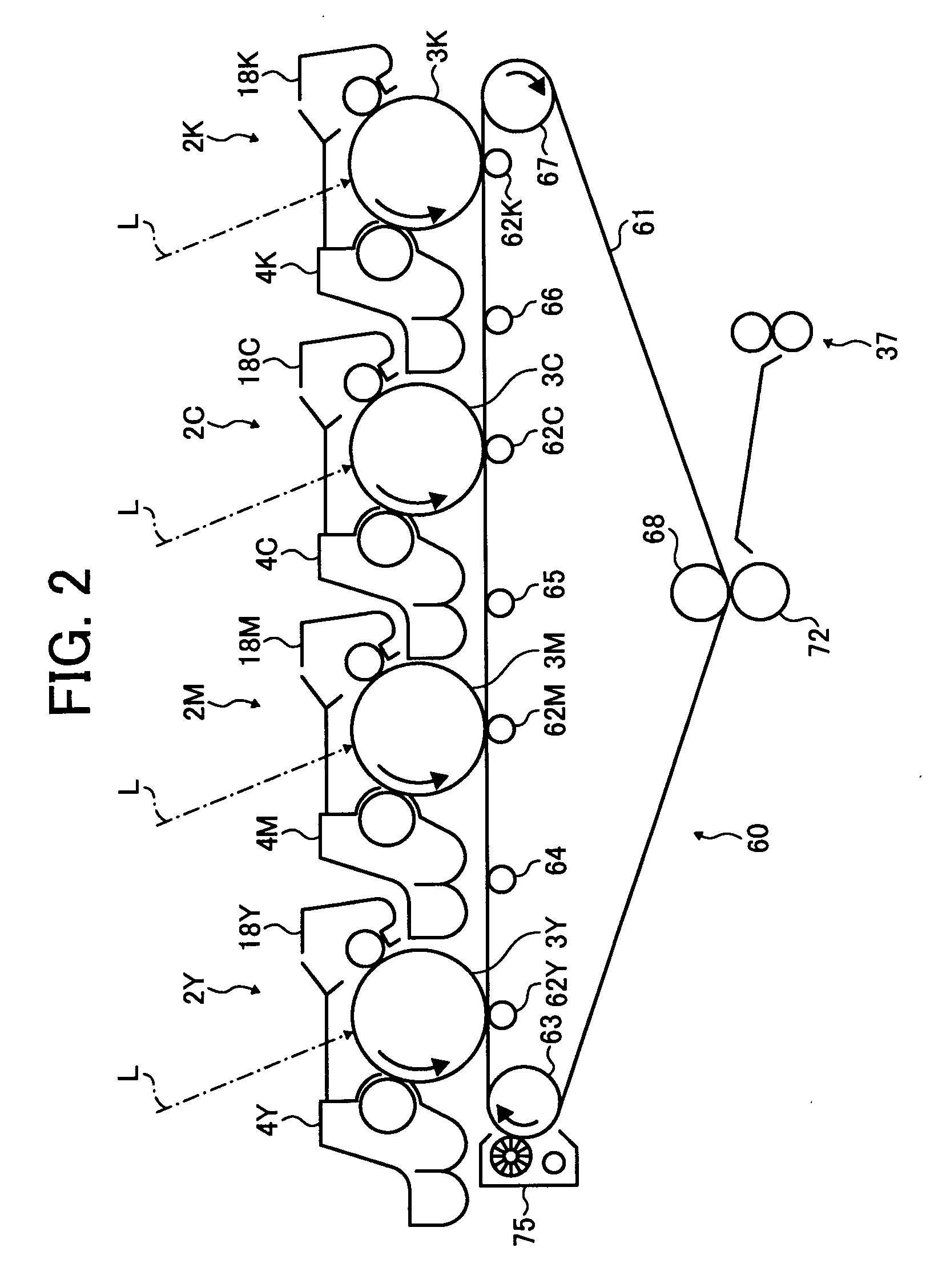

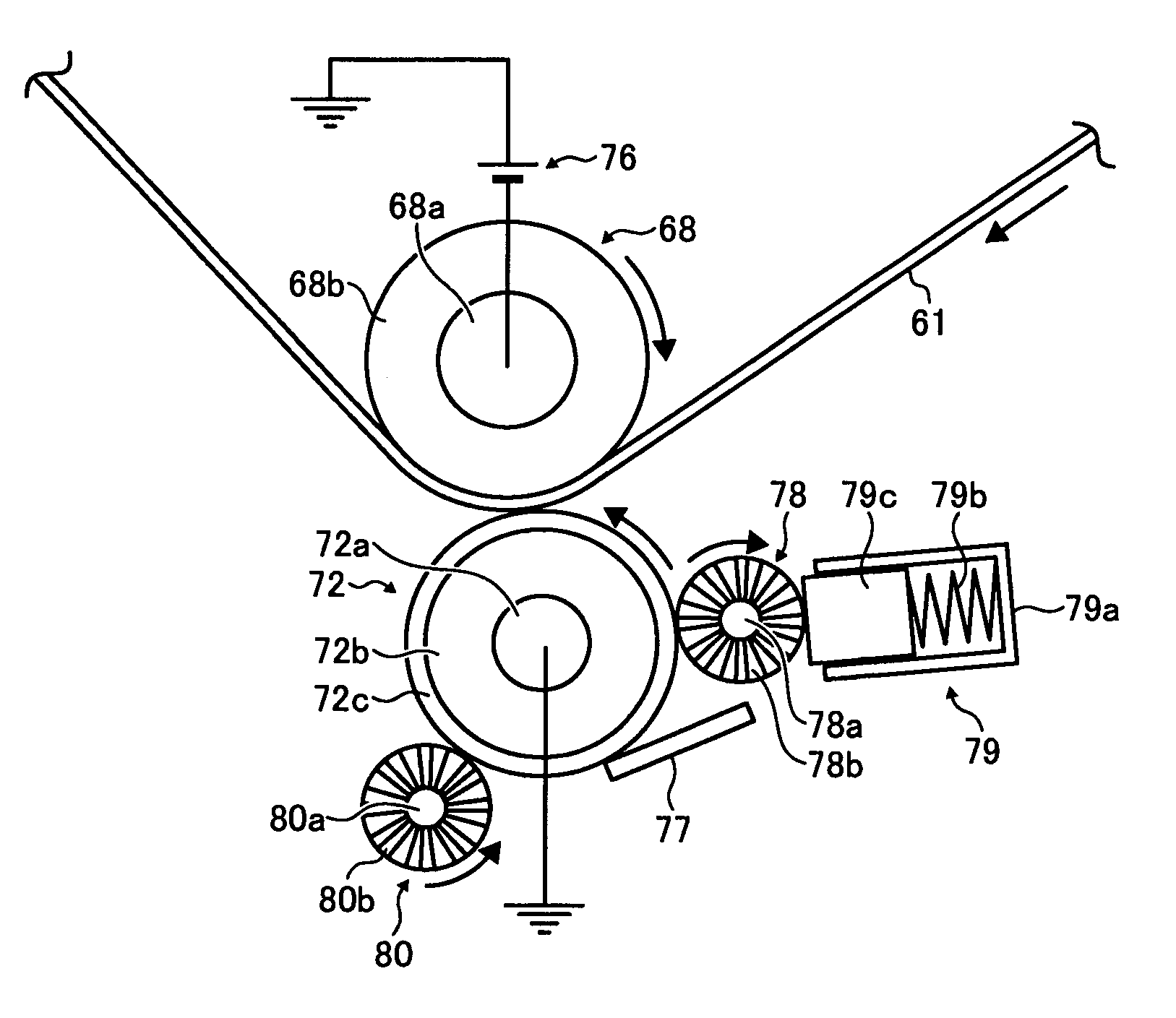

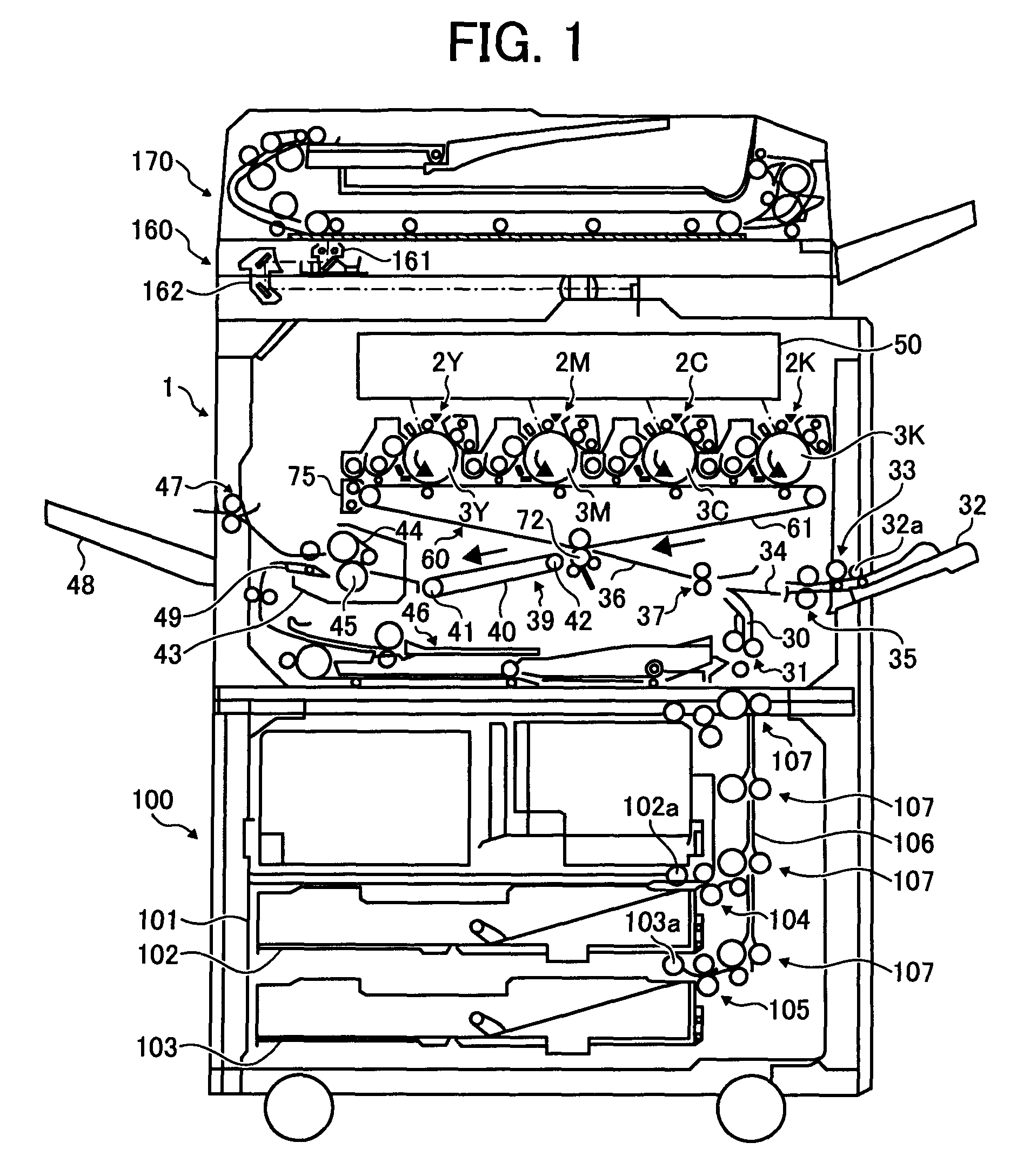

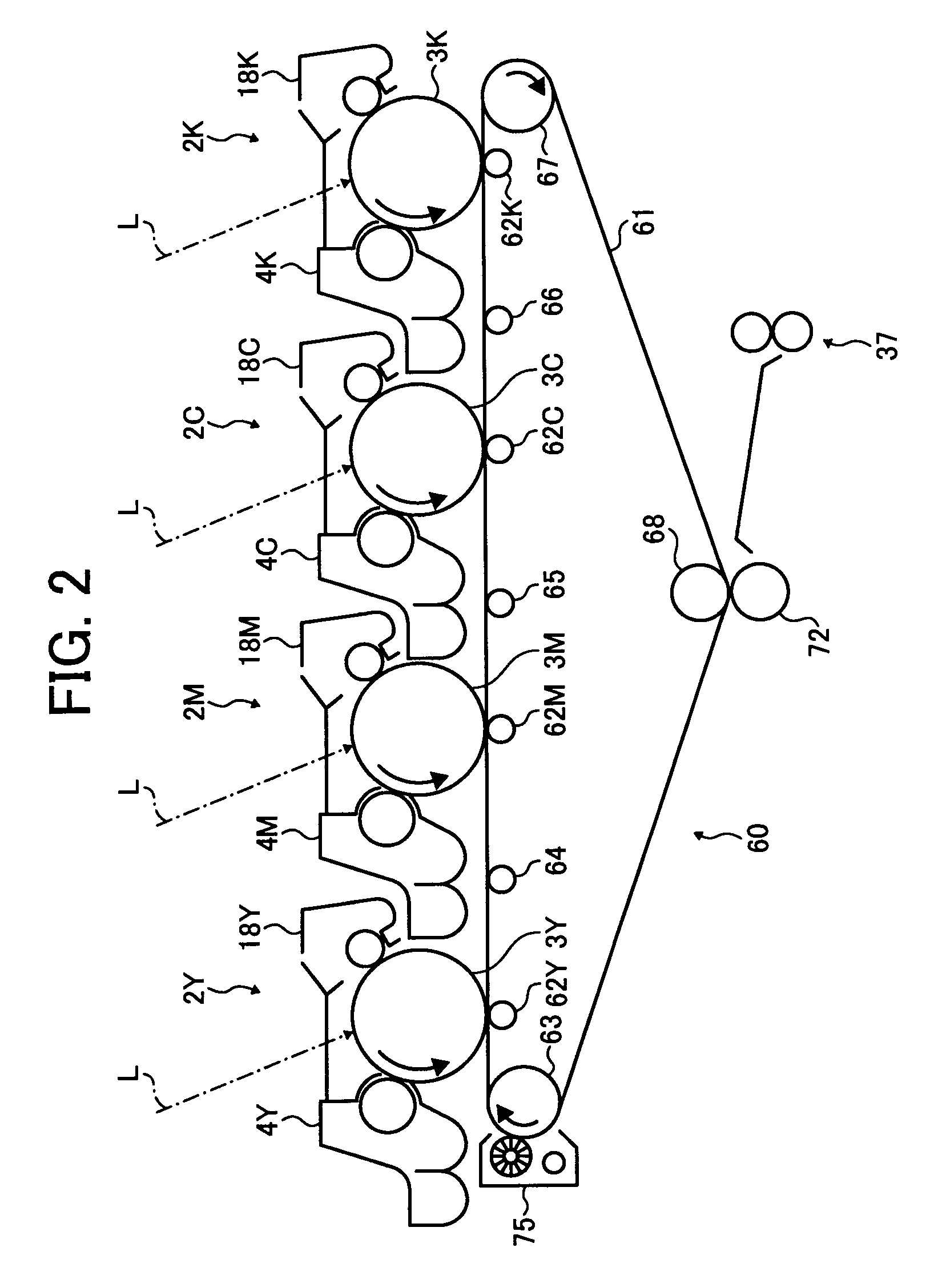

Transferring device having two devices for cleaning a transferring member, and image forming apparatus

ActiveUS20080124155A1Small diameterImprove roundnessElectrographic process apparatusForeign matterImage formation

A transferring device installed in an image forming apparatus includes an image bearing member configured to bear toner images on the surface. There is a transferring member configured to contact the image bearing member to form a transferring nip. A lubricant supplying member is configured to supply a lubricant to the surface of the transferring member, and there is a transferring member cleaning member such as a blade configured to remove residual toner and which contacts the surface of the transferring member. There is also a foreign material removing member configured to remove residual foreign material from the surface of the transferring member.

