Patents

Literature

35results about How to "Increase steam pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

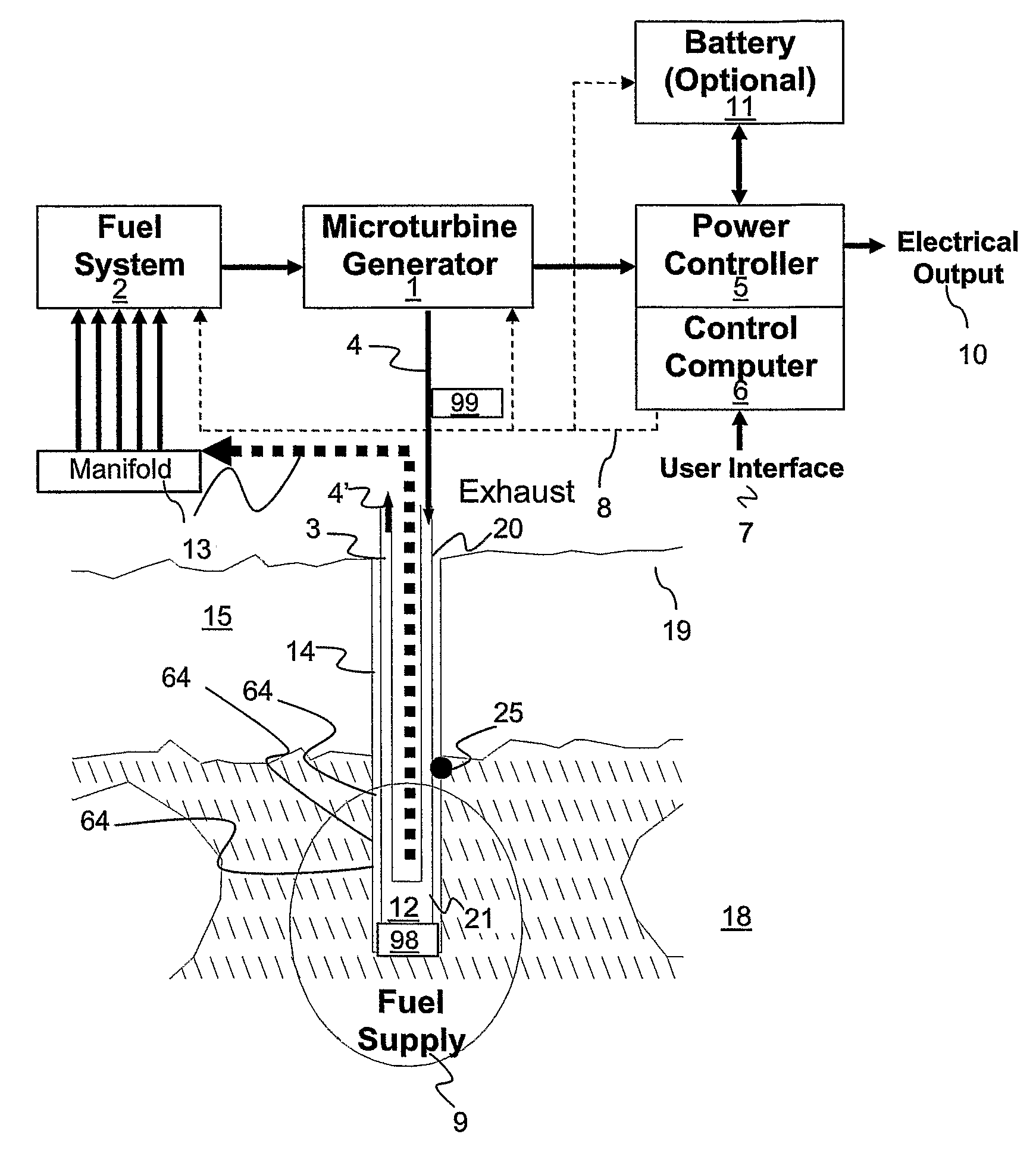

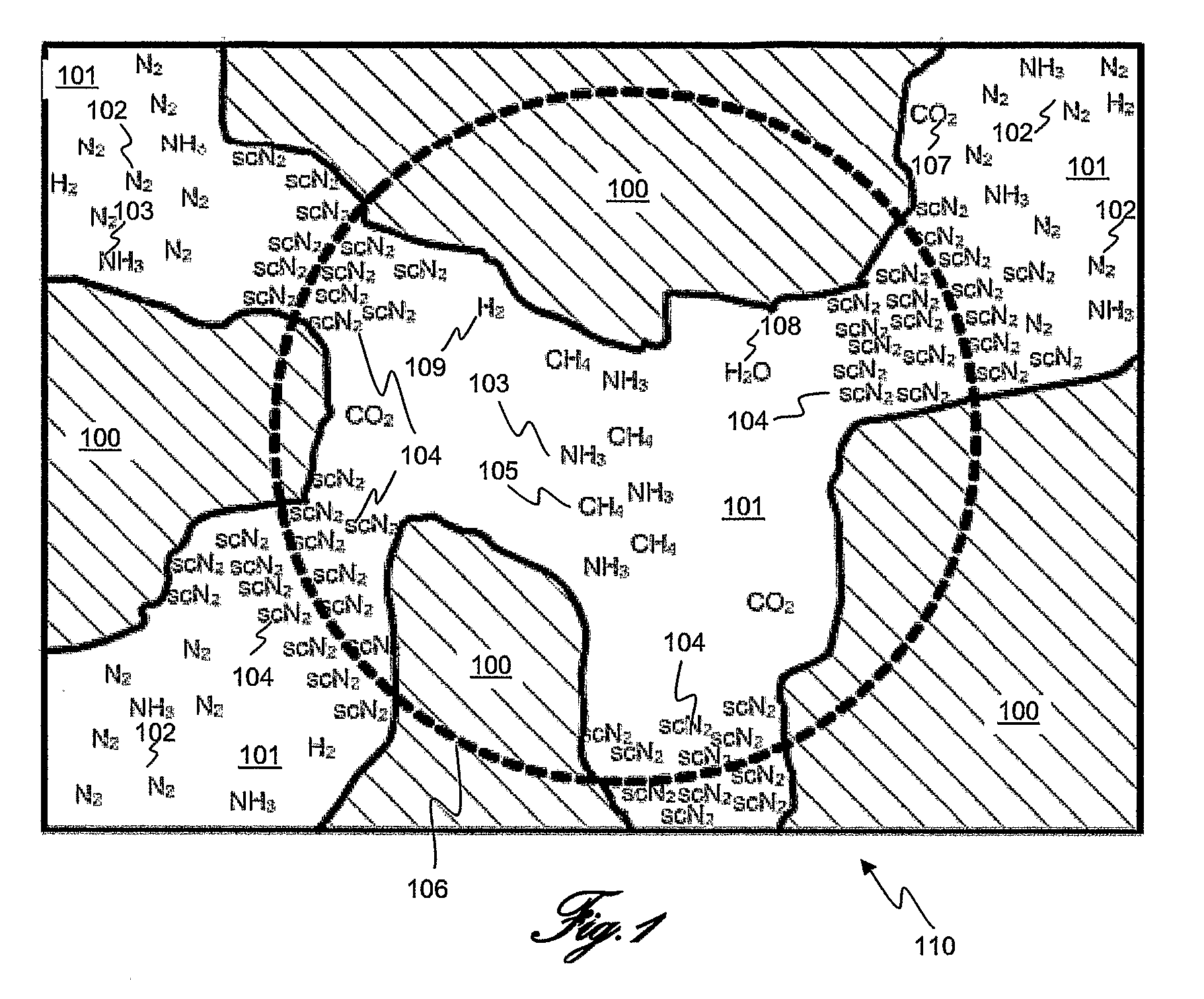

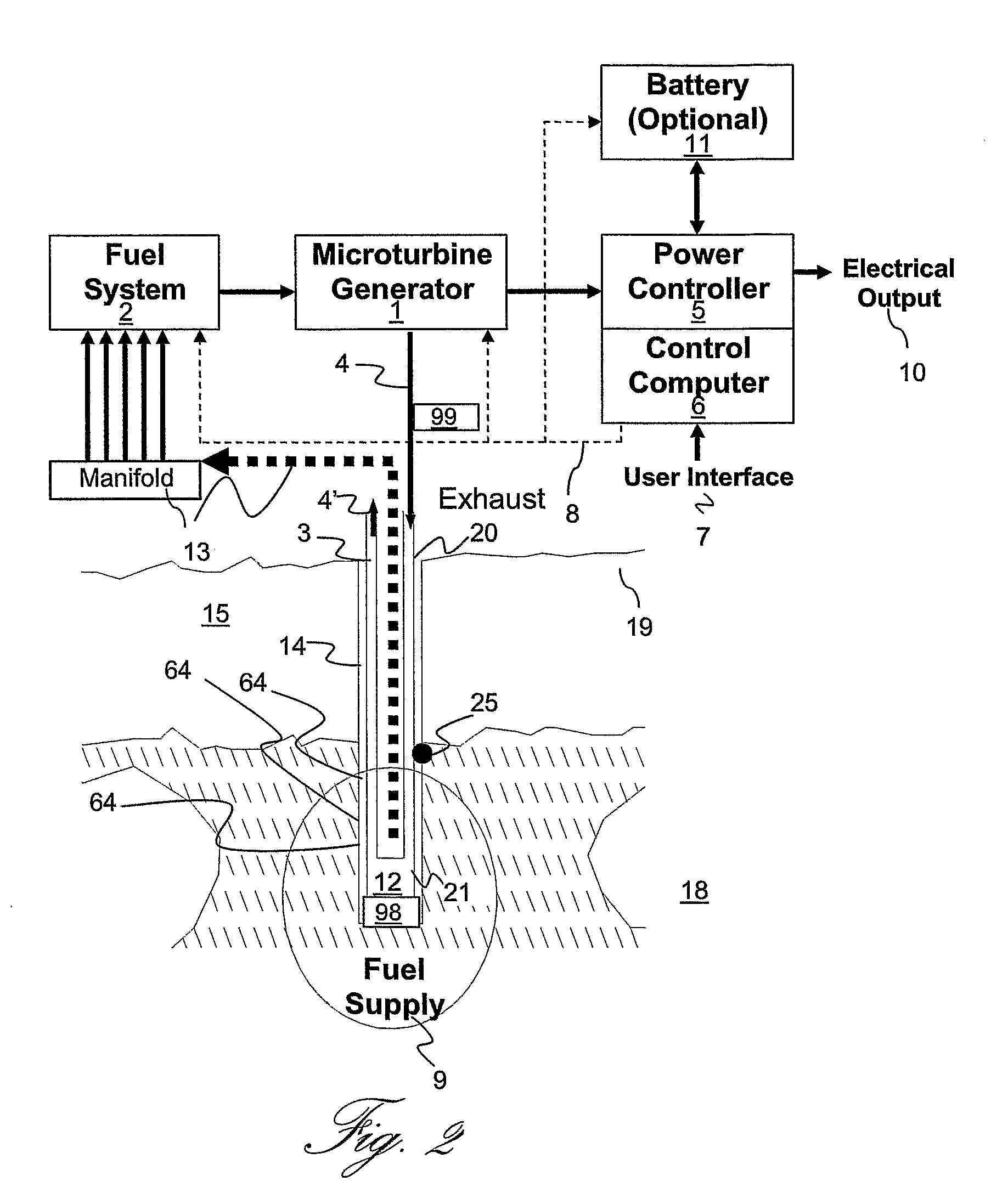

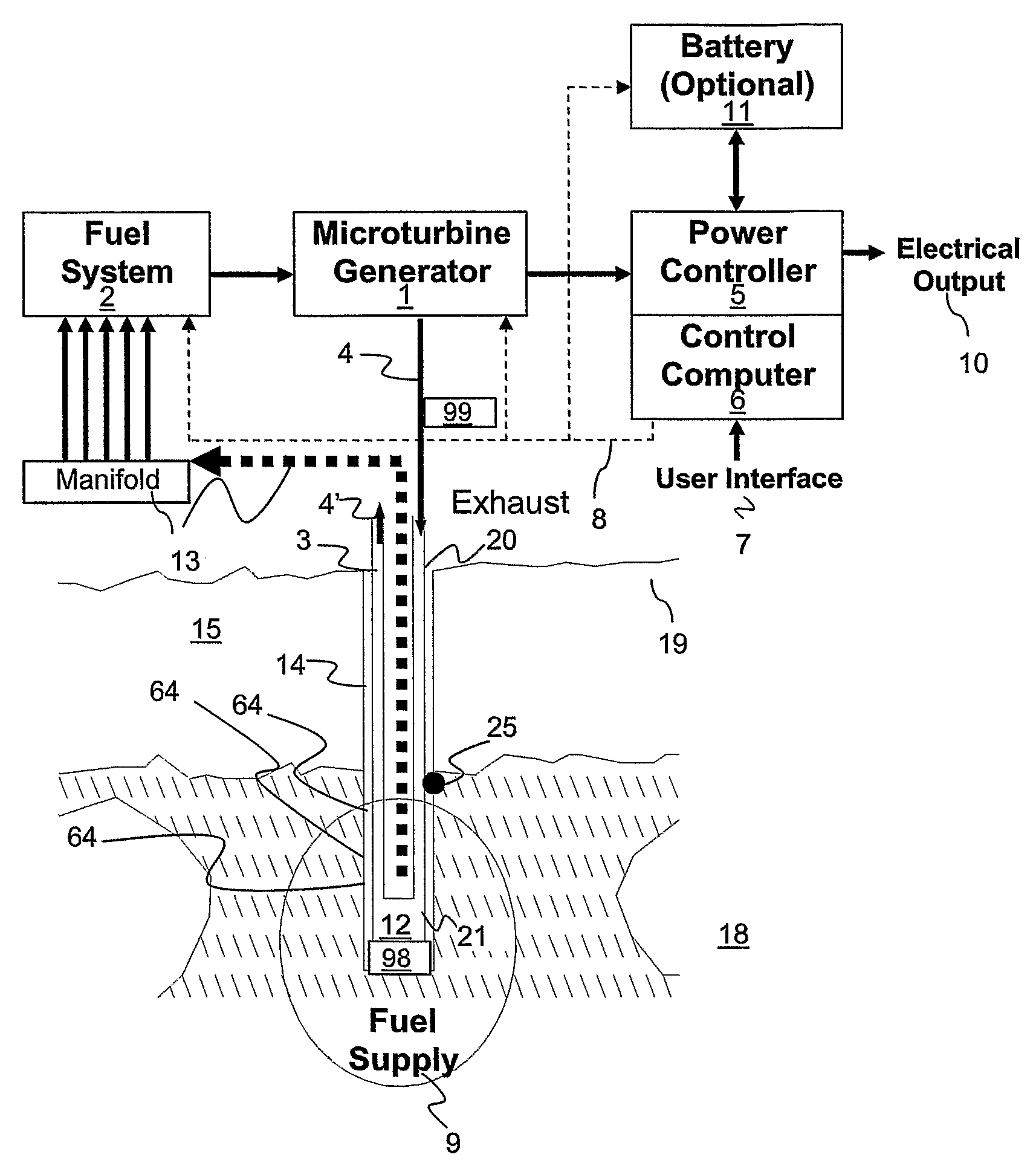

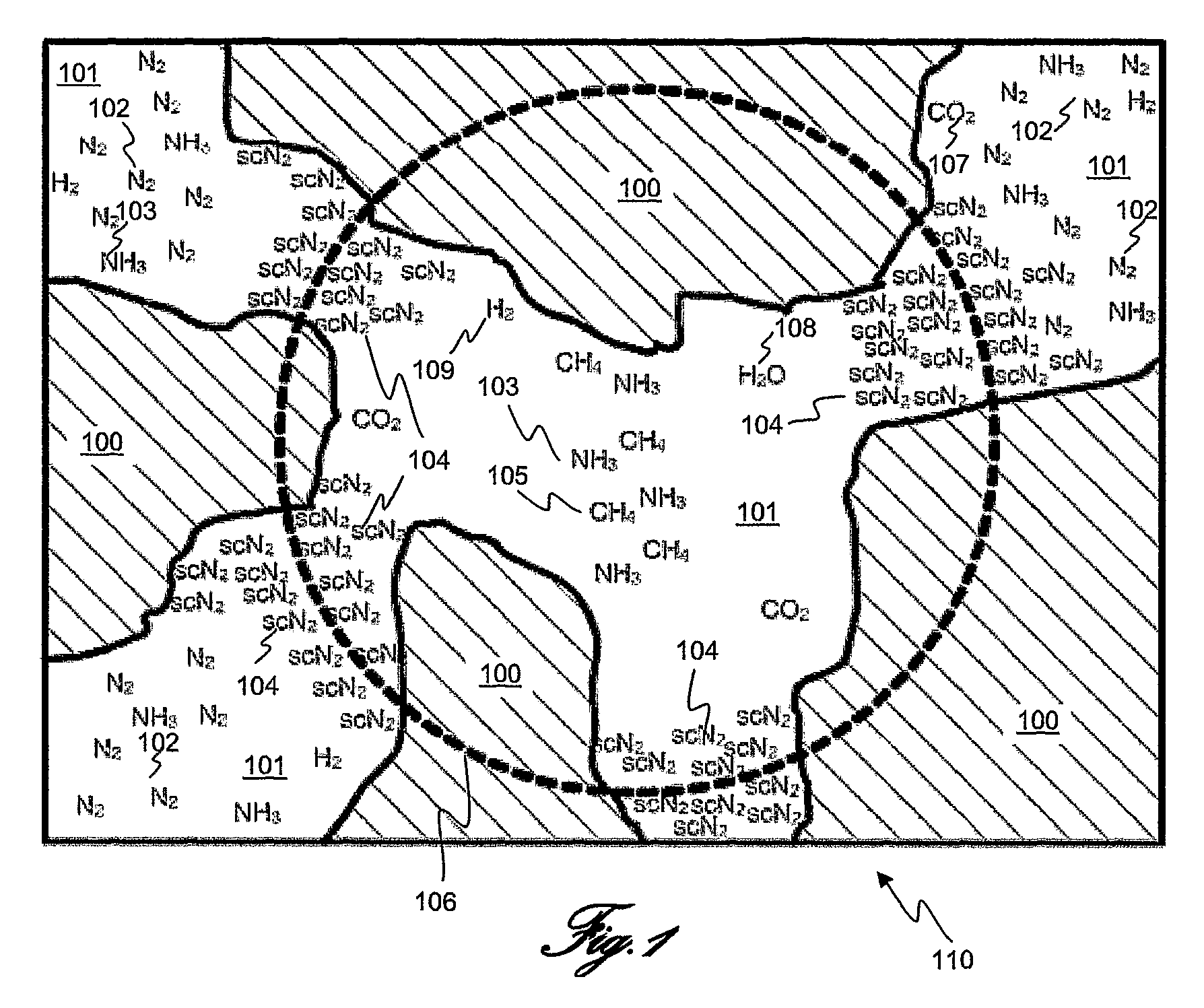

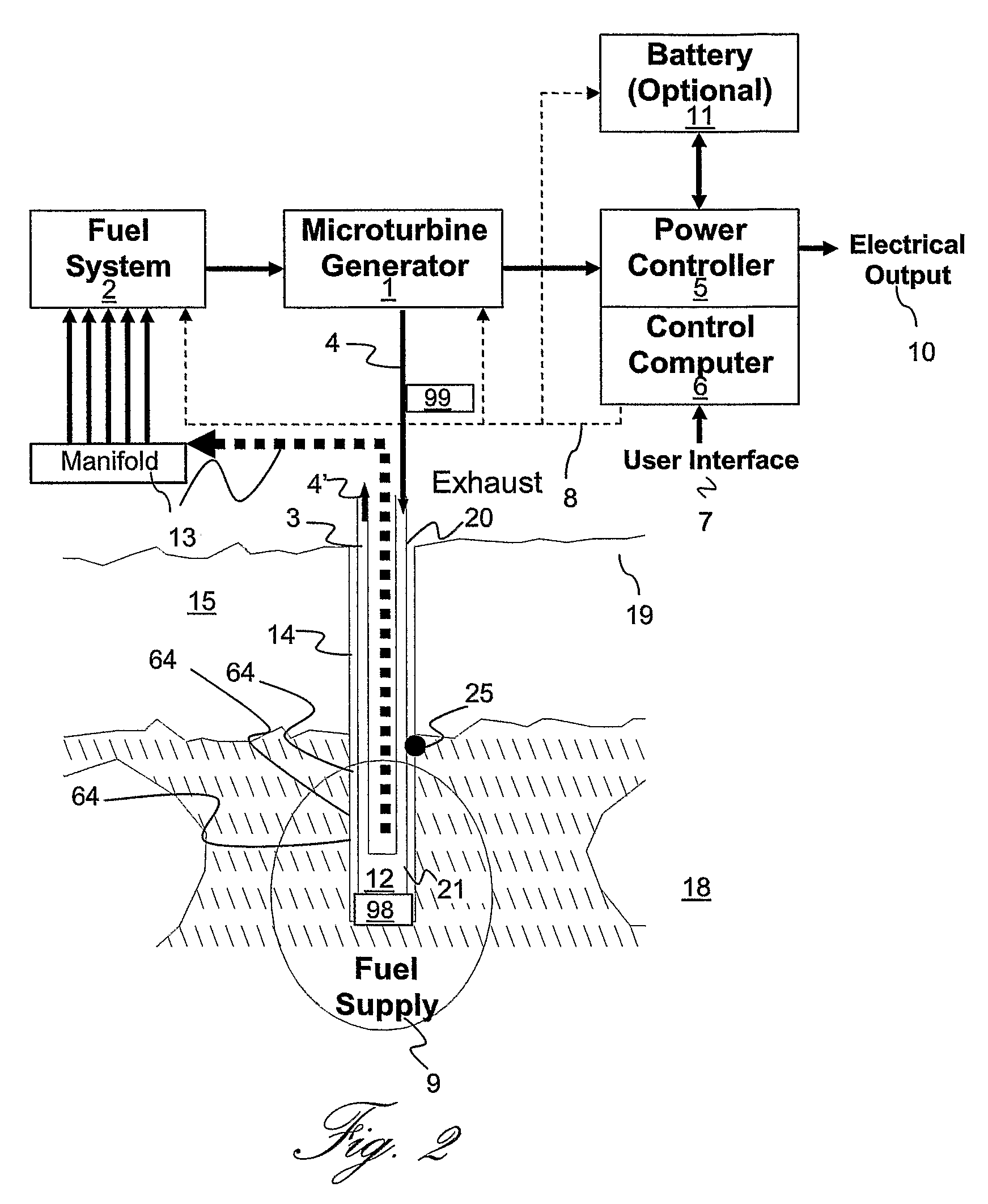

Supercritical fluid recovery and refining of hydrocarbons from hydrocarbon-bearing formations applying fuel cell gas in situ

ActiveUS20100163226A1Increase steam pressureIncreased pressureInsulationFluid removalTarHydrogen compounds

A plume of combined gases are infused into hydrocarbon-bearing formations, “inert” as the major gas and “reactive” as the minor gas, where the minor gas reacts with hydrocarbons to fully saturate hydrocarbons with supercritical fluid, which migrate hydrocarbons out of formations, even at great distances from the regulated fuel cell source. Coal, tar sands, petroleum-contaminated soil, and / or oil wells that have lost gas pressure can also be desorbed by this in-situ method.

