Method for over-pit and under-pit cooperative control of roofs of far and near fields of an extra-large stoping space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

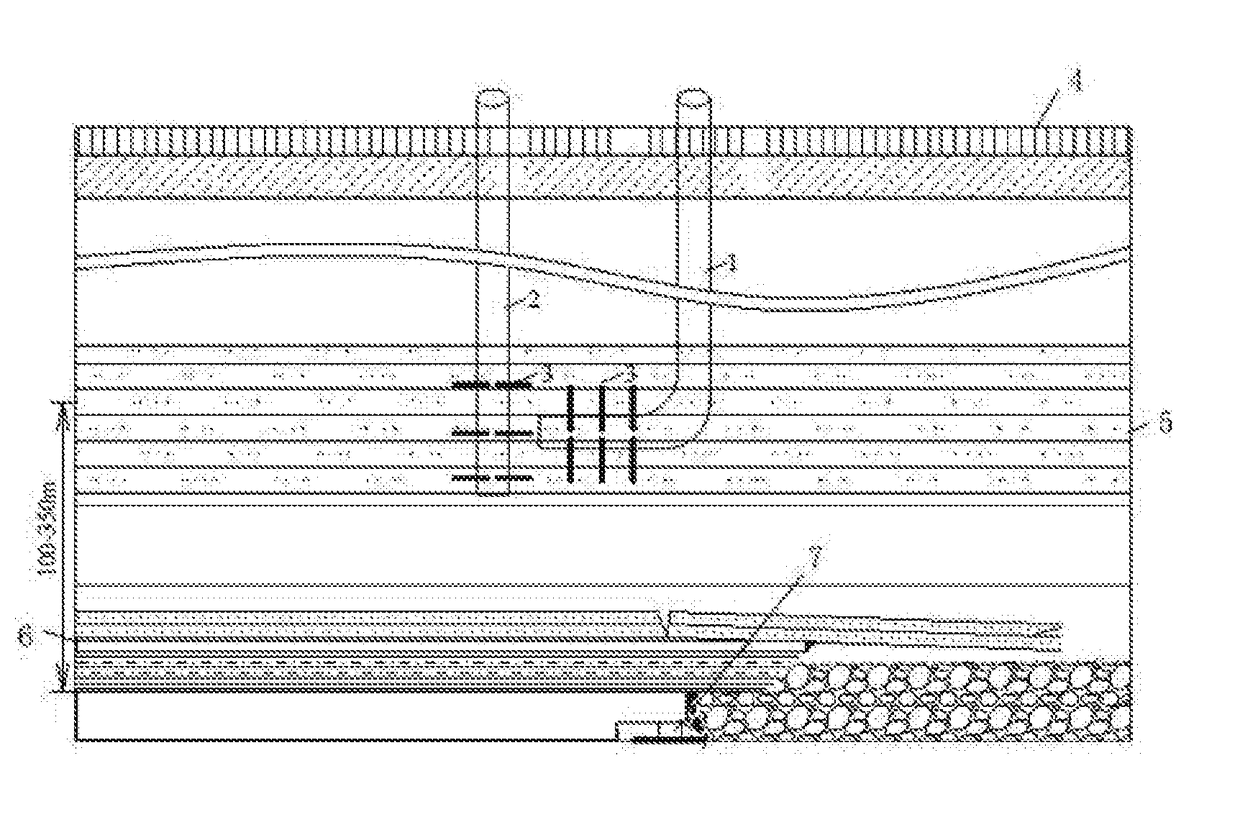

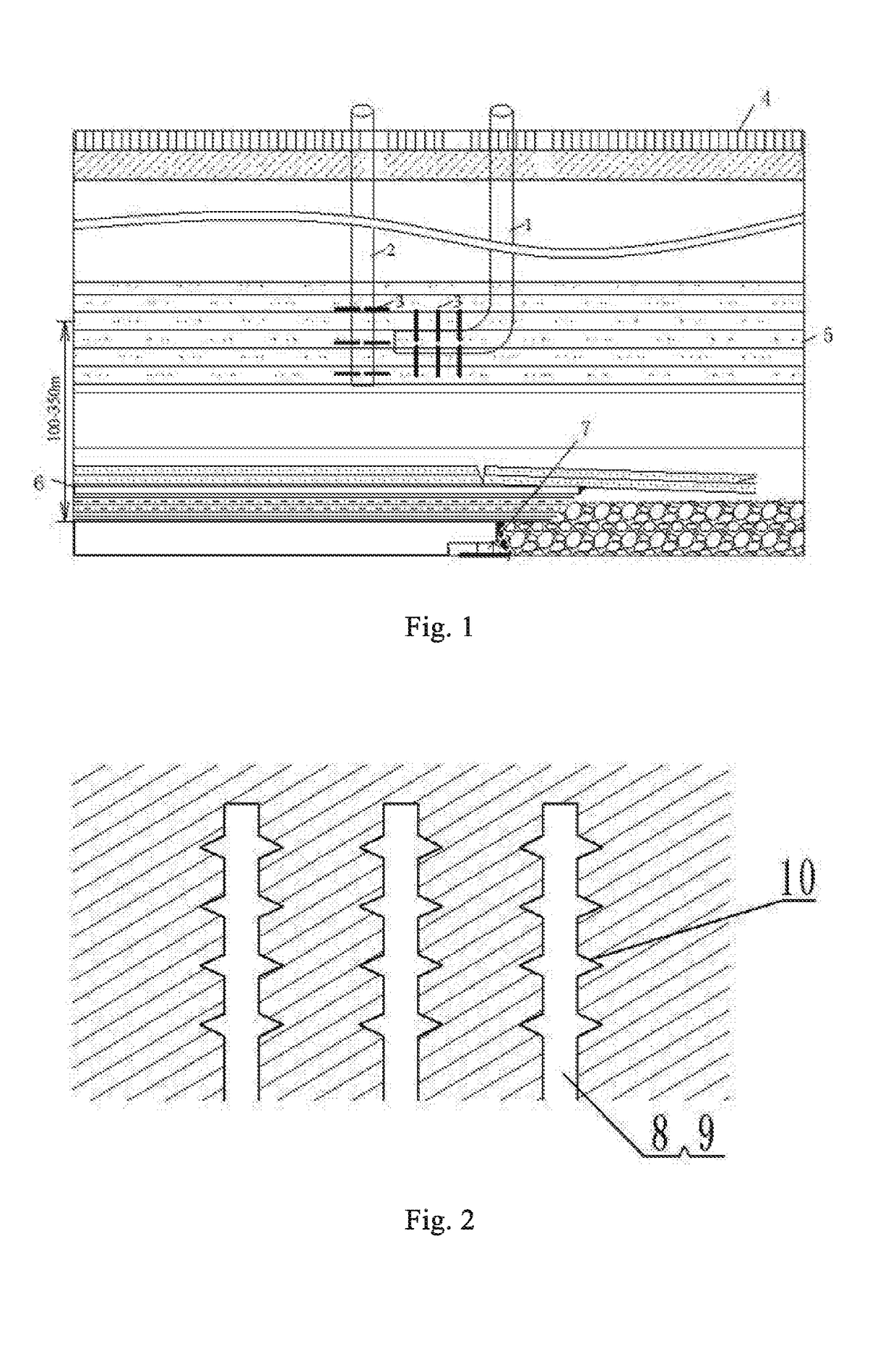

[0022]The method for over-pit and under-pit cooperative control of a roofs of far and near fields of an extra-large stoping space includes a method for controlling a hard roof by means of hydraulic fracturing via an over-pit vertical bore of far field of an extra-large stoping space, a method for controlling a hard roof by means of hydraulic fracturing via an over-pit L-shaped bore of far field of an extra-large stoping space, a method for controlling a hard roof via an over-pit strong repeating impact pulse of high energy density of far field of an extra-large stoping space, a method for controlling a hard roof via down-pit water injection of near field of an extra-large stoping space, a method for controlling a hard roof via down-pit stratified blasting of near field of an extra-large stoping space, and a method for controlling a hard roof via weakening by hydraulic fracturing of near field of an extra-large stoping space;

[0023]firstly, the hard roof of far field is controlled by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com