Owner:RICOH KK

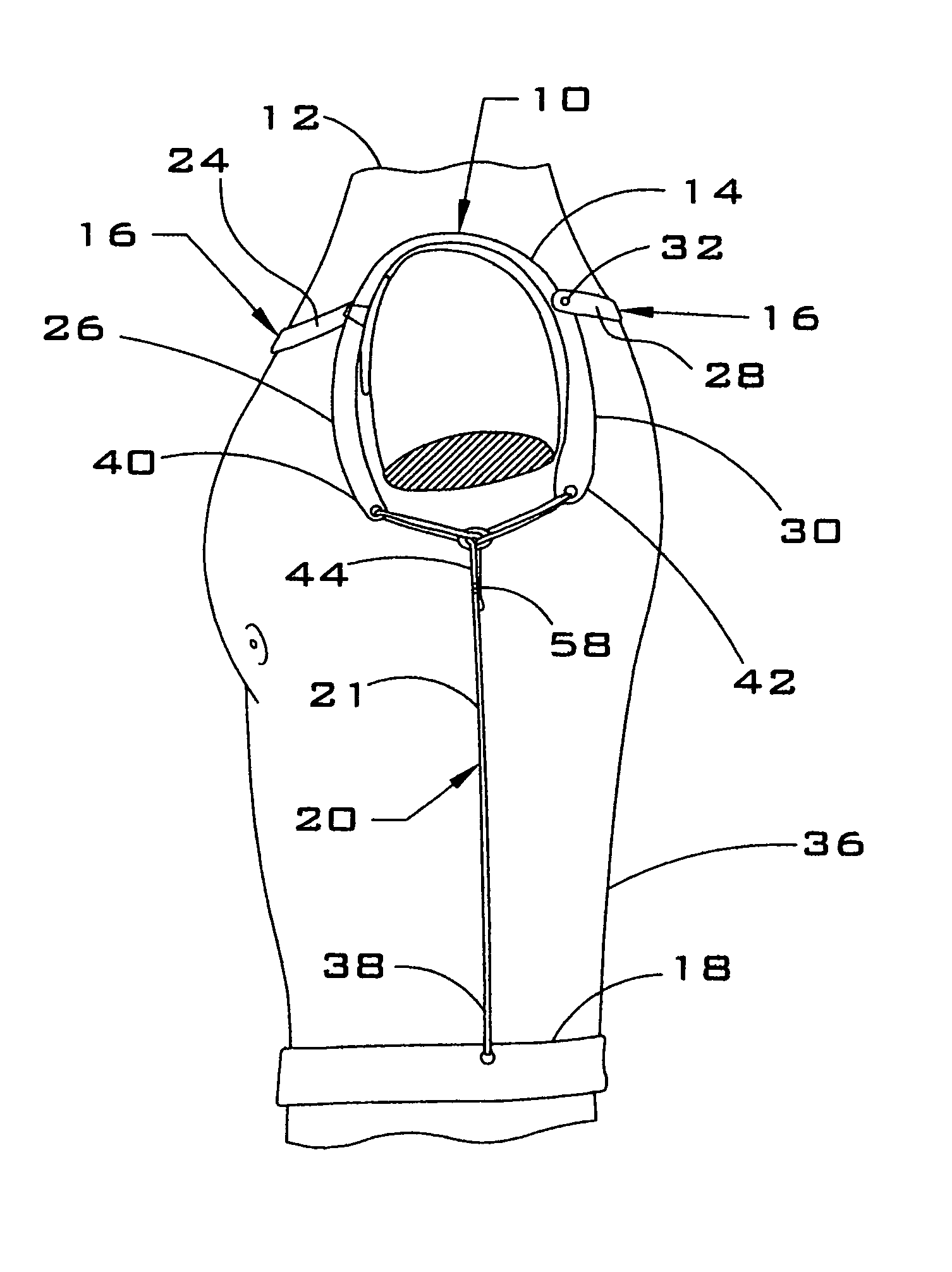

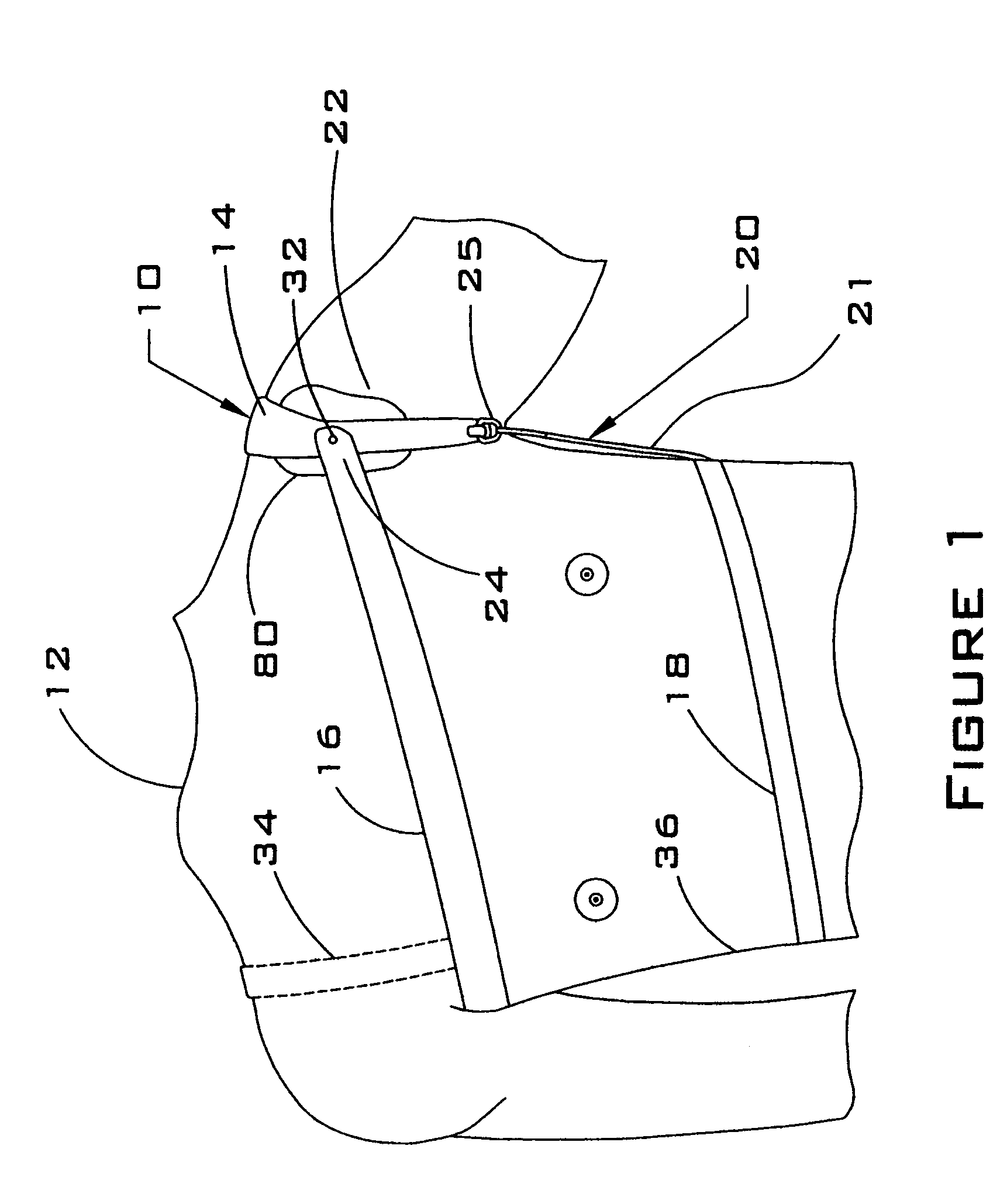

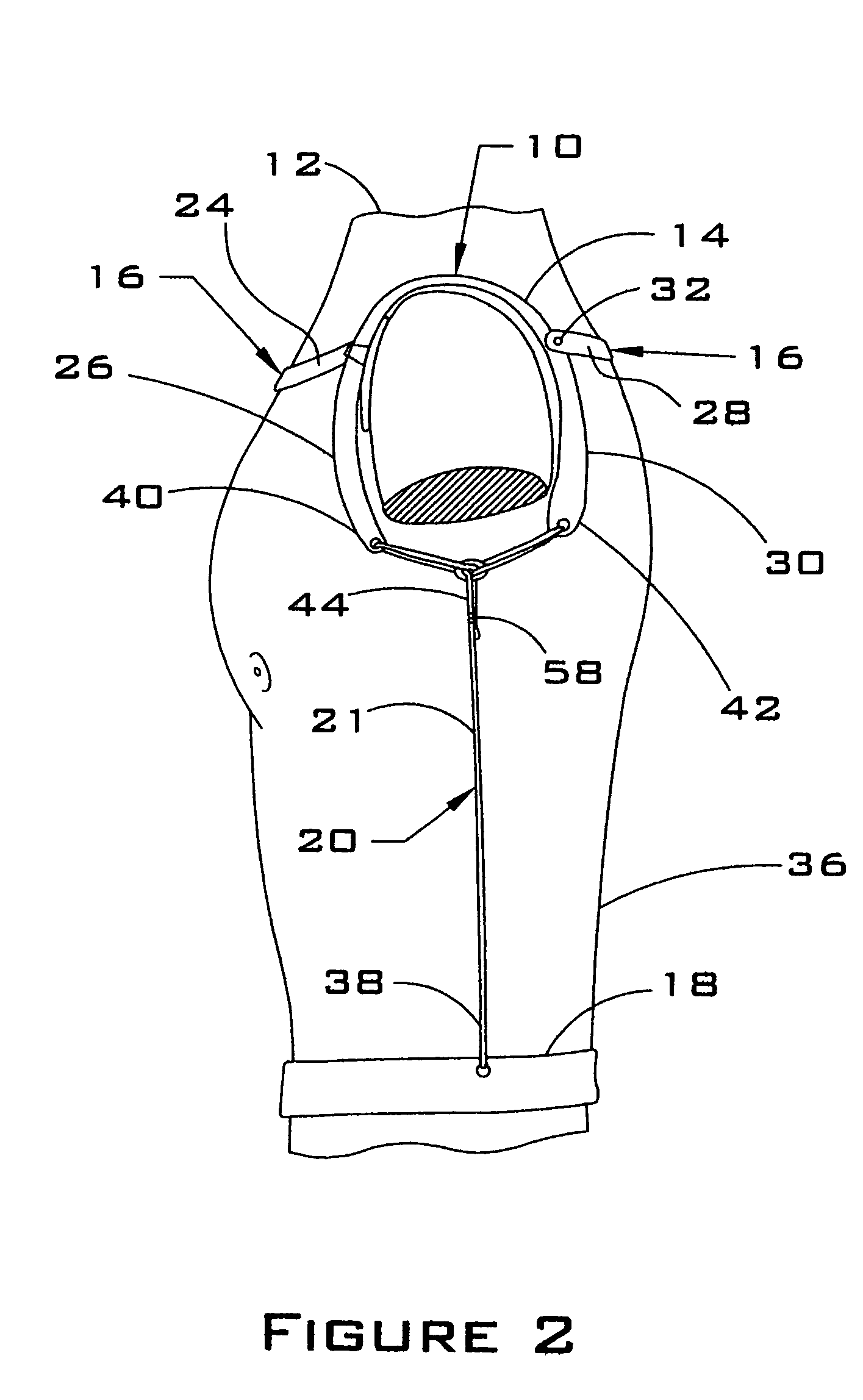

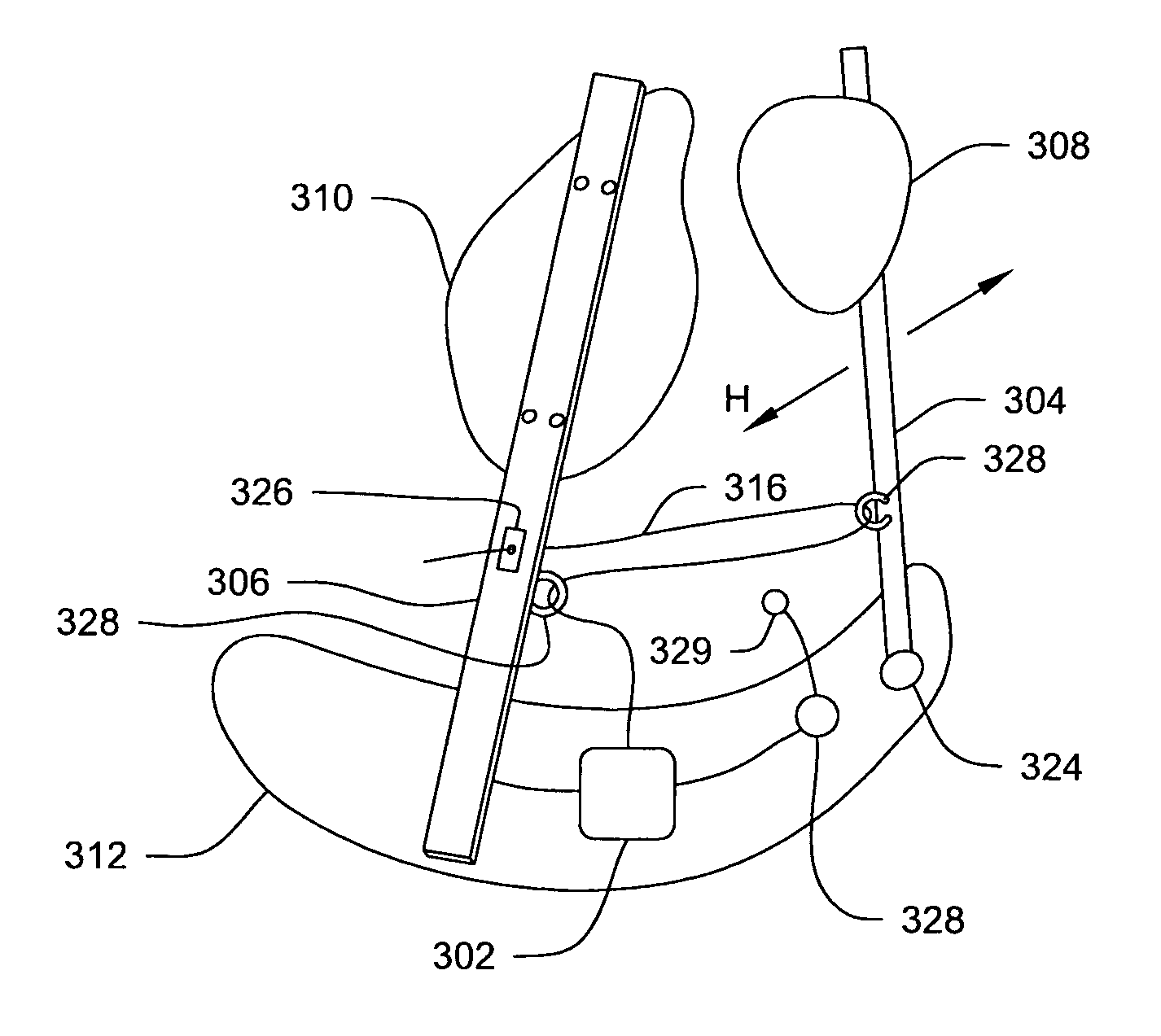

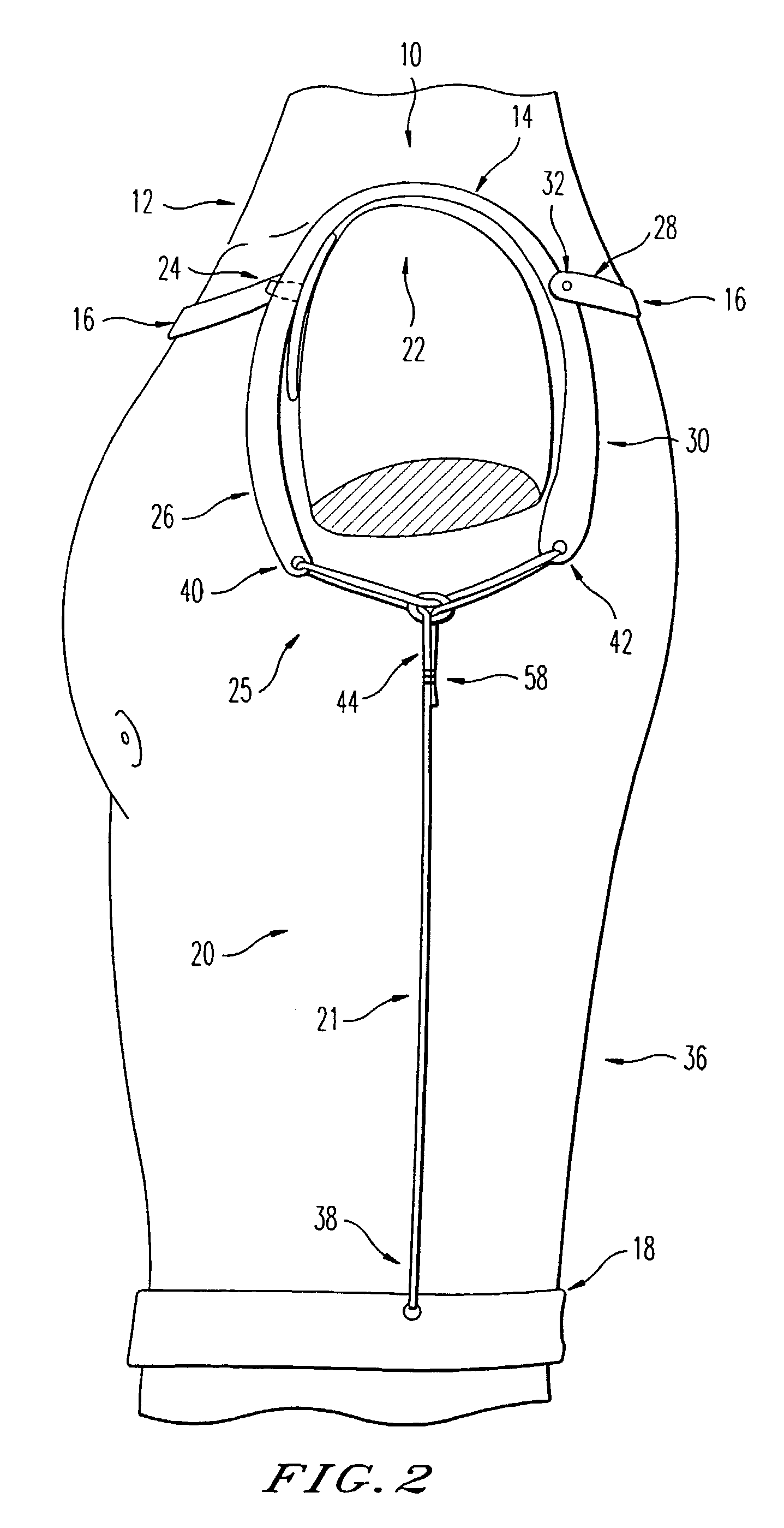

Shoulder brace

InactiveUS7207963B2Not excessively inhibiting motionRaise the possibilityRestraining devicesOrthopedic corsetsShoulder joint capsulePhysical therapy

A shoulder brace including a shoulder member mountable to a patient's shoulder, and a positioning device that increases pressure to the shoulder in accordance with the position of the patient's arm. In one embodiment, the shoulder brace includes a shoulder member with an open portion forming substantially rigid first and second arms and a positioning device that varies the spacing of the first and second arms according to the position of the patient's arm. In another embodiment, the positioning device includes a tensioning ring and first and second tension triggering straps that provide anterior and posterior compression of the shoulder joint when the arm is moved into a danger zone. In another embodiment, the shoulder brace includes a first mounting member mountable to the pectoral area, a second mounting member mountable to the upper arm, and a connecting member that connects the first and second mounting members.