Owner:CRITICAL POINT ENERGY

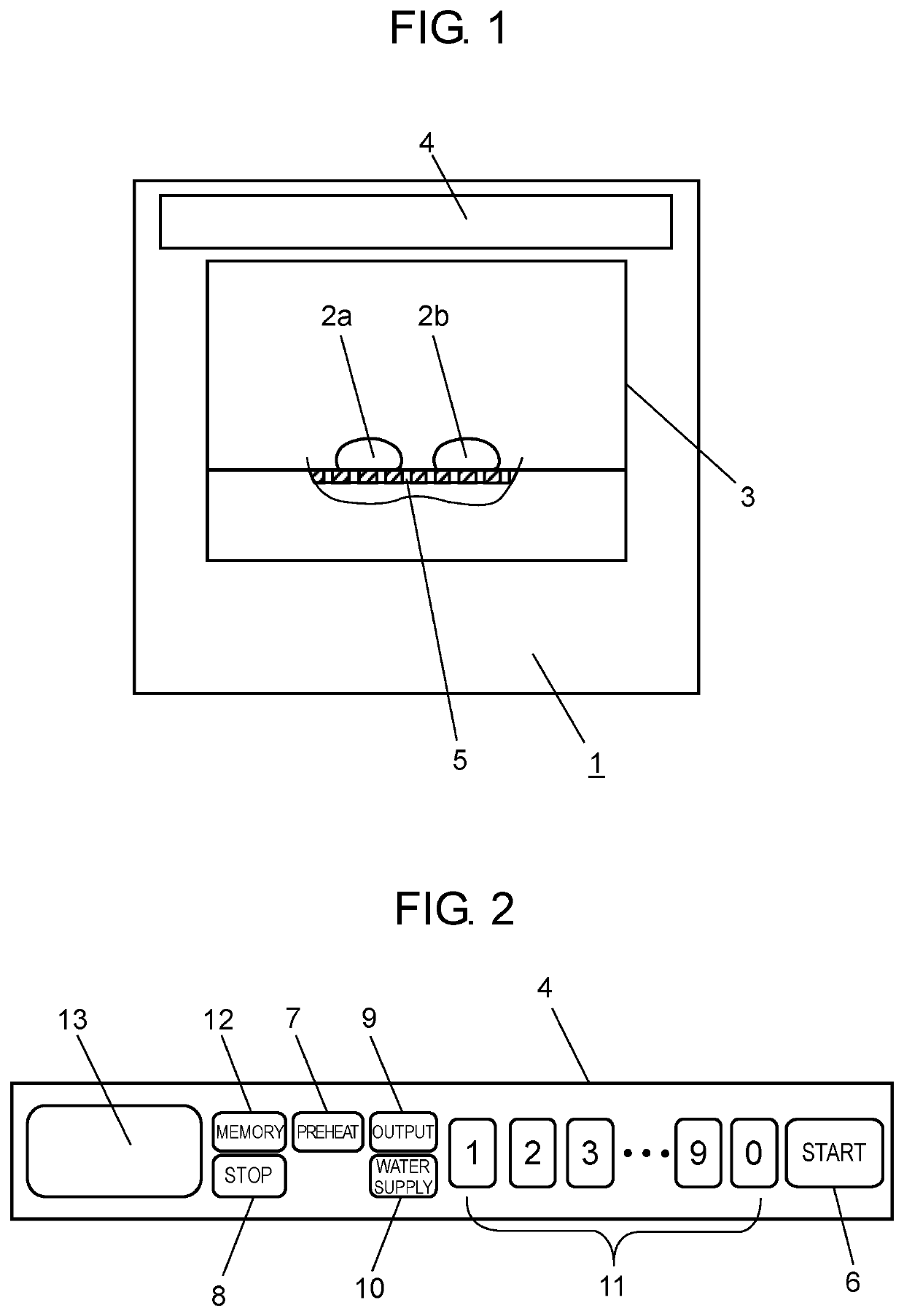

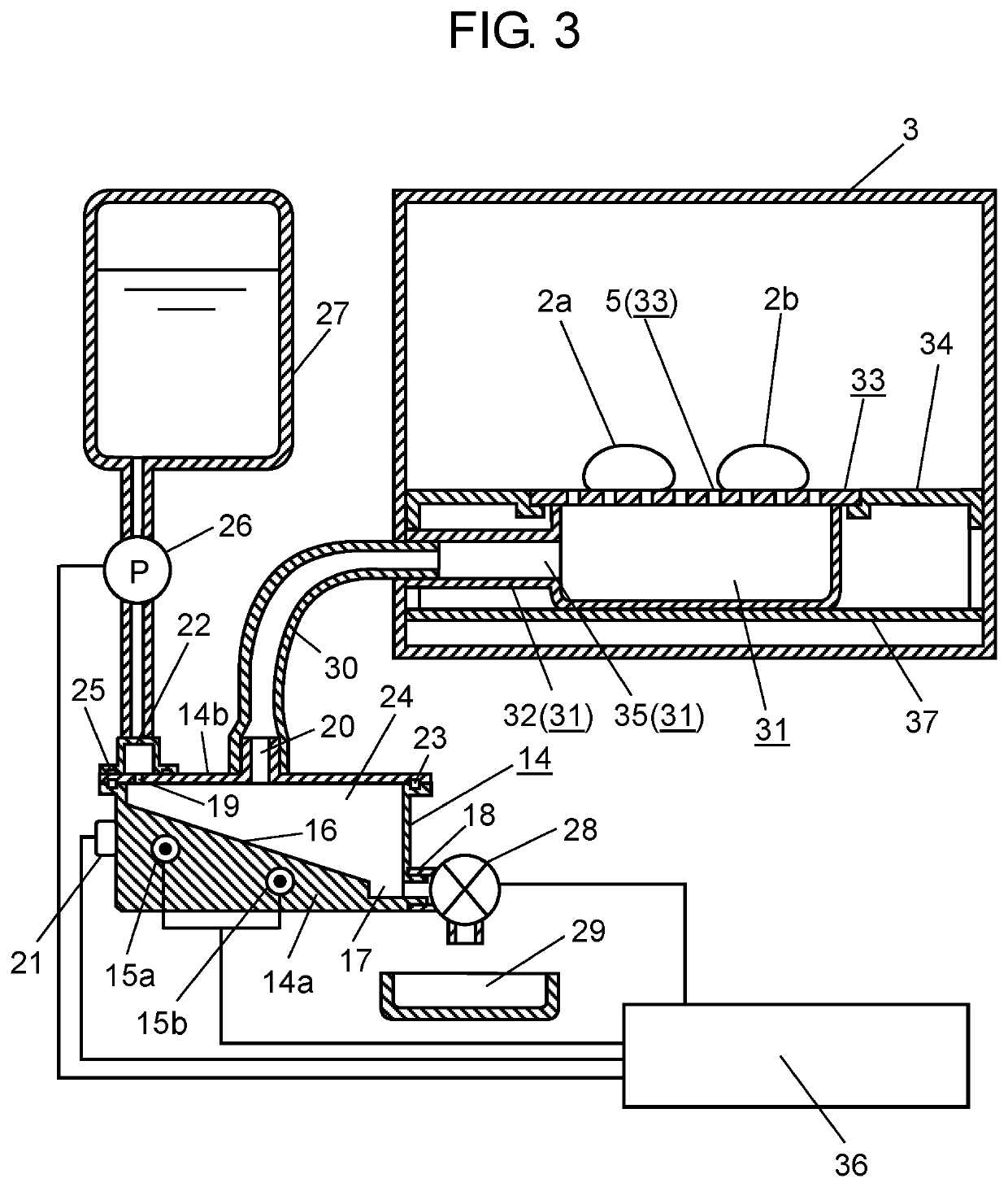

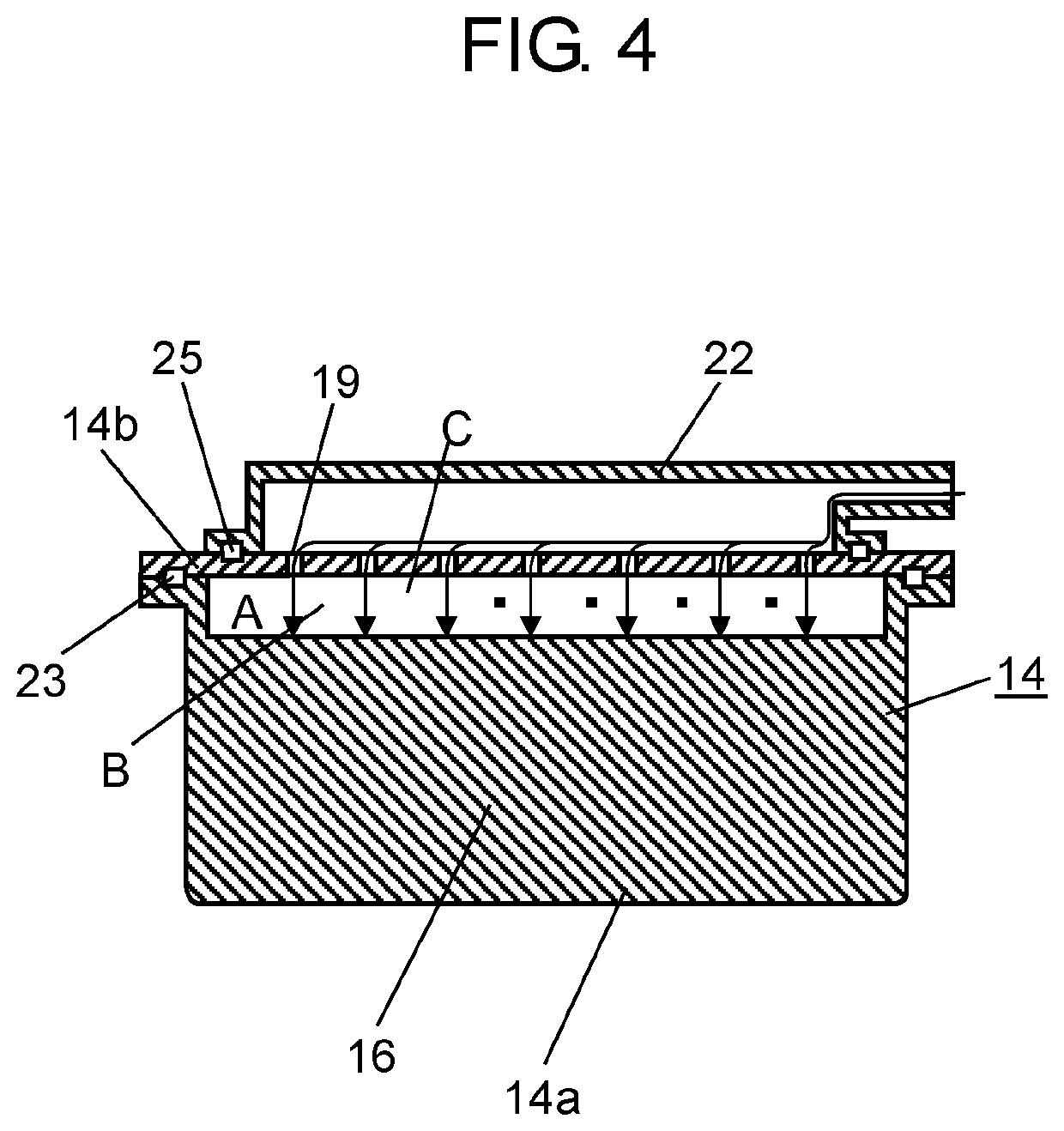

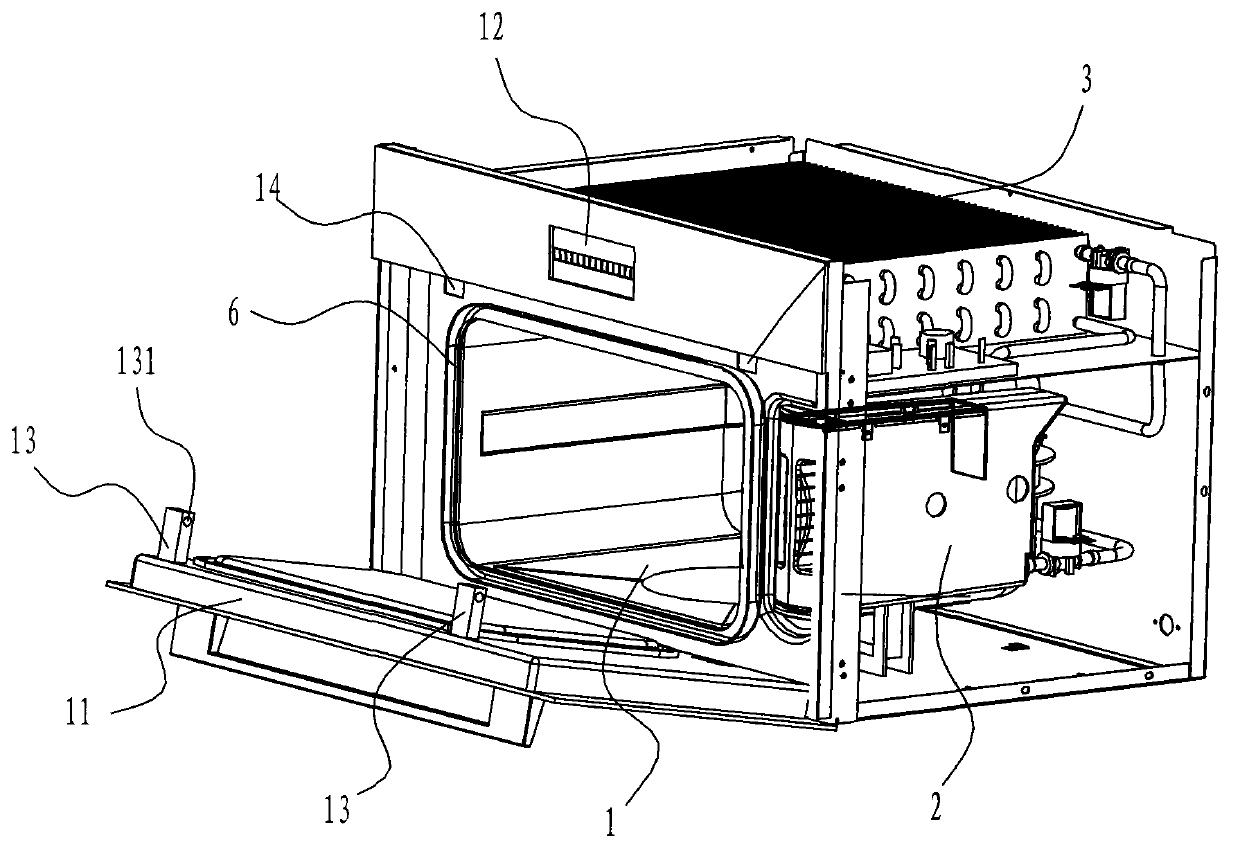

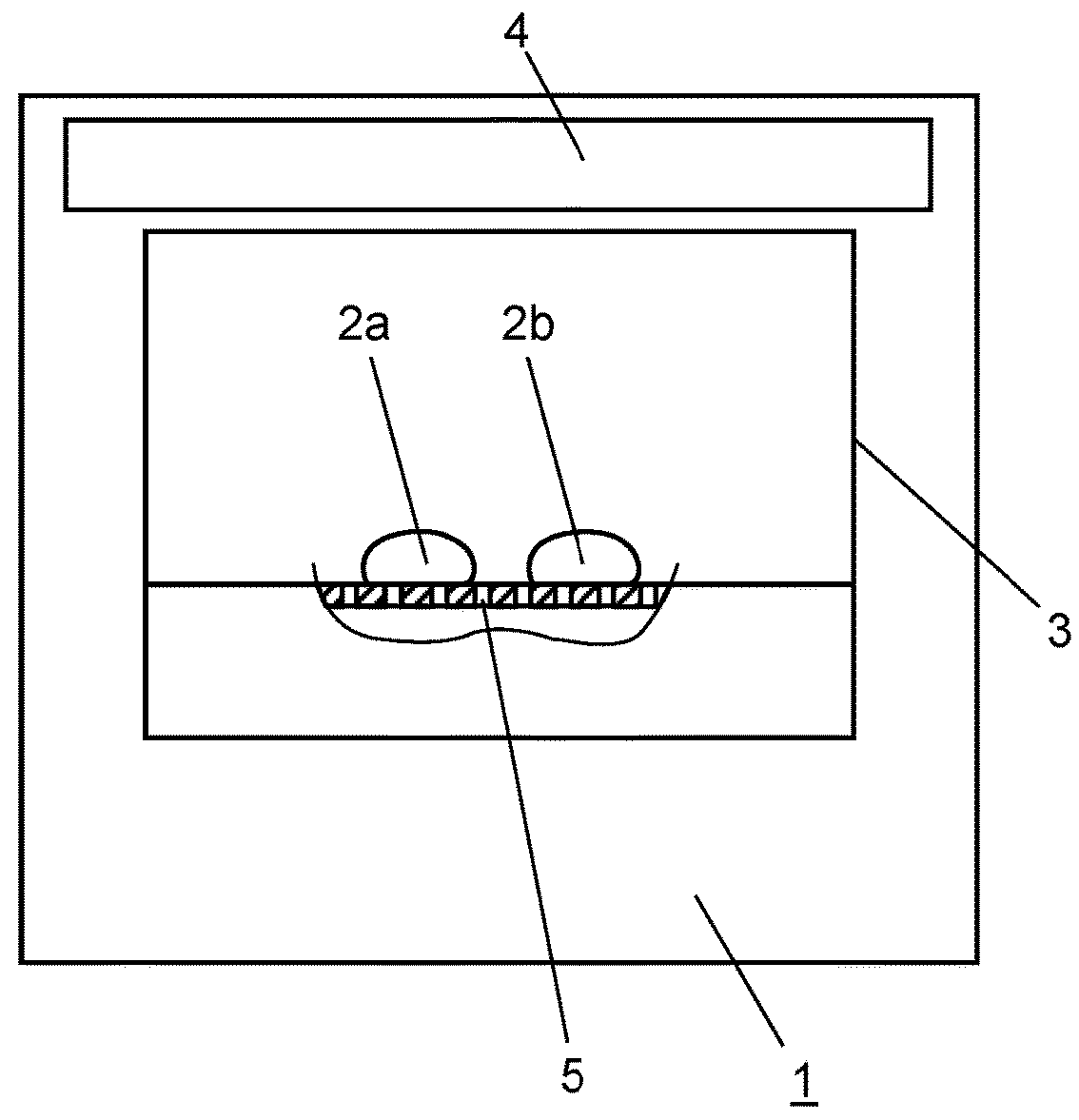

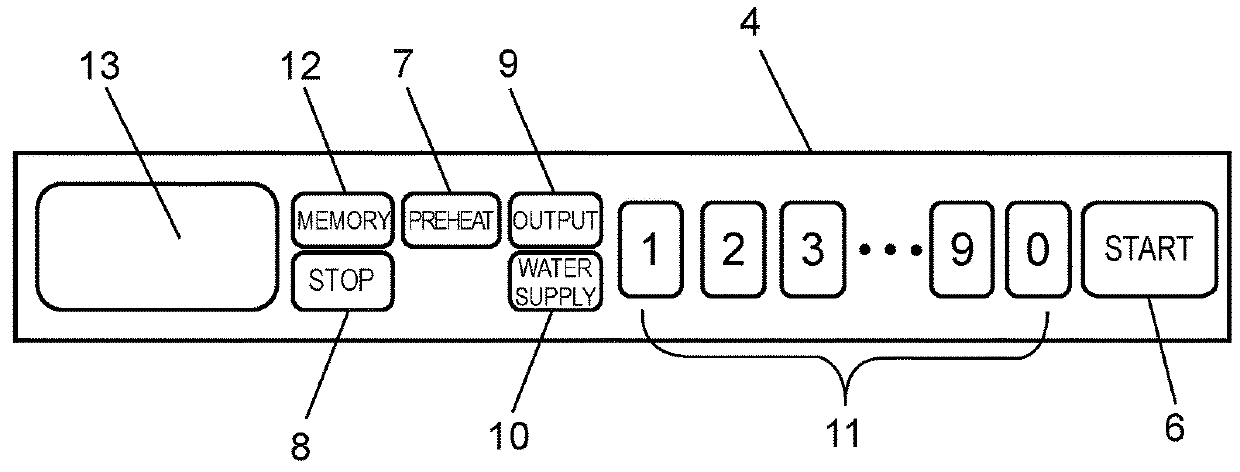

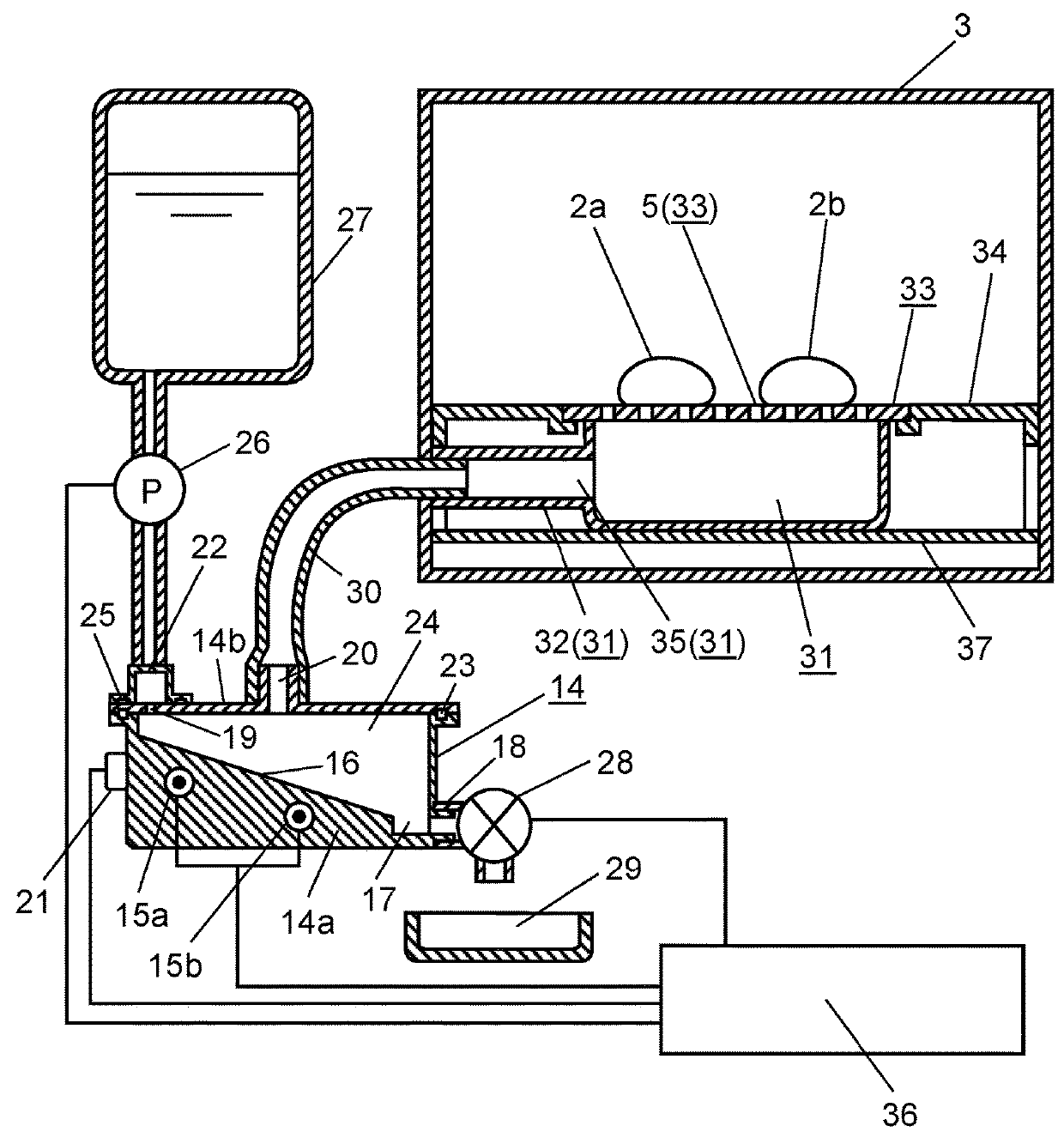

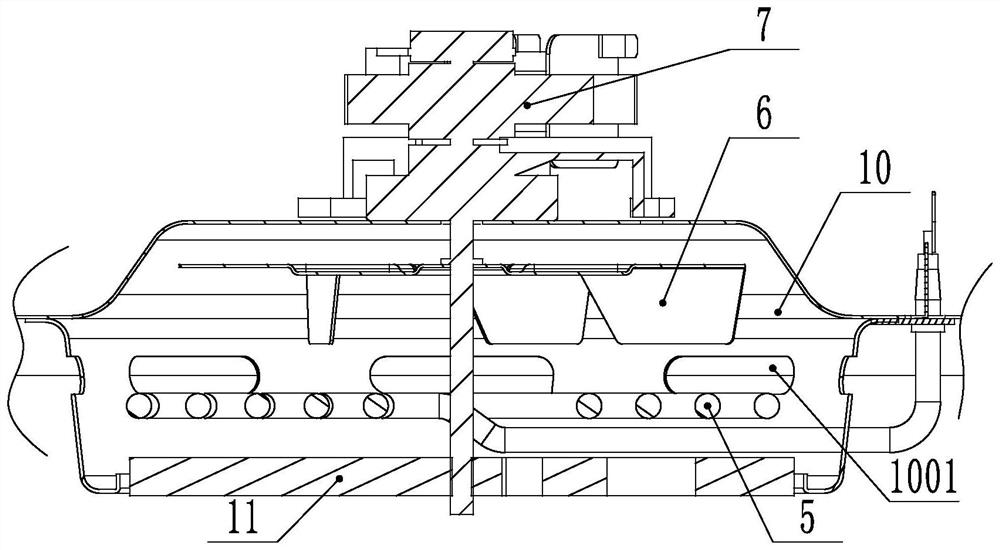

Heating cooker

ActiveUS10638869B2Shorten the timeGreat effortDomestic stoves or rangesLighting and heating apparatusThermodynamicsSteam pressure

