Patents

Literature

91results about How to "Increased pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

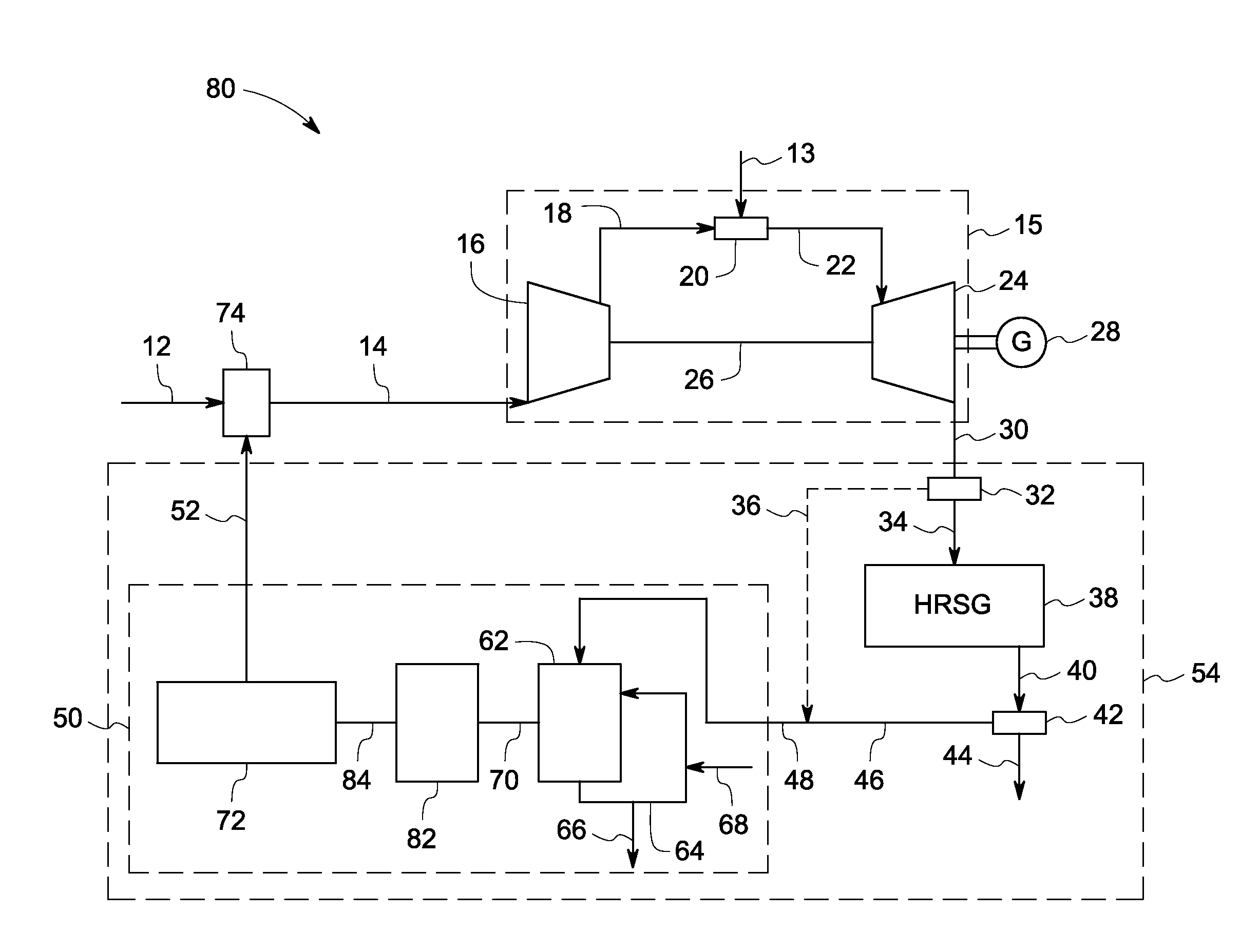

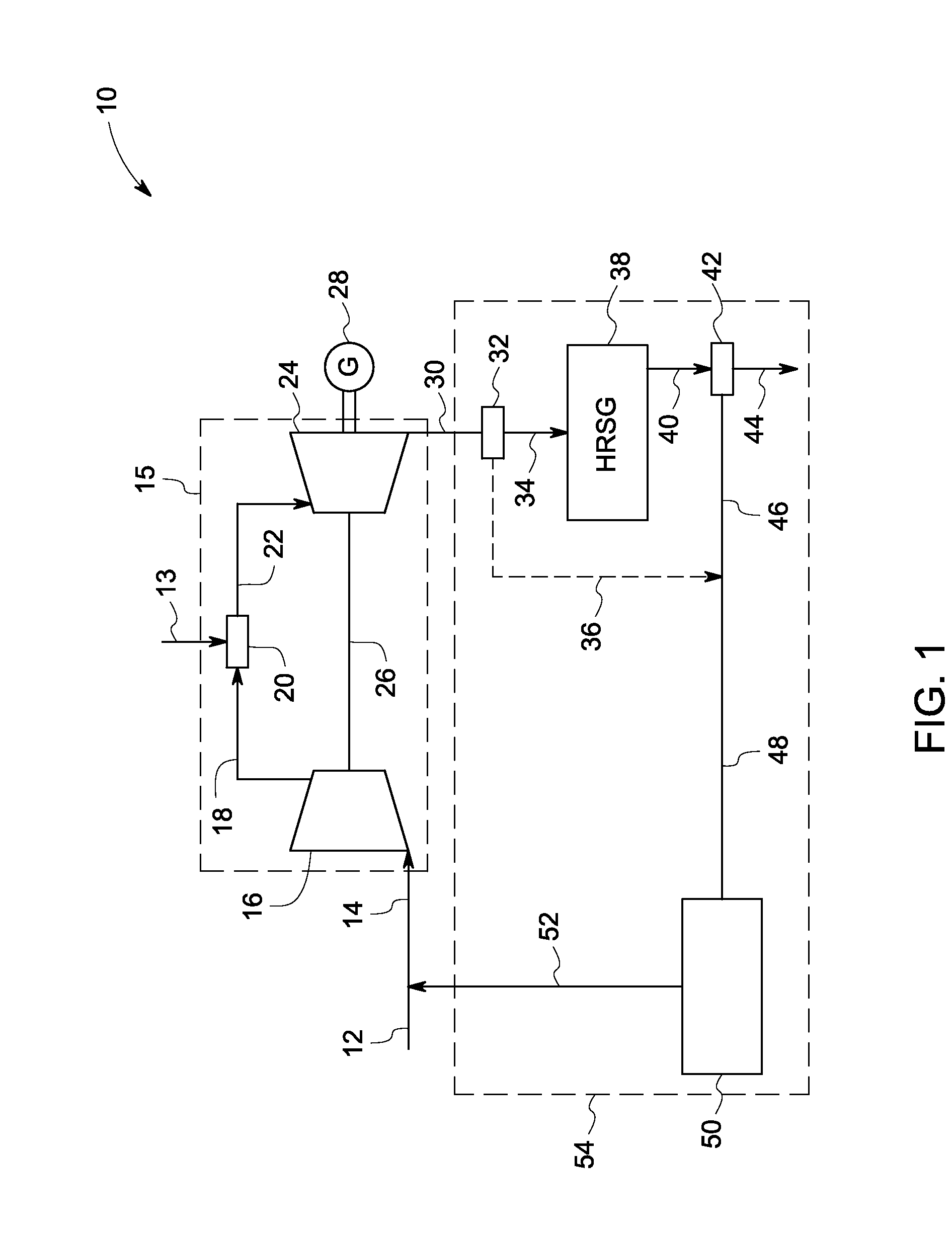

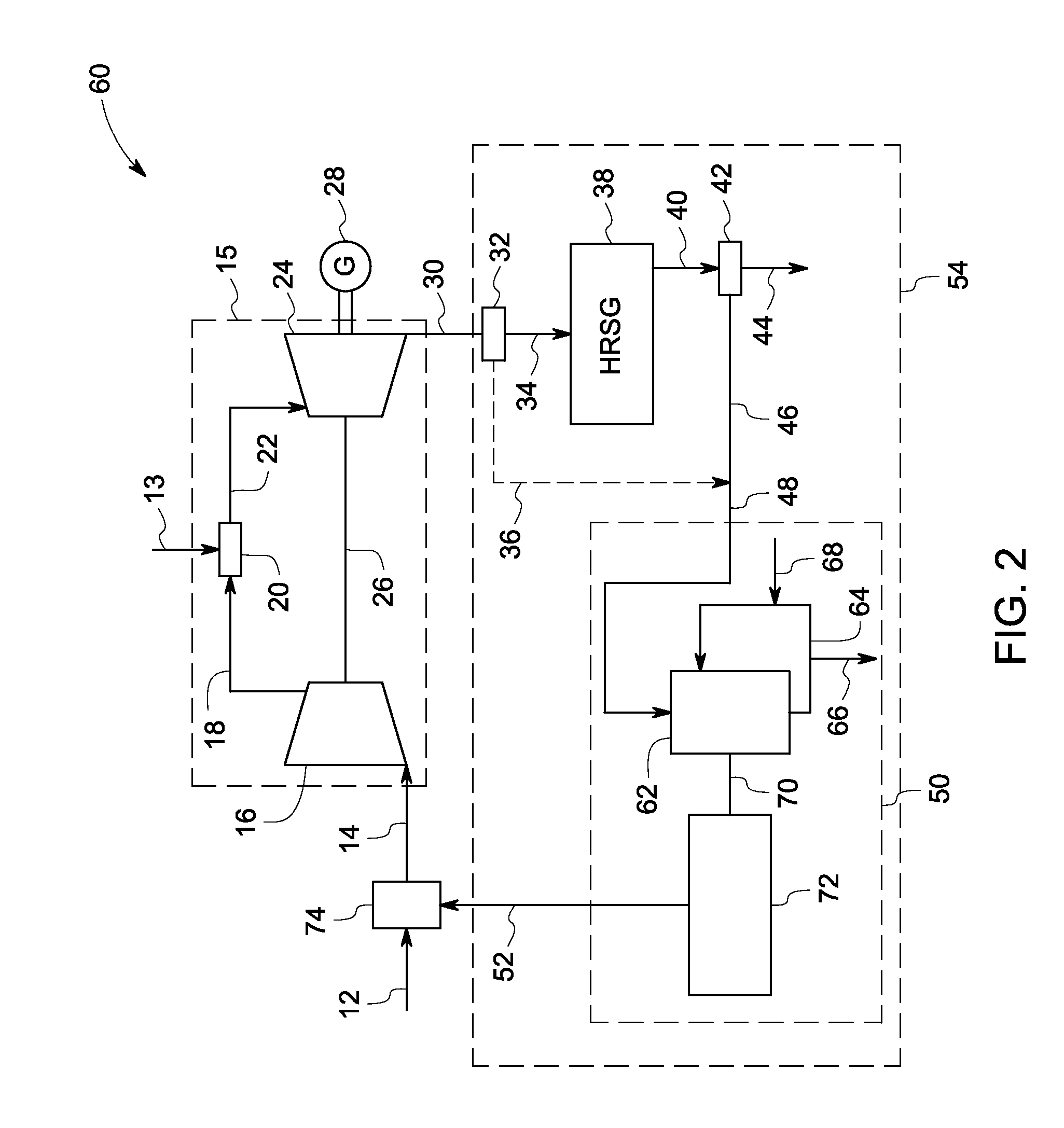

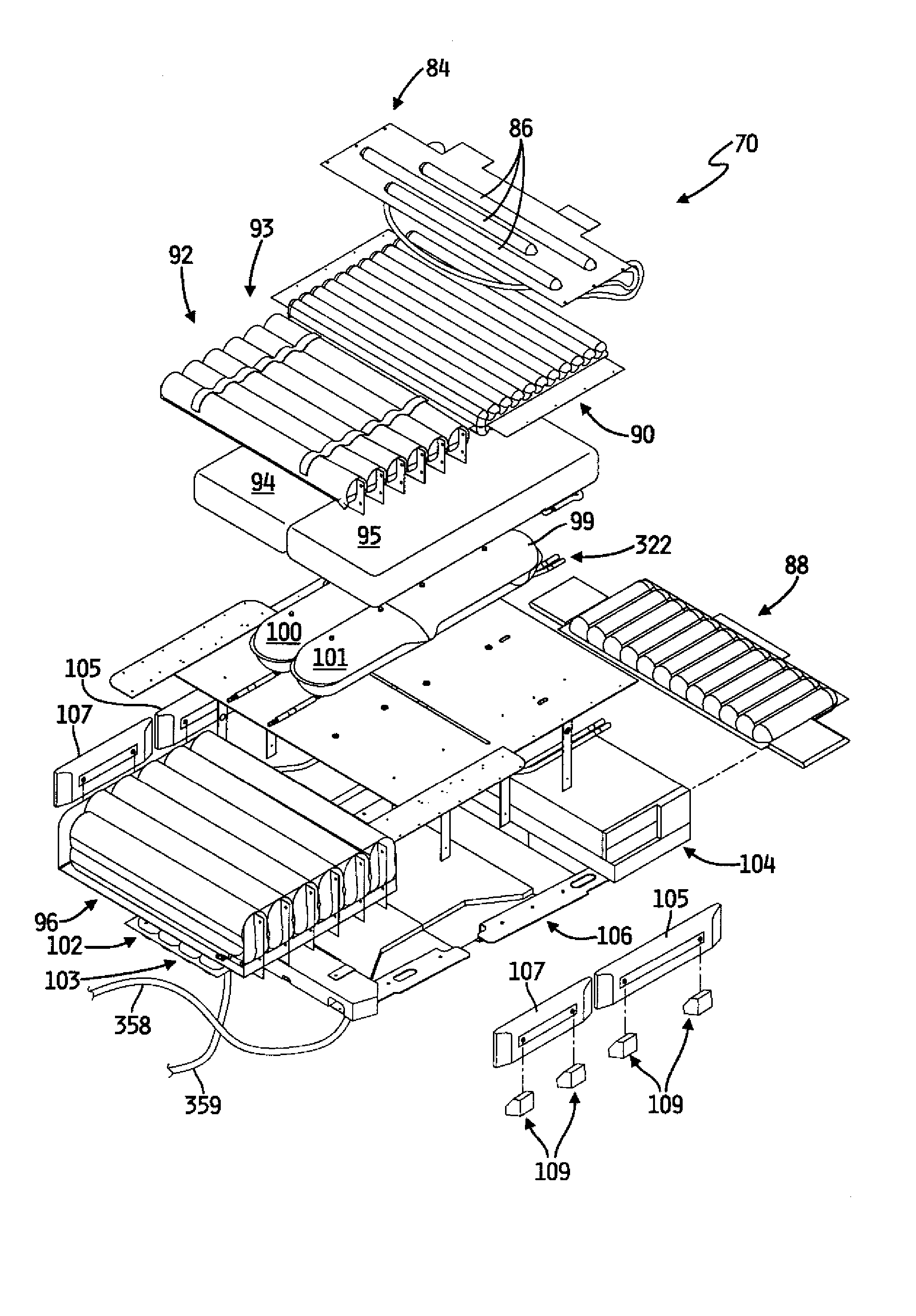

Systems and methods for power generation with exhaust gas recirculation

ActiveUS20080309087A1Reduce nox emmissionIncreased pressureNon-fuel substance addition to fuelGas turbine plantsHeat recovery steam generatorExhaust fumes

A power generation system includes a gas turbine system. The turbine system includes a combustion chamber configured to combust a fuel stream a compressor configured to receive a feed oxidant stream and supply a compressed oxidant to the combustion chamber and an expander configured to receive a discharge from the combustion chamber and generate an exhaust comprising carbon dioxide and electrical energy. The system further includes a retrofittable exhaust gas recirculation system including a splitter configured to split the exhaust into a first split stream and a second split stream, a heat recovery steam generator configured to receive the first split stream and generate a cooled first split stream and a purification system configured to receive the first cooled split stream and the second split stream and generate a recycle stream, wherein the recycle stream is mixed with the fresh oxidant to generate the feed oxidant stream.

Owner:GENERAL ELECTRIC CO

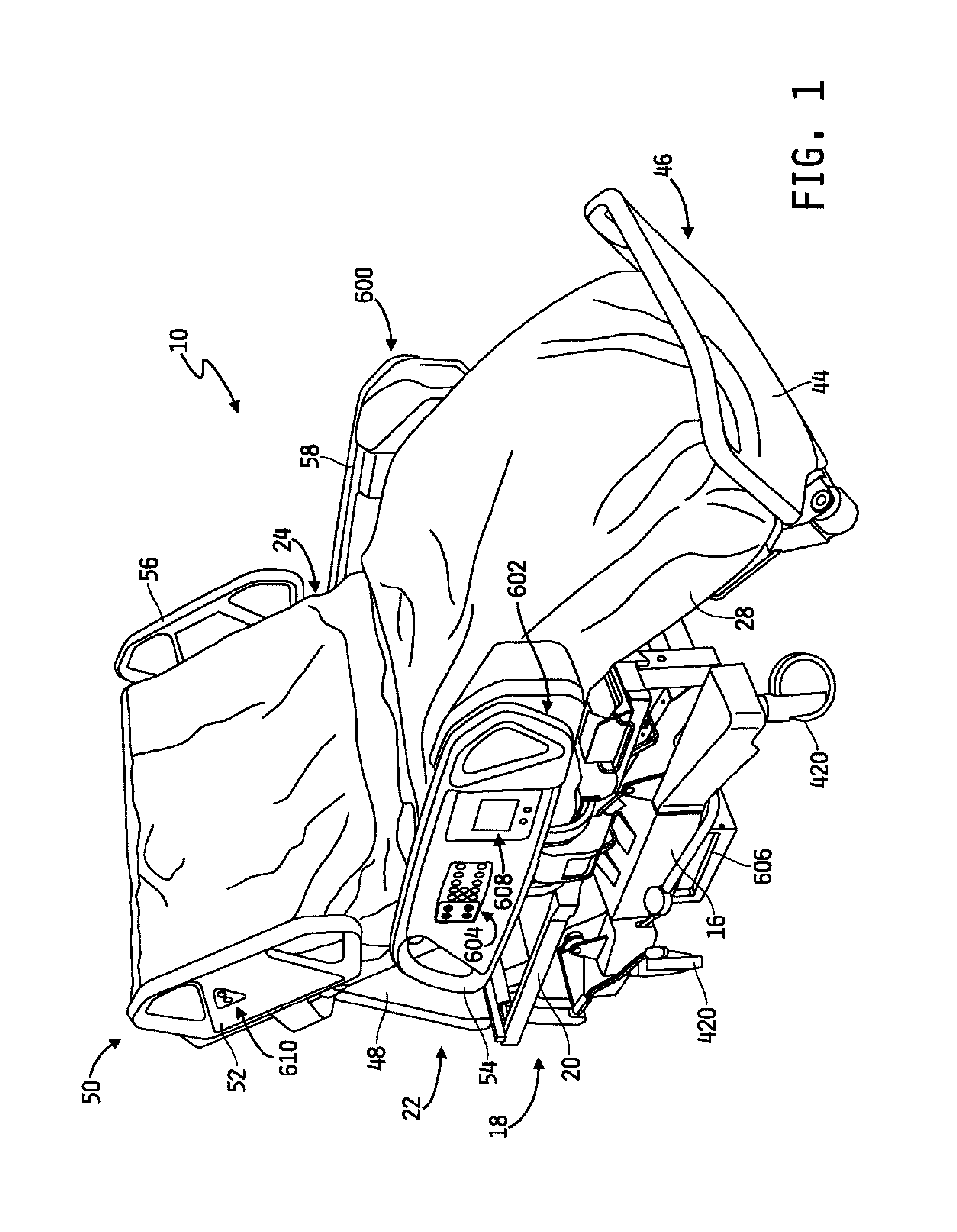

Pulmonary mattress

ActiveUS20070266499A1Increased pressureMaintain pressureStuffed mattressesSpring mattressesControl networkEngineering

Owner:HILL ROM SERVICES

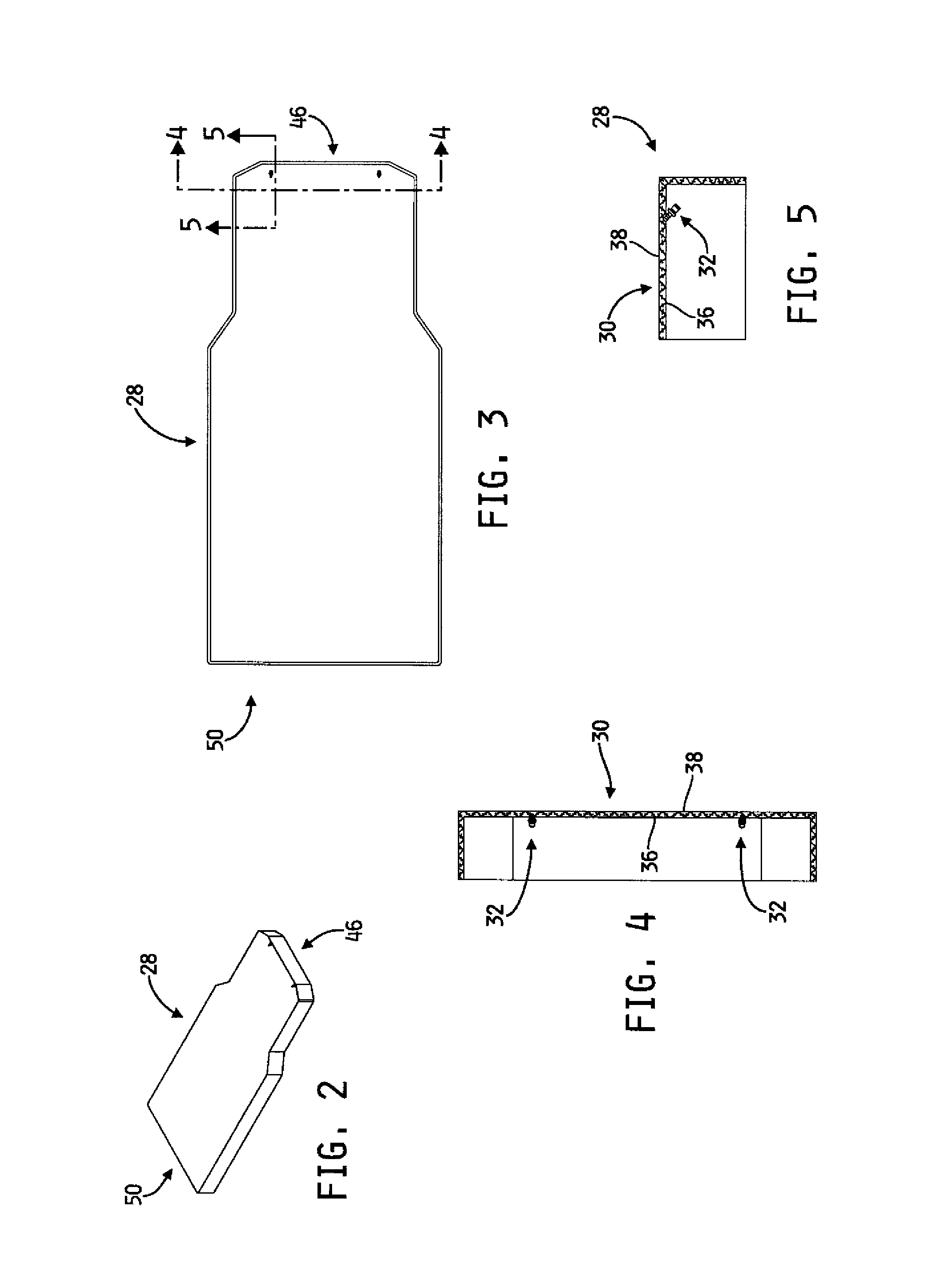

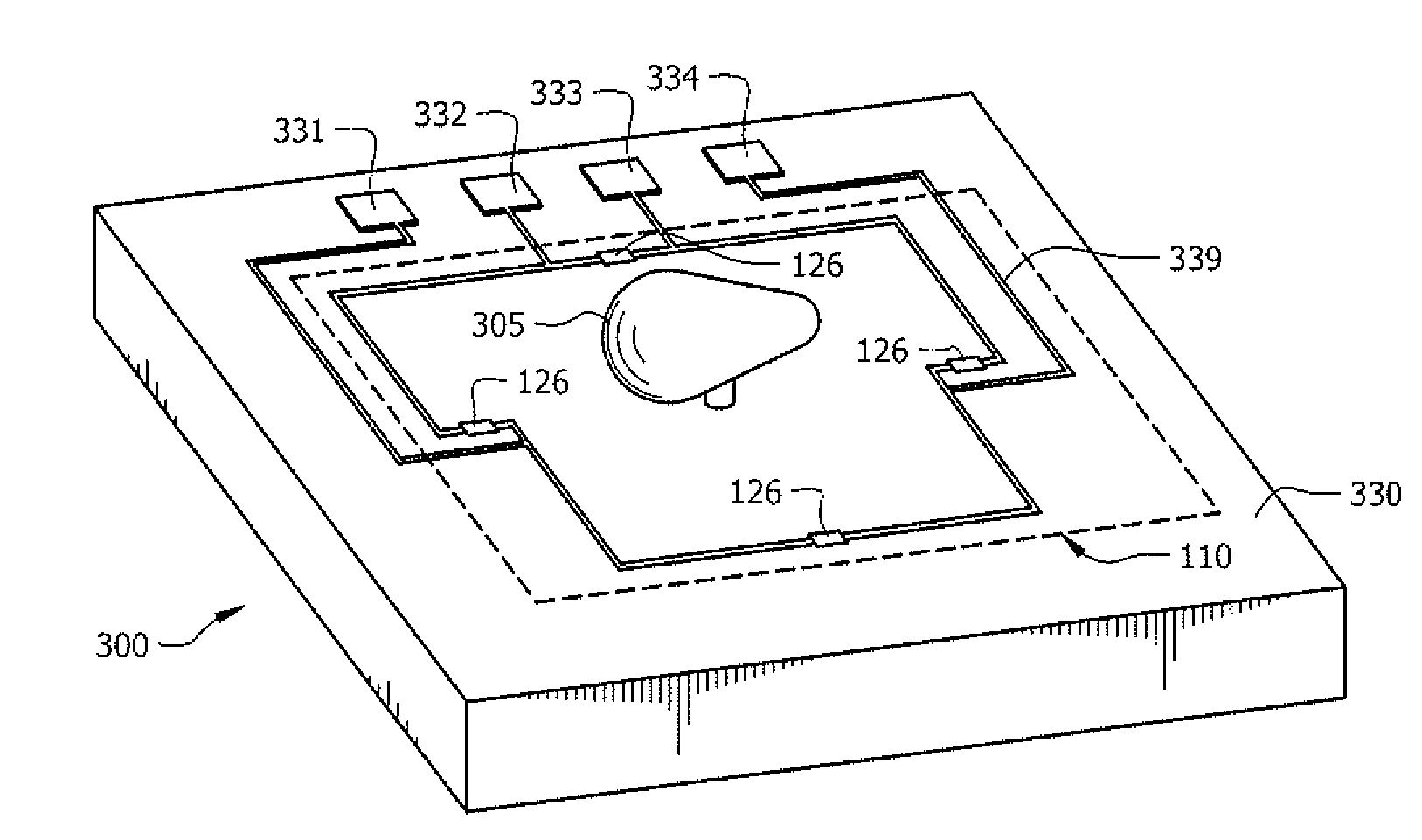

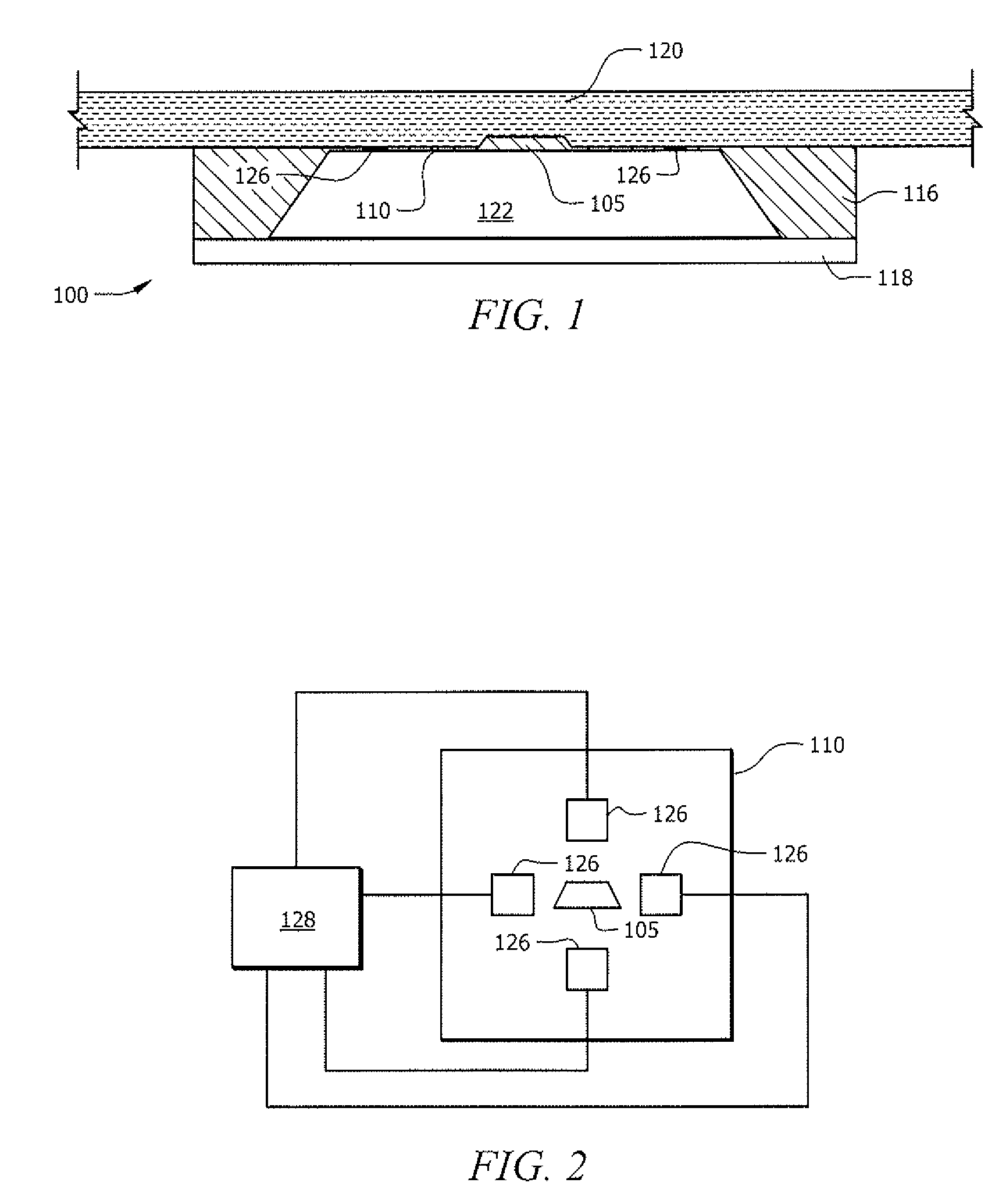

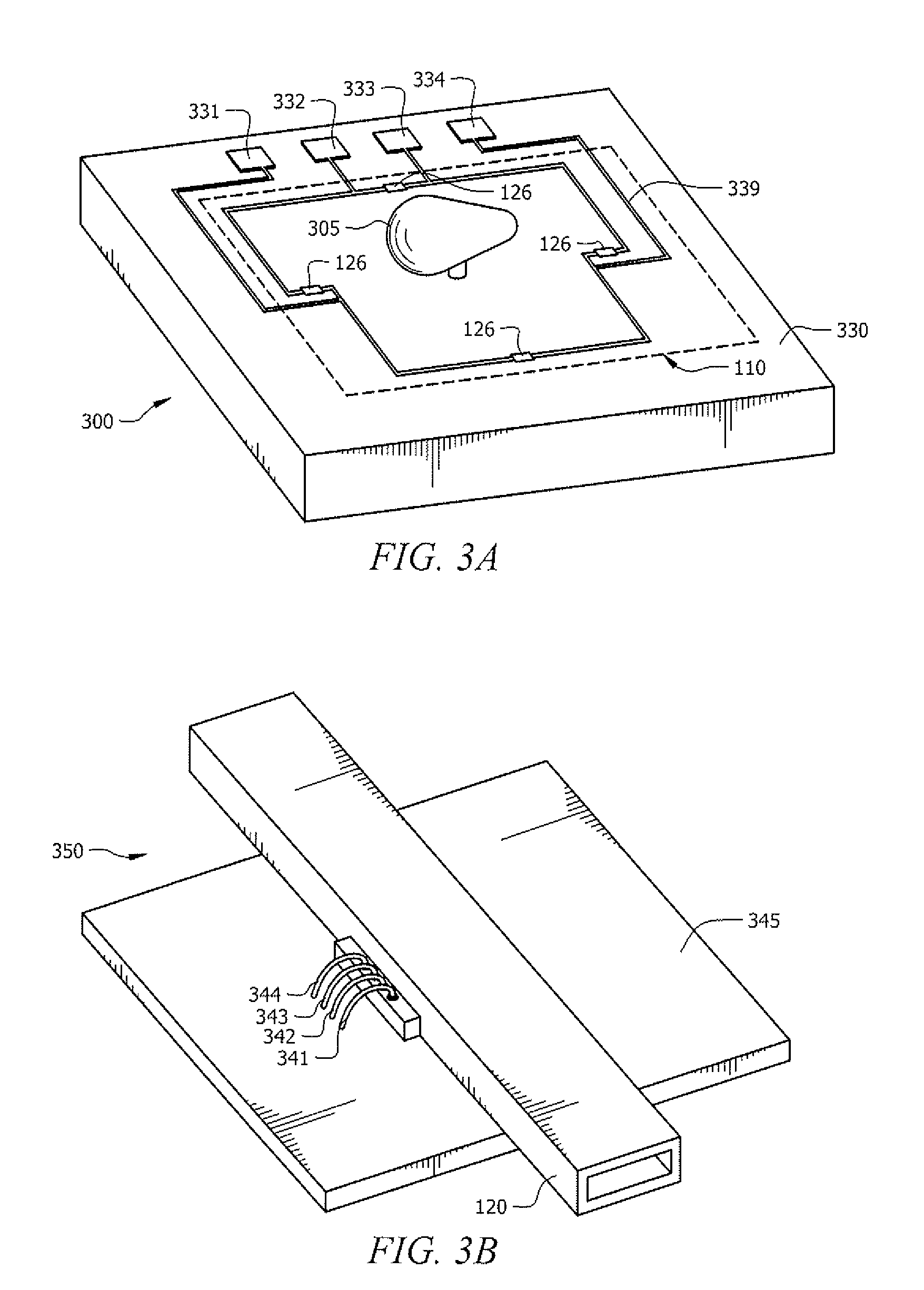

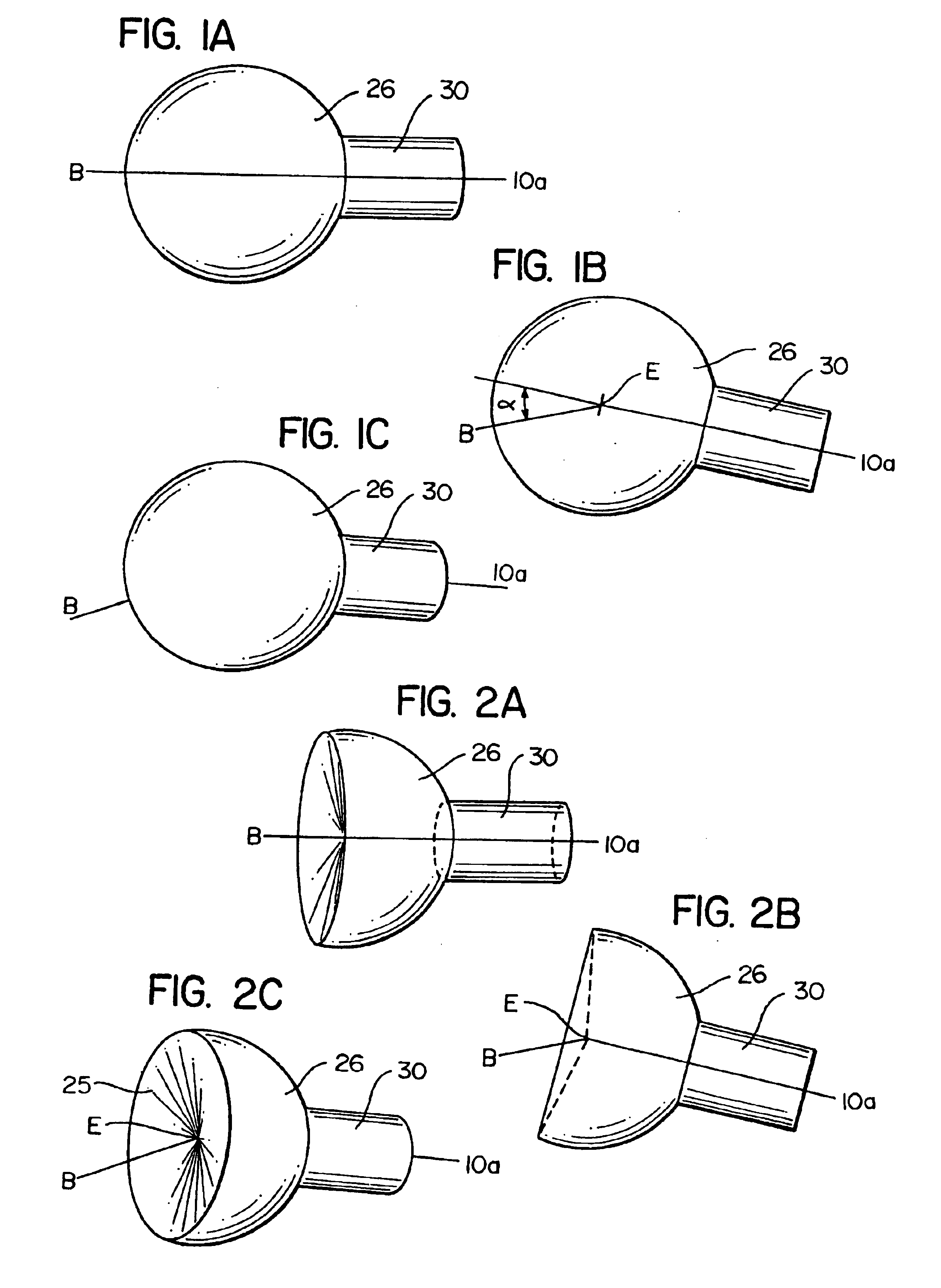

Pressure-based fluid flow sensor

InactiveUS7647842B1Increase deflectionIncreased pressureVolume/mass flow by dynamic fluid flow effectVolume/mass flow by differential pressureSignal onEngineering

A volumetric fluid flow sensor (100) includes a flow channel (120) for flowing a fluid therein; and a diaphragm (110) having an outer surface within the flow channel (120). The diaphragm (110) includes at least one flow disrupting feature mechanically coupled to or emerging from the outer surface of the diaphragm (110). A sensing structure (126) is coupled to the diaphragm (110) for generating a sensing signal responsive to a pressure signal on the diaphragm (110).