Owner:FOUNTAINHEAD

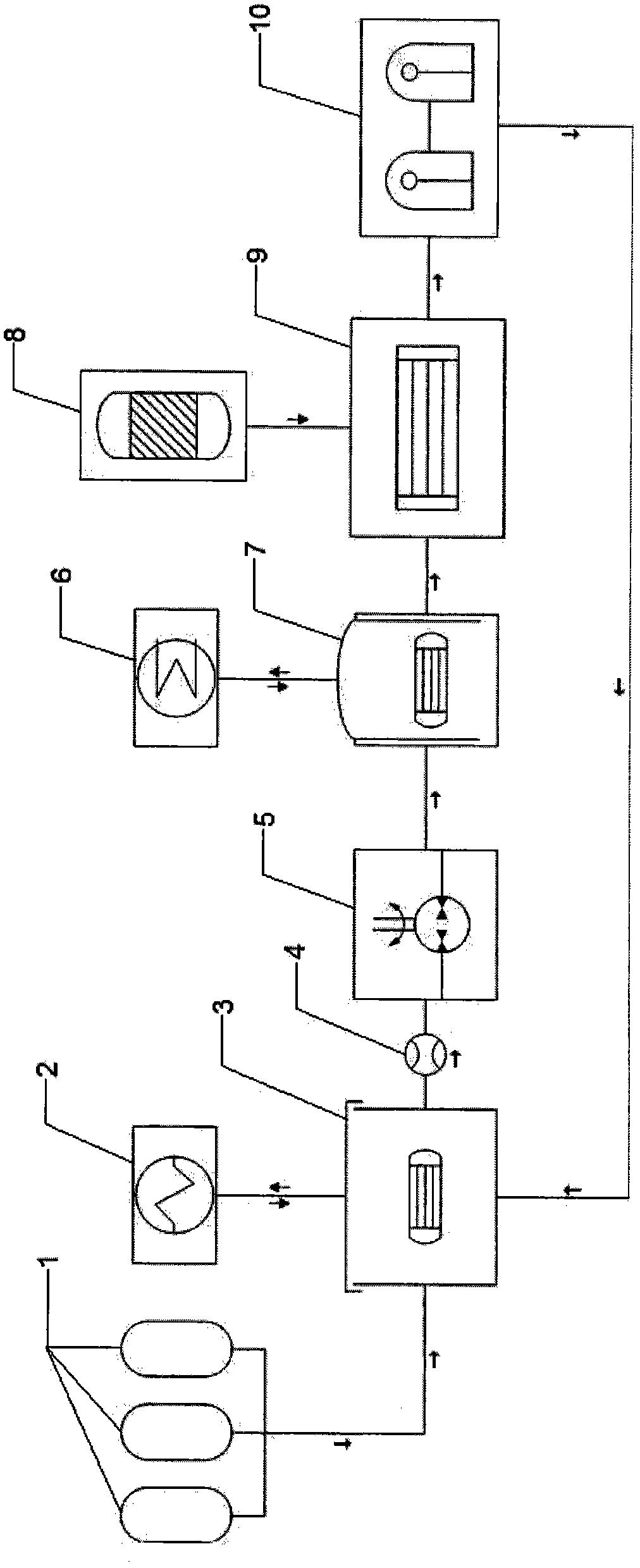

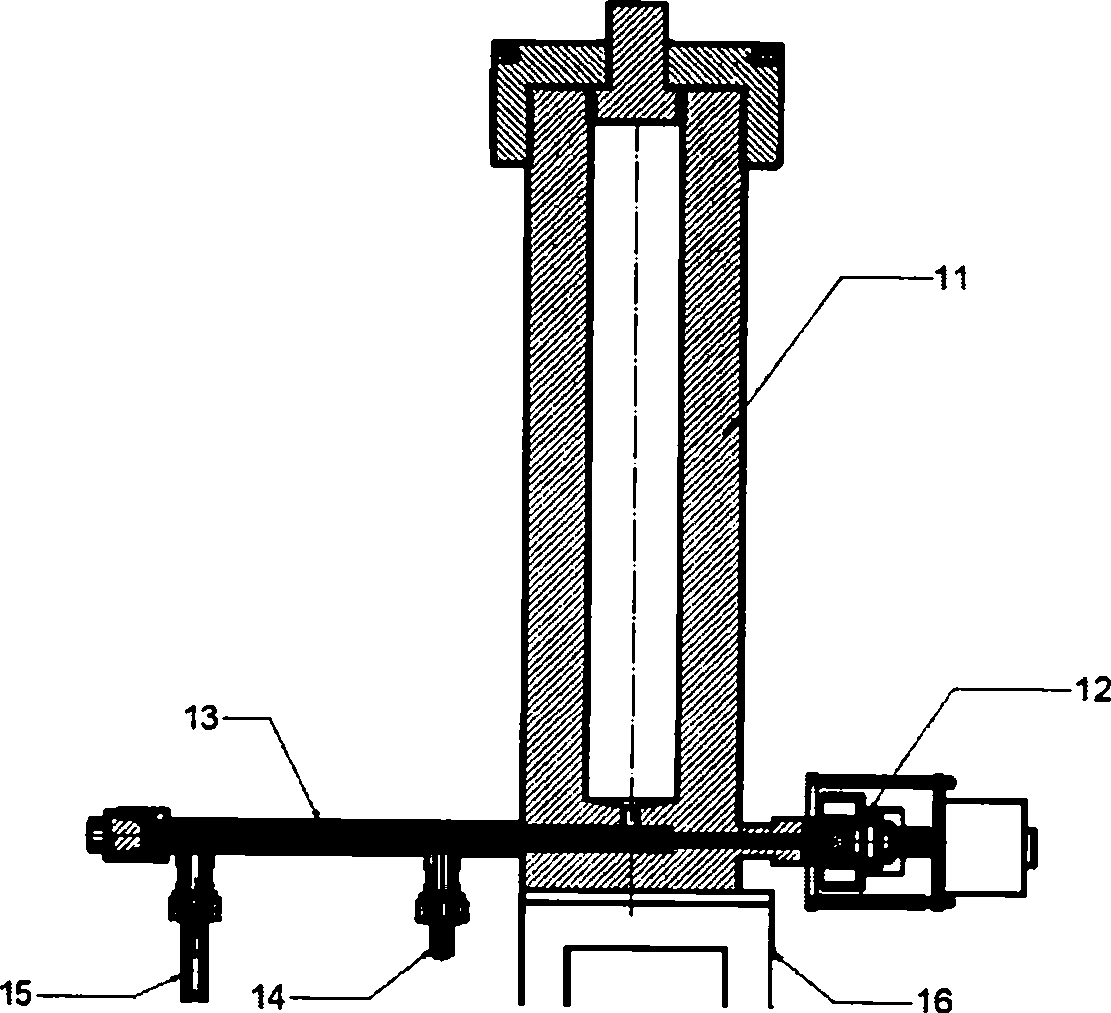

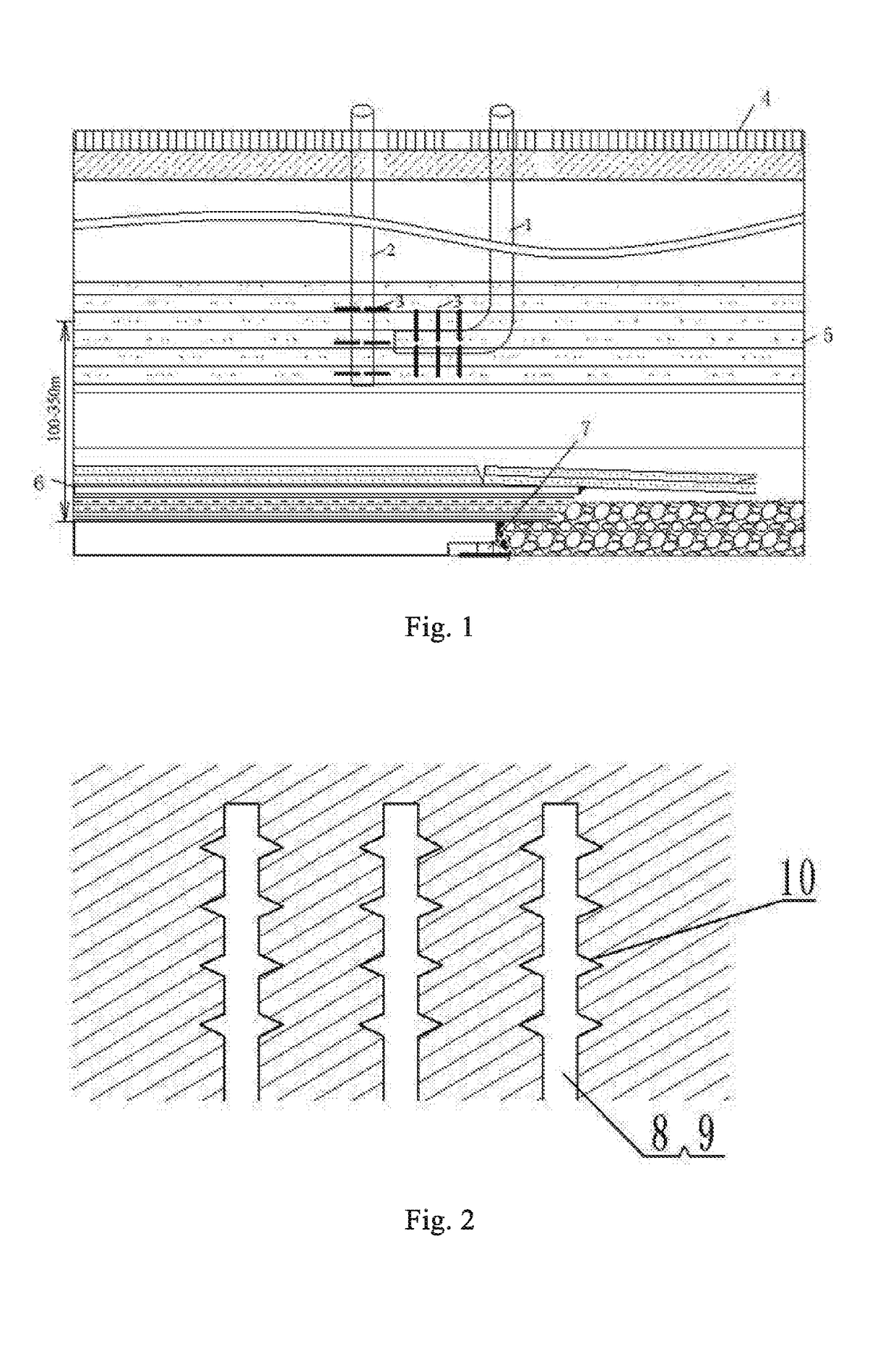

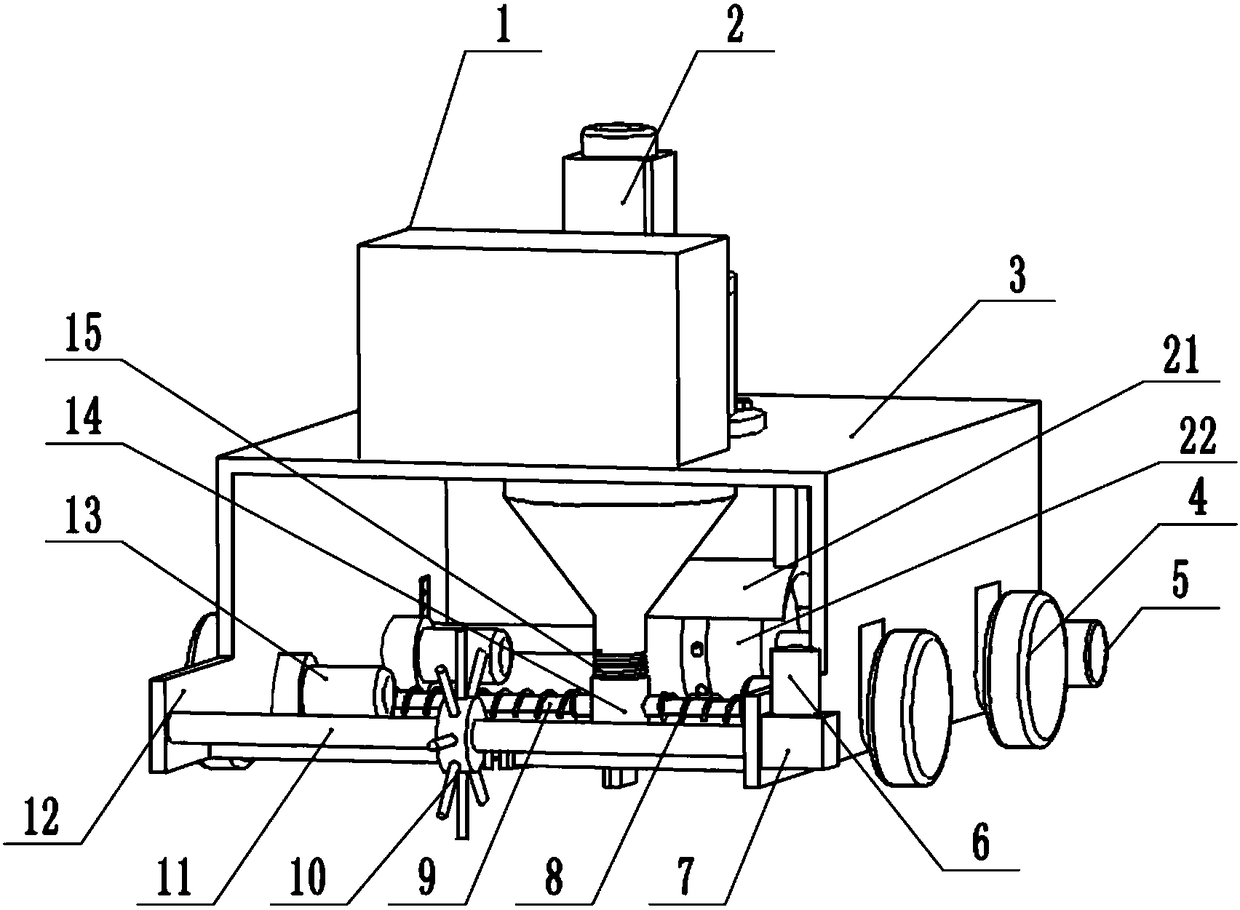

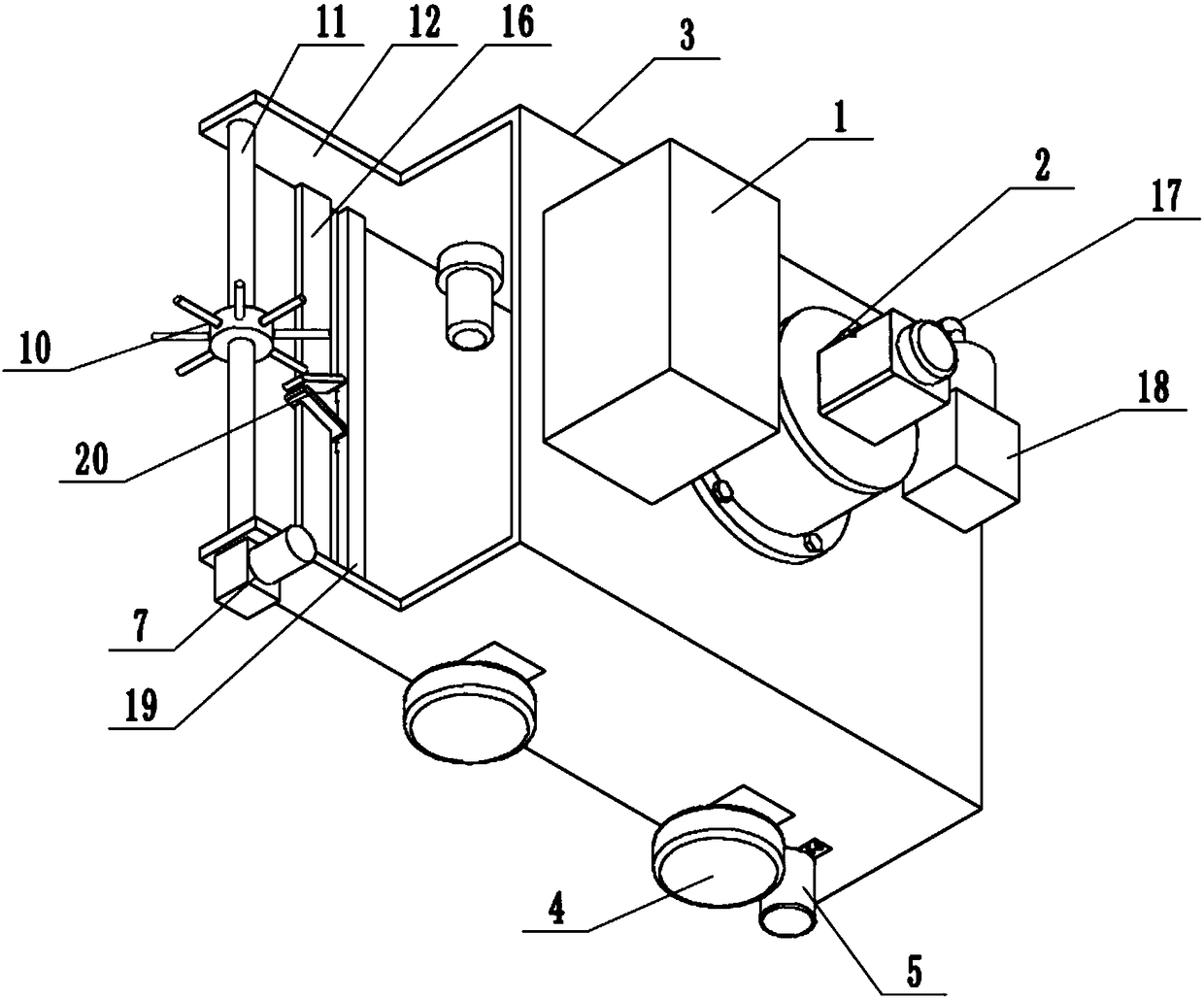

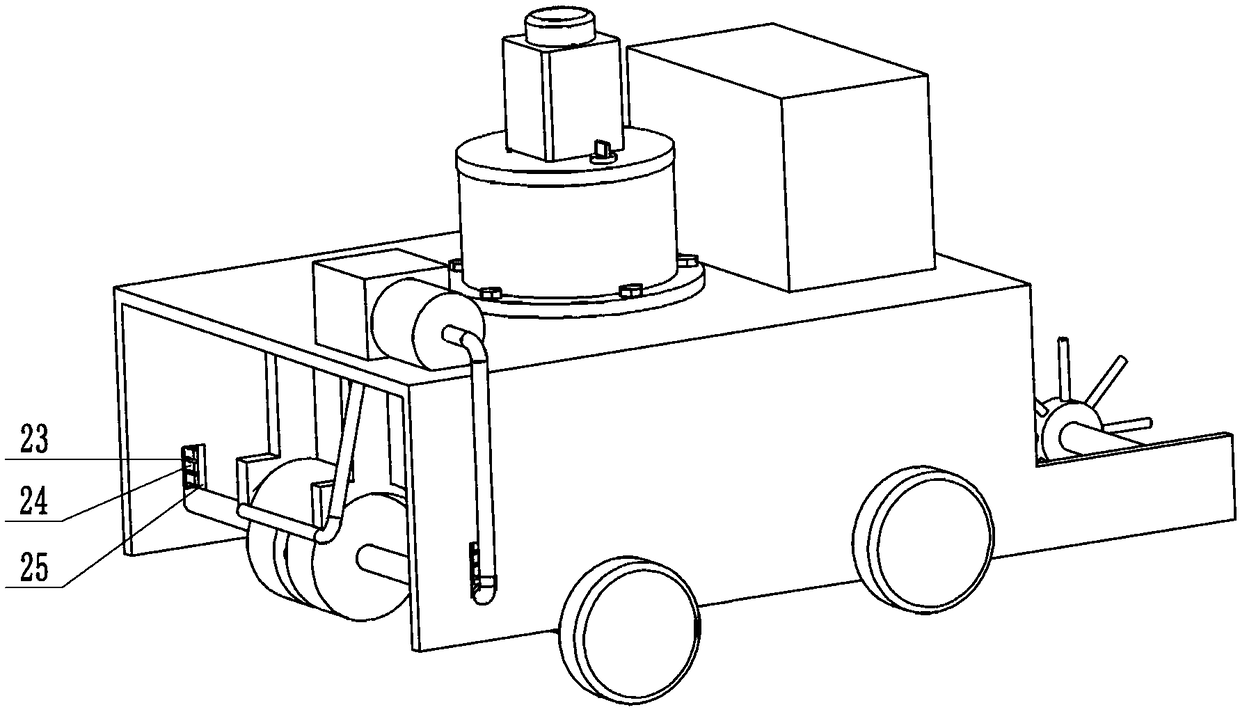

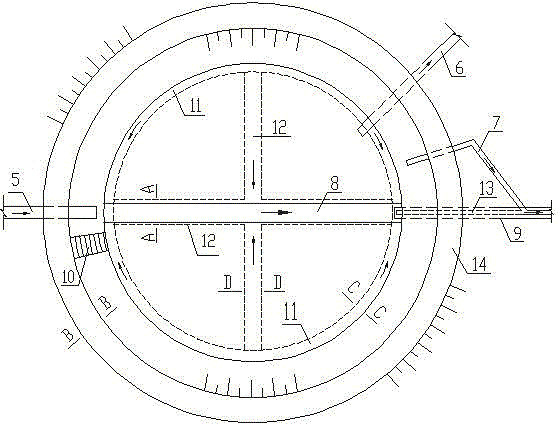

Supercritical carbon dioxide abrasive jet flow perforation simulation experiment system

ActiveCN103742075AEnhance investigation abilityStrong pressureLiquid/gas jet drillingFluid removalChemistryNozzle

The invention discloses a supercritical carbon dioxide abrasive jet flow perforation simulation experiment system used for simulating the processes that supercritical carbon dioxide abrasive jet flow scours broken rocks and damages a sleeve pipe, comparing and analyzing different jet flow experiment effects, revealing different factor influencing rules and the like. The supercritical carbon dioxide abrasive jet flow perforation simulation experiment system is composed of a carbon dioxide liquefying device, a supercritical carbon dioxide generating device, a supercritical carbon dioxide abrasive jet flow experiment device and a carbon dioxide recycling device, wherein the supercritical carbon dioxide abrasive jet flow experiment device is composed of a jet flow surrounding pressing barrel device and an abrasive adding device and is a kernel module of the system, supercritical carbon dioxide fluid forms jet flow when passing a sprayer, and abrasives are conveyed through a stranding cage and a sand adder to be mixed with the jet flow, so that the supercritical carbon dioxide abrasive jet flow is formed and carries out perforation inside the surrounding pressing barrel. The supercritical carbon dioxide abrasive jet flow perforation simulation experiment system is safe, simple and convenient to operate, high in efficiency and capable of simulating the perforation operation of the supercritical carbon dioxide abrasive jet flow in various work conditions and being applied to experiments of fluid like liquid nitrogen.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

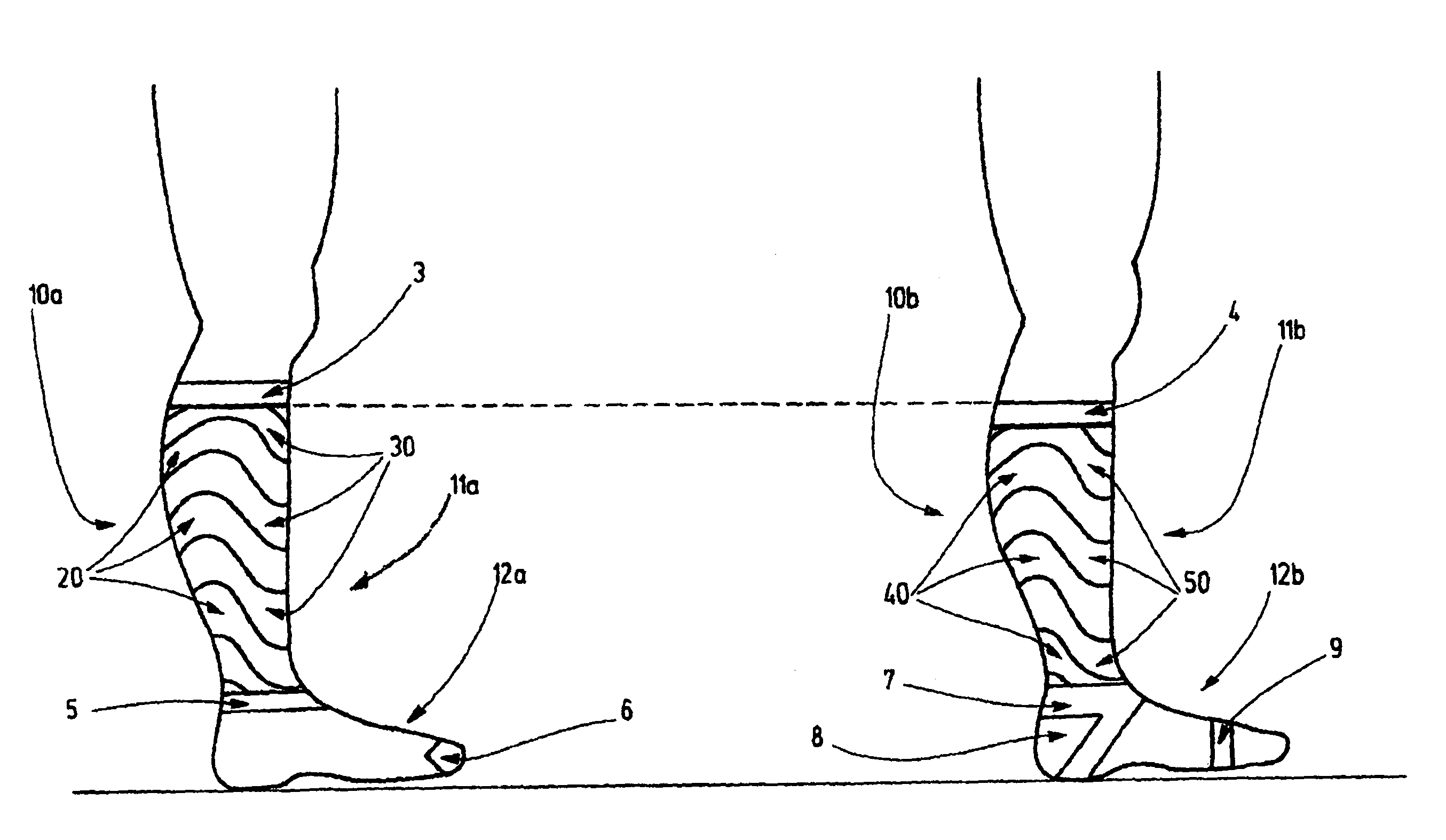

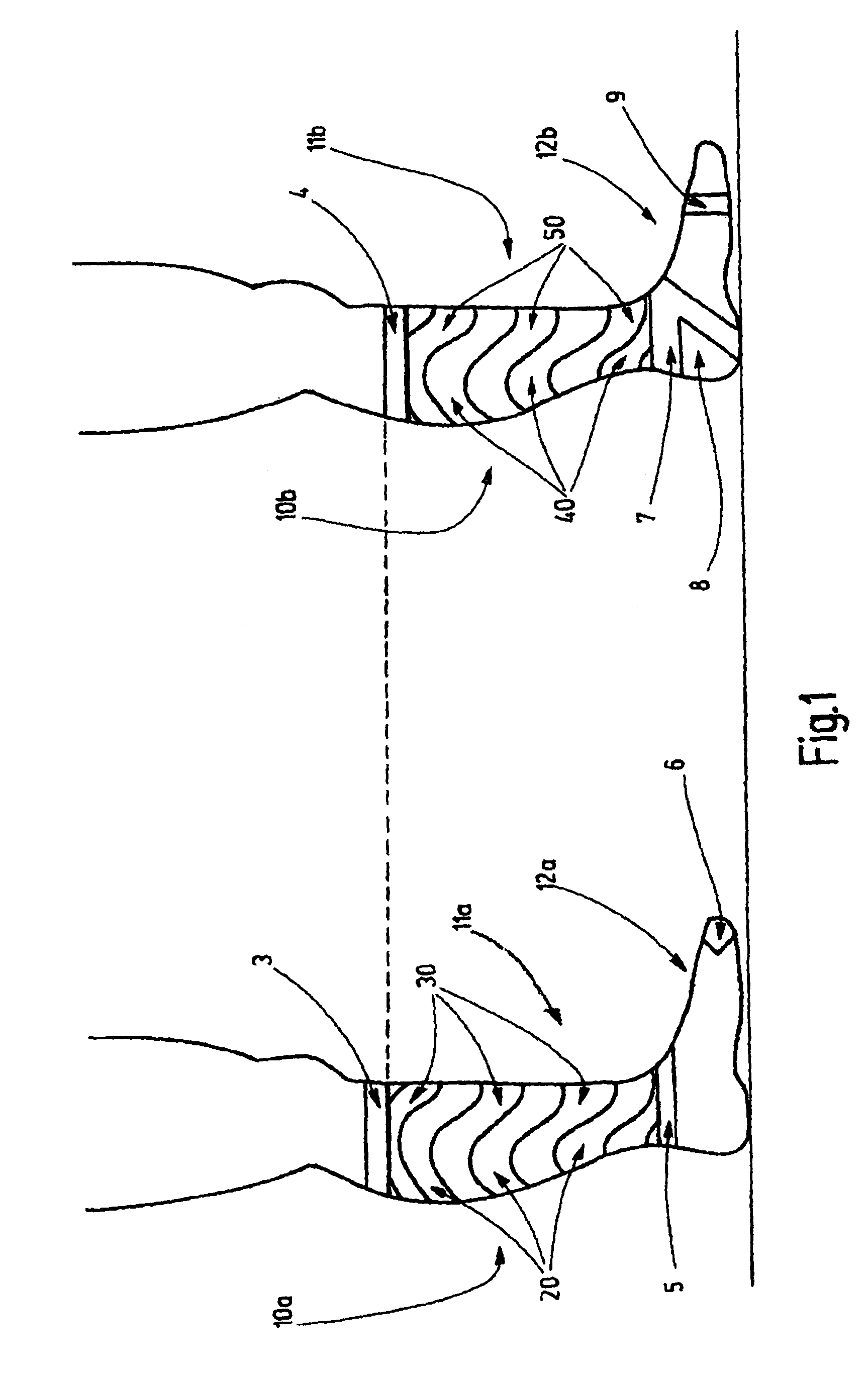

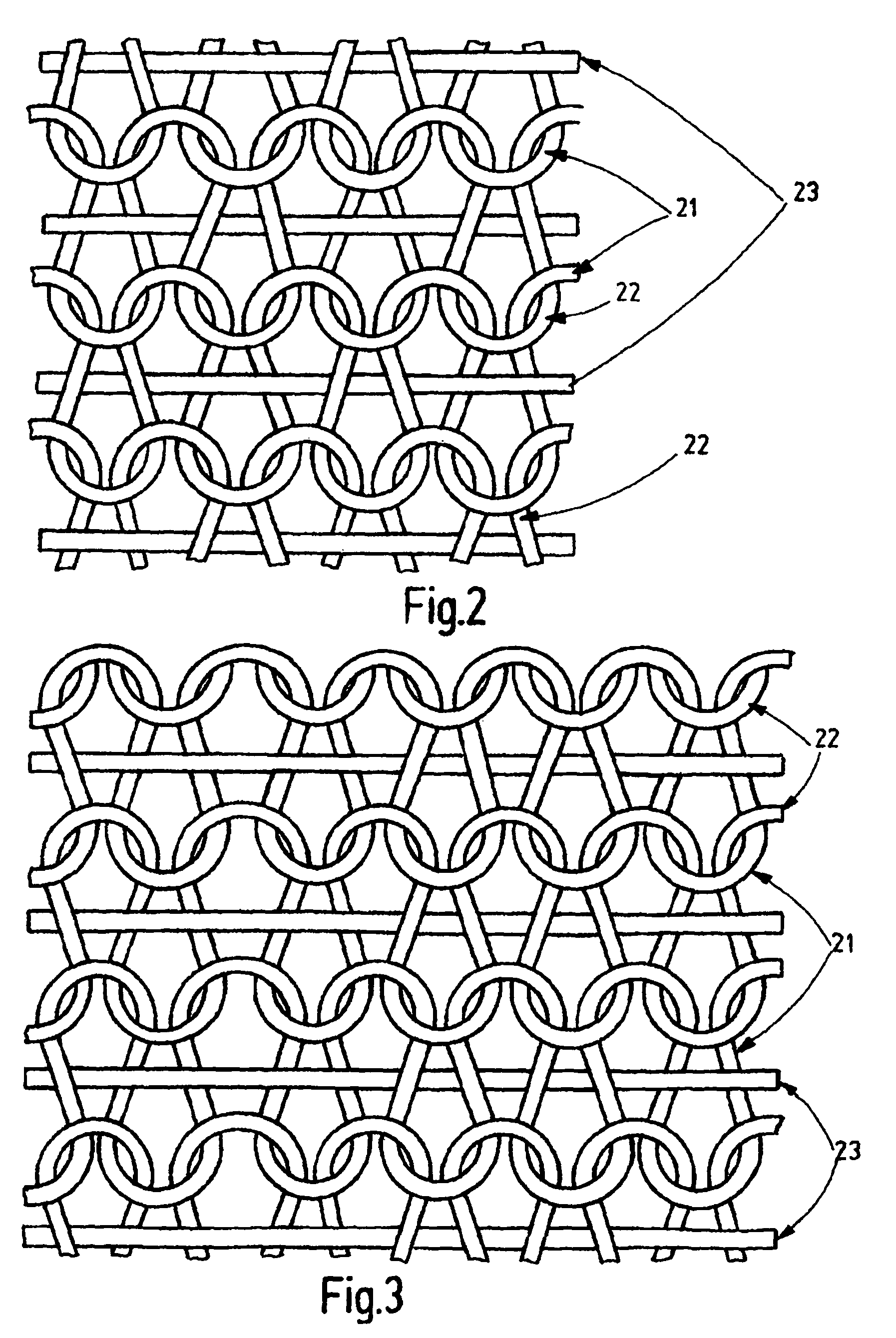

Compression or support stocking

InactiveUS8317736B2Good fixationPromote wound healingInsolesFeet bandagesPhysical therapySupport stockings

A compression or support stocking encases a human leg. The stocking has a first understocking and a first overstocking, each with a leg section and a foot section, which can be worn over each other, wherein the understocking has a continuous pressure progression in the area between measuring points B and B1, and the pressure at measuring point B1 amounts to 90%-100% of the pressure at measuring point B. The compression or support stocking can be used for treating Ulcus cruris venosum.