By preheating temperature raising unit of a steam and hot water generating device beforehand to a predetermined temperature, and supplying water in an amount equal to or more than predetermined amount V (per unit time) to the temperature raising unit, a large amount of steam is instantaneously generated. At this time, hot water adhered to the temperature raising unit rises along with the steam, and the steam and hot water flowed through a steam hole, a relay tube, and a steam chamber are caused to eject instantaneously with accumulated steam pressure from a steam and hot water discharging port. The steam and hot water then hit and heat food products accommodated in a cooking chamber. Thus, a heating cooker capable of promptly heating a food product with steam can be provided.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

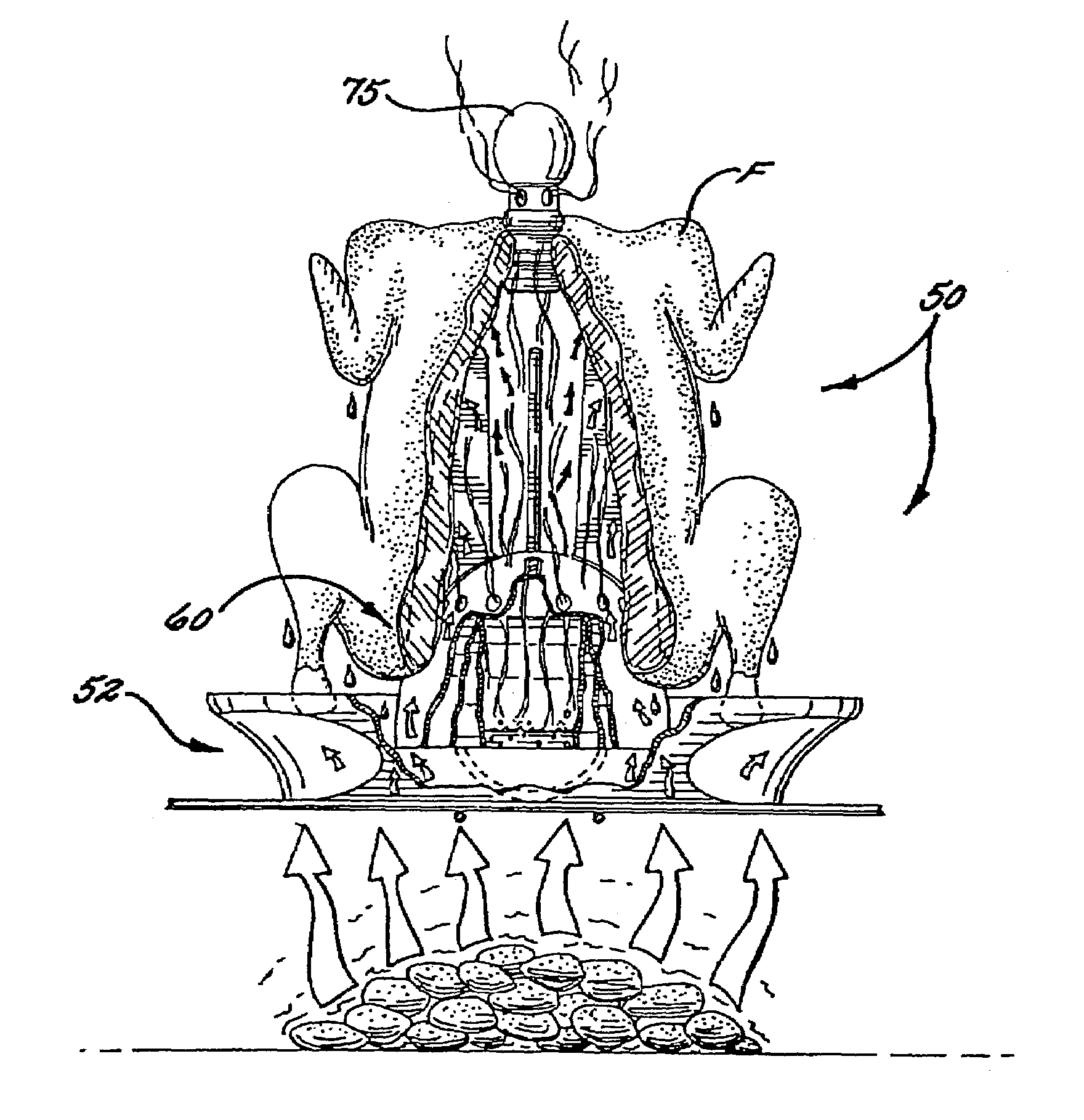

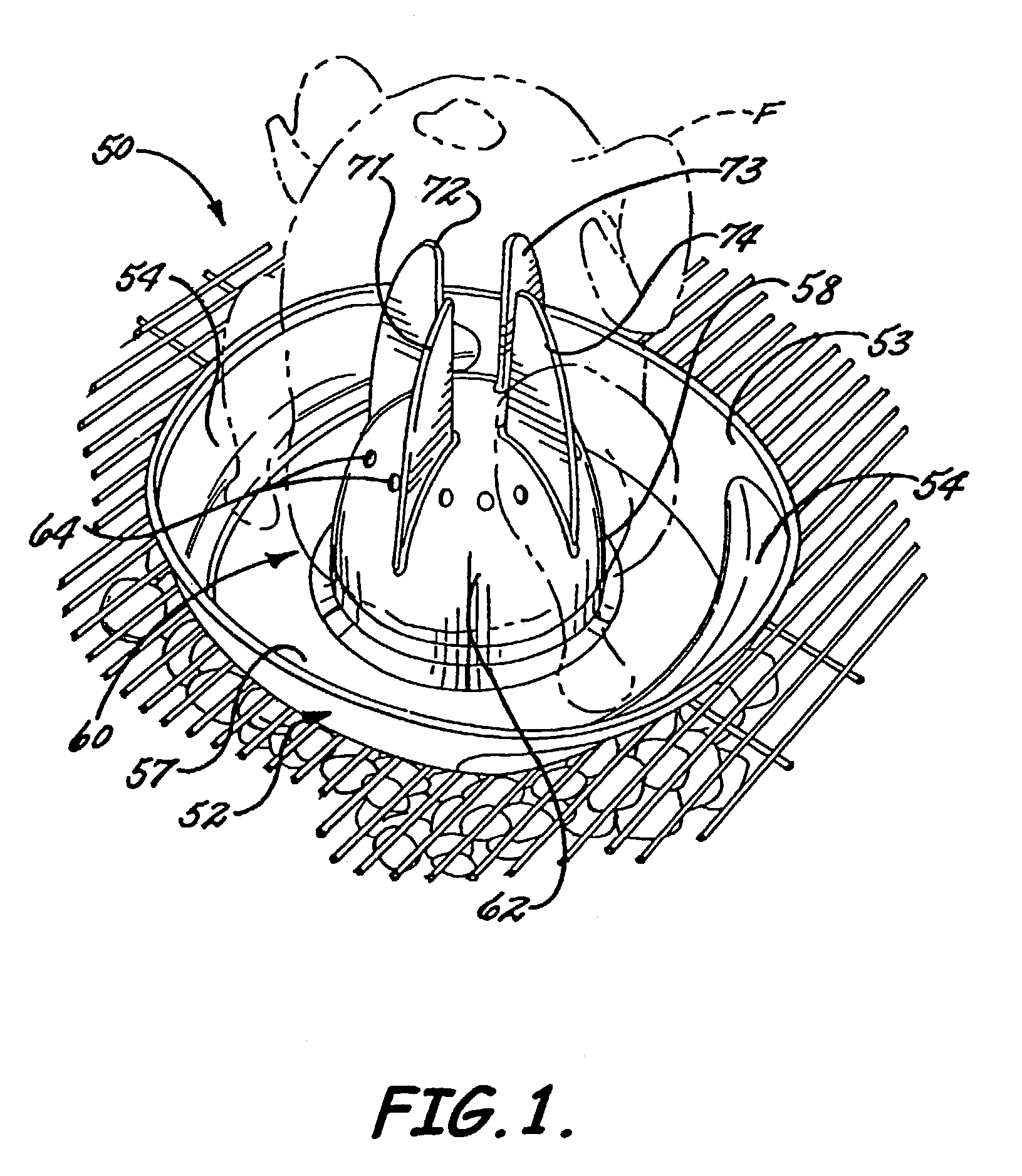

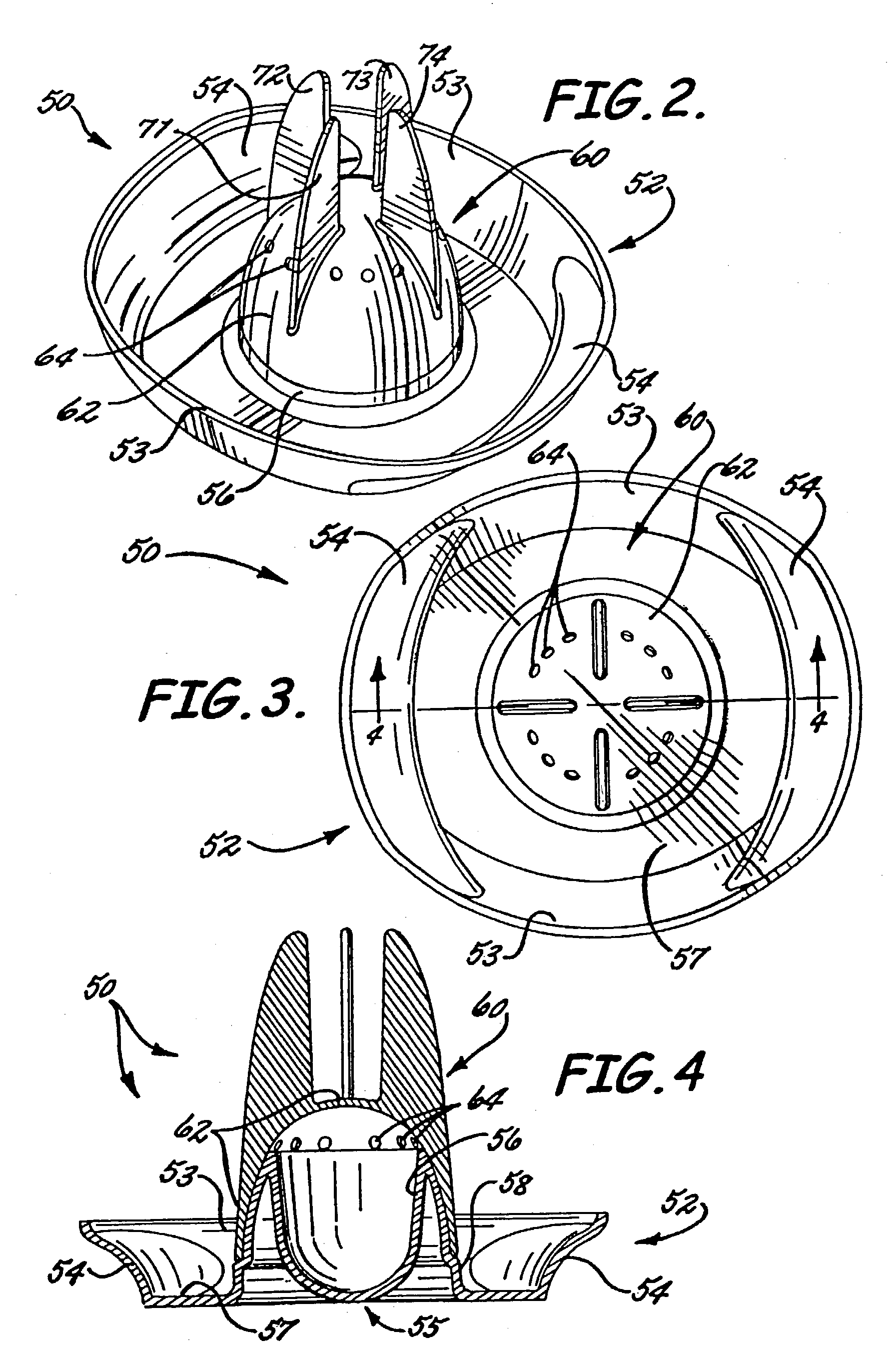

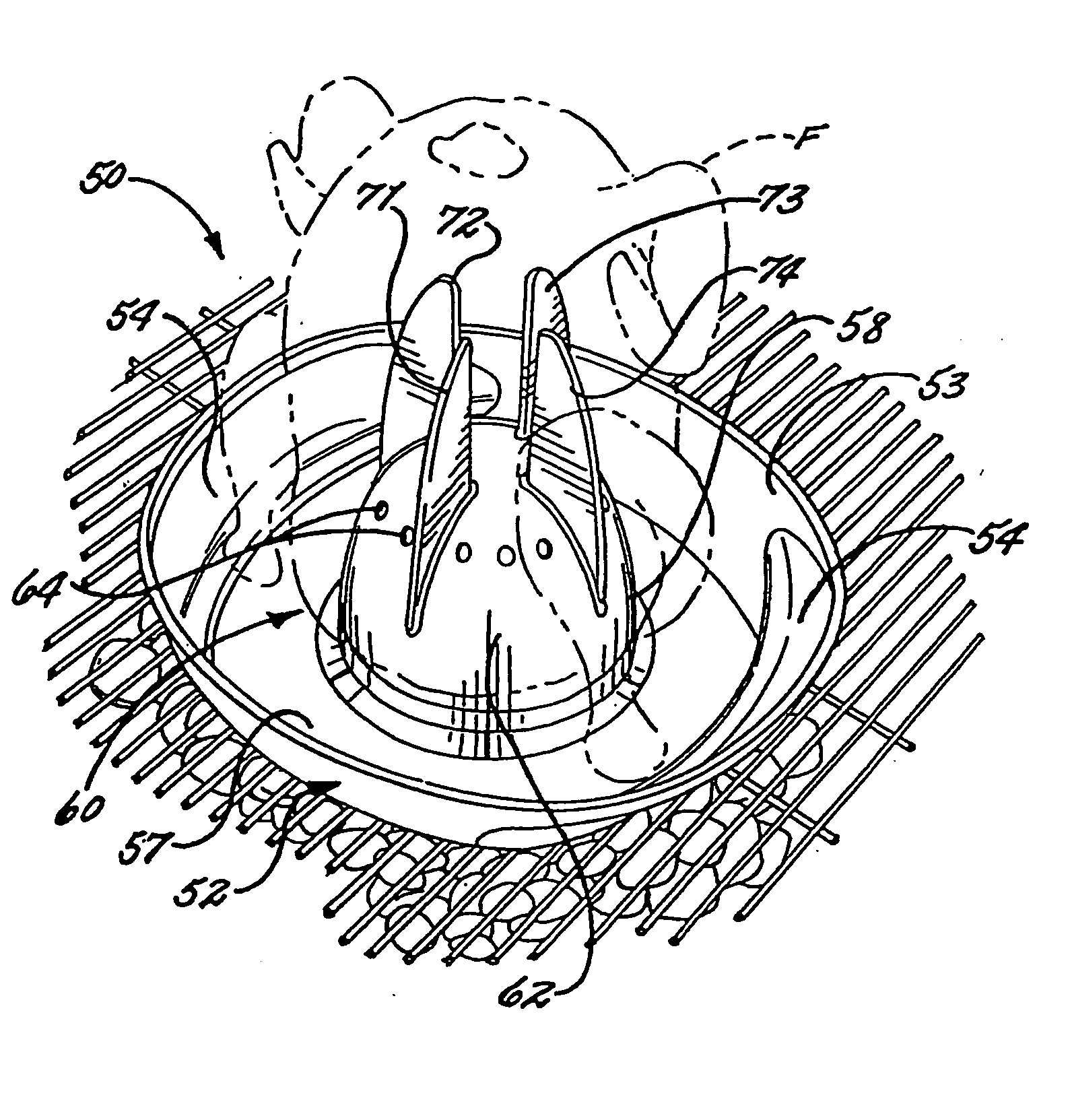

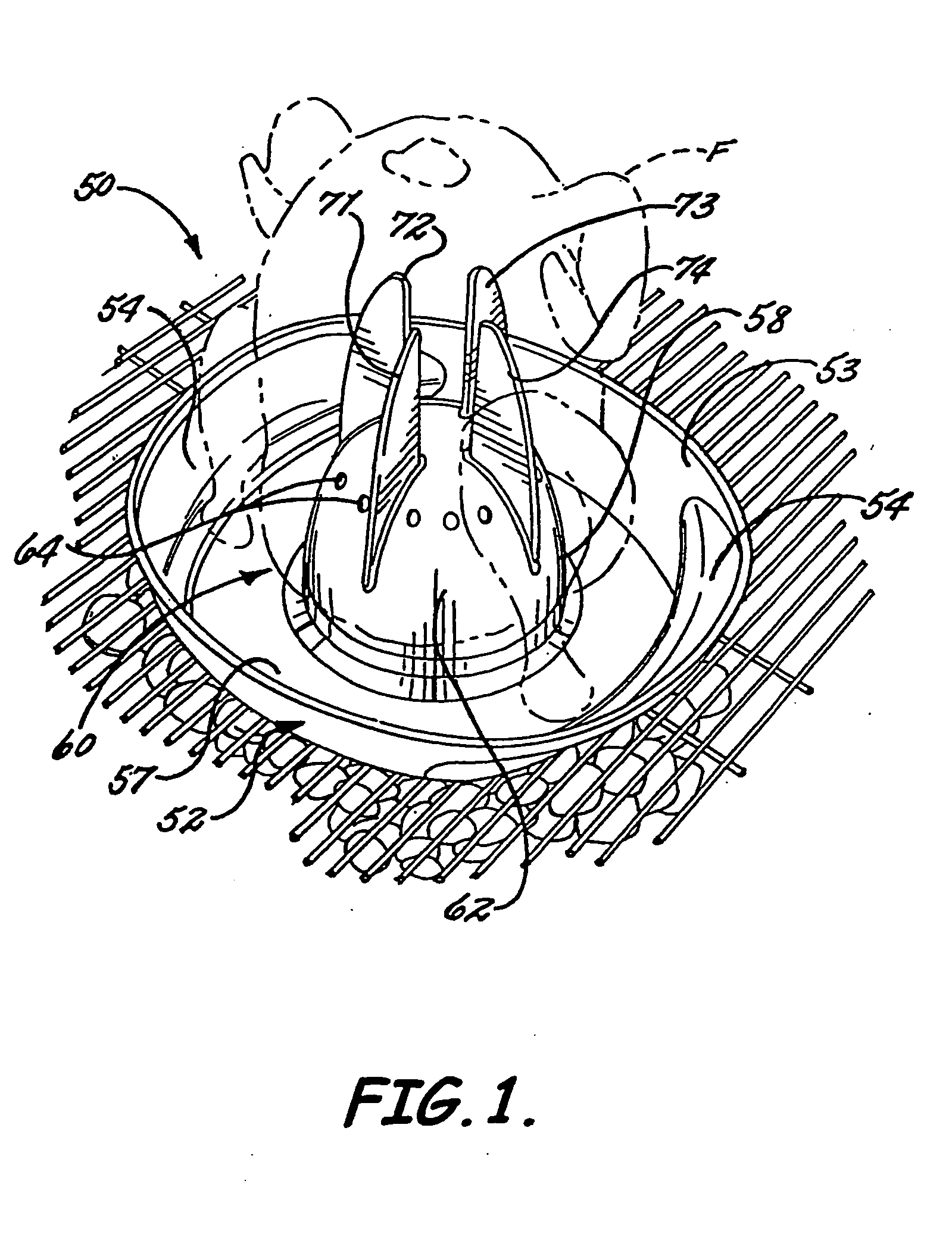

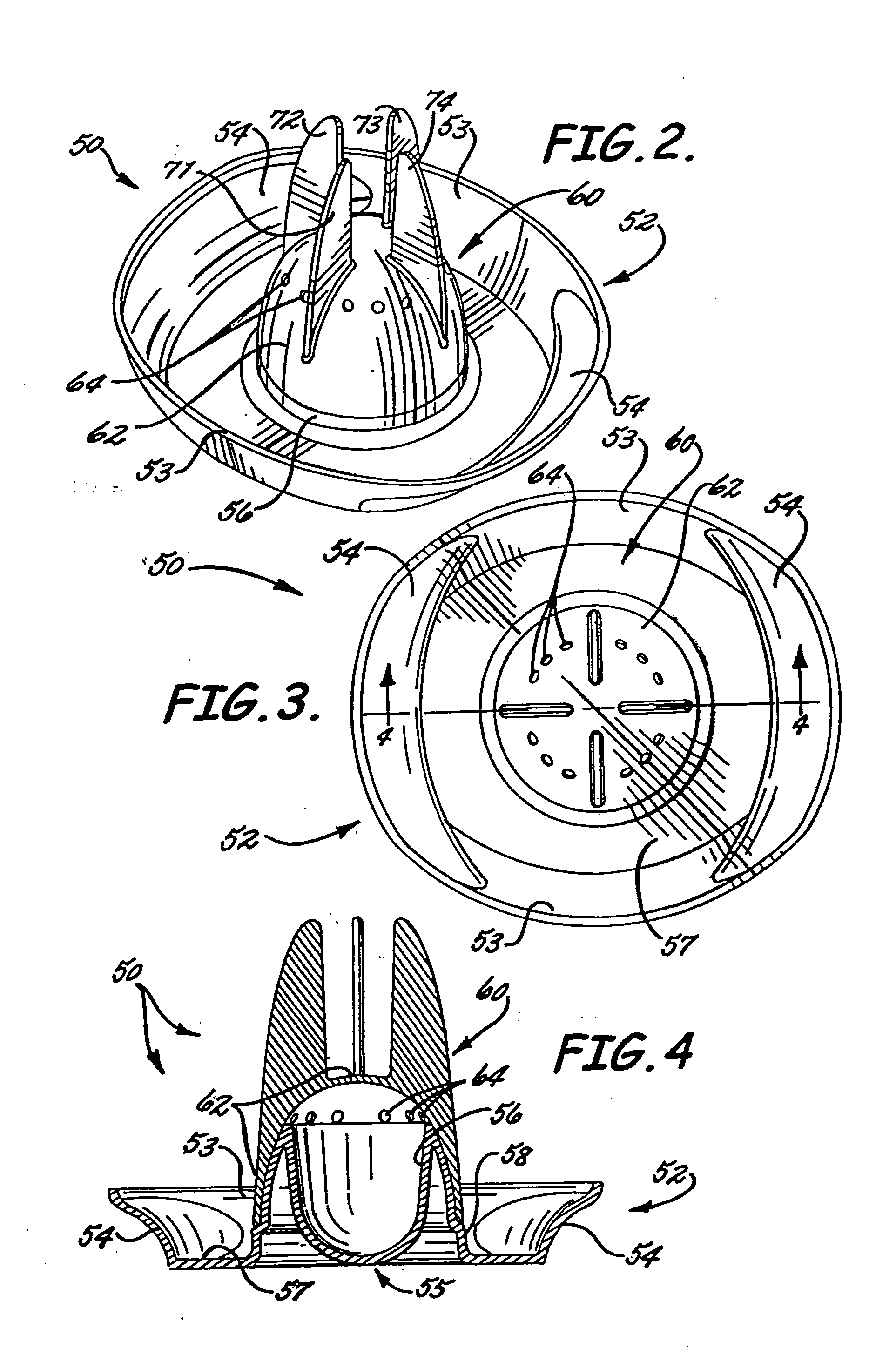

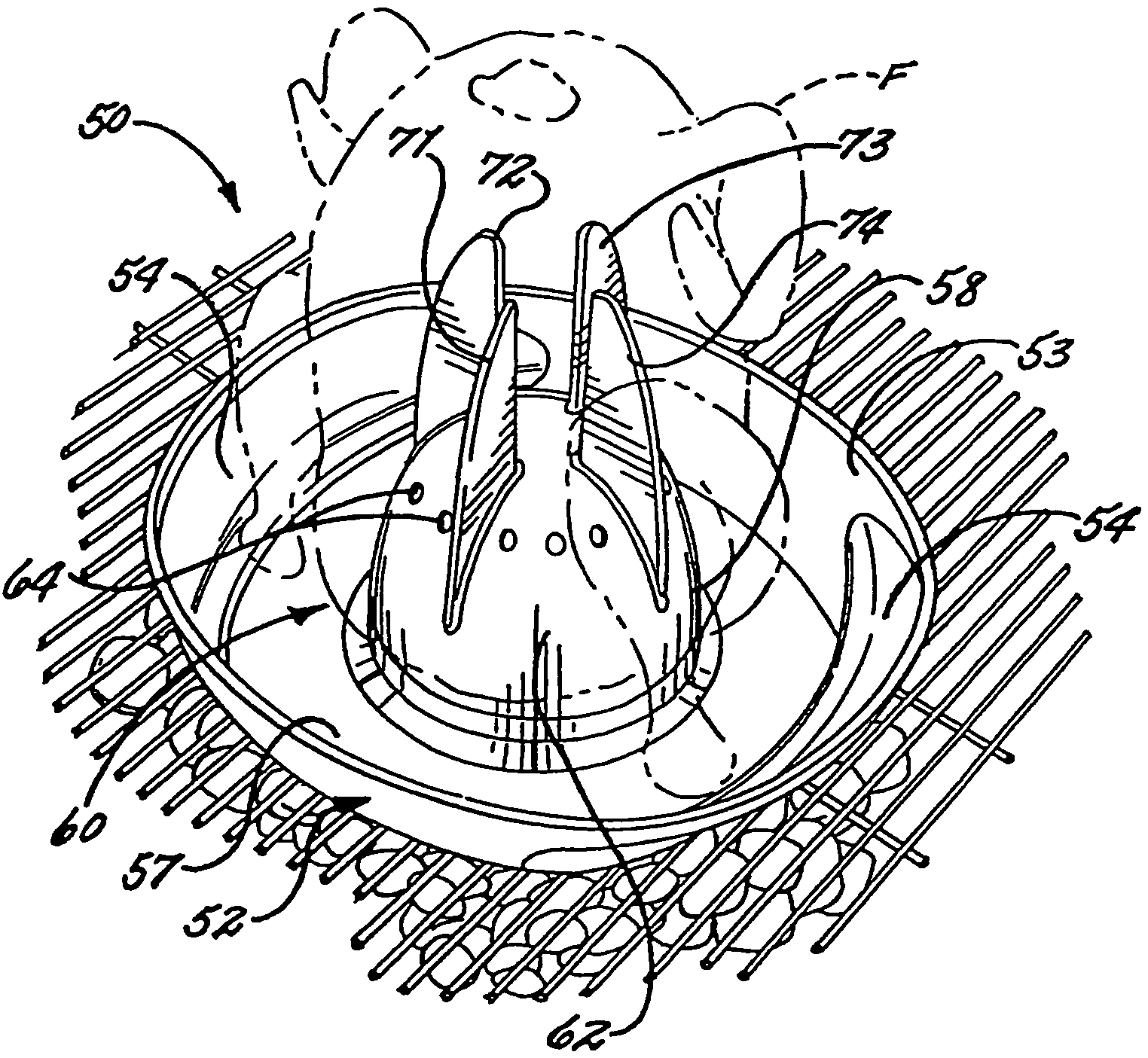

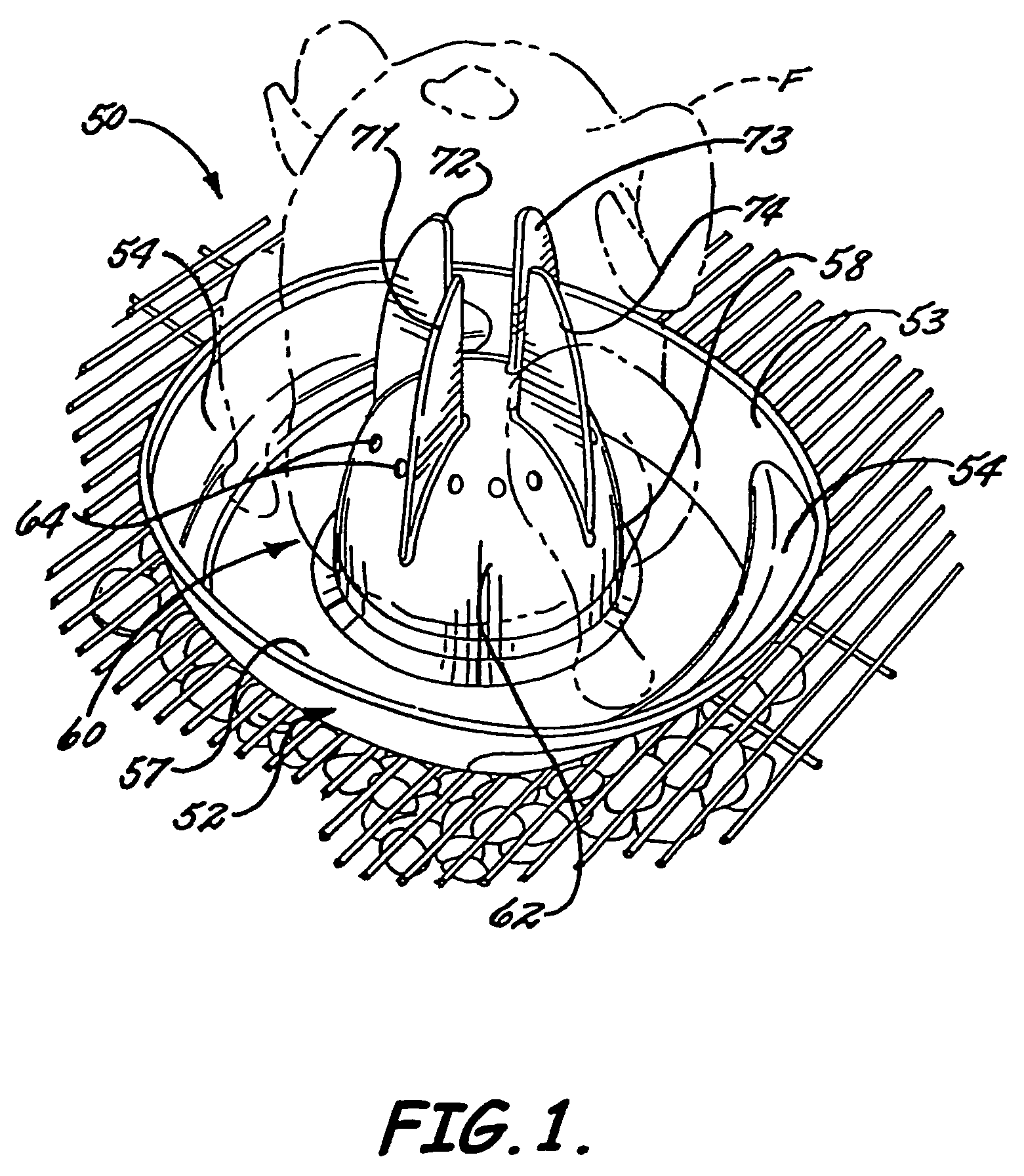

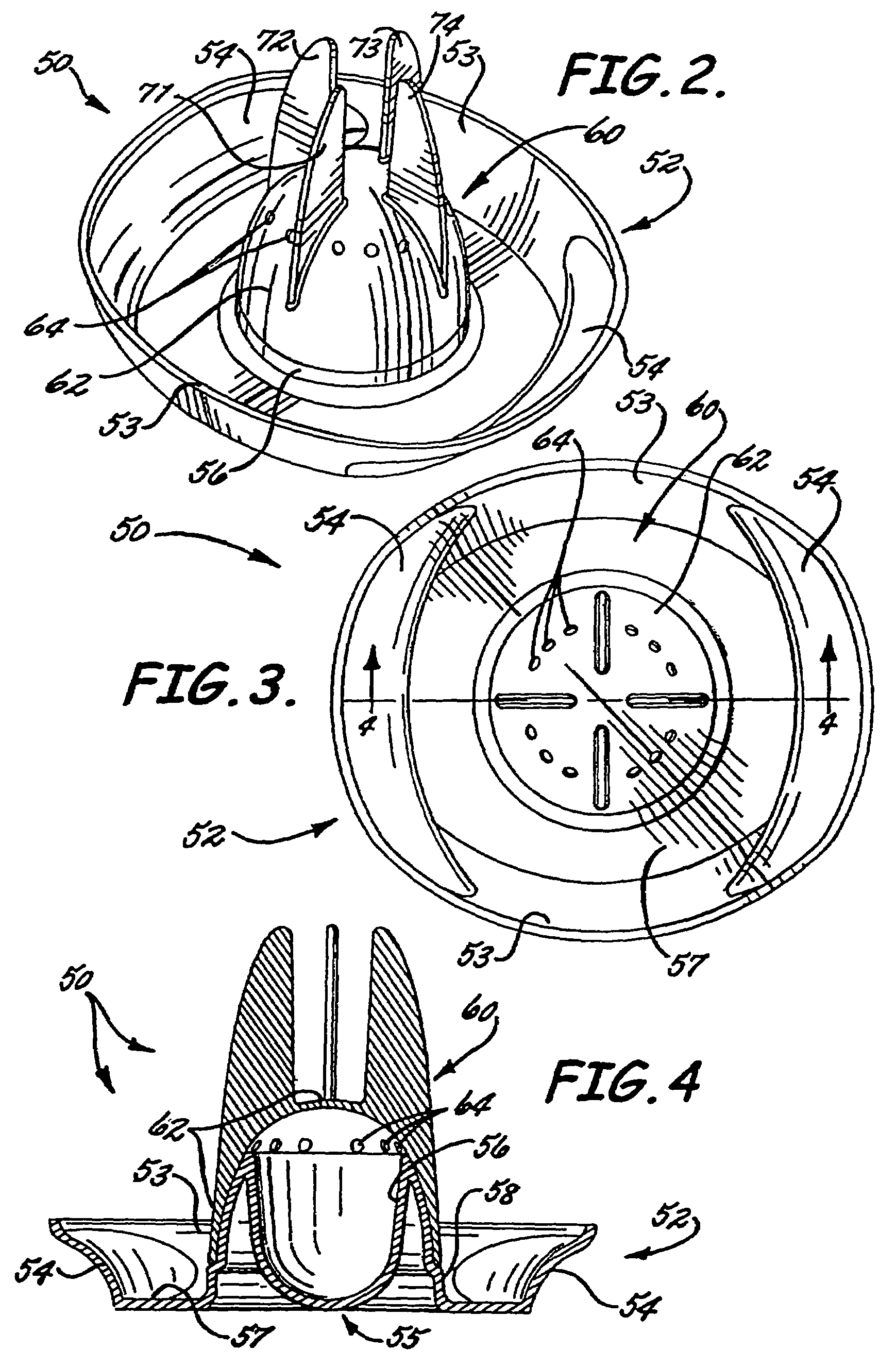

Apparatus for cooking meat and methods of cooking same

InactiveUS7144596B2Increase exposureEnhanced steam absorptionMilk preservationMeat/fish preservation by heatingEngineeringCooking methods

Owner:INNOVATIVE CULINARY CONCEPTS

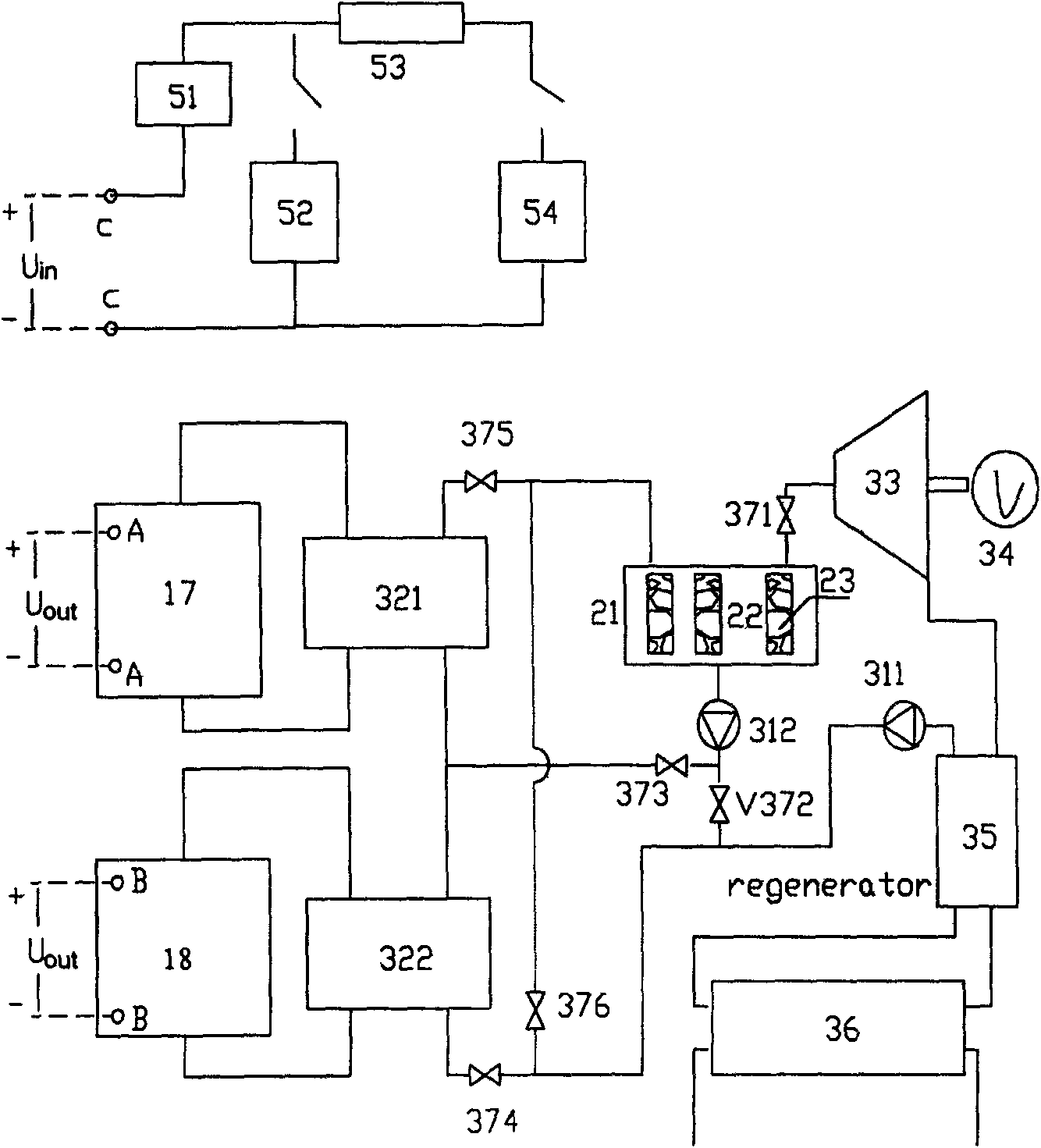

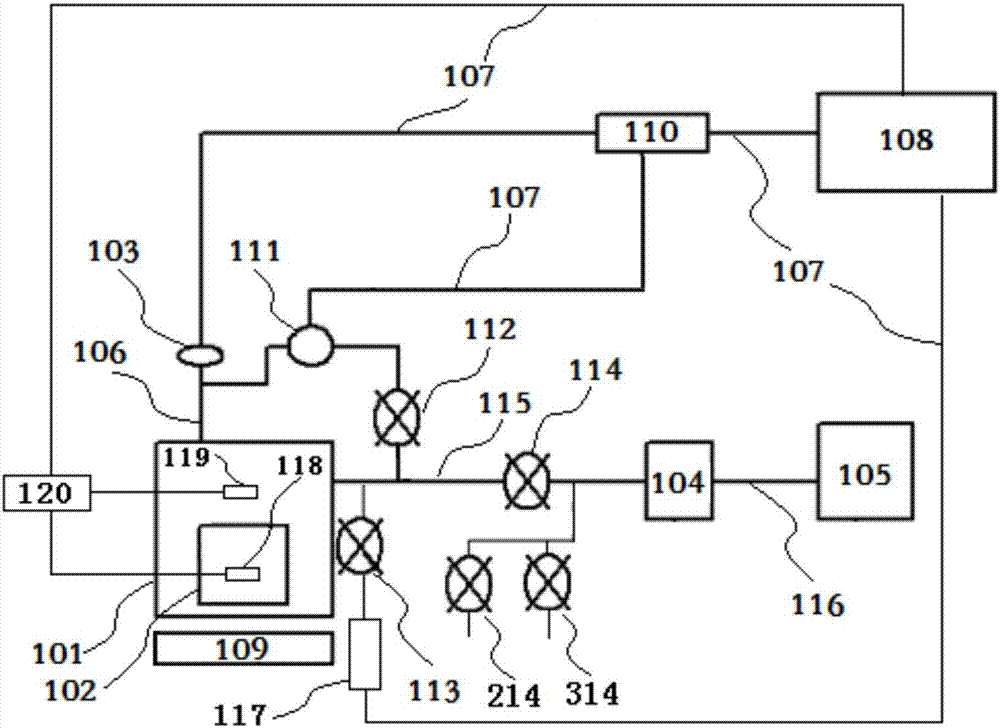

Solar-energy low-temperature thermal power-generation and photovoltaic power-generation combination system

InactiveCN101608606AValid conversionIncrease steam pressureFrom solar energyPhotovoltaicsOrganic Rankine cycleLiquid storage tank