Owner:HONEYWELL INT INC

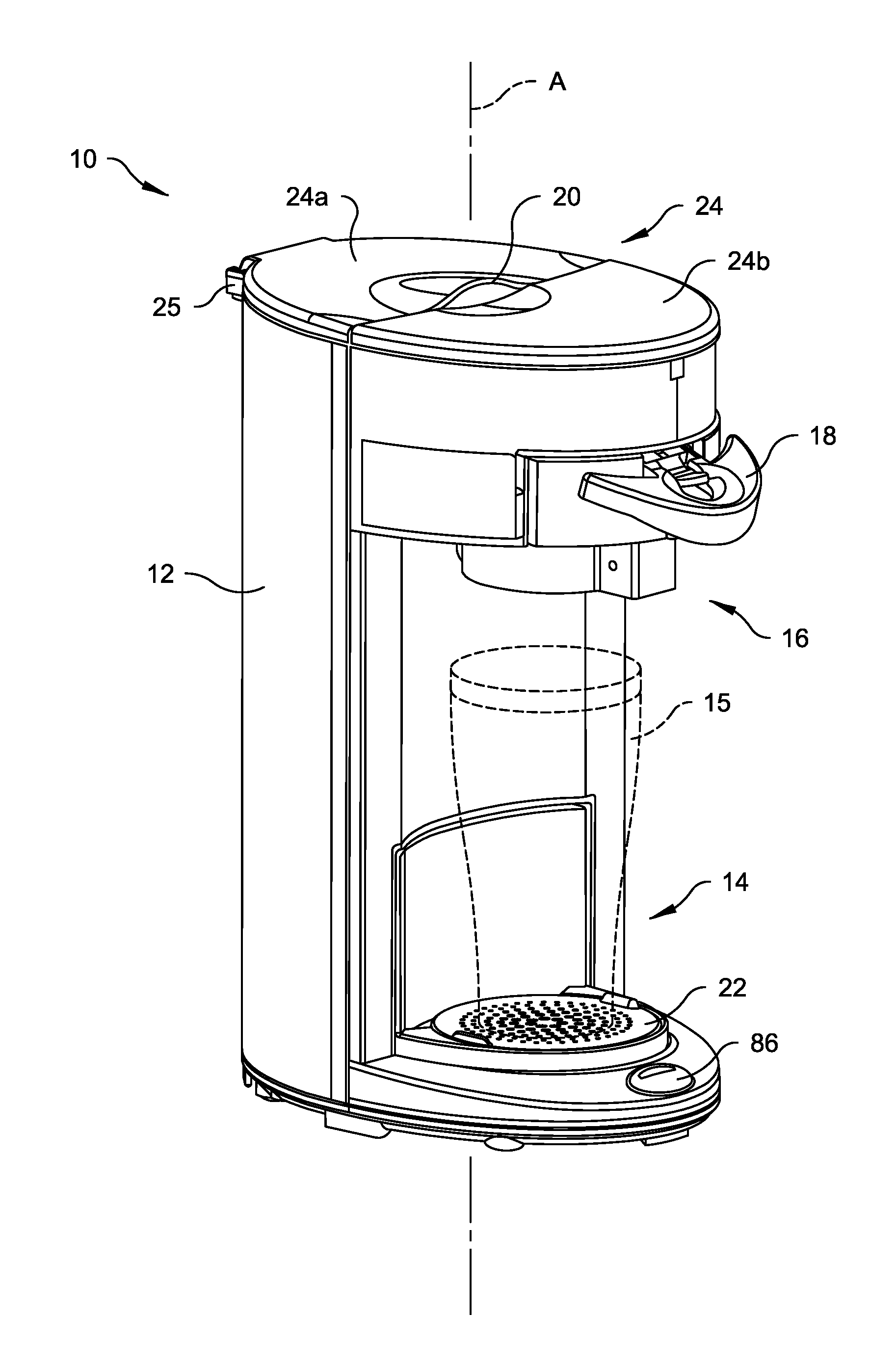

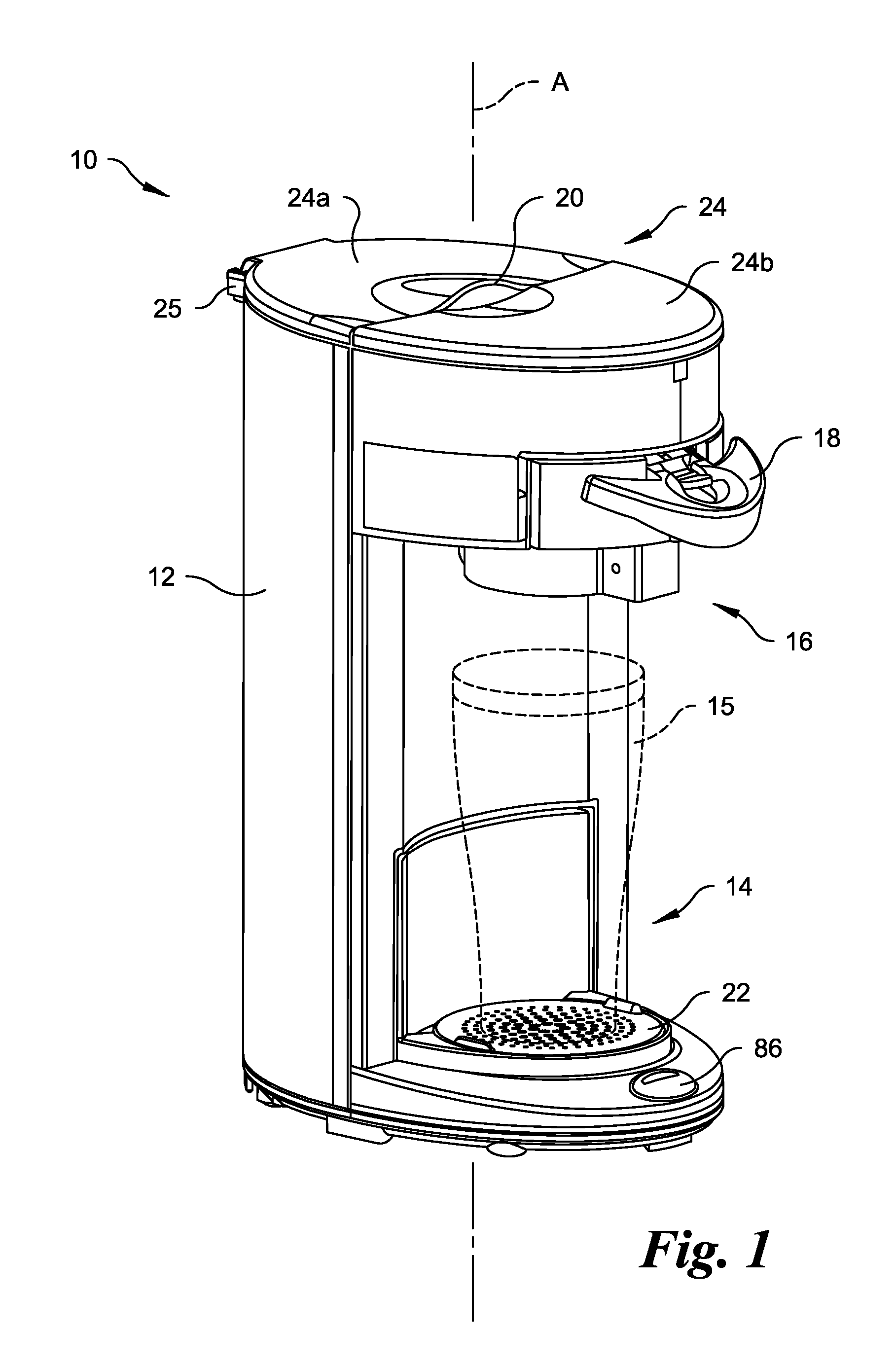

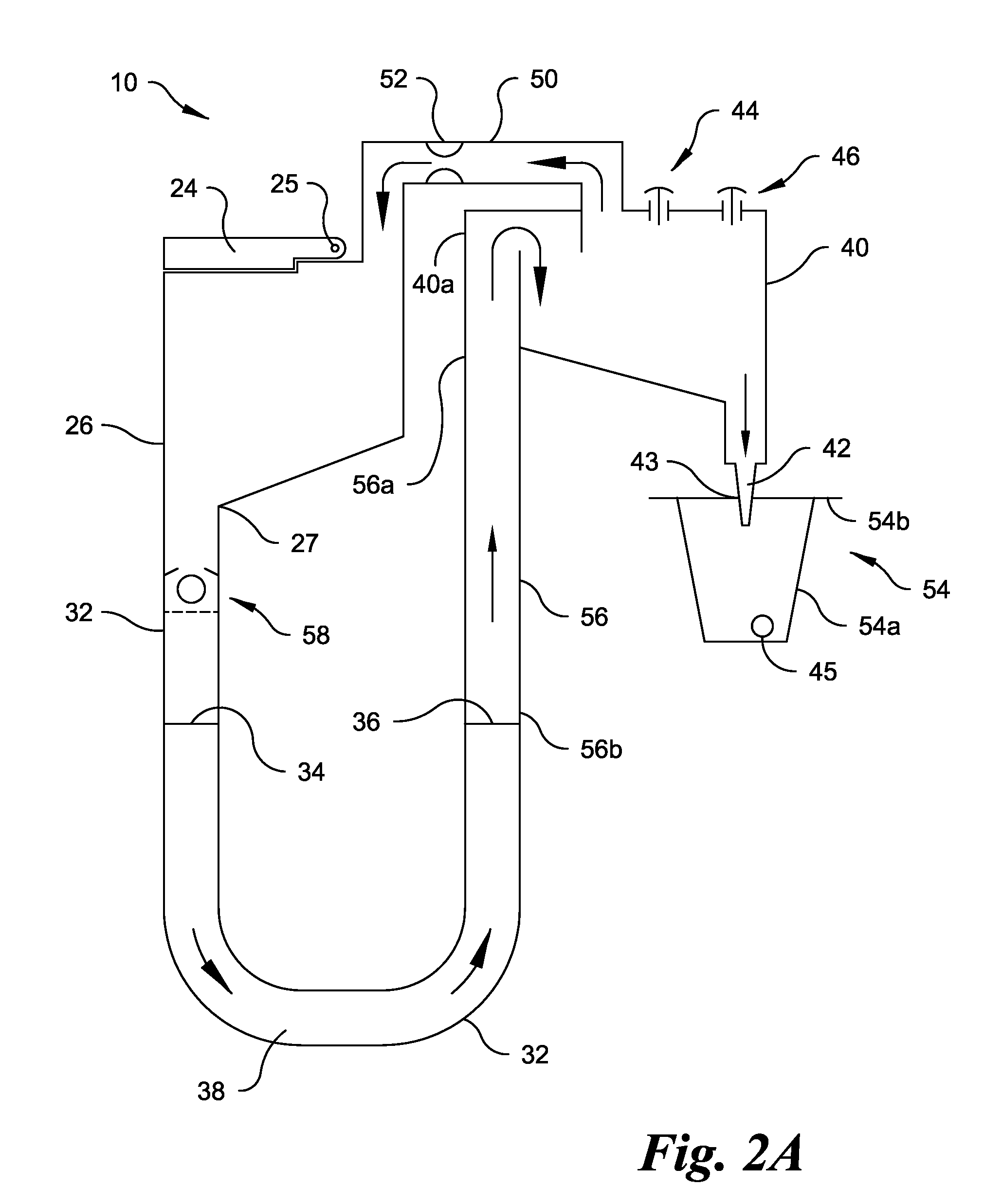

Kitchen Appliance for Preparing a Beverage and Method of Operating Same

ActiveUS20130239817A1Increase in temperatureIncreased pressureTea extractionBeverage vesselsEngineering

A kitchen appliance includes a first reservoir for receiving a liquid to be used for preparing a beverage and a hot water generator (‘HWG’) which has an inlet end, an outlet end and a passageway therebetween. The inlet end of the HWG is connected to the first reservoir. Liquid from the first reservoir flows into the HWG through the inlet end. A second reservoir is connected to the outlet end of the HWG. The second reservoir includes a discharge port. A fluid path connects the first and second reservoirs and bypasses the HWG. The kitchen appliance is operable for both pressurized brew / heat cycles and un-pressurized brew / heat cycles.

Owner:HAMILTON BEACH BRANDS

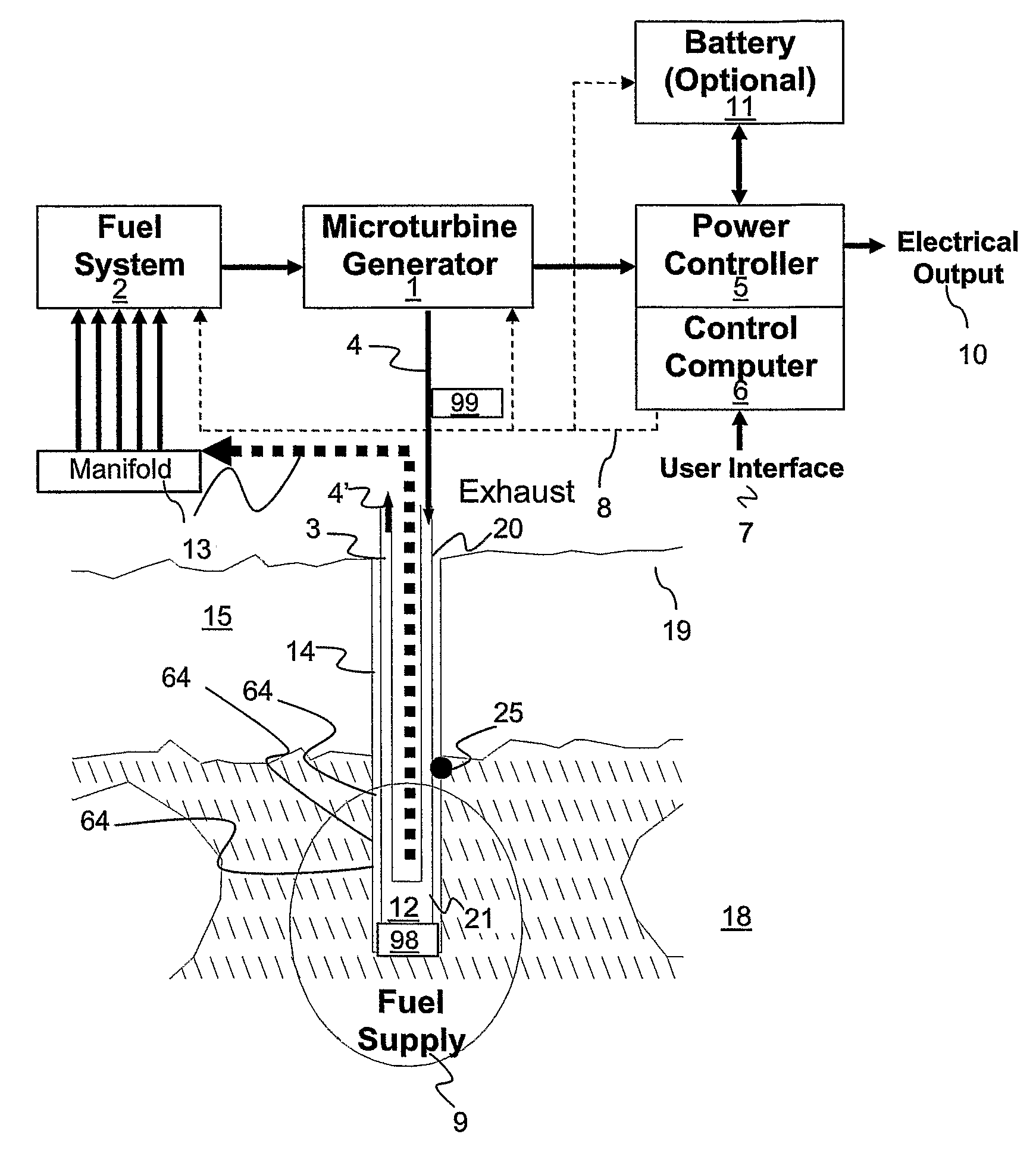

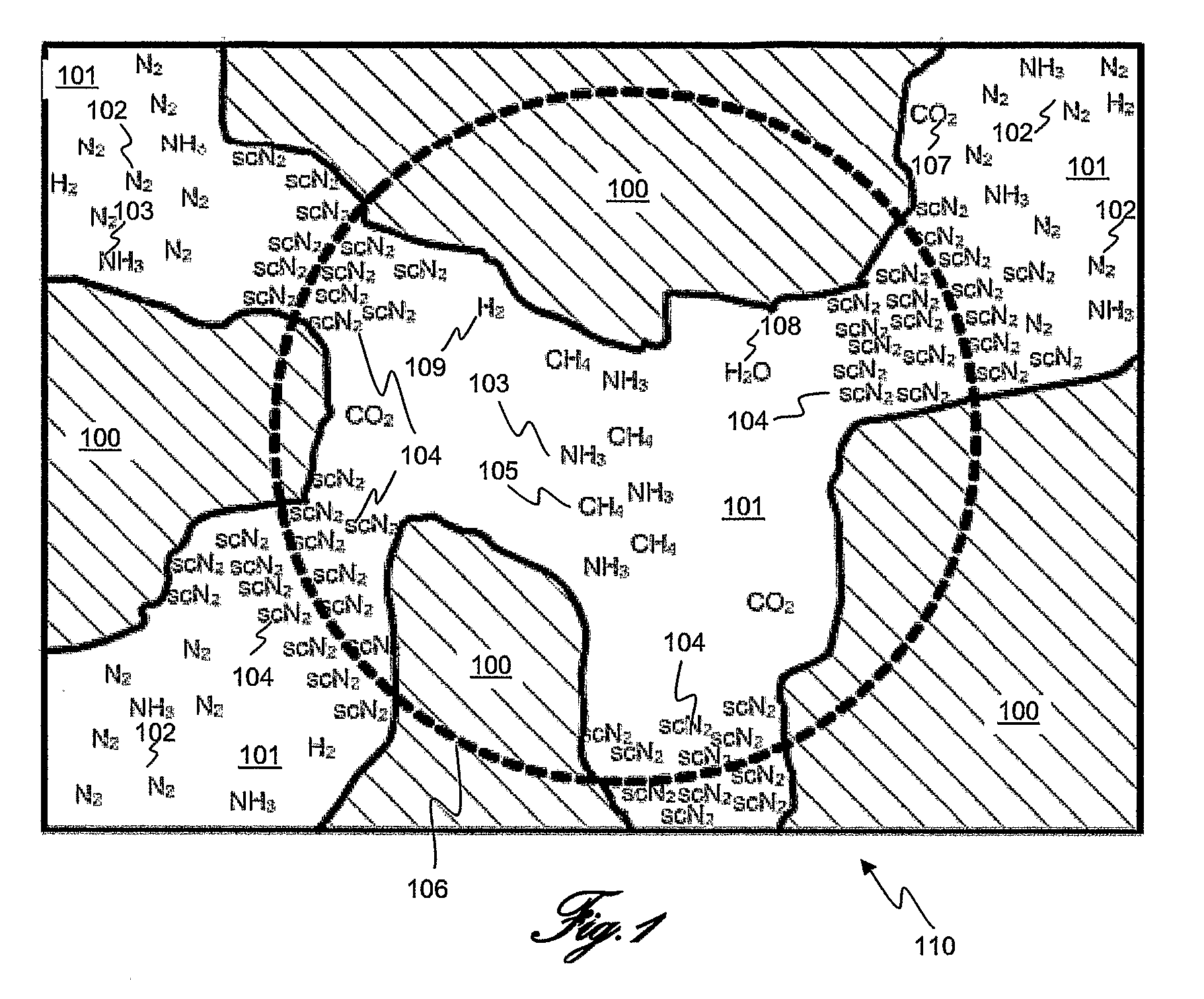

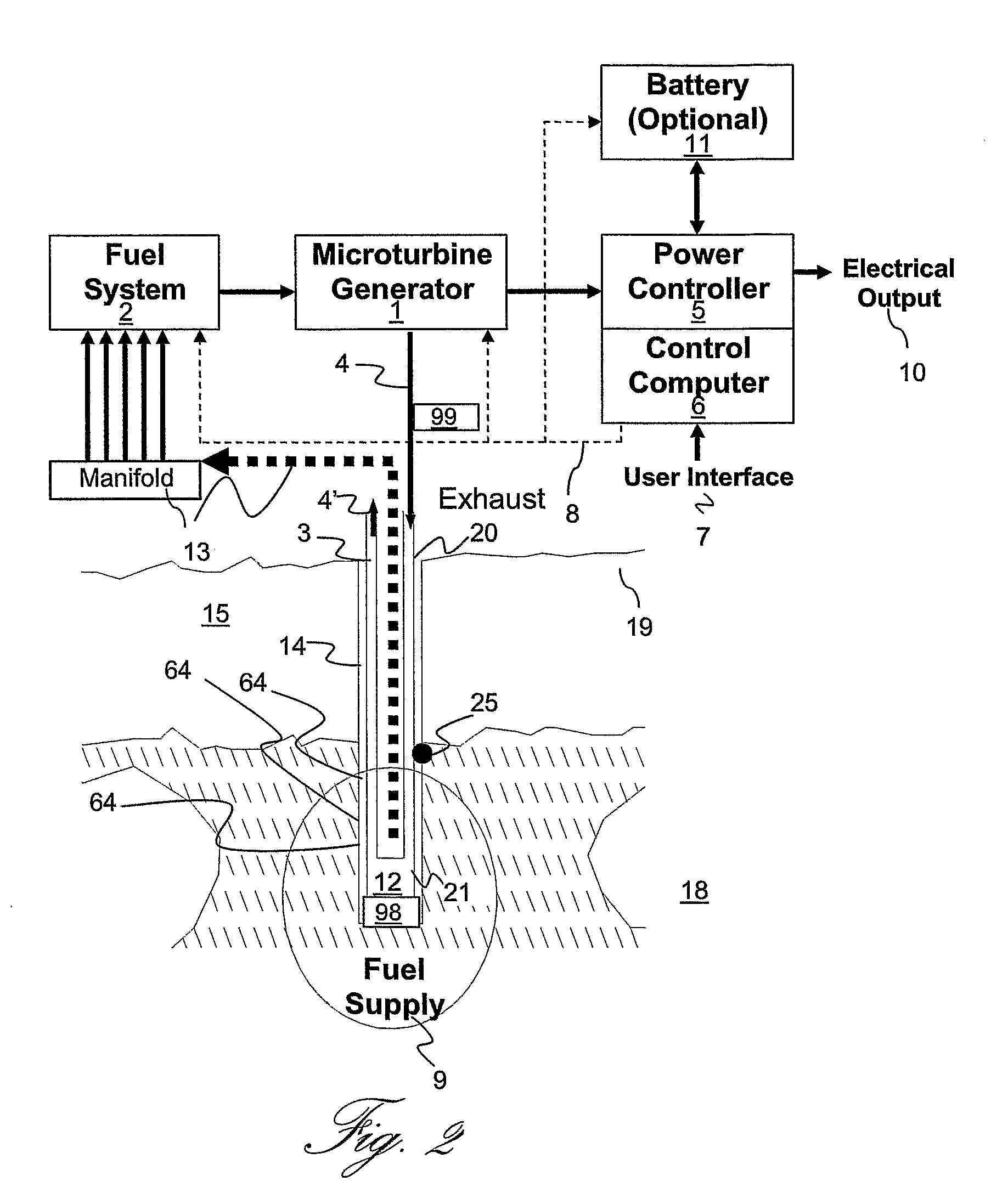

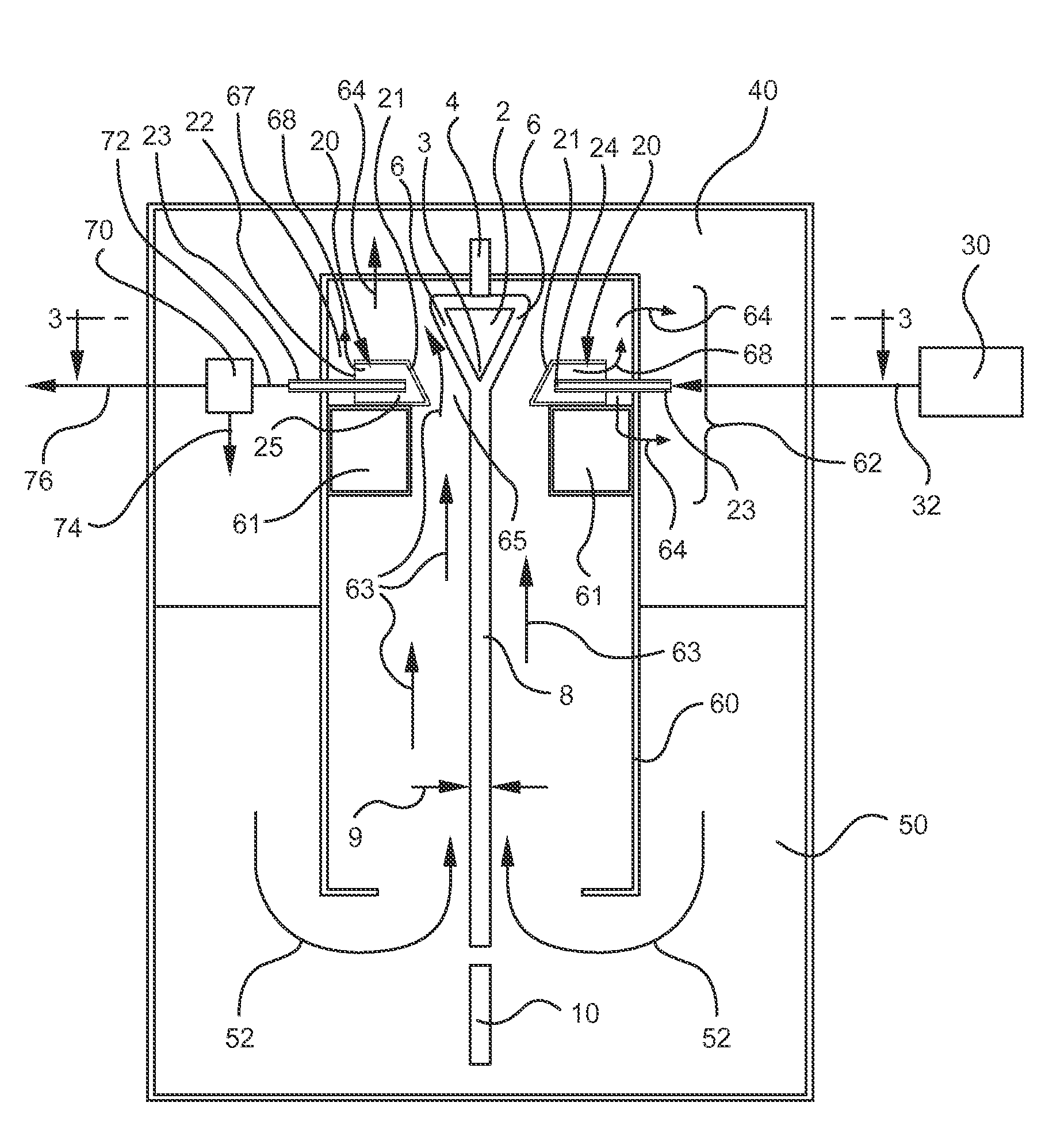

Supercritical fluid recovery and refining of hydrocarbons from hydrocarbon-bearing formations applying fuel cell gas in situ

ActiveUS20100163226A1Increase steam pressureIncreased pressureInsulationFluid removalTarHydrogen compounds

A plume of combined gases are infused into hydrocarbon-bearing formations, “inert” as the major gas and “reactive” as the minor gas, where the minor gas reacts with hydrocarbons to fully saturate hydrocarbons with supercritical fluid, which migrate hydrocarbons out of formations, even at great distances from the regulated fuel cell source. Coal, tar sands, petroleum-contaminated soil, and / or oil wells that have lost gas pressure can also be desorbed by this in-situ method.

Owner:CRITICAL POINT ENERGY

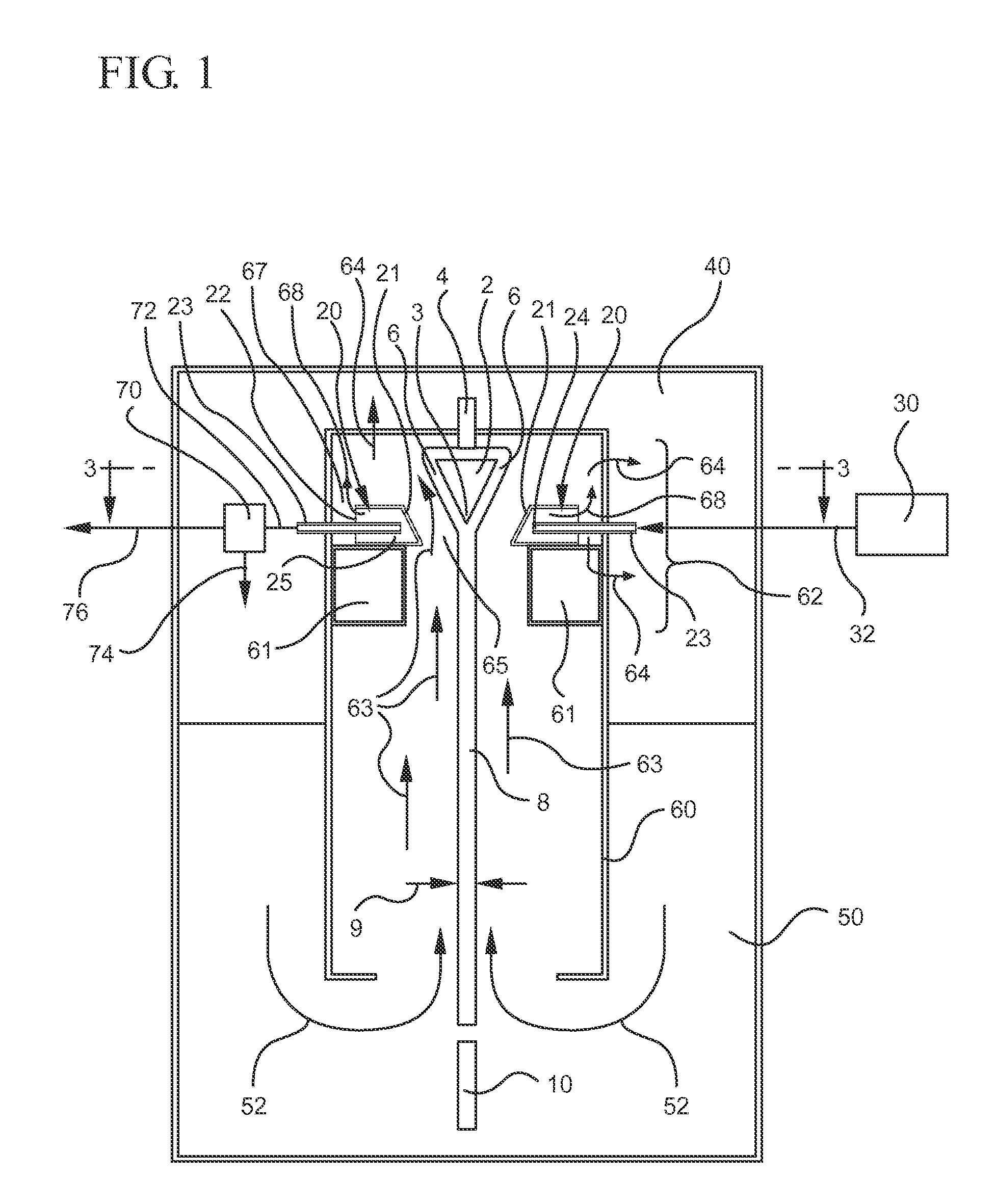

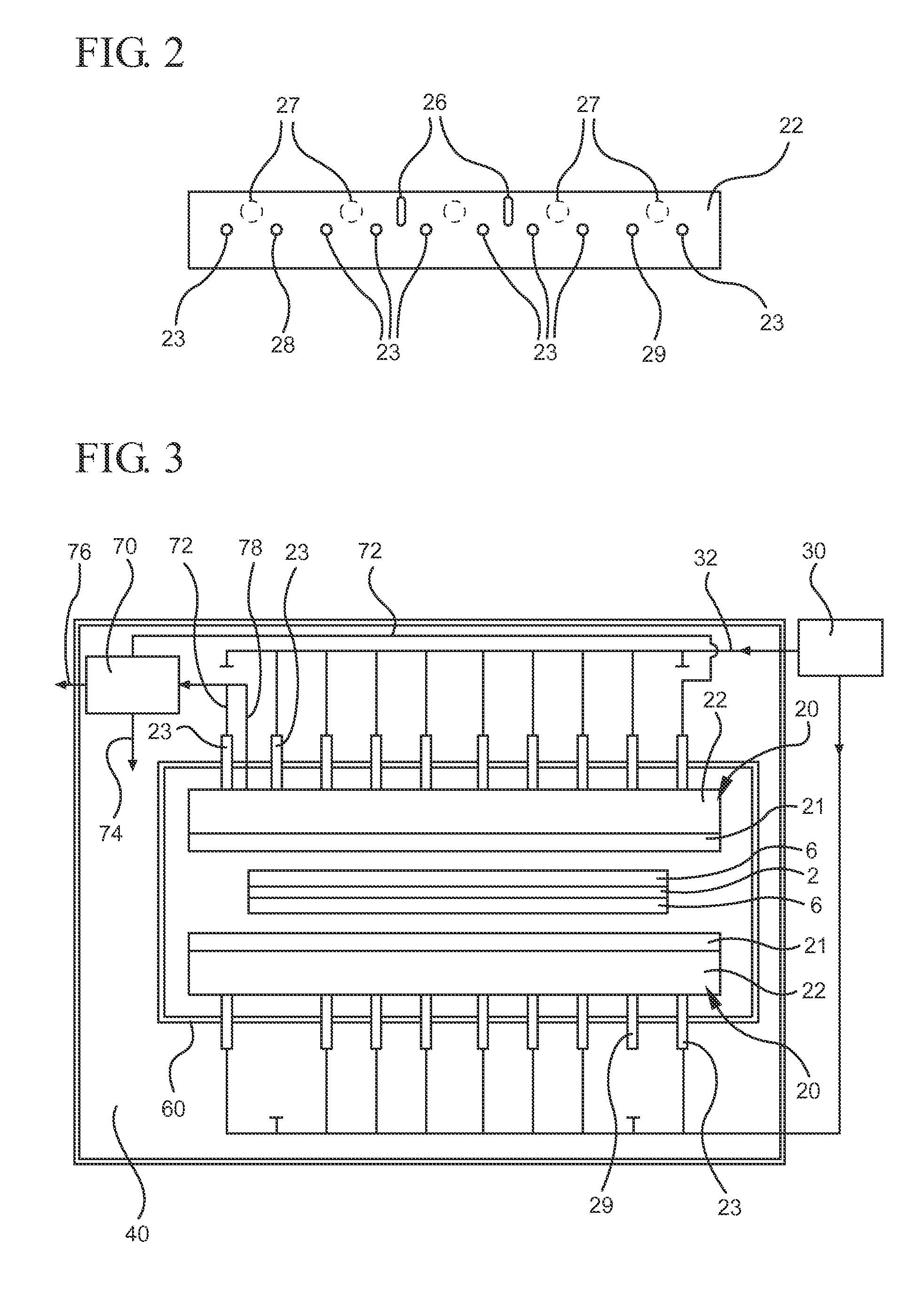

Method and Apparatus for Pressure Control of Glass-Making Thickness-Control Zone

InactiveUS20110126591A1Increased pressureUndesired thickness variationGlass drawing apparatusGlass forming apparatusControl zonePressure management

Managing pressure within a thickness-control-zone (muffle door) housing (20) relative to pressures in a glass-making machine enclosure (60) and an upper chamber (40)—that is disposed outside the enclosure—so as to minimize or control undesired airflows that would adversely affect thickness (9) of glass ribbon (8). According to one pressure-management technique, the pressure at a location (25) in the housing (20) is managed so as to be less than the pressure at a location (65) that is within the enclosure (60) as well as both outside and adjacent to the housing. In the event of a leak, as by a crack or unintended opening in the housing, for example, this pressure difference reduces or prevents airflow toward the ribbon and, thereby, undesired thickness variation in the ribbon. According to a second pressure-management technique, the pressure at location (25) is managed so as to be greater than the pressure in the upper chamber.

Owner:CORNING INC

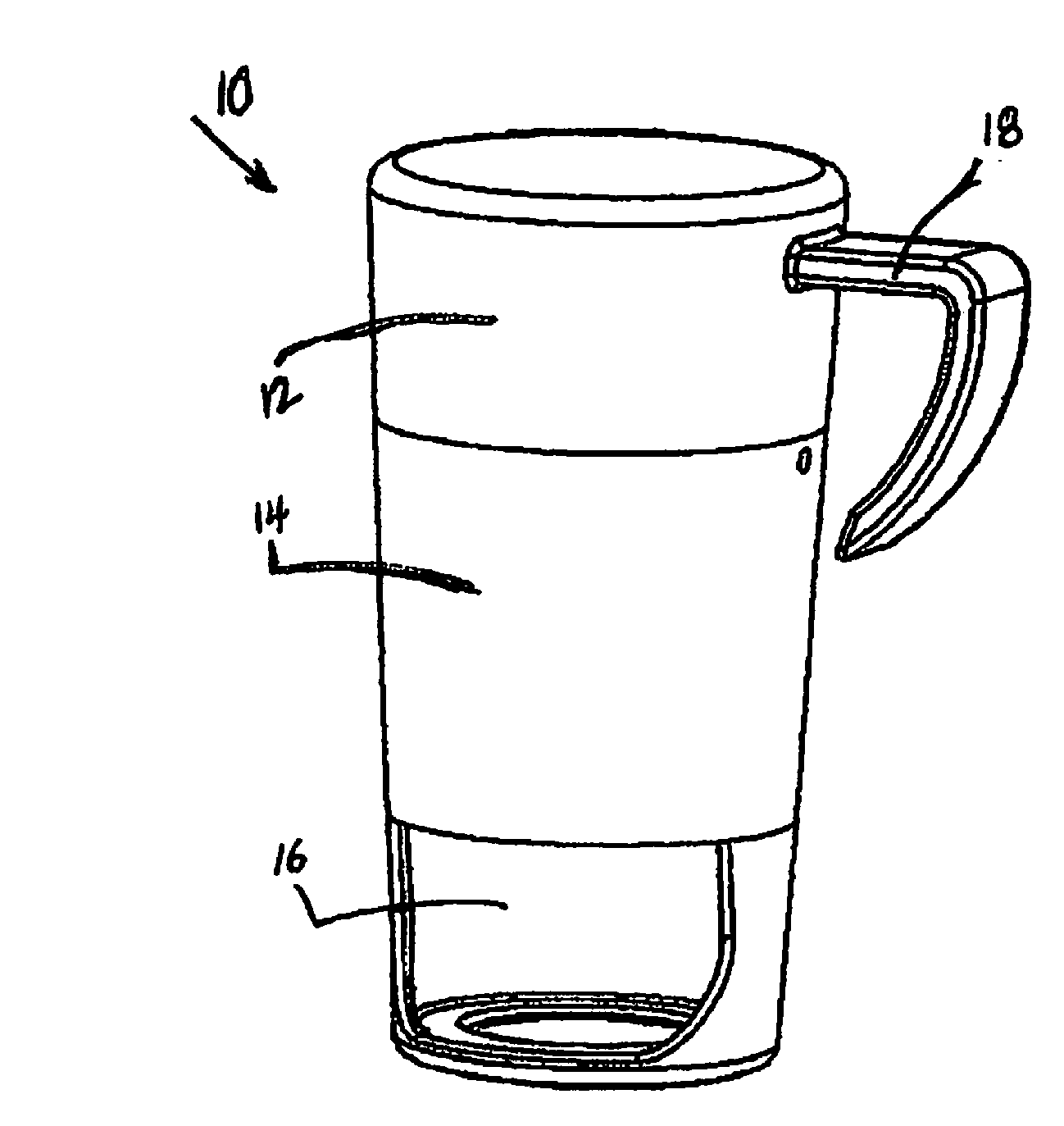

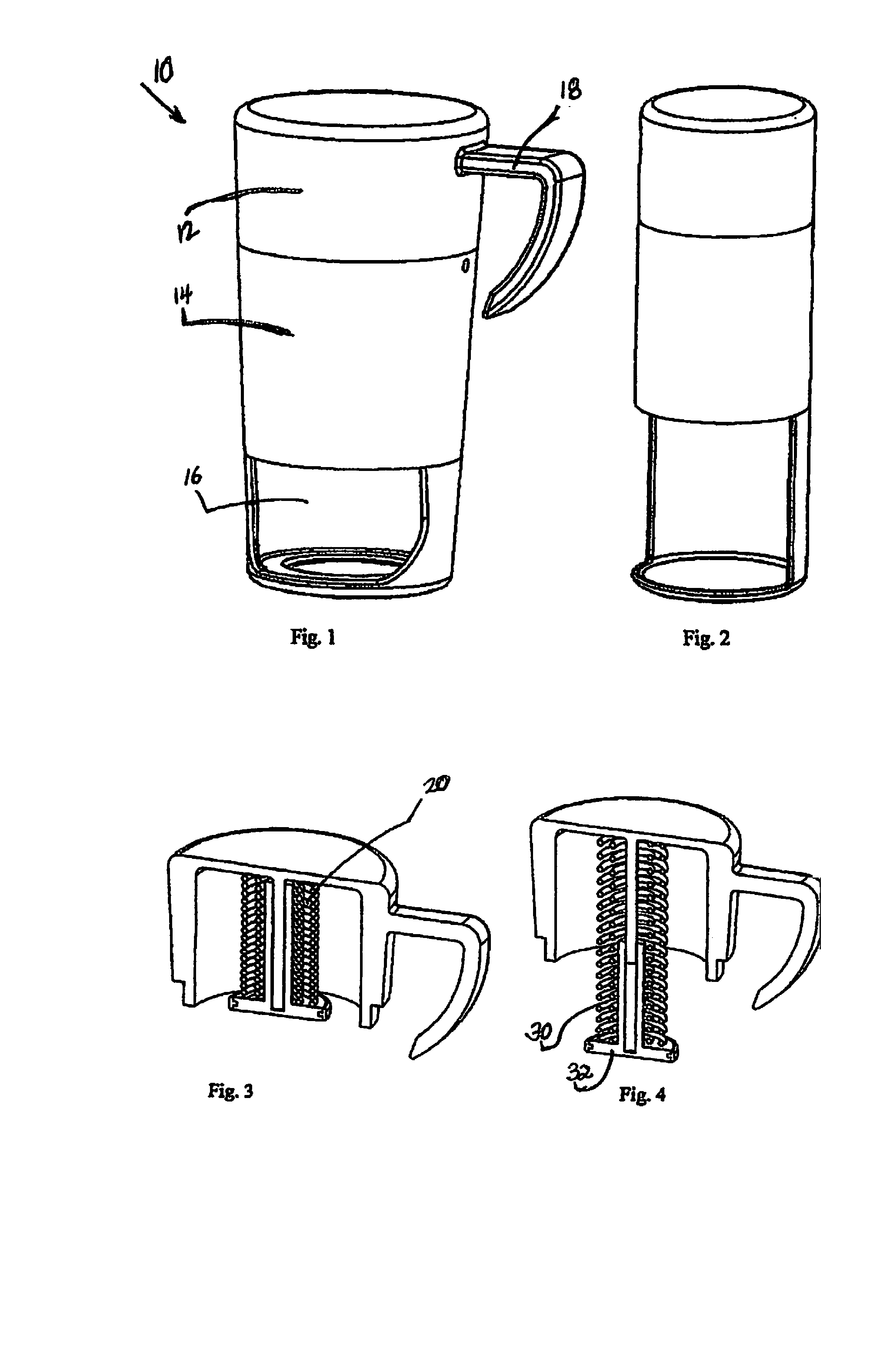

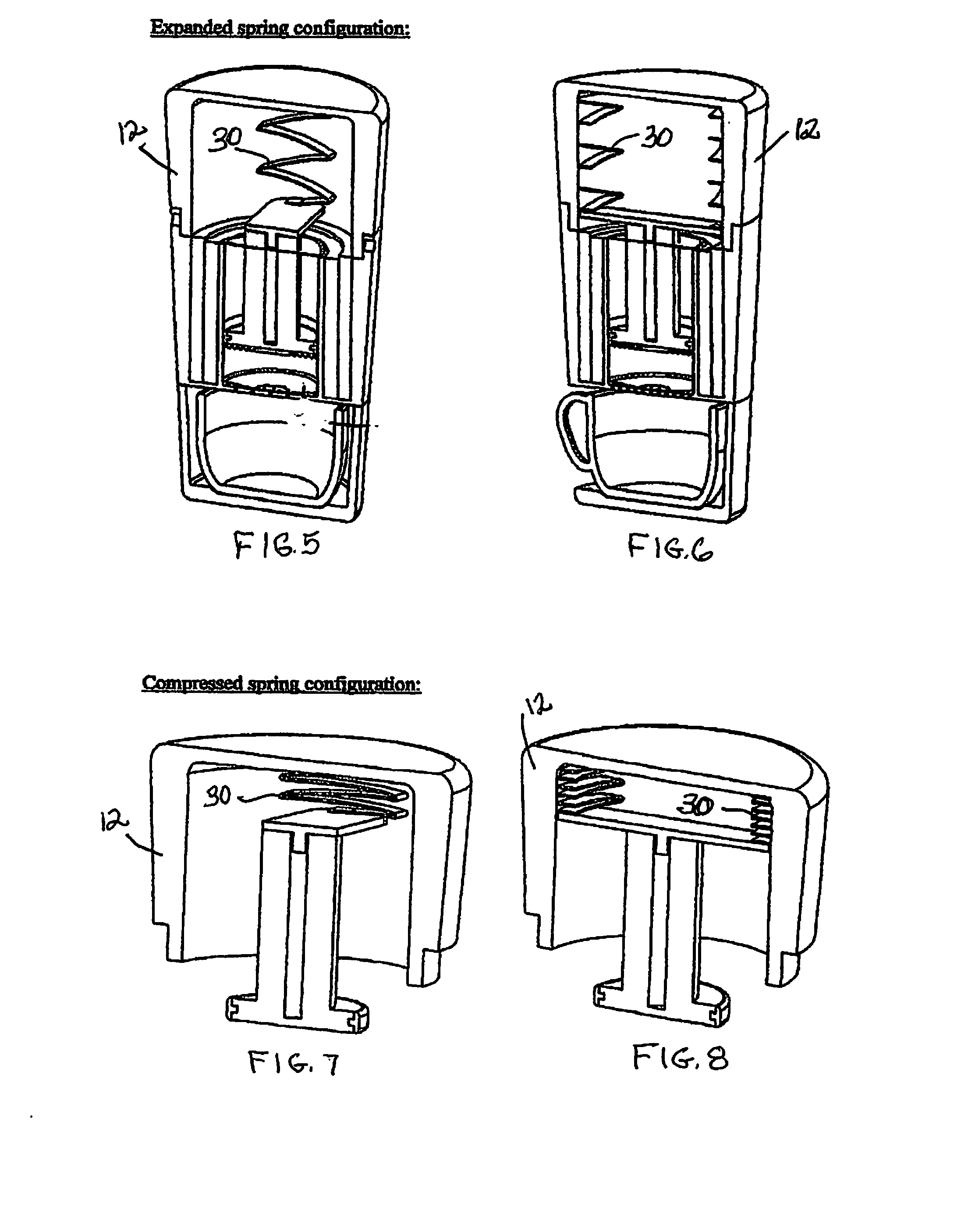

Coffee maker

InactiveUS20130078342A1Decrease in volumeIncreased pressureReady-for-oven doughsBeverage vesselsPistonCoffee grounds

Methods and apparatus for a coffer maker. A beverage preparation apparatus includes a coffee link chamber for receiving coffee grounds and water, a coffee receiving chamber for receiving prepared coffee, the heating source operative check heat for coffee brewing chamber, at least one biasing element formed of a shape memory materials, and at least one piston element couples to the biasing element, whereby when the coffee brewing chamber reaches a transition temperature of the shape memory material, a biasing element deforms, releasing a spring force urging the piston element into the coffee brewing chamber to decrease the volume and increase the pressure within the coffee brewing chamber, and forcing heated water through the coffee grounds through a filter and into a coffee collection container situated in the coffee receiving chamber.