Owner:PAUL HARTMANN AG

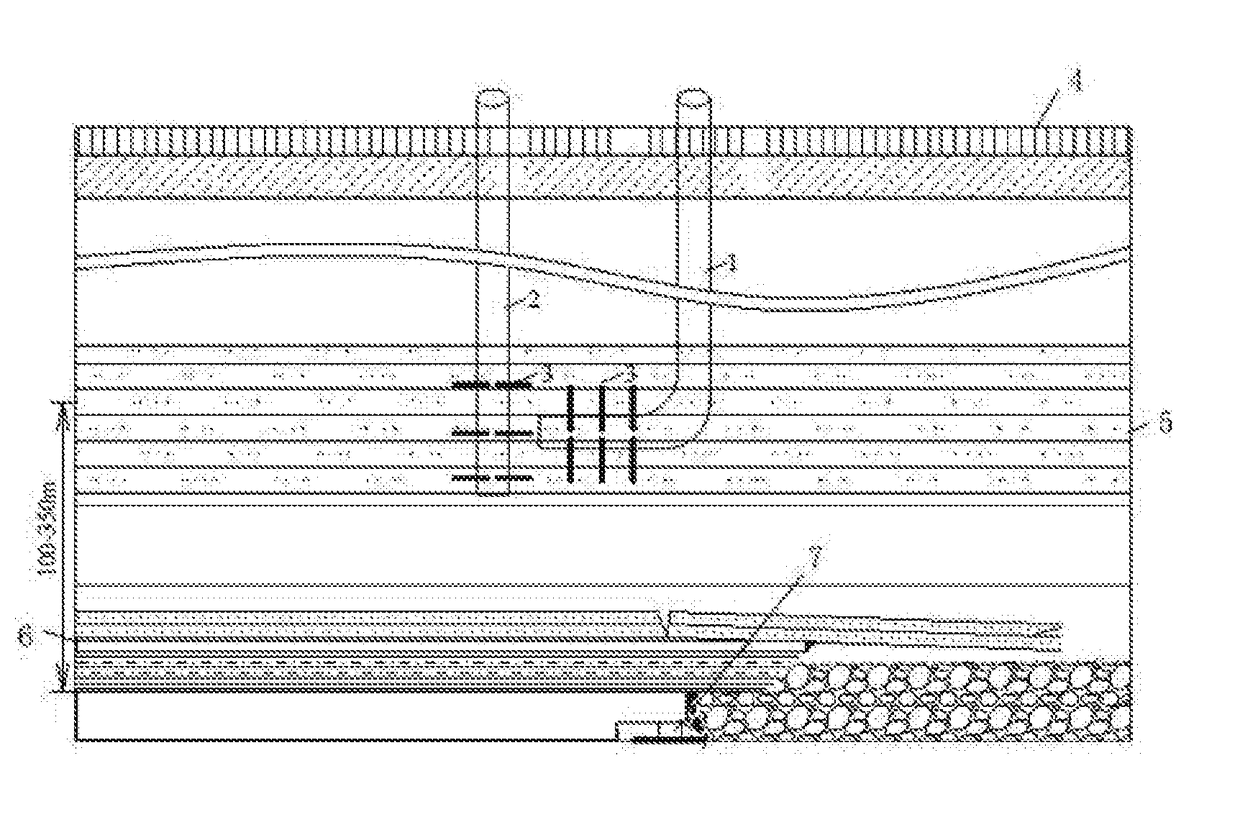

Method for over-pit and under-pit cooperative control of roofs of far and near fields of an extra-large stoping space

InactiveUS20180080320A1StrengthensMaximize advantageDisloding machinesUnderground miningShock waveCoal

The invention relates to a control method for a hard roof of a coal mine, specifically to a method for over-pit and under-pit cooperative control of roofs of far and near fields of an extra-large stoping space. The method provided by the invention overcomes the problem of lack of comprehensive and cooperative control methods for hard roofs of far and near fields of an extra-large stoping space in the prior art. According to a technical scheme in the invention, the method comprises an over-pit vertical hole hydraulic fracturing method, an over-pit L-shaped hole hydraulic fracturing method, an over-pit highly-energy-gathered repetition pulse strong shock wave method, an under-pit water injection method, an under-pit layered blasting method and an under-pit hydraulic fracturing method. The method has the advantages that 1) the problem of great mine pressure of the extra-large stoping space is effectively controlled through over-pit and under-pit cooperative control of the hard roofs of far and near fields; 2) advantages of the variety of methods are given to full play and disadvantages of the variety of methods are mutually compensated, so weakening effect on the hard roofs is substantially improved; and 3) all the over-pit and under-pit holes can be used independently or be used in a shared way, so time, manpower, material resources and money used for hole perforation can be greatly reduced.

Owner:DATONG COAL MINE GRP

Transferring device having two devices for cleaning a transferring member, and image forming apparatus

ActiveUS7742721B2Small diameterImprove roundnessElectrographic process apparatusForeign matterImage formation

A transferring device installed in an image forming apparatus includes an image bearing member configured to bear toner images on the surface. There is a transferring member configured to contact the image bearing member to form a transferring nip. A lubricant supplying member is configured to supply a lubricant to the surface of the transferring member, and there is a transferring member cleaning member such as a blade configured to remove residual toner and which contacts the surface of the transferring member. There is also a foreign material removing member configured to remove residual foreign material from the surface of the transferring member.

Owner:RICOH KK

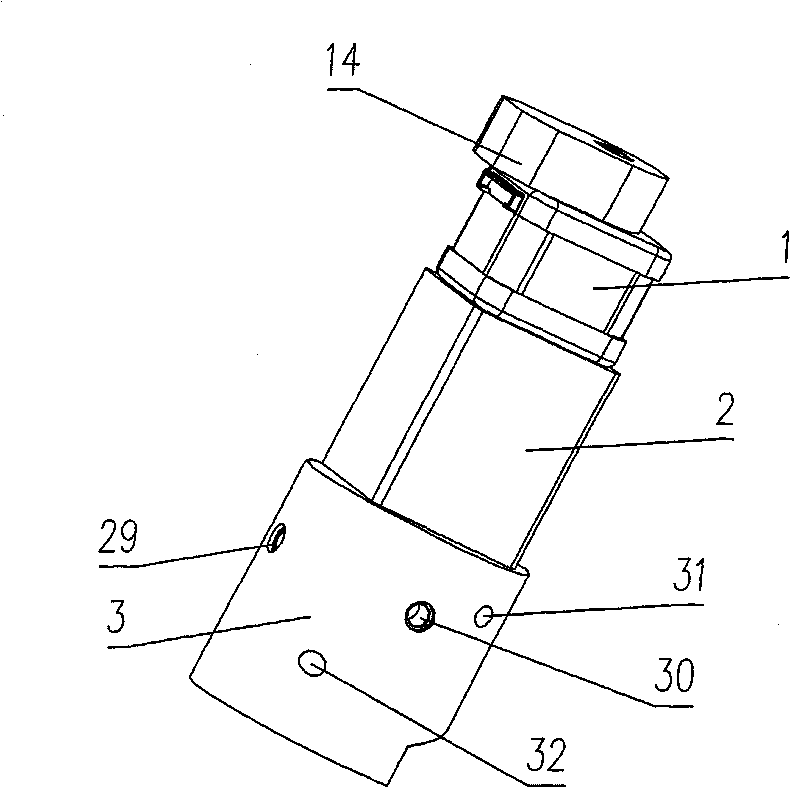

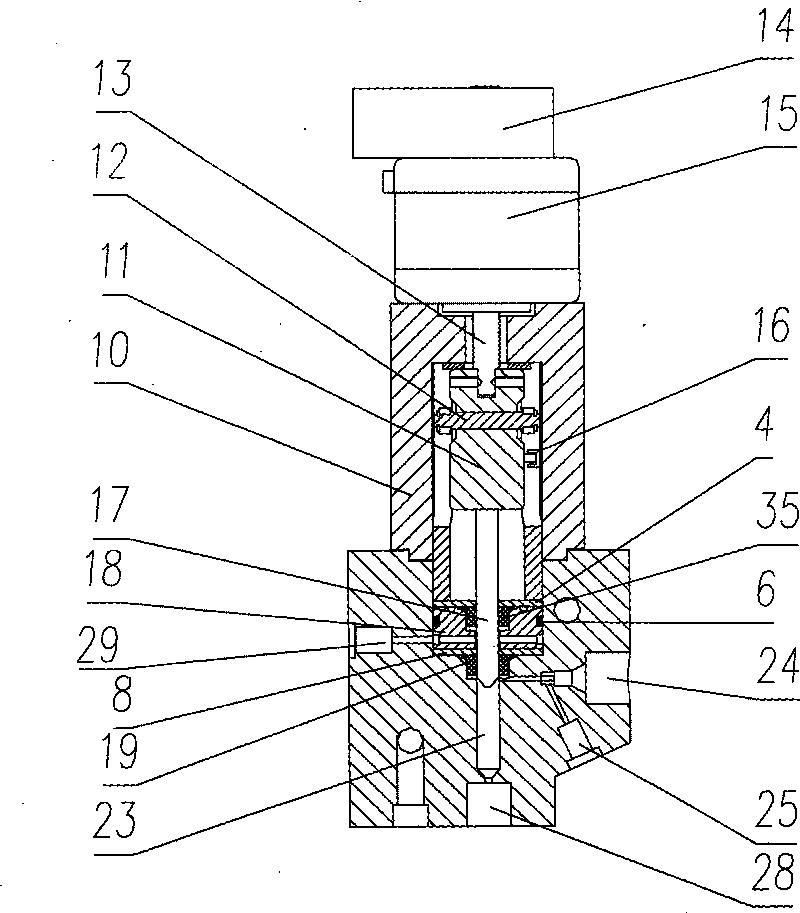

Precision plunger metering pump

InactiveCN101709693AHigh surface hardnessImprove cylindricityPumpsPositive-displacement liquid enginesRubber ringEngineering

The invention relates to a precision plunger metering pump, comprising three parts, including a driving mechanism, a sealing mechanism and a pump head, wherein by utilizing a photoelectric encoder, the driving mechanism accurately controls the movement of a stepper motor, thereby effectively preventing the error of pump output caused by the falling out of step or the idling of the motor from being generated; a sealing ring in the sealing mechanism is matched with a plunger piston to realize precision fit, and the sealing ring based on a stainless steel spring enclasping mechanism solves the problems of low enclasping force and easy aging of a traditional rubber ring and prolongs the service life; the pump head has the design of water washable airtight cabin, realizes the washing and sealing functions of the plunger piston and the sealing ring and prolongs the sealing life; the technic level of processing the plunger piston and slab rubber achieves the purpose that a miniature precision plunger metering pump can provide 20MPa pressure intensity; and the slab rubber has good polishing performance, extremely high transparency, compact structure, small volume and delicate appearance. The precision plunger metering pump can be applied to the precise metering of fluid in the fields of medication, sanitation, biology and chemistry.

Owner:THE FIRST RES INST OF MIN OF PUBLIC SECURITY +1

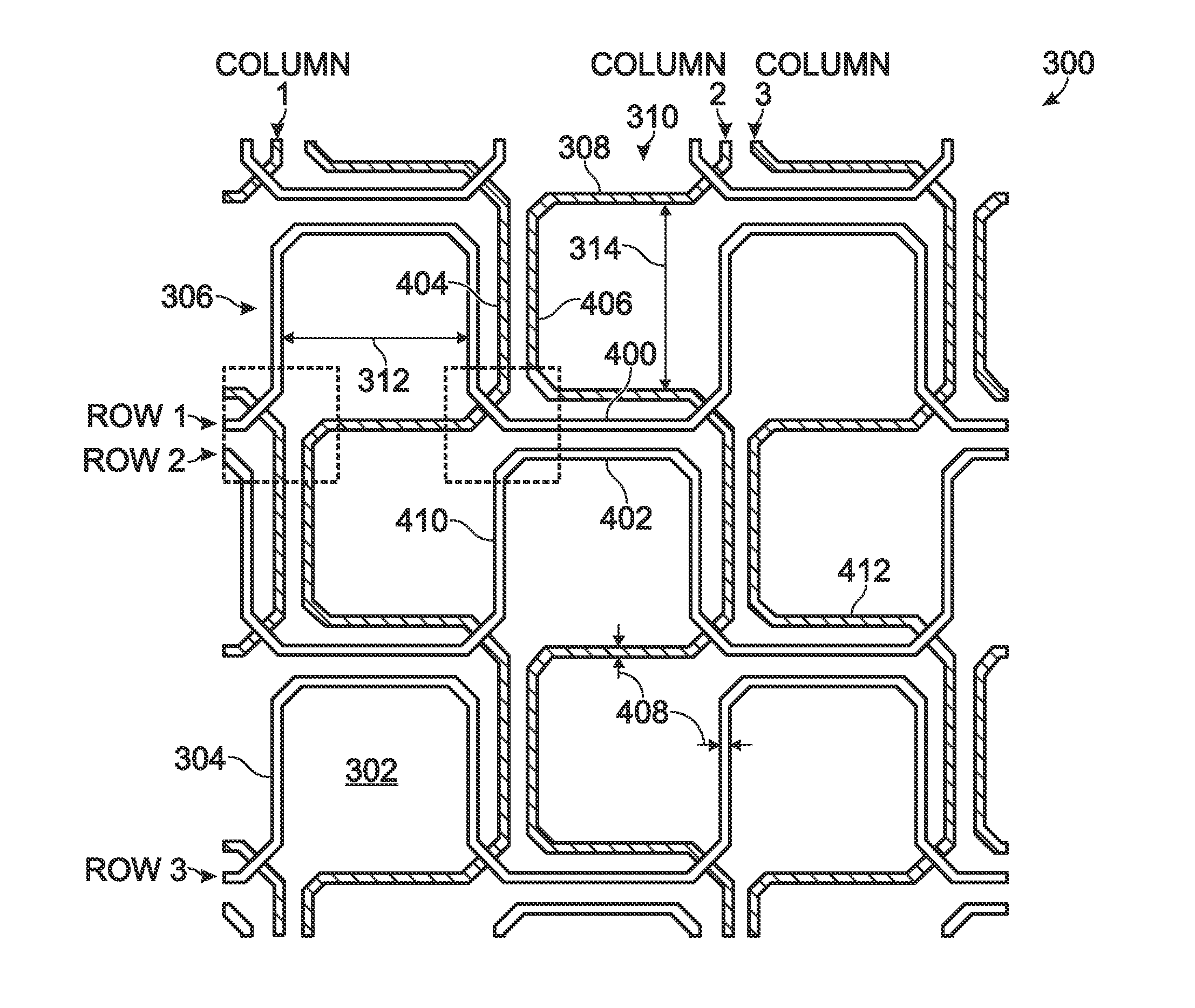

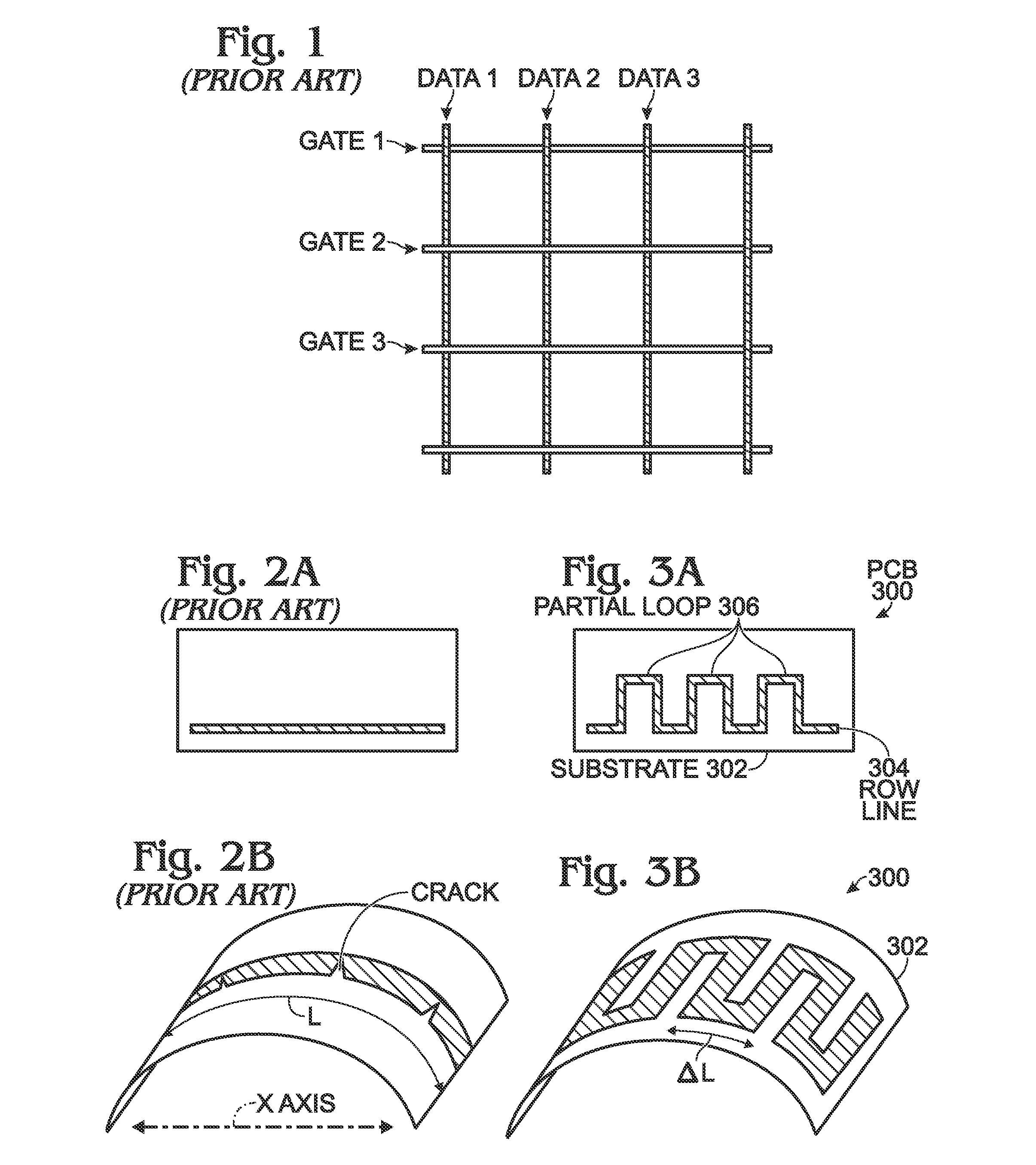

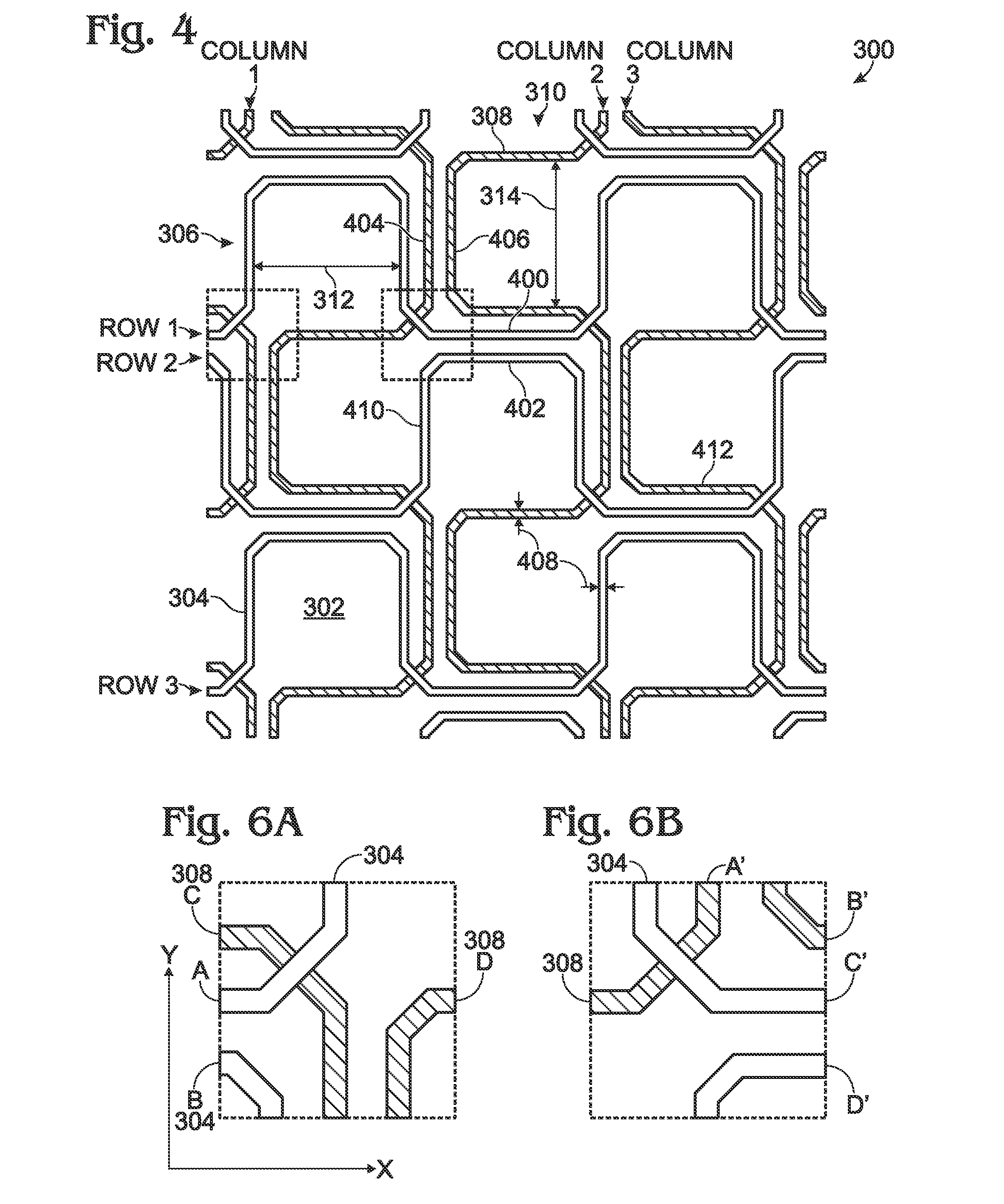

Pixel Design for Flexible Active Matrix Array

InactiveUS20160066408A1Mitigate stress/strainStress resistantTransistorCircuit bendability/stretchabilityActive matrixPrinted circuit board

A flexible active matrix array is provided, made with a flexible substrate and an array of pixels overlying the substrate, where each pixel includes an active device and a light controlling device. The array also includes a plurality of parallel row lines overlying the substrate, with each row line formed in serpentine pattern with a plurality of partial-loops, to supply a first signal to a corresponding plurality of pixels. A plurality of parallel column lines overlies the substrate, orthogonal to the row lines. Each column line is formed in a serpentine pattern with a plurality of partial-loops, to supply a second signal to a corresponding plurality of pixels. Each pixel has a border, with each row line partial-loop formed along about 75% of a pixel border, and each column line partial-loop formed along about 75% of a pixel border. Also provided is a printed circuit board with serpentine traces.