The invention relates to a solar-energy low-temperature thermal power-generation and photovoltaic power-generation combination system, comprising a compound parabolic collector system, a heat storage system, an organic rankine cycle power-generation system, a photovoltaic module and a photovoltaic power-supply system, wherein the compound parabolic collector system comprises a high-temperature end compound parabolic collector array and a low-temperature end compound parabolic collector array, and the photovoltaic module is arranged on the upper part of a heat absorber of the compound parabolic collector; the heat storage system comprises a liquid storage tank in which coil pipes are equally arranged, and PCM (phase change material) is filled in the coil pipes; the organic rankine cycle power-generation system comprises an evaporator, a steam turbine, a generator, a heat regenerator, a condenser, two pumps and six valves. The total power-generation efficiency of the combination system is greatly enhanced; and the adoption of the heat storage system avoids the application of additional accumulators and complicated tracking devices, thus reducing cost; and the adoption of two-class evaporator reduces non-reversibility of heat transmission of heat-exchanging fluid and organic work-medium so as to reduce average running temperature, thus being in favor of prolonging service life of photovoltaic cells.

Owner:UNIV OF SCI & TECH OF CHINA

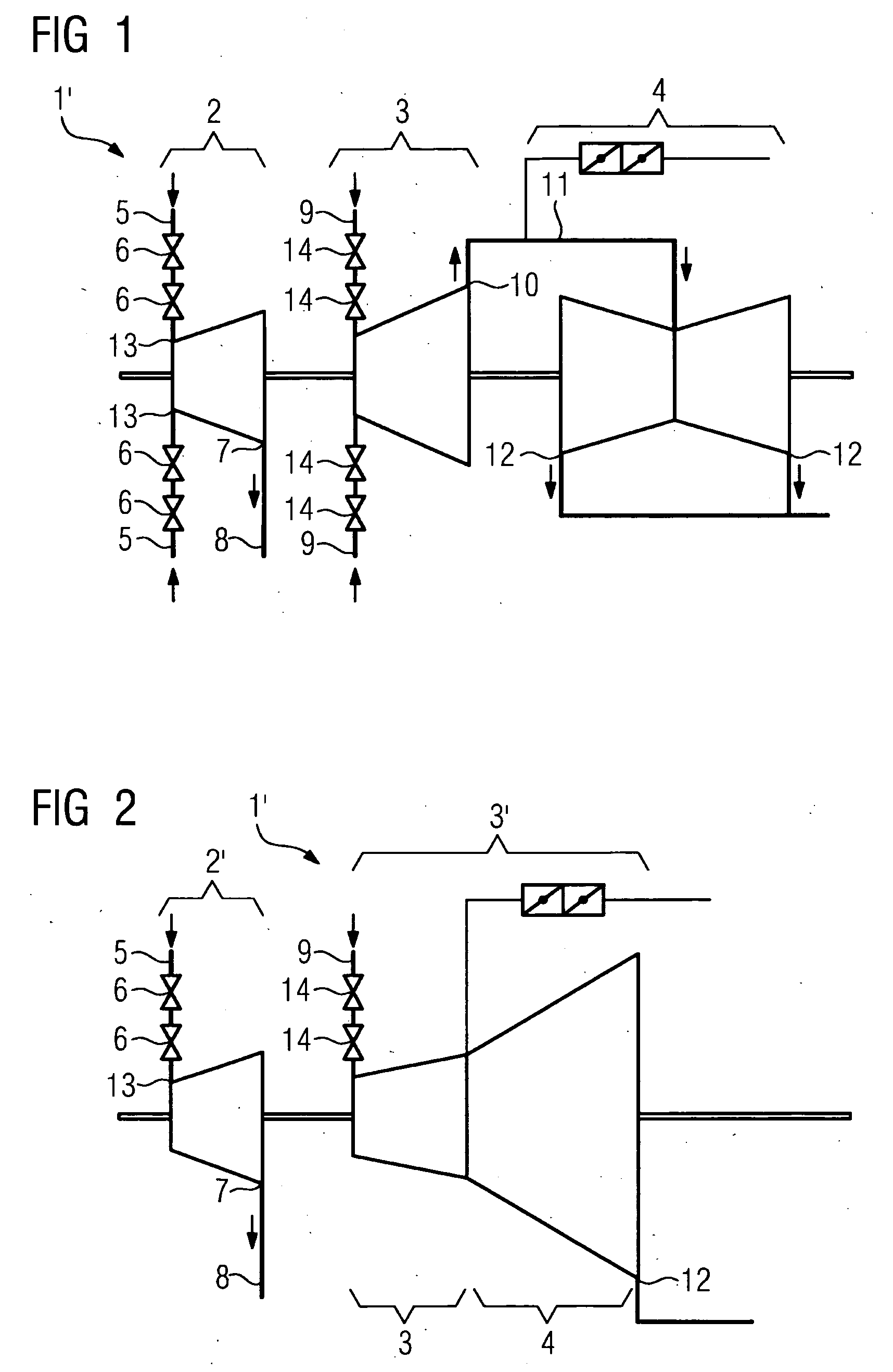

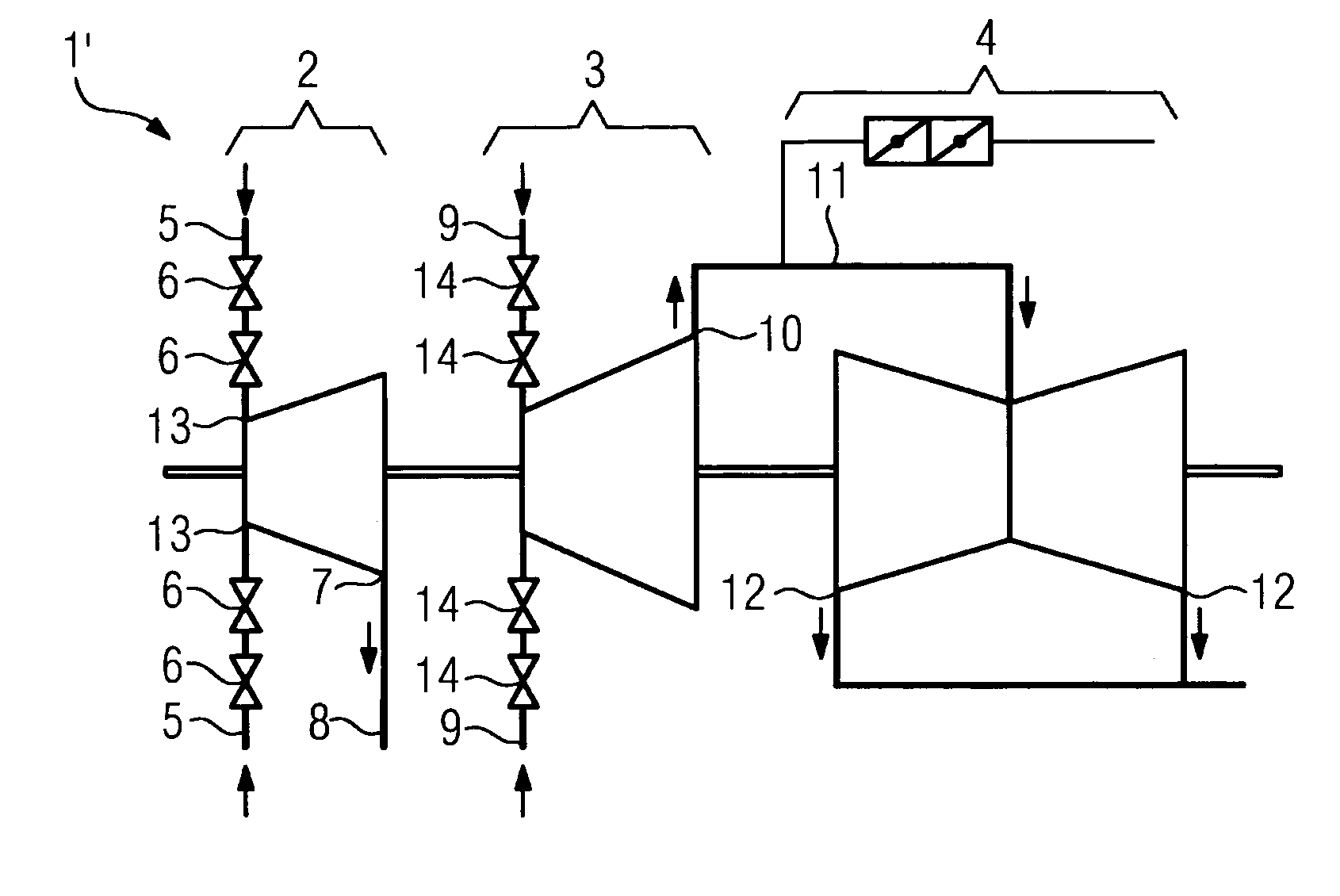

Steam turbine structure

ActiveCN102383879AImprove pressure bearing capacityStrong pressure capacityStatorsSteam engine plantsSteam pressureLow-pressure area