Owner:LOEBL ODED

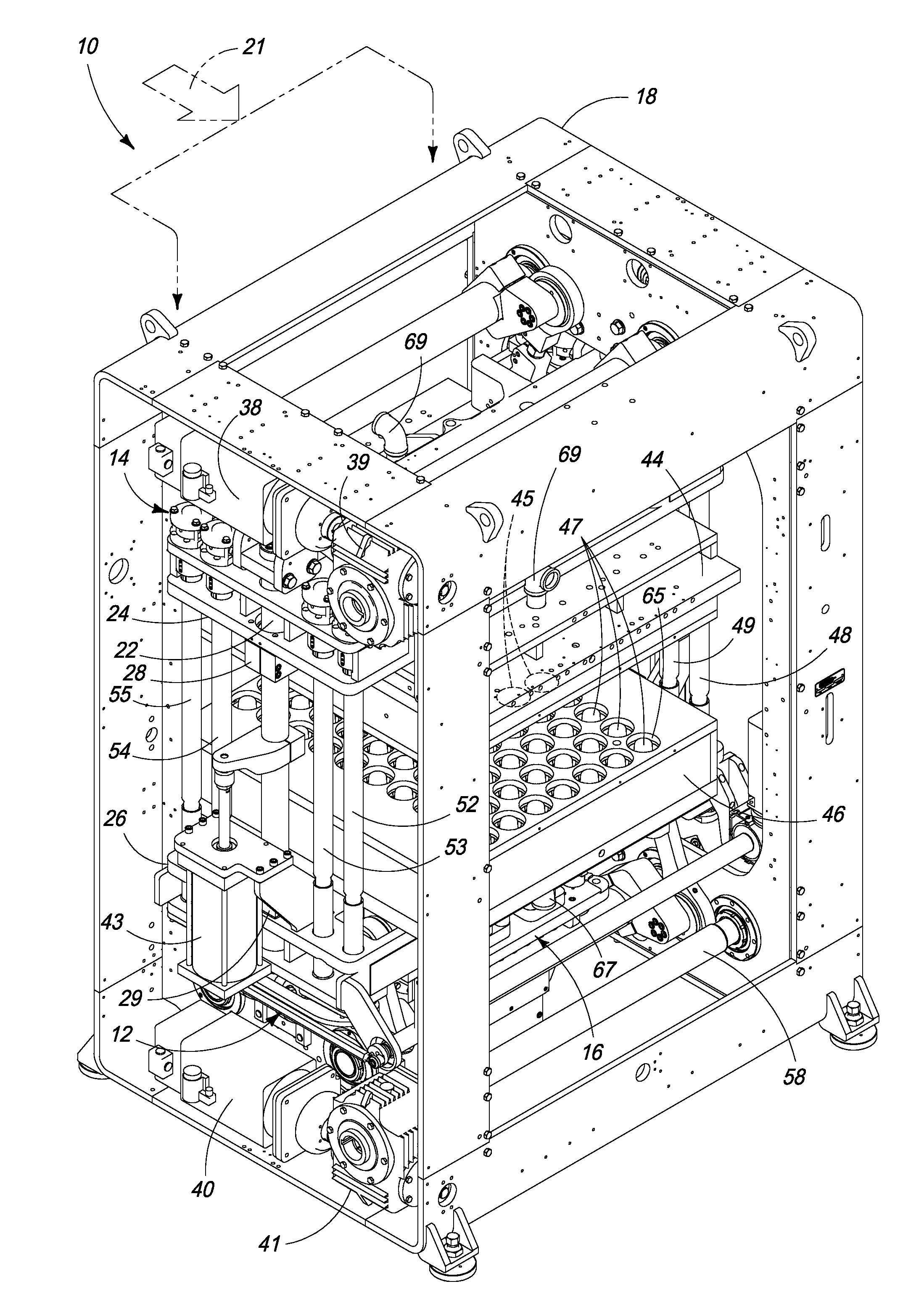

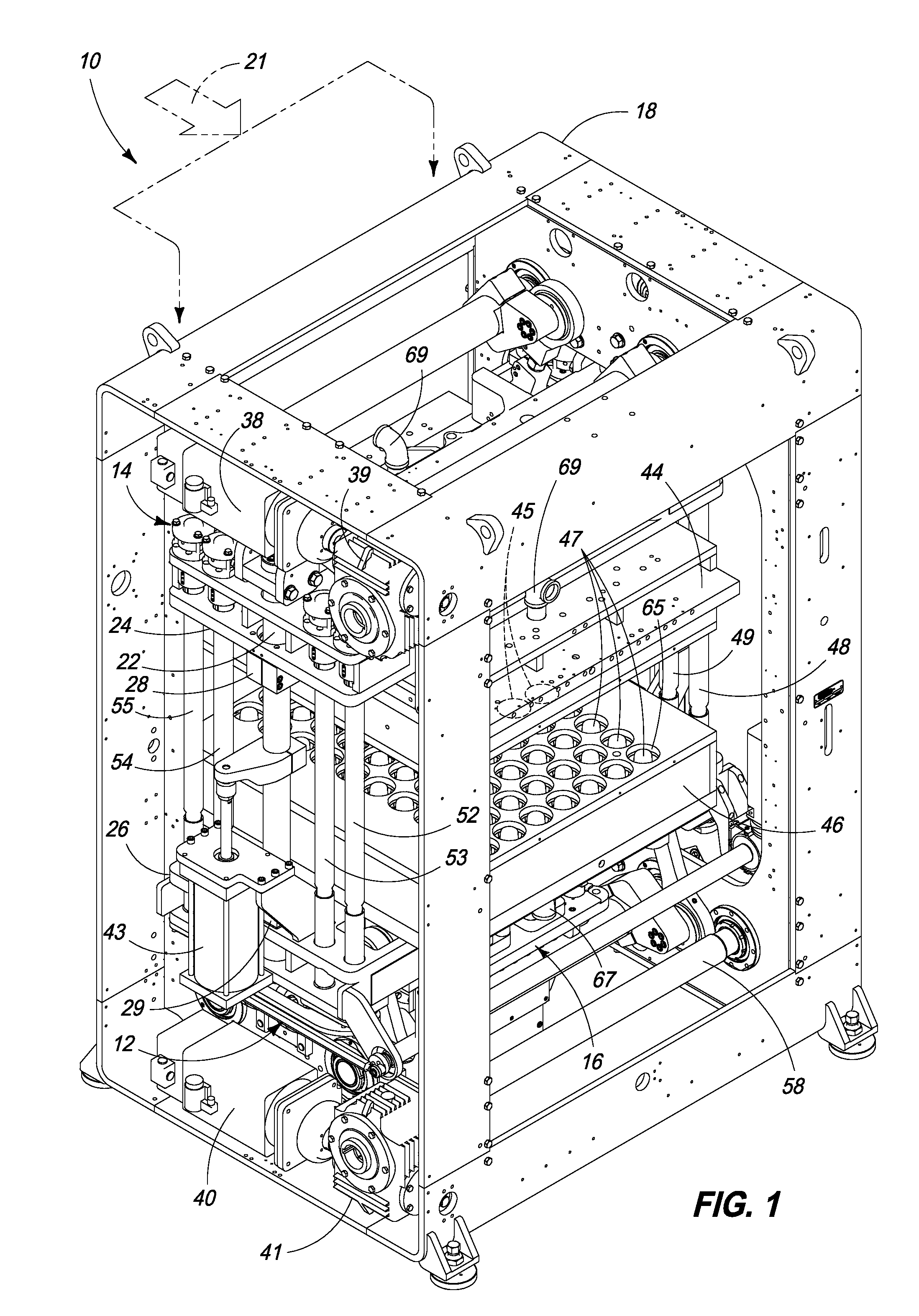

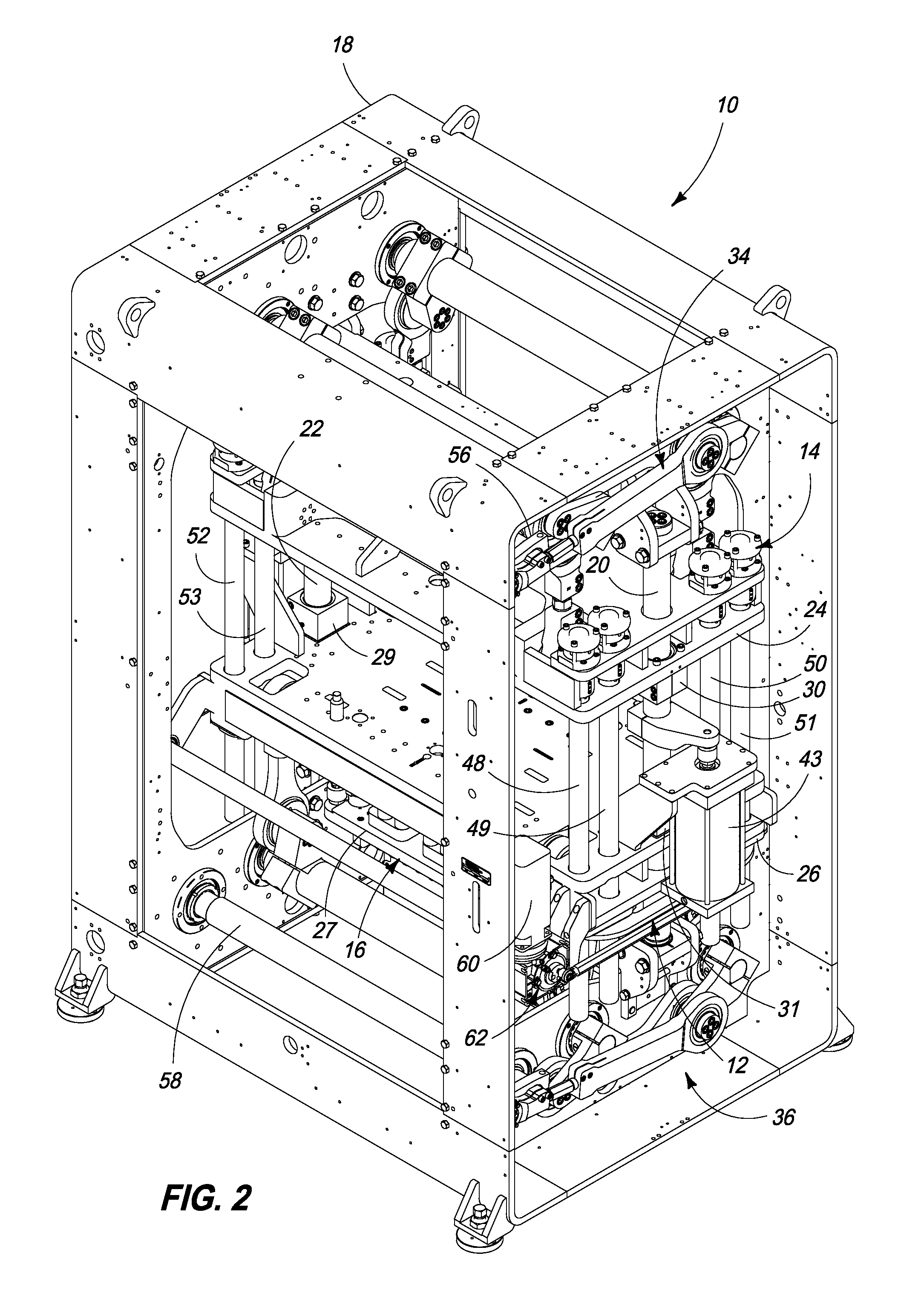

Thermoforming Machine Having Platen Locks and Method

InactiveUS20130119584A1Increase structural load capacityIncreased pressureCheese manufactureButter manufactureEngineeringMechanical engineering

A thermoforming machine is provided having a frame, a first platen, a second platen, a platen load shaft, and a load shaft latch. The first platen supports a first mold. The second platen supports a complementary second mold and is carried by the frame for movement toward and away from the first platen to engage and disengage with the first mold. The platen load shaft has a lock ledge with an engagement surface transverse to the load shaft. The load shaft is supported by the frame and extends between the first platen and the second platen. The load shaft latch has an engagement surface transverse to a central axis of the load shaft and is movable to engage and disengage the lock ledge transverse engagement surface. A method is also provided.

Owner:IRWIN RES & DEV

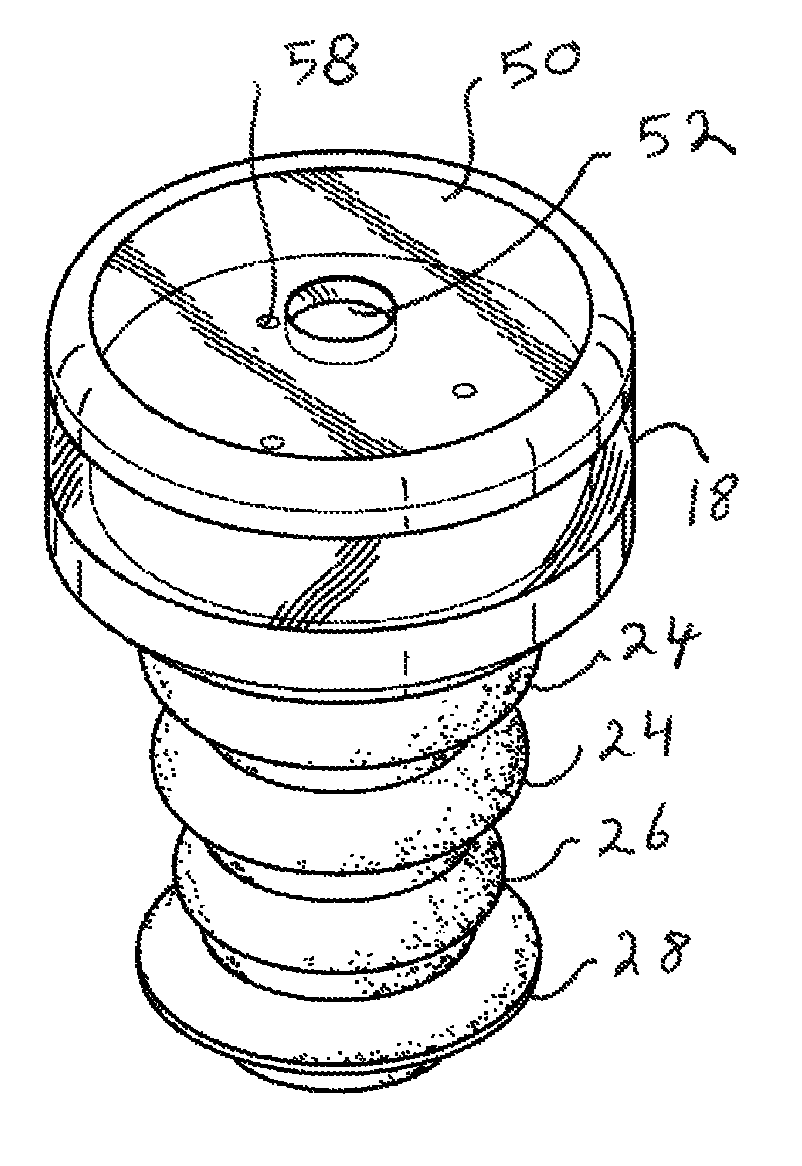

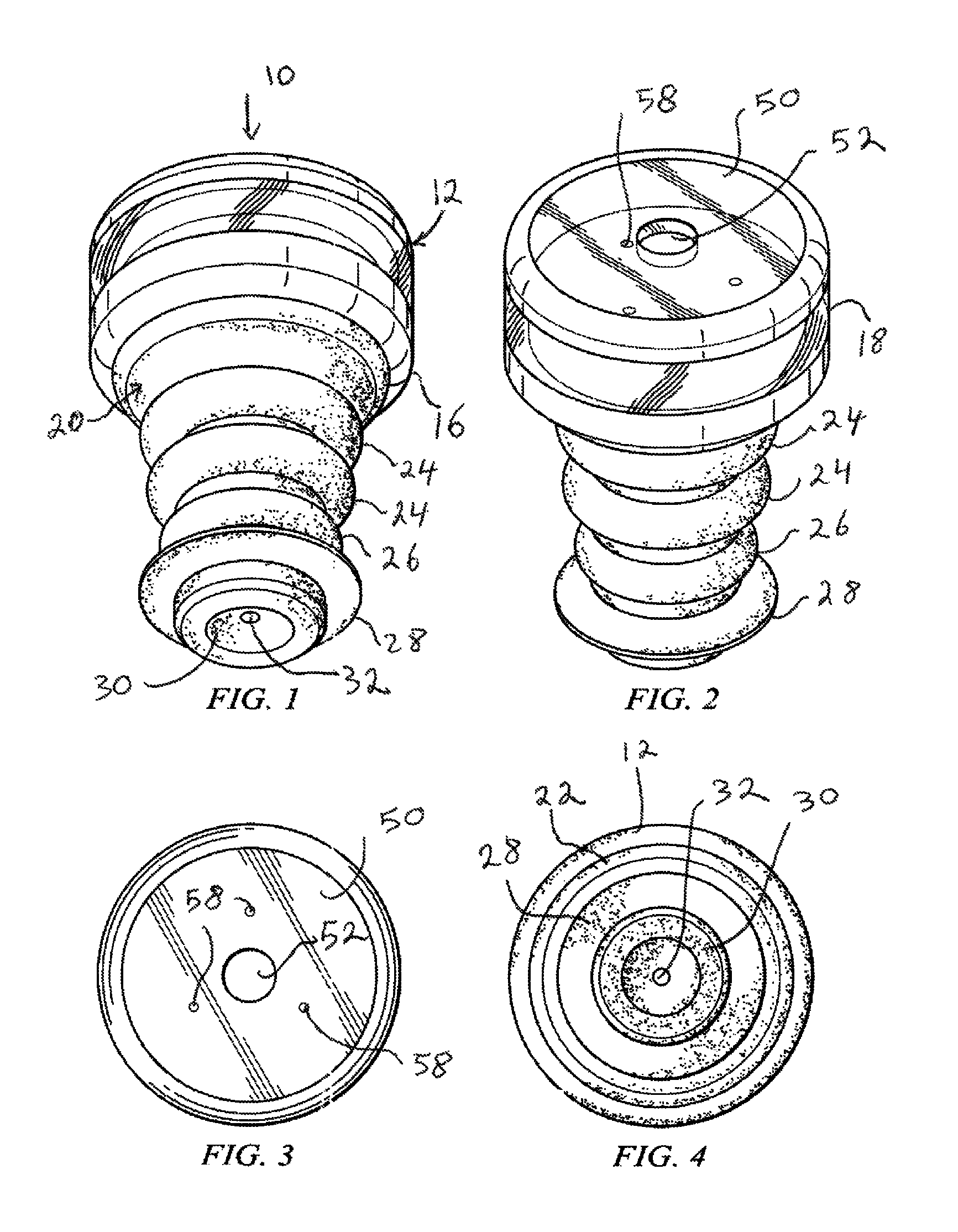

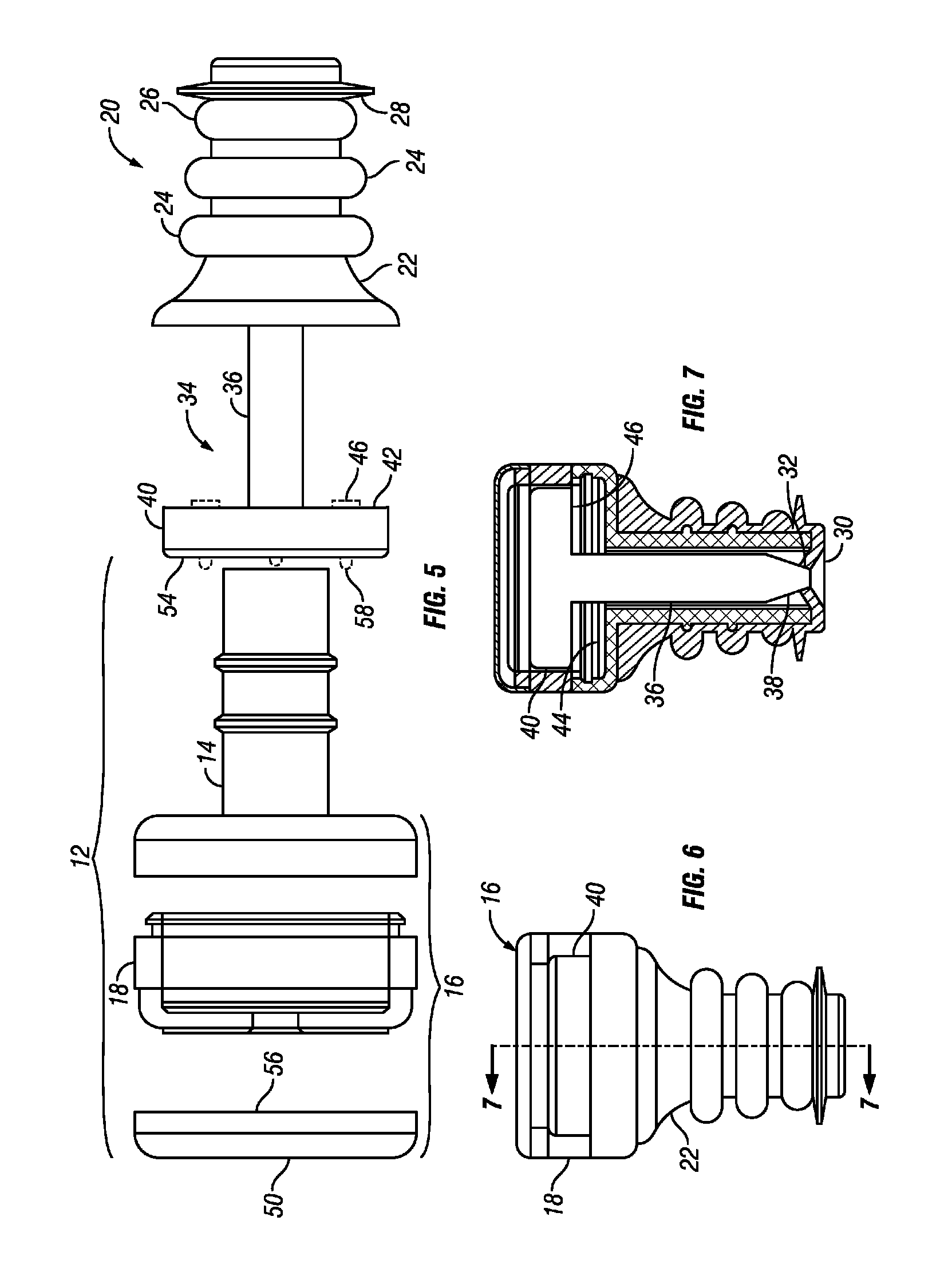

Bottle stopper for evacuation pump

InactiveUS8783486B1Increase vacuumIncreased pressureClosure using stoppersDisc closuresLong lastingEngineering

A stopper includes a hollow casing with a resilient, ribbed sleeve that forms a valve seat. An interior plunger has a tip configured to mesh with the valve seat when in its down position and to open the valve when in its up position. An upper flange in the plunger provides an additional seal and is visible through a transparent wall in the casing. A vacuum in the bottle draws the plunger downward increasing the pressure with which the plunger presses against the seat, thus securing a long-lasting seal that maintains the vacuum in the bottle. When the vacuum is released, the resilience of the seat structure pushes the plunger upward, rendering it visible as an indicator of vacuum through the transparent wall. An opening in the casing allows connection to a pump to create the vacuum in the bottle.

Owner:HOYT CHASE H +1

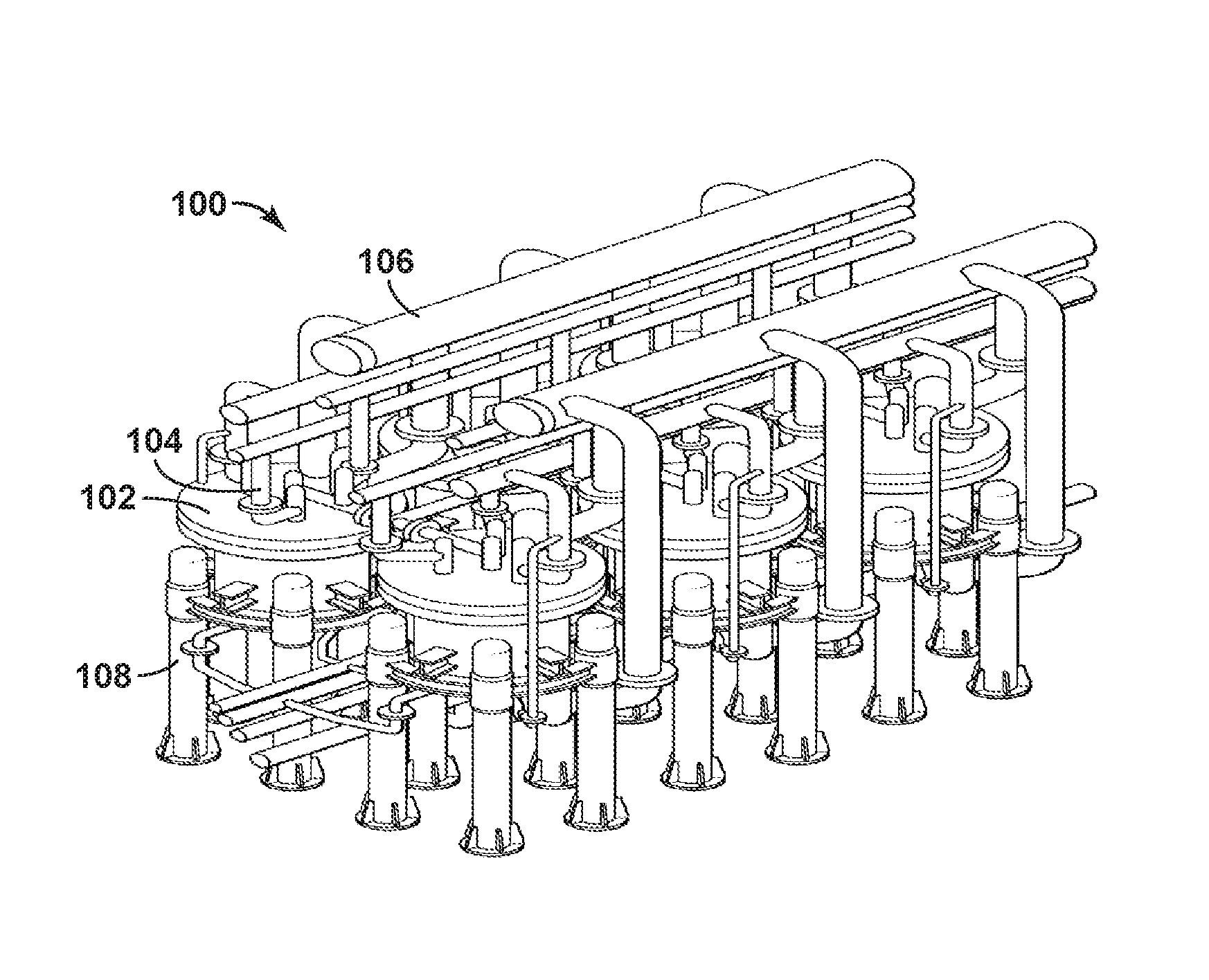

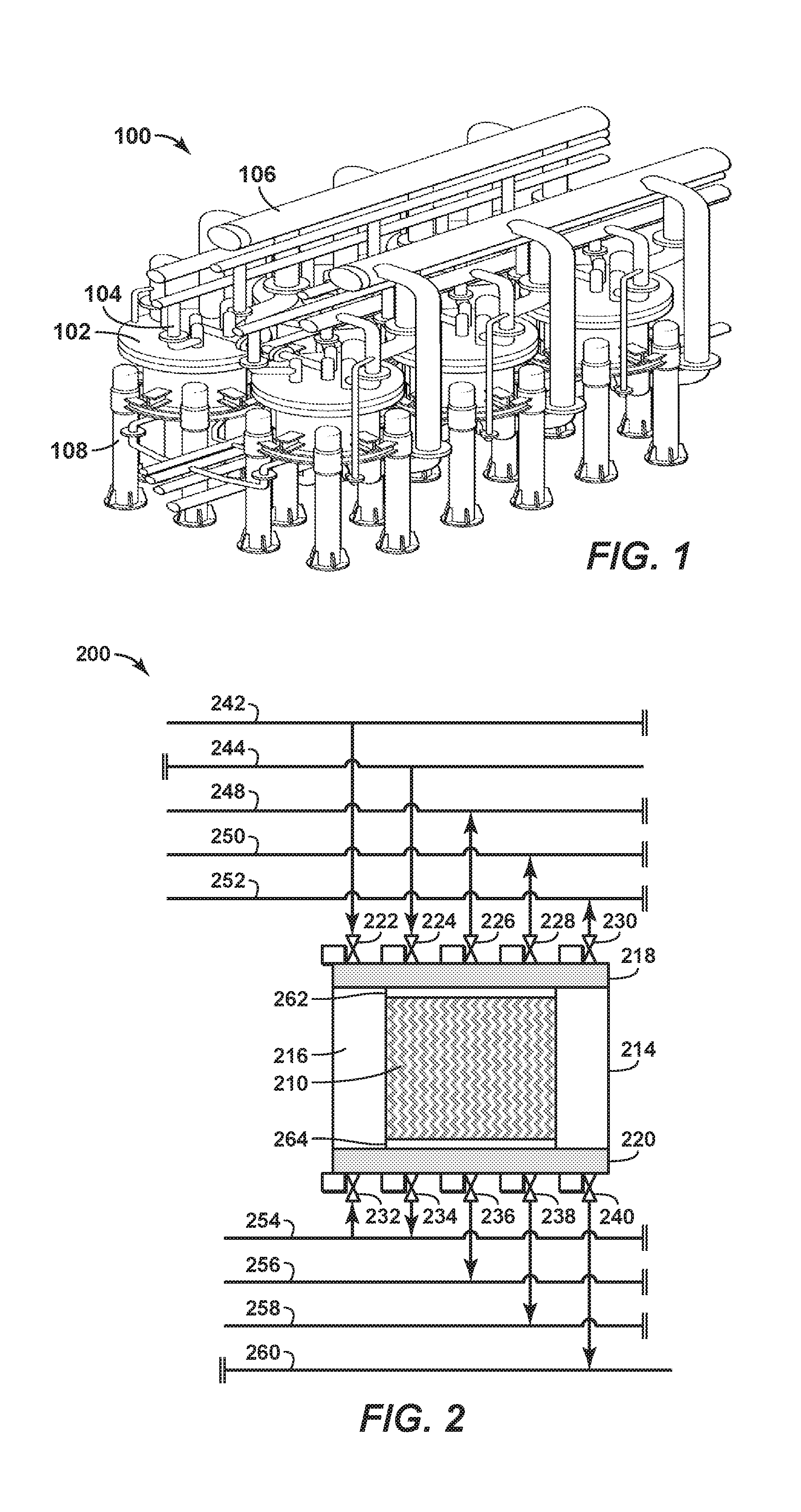

Apparatus and System for Swing Adsorption Processes Related Thereto

ActiveUS20160332105A1Reduce pressureIncreased pressureGas treatmentDispersed particle separationContactorPollutant

Provided are apparatus and systems for performing a swing adsorption process. This swing adsorption process may involve passing fluids through an adsorbent bed unit having a contactor disposed within to separate contaminates from other target components. The process includes a purge stream that introduced into the contactor at a location between a first portion and a second portion of the contactor.

Owner:EXXONMOBIL UPSTREAM RES CO

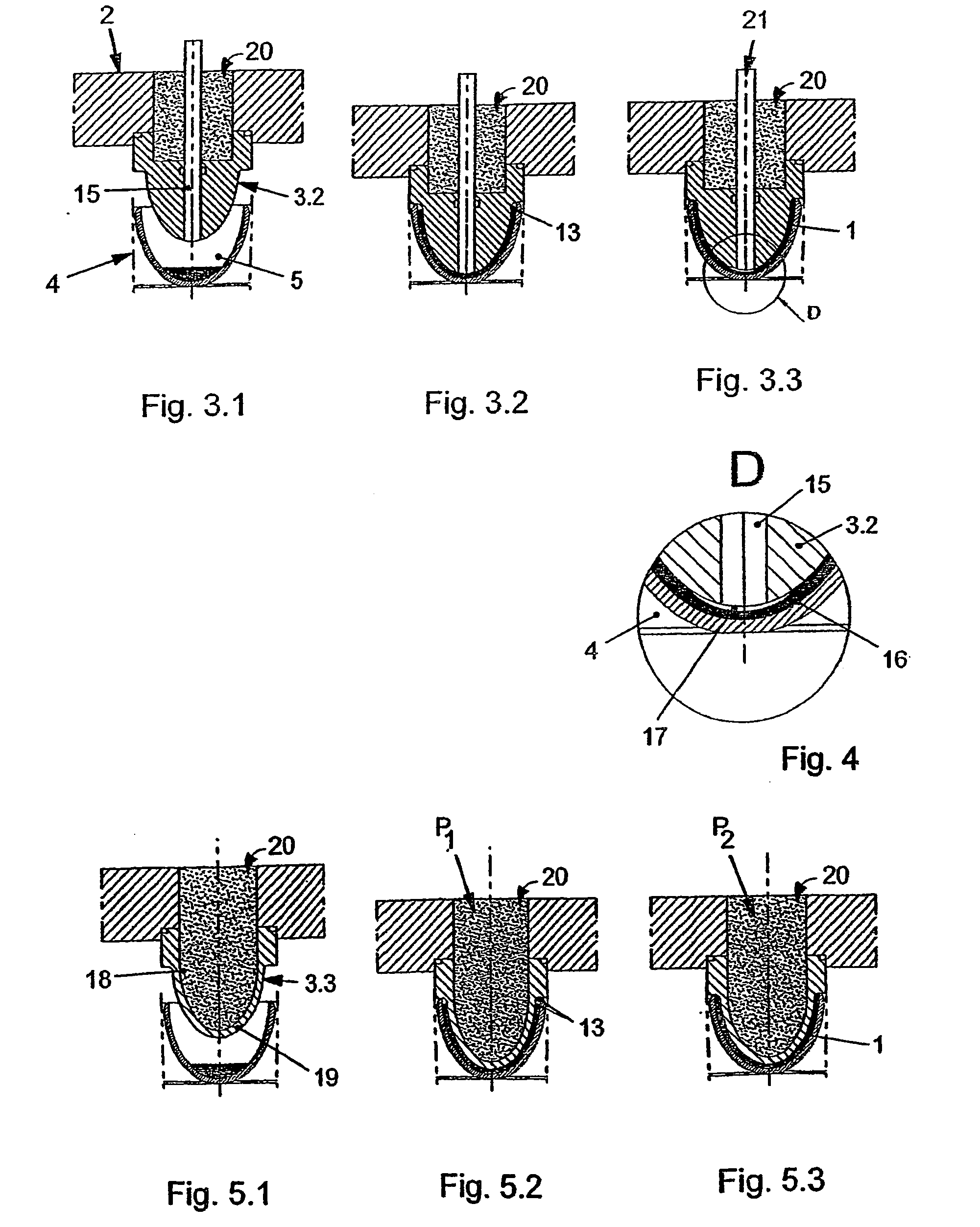

Method and device for producing confectionary products

Owner:TNG SWISS AG

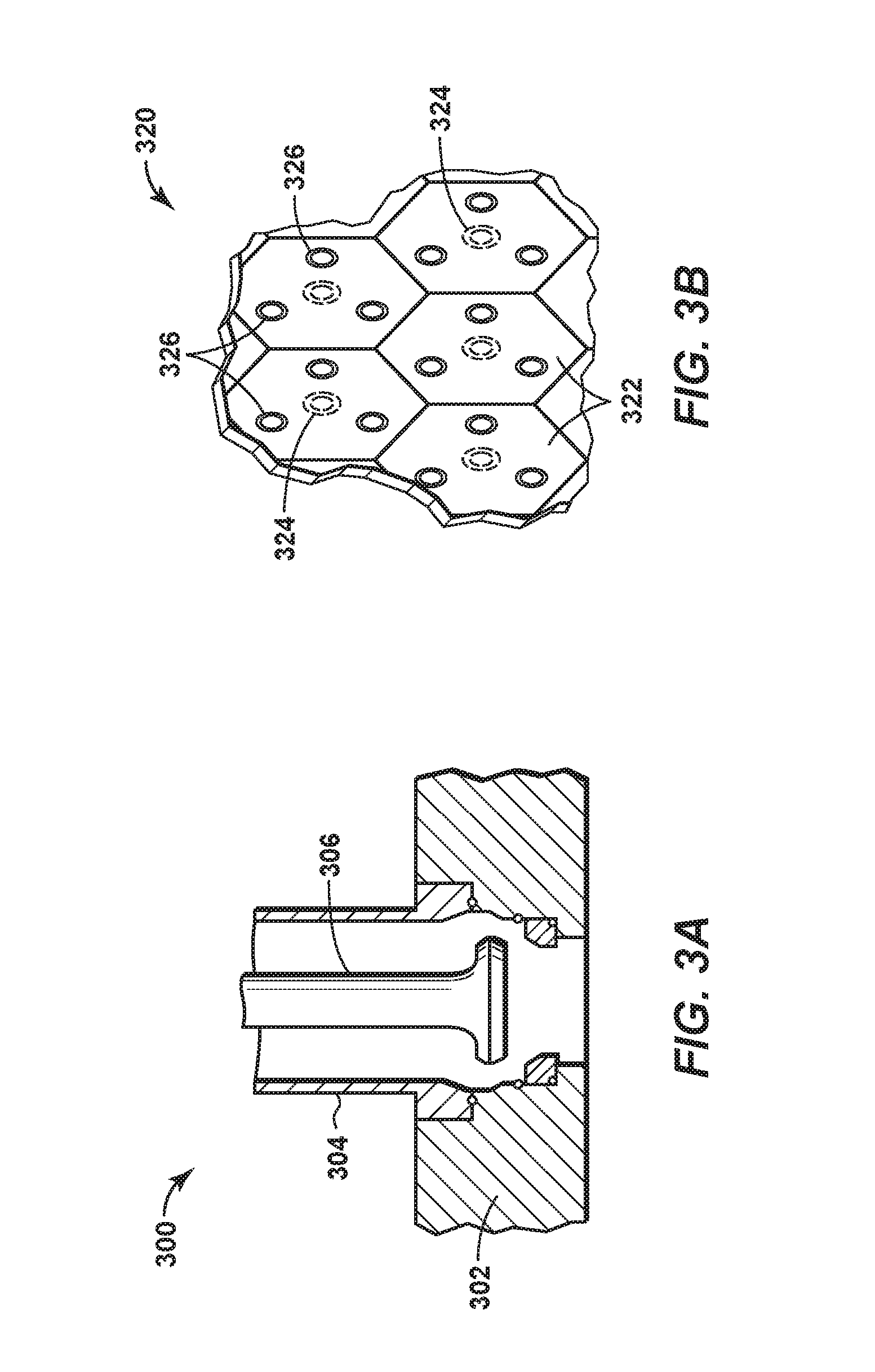

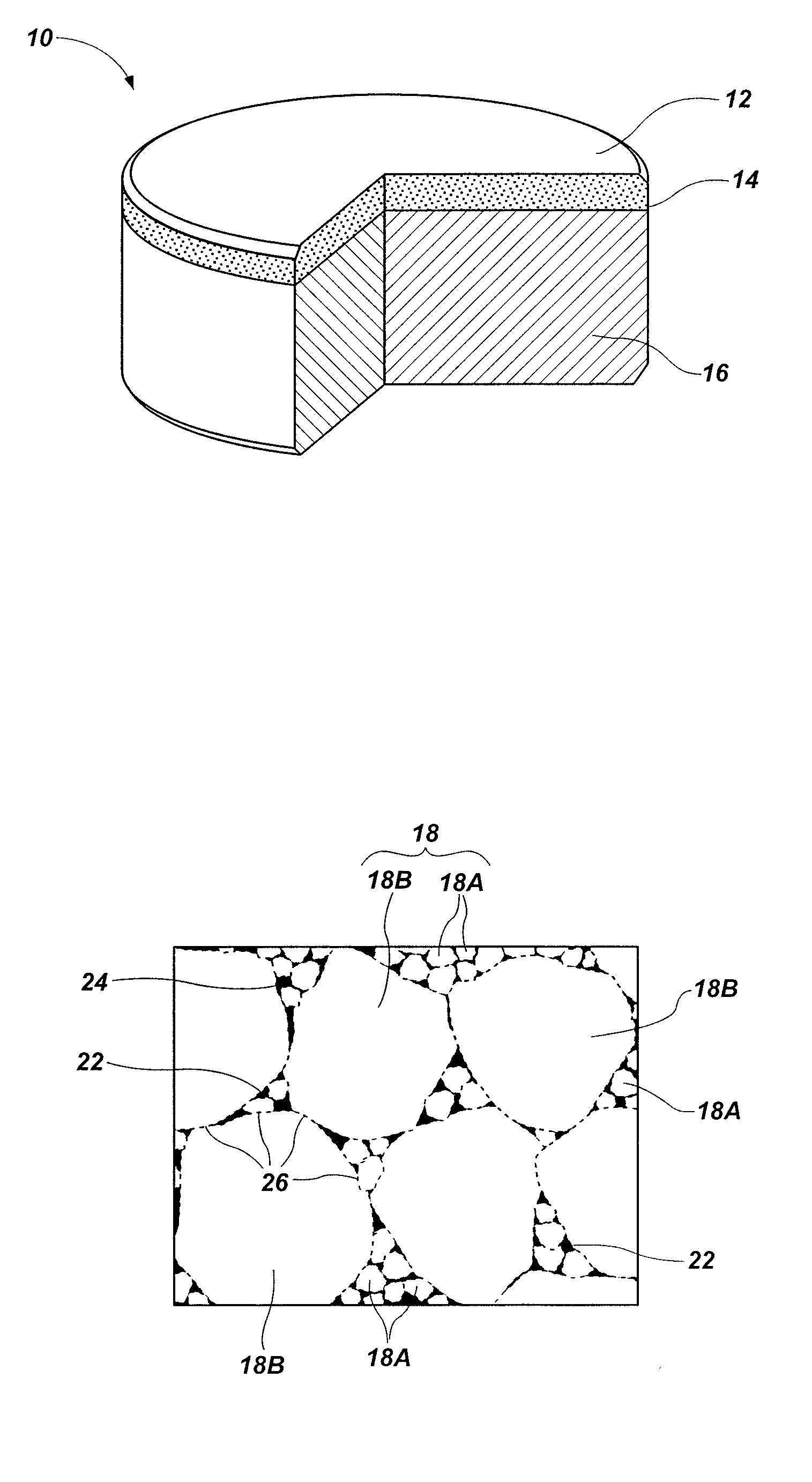

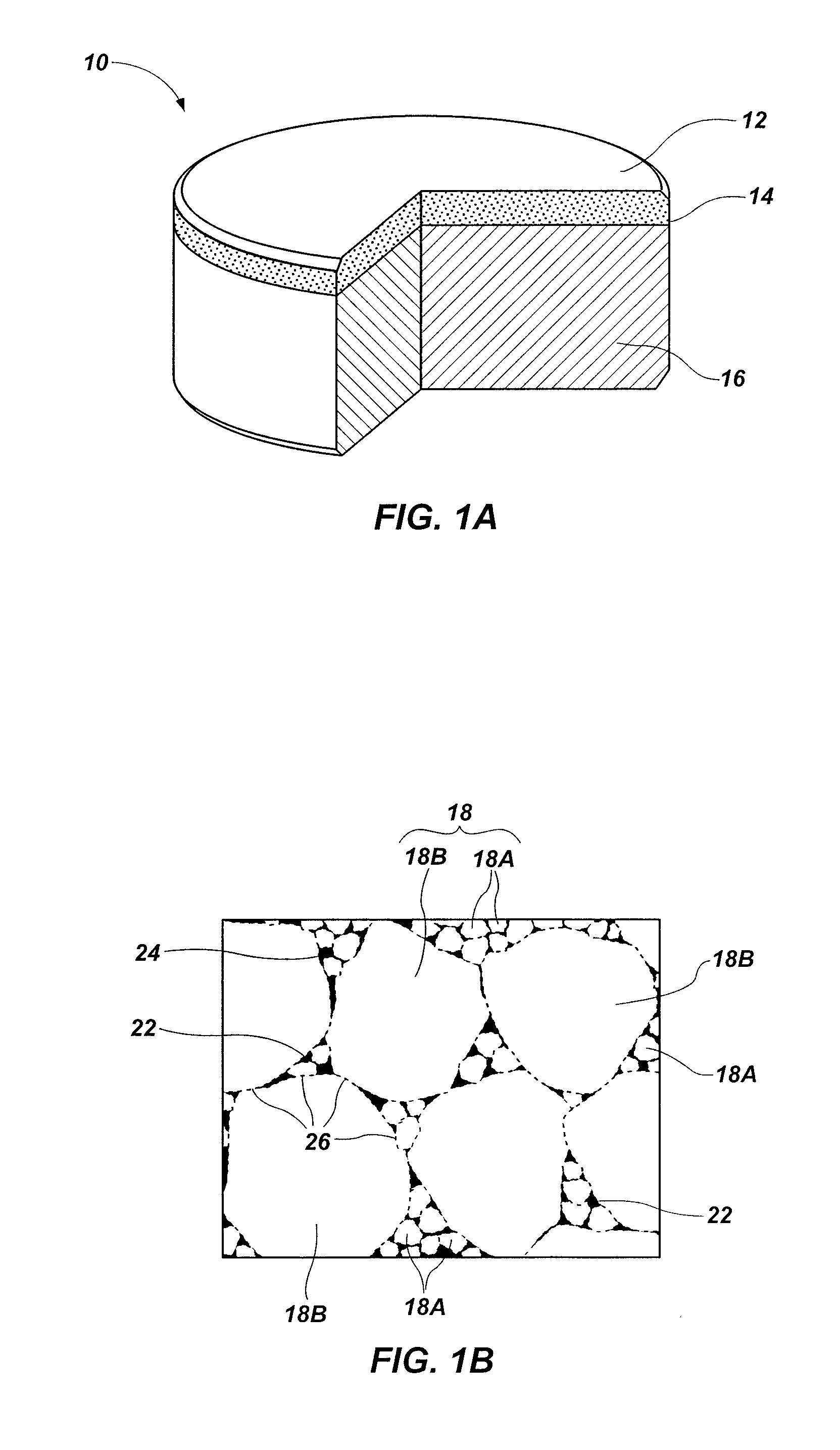

Combined field assisted sintering techniques and hthp sintering techniques for forming polycrystalline diamond compacts and earth-boring tools, and sintering systems for performing such methods

ActiveUS20130086847A1Increased pressureIncrease in temperaturePigmenting treatmentMaterial nanotechnologyPolycrystalline diamondHigh pressure

Methods of forming polycrystalline diamond compacts include employing field assisted sintering techniques with high temperature and high pressure sintering techniques. For example, a particle mixture that includes diamond particles may be sintered by subjecting the particle mixture to a high temperature and high pressure sintering cycle, and pulsing direct electrical current through the particle mixture during at least a portion of the high temperature and high pressure sintering cycle. The polycrystalline diamond compacts may be used to form cutting elements for earth-boring tools. Sintering systems are configured to perform such sintering processes.