Owner:SHARP KK

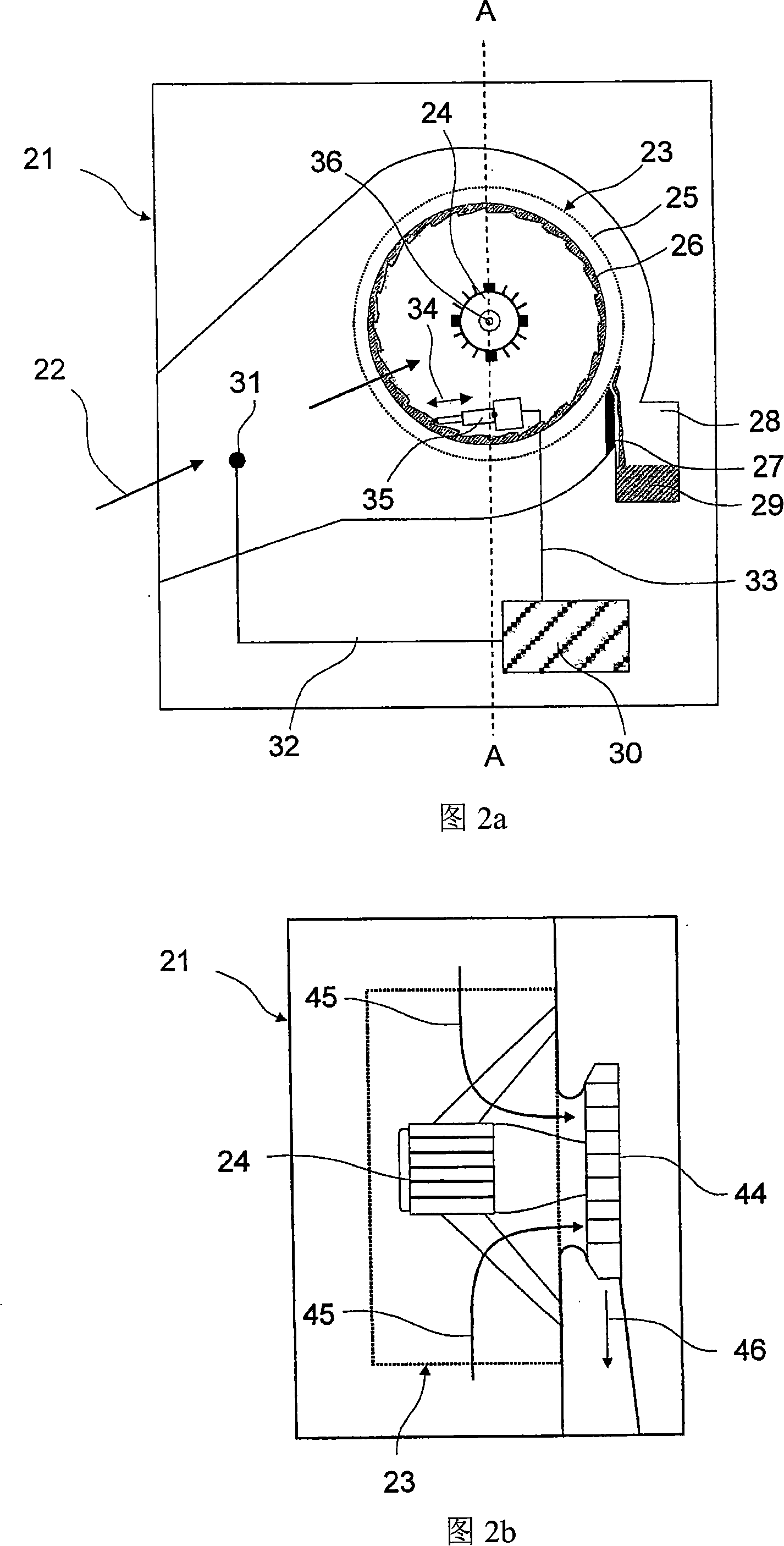

Device for preparing coffee

Device (1) for the preparation of coffee, wherein a water / coffee powder mixture is introduced into a cylindrical space (10). The cylindrical peripheral wall (15) is made as a vertical screen and by rotation / centrifugation the prepared beverage is forced through the filter to the outside, whilst granular coffee material remains behind. The top part (17) and the bottom part (19) of the holder (16) are made such they can be moved with respect to the cylinder wall. The motor (26) for rotation is above or below the top part or, alternatively, bottom part. Furthermore, there is a construction for producing the displacement of the top part or bottom part of the holder with the same motor.

Owner:SPINN HLDG

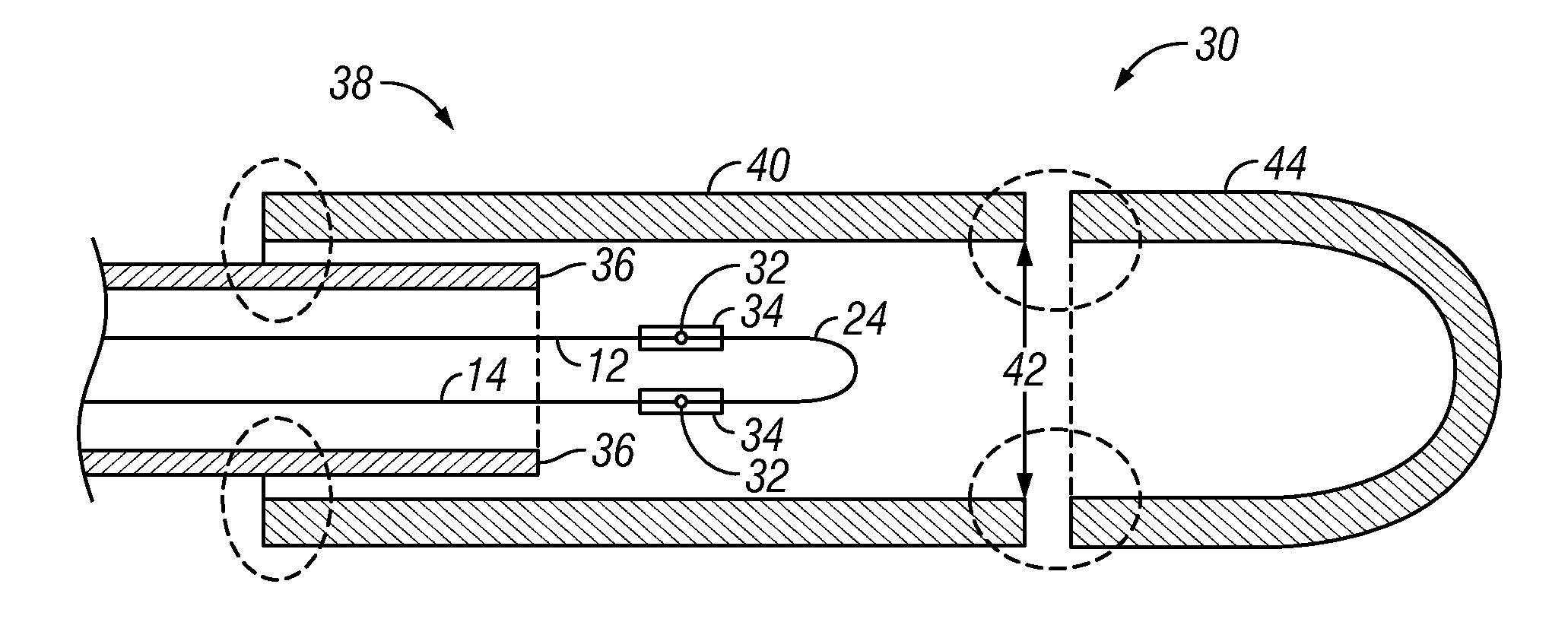

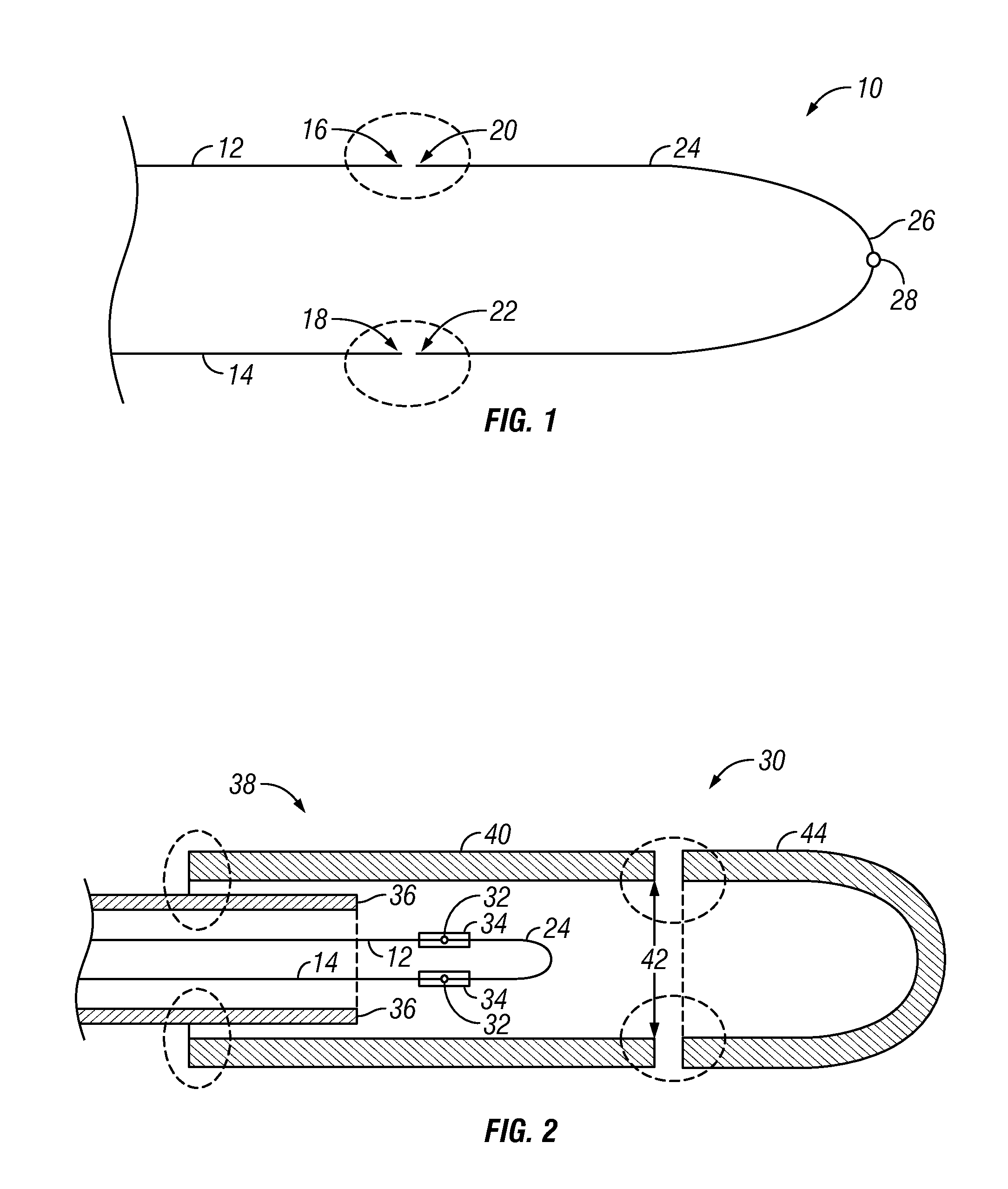

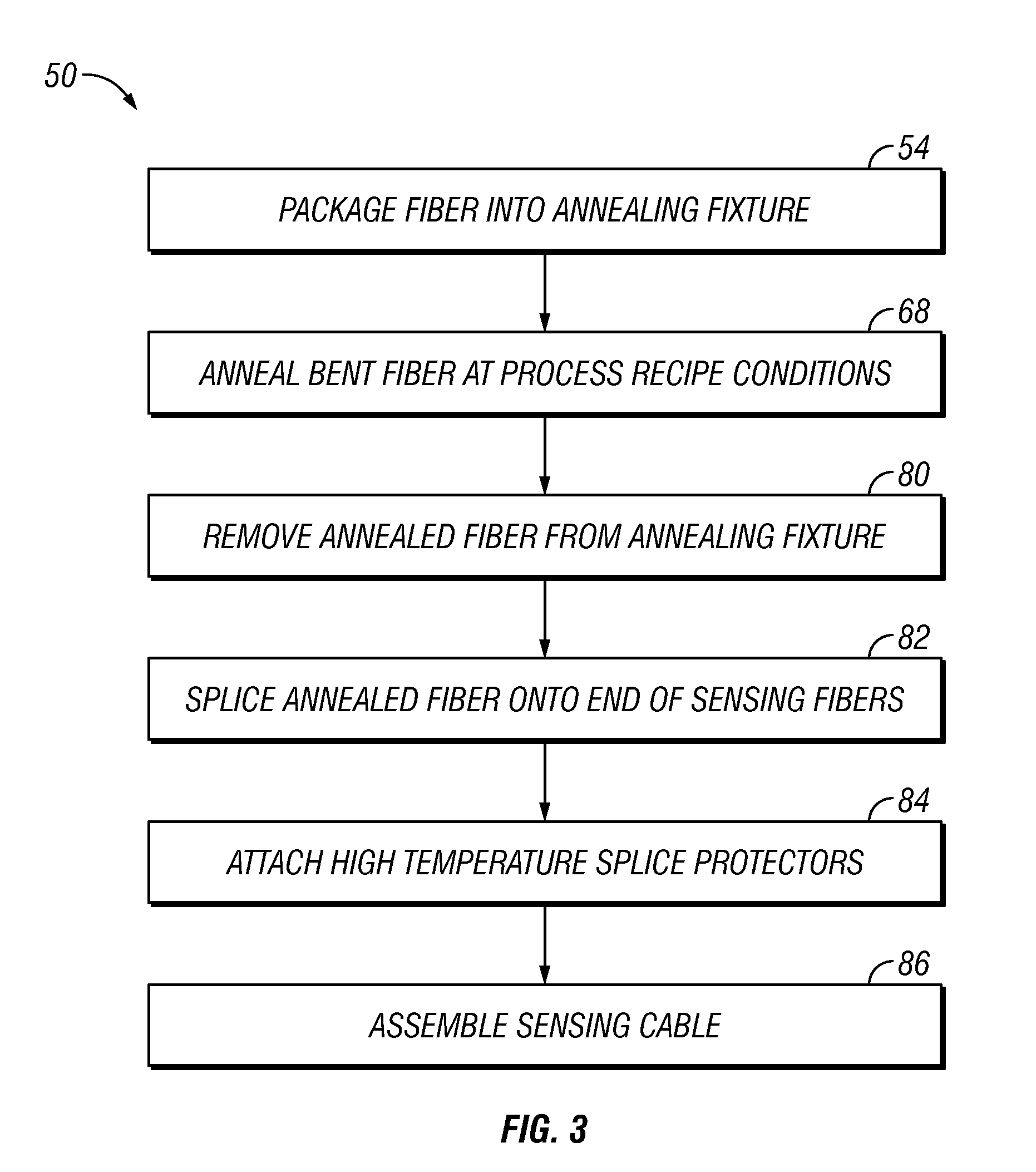

High temperature fiber optic turnaround

InactiveUS20120039561A1Robust pressure barrierEasy to installGlass making apparatusThermometers using physical/chemical changesEngineeringFiber

A sensing cable includes a pair of sensing fibers that are connected to one another by a U-shaped turnaround section. The turnaround section is a section of sensing fiber coated with a jacket that includes metallic components. The turnaround section is bent and, then, annealed according to a method of the present invention. The turnaround section is robust and reduced in size (i.e., radius). The sensing cable also includes an inner sleeve that surrounds the sensing fibers and an elongated outer armor casing (i.e., including an armor tube and a sealing cap) that encases a terminating end thereof. The armor tube and the sealing cap protect the sensing fiber from mechanical and chemical harm, are reduced in size and facilitate insertion of the sensing cable into downhole environments. The sensing cable has improved operating range up to 300° C.

Owner:QOREX

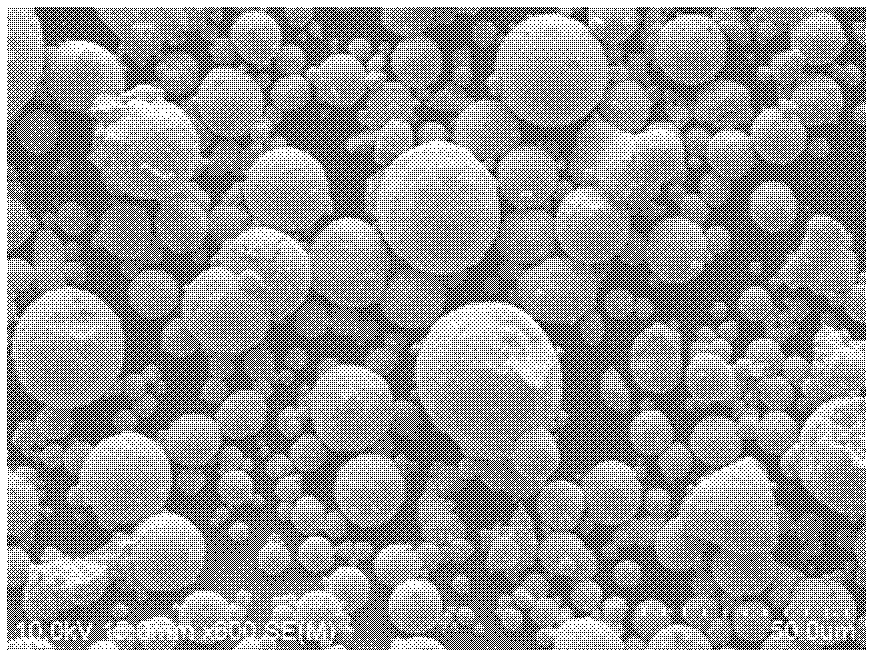

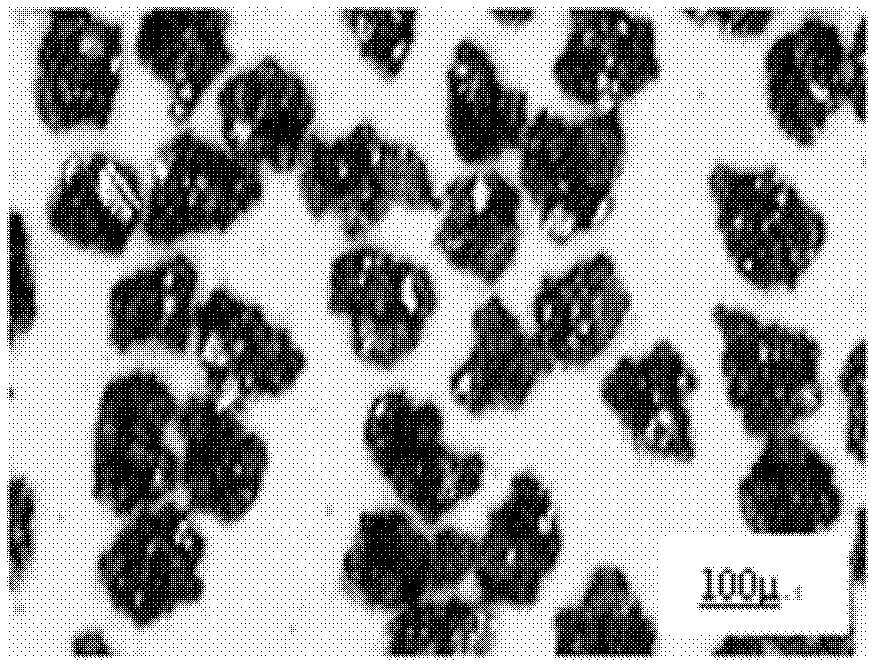

FeMnNi powder accelerant with low cost and preparation method and application

InactiveCN103170347ALow costMany holesDiamondMetal/metal-oxides/metal-hydroxide catalystsNitrogenGraphite

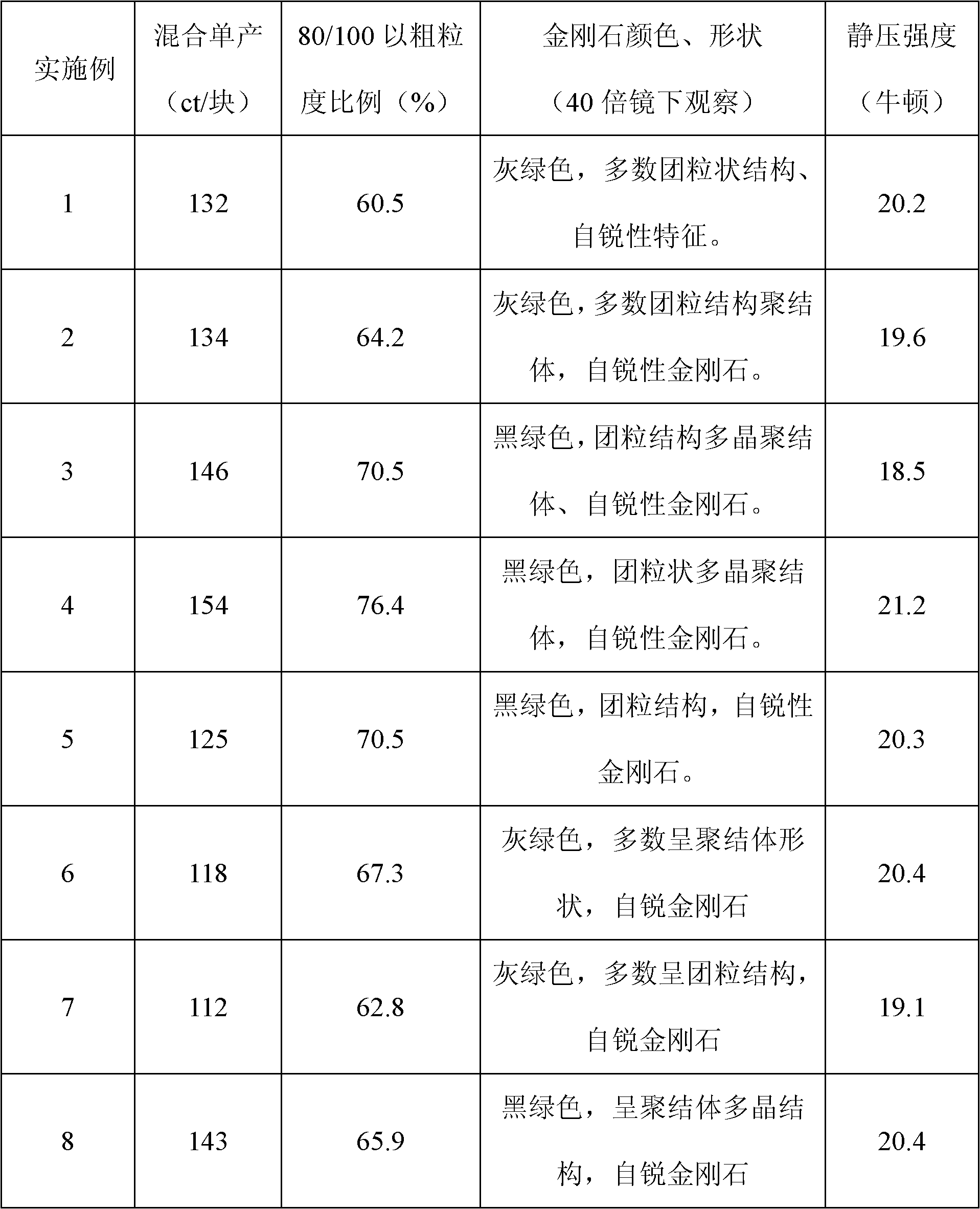

The invention relates to a FeMnNi powder accelerant with low cost, wherein the alloy comprises the components in percentage by weight as follows: 30-50% of Mn, 0-10% of Ni, 1-3% of Cr, 0.1-0.8% of C, 0.05-0.2% of Si and the balance of Fe. The oxygen content of a powder accelerant product optimized is less than or equal to 300ppm, and the nitrogen content is less than or equal to 180ppm. The accelerant is prepared by a gas atomization process of inertial gas, so that the accelerant powder is spherical or approximately spherical with uniform alloy composition. Diamond synthesized by the accelerant and graphite in proportion is greyish-green or dark green in color, and the crystal form of the diamond is a polygonal aggregate in a granular structure. The per mixed unit yield reaches over 154 carat / block by cavity with diameter of 40mm, the static pressure strength is average about 20N, and the coarsness proportion of 80 / 100 reaches over 60%, so that the accelerant is an ideal raw material for manufacturing an efficient diamond grinding apparatus for crisp and hard materials.