The invention discloses a steam turbine structure, which comprises an ultrahigh pressure cylinder, a reheating high-pressure cylinder, one or two reheating intermediate-pressure cylinders and two or three low-pressure cylinders. The ultrahigh pressure cylinder is a double-layer cylinder, an outer cylinder of the ultrahigh pressure cylinder consists of two cylindrical blocks which are connected through axial bolts, and a rotor in the ultrahigh pressure cylinder is a small-diameter rotor. Since the axial action area of the ultrahigh pressure cylinder is much smaller than that of a horizontal central parting surface, the ultrahigh pressure cylinder in the above structure has higher bearing capacity as compared with that of an existing ultrahigh pressure cylinder block which is divided into an upper half structure and a lower half structure by the central parting surface, and further, an axial flange can be arranged in a lower-pressure area, working stress of the axial flange can be greatly reduced, bearing capacity of the ultrahigh pressure cylinder can be improved further, so that the ultrahigh pressure cylinder can bear higher steam pressure.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

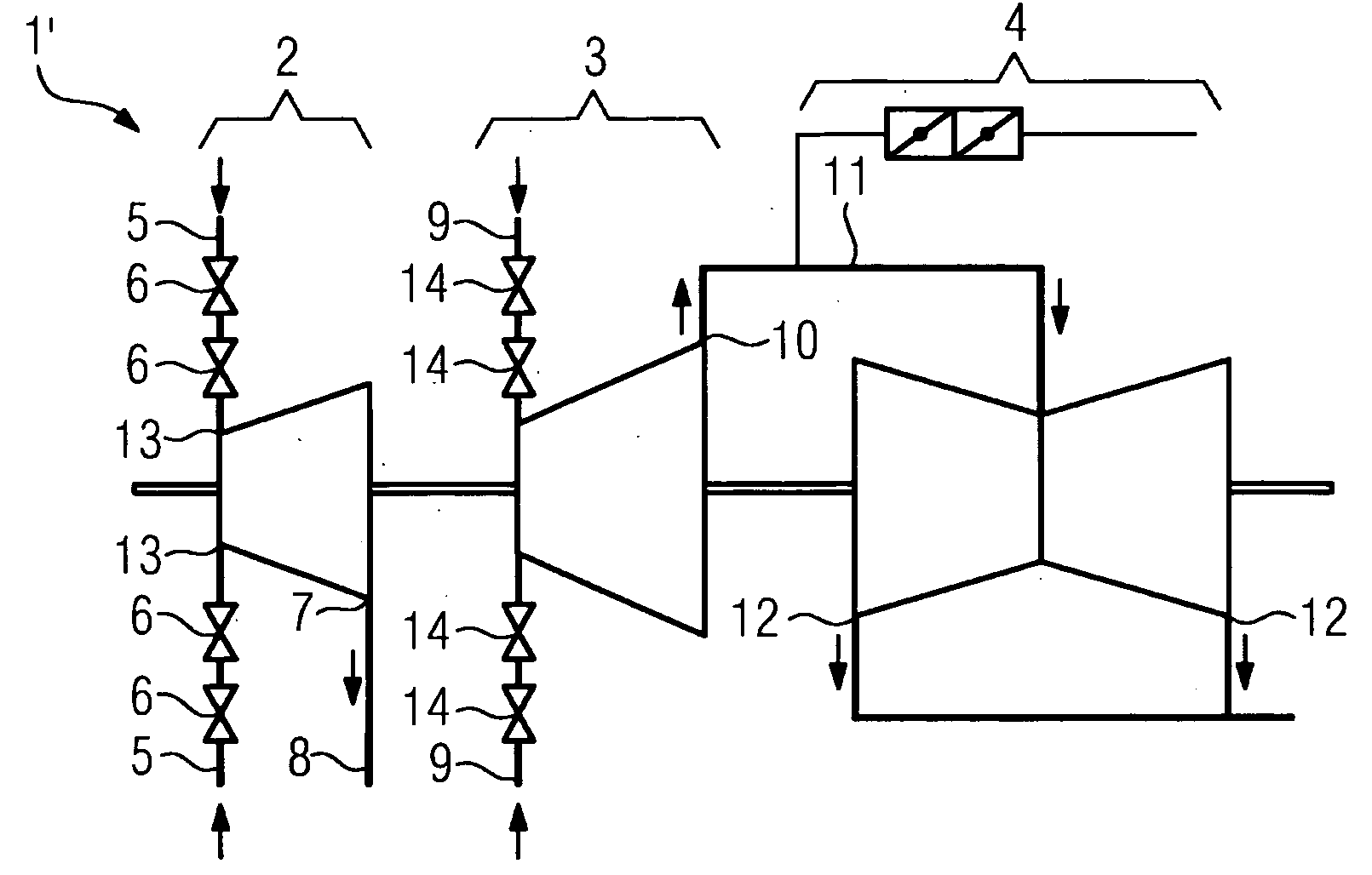

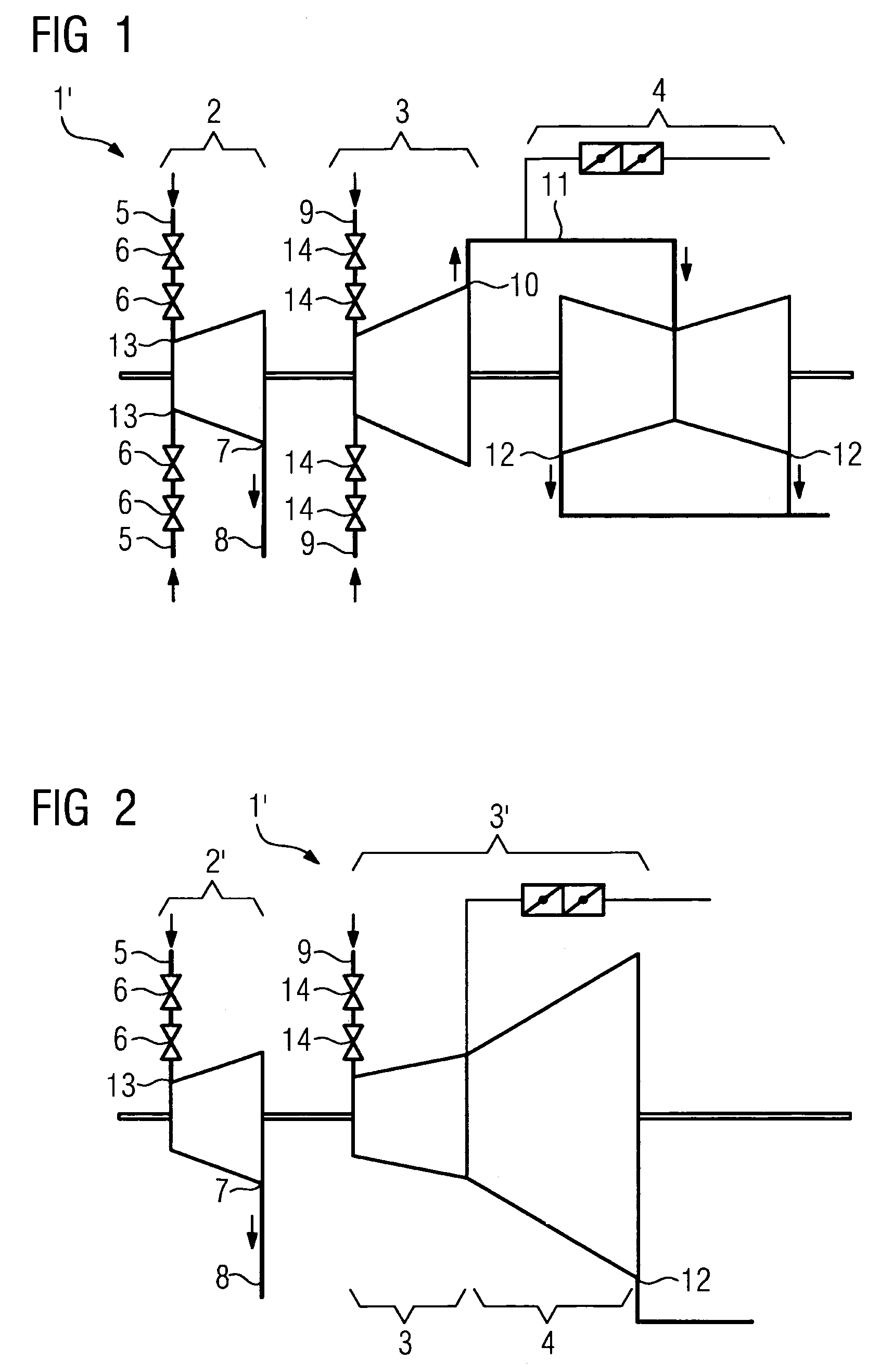

Method for Warming-Up a Steam Turbine

InactiveUS20090249788A1Improve conductivityIncrease steam pressureEngine componentsSteam engine plantsHigh pressureTurbine

The invention relates to a method for heating a steam turbine comprising a high-pressure turbine section and a medium-pressure turbine section and / or a low-pressure turbine section. Said method is characterized by the essential aspect that the high-pressure turbine section is impinged upon by steam having relatively great conductivity while the medium-pressure turbine section or the low-pressure turbine section remains closed during said impingement following a cold start. As soon as the conductivity drops below a certain value, the medium-pressure turbine section or the low-pressure turbine section is also impinged upon by steam.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

Method for warming-up a steam turbine

InactiveUS7765807B2Improve conductivityIncrease steam pressureUsing mechanical meansEngine componentsHigh pressureTurbine

The invention relates to a method for heating a steam turbine comprising a high-pressure turbine section and a medium-pressure turbine section and / or a low-pressure turbine section. Said method is characterized by the essential aspect that the high-pressure turbine section is impinged upon by steam having relatively great conductivity while the medium-pressure turbine section or the low-pressure turbine section remains closed during said impingement following a cold start. As soon as the conductivity drops below a certain value, the medium-pressure turbine section or the low-pressure turbine section is also impinged upon by steam.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

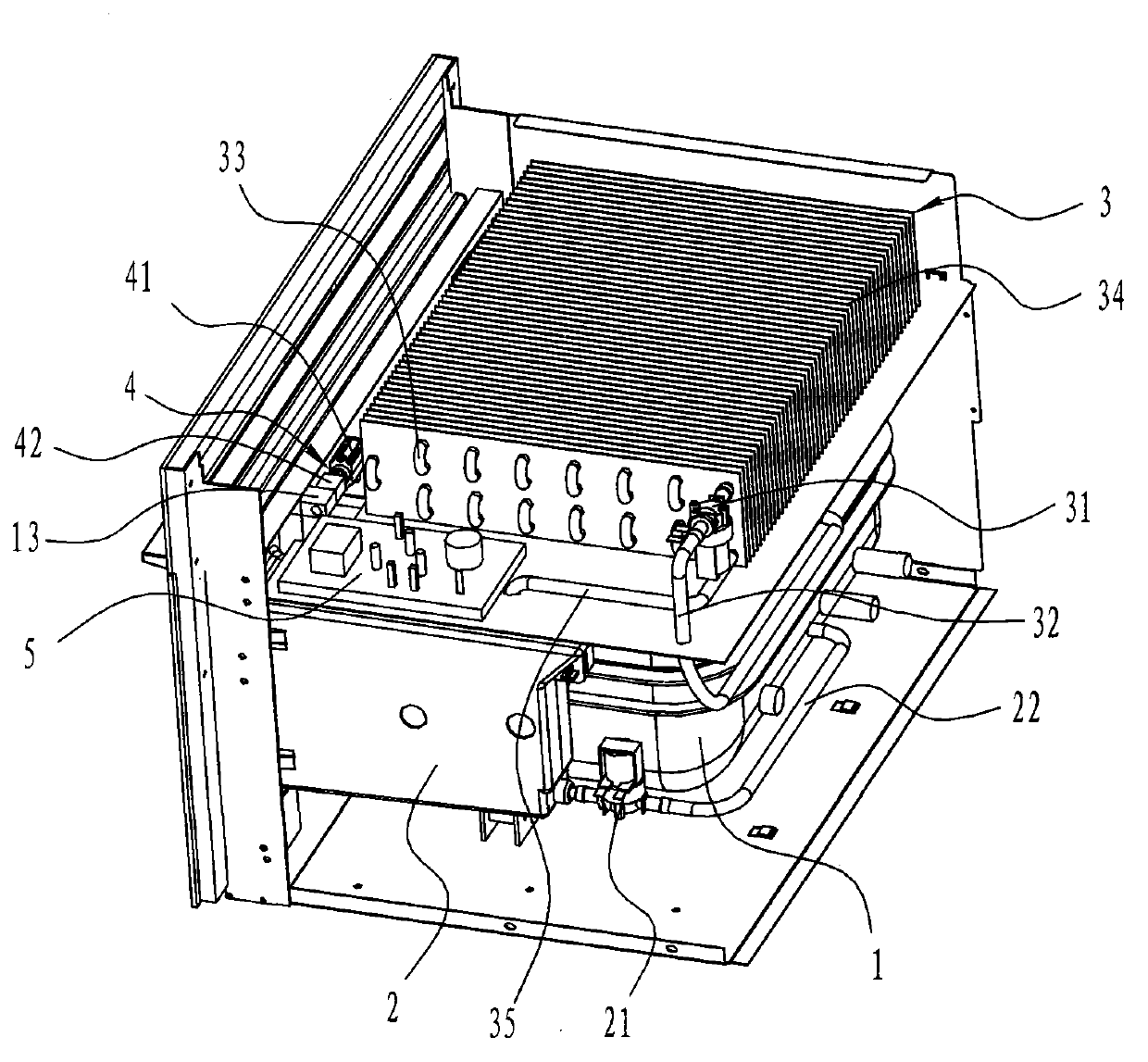

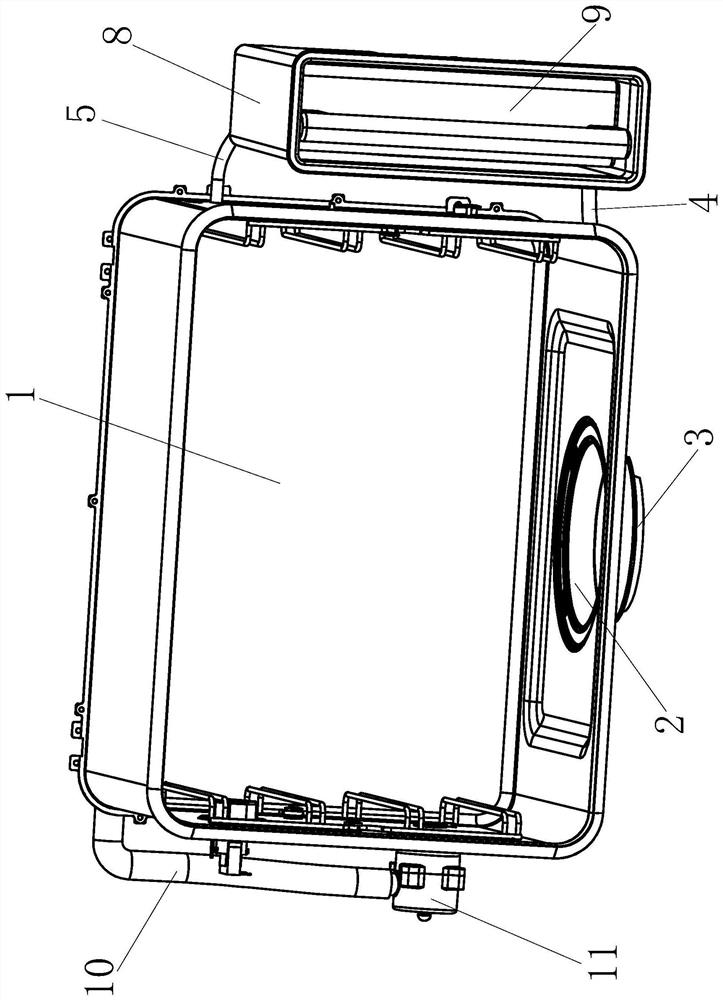

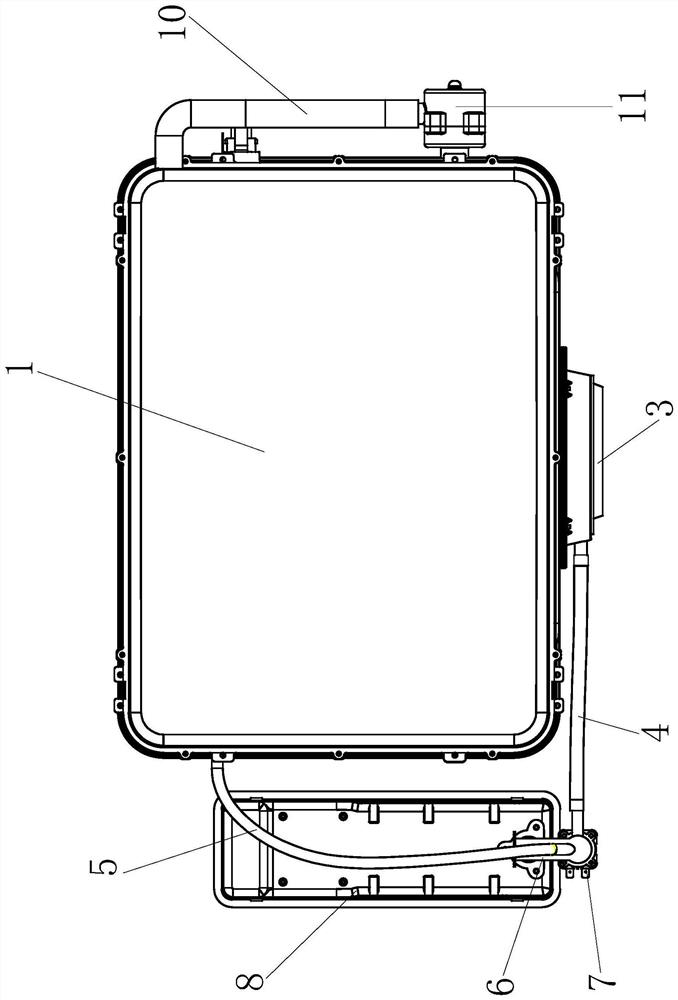

Food heater

ActiveCN103654367AImprove high pressure performanceIncrease steam pressureSteam cooking vesselsSteam pressureWater storage tank

The invention discloses a food heater. The food heater comprises a box body with a heating assembly, and a box door is arranged on the outer surface of the box body. The food heater further comprises an inner container which is sealed by the box door and used for heating food, a steam recovery device and a control circuit, wherein a door lock is arranged between the box door and the inner container, and transnormal steam pressure in the heating box body can be borne by the door lock; the heating assembly comprises a heating part and a water storage tank, water quantitatively output of the water storage tank is heated into steam through the heating part, and food is heated by the steam in the inner container; the steam recovery device is composed of a condenser, a steam pipe and a return pipe, the heating box body and the condenser are connected through the steam pipe, and the condenser and the water storage tank are connected through the return pipe; the control circuit controls the food heater to complete the whole work process; due to a sealing structure between the box door and the inner container, steam pressure in the heating box body is increased, heating efficiency of the heather is improved, a large part of steam is returned to the water storage tank after being condensed through the transnormal pressure in the heating box body, heated water can be utilized in a circulating mode, and environmental pollution caused by steam leakage can be avoided or reduced.