Owner:BAKER HUGHES INC

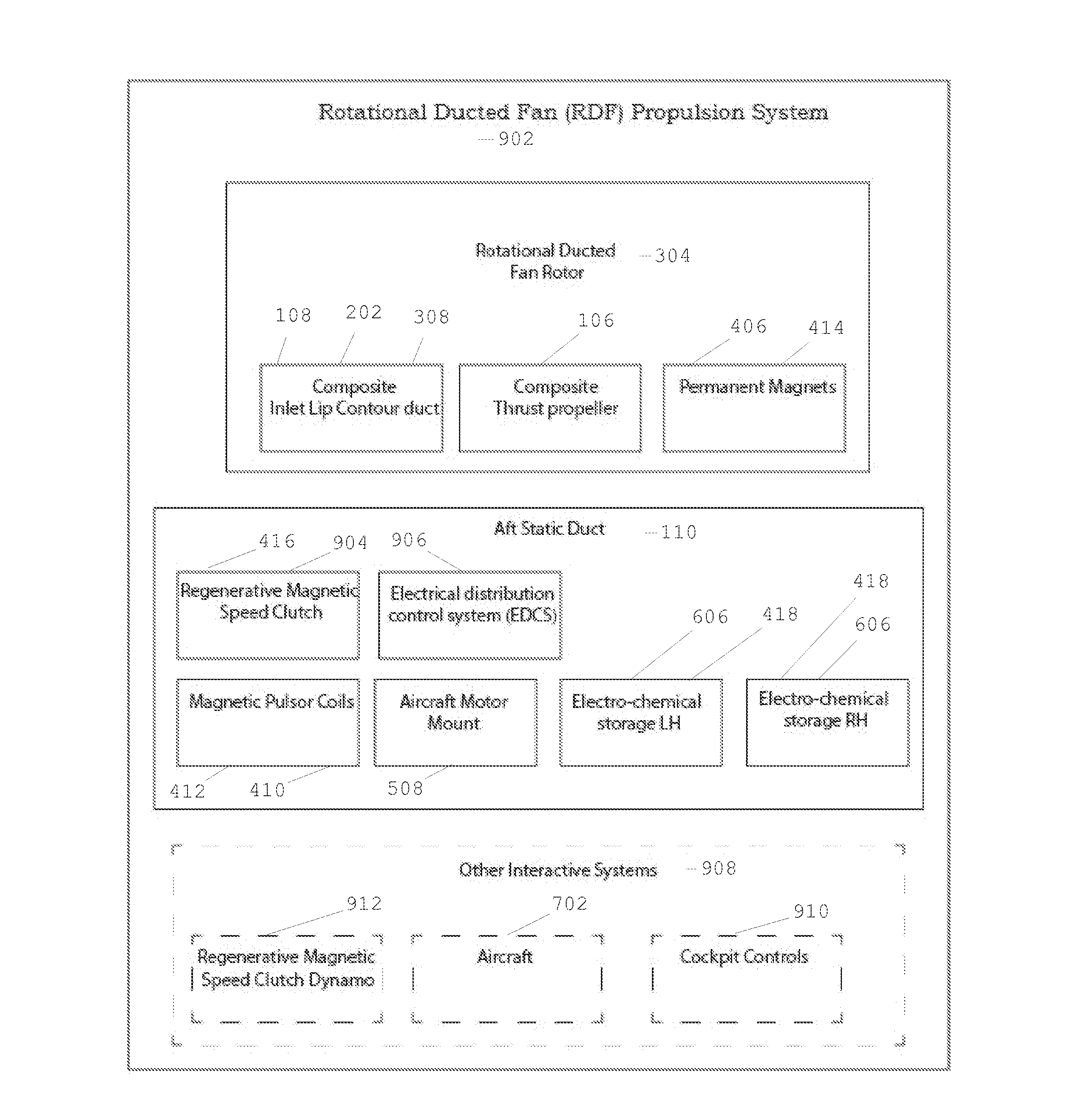

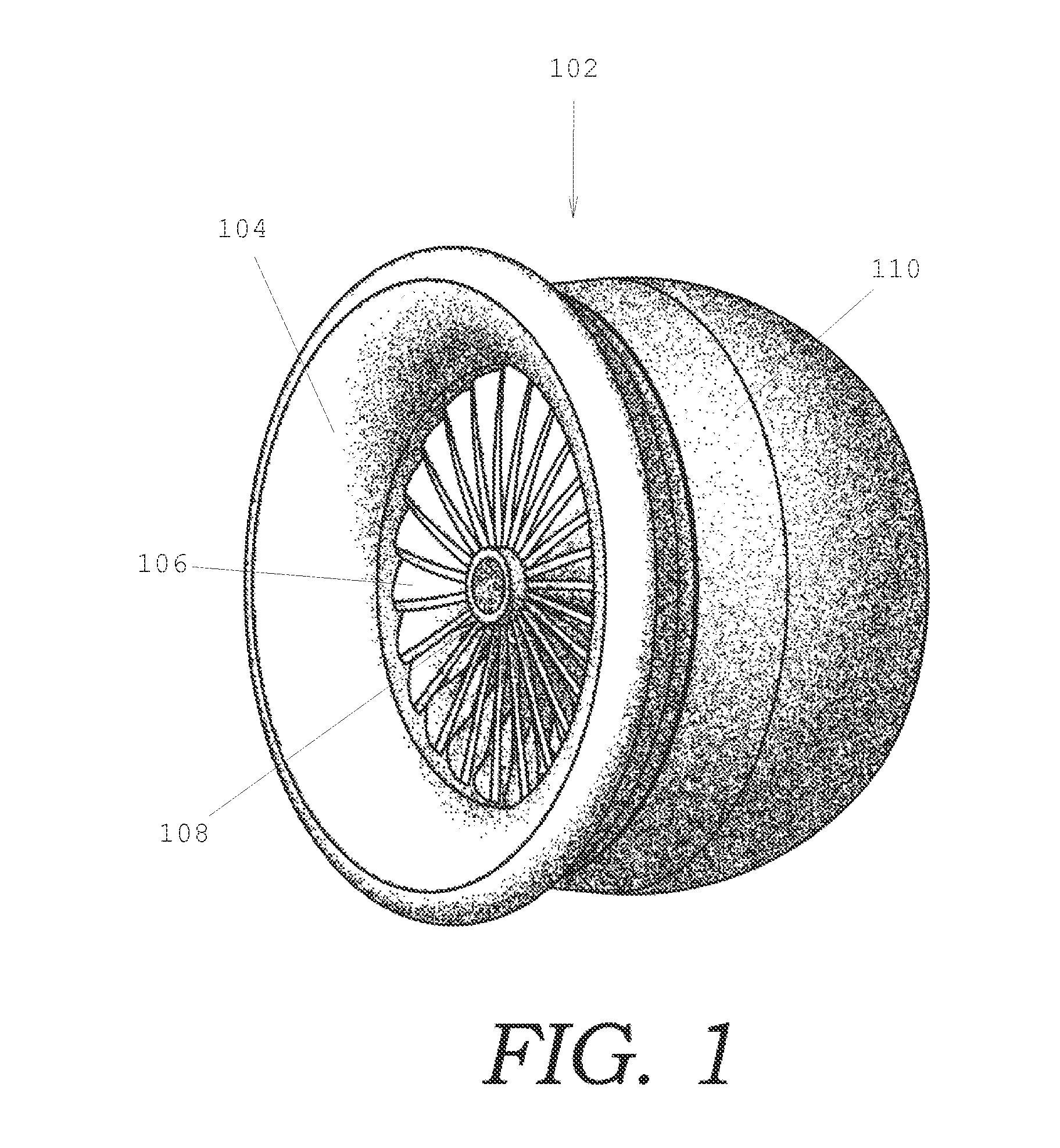

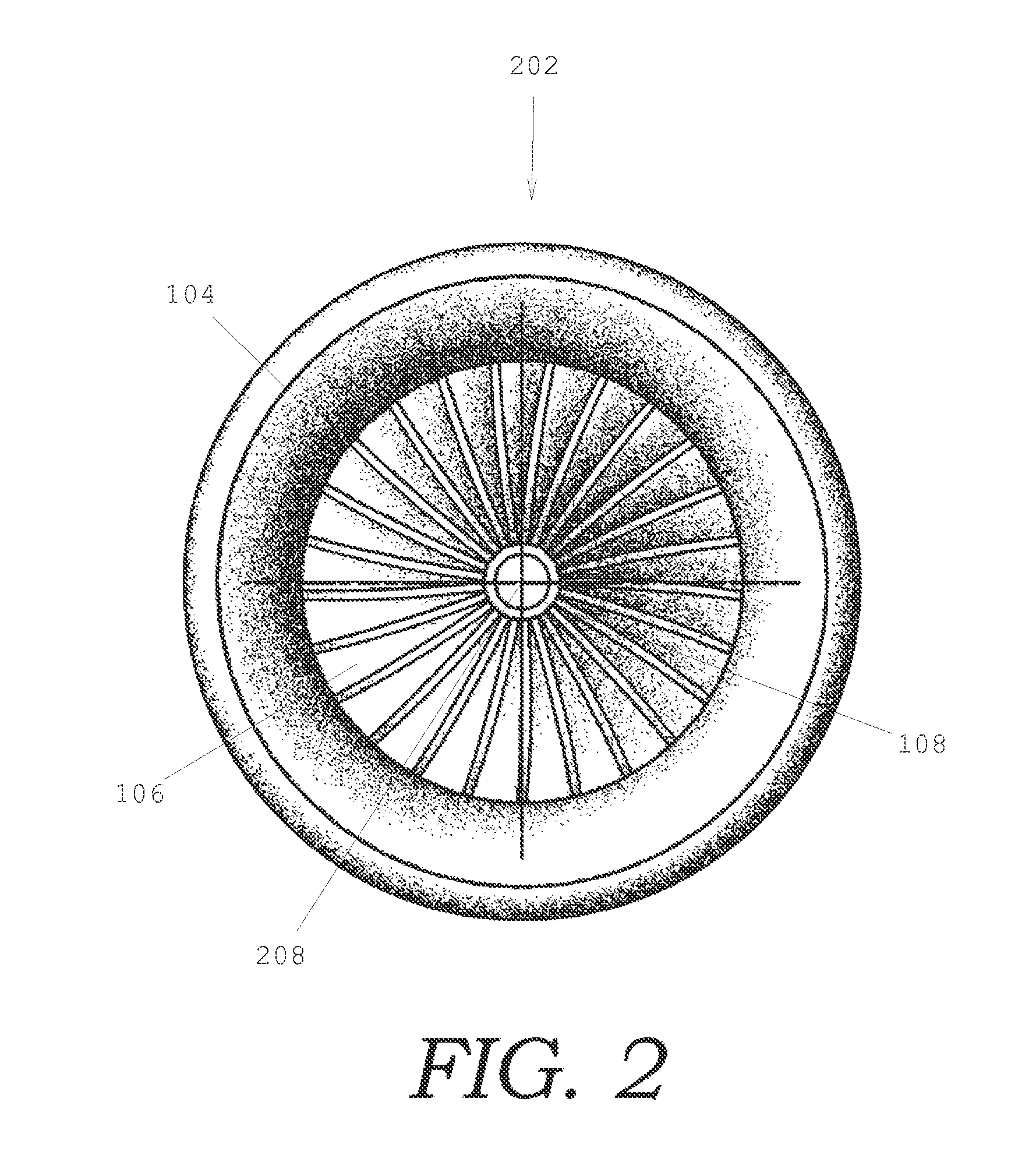

Rotational ducted fan (RDF) propulsion system

InactiveUS20150226086A1Decreased pressureIncreased pressurePropellersAircraft power plant componentsPropellerElectrochemical energy storage

In accordance with the present invention, an embodiment of a rotational ducted fan motor comprises a monolithic rotational ducted fan rotor, an electric propulsion system, a static aft-shroud comprising electrochemical-energy-storage, and an engagement system. The rotational ducted fan rotor is the portion of a ducted fan motor comprising a propeller, a duct, and a center hub, and having the effect of increasing the pressure difference from upstream to downstream of the propeller. The electric propulsion system comprises permanent magnets affixed to the rotational ducted fan rotor, repelling magnetic coils affixed to the static aft-shroud and electrical power provided by the electrochemical-energy-storage comprised within the aft-shroud.

Owner:SAMUELSON DEVIN GLENN

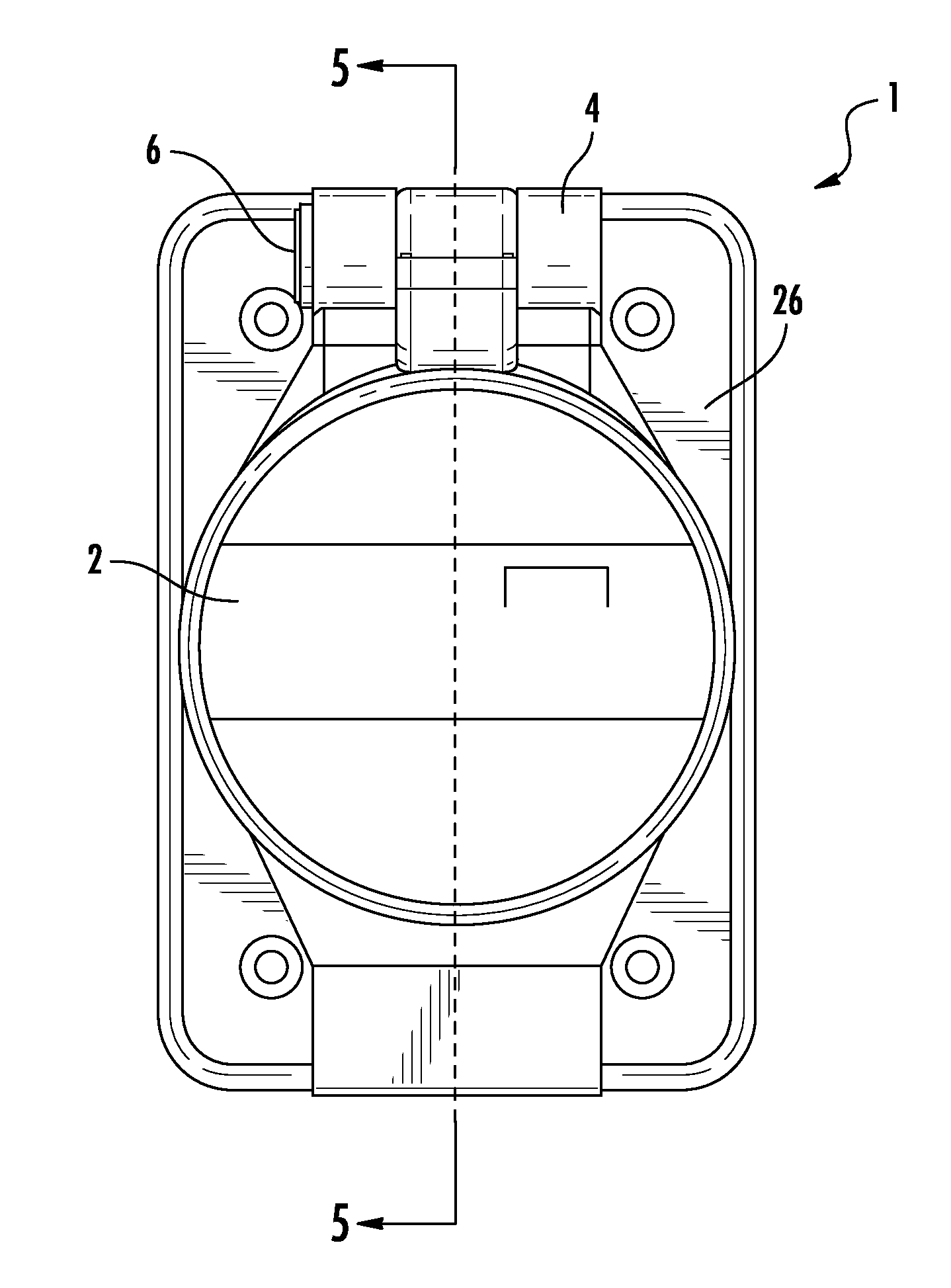

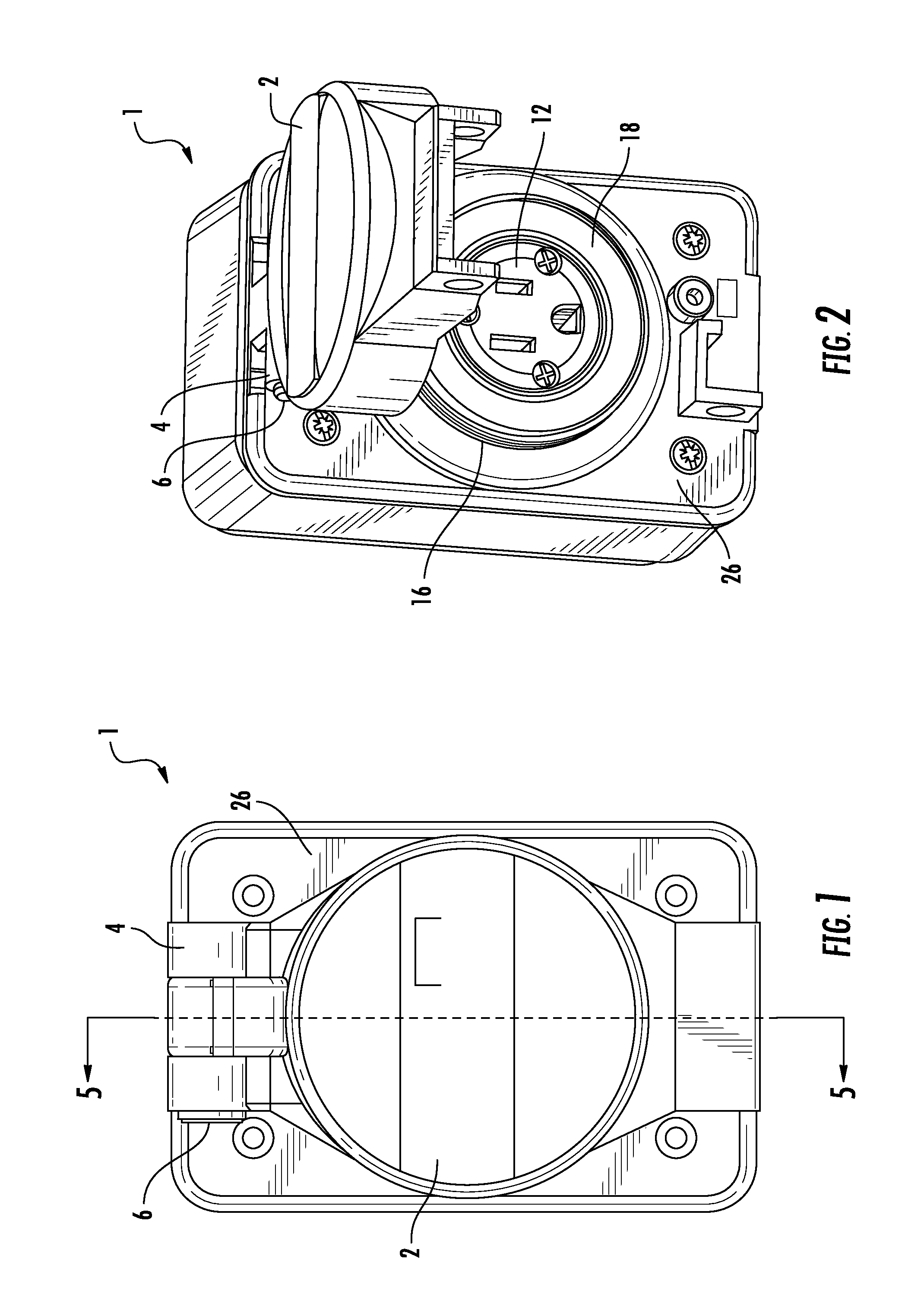

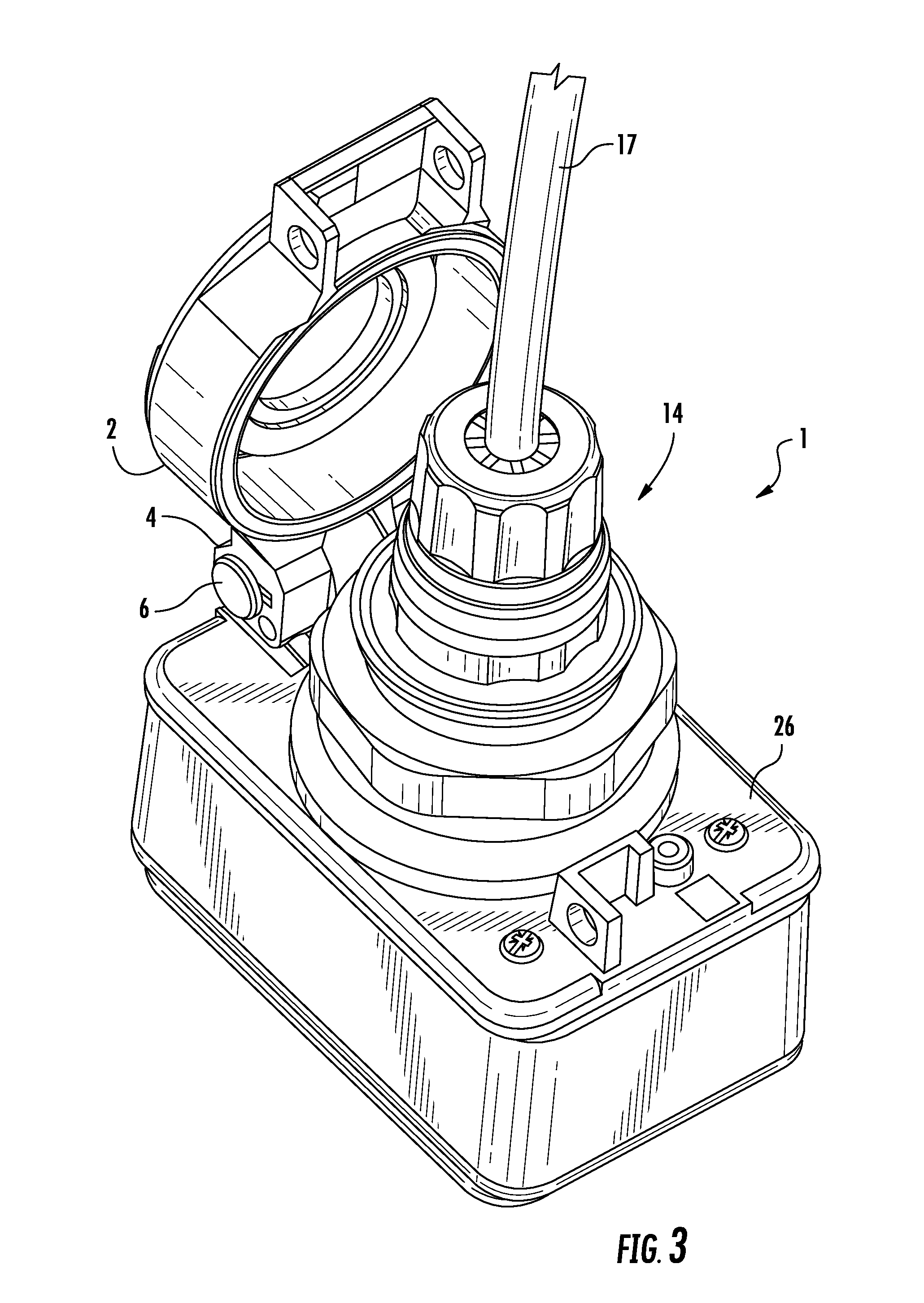

Weather resistant flip lid cover with improved sealing arrangement

A weather resistant flip lid cover for au electrical box or connector preferably includes first and second seals. A hinge pivotally couples the flip lid cover to the electrical box or connector. The first and second seals are preferably concentric. When the flip lid cover is in a closed position the first and second seals engage first and second sealing surfaces on the electrical box or connector to form a seal that complies with the requirements of NEMA Type 4, Type 12, and / or IP66. The first seal is preferably a V-ring. The biasing force of the flip lid cover is preferably sufficient to form a weather resistant seal. The seals may form an inner air chamber therebetween so that when the flip lid cover is moved to the closed position a pressure in the inner compartment is increased and presses a lip of the V-ring against the first sealing surface.

Owner:LEVITON MFG

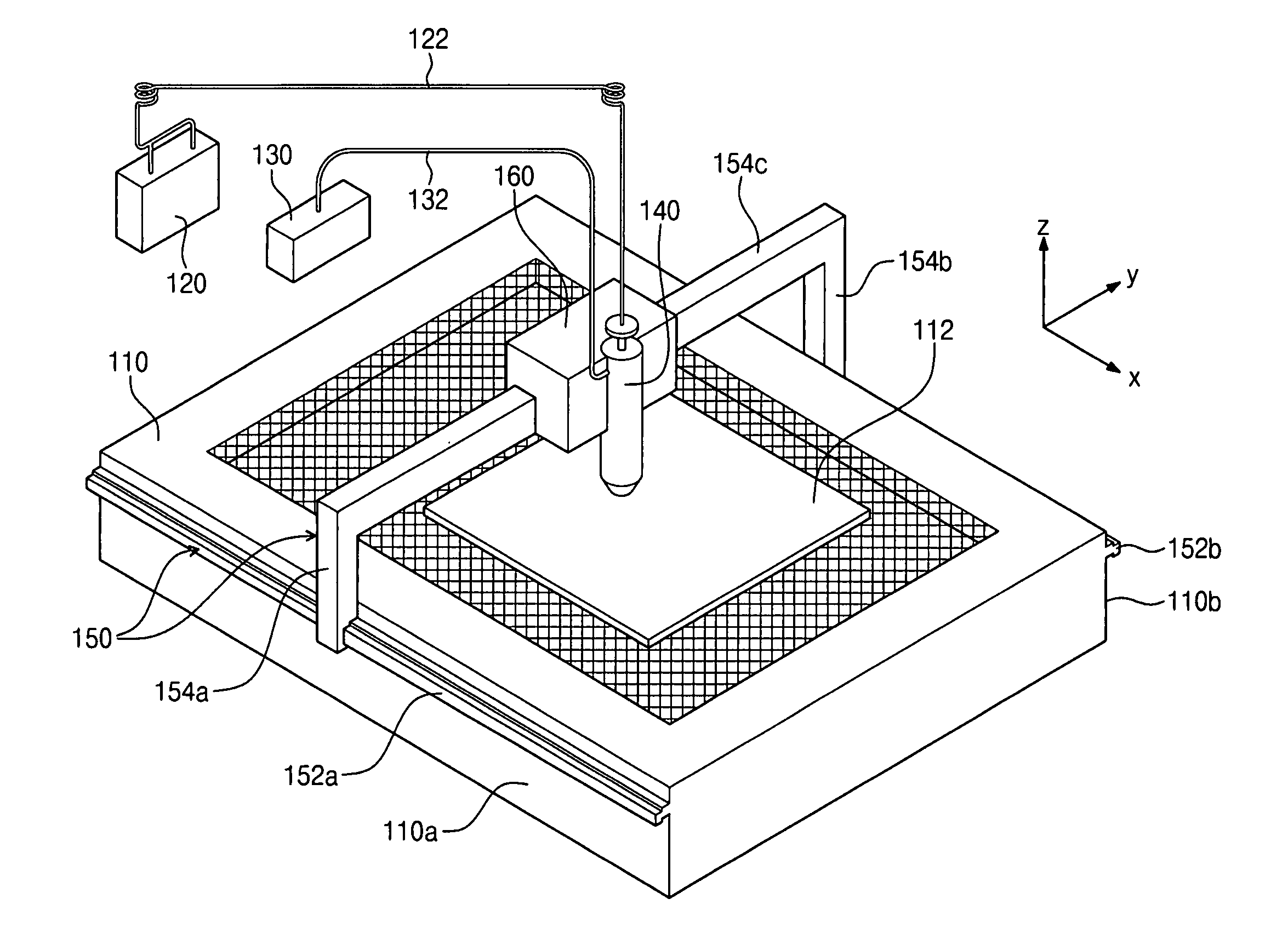

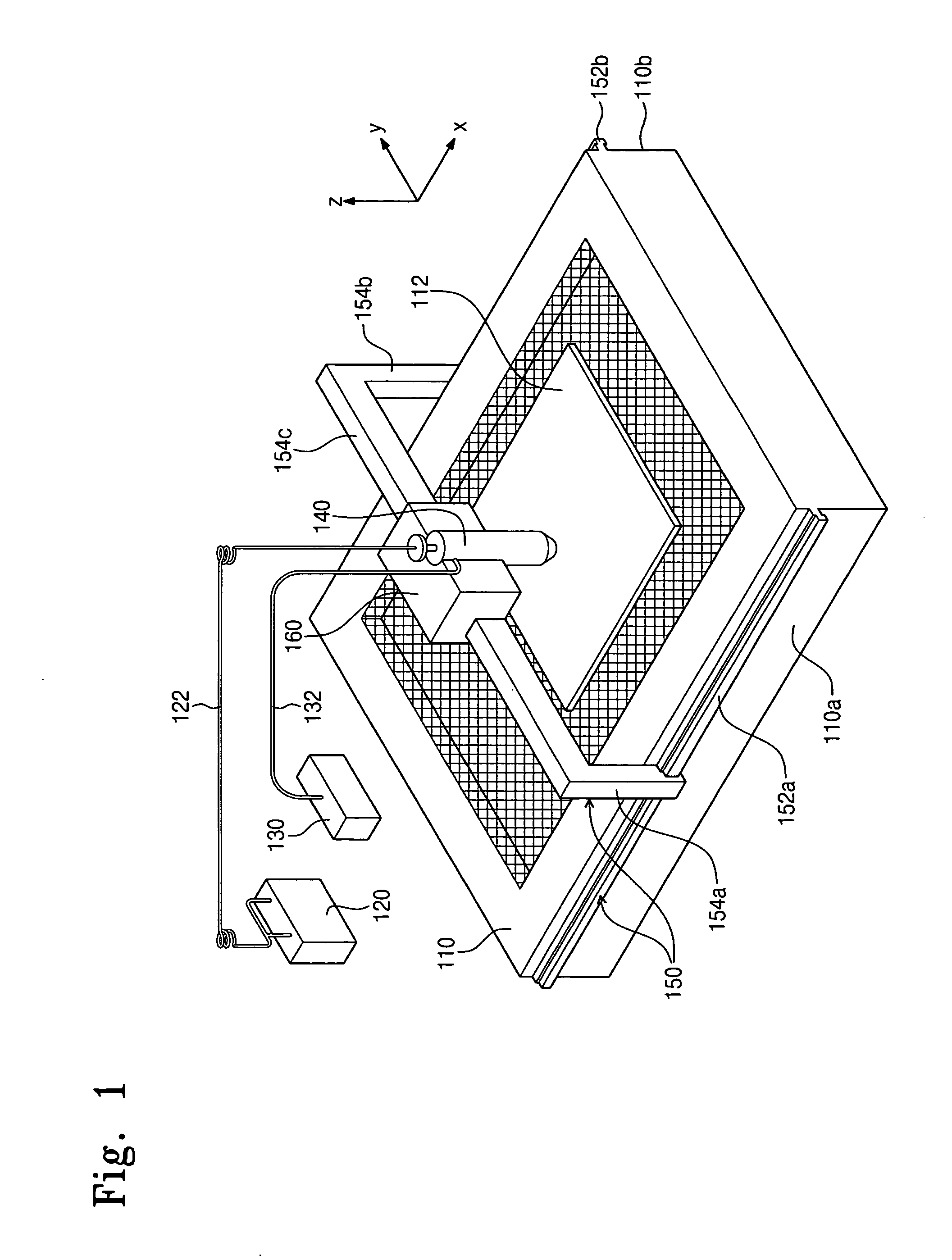

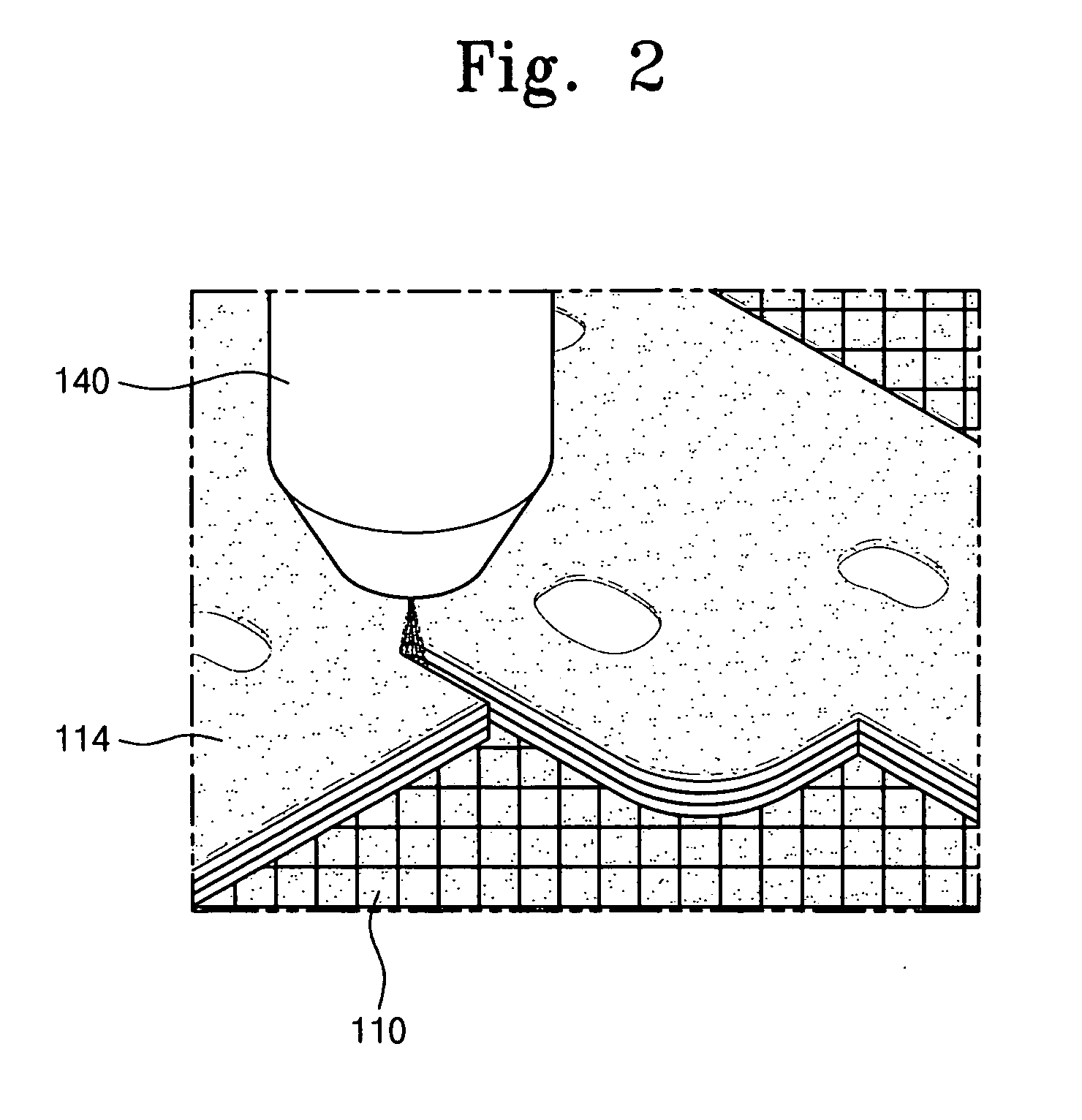

Substrate processing apparatus and method of operating the same

ActiveUS20120282845A1Increased pressureSemiconductor/solid-state device manufacturingAbrasive feedersProcess engineering

Provided is a substrate processing apparatus including a first conduit configured to supply a processing solution to a substrate loaded on a supporter, and a second conduit in fluid communication with the first conduit, the second conduit configured to supply a gas to the first conduit to be mixed with the processing solution, wherein the first conduit includes an opening to permit the processing solution mixed with the gas to be injected onto the substrate.