Owner:GRIMAT ENG INST CO LTD

Device for attaching double-faced adhesive tape to cloth curtain

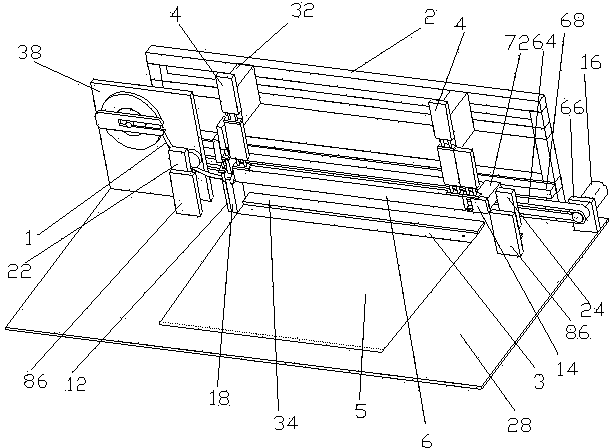

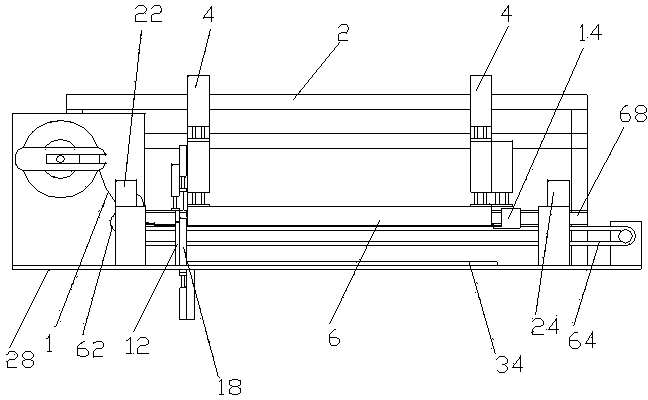

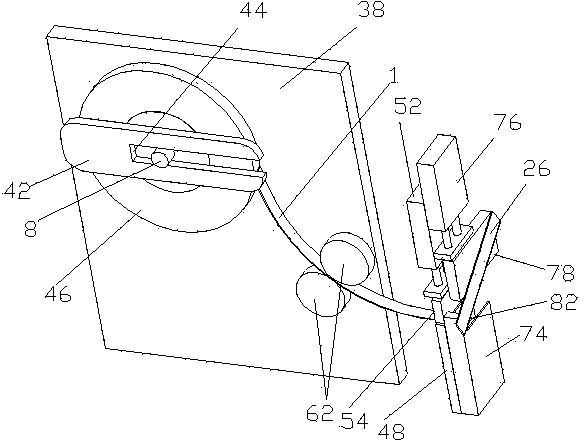

ActiveCN103625978AFitting position is accurateHigh precisionArticle deliveryVertical planeAdhesive belt

The invention relates to a device for attaching double-faced adhesive tape to a cloth curtain. The device comprises a rack and a press fit mechanism arranged on the rack. The press fit mechanism comprises a press fit cylinder which is perpendicularly arranged on the rack, and a cloth curtain pressing plate which is arranged at the bottom end of the press fit cylinder. The device is characterized in that a positioning mechanism is arranged on one side of the cloth curtain pressing plate, wherein the positioning mechanism comprises a supporting shaft which is longitudinally arranged on the rack, and a movable clamping piece which is arranged between the supporting shaft and the cloth curtain pressing plate; a feeding mechanism is arranged on the side, facing the press fit mechanism, of the positioning mechanism, wherein the feeding mechanism comprises a first clamping piece which can move transversely in the extension direction of the cloth curtain pressing plate. The device further comprises a cutting mechanism, wherein the cutting mechanism comprises a cutting piece which is arranged between the movable clamping piece and the cloth curtain pressing plate, and two second clamping pieces which are arranged on the two transverse sides of the cloth curtain pressing plate respectively, and the cutting piece comprises a cutter which can move in a vertical plane to cut the adhesive tape; the movable clamping piece, the first clamping piece and the second clamping pieces can clamp and release the adhesive tape respectively. The device is good in adhesive tape attaching quality and high in adhesive tape attaching efficiency.

Owner:KUSN HUANGTIAN AUTO PARTS INDAL

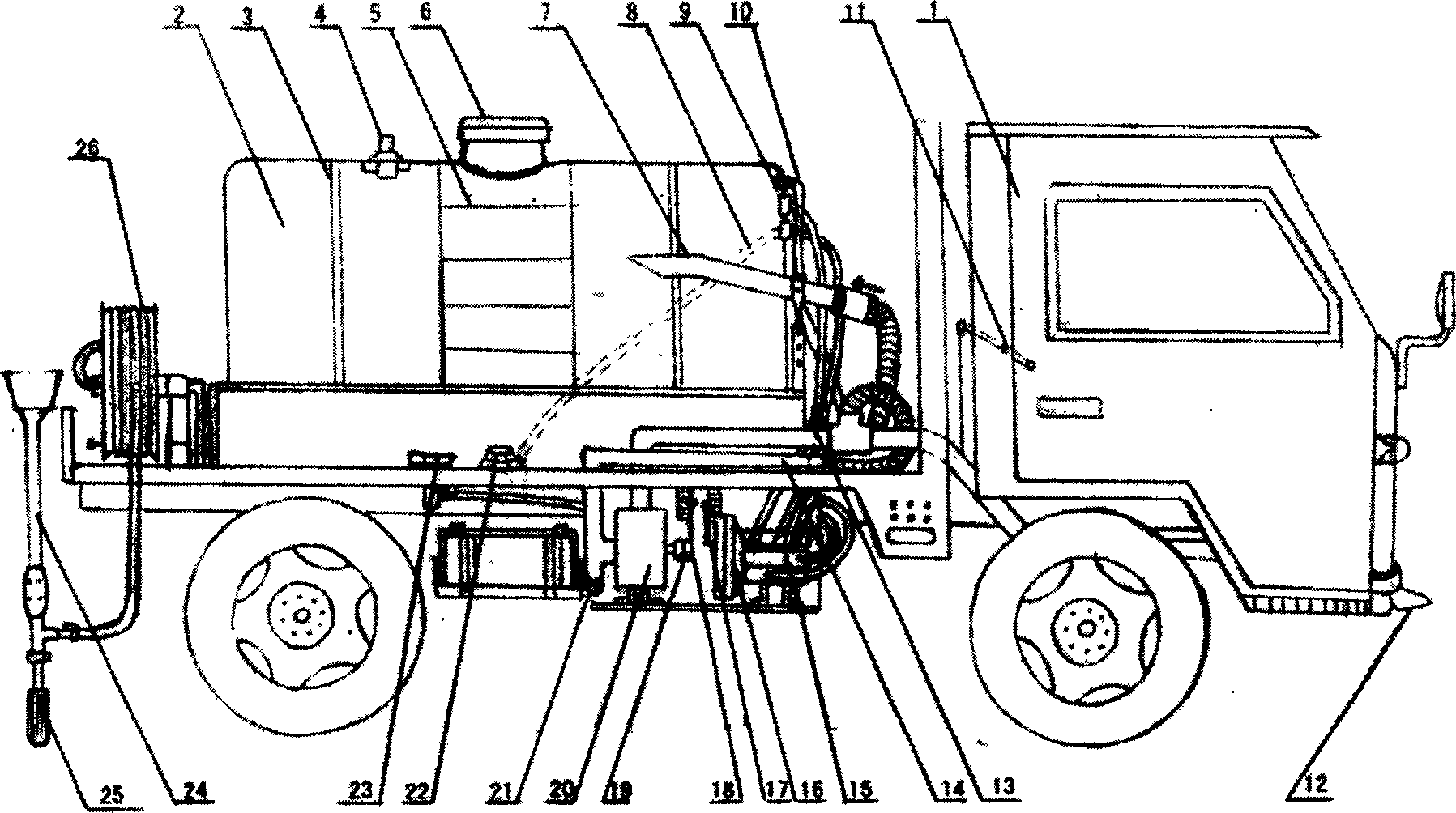

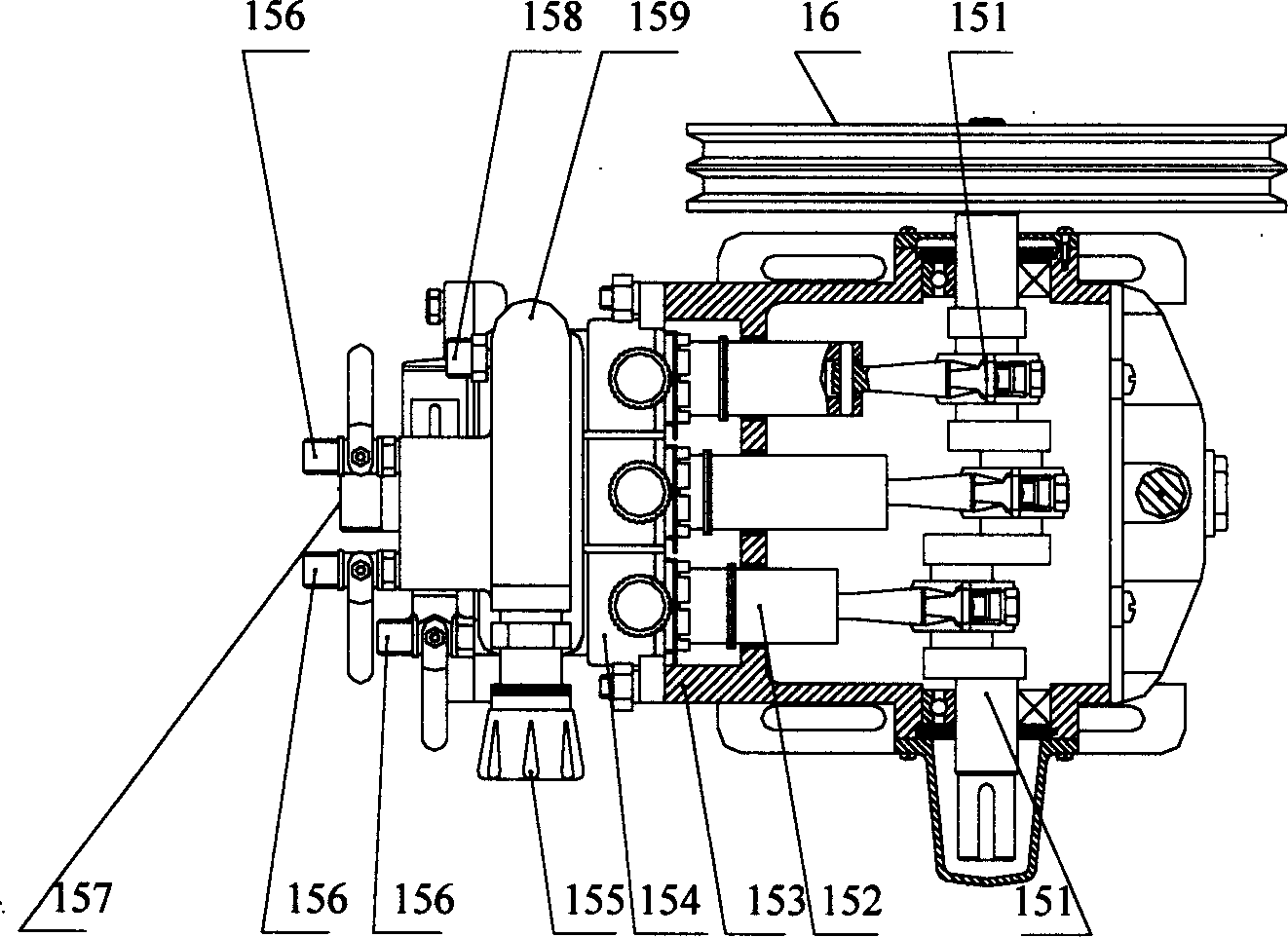

Water spraying and medicine spraying car

InactiveCN1586151ADrive fastStrong pressureWatering devicesCultivating equipmentsEngineeringHigh pressure

The water spraying and pesticide spraying truck is manufactured via reassembling a light truck and features that it has three-cylinder plunger pump in the bottom of the carriage and with belt wheel connected to the belt wheel of power take off in the chassis, plunger pump belt tenser and water pump belt tenser. The said structure makes the truck possess several uses, including pumping water, spraying water, flushing and atomizing, fast driving speed, high pressure, great flow rate and other advantages, and is especially suitable in irrigation, prevention and control of diseases and pests for afforesting flowers and trees.

Owner:广东风华环保设备股份有限公司

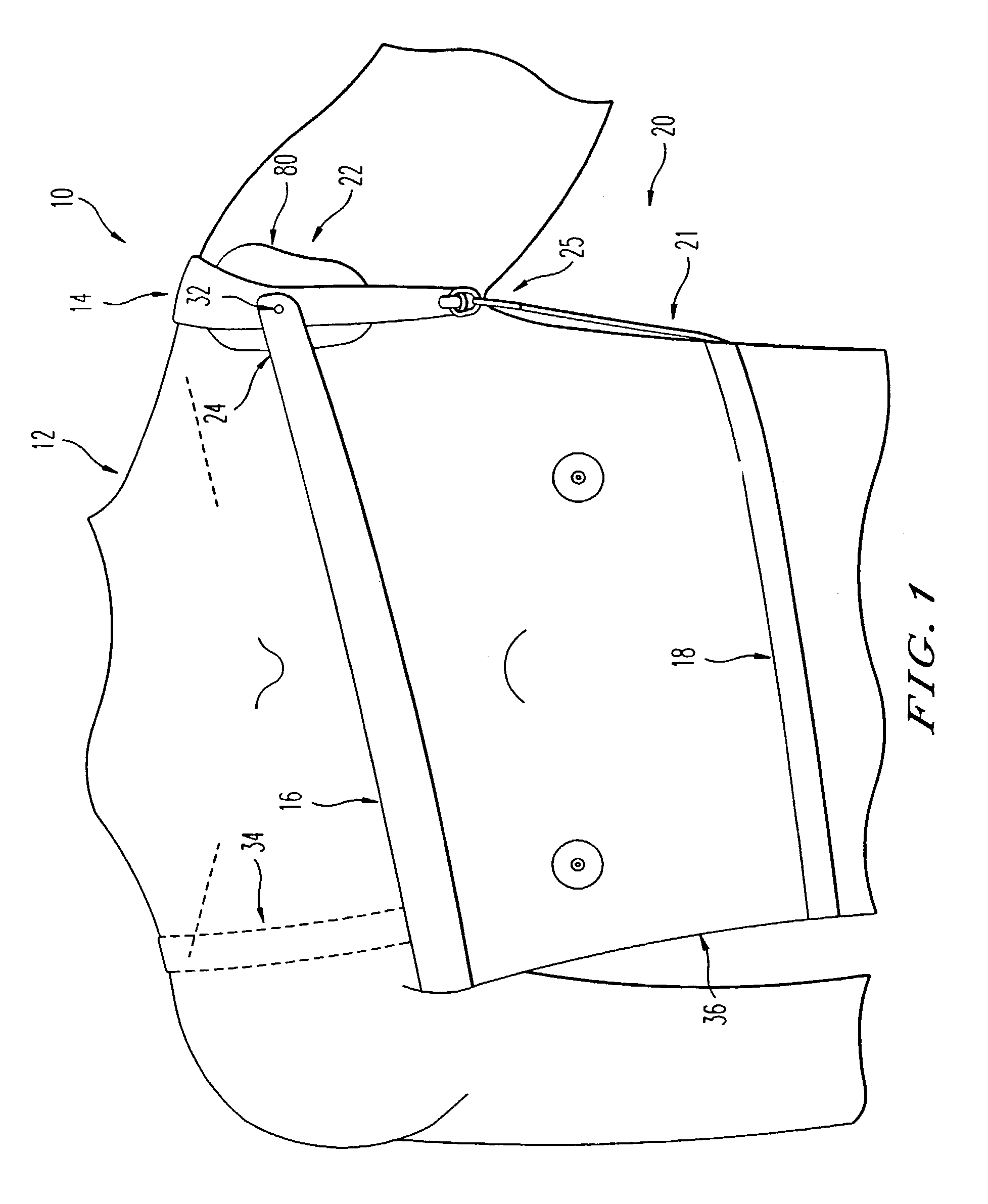

Shoulder brace

InactiveUS7135005B2Not excessively inhibiting motionRaise the possibilityRestraining devicesNon-surgical orthopedic devicesEngineeringShoulder joint capsule

A shoulder brace (10) including front (80) and rear pressure pads to be respectively positioned on front and rear portions of an individual's shoulder joint, a support member (18) to be positioned at a mid-section of the individual, a front frame member connected to the support member and the front pressure pad, and a rear frame member connected to the support member and the rear pressure pad. Also included is an arm cuff to be positioned on the arm of the individual, and a compression mechanism (20) configured to compress the front and rear frame members in accordance with a movement of the individual's arm such that the front and rear pressure pads press against the individual's shoulder joint.

Owner:FOUNTAINHEAD

Ceramic tile seam filling device

The invention provides a ceramic tile seam filling device and belongs to the field of ceramic tile mounting devices. The ceramic tile seam filling device comprises a storage battery, a material pressing component, a shell, wheels, a driving motor I, a driving motor II, a transmission case, springs, a sliding rod, brush rollers, a transmission shaft I, a forward extension plate, driving motors III,a material injecting component, a flexible pipe, a transverse plate I, a guide pipe, a peristaltic pump, a transverse plate II, a guide plate, a material scraping component and a material plasteringcomponent, wherein the material pressing component is arranged at the middle position of the shell; the storage battery and the peristaltic pump are mounted on the upper surface of the shell; the material injecting component is arranged at the lower part of the material pressing component and is connected with the material pressing component through the flexible pipe; the sliding rod is arranged at the middle position of the material injecting component in a penetration manner; two springs are arranged on the sliding rod; the material injecting component is arranged at a middle position between the two springs; the forward extension plate is arranged at one end of the shell. According to the ceramic tile seam filling device, the material pressing component is capable of supplying powerfulpressure to the filling agent; the material pressing component is used for beautifying the filled ceramic tile seams; a better filling effect is achieved.

Owner:闫轩晨

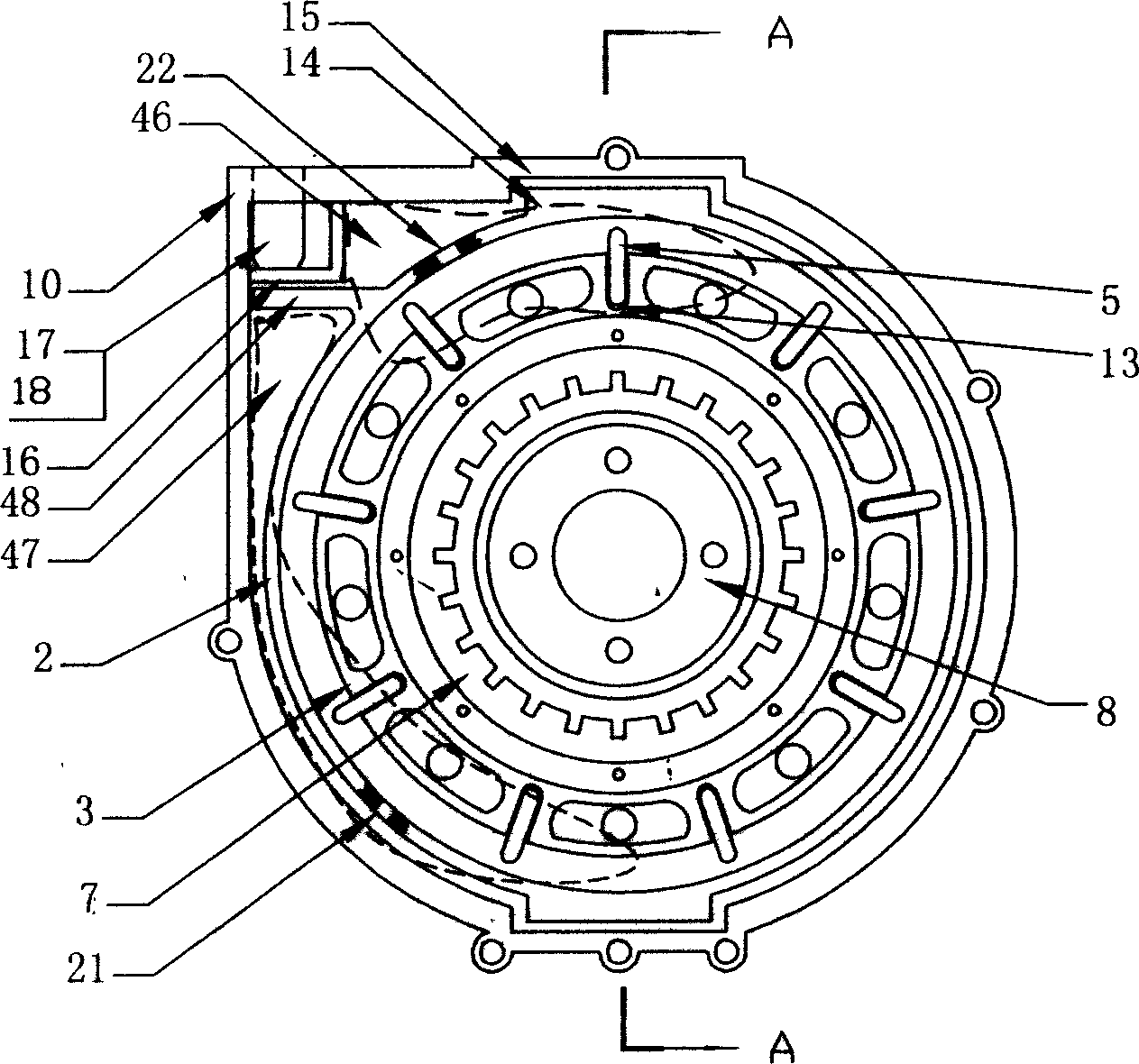

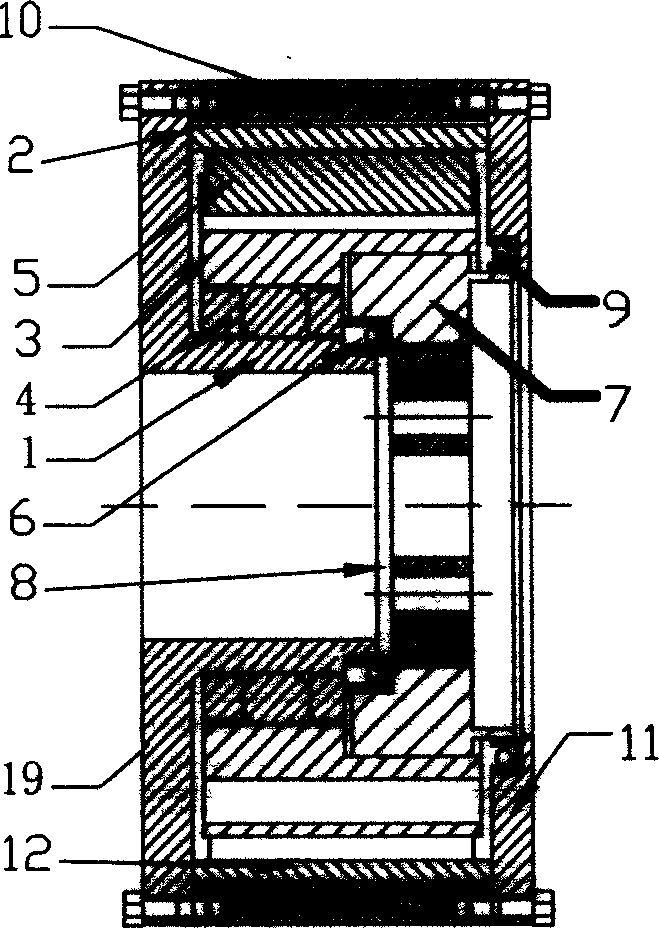

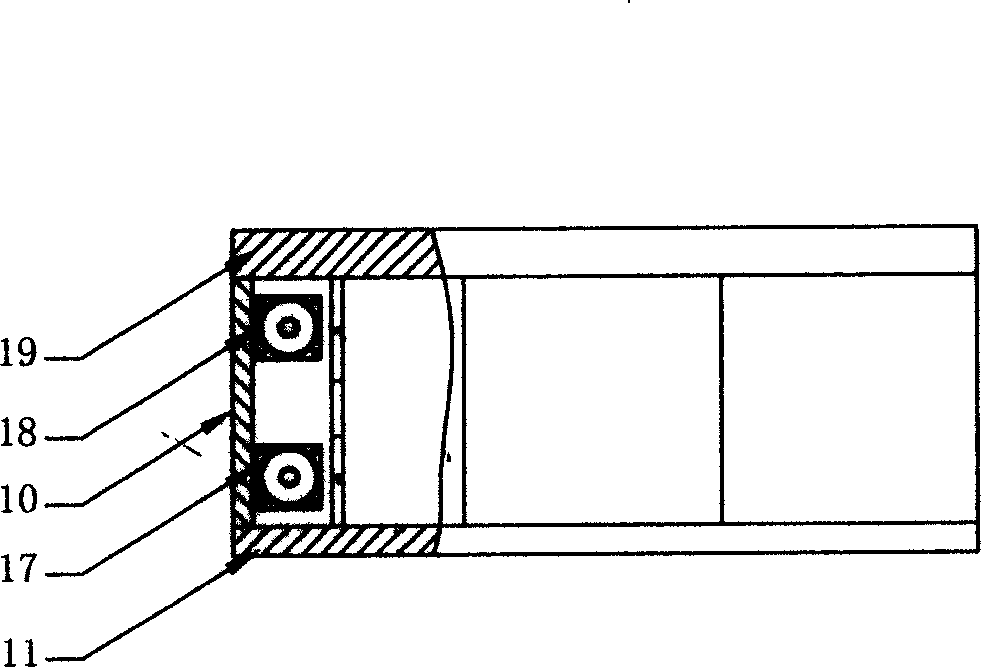

Wiper blade type hydraulic retarder for automobile

InactiveCN1667290AThere will be no burning phenomenonReduce weightBraking element arrangementsLiquid resistance brakesDrive shaftReducer

The invention relates to a doctorblade hydraulic pressure reducer for automobile that includes body case, rotator, stator, insulator, voltage regulator. The body case is made up of cylinder shaped curst, front pressure board, back pressure board. Location limited device and control device are set in the body case. Plural doctorblade bases are set on the out wall of the rotator, and each doctorblade is in its own base. And can freely radial move in the plane of the rotator. The rotator would limit the moving trace of the doctorblade. The right end of the rotator inner wall is connected to driving shaft device. Driving shaft connection device would make rotator rotate by the driving shaft. The invention has small volume, light weight, and high stability.