Owner:宁波市安通机械有限公司

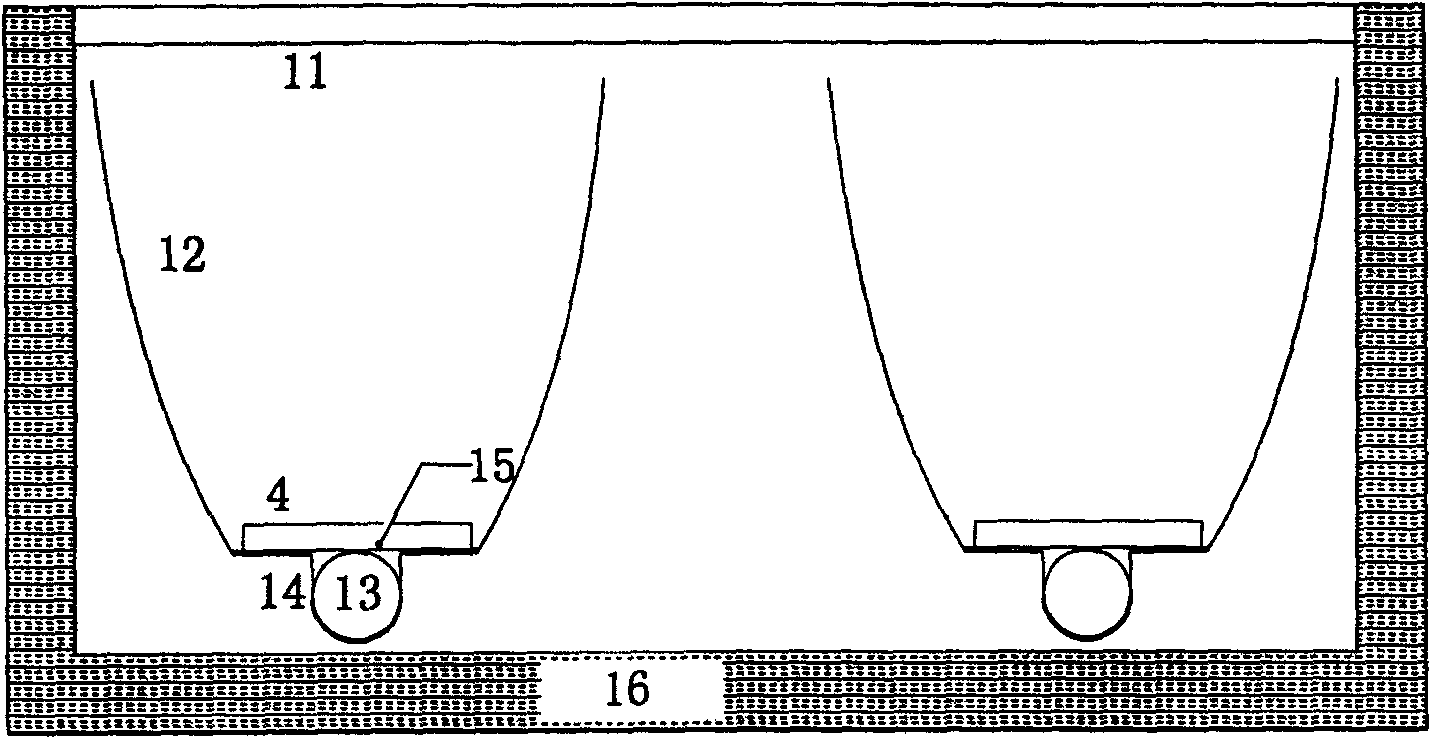

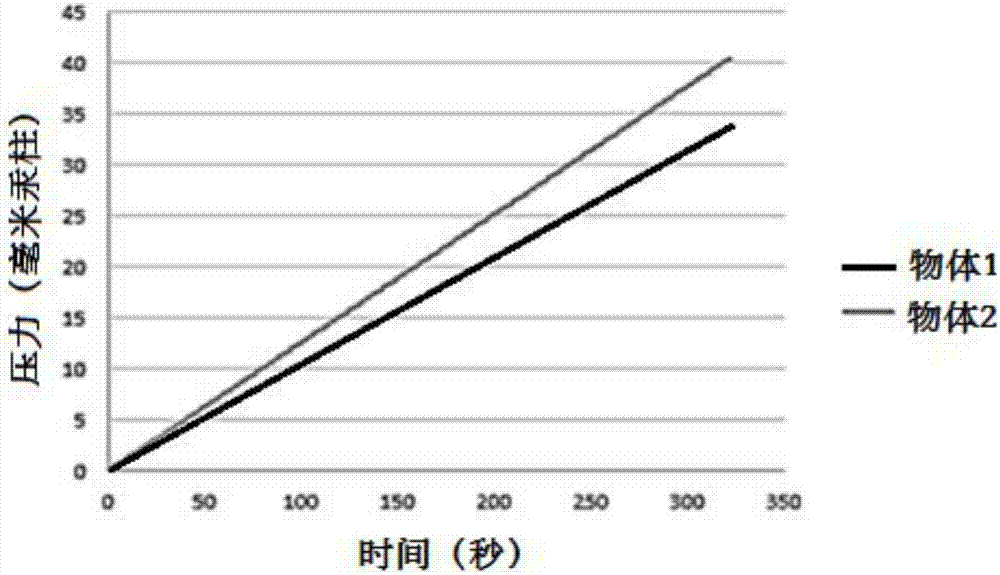

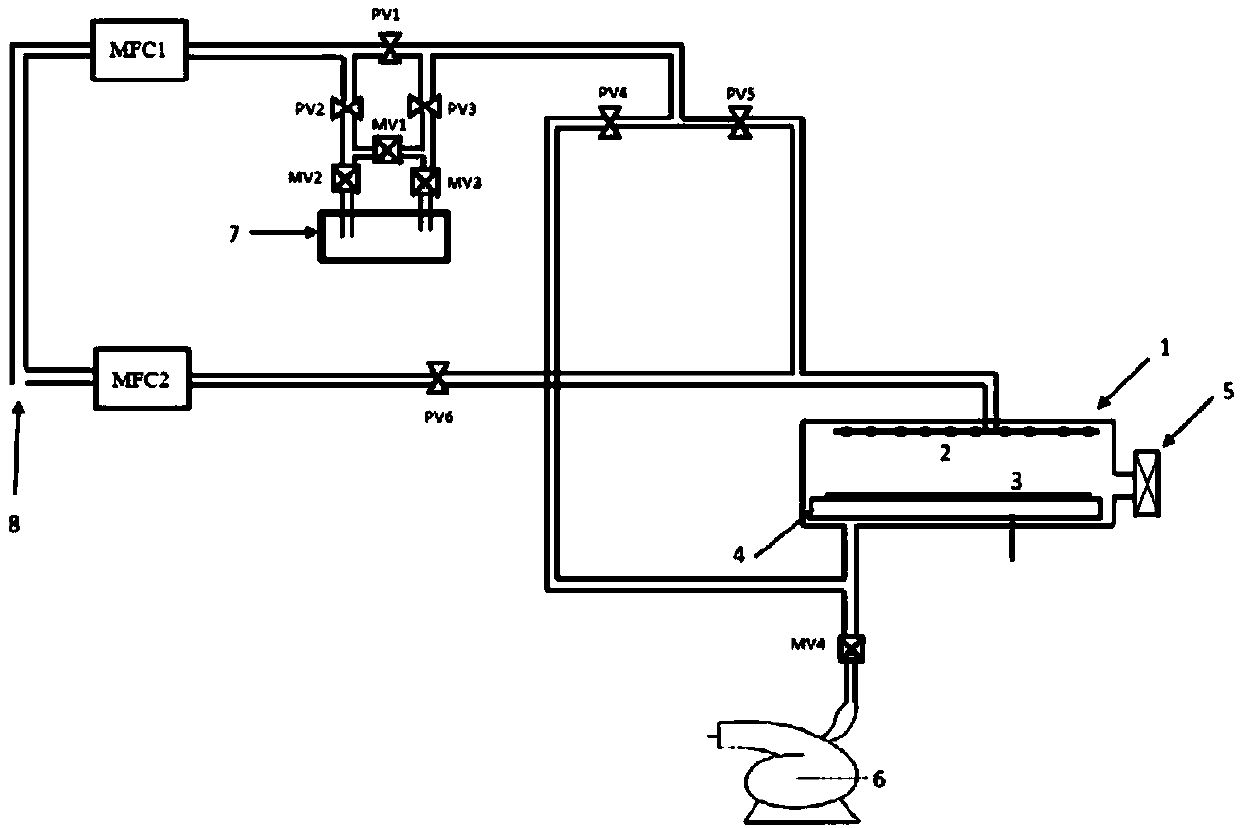

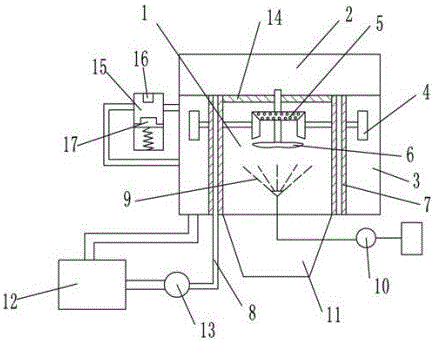

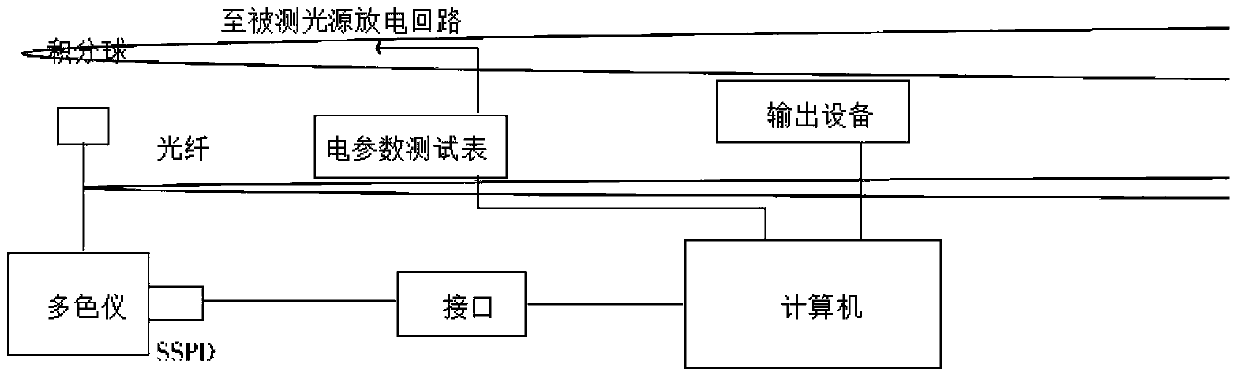

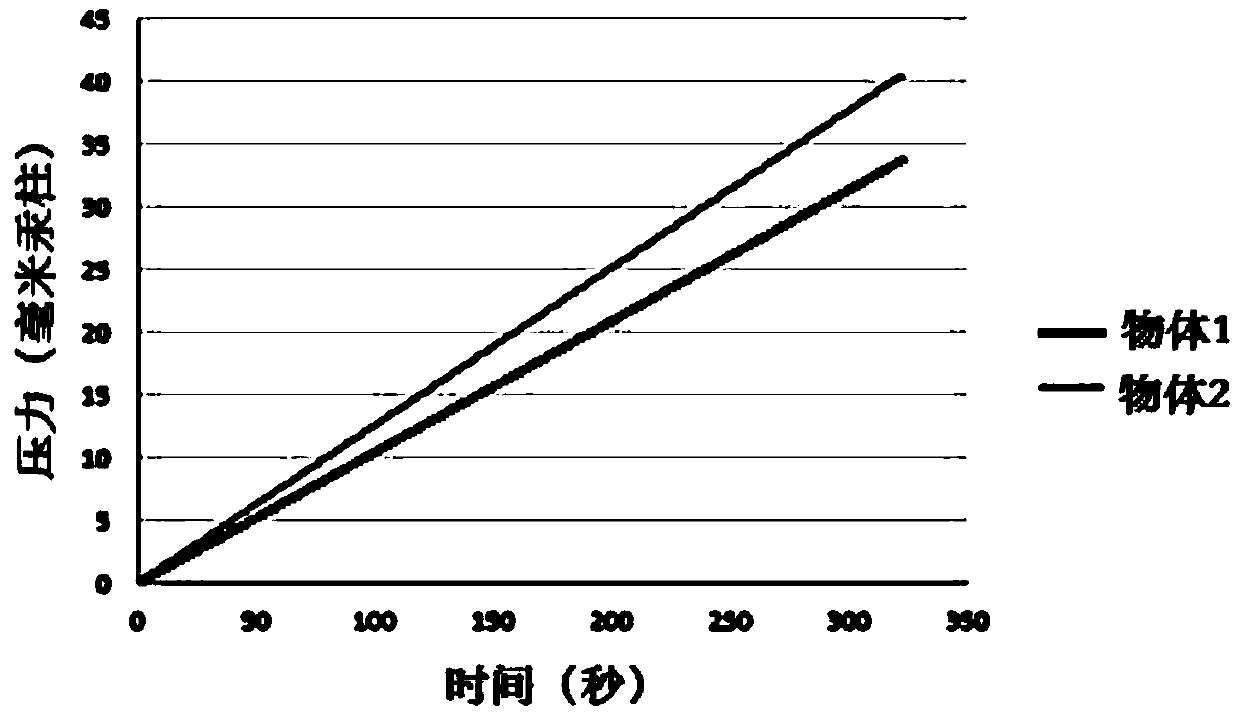

Method for measuring water content of dried object, vacuum drying device and control method thereof

ActiveCN107014156AEasy to implementLarge measuring rangeDrying using combination processesDrying solid materials without heatEvaporationPulp and paper industry

The invention provides a method for measuring the water content of a dried object, a vacuum drying device and a control method of the vacuum drying device. The method for measuring the water content of the dried object is used for calculating the water content of the dried object in a drying container in the vacuum drying process. The method calculates the water evaporation amount of the dried object at the drying temperature according to the system parameter values of the drying container in the closed state and calculates the current water content of the dried object according to the water evaporation amount. The method for measuring the water content of the dried object is simple, convenient to use and easy to achieve, efficient in the measuring process, and wide in measuring range and reliable in measuring result. The invention further provides the vacuum drying device and the control method of the vacuum drying device. The vacuum drying device controls the drying process by conducting real-time measurement on the water content of the dried object, the control method can meet the requirements for rapidness and continuity, manual intervention is not required, and the preset target water content of the dried object can be accurately and rapidly achieved.

Owner:常州广建仪器科技有限公司

Supercritical fluid recovery and refining of hydrocarbons from hydrocarbon-bearing formations applying fuel cell gas in situ

A plume of combined gases are infused into hydrocarbon-bearing formations, “inert” as the major gas and “reactive” as the minor gas, where the minor gas reacts with hydrocarbons to fully saturate hydrocarbons with supercritical fluid, which migrate hydrocarbons out of formations, even at great distances from the regulated fuel cell source. Coal, tar sands, petroleum-contaminated soil, and / or oil wells that have lost gas pressure can also be desorbed by this in-situ method.

Owner:CRITICAL POINT ENERGY

Apparatus for cooking meat

InactiveUS20050039609A1Increase exposureEnhanced steam absorptionCooking vesselsMeat processingEngineeringMechanical engineering

Owner:INNOVATIVE CULINARY CONCEPTS

Apparatus for cooking meat

InactiveUS7146905B2Increase exposureEnhanced steam absorptionMeat processingCooking vesselsEngineeringMechanical engineering

Owner:INNOVATIVE CULINARY CONCEPTS

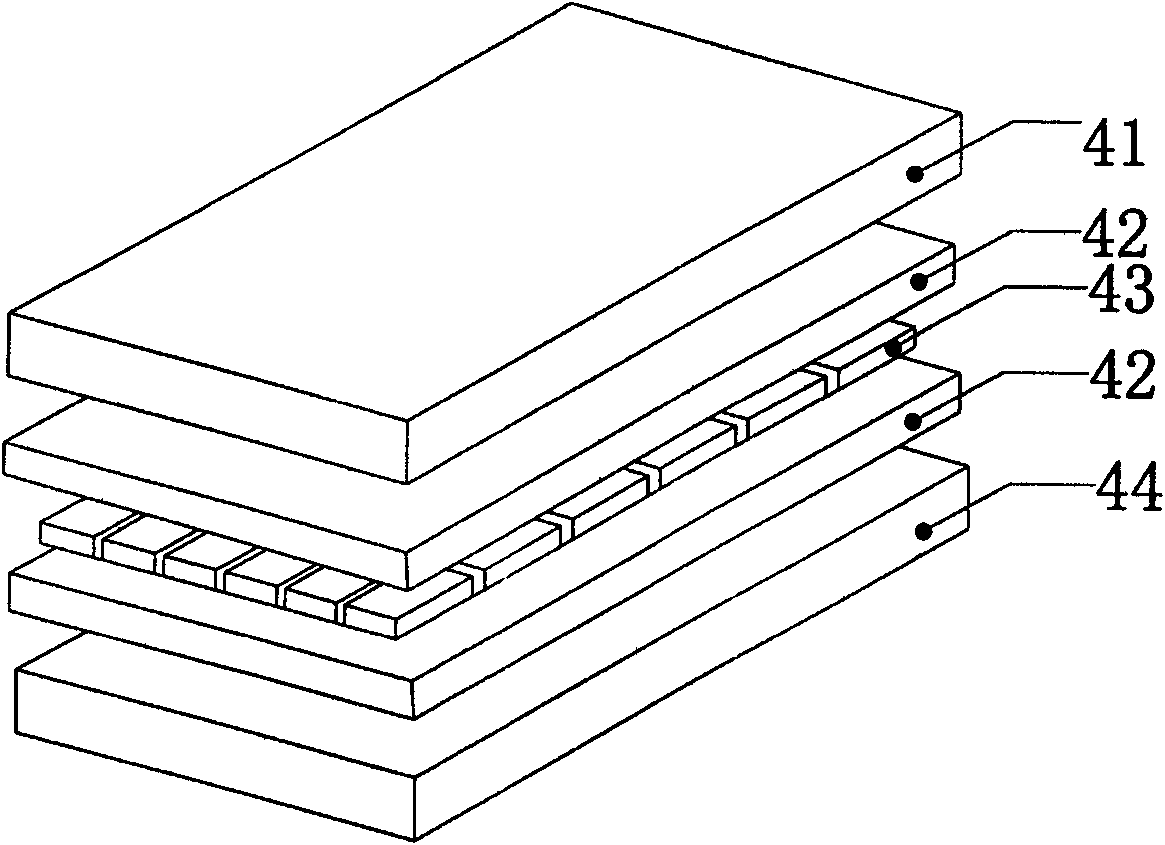

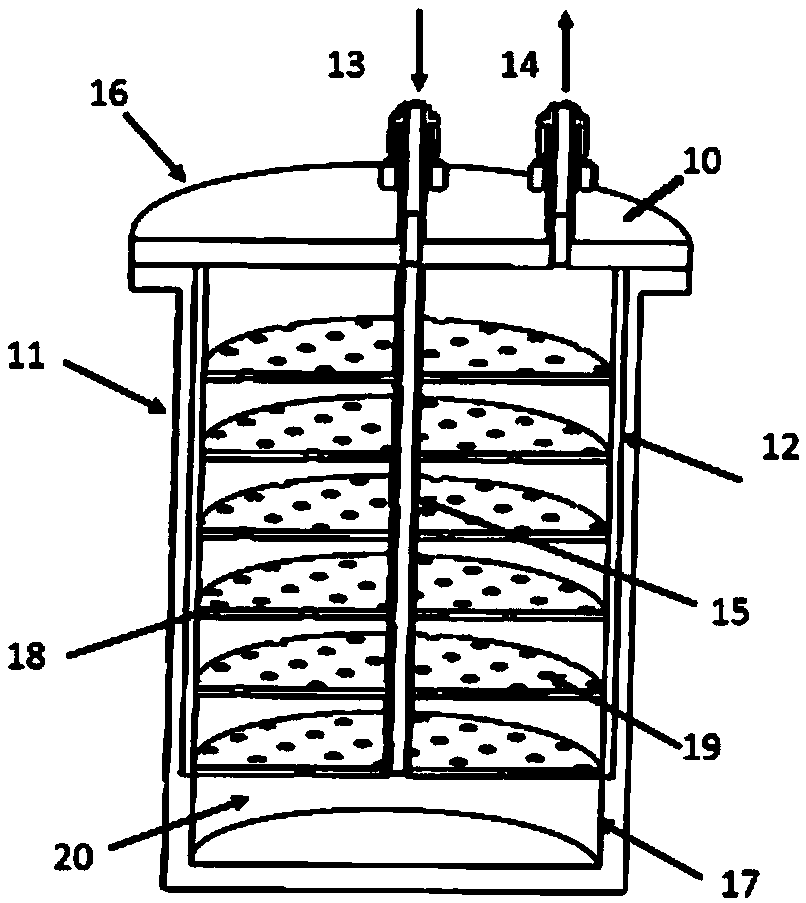

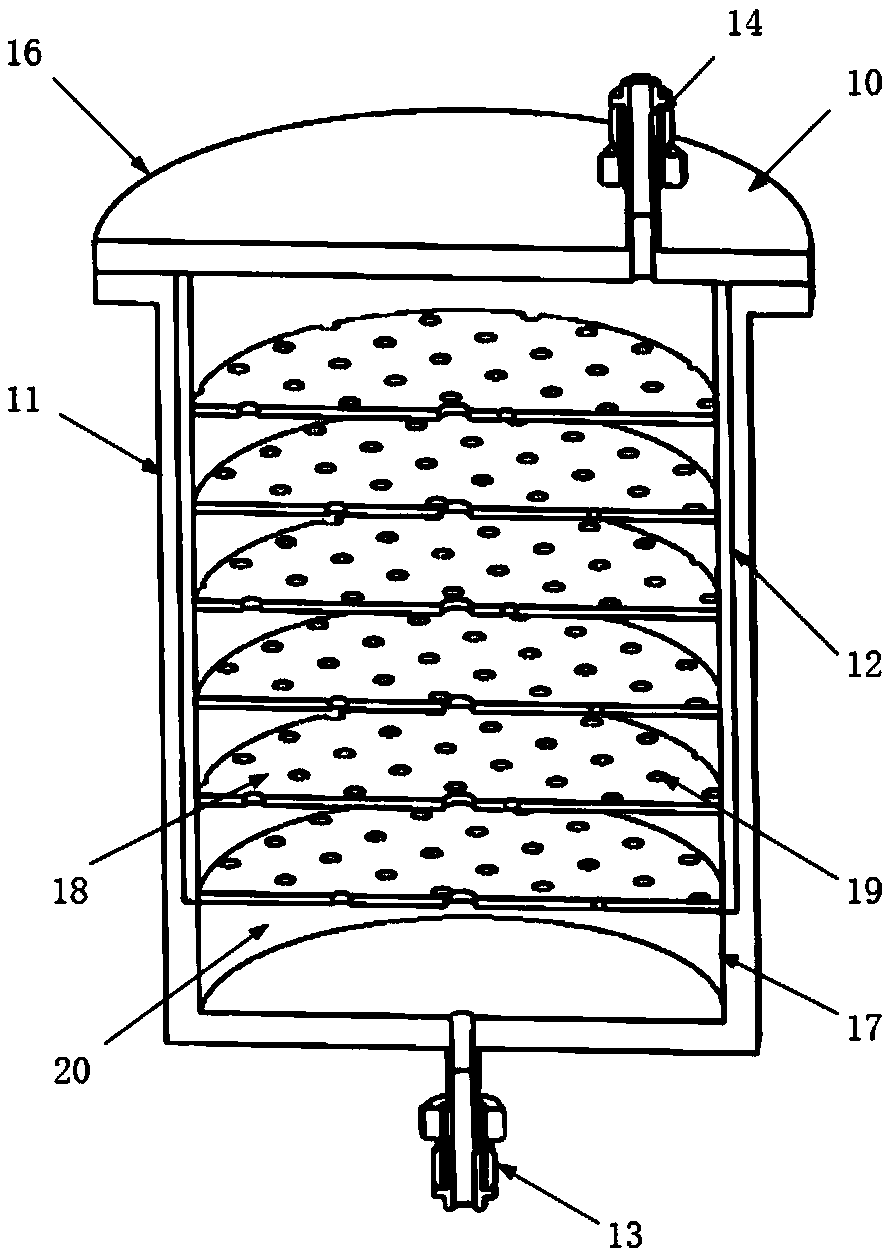

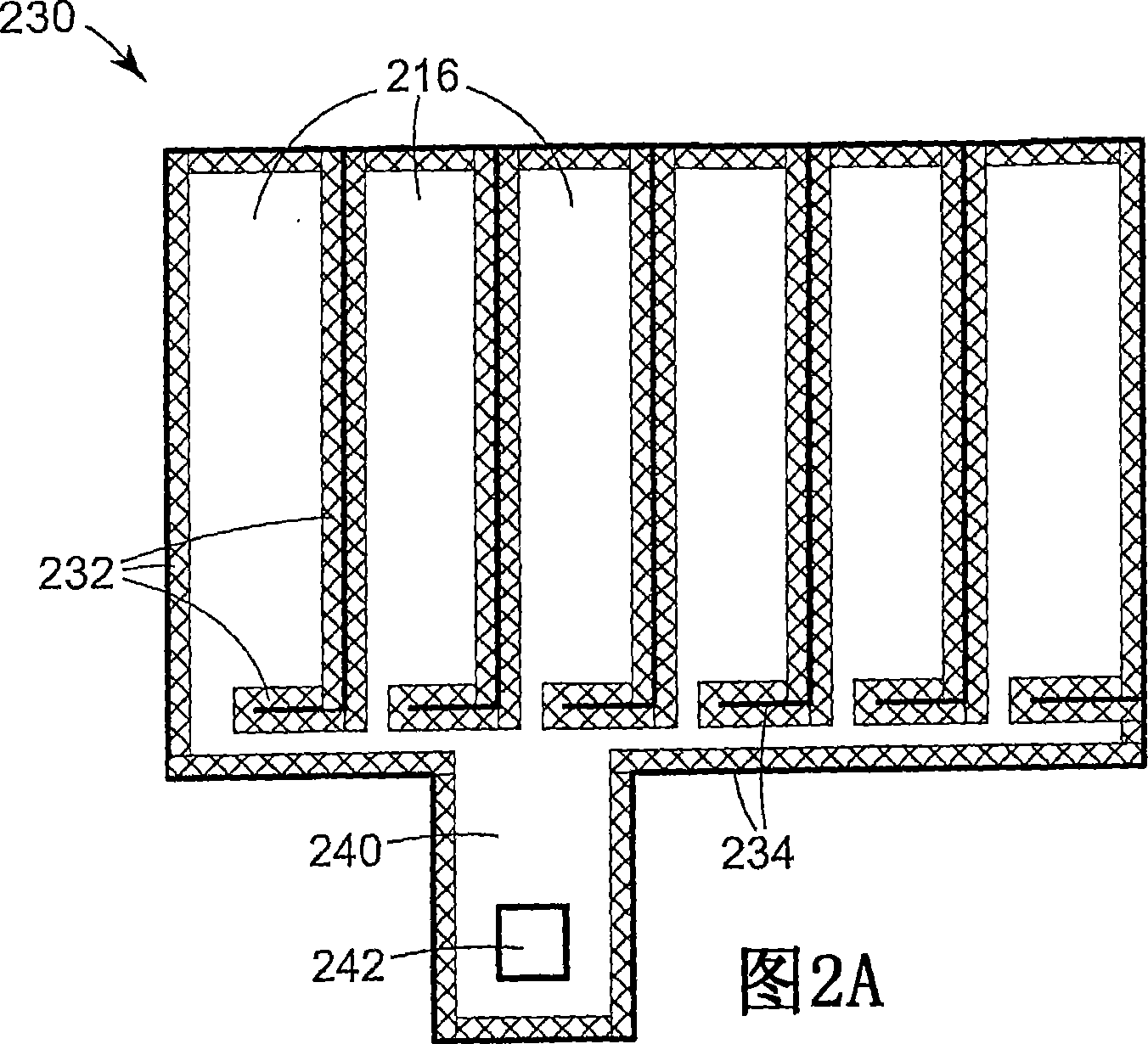

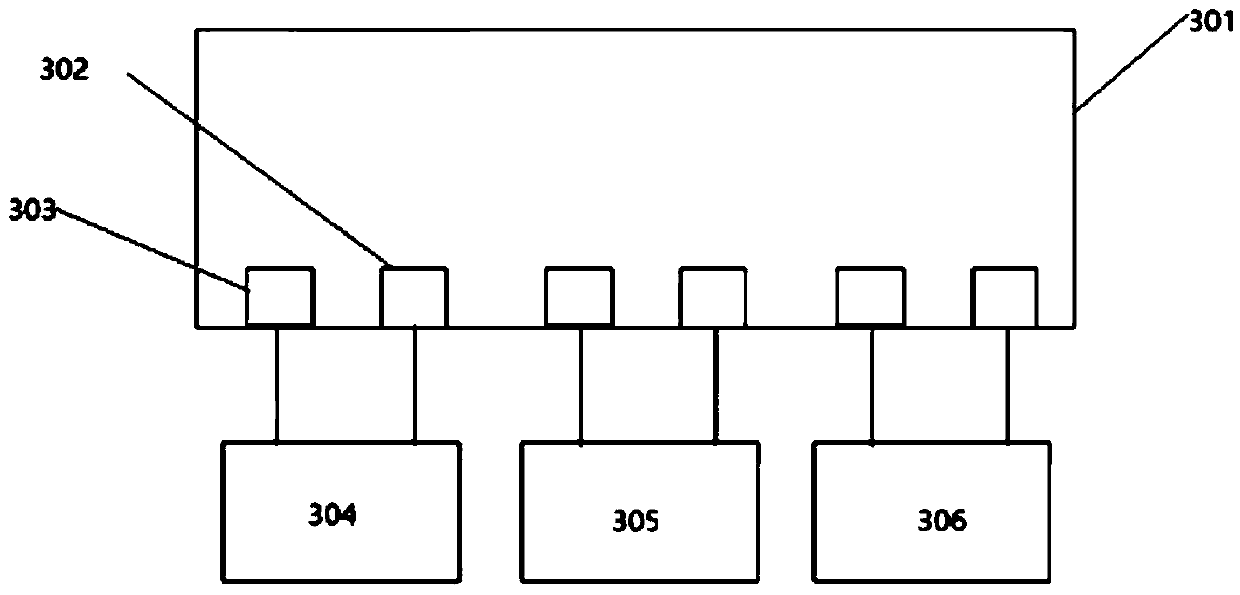

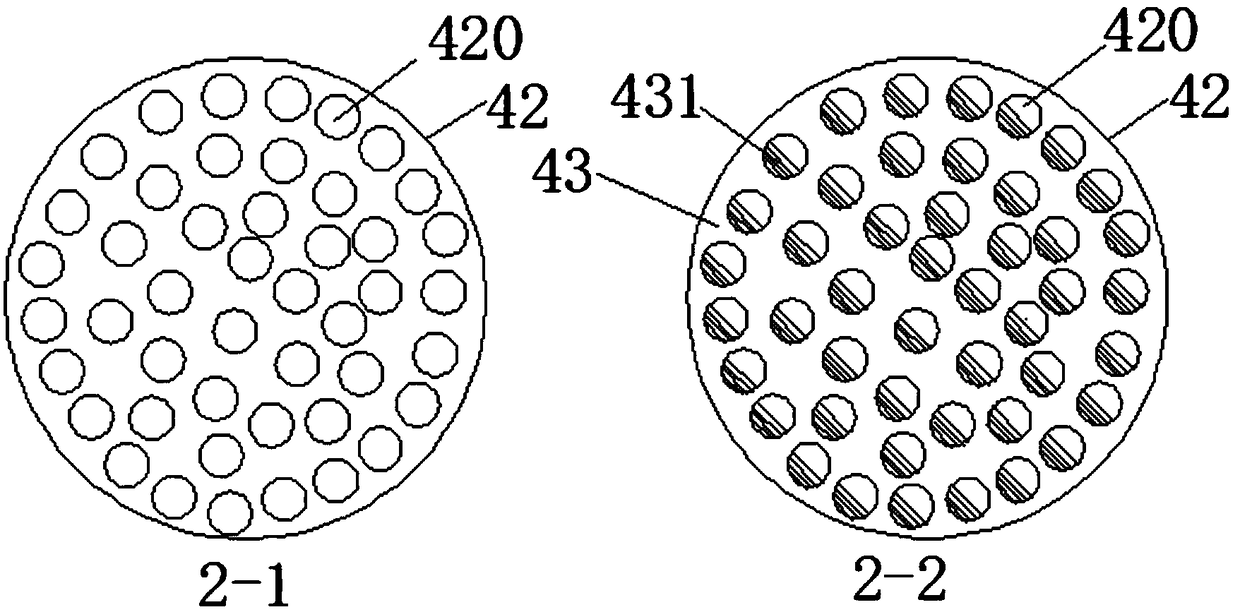

Solid precursor vapor pressure stabilization and purification device and ALD deposition equipment