Owner:SAMSUNG DISPLAY CO LTD

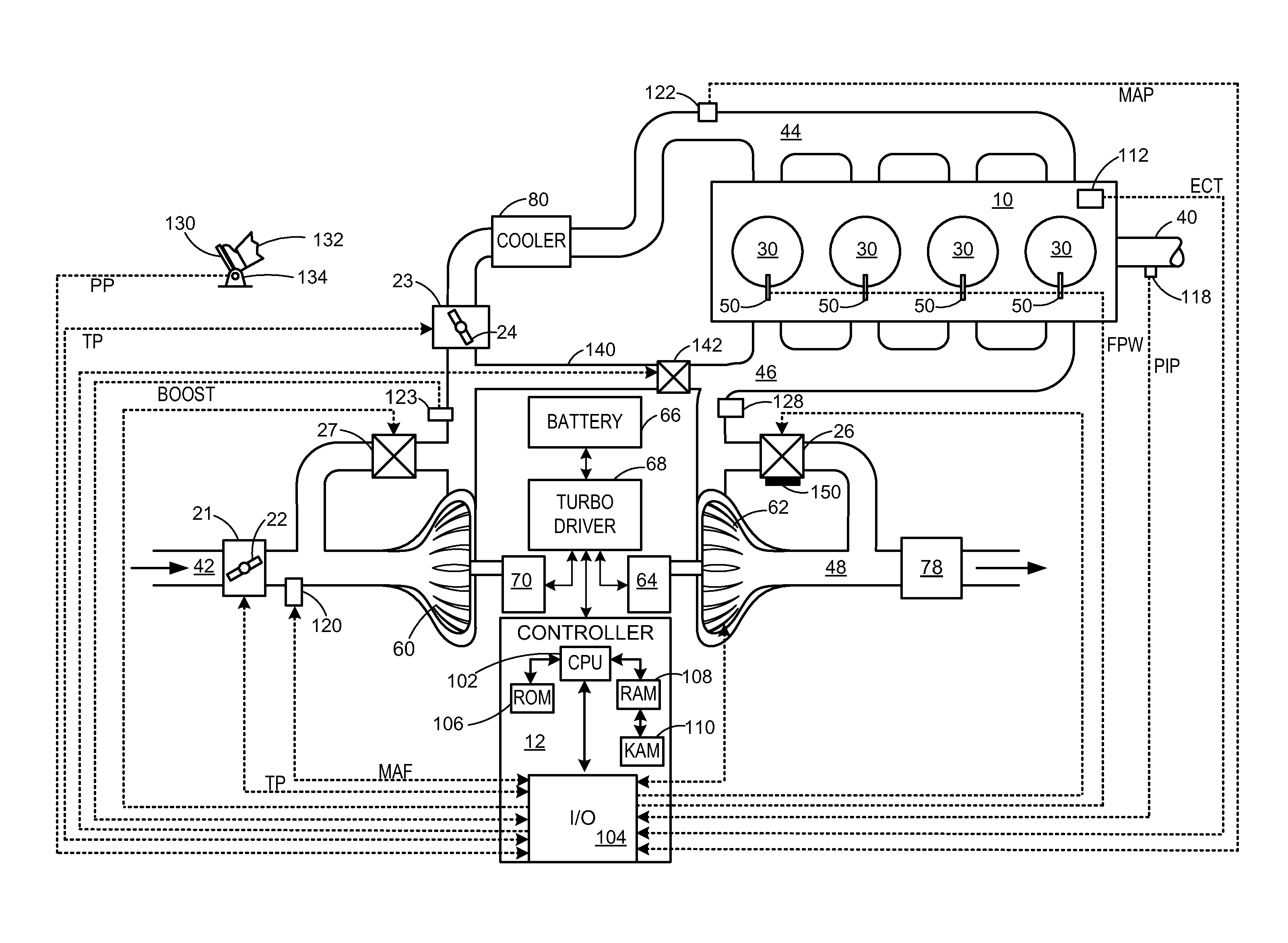

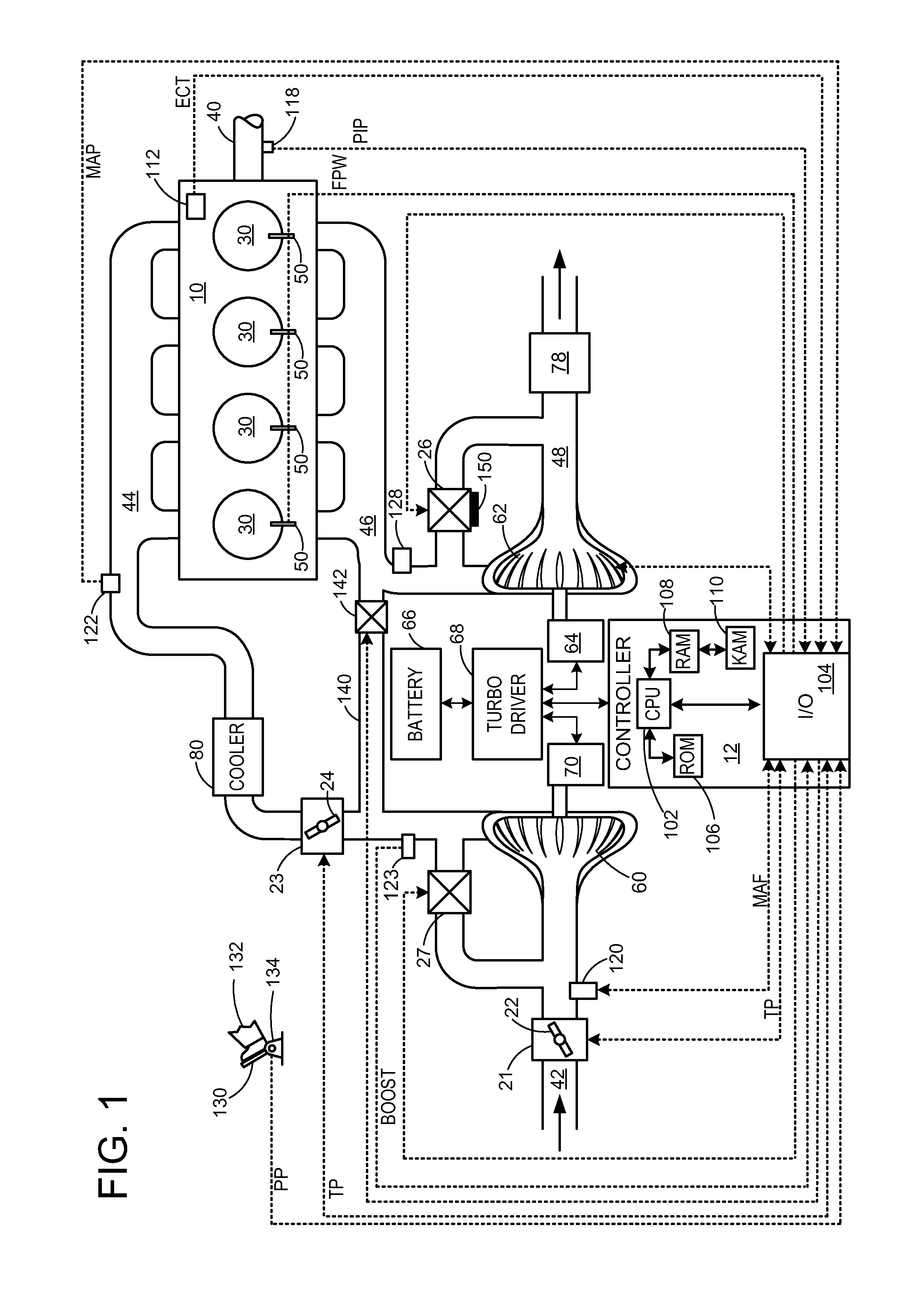

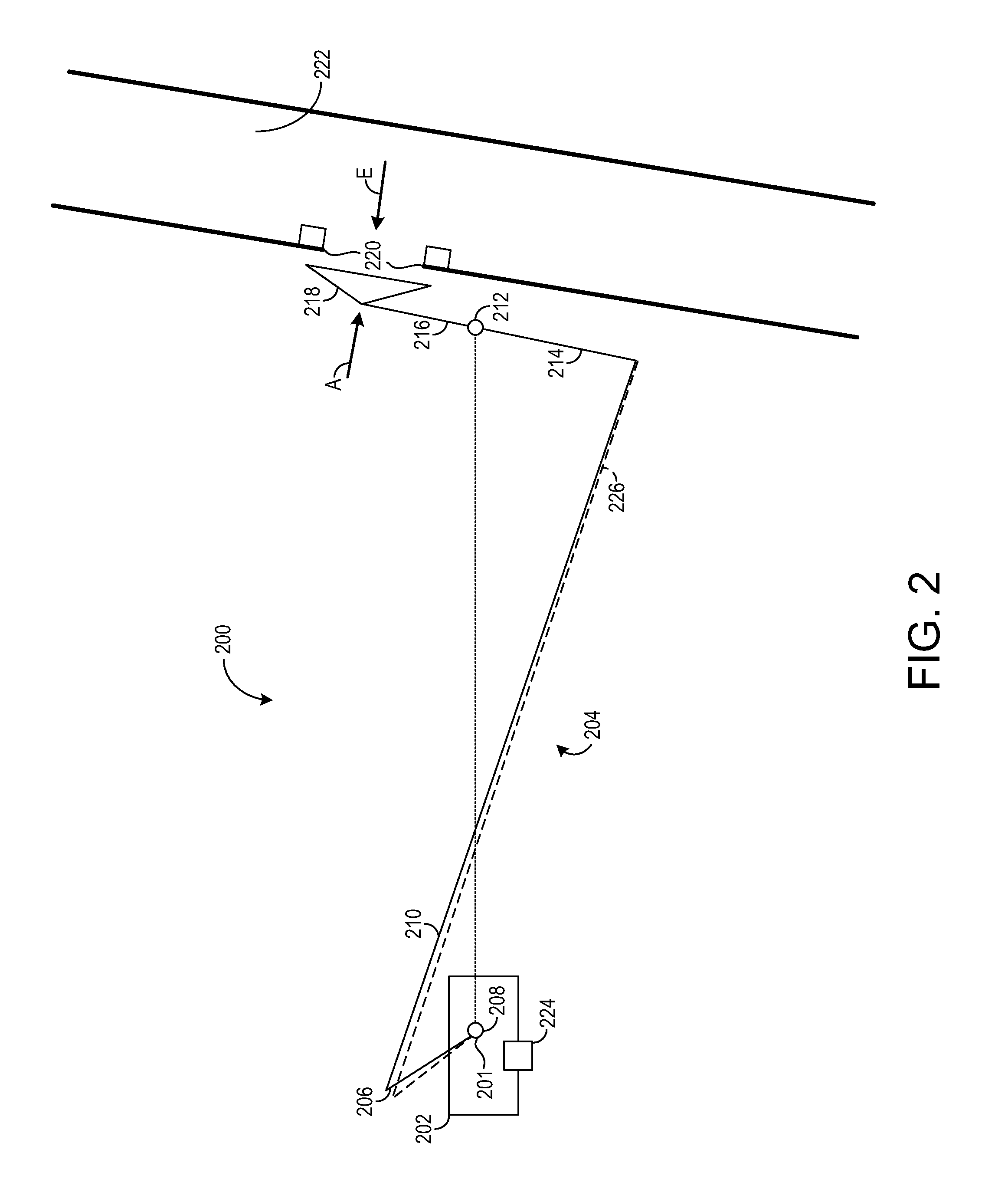

Wastegate valve position correction

ActiveUS20150082788A1Increase engine torque/power output densityIncreased pressureInternal combustion piston enginesEngine controllersPower flowLinkage concept

Various methods for compensating a deflected linkage in a wastegate arrangement are provided. In one example, current is applied to an actuator to move a wastegate valve coupled through a linkage to the actuator for diverting gasses from a turbocharger. The position of the actuator is indicated, and a correction to said indicated actuator position is applied compensating for deflection of the linkage based at least on said applied current. Said applied current is adjusted when said corrected actuator position reaches a position corresponding to a desired valve position.

Owner:FORD GLOBAL TECH LLC

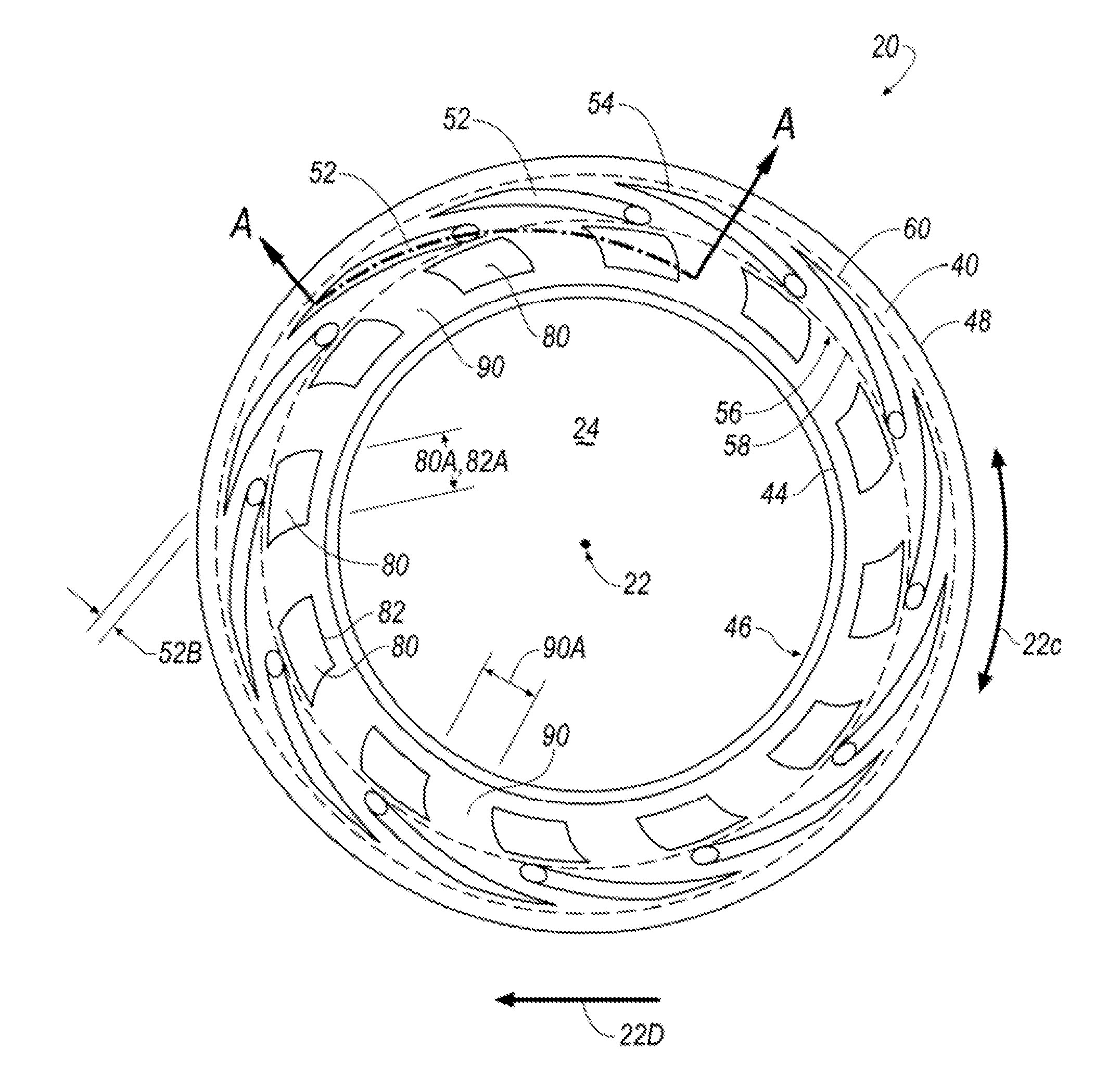

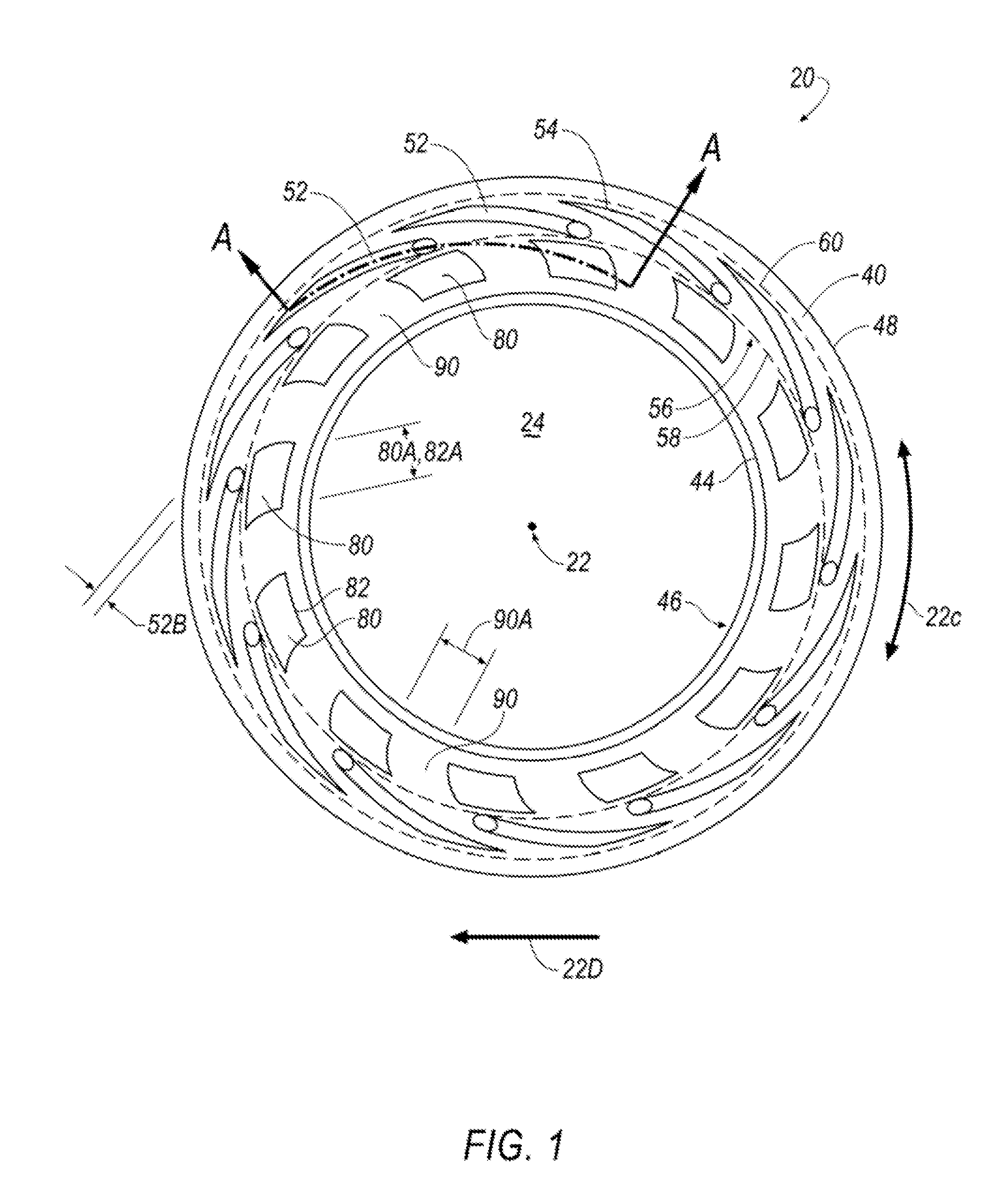

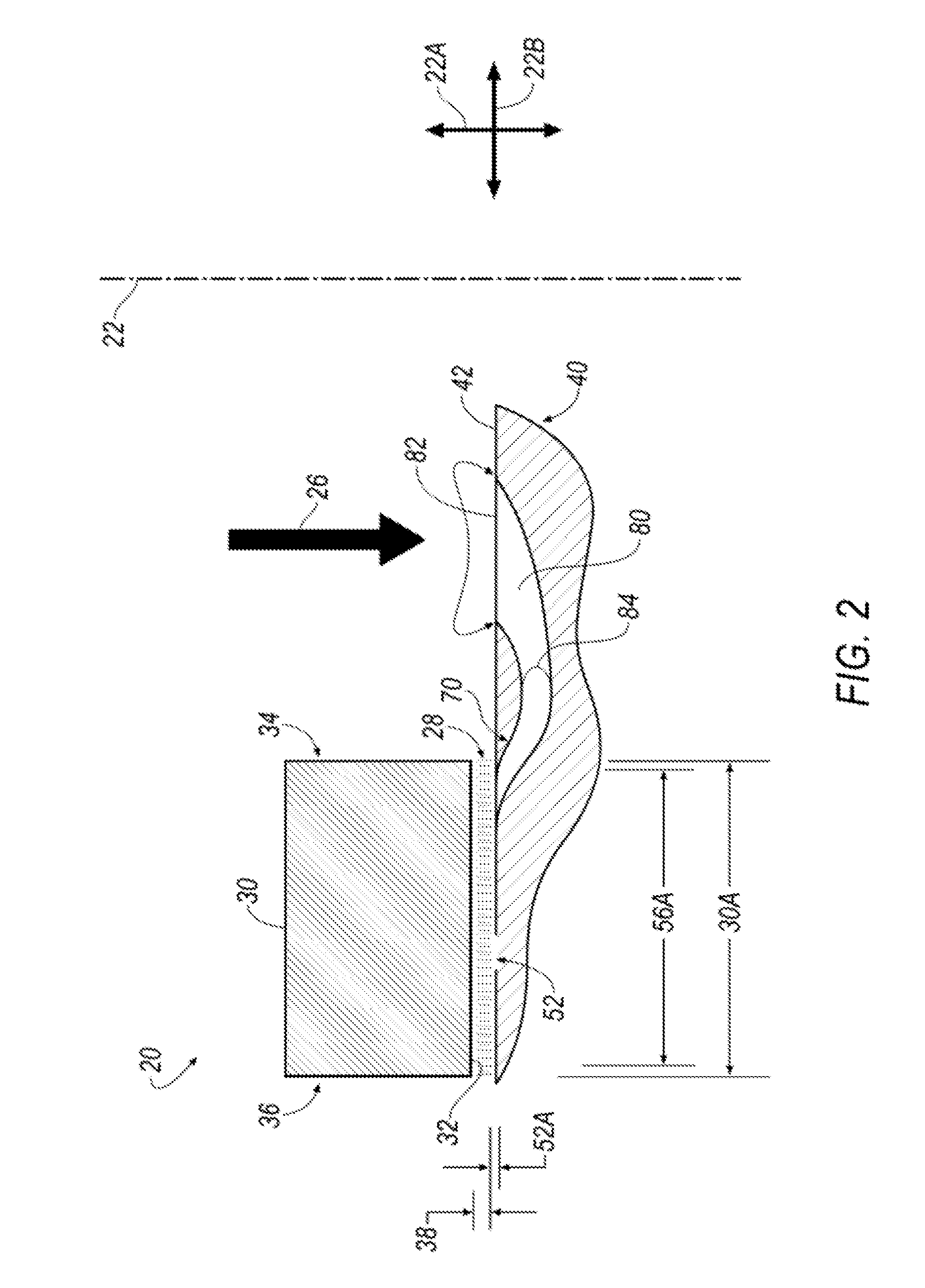

Hydrodynamic mating ring with integrated groove inlet pressure control

A hydrodynamic mating ring of the present disclosure may include a sealing face, a hydrodynamic groove disposed in the sealing face, an impeller portion, and an inlet conduit configured to provide fluid communication between the hydrodynamic groove and the impeller portion. A method of sealing may include providing a mating ring having a sealing face, a plurality of hydrodynamic grooves disposed in the sealing face, a plurality of impeller portions, and a plurality of inlet conduits configured to provide fluid communication between respective ones of the plurality of hydrodynamic grooves and the plurality of impeller portions. The method may include rotating the mating ring, and increasing at least one of a pressure, a volume, and a flow rate of fluid to the hydrodynamic grooves via the plurality of impeller portions drawing said fluid into the plurality of inlet conduits.

Owner:EATON INTELLIGENT POWER LIMITED

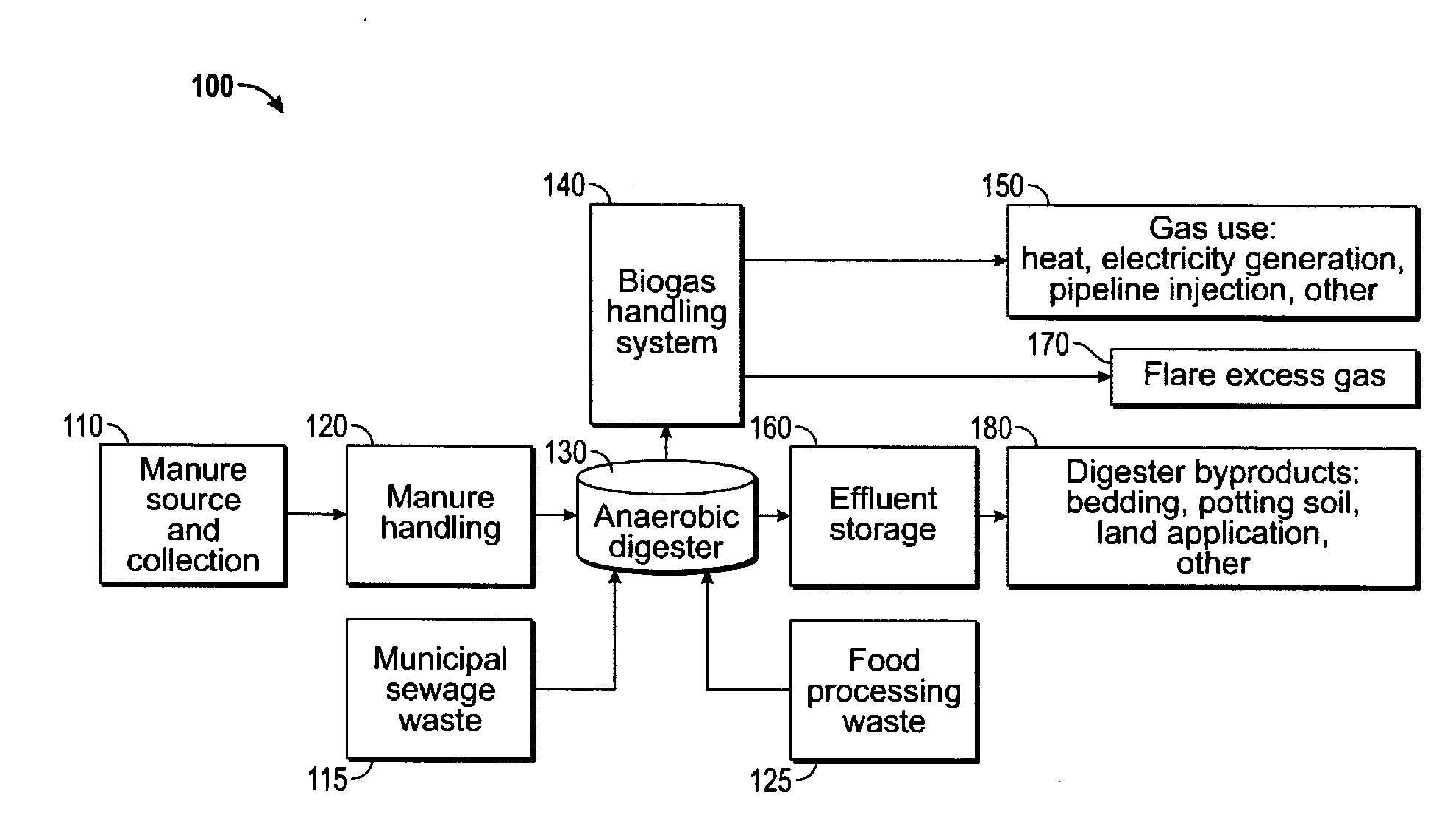

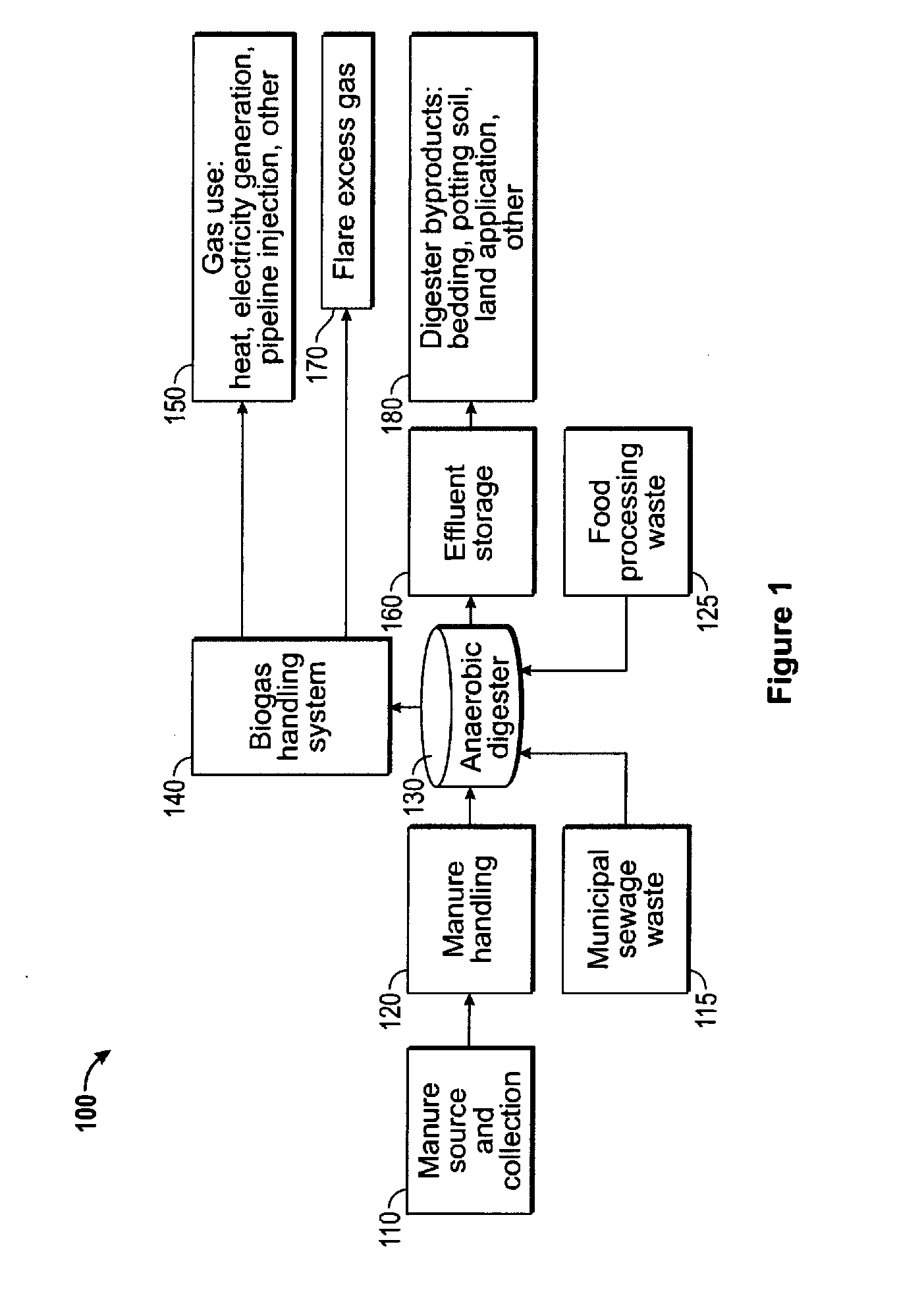

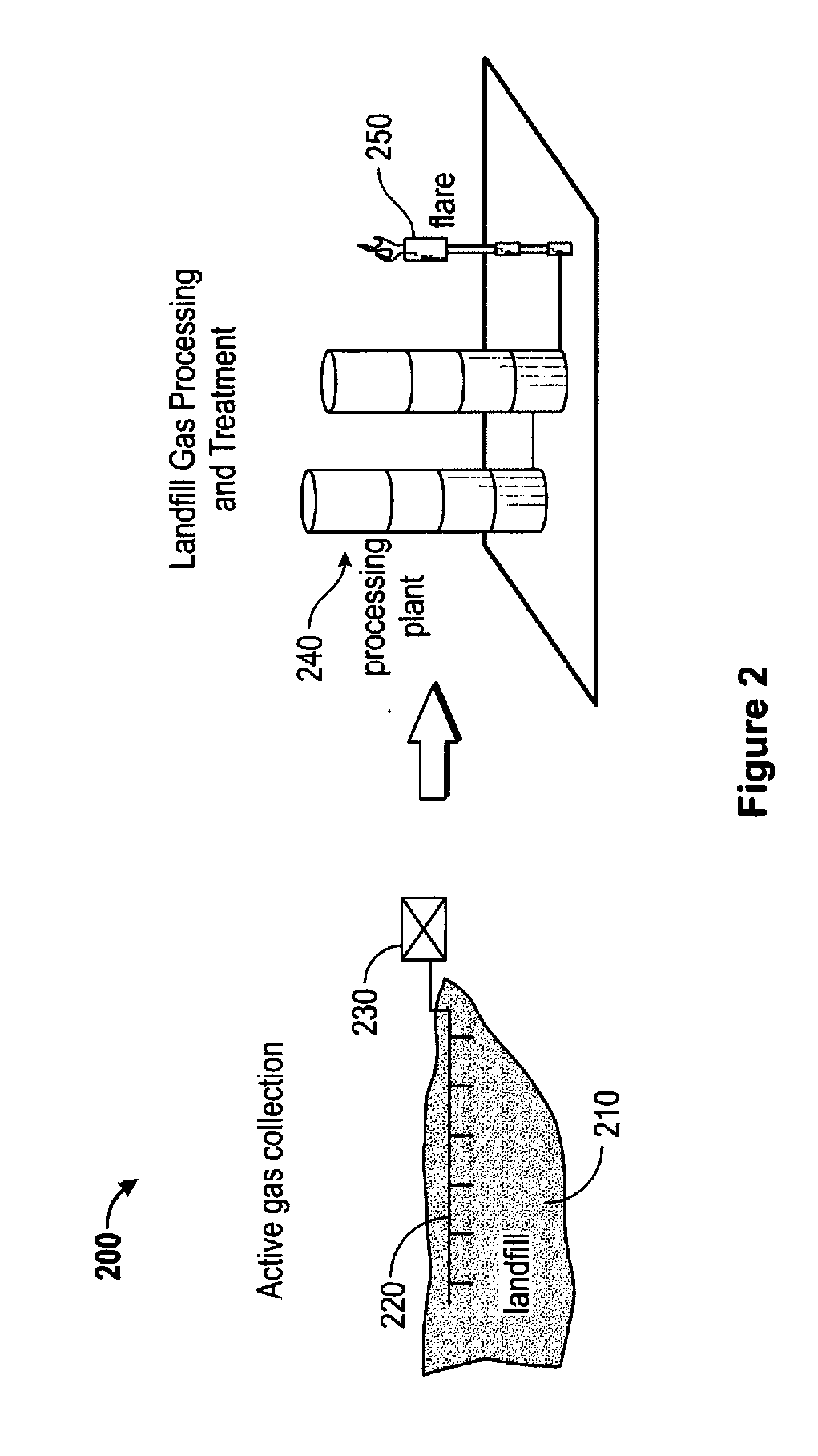

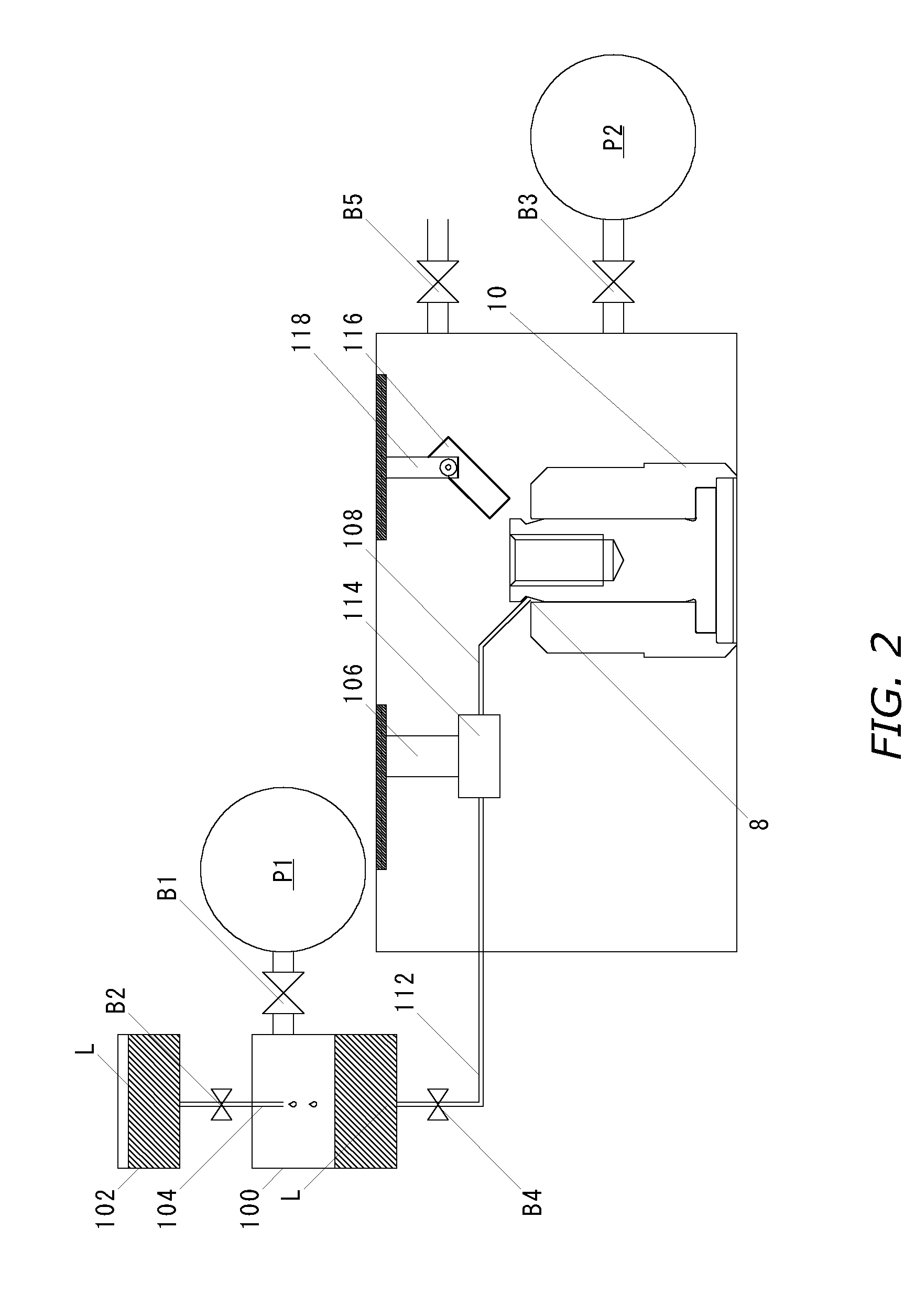

System for the treatment and purification of biogas

A system and method for the purification of biogas, the system comprising: a gas compressor for increasing the pressure of the biogas for processing; a gas processor for removing any CO2, volatile organic compounds, and H2S, from the gas; an optional biological sulfur removal system for treating offgas from the gas processor; a regenerative thermal oxidizer system for treating gas from the biological sulfur removal system for thermal destruction of volatile organic compounds, H2S, and CH4 slipped from the gas processor; a catalytic oxygen removal system for receiving product gas from the gas processor and removing oxygen from the product gas; and a caustic scrubber for receiving product gas from the catalytic oxygen removal system and neutralizing any acid formed during catalytic oxygen removal.

Owner:CLEAN ENERGY RENEWABLE FUELS

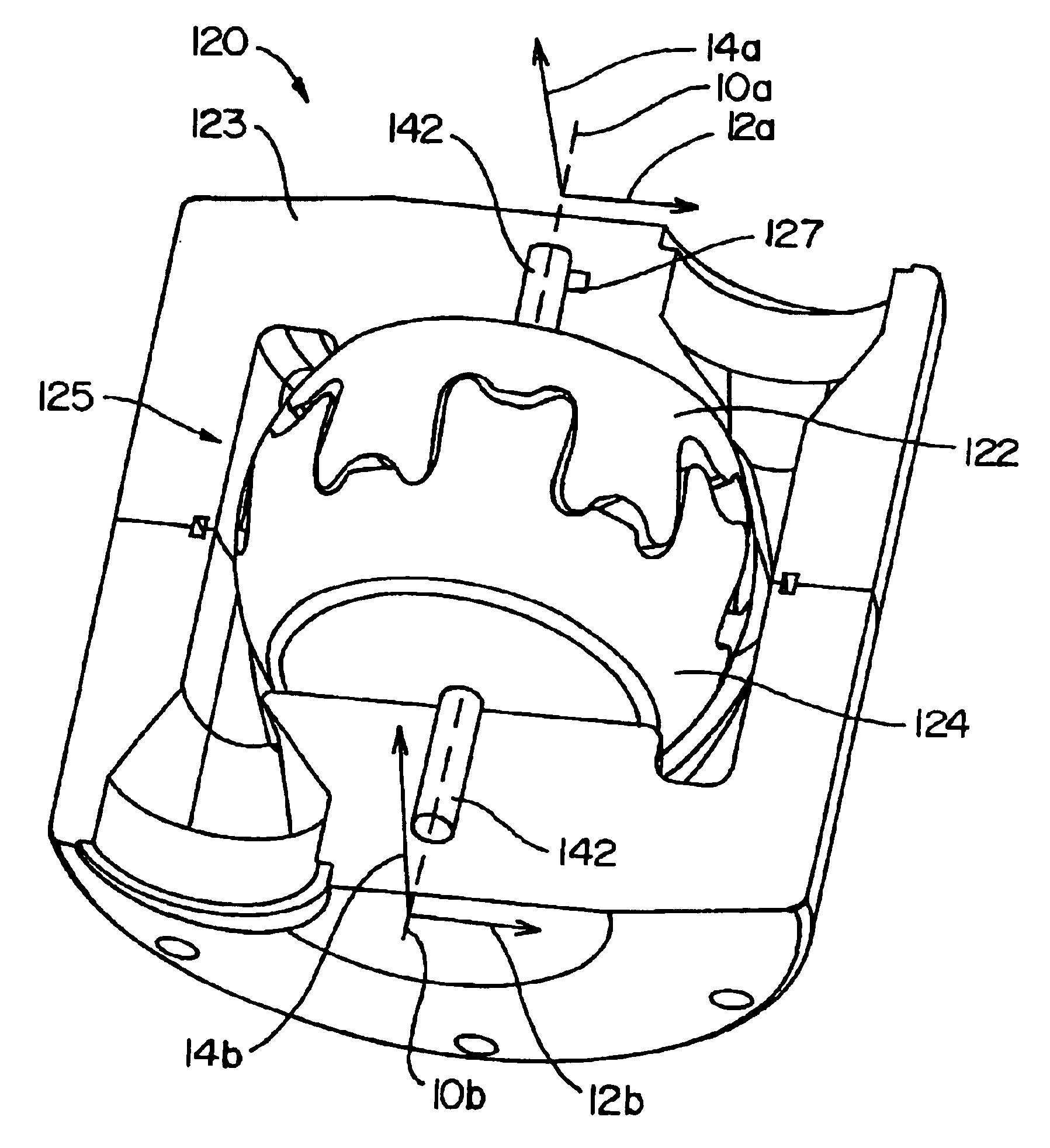

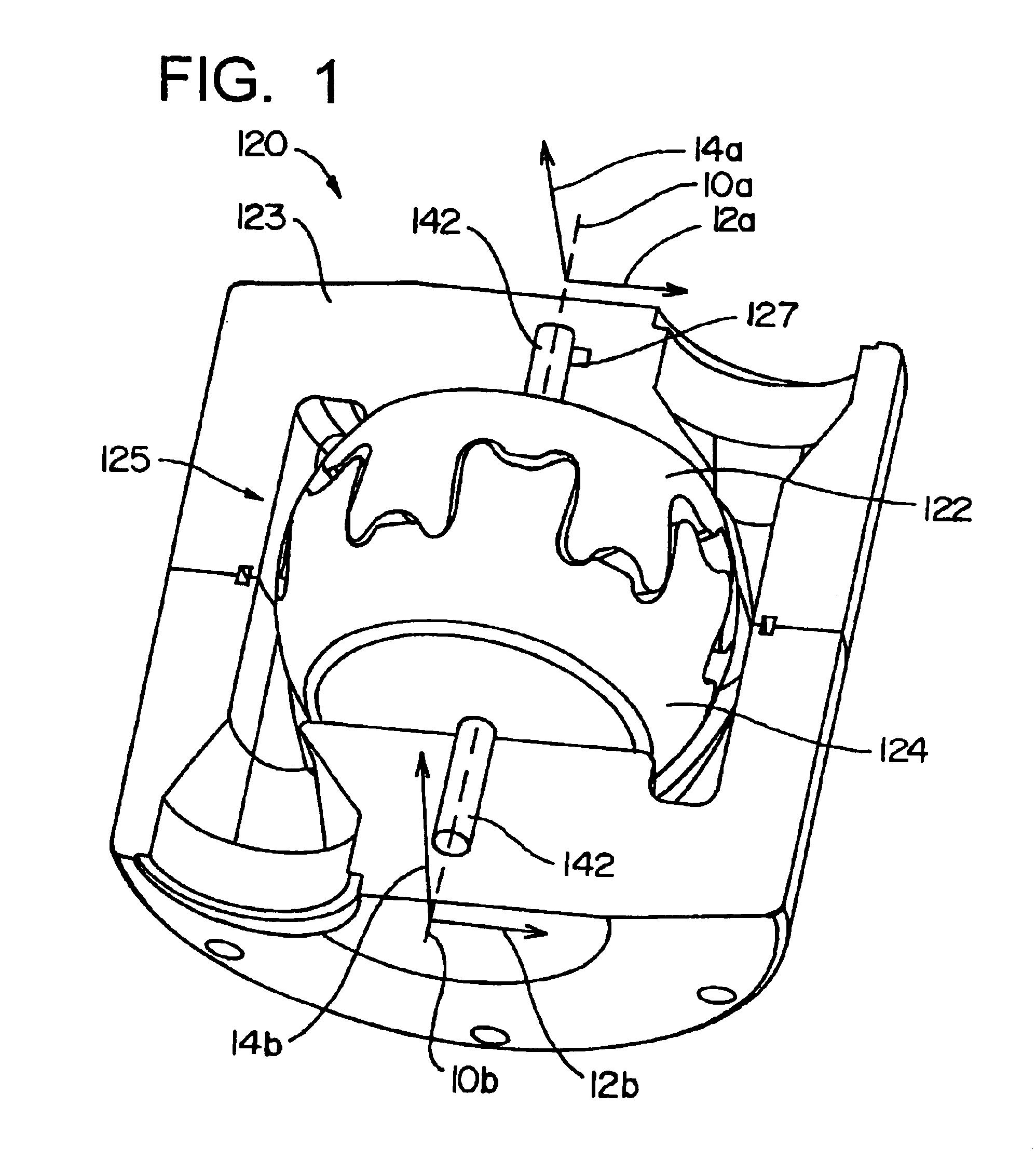

Positive displacement flow meter method and apparatus

InactiveUS6923055B2Increased pressureVolume/mass flow measurementRotary piston enginesPositive displacement meterEngineering

A flow meter comprising a rotor assembly that is comprised of two rotors having axis of rotation offset from collinear where the two rotors define operating chambers that changing volume with respects to rotation and allow fluid to pass from an inlet port to an outlet port when the number of rotation is indicated the volumetric flow therethrough.