Owner:佛山市顺车安汽车配件科技有限公司

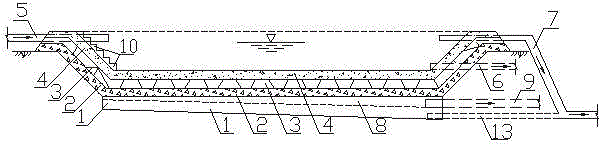

Pool with multi-layer structure and building method thereof

InactiveCN103147614AAvoid deformationPrevent collapseFoundation engineeringWater supply tanksWater dischargeEngineering

The invention relates to a pool with a multi-layer structure and a building method of the pool. The bottom of the pool is arranged under the ground, a part which extends from the highest place of an excavation side of a side wall of the pool to the ground at one non-excavation side is provided with a top press region; an underground water discharge layer is arranged under the bottom surface of the pool, and a base cushion layer, a seepage-proof layer and a protecting layer, which are connected with one another into a whole, are sequentially arranged on the underground water discharge layer, the excavation side of the side wall of the pool and the top press region; and a ring-shaped underground water discharge blind drain is arranged under the underground water discharge layer along the lowest place of the excavation side of the side wall of the pool, at least one linear underground water discharge blind drain is arranged under the excavation side at the bottom of the pool, two ends of the linear underground water discharge blind drains are communicated with the ring-shaped underground water discharge blind drain, and a water outlet of the ring-shaped underground water discharge blind drain is connected with an underground water discharge pipe. The pool is ingenious in conception, is resalable in design, and has the advantages of being high in foundation deformation resistance, high in stability, good in water-storing and seepage-proof effect, low in project cost, long in the facility service life, wide in application range, simple in construction and the like.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

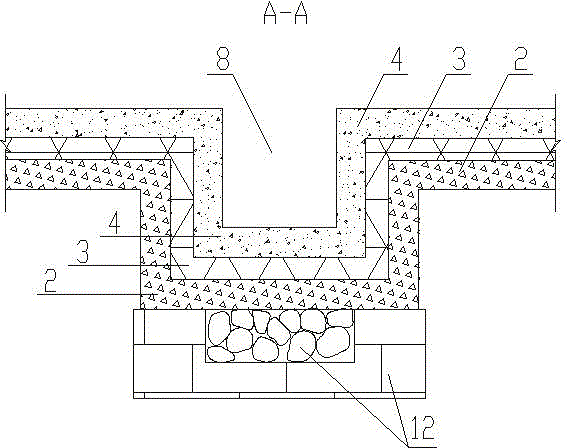

High hydrostatic pressure-resistant small piezoelectric hydrophone and manufacturing method thereof

ActiveCN102901981ACapable of withstanding high hydrostatic pressureWith mass productionSeismic signal receiversSeismology for water-covered areasHydrophoneElectricity

The invention discloses a high hydrostatic pressure-resistant small piezoelectric hydrophone and a manufacturing method thereof. The small piezoelectric hydrophone comprises a high-strength polyurethane coating layer, a piezoelectric ceramic round tube, a flexible rubber plug, a locating ring and two fine wires, wherein the appearance of the piezoelectric ceramic round tube is cylindrical; the polarization direction of the piezoelectric ceramic round tube is radially polarized; a gap with the width of 1-2mm is reserved on the excircle surface electrode of the piezoelectric ceramic round tube; the excircle surface electrode is divided into two sections; the polarization directions of the two sections of the round tube are opposite; the excircle electrode plus a direct current forward voltage is a positive electrode of the hydrophone; an excircle electrode plus a direct current negative voltage is a negative electrode of the hydrophone; the inner circle surface of the piezoelectric ceramic round tube is a common electrode; the appearance structure of the piezoelectric ceramic round tube is an integrated round tube; the circuit is formed by connecting two sections of round tubes with opposite polarities in series; and the locating ring is fixed at the gap. The high hydrostatic pressure-resistant small piezoelectric hydrophone has the beneficial effects of simple and reliable structure, small size, waterproofness, oil resistance and stable performance.

Owner:THE 715TH RES INST OF CHINA SHIPBUILDING IND CORP

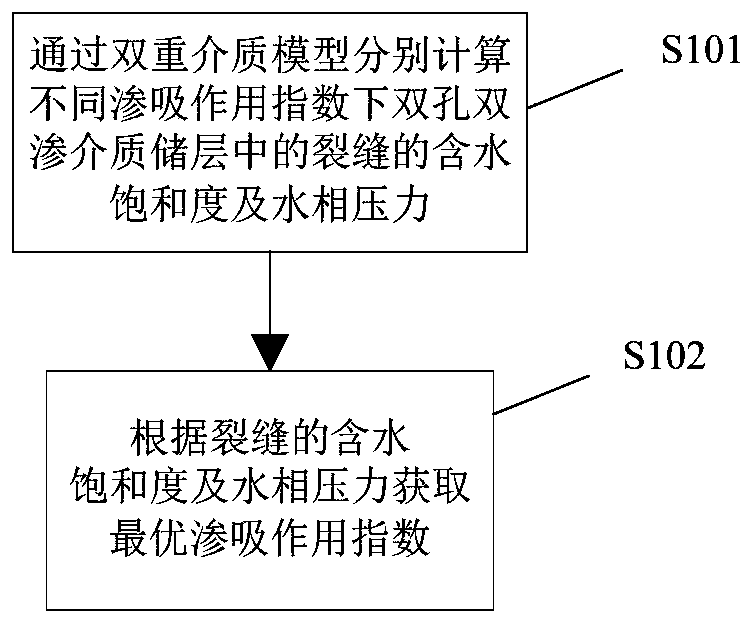

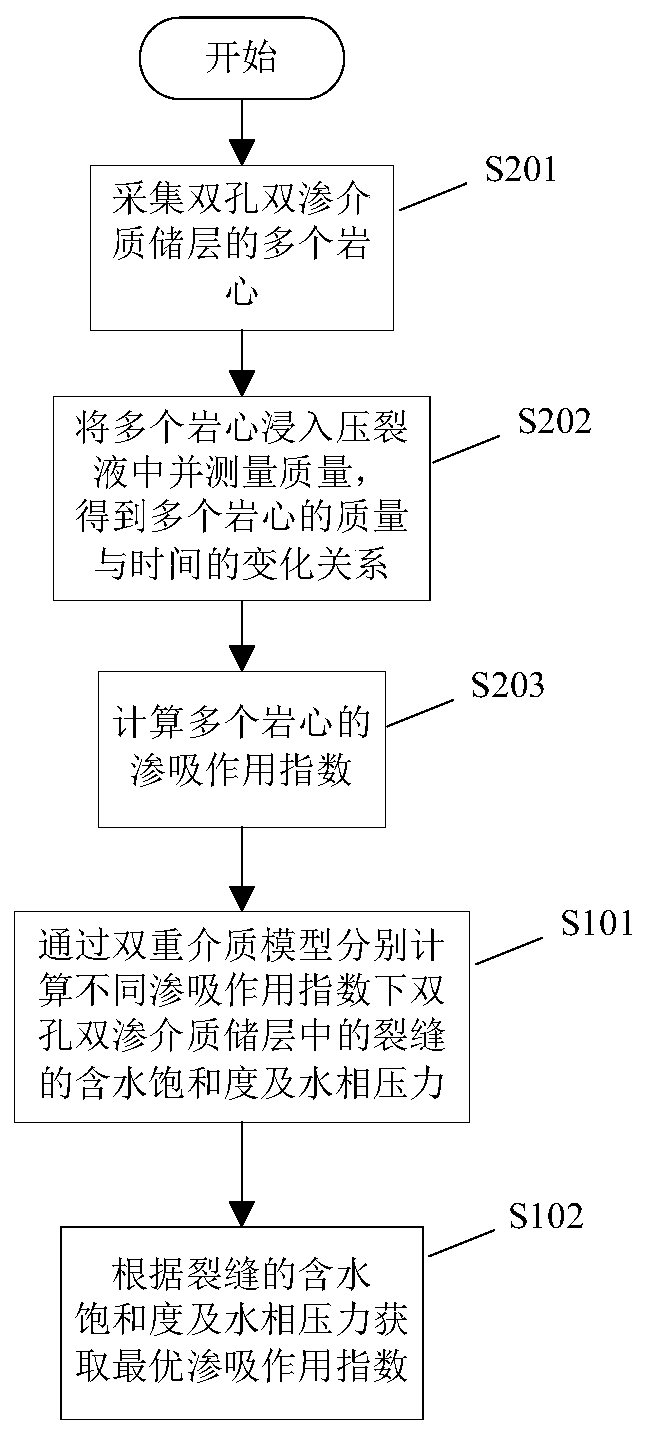

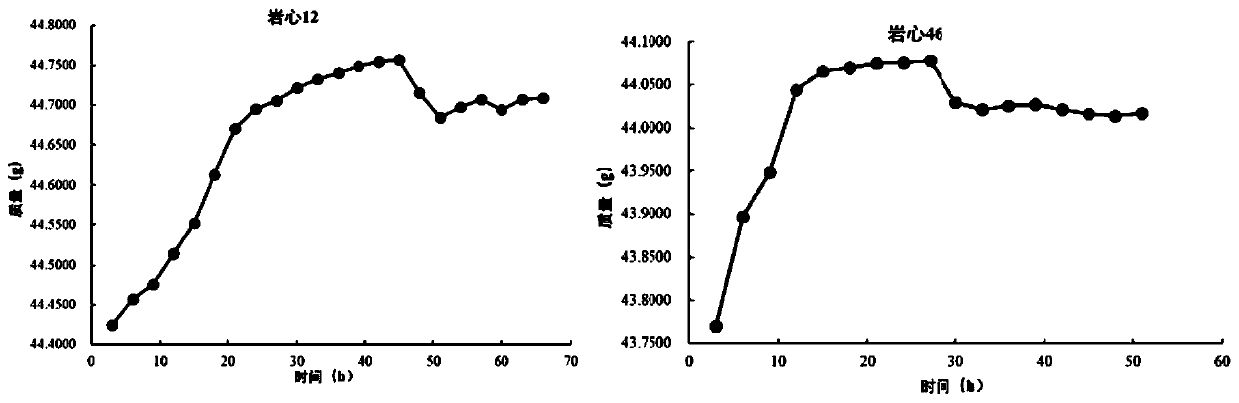

Fracturing fluid permeating and sucking production increasing simulation method and device of double-hole and double-permeability medium reservoir

The embodiment of the invention provides a fracturing fluid permeating and sucking production increasing simulation method and device of a double-hole and double-permeability medium reservoir and belongs to the technical field of oil and gas exploitation production increasing. According to the method and device, the water-containing saturation degrees and the water phase pressure of a crack in thereservoir under different permeating and sucking effect indexes are calculated through a double-medium model, and therefore an optimal permeating and sucking effect index is obtained; under the optimal permeating and sucking effect index, the pressure of the crack in the reservoir is optimal, and the recovery ratio is highest; and thus, the fracturing fluid permeating and sucking production increasing simulation method and device of the double-hole and double-permeability medium reservoir provides a reliable means for further research on increasing of the recovery ratio of a compact sandstonereservoir.

Owner:XI'AN PETROLEUM UNIVERSITY

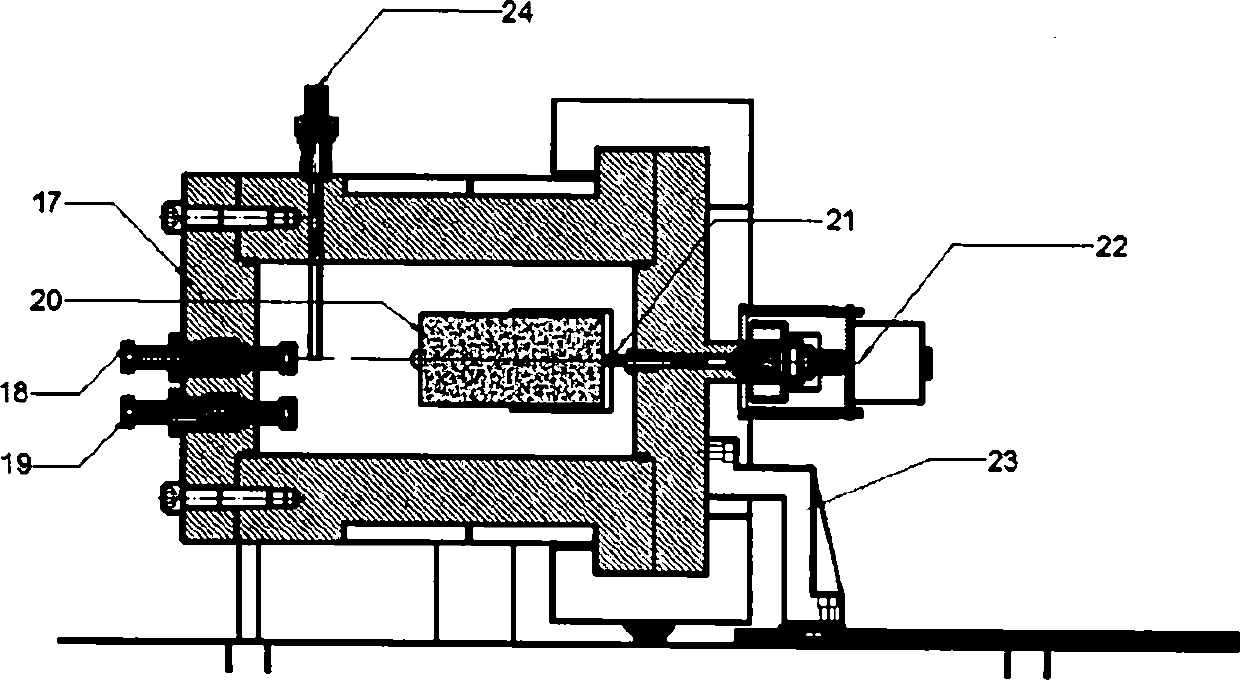

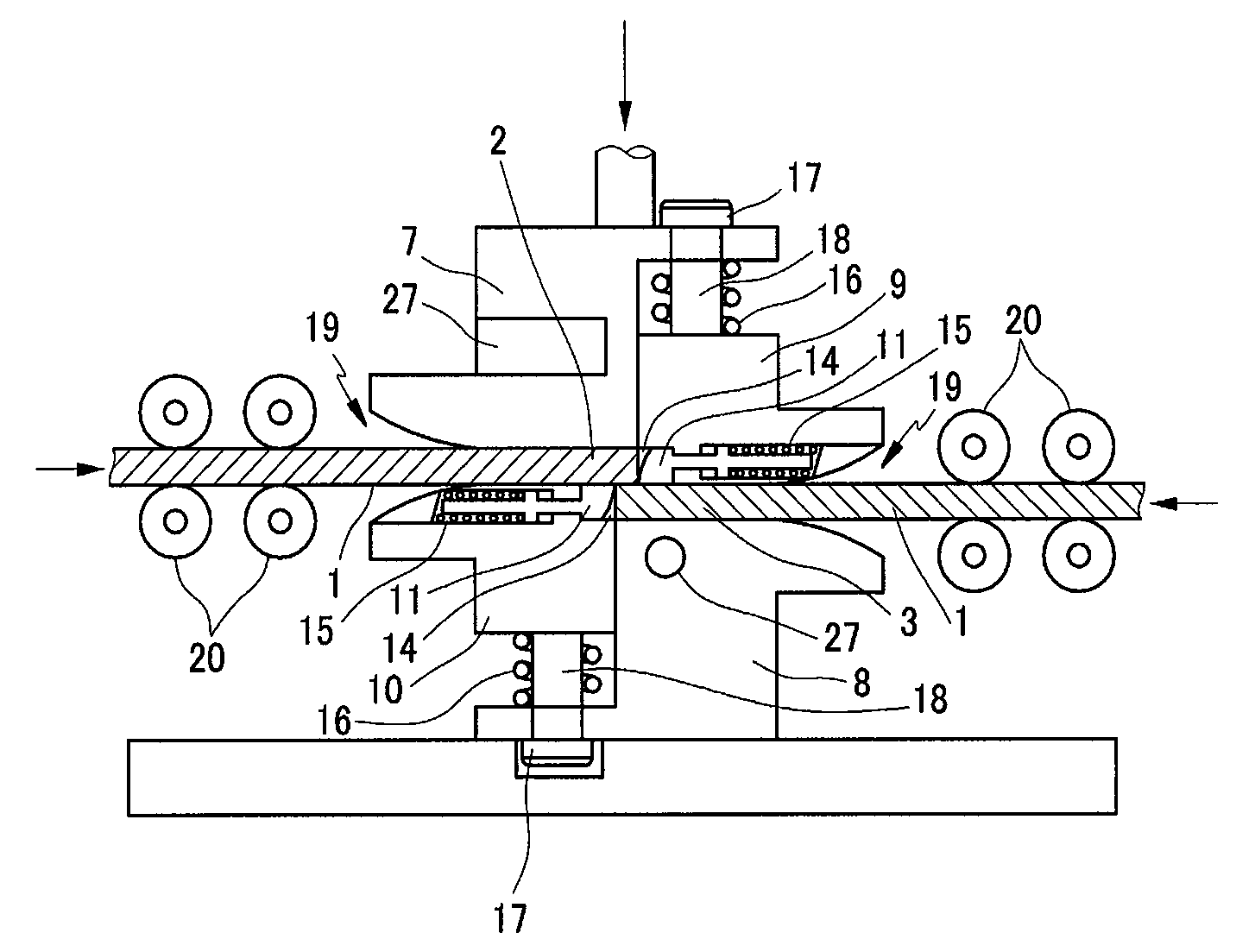

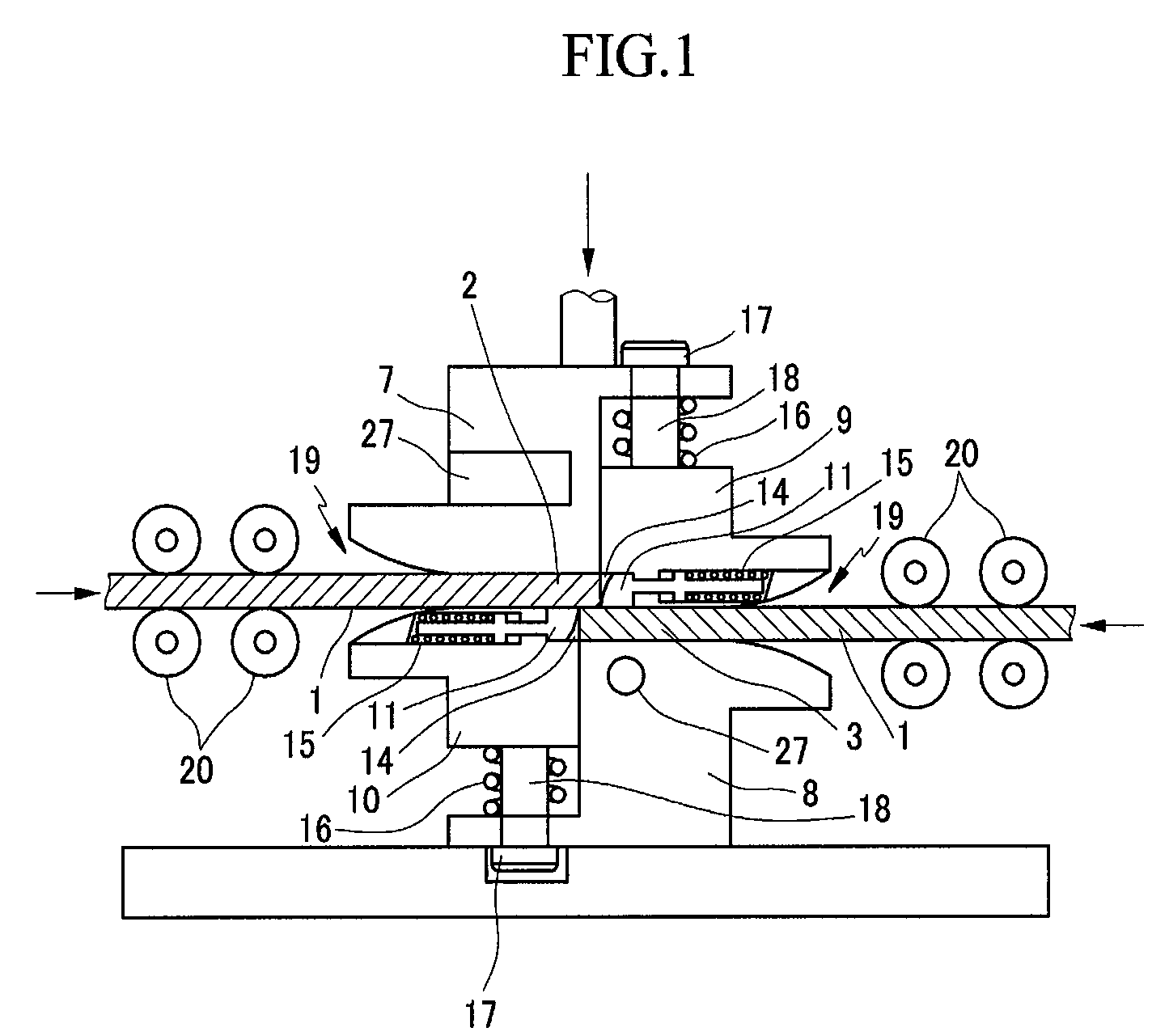

Apparatus and method for hot bonding metal plates

ActiveUS7748595B2Strong pressureStrong clamping forceExhaust apparatusWelding/cutting auxillary devicesBond ForceMetal

The present invention relates to an apparatus and a method for hot bonding metal plates having advantages that removing an oxidation film of the metal plates and bonding the metal plates are simultaneously accomplished and a bonding force between the metal plates is enhanced by applying a strong bonding pressure to the metal plates. The present invention has advantages that overlapped metal plates are compressed vertically and a shaving blade is formed at a shaving mold. Therefore, as the metal plates move, an oxidation film coated on the overlapped surfaces of the metal plates is removed. In addition, a home is formed at the shaving mold so that excess metal together with an oxidation film coated on front portions of the metal plates are removed and simultaneously the metal plates are bonded with a strong pressure.