PendingCN110885970AStable supply flowIncrease steam pressureChemical vapor deposition coatingVapor pressureSolid particle

The embodiment of the invention provides a solid precursor vapor pressure stabilization and purification device. The solid precursor vapor pressure stabilization and purification device comprises a shell, wherein a closed processing space is formed in the shell. The shell is provided with an air inlet and an exhaust port which communicate with a processing space. The solid precursor vapor pressurestabilization and purification device further comprises a plurality of uniform flow components. The plurality of uniform flow components are arranged in the shell and are sequentially arranged in thevertical direction. The processing space is divided into a plurality of sub-spaces which are sequentially arranged from bottom to top. The uniform flow components are provided with through holes. Theadjacent sub-spaces communicate through the through holes. An air inlet communicates with the sub-space located on the lowermost portion. The exhaust port communicates with the sub-space located on the uppermost portion. The invention further provides ALD deposition equipment. The pressure stabilization and purification device can improve the stability of steam of a low-vapor pressure precursor,and reduce the pollution of precursor solid particles to a transmission pipeline, a chamber and a product.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

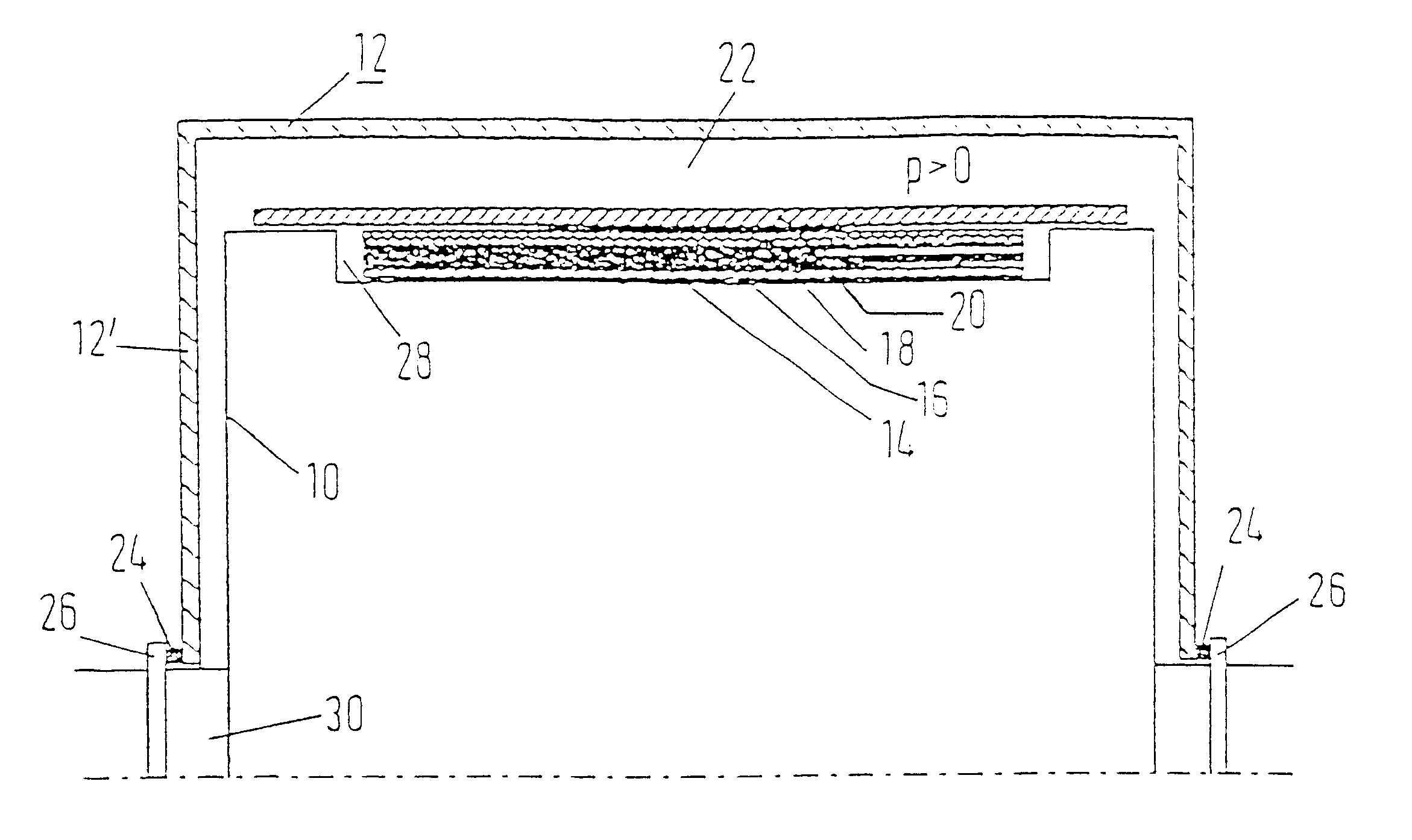

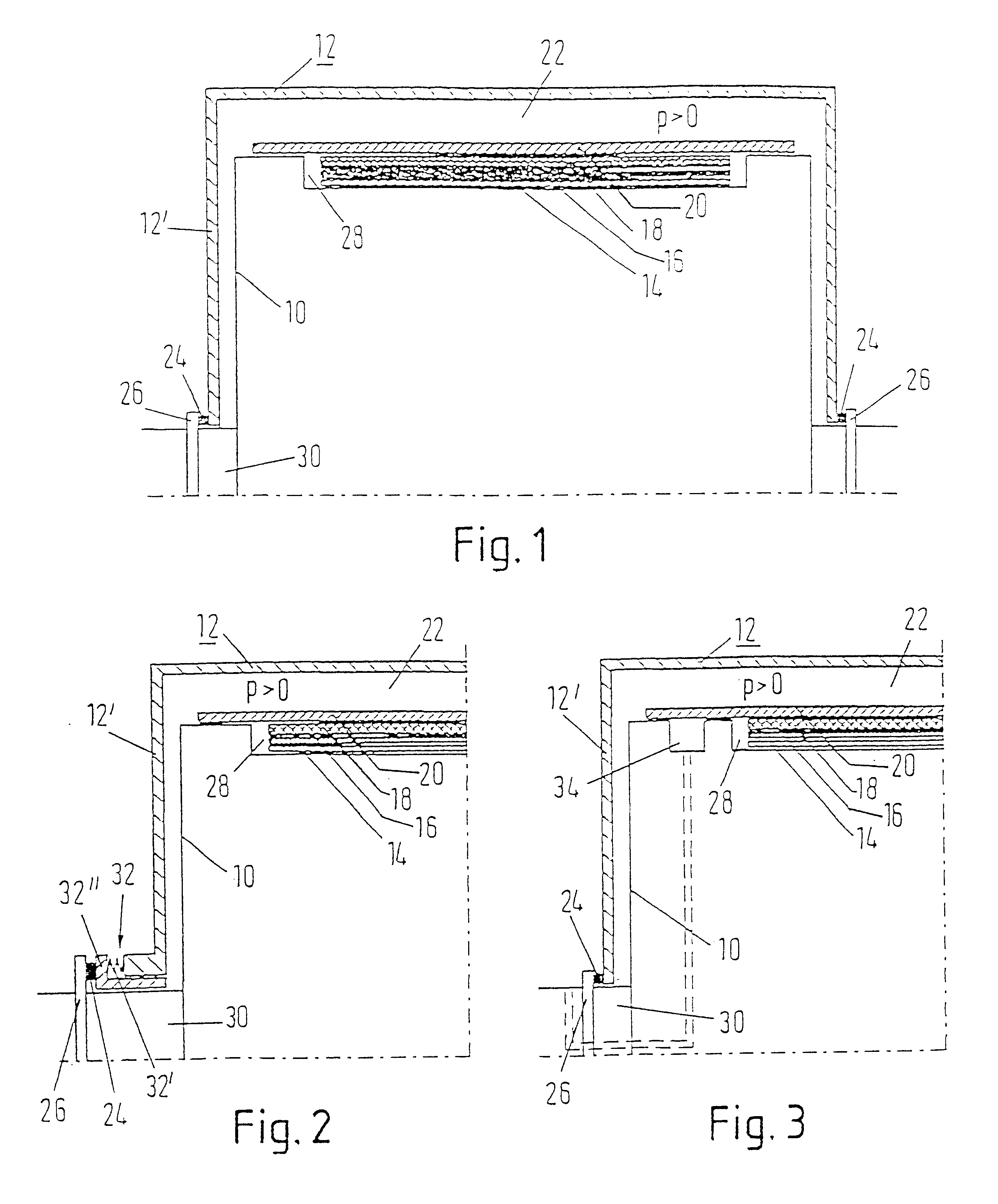

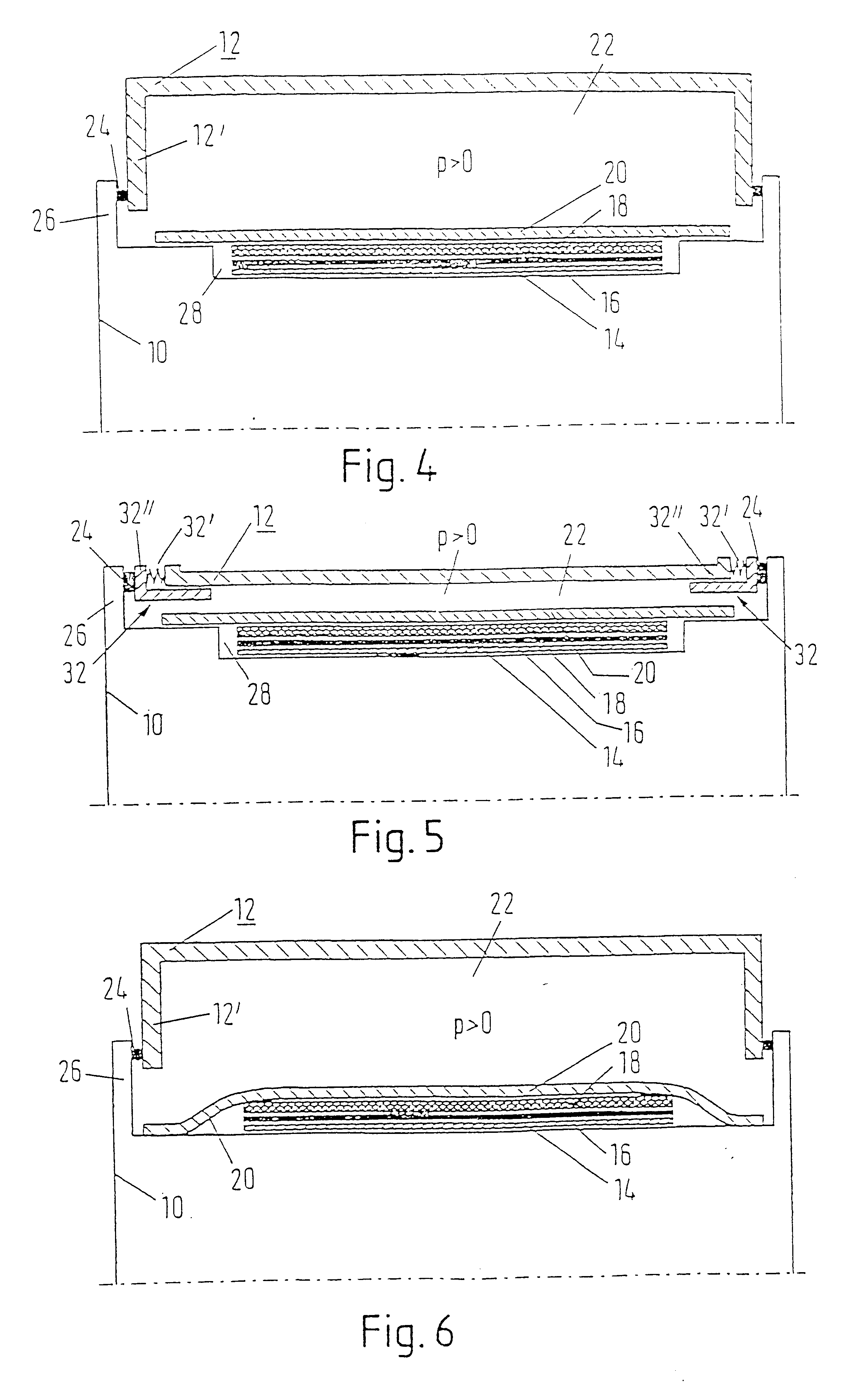

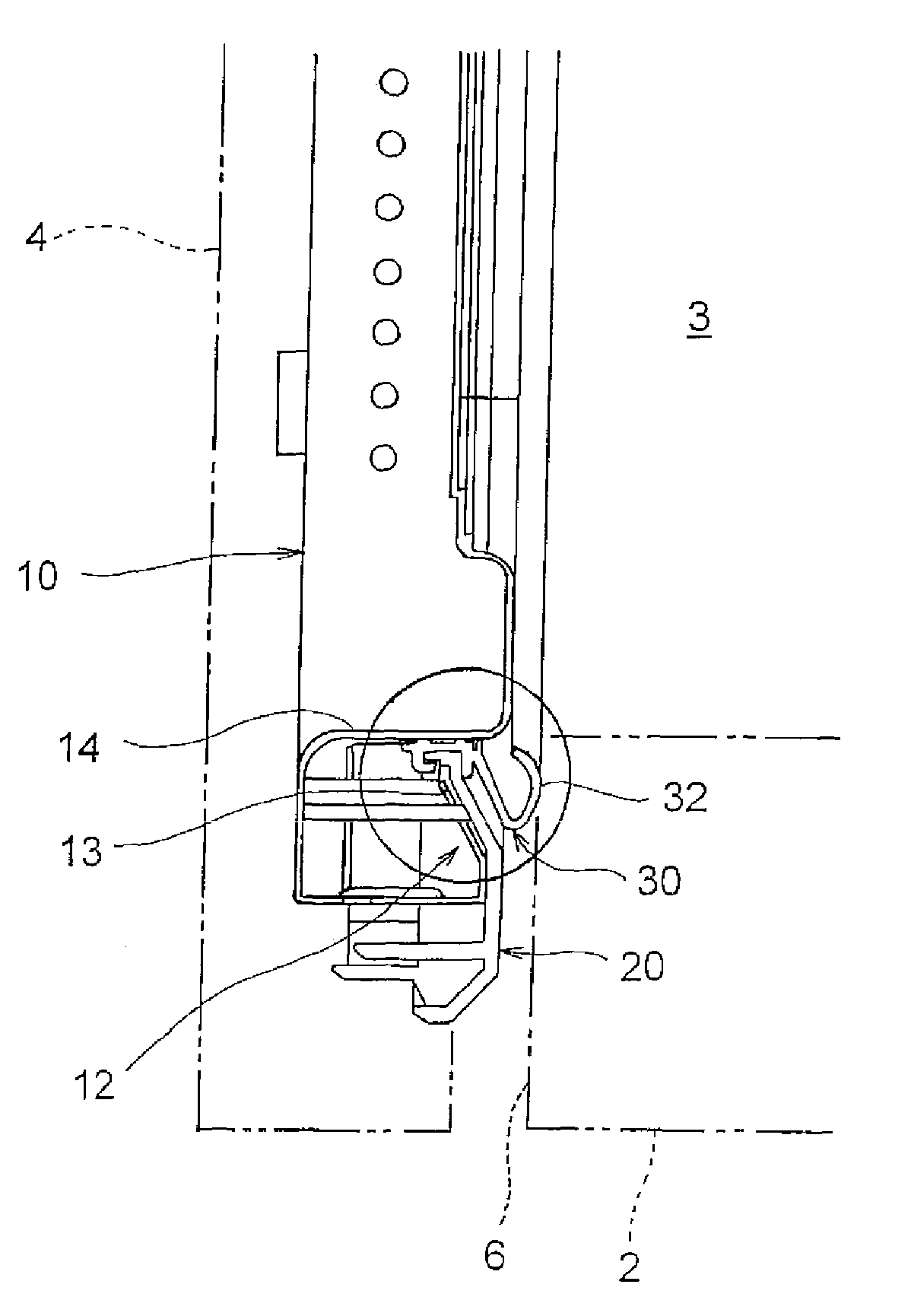

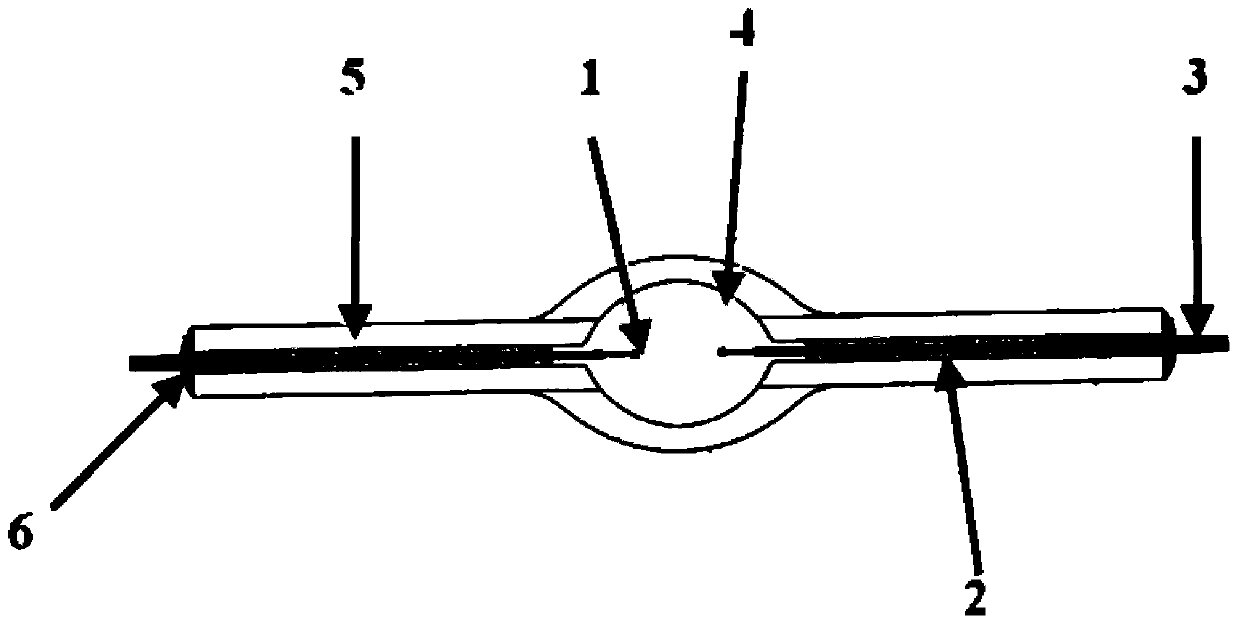

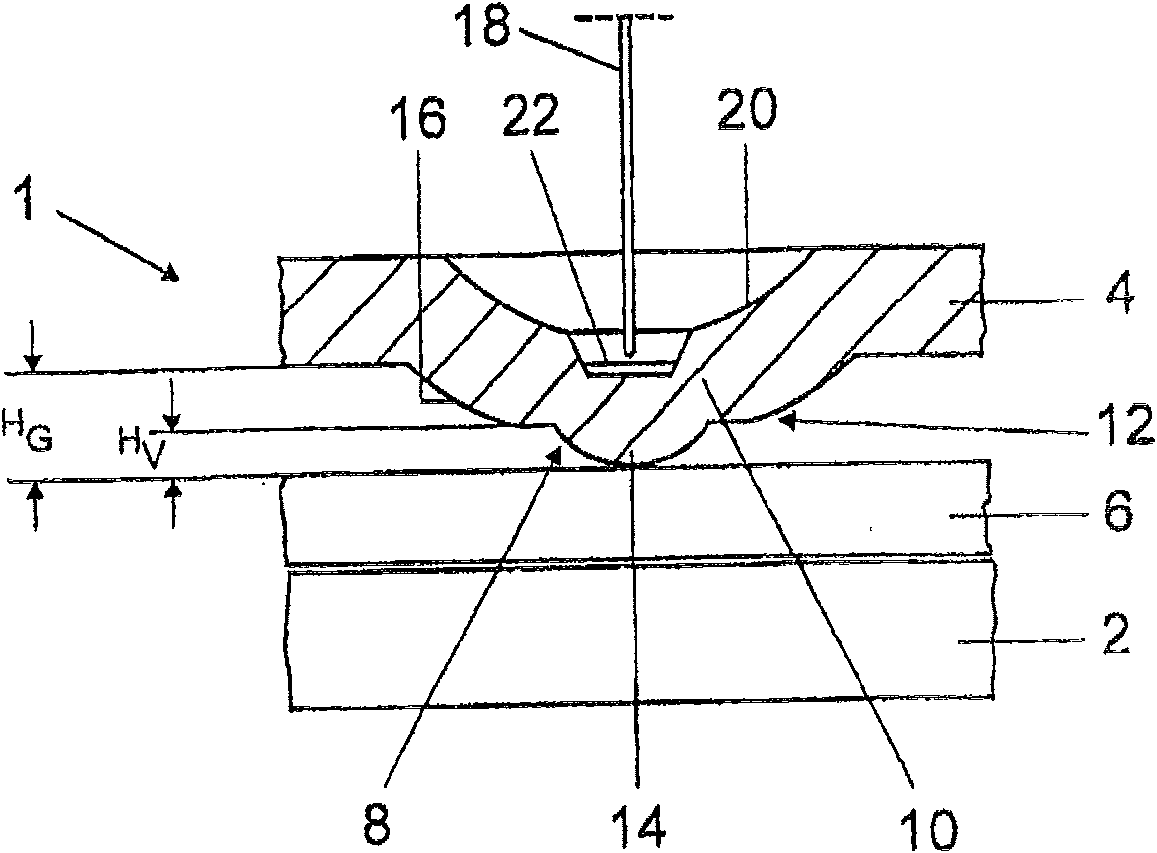

Machine for producing and/or treating a material web

InactiveUS6397493B1Reliable and reliableMinimal costDrying using combination processesDrying solid materials with heatEngineeringEdge region

An apparatus for at least one of producing and treating a material web is provided including at least one wire; an outer sealing belt, which is wider than said at least one wire, comprising a pair of lateral edge regions; at least one heatable unit, having an outer cylindrical surface, wherein said at least one wire and said outer sealing belt are at least partially wrapped around said at least one heatable unit; an overpressure cap arranged to form a pressure chamber containing a medium under pressure, said medium under pressure exerting a pressure on said at least one heatable unit; and at least one of: (a) a seal formed between said lateral edge regions and said heatable unit; and (b) a seal formed between end faces of said overpressure cap and an opposing wall to seal said pressure chamber from an external environment.

