Rotational ducted fan (RDF) propulsion system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

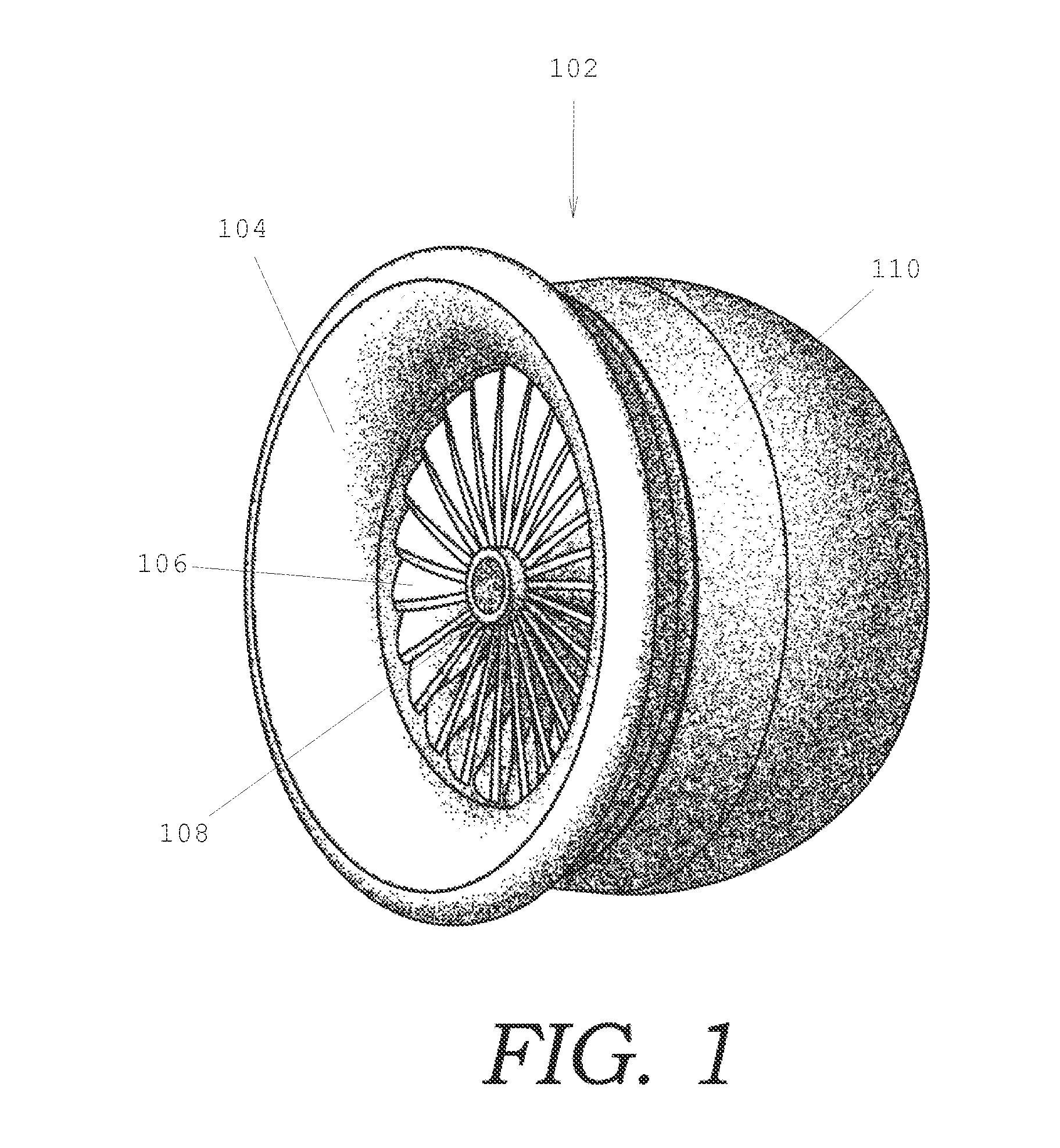

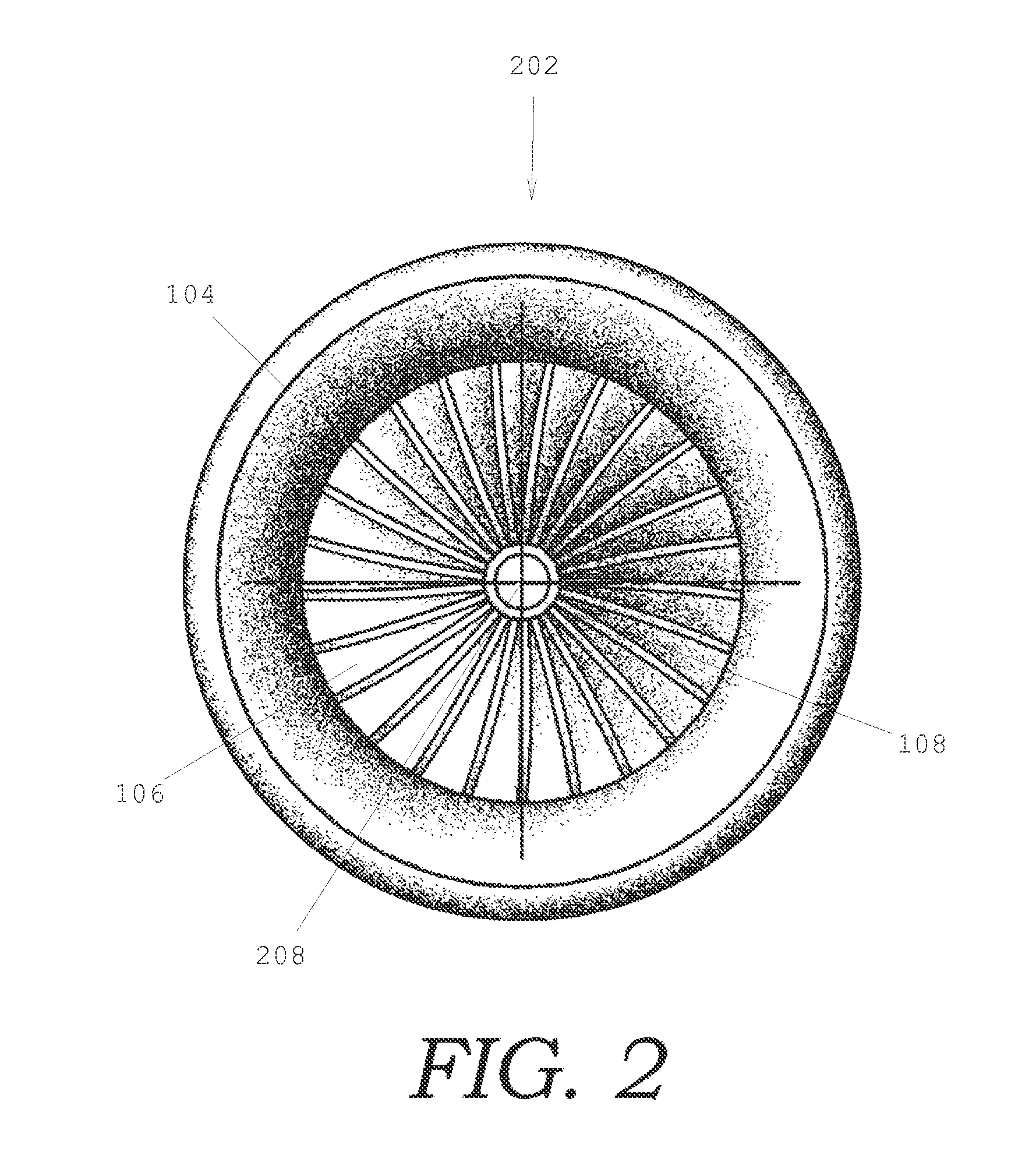

[0064]FIG. 1 is a perspective view of a rotational ducted fan motor. Referring more particularly to the drawings, embodiments of the disclosure may be described in the context of an aircraft propulsion system. The embodiment shown in FIG. 1 comprises a static non-rotating aft duct 110, and a rotational ducted fan 202. The rotational ducted fan is described as a dynamic rotor that rotates about an axis parallels to its thrust, and is comprised of an outer shroud or duct that is dynamic and rotates orbitally about a center axis that is parallel to its generally cylindrical shape, and concentric to a center hub and an arrangement of a plurality of propeller blades or airfoils axially perpendicular to the axis of rotation. The rotational ducted fan or orbital fan duct is comprised of a cylinder that has a plurality of propeller blades affixed axially at their substantially larger diameter or blade tip to the inner surface of an approximately cylindrically shaped duct. There may be a cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com