Owner:E3P TECH

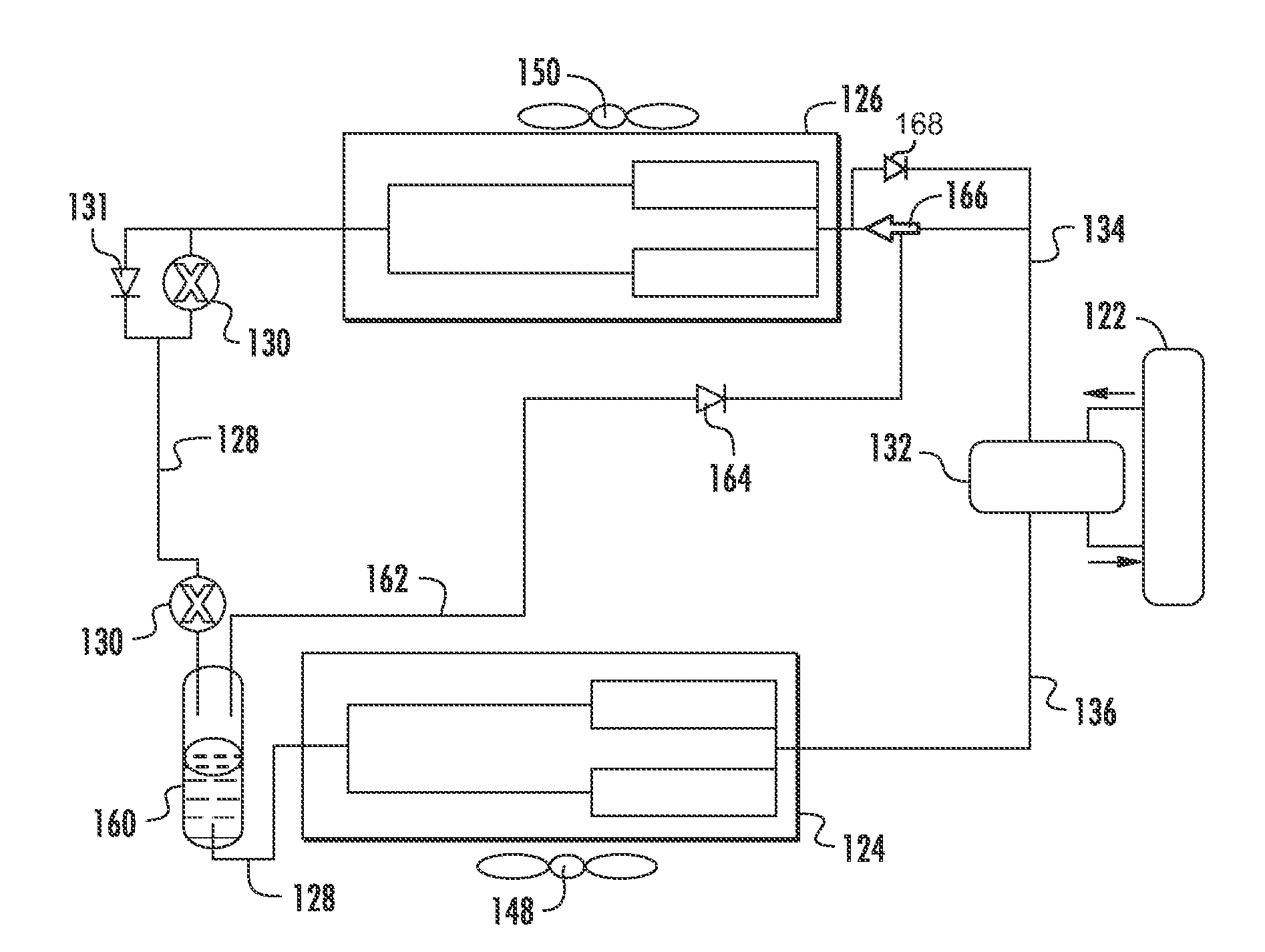

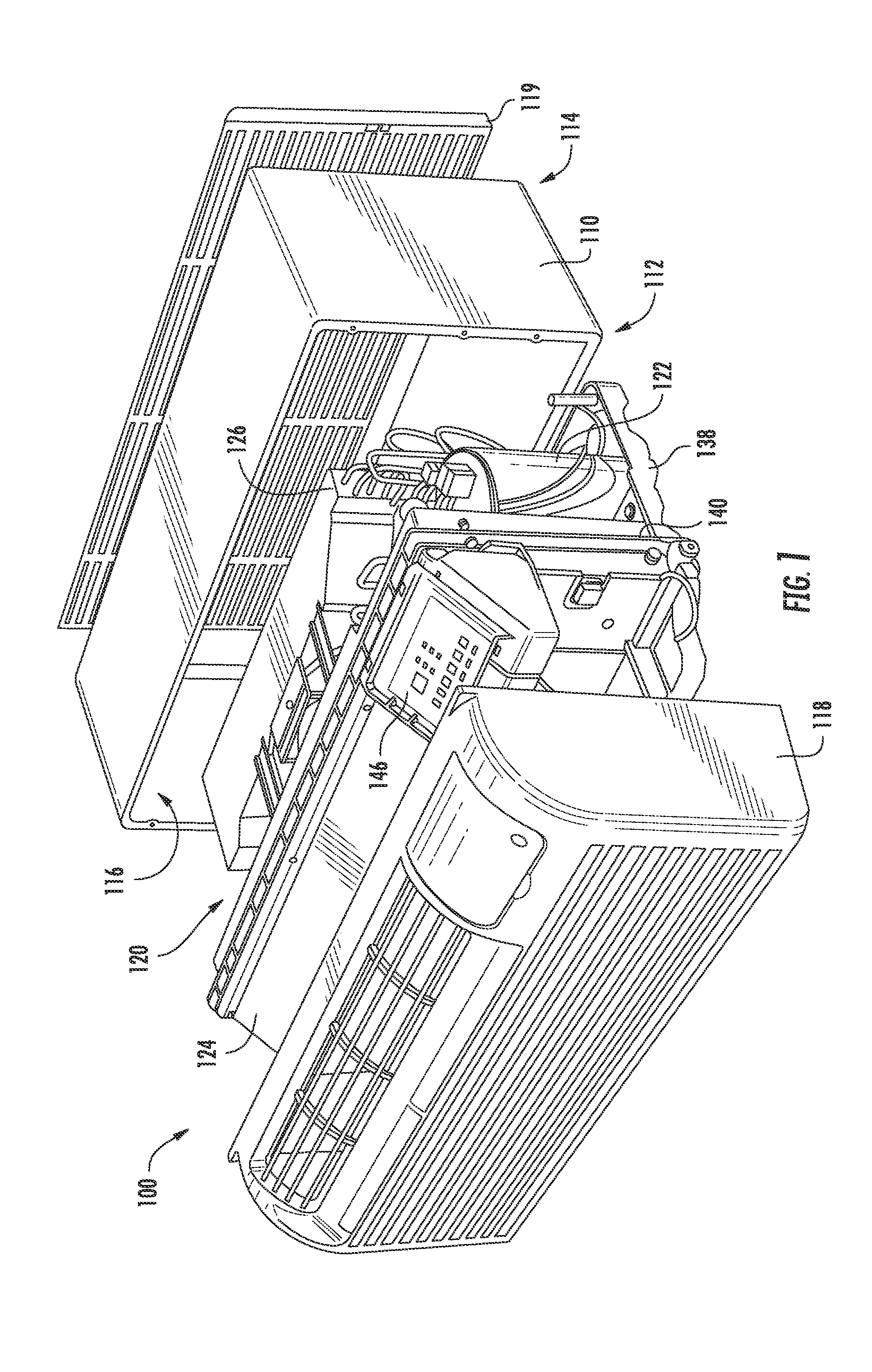

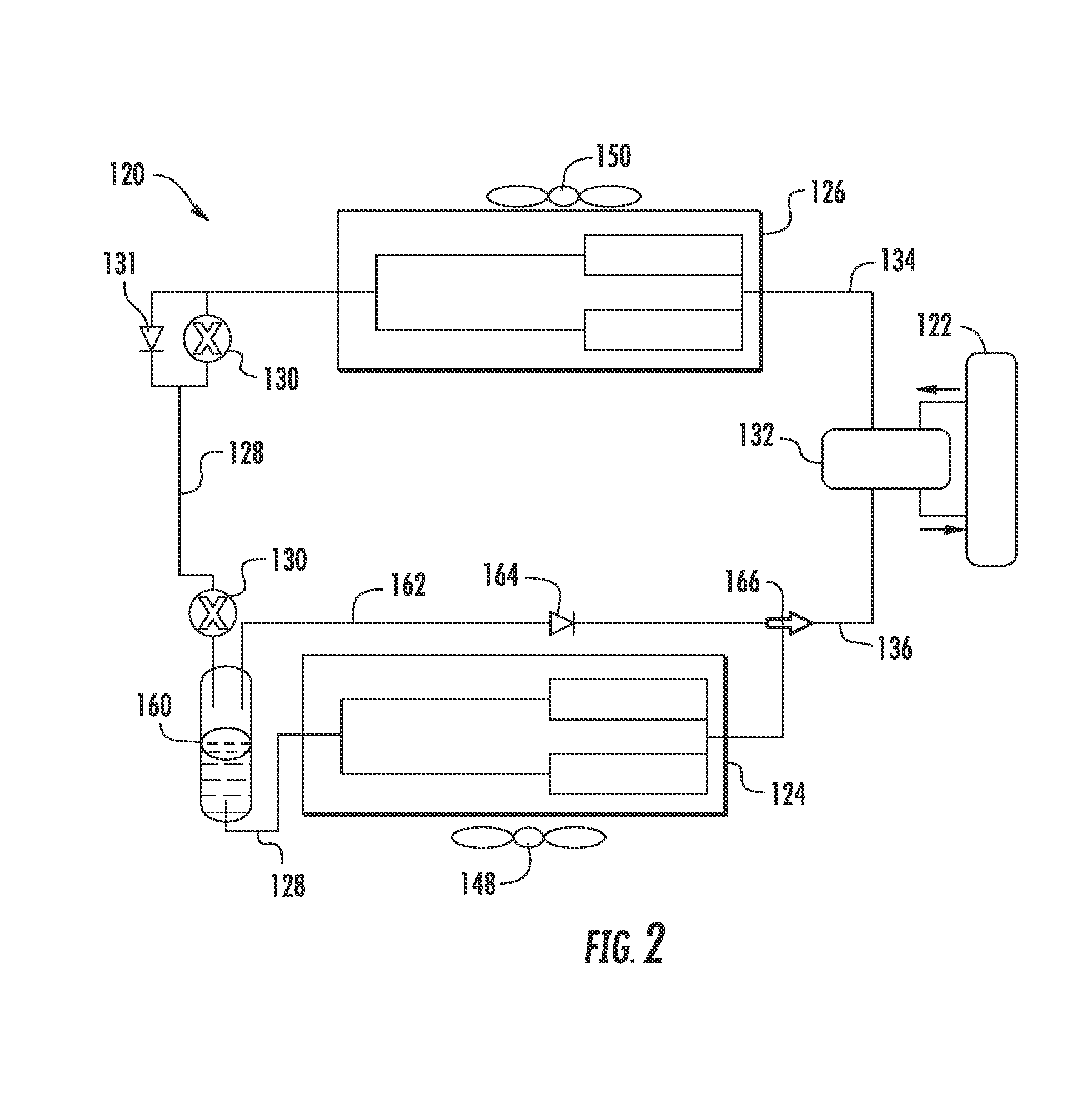

Packaged terminal air conditioner unit

InactiveUS20160109160A1Increased pressureMechanical apparatusFluid circulation arrangementPackaged terminal air conditionerElectrical and Electronics engineering

A packaged terminal air conditioner unit includes a phase separator positioned within a casing of the packaged terminal air conditioner unit. The phase separator is coupled to a supply conduit that extends between an exterior coil and an interior coil of the packaged terminal air conditioner unit. The phase separator is configured for separating liquid refrigerant within the supply conduit from vapor refrigerant within the supply conduit.

Owner:HAIER US APPLIANCE SOLUTIONS INC

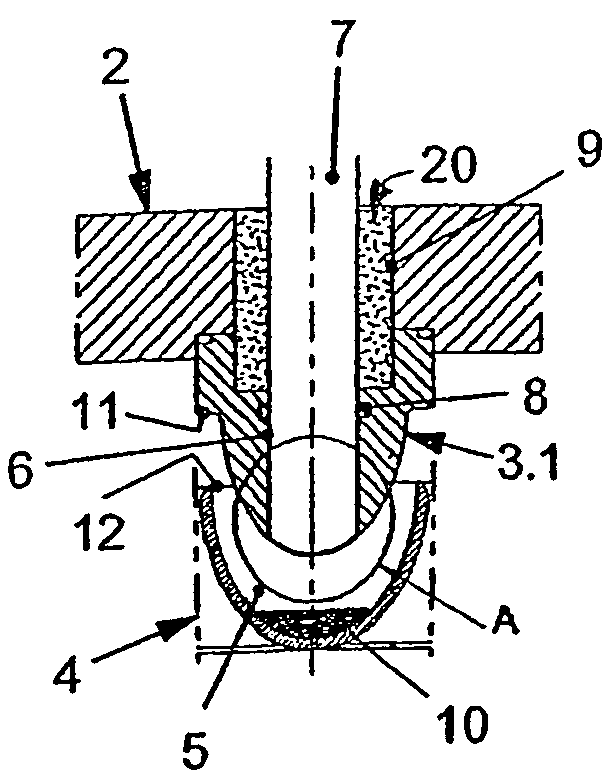

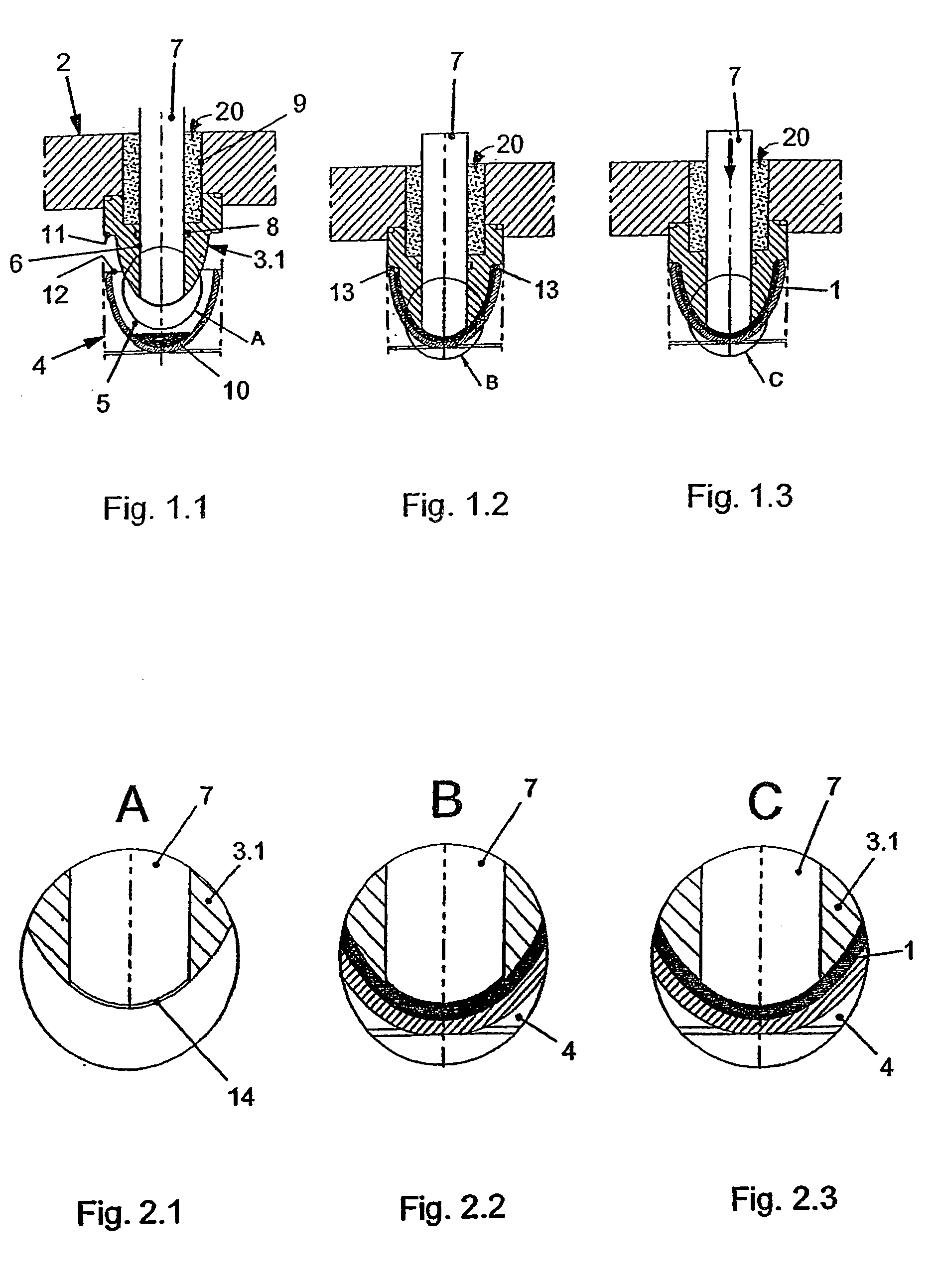

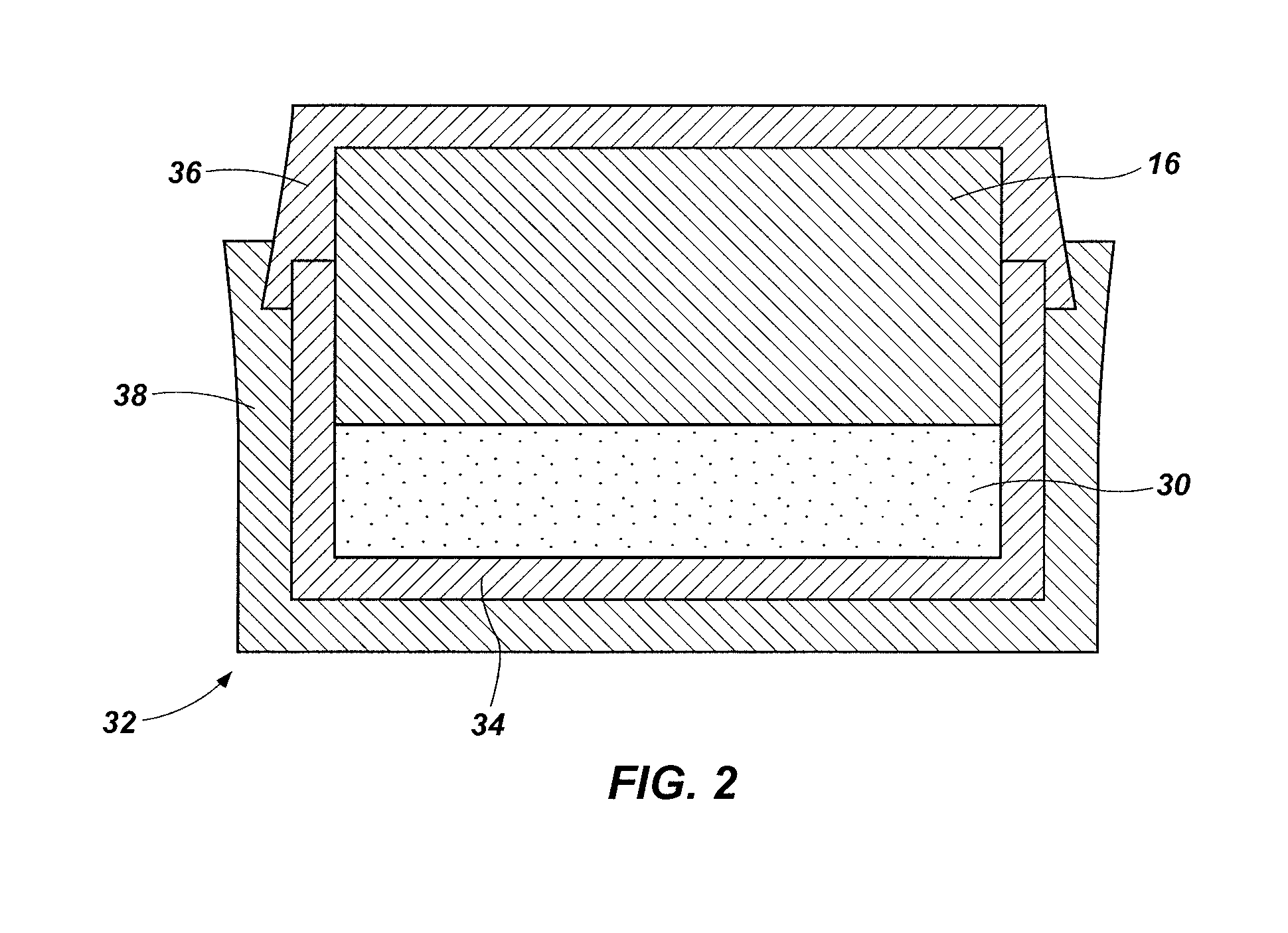

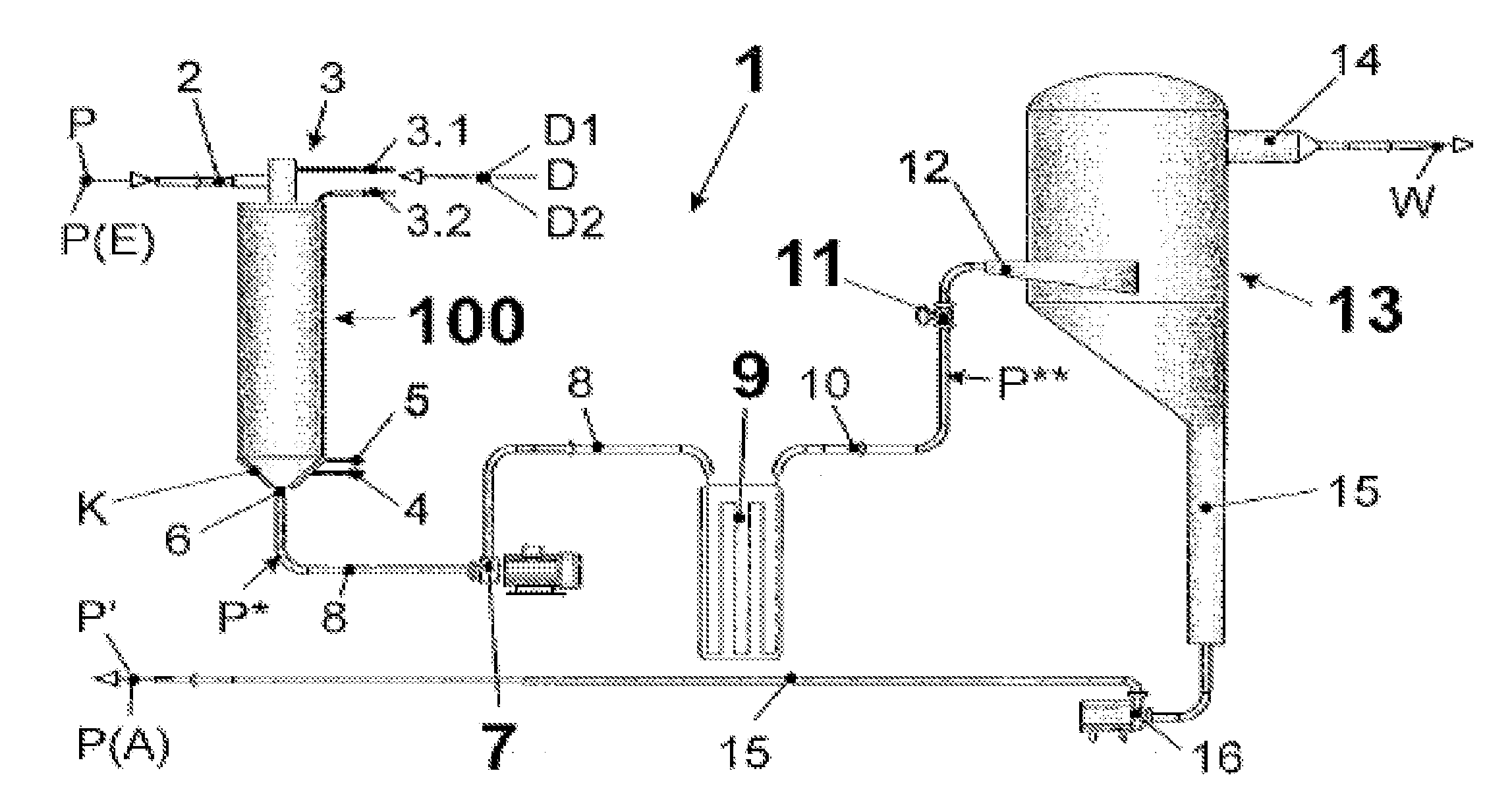

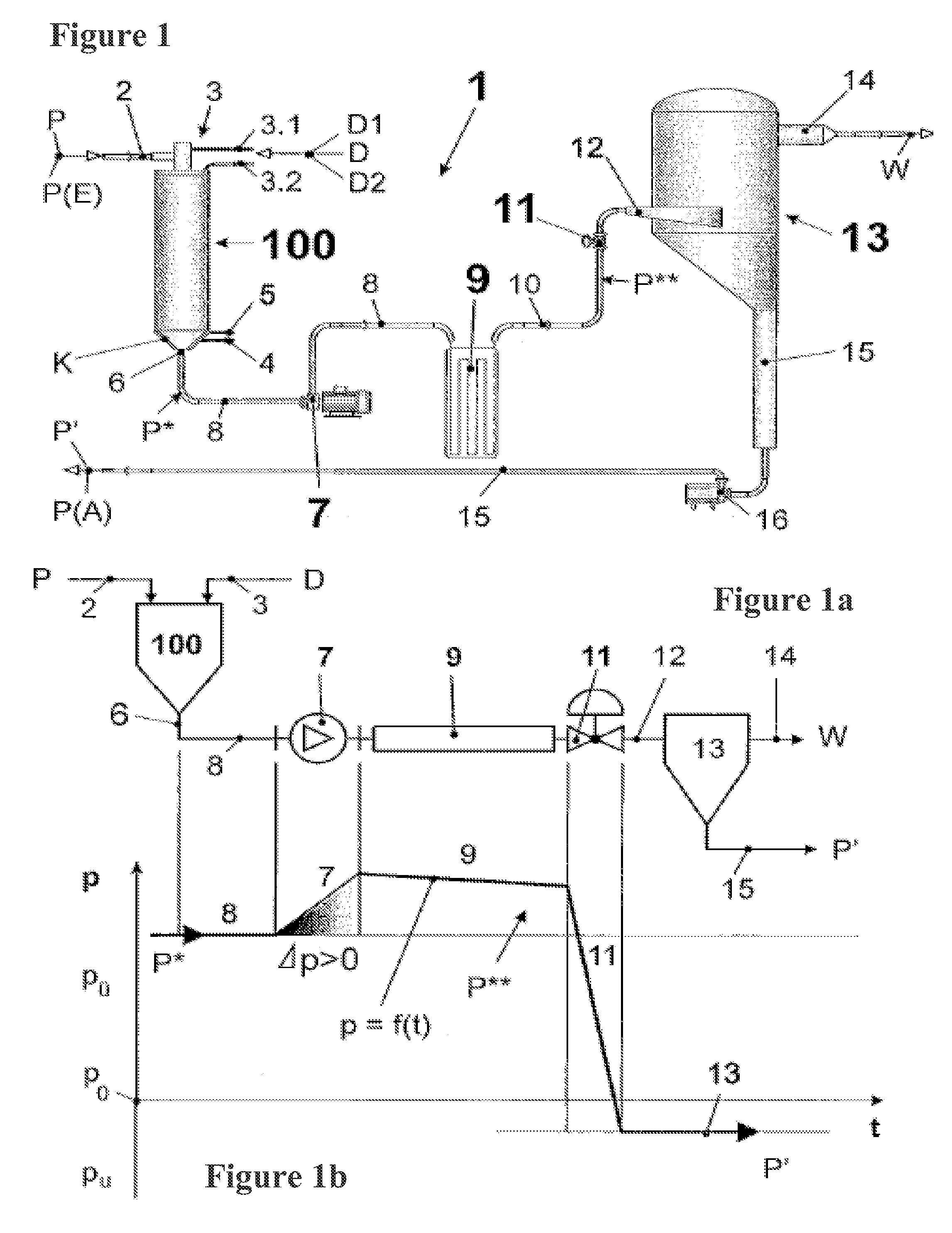

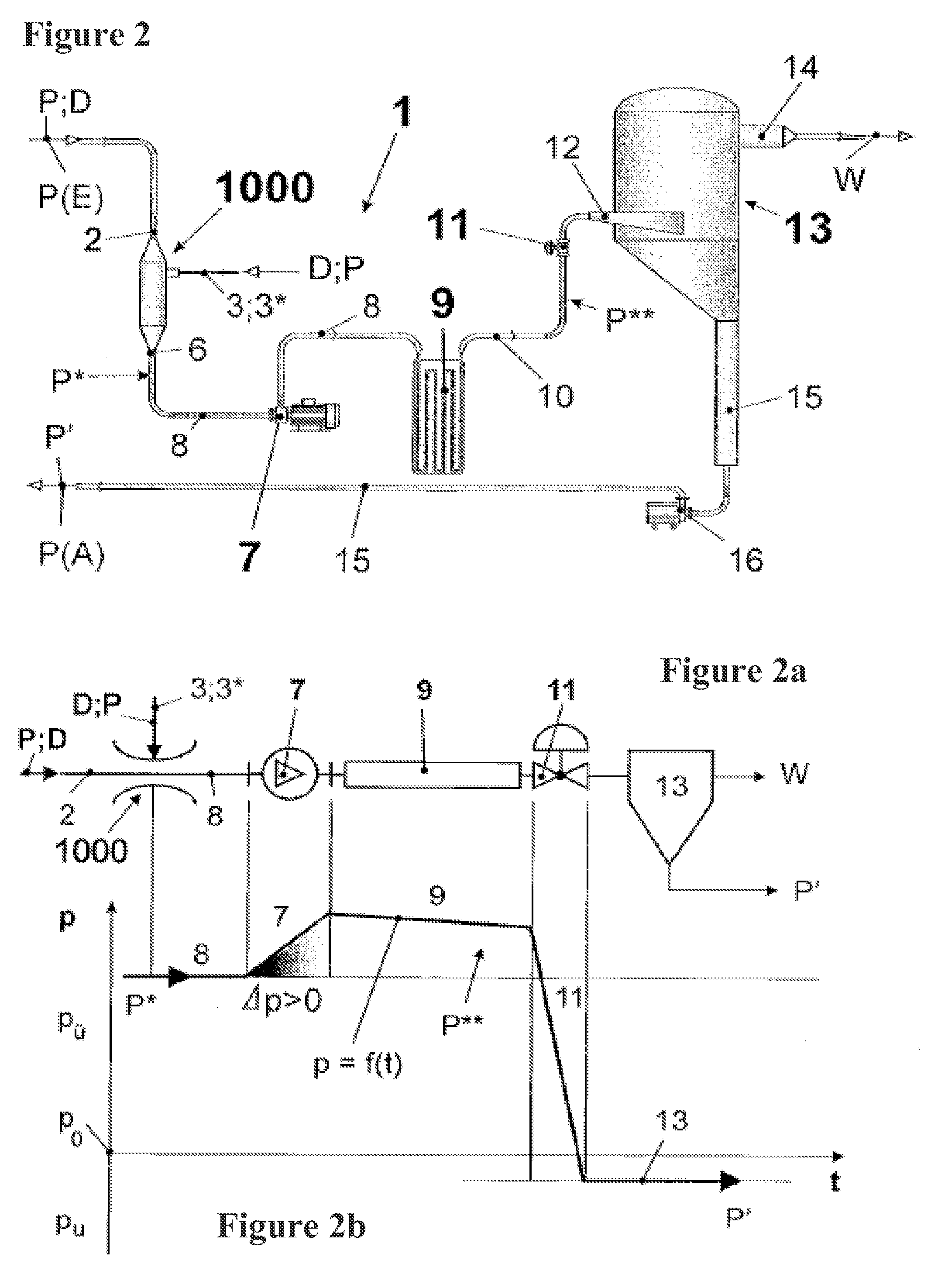

Method and UHT Installation for Treating Heat-Sensitive Liquid Food Products

ActiveUS20120321771A1Increased pressureImprove burnsMilk preservationMeat/fish preservation by heatingPreamblePressure level

The invention concerns a process for the treatment of heat-sensitive fluid food products (P) in a UHT system (1), particularly dairy products such as milk, cream, milk protein concentrate, according to the preamble of Claim 1. The invention has the task, in a UHT system whose basic structure using an infusion chamber is described in [4], of ensuring an equal and constant dwell time as well as an equal and constant temperature trend for the entire treated food product downstream of an outlet of a mechanism in which the food product is subjected to direct heating by the introduction of steam, and to minimize fouling during heat maintenance of the food product in this area. This is achieved using process technology in that:The heated food product (P*) upstream of its heat main undergoes a predetermined pressure increase (Δp) at a predetermined, unchanging location, andThe pressure level upstream of the location before the relief lies above the pressure upstream of the location before the pressure increase (Δp) (FIG. 1).

Owner:GEA TDS

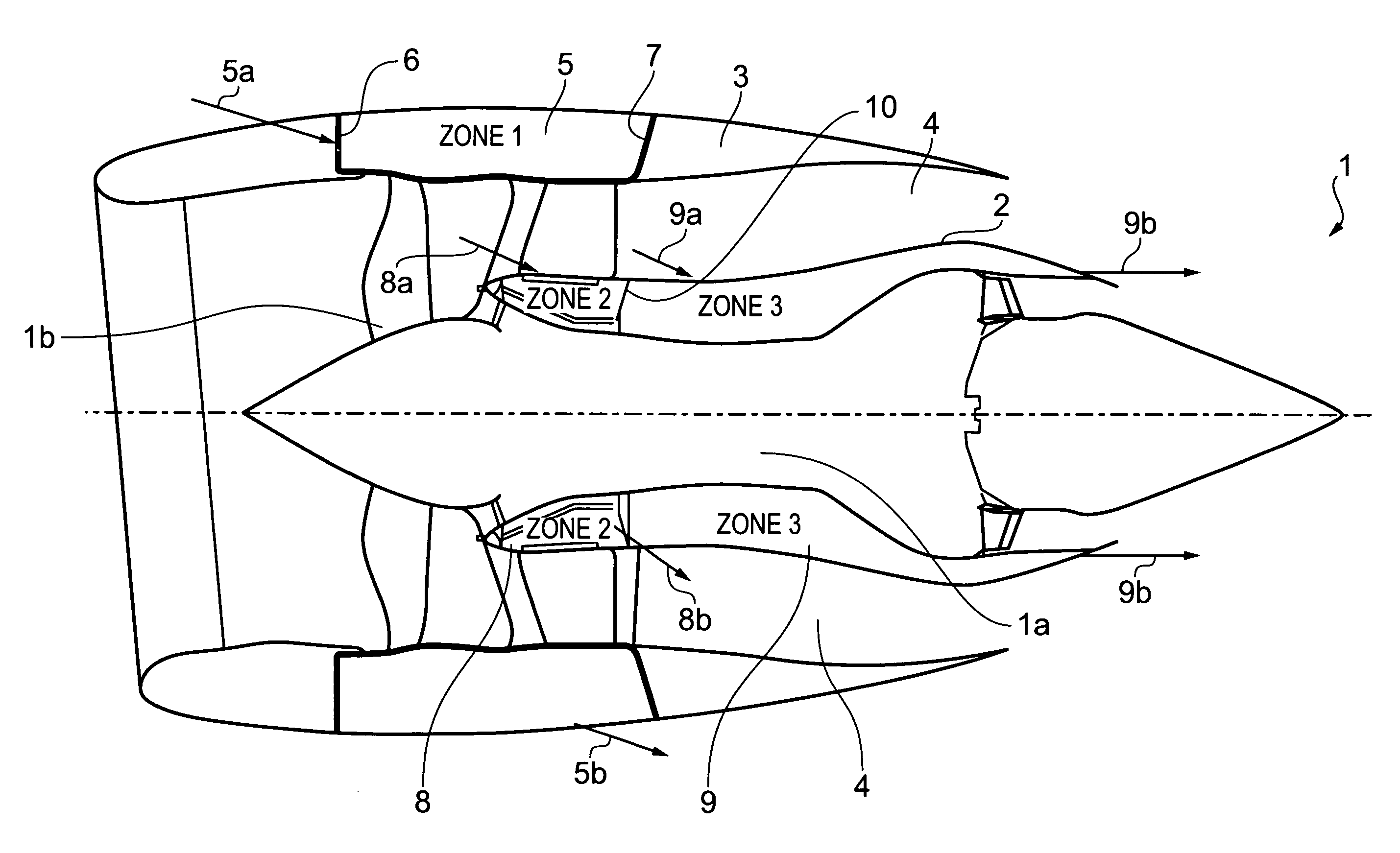

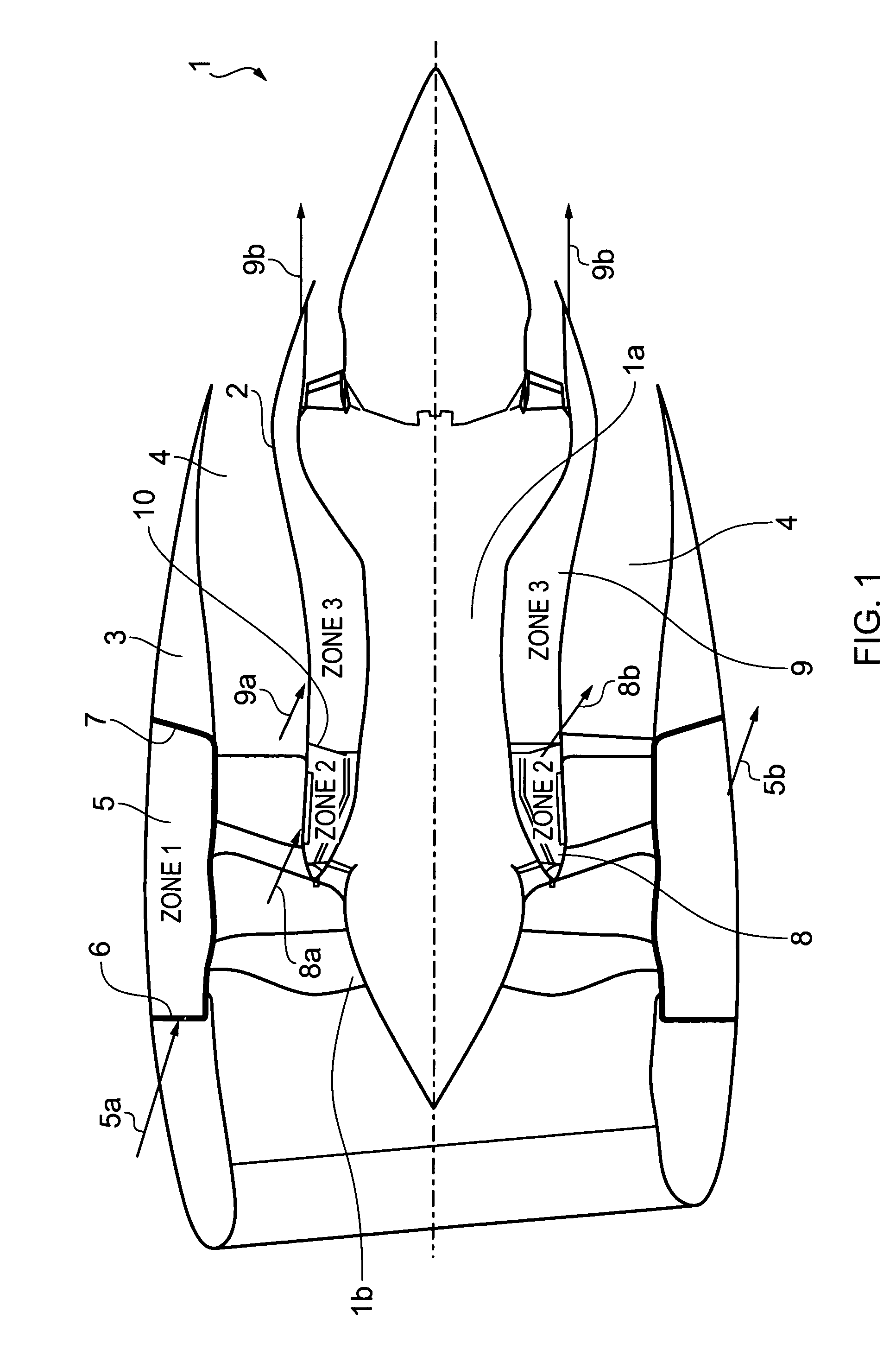

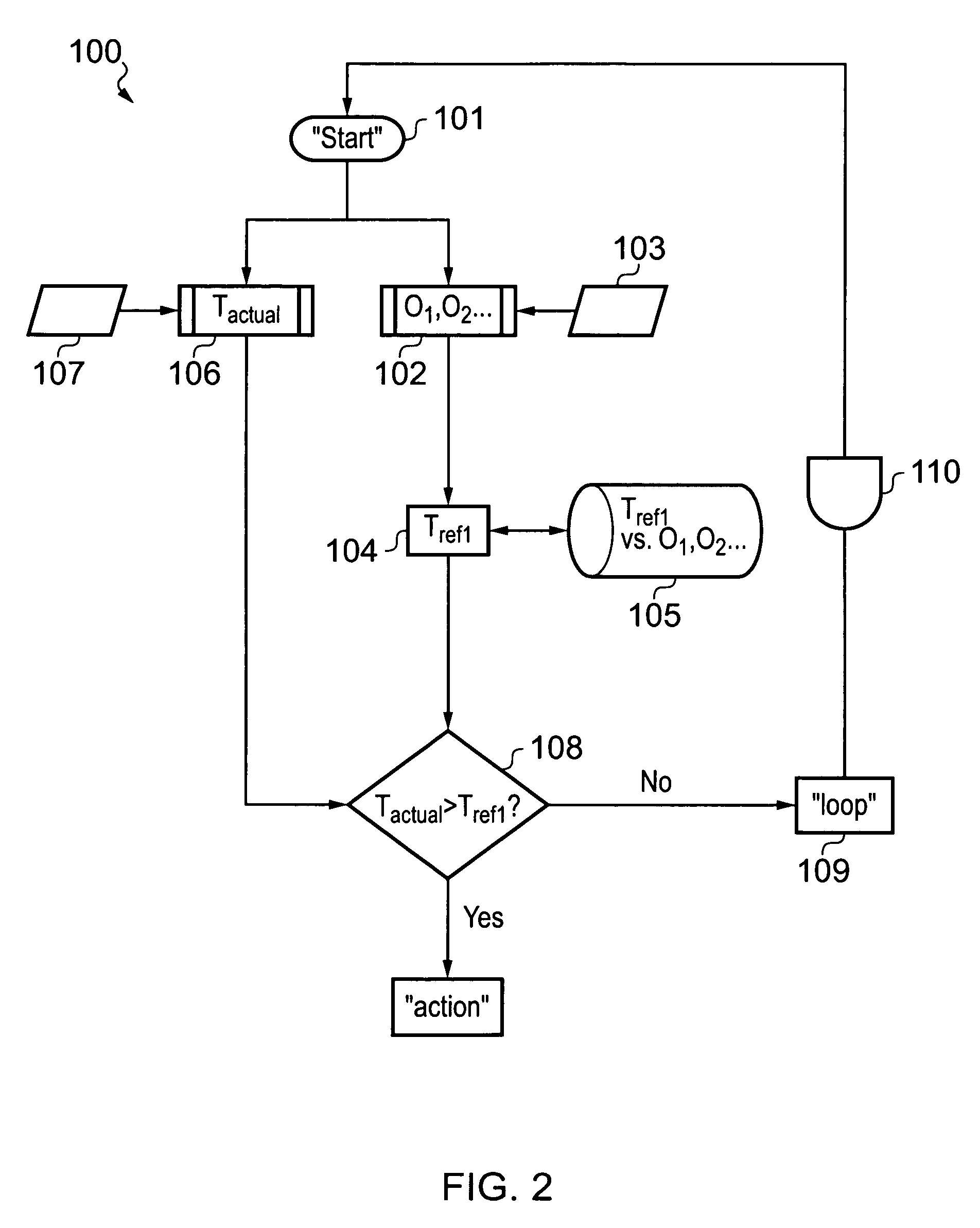

Method for detecting overpressure inside a compartment associated with a gas turbine nacelle

A method, for detecting overpressure inside a compartment associated with a gas turbine nacelle, includes: a) measuring one or more predetermined operating conditions nominally affecting the temperature inside the compartment; b) determining a reference temperature for the compartment, corresponding to a nominal reference zone pressure, on the basis of the measured operating condition or conditions; c) measuring the actual temperature inside the compartment, corresponding to the actual compartment pressure; and d) using the measured actual temperature in the compartment and the determined reference temperature for the compartment to assess the gas pressure inside the compartment. A system for assessing the gas pressure inside the compartment caused by an associated pressure system failure includes using a quantified mass leakage flow to assess gas pressure inside the compartment. The quantified mass leakage flow may also be used to detect excessive mass leakage flow by comparing the quantified mass leakage flow with a predetermined mass flow leakage.