Owner:SUNG WOO HITECH +1

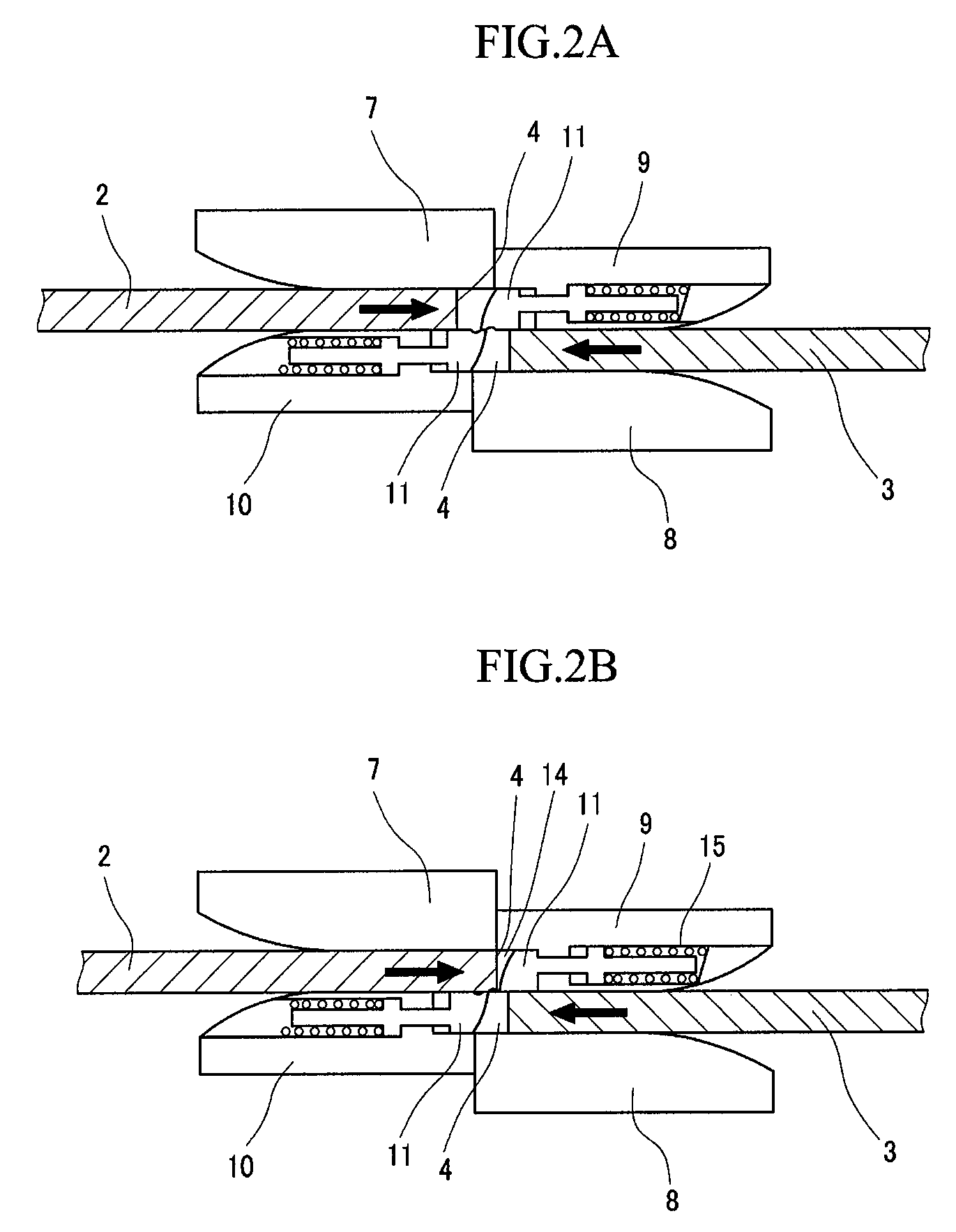

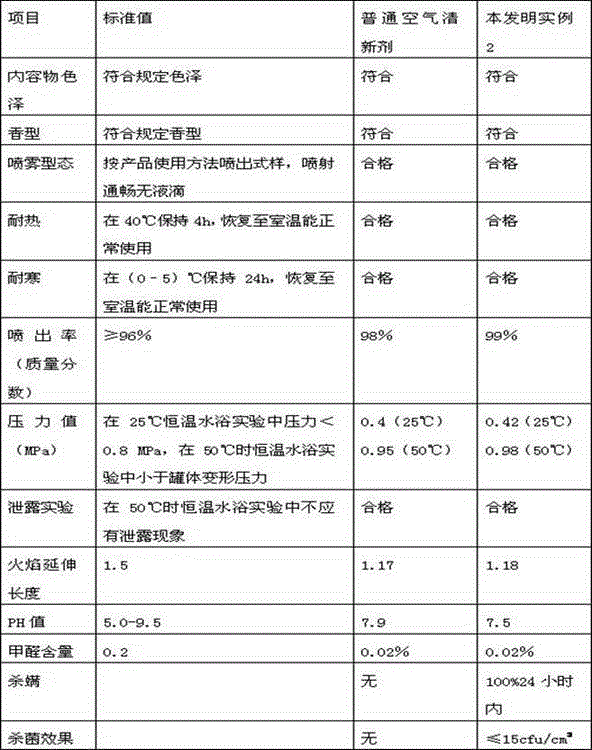

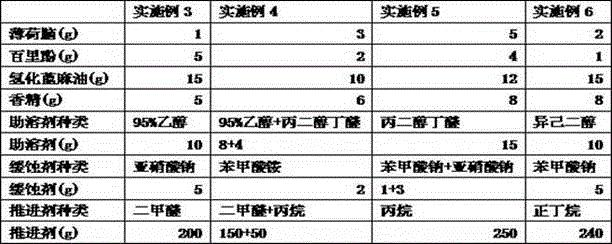

Water-based air freshening aerosol and preparation method thereof

InactiveCN105999342AEasy to useExcellent ejection rateBiocideDead animal preservationWater basedMenthol

The invention discloses a water-based air freshening aerosol and a preparation method thereof, and belongs to the technical field of air fresheners. The aerosol is prepared from, by weight, 0.1%-0.5% of menthol, 0.1%-0.5% of thymol, 1.0%-1.5% of hydrogenated castor oil, 1.0%-1.5% of cosolvent, 0.5%-0.8% of essence, 0.2%-0.5% of corrosion inhibitor, 20%-25% of propellant and the balance deionized water. The preparation method of the water-based air freshening aerosol comprises the steps that menthol, thymol and essence are added into the cosolvent to be dissolved, the hydrogenated castor oil is added, all the materials are mixed to be uniform, and a transparent emulsion is obtained; the corrosion inhibitor is added into the deionized water and mixed to be uniform, and a transparent solution is obtained; the prepared transparent emulsion and the prepared transparent solution are mixed, the propellant is added, and all the materials are prepared into the aerosol. The aerosol is good in use effect, foam cannot be generated when the aerosol is used, the usage environment is more refreshing, and the sterilizing and acarus killing effects are achieved.

Owner:成都彩虹电器(集团)中南有限公司

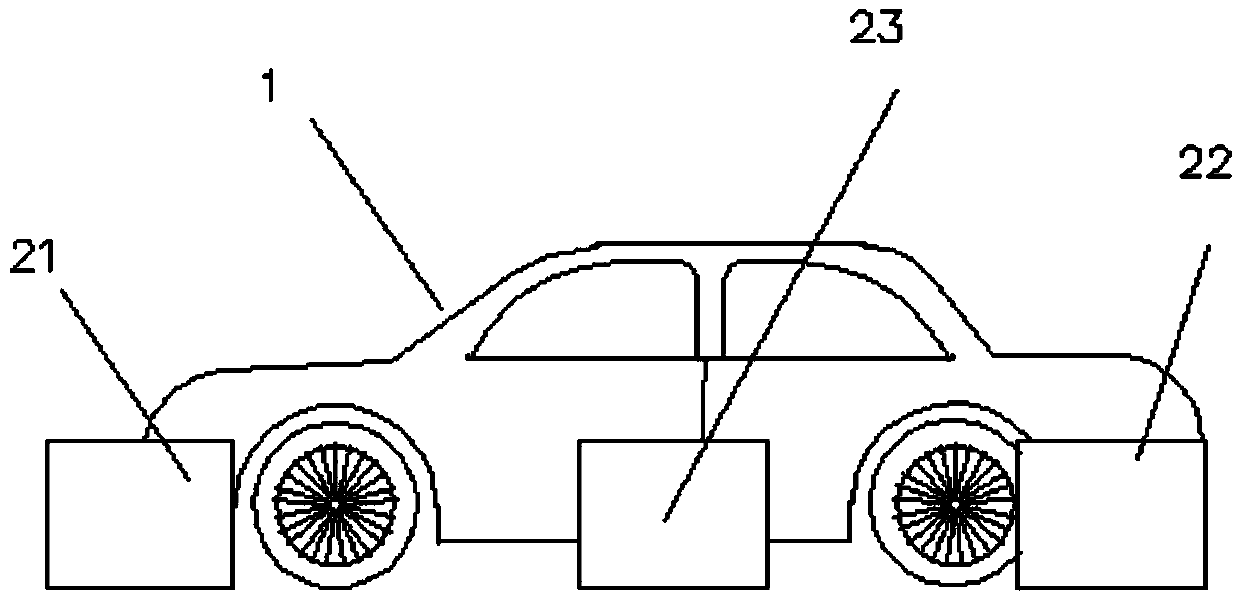

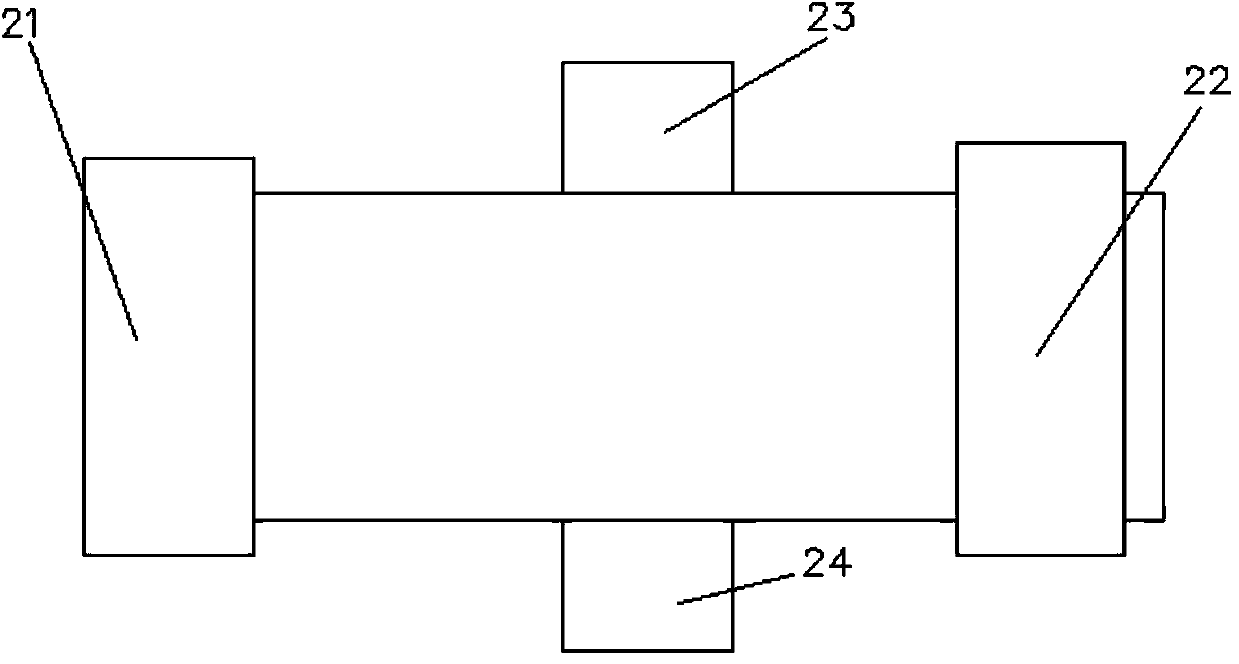

Escape device for automobile falling into water

InactiveCN103802775AFor emergency rescue purposesImprove driving comfortPedestrian/occupant safety arrangementDry iceFire extinguisher

The invention discloses an escape device for an automobile falling into water. The escape device comprises an air bag and a high-pressure carbon dioxide gas storage steel cylinder communicated with the air bag through a first vent pipeline, wherein a first on-off valve is arranged on the first vent pipeline. The escape device for the automobile falling into the water further comprises a filter; sodium peroxide is stored in the filter; the filter is communicated with the high-pressure carbon dioxide gas storage steel cylinder through a second vent pipeline and / or the first vent pipeline; a valve is arranged at the air inlet end of the filter; the air outlet end of the filter is communicated with an automobile compartment; the high-pressure carbon dioxide gas storage steel cylinder is a dry-ice fire extinguisher. The escape device disclosed by the invention provides buoyancy for the automobile which falls into water, accidentally or caused by urban inland inundation, through the air bag, so that the driver and passengers have time to escape; in addition, the escape device provides short-time life support for the driver and passengers who cannot leave from the automobile in time or cannot normally open the air bag due to mechanical faults of the automobile; meanwhile, the problems of automobile fire, and accident impact before the automobile falls into the water are solved.

Owner:罗汉卿

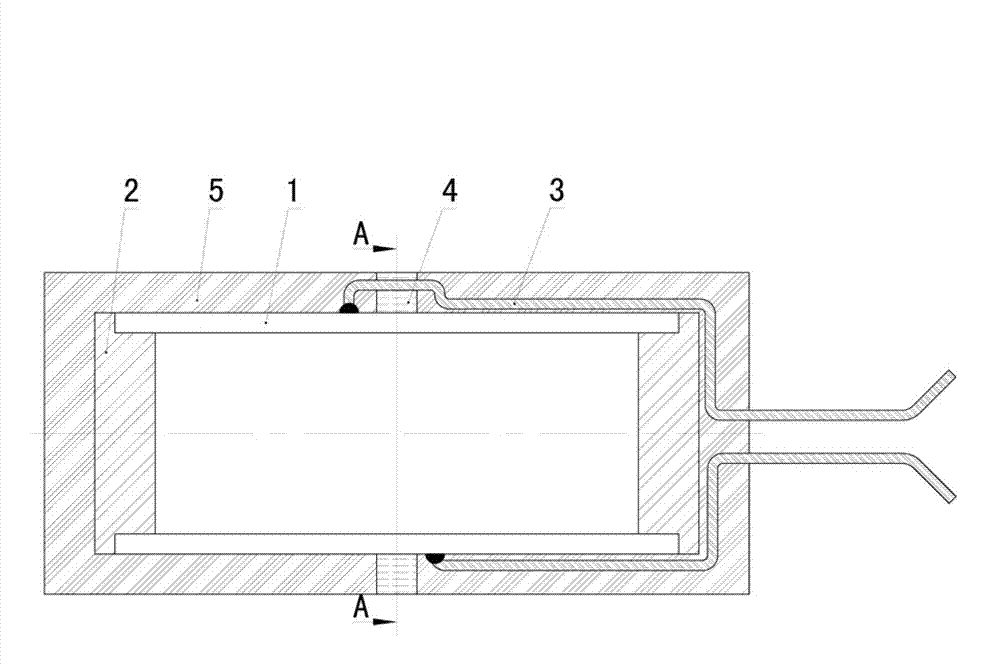

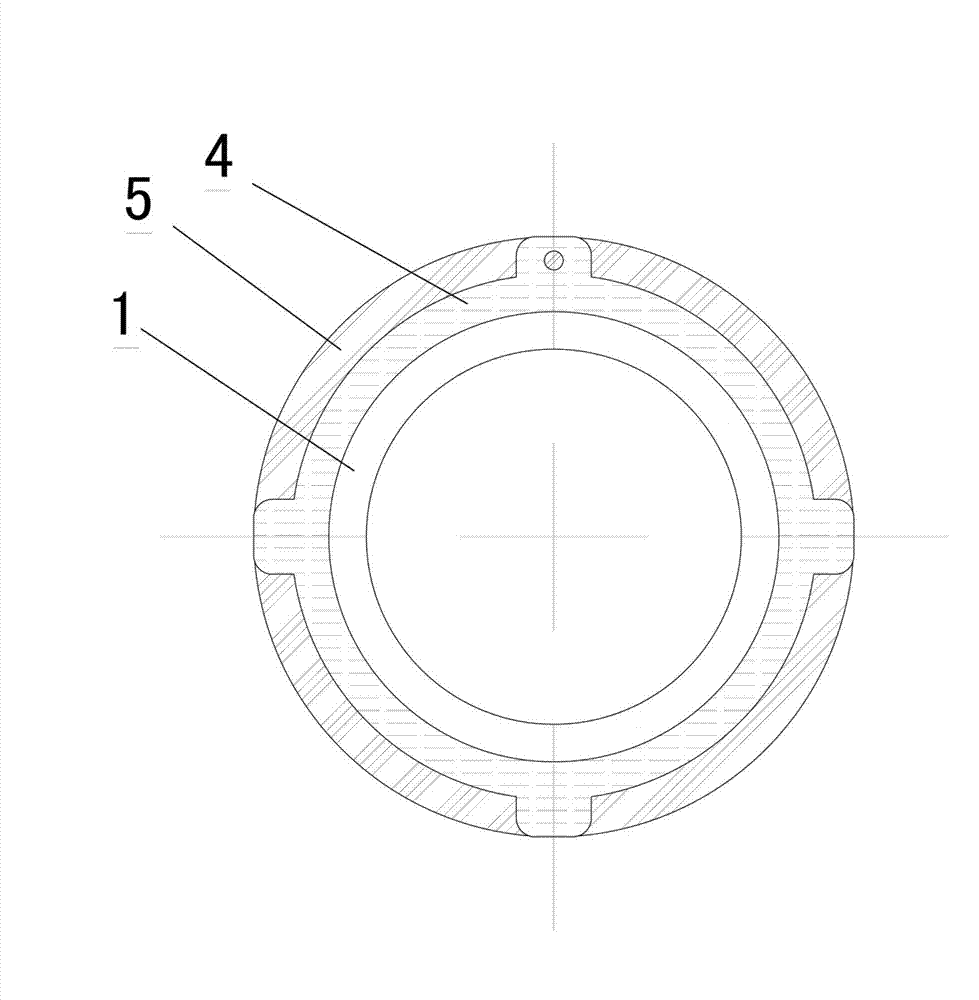

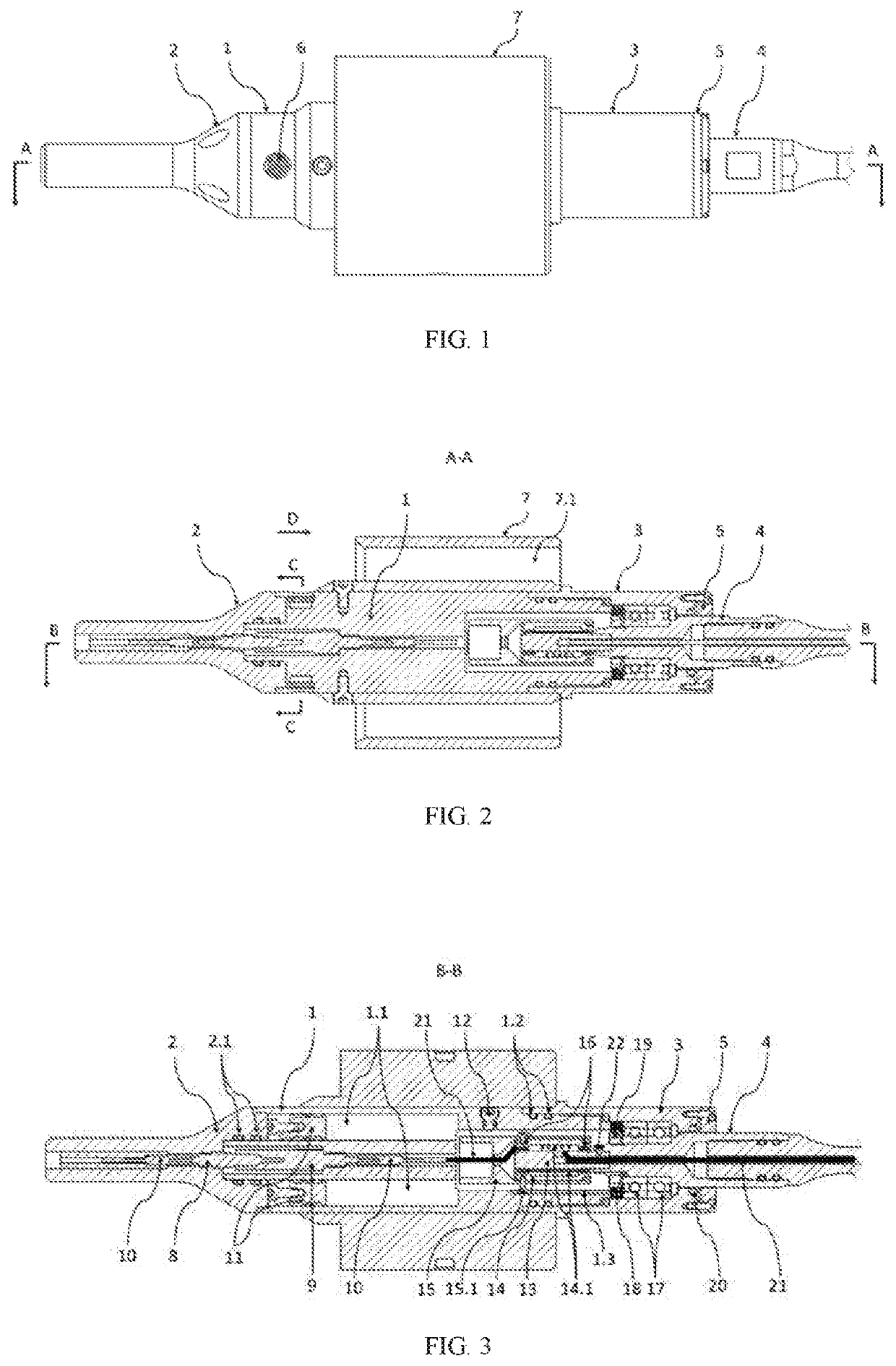

Conductive Slip Ring for Logging While Drilling Instrument

ActiveUS20200067247A1Simple structureLow costSurveyRotary current collectorElectric power transmissionEngineering

The present disclosure relates to a conductive slip ring for logging while drilling (LWD) instrument. The present disclosure utilizes a mechanical conductive slip ring to solve the problems of transmission of electric power and signals between two structures that have relative rotation, and the conductive slip ring has a simple structure, doesn't involve any complex circuit, and has low cost and high reliability. With the conductive slip ring in the present disclosure, there is no power transmission efficiency problem or signal transmission error rate problem. The conductive slip ring has high temperature-resistant, pressure-proof, and vibration-roof abilities, and can be applied widely.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com