Owner:ROLLS ROYCE PLC

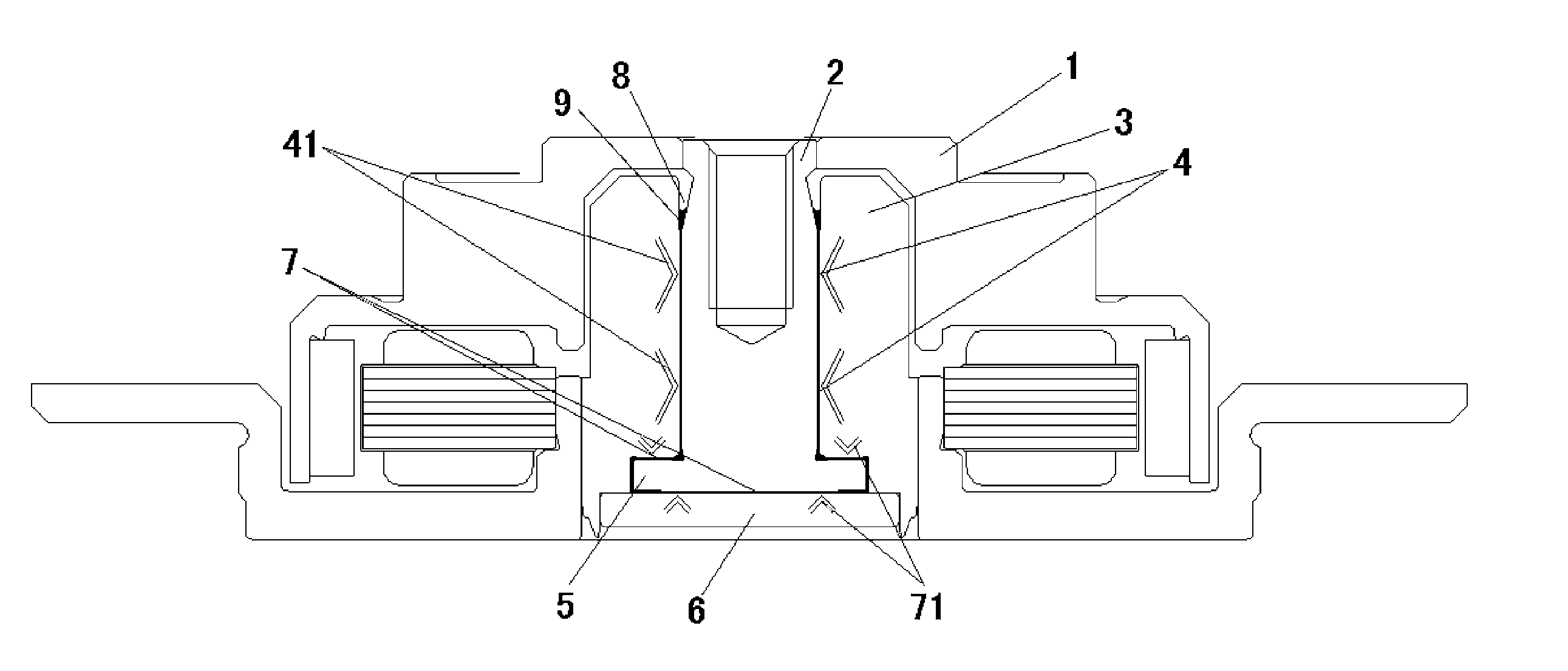

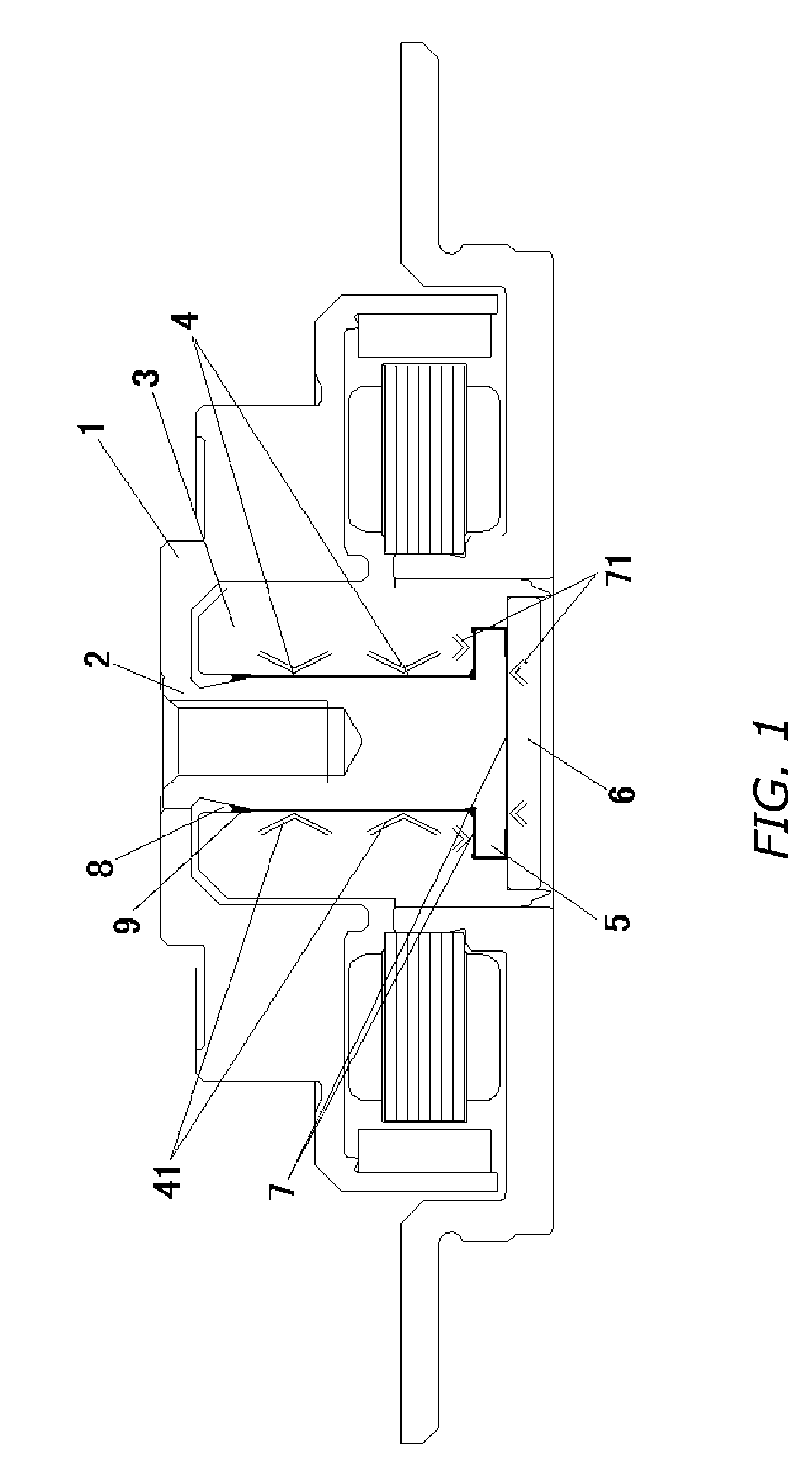

Manufacturing Method of Fluid Dynamic Pressure Bearing

ActiveUS20050000092A1Accurately supplyIncreased pressureLubricant transferMetal-working apparatusEngineeringAir bubble

The present invention aims to prevent the occurrence of air bubbles during a filling process of oil or at a stage where a fluid dynamic pressure bearing is incorporated into a motor to be used as a bearing, thereby performing an effective degassing. Upon supplying oil through a pipe that communicates between a first vacuum chamber and a second vacuum chamber upon filling the oil, stored in the first vacuum chamber that is under a reduced pressure environment having a pressure lower than that in the surrounding environment, to the fluid dynamic pressure bearing held in the second vacuum chamber that is similarly under a reduced pressure environment having a pressure lower than that in the surrounding environment, the pressure in the first vacuum chamber is reduced to be lower than the pressure in the second vacuum chamber at the time of filling lubricating fluid.

Owner:NIDEC CORP

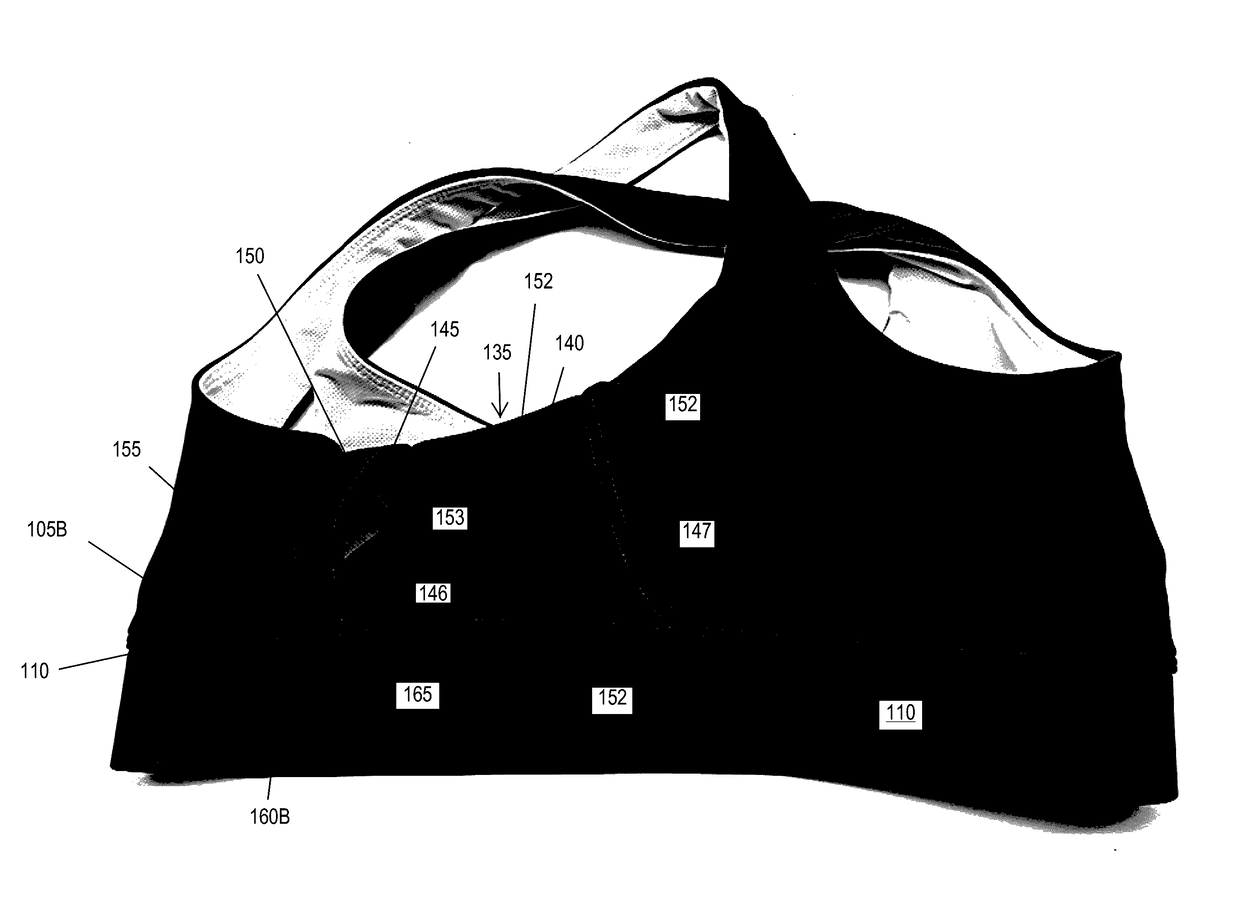

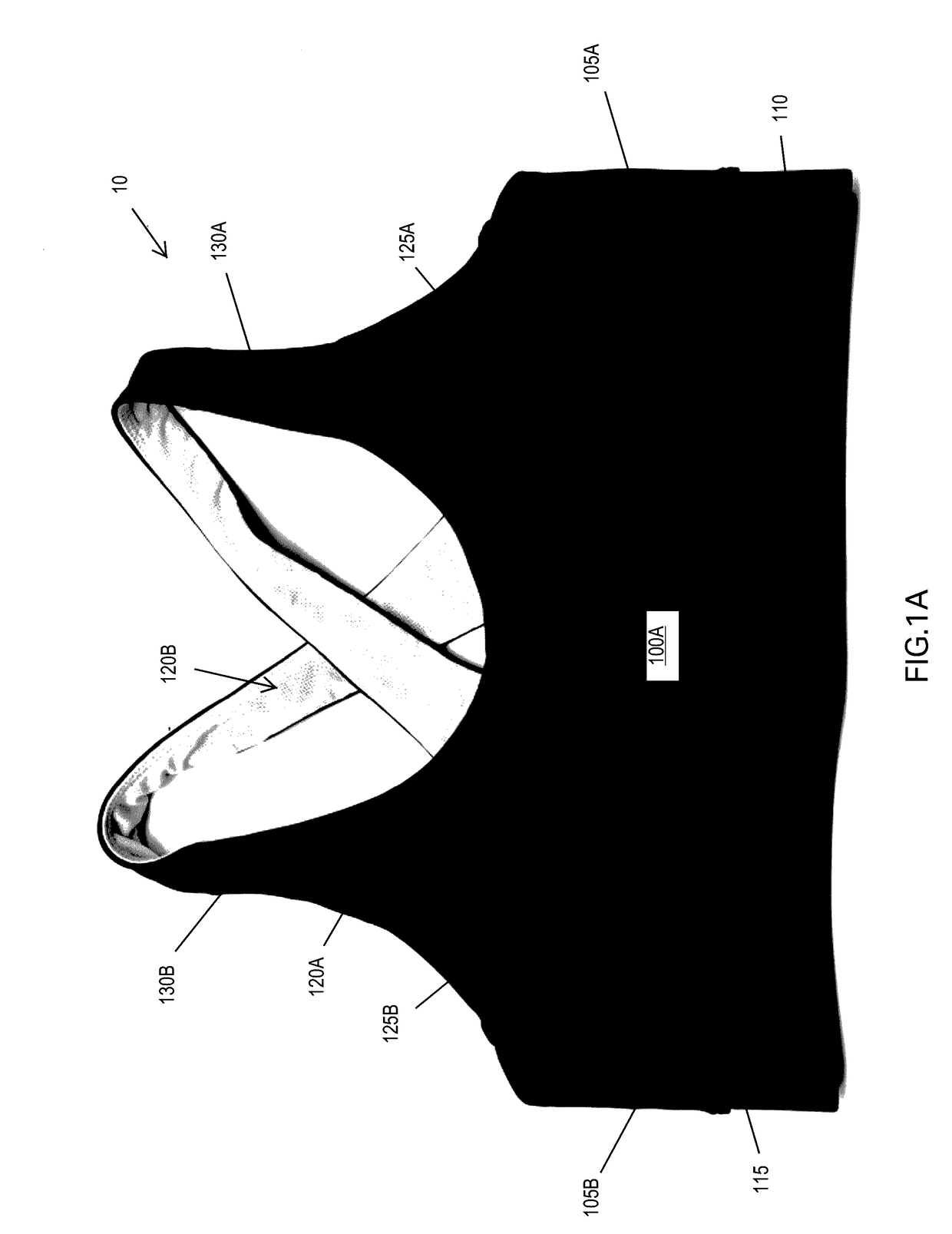

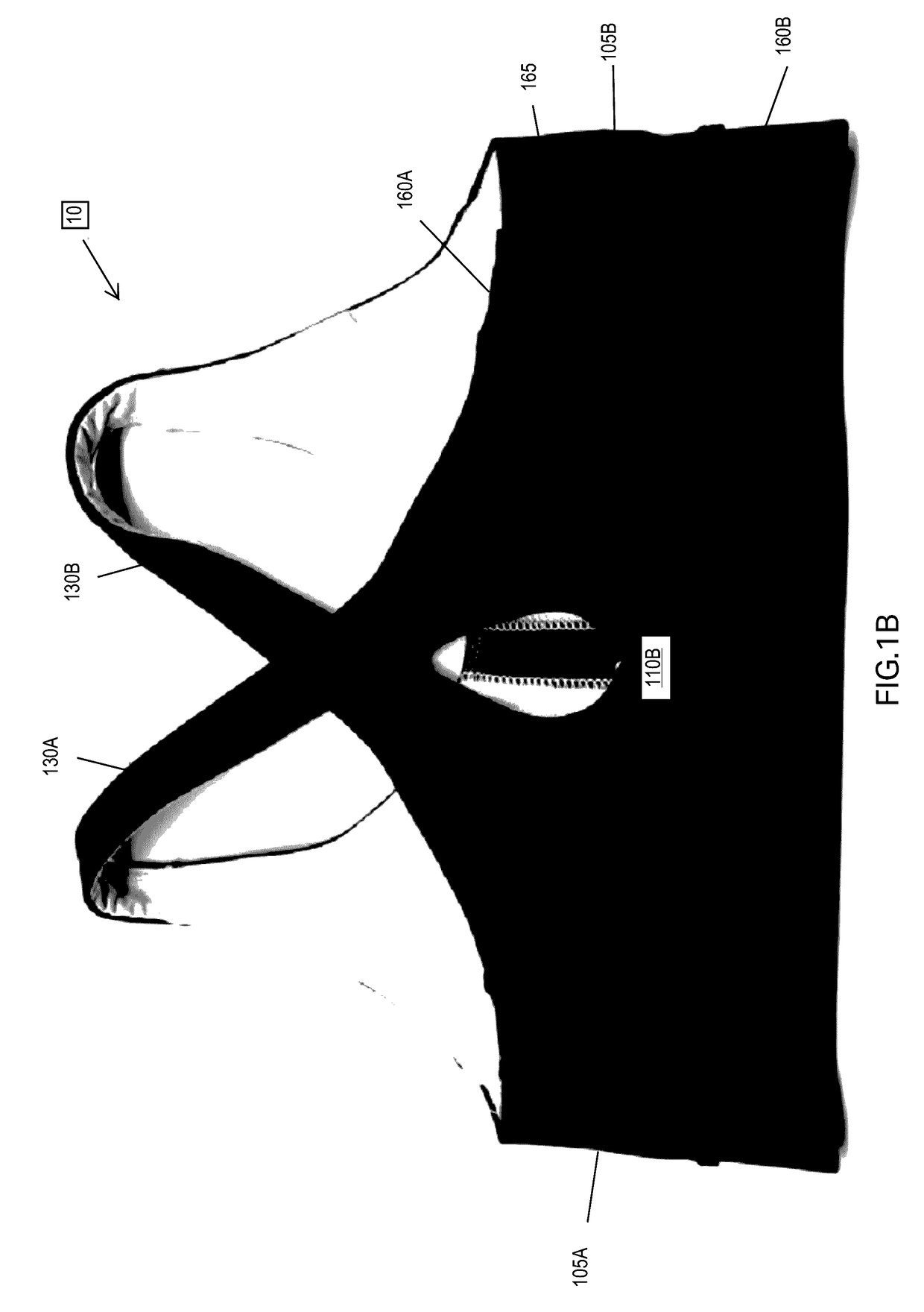

Article of Apparel with Storage System

InactiveUS20170127731A1Increased pressureBrassieresHandkerchiefsMechanical engineeringWater resistant

The present invention is directed toward an article of apparel including a storage system. In an embodiment, the article of apparel is an athletic brassiere (sports bra) including cups and lateral wings that wrap along the sides of the user. At least one of the wings defines a pocket adapted to receive an object for storage. The pocket includes a tension closure member that applies increasing pressure across the pocket opening as the load on the member increases. The storage system may further include an envelope adapted to be received by the pocket. The envelope, which may be water resistant, includes a tension closure member operable to apply increasing pressure along the envelope opening as load across the member increases.

Owner:UNDER ARMOUR

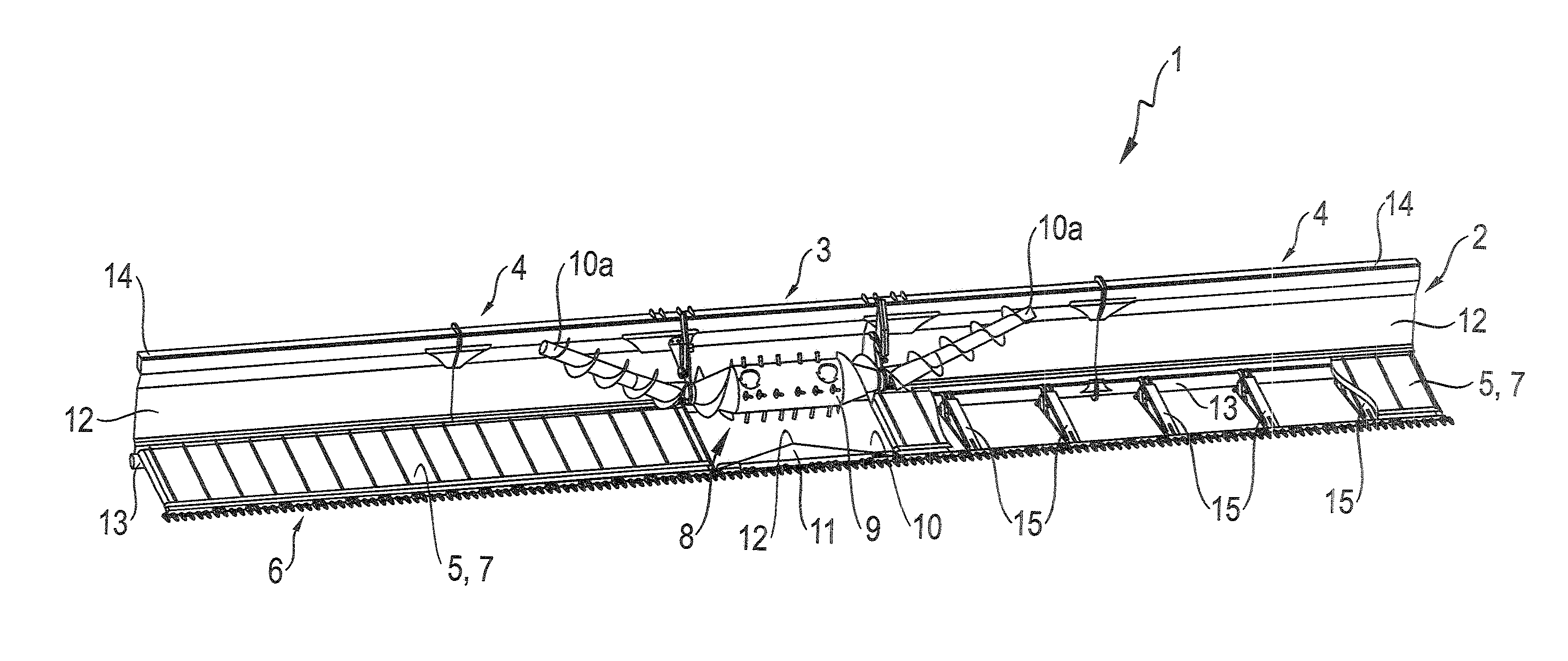

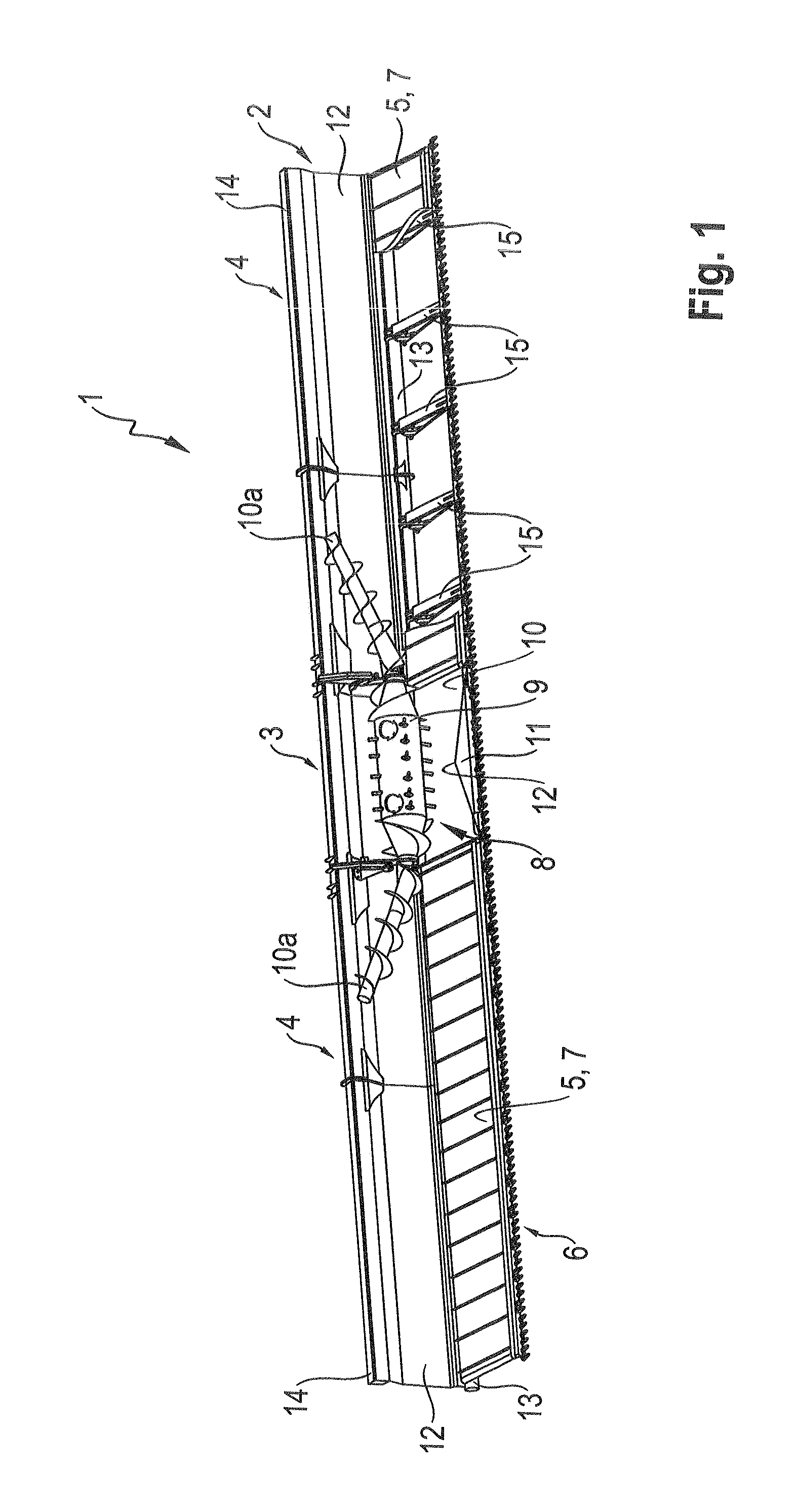

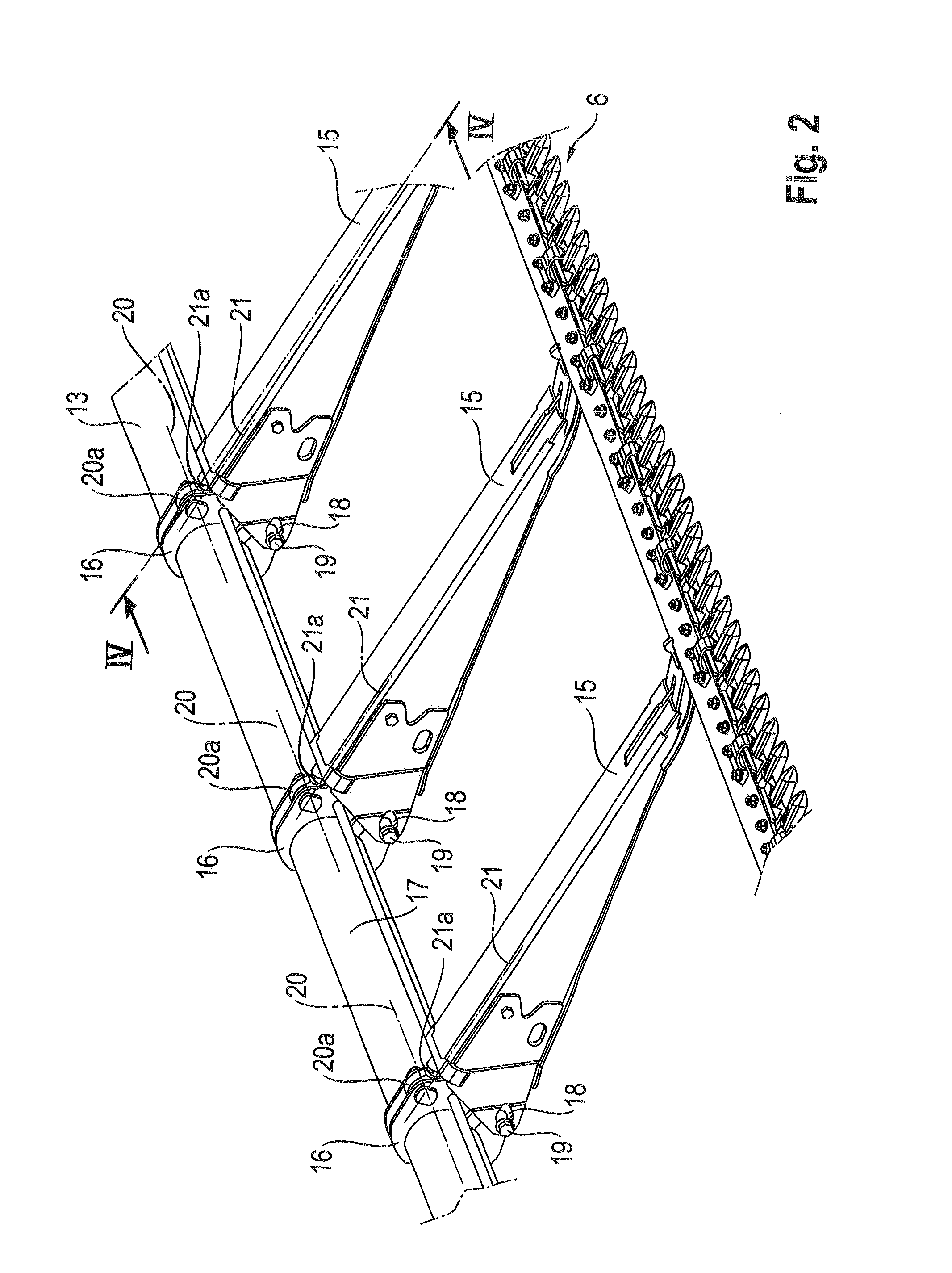

Header

A header for an agricultural machine includes a middle section disposed on a main frame and two side sections adjacent the middle section, a flexible knife bar extending across the width of the header and a conveying device behind the knife bar and designed at the side sections as an endless belt disposed adjacent to the middle section for transporting crop cut by the knife bar laterally. The side sections have supporting arms pivotably disposed on the main frame to support the knife bar of a side section and are rigidly connected to the knife bar. Each supporting arm is connected to the main frame permitting swivelling about a first rotational axis in the vertical direction and about a second rotational axis extending perpendicular to the first.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

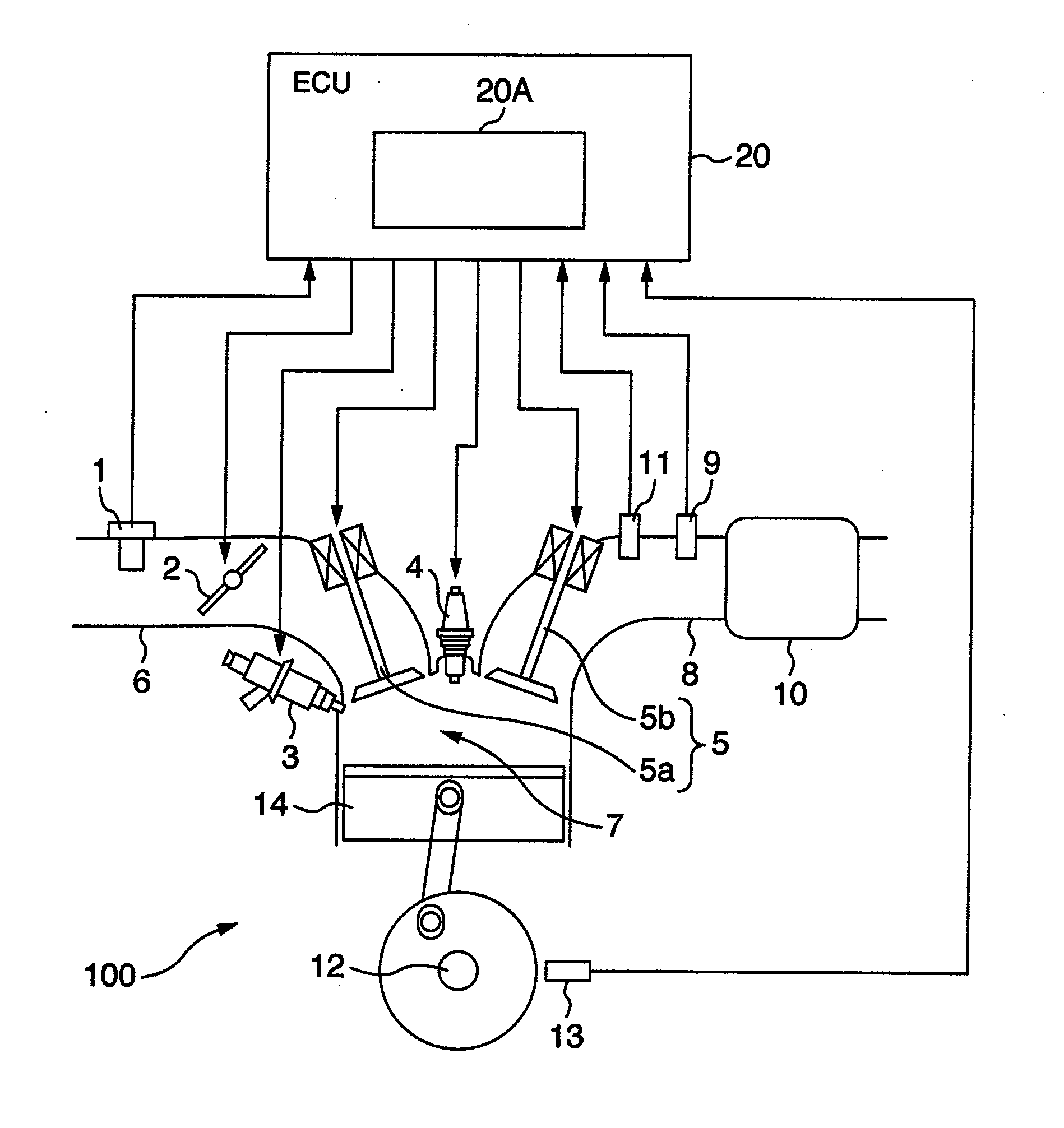

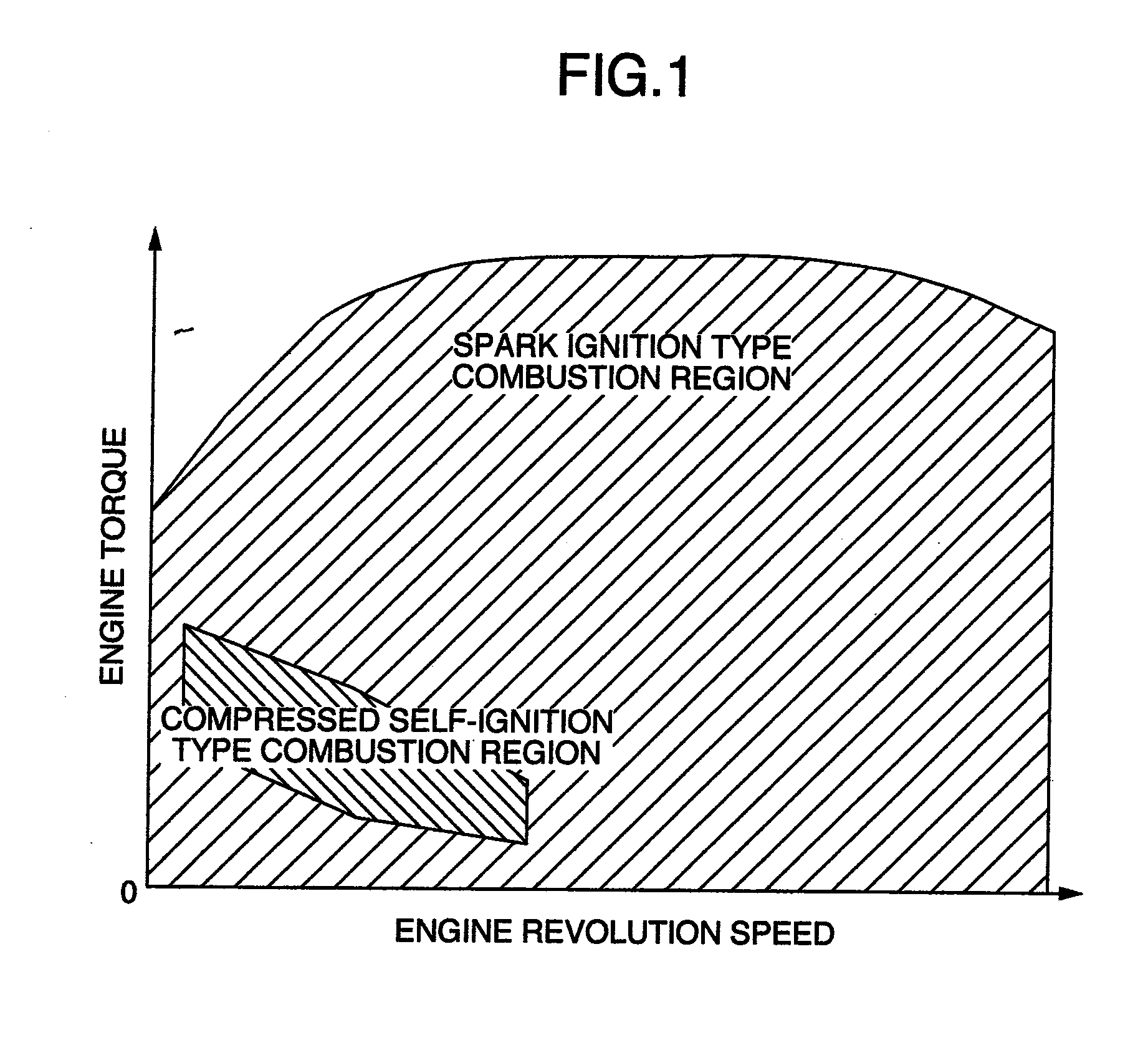

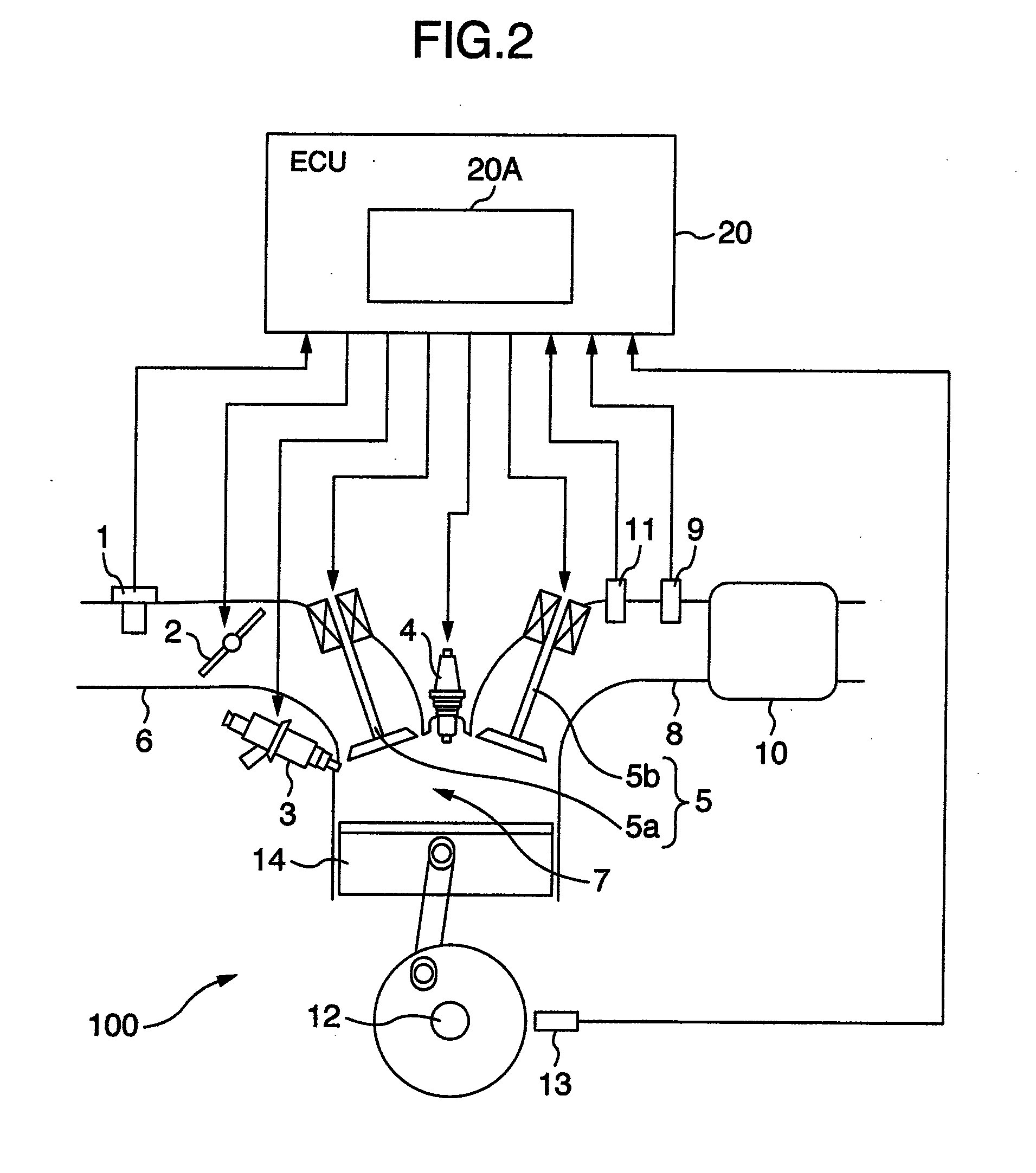

Engine Controller

ActiveUS20080281497A1Significant response delayIncreased pressureAnalogue computers for vehiclesElectrical controlSpark-ignition engineEngine control unit

In an engine controller capable of carrying out spark ignition type combustion and compressed self-ignition type combustion, in order to suppress operation performance deterioration and exhaust performance deterioration at the time of switching a combustion mode from the compressed self-ignition type combustion to the spark ignition type combustion, intake pipe pressure downstream a throttle is quickly reduced by making the throttle opening degree smaller than a target throttle opening degree of the spark ignition type combustion immediately after switching for a certain period during the combustion mode is switched from the compressed self-ignition type combustion to the spark ignition type combustion. As a result, responsiveness of an intake amount at the time of switching the combustion mode from the compressed self-ignition type combustion to the spark ignition type combustion is enhanced, and combustion switching without exhaust deterioration and torque variation is realized.

Owner:HITACHI LTD

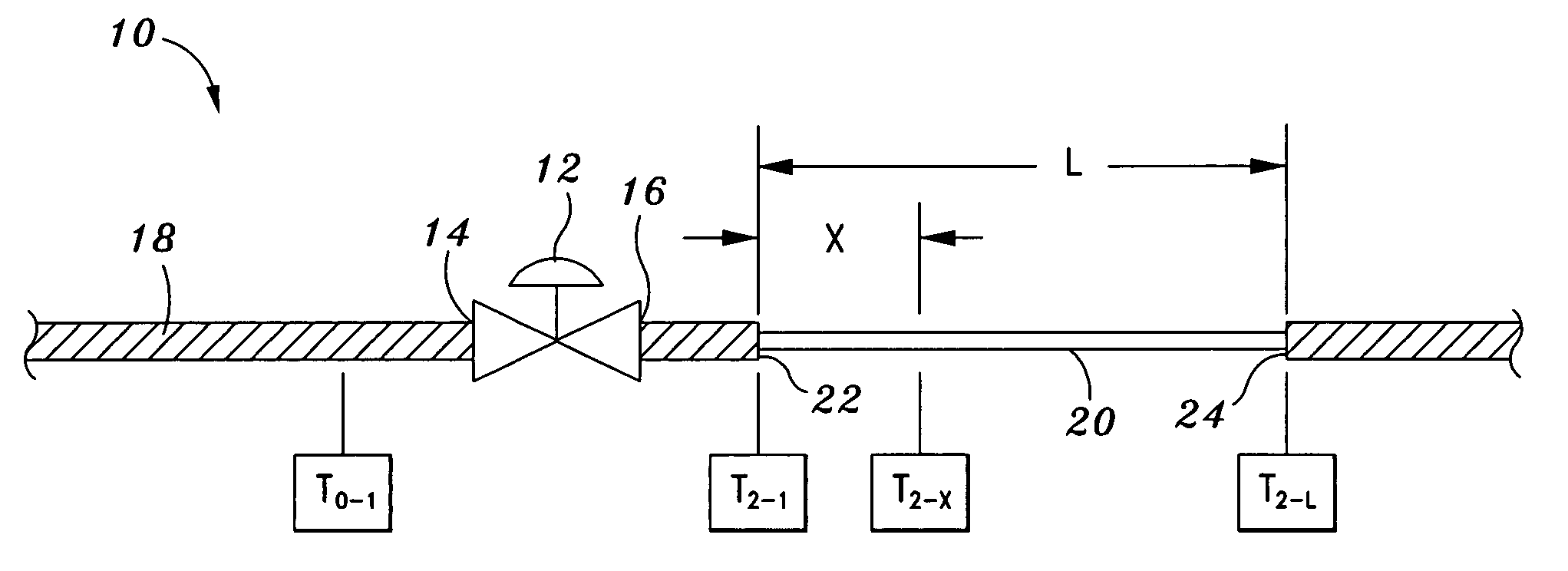

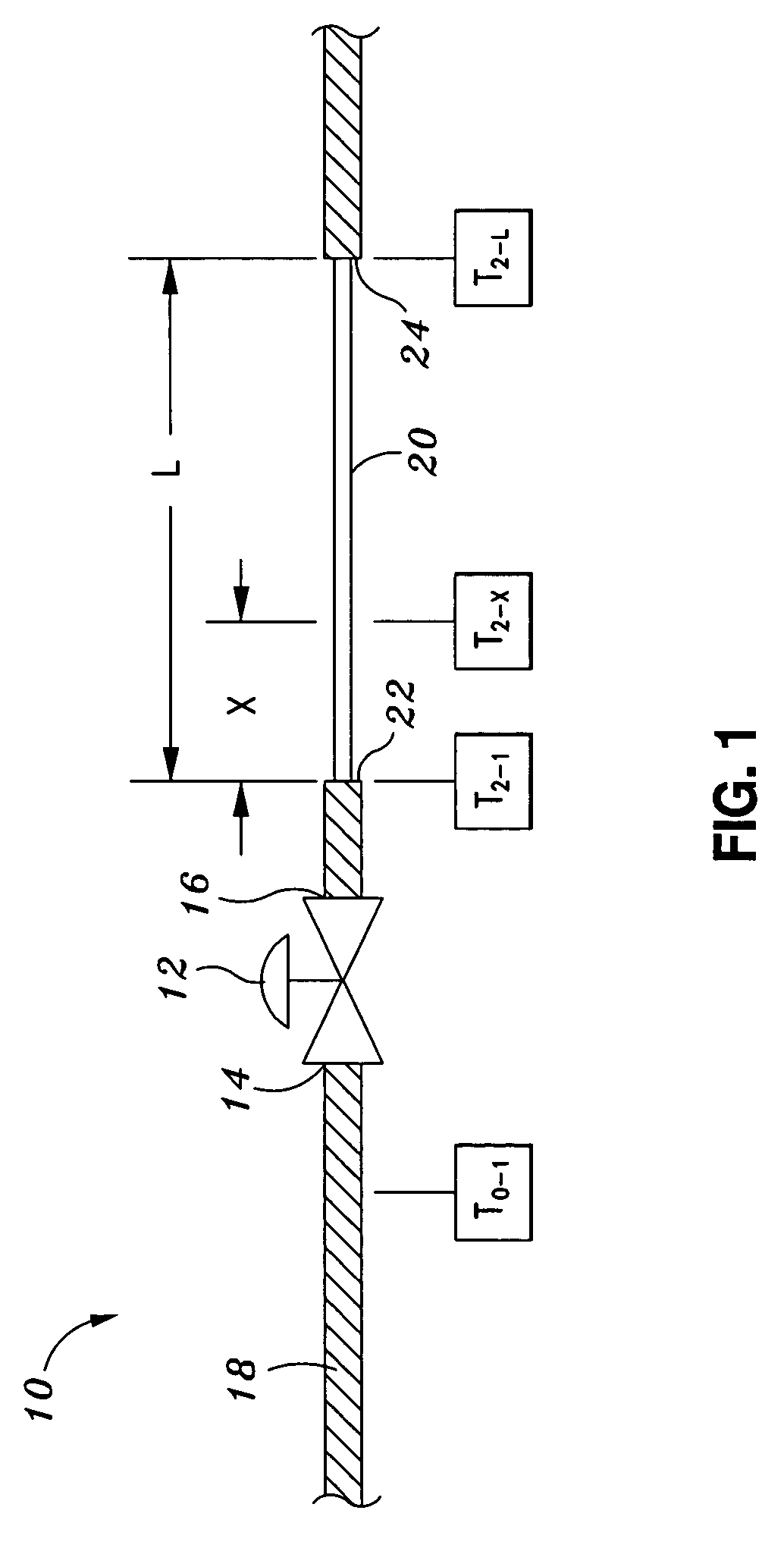

Method of determining valve leakage based on upstream and downstream temperature measurements

Disclosed is a method for measuring leakage flow rate of a valve wherein fluid flows through the valve in a single-phase flow of a gas or steam. The underlying principle upon which the leakage flow rate may be determined is that the heat loss across a length of bare pipe located downstream of the valve causes a decrease in the temperature of the leakage flow. Also disclosed is a method for measuring the leakage flow rate when the fluid passing through the valve transitions from a liquid-phase flow into a two-phase flow of liquid and steam. In two-phase flow, the underlying principle upon which the leakage flow rate may be determined is that any leakage of the valve will cause an increase in the pressure on the downstream side of the valve because of frictional resistance to flow in the downstream piping which corresponds to an increase in temperature thereof.

Owner:IMI VISION LTD

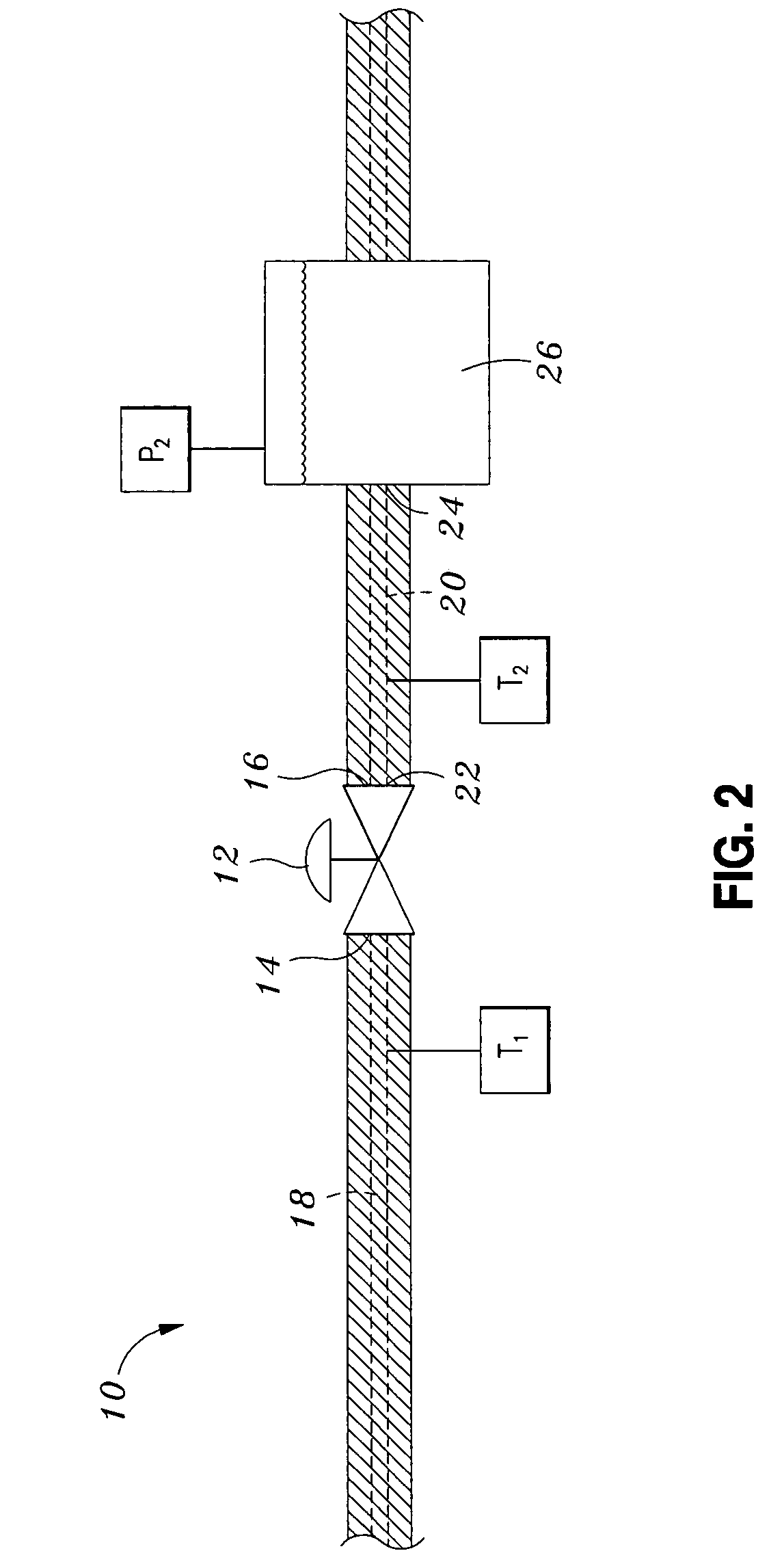

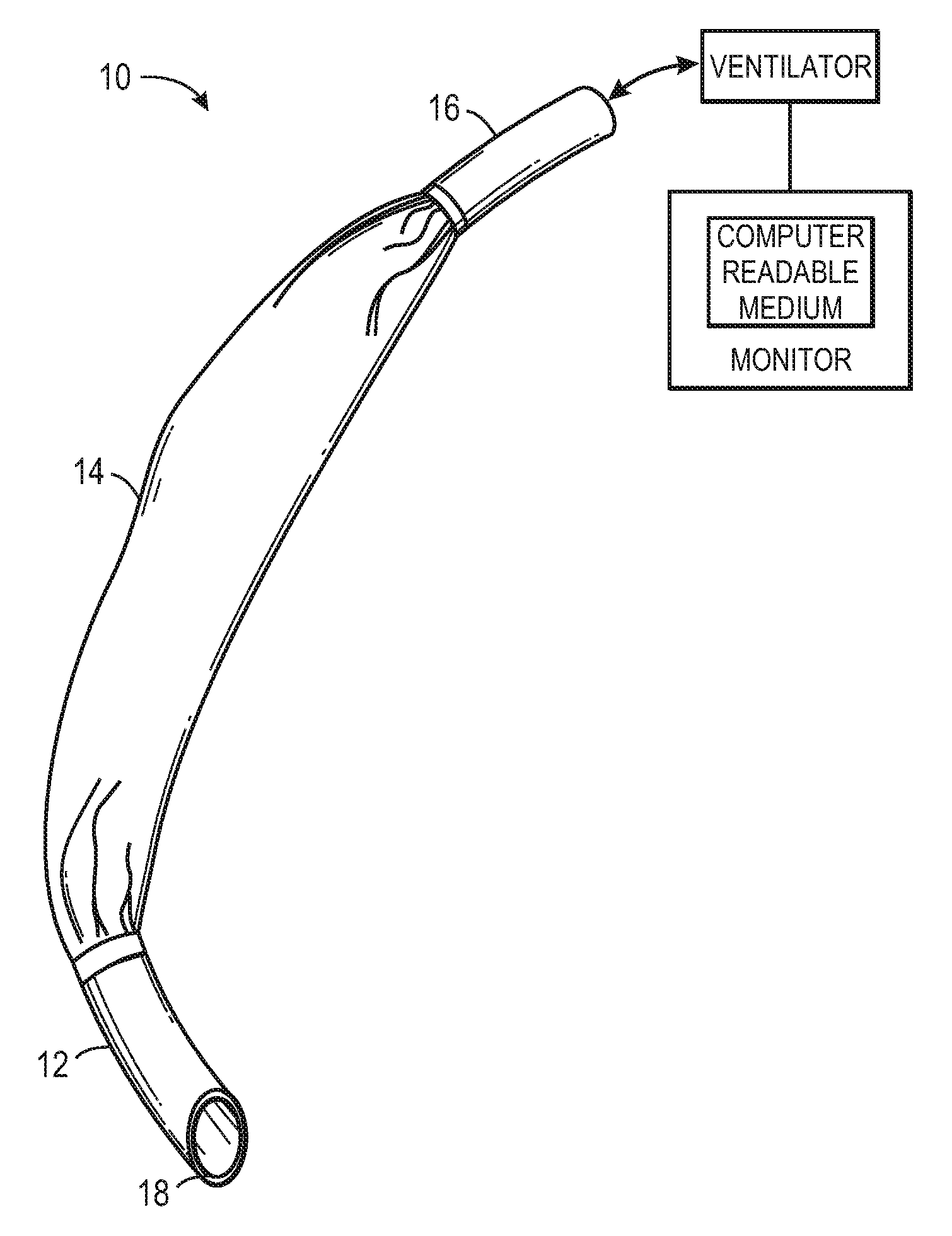

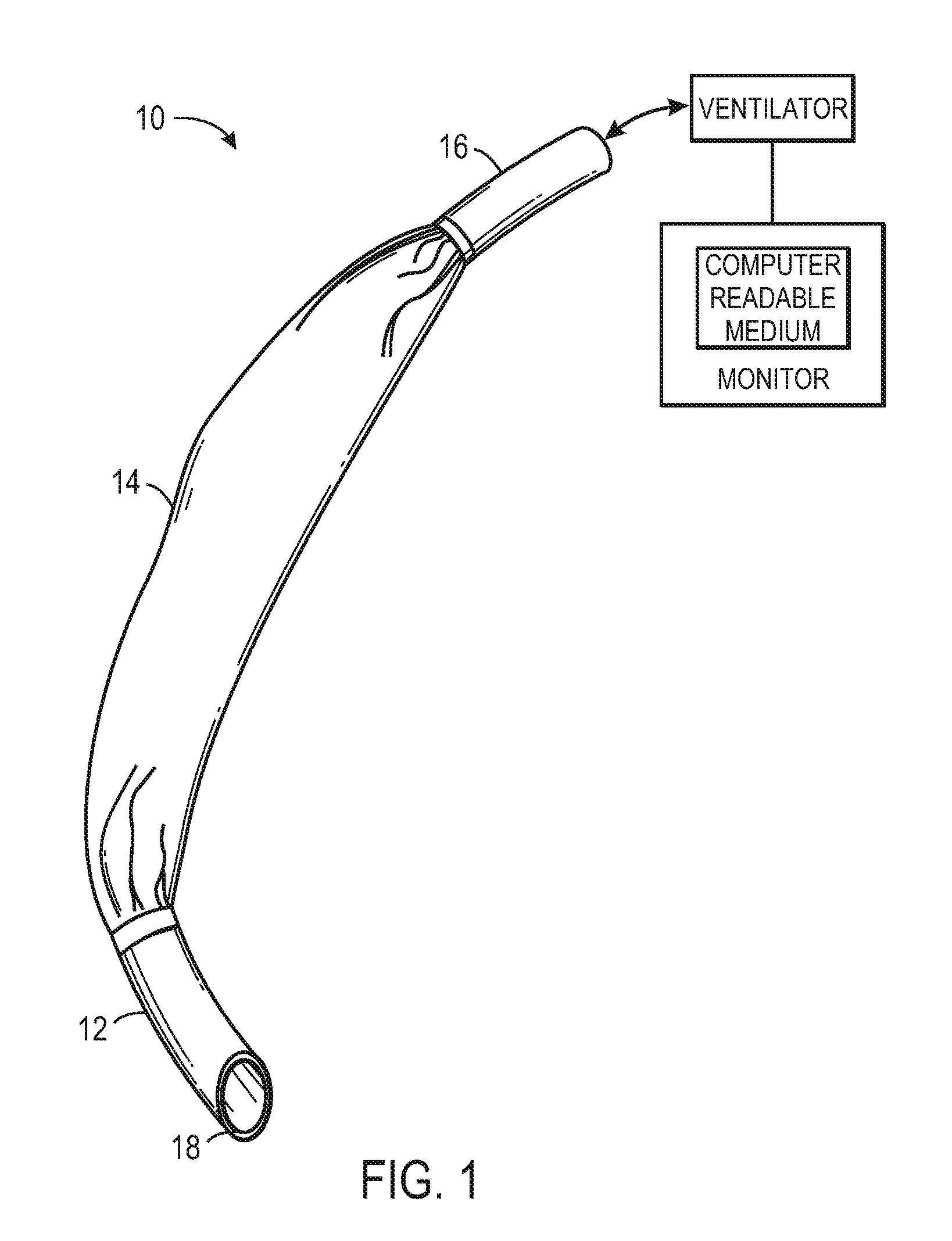

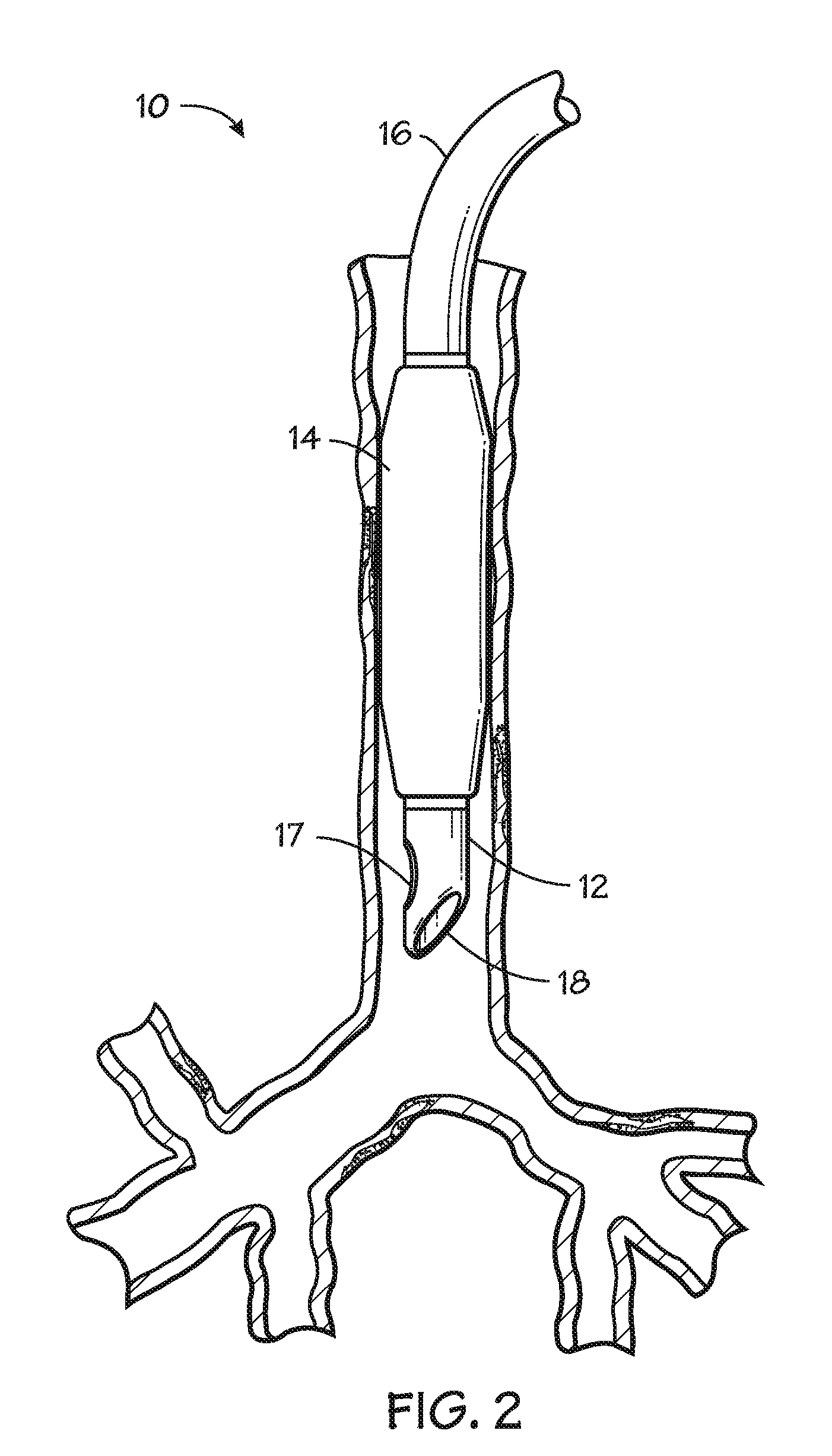

Self-sizing adjustable endotracheal tube

ActiveUS20100313896A1Decreased pressureIncreased pressureTracheal tubesMedical devicesWork of breathingTracheal tube

There is disclosed an endotracheal tube which has a minimal cross-sectional profile for easy viewing of anatomical features during intubation. After the tube is placed into the trachea, the tube is adapted to increase the diameter. In this manner the tube diameter may be expanded to allow for decreased Work of Breathing (WOB) for patient, while not having so large a diameter as to cause tracheal discomfort.

Owner:TYCO HEALTHCARE GRP LP

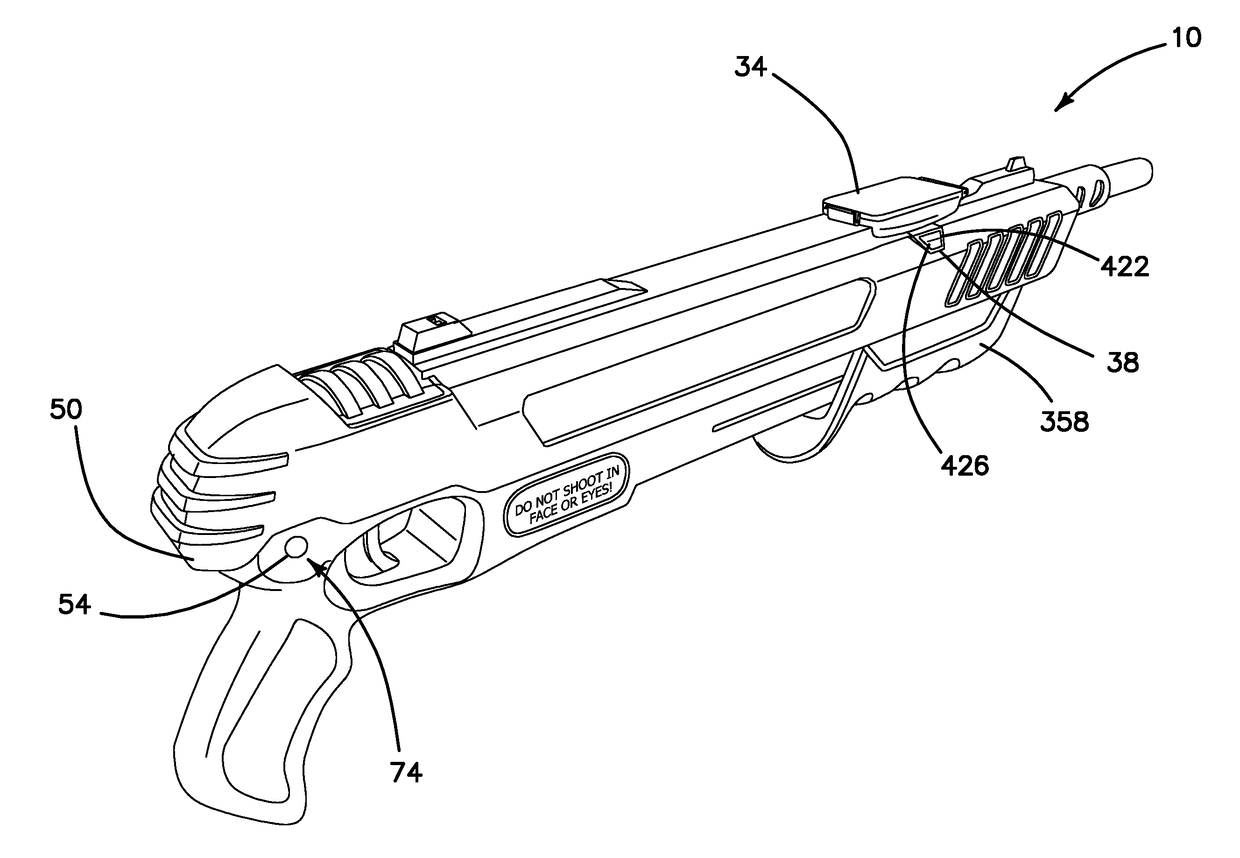

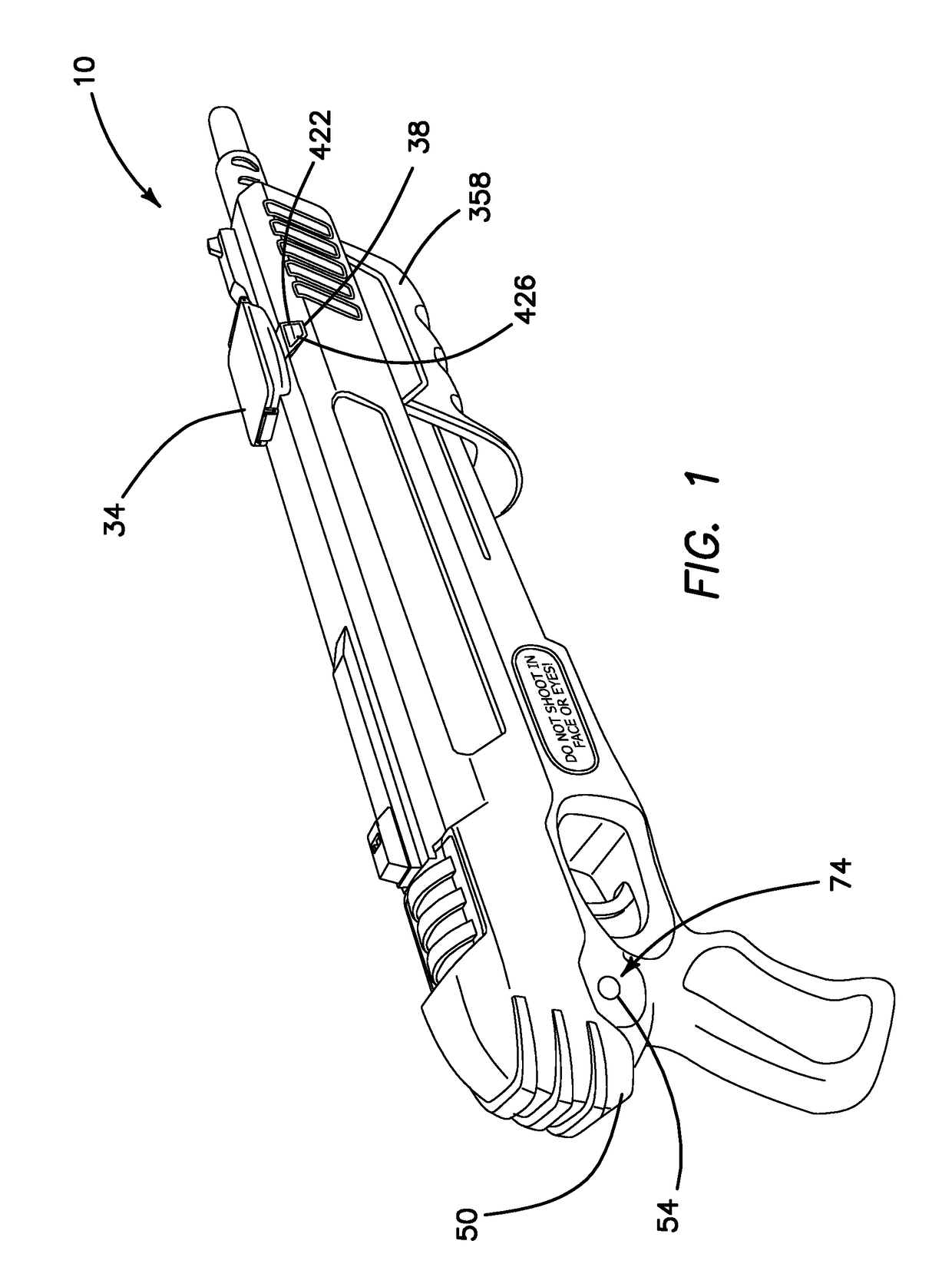

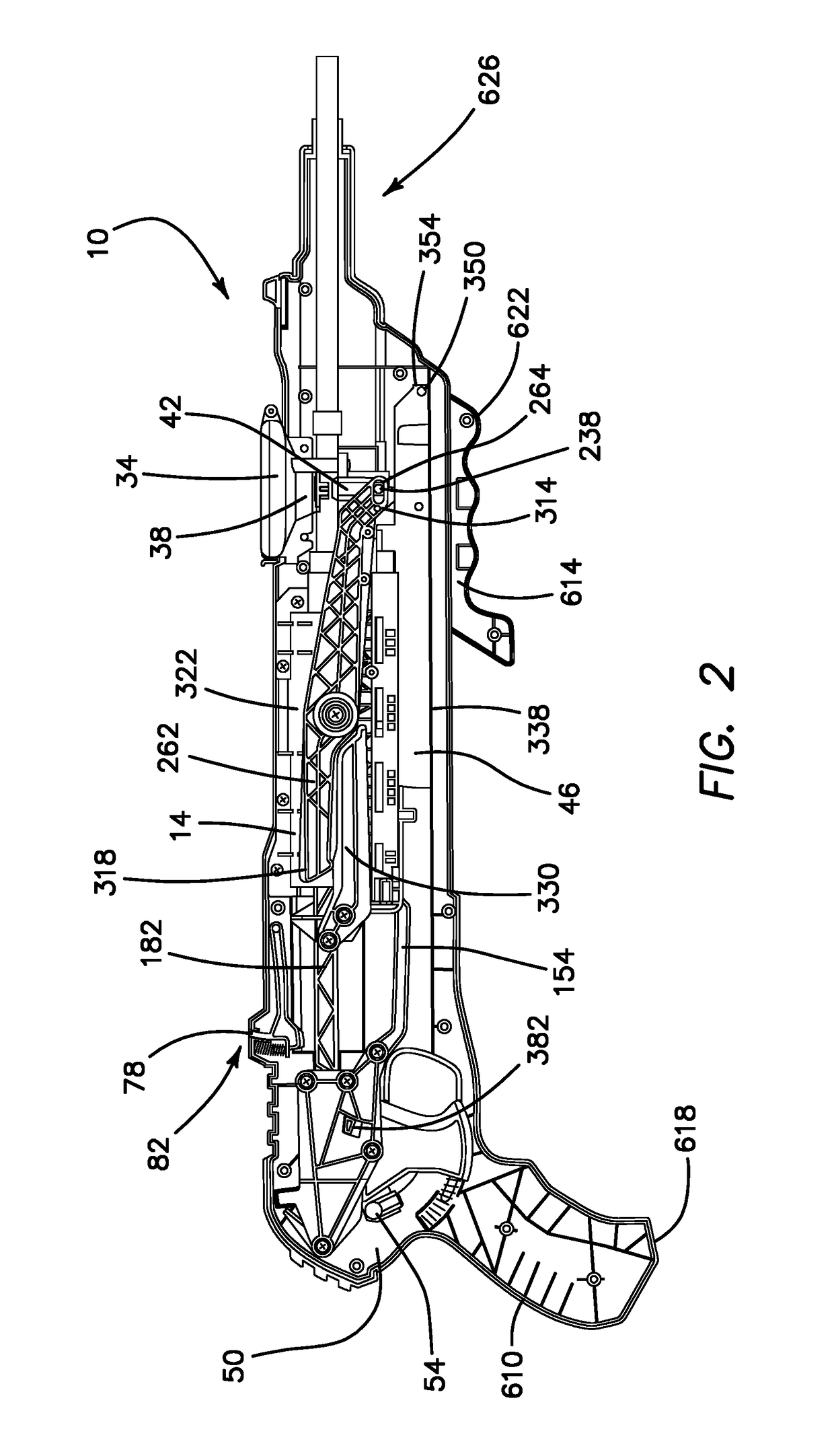

Compact improved bug killing gun

ActiveUS20180335271A1Increase forceIncreased pressureProjectileSafety arrangementEngineeringProjectile

A compact improved bug killing gun includes a compressed gas source fluidly connected to a chamber connected to a barrel. A compressed gas release mechanism is connected to the compressed gas source. A projectile storage magazine stores particulate projectiles and is located adjacent the chamber. A projectile loading mechanism moves the projectiles into the chamber from the magazine. A cocking mechanism is mechanically connected to the compressed gas source, the compressed gas release mechanism, and the projectile loading mechanism. When the gun is cocked, the projectile loading mechanism loads a quantity of the particulate projectiles into the chamber. When the compressed gas release mechanism is activated the projectiles are ejected from the chamber into the barrel and expelled from the gun. The gun optionally includes a laser sighting mechanism. The battery operated laser sighting mechanism is removably attached to the barrel or permanently attached with an integral, trigger operated switch.

Owner:MAGGIORE LOREN

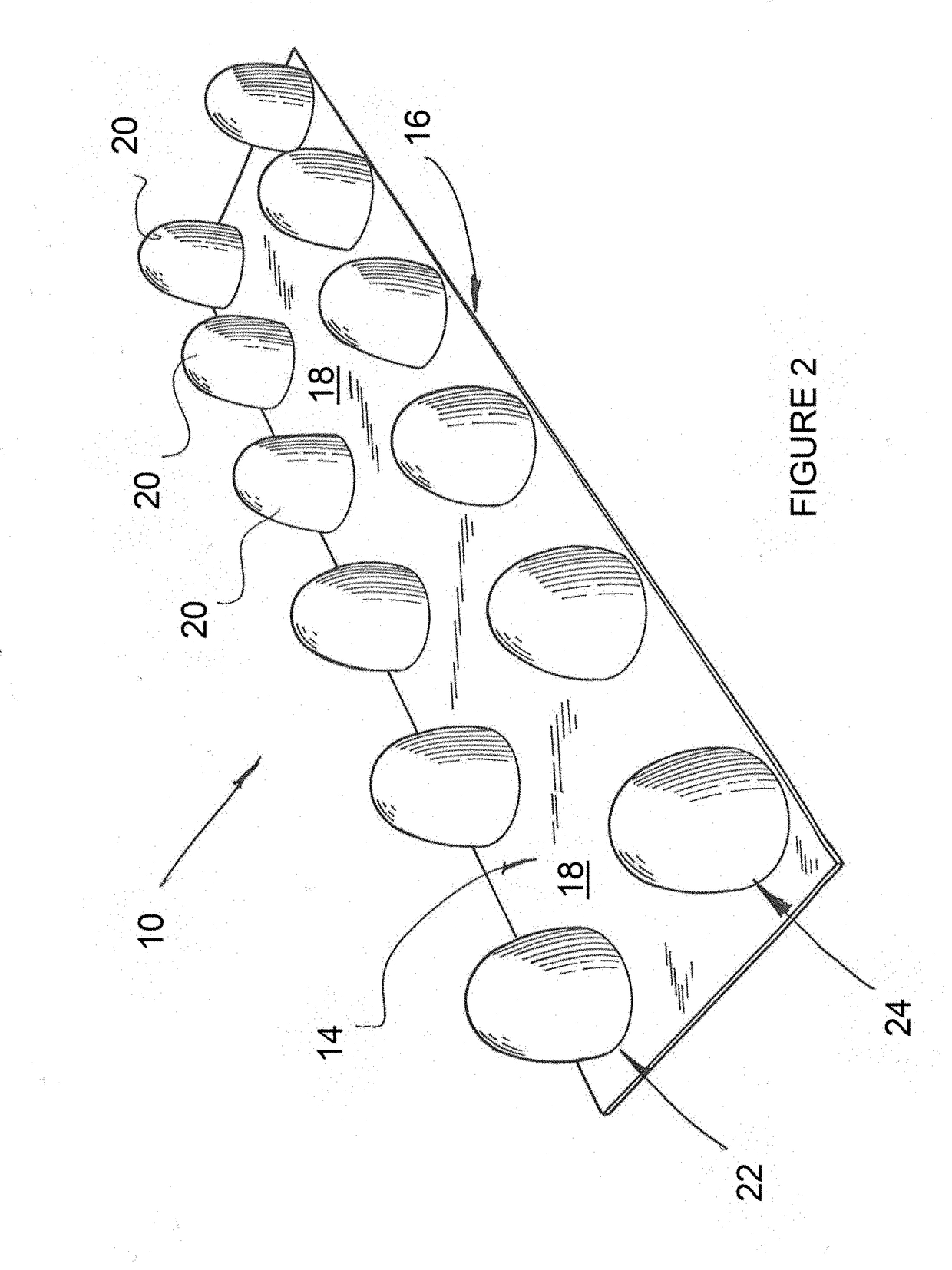

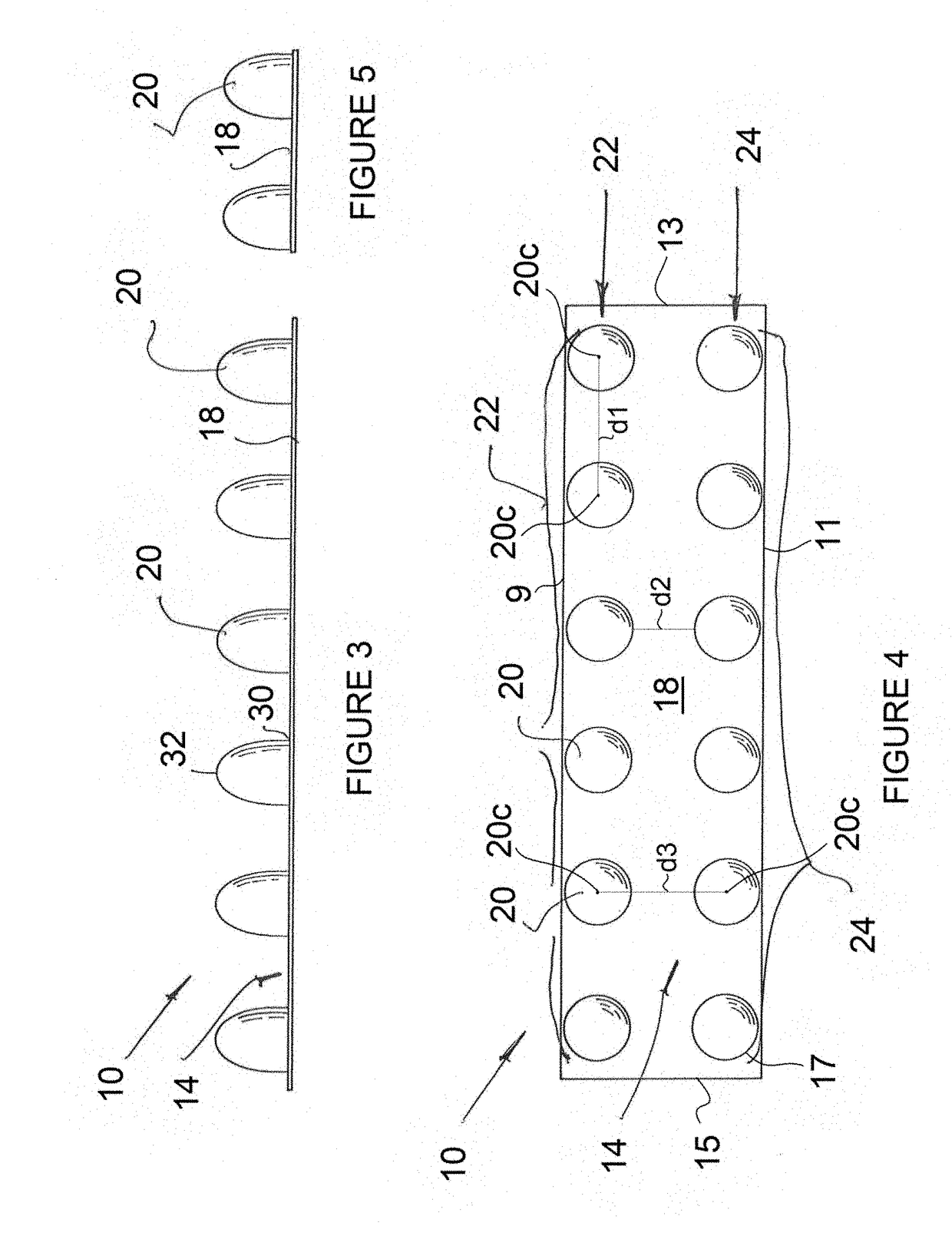

Massage device and method of use thereof

InactiveUS20190046395A1Increased pressureSmall cross-sectional areaDevices for pressing relfex pointsRoller massageMassageVertebral column

A massage device is disclosed comprising a base having a mounting surface and an opposed massage formation surface and first and second rows of massage formations extending along the base. The first and second rows of massage formations extend parallel to each other and are laterally spaced a distance apart from each other so that they engage muscle groups on either side of the vertebral column. Each of the first and second rows may conveniently have five to seven massage formations. The disclosure extends to a method of massaging a part of a person, e.g. their back, using the massage device.

Owner:ROUTLEDGE RAYMOND THOMAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com