Owner:VOITH SULZER PAPIERTECHN PATENT

Heating cooker

ActiveUS20180263401A1Shorten the timeGreat effortDomestic stoves or rangesLighting and heating apparatusWater dischargeSteam pressure

By preheating temperature raising unit of a steam and hot water generating device beforehand to a predetermined temperature, and supplying water in an amount equal to or more than predetermined amount V (per unit time) to the temperature raising unit, a large amount of steam is instantaneously generated. At this time, hot water adhered to the temperature raising unit rises along with the steam, and the steam and hot water flowed through a steam hole, a relay tube, and a steam chamber are caused to eject instantaneously with accumulated steam pressure from a steam and hot water discharging port. The steam and hot water then hit and heat food products accommodated in a cooking chamber. Thus, a heating cooker capable of promptly heating a food product with steam can be provided.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

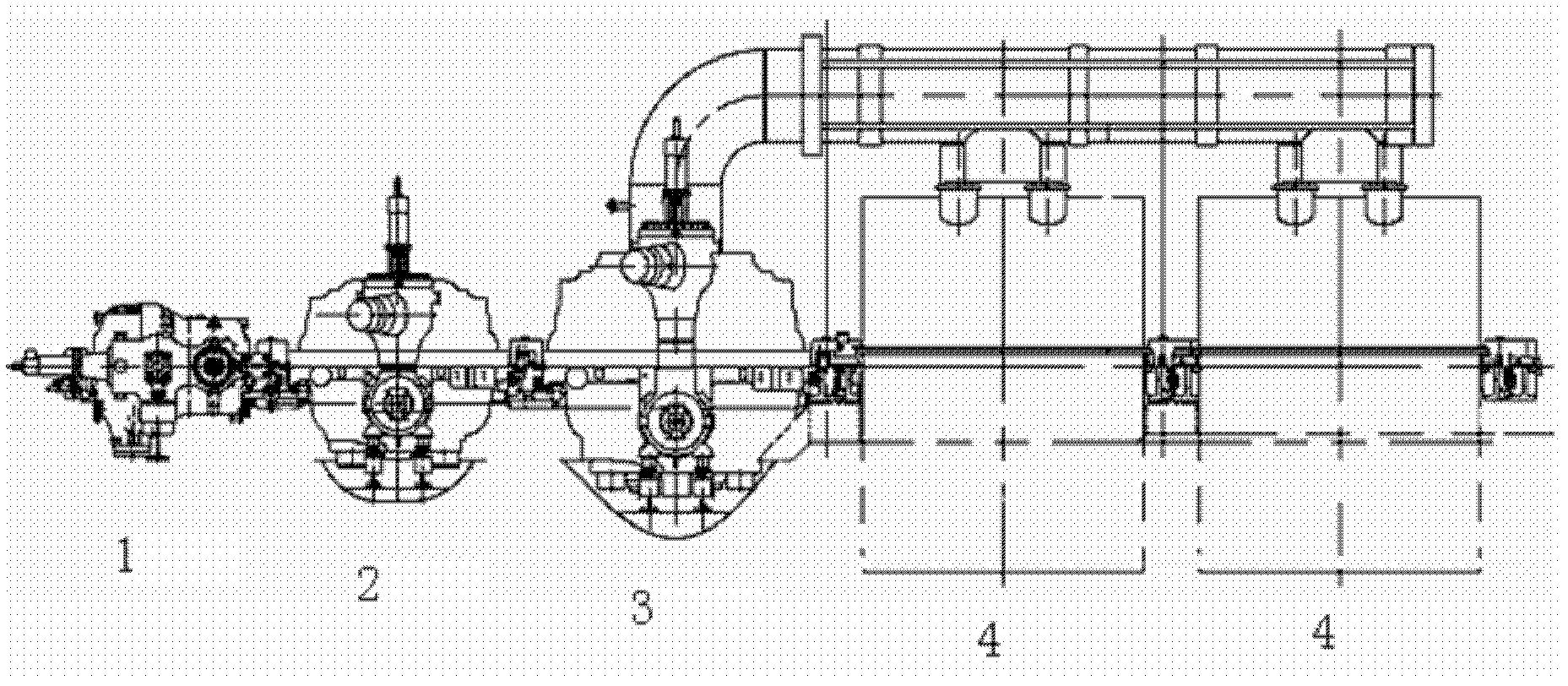

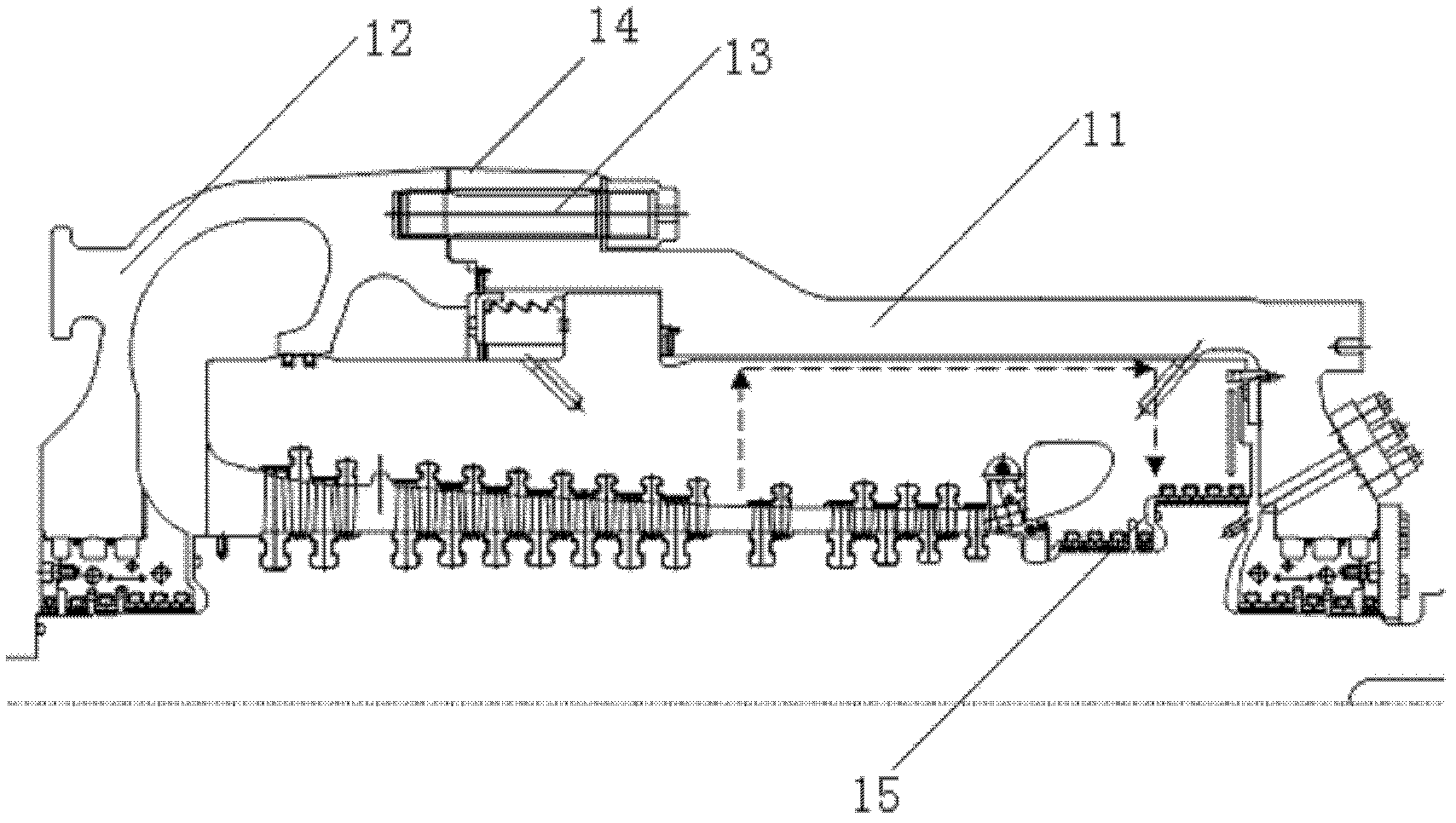

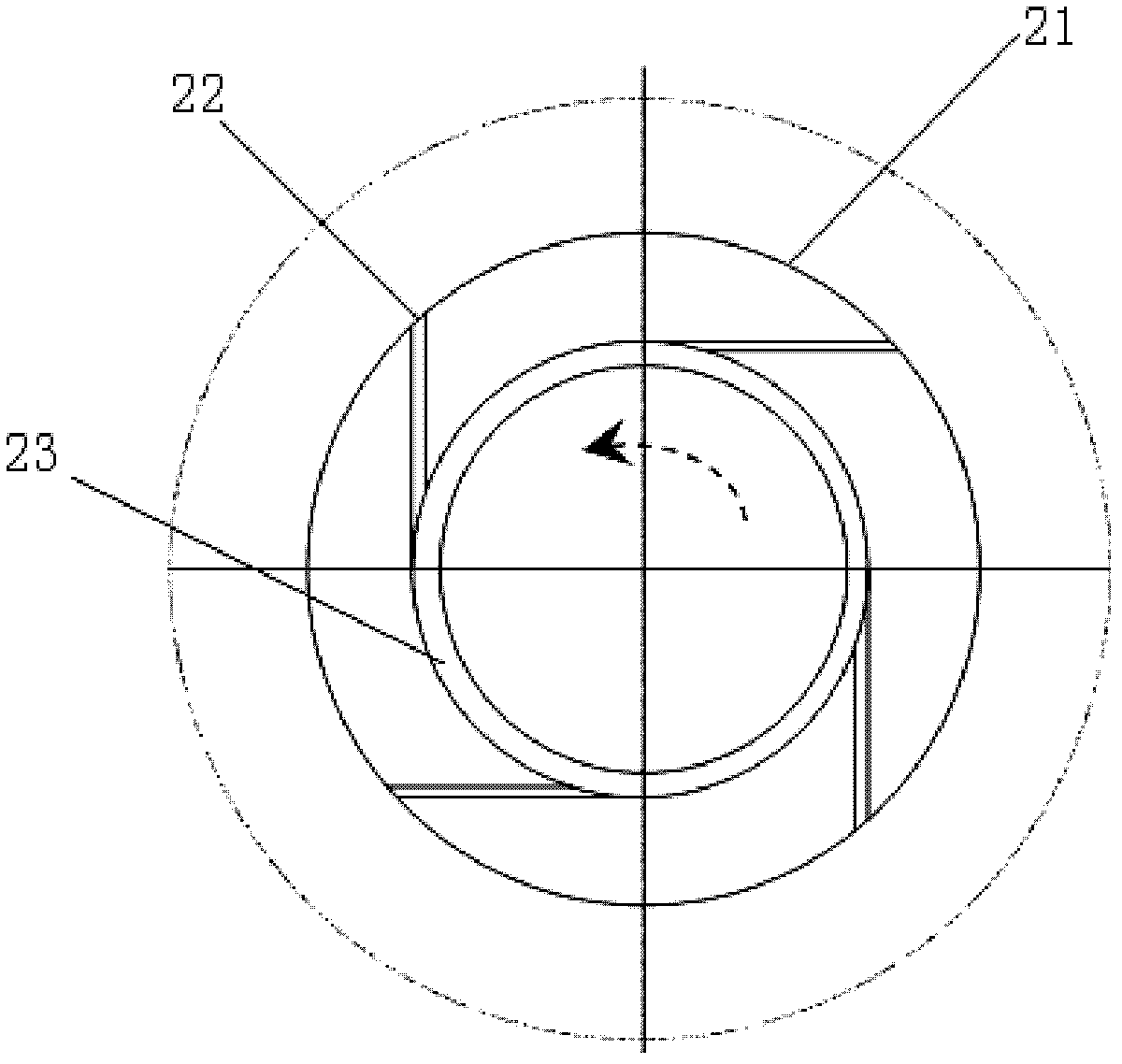

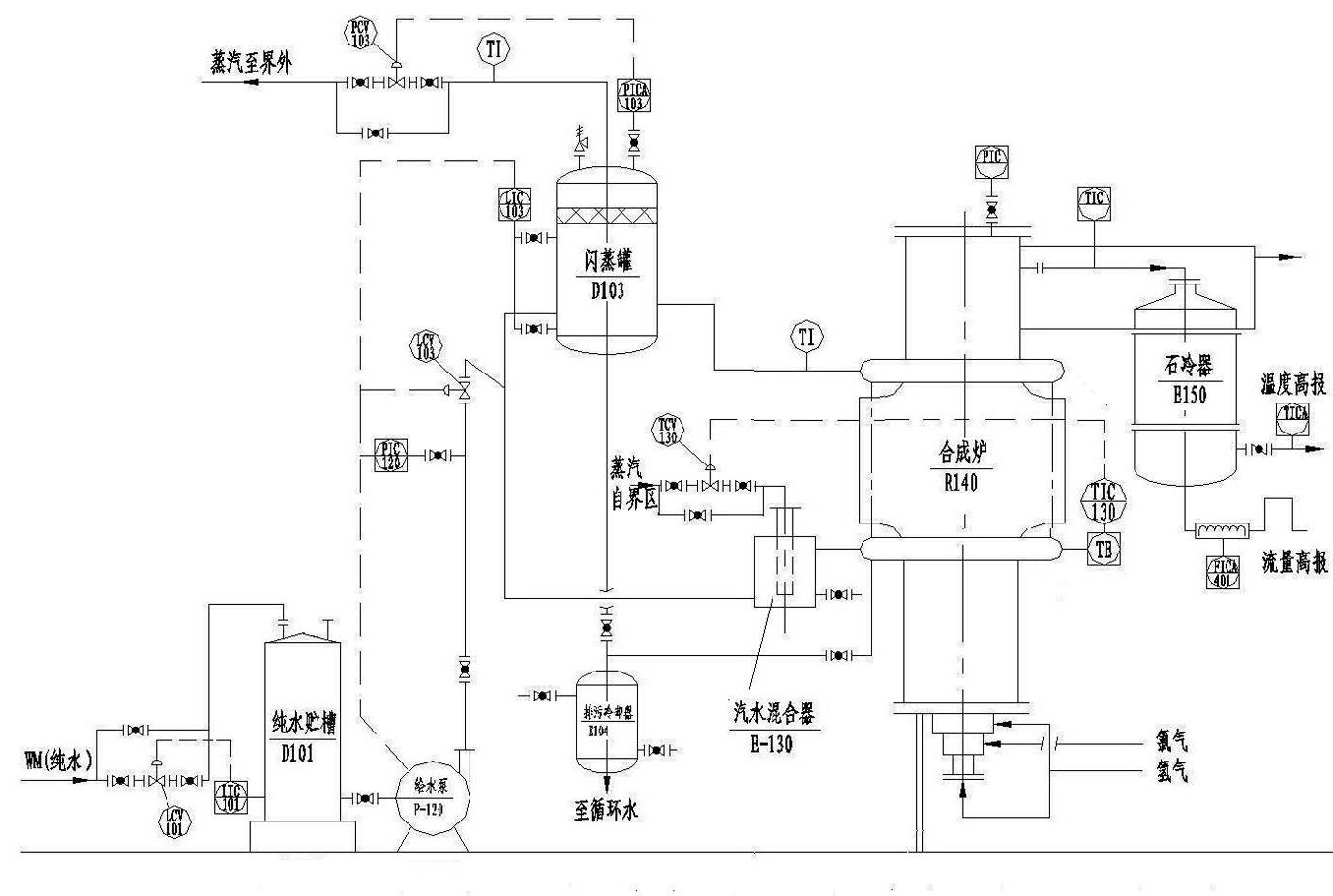

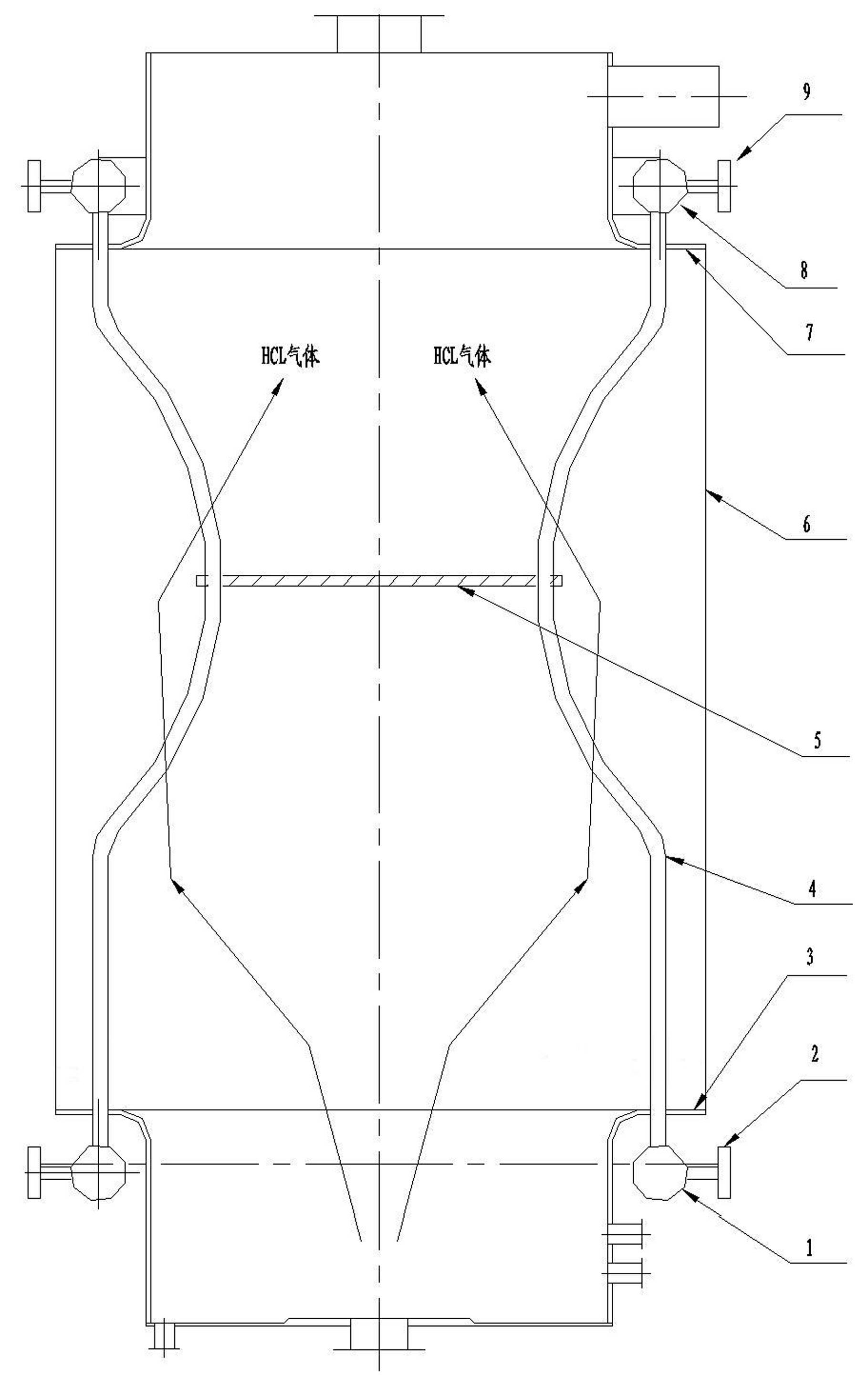

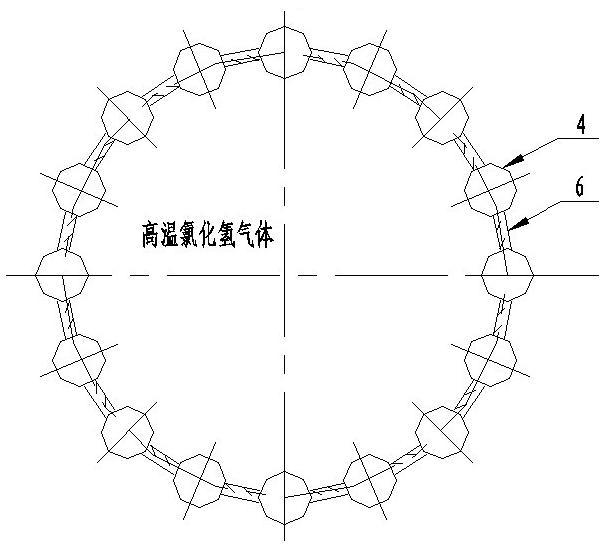

Technology for secondarily producing medium pressure steam during synthesizing chlorine and hydrogen into hydrogen chloride and equipment thereof

ActiveCN102515103AIncrease steam pressureWide range of steam useChlorine/hydrogen-chlorideEnergy inputChemistryHydrogen synthesis

The invention discloses a technology for secondarily producing medium pressure steam during synthesizing chlorine and hydrogen into hydrogen chloride and equipment thereof, wherein the high-temperature water forms an automatic closed loop heat exchange unit through improving the technology and the equipment, meanwhile, the following four problems can be solved: 1, equipment corrosion problem; 2, damage problem which is caused by equipment expansion and contraction; 3, welding deformation problem during the equipment manufacturing process; and 4, equipment sealing problem. The invention is a chlorine and hydrogen synthesis waste heat recovery technology which has higher steam pressure and wider steam utilization scope.

Owner:SICHUAN PROVINCE JINLU RESIN

Treatment method for concentration of strong brine

ActiveCN106745422AImprove processing efficiencyLow boiling pointWater/sewage treatment by heatingSaline waterSalt water

The invention belongs to the technical field of wastewater treatment, and specifically discloses a treatment method for concentration of strong brine. The strong brine is fed into a high-dispersion screen of a high-dispersion chamber through a water outlet of a high-pressure water pump and is dispersed into micro superfine liquid particles; a negative pressure blade rotates to enable a negative pressure to be formed in the high-dispersion chamber; a steam pump is turned off to impel a spring to drive a piston to move downwards; and a switch is turned on, the steam pump is started, the temperature of the high-dispersion chamber is raised, and the high-dispersion chamber continuously performs high-dispersion concentration on the strong brine at a relatively high temperature. The scheme provides a treatment method for concentration of the strong brine, which enables the high-dispersion chamber to keep a relatively high temperature, and enables liquid to have sufficient vapor pressure.

Owner:BEIJING UNITY BENEFICIAL TECH CO LTD

Steam turbine structure

ActiveCN102383879BImprove pressure bearing capacityStrong pressure capacityStatorsSteam engine plantsSteam pressureLow-pressure area

The invention discloses a steam turbine structure, which comprises an ultrahigh pressure cylinder, a reheating high-pressure cylinder, one or two reheating intermediate-pressure cylinders and two or three low-pressure cylinders. The ultrahigh pressure cylinder is a double-layer cylinder, an outer cylinder of the ultrahigh pressure cylinder consists of two cylindrical blocks which are connected through axial bolts, and a rotor in the ultrahigh pressure cylinder is a small-diameter rotor. Since the axial action area of the ultrahigh pressure cylinder is much smaller than that of a horizontal central parting surface, the ultrahigh pressure cylinder in the above structure has higher bearing capacity as compared with that of an existing ultrahigh pressure cylinder block which is divided into an upper half structure and a lower half structure by the central parting surface, and further, an axial flange can be arranged in a lower-pressure area, working stress of the axial flange can be greatly reduced, bearing capacity of the ultrahigh pressure cylinder can be improved further, so that the ultrahigh pressure cylinder can bear higher steam pressure.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

Method for dissolving sodium silicate by virtue of static pressure kettle

InactiveCN103638834AAvoid wastingSlow coolingChemical industryAlkali metal silicatesEngineeringHigh pressure

The invention provides a method for dissolving sodium silicate by virtue of a static pressure kettle. The method comprises the following steps: switching off a discharging valve of the static pressure kettle; switching on an emptying valve of the static pressure kettle; opening a charging hole of the static pressure kettle; adding hot soil sodium silicate produced through a horse shoe flame kiln into the static pressure kettle, tightly covering the charging hole of the static pressure kettle, and adding water into the static pressure kettle by utilizing a high-pressure pump; switching off the emptying valve of the static pressure kettle; introducing steam into the static pressure kettle; cutting off an air source after the pressure in the static pressure kettle reaches a first specified vapor pressure; switching on the discharging valve of the static pressure kettle to discharge materials after the concentration of liquid sodium silicate in the static pressure kettle reaches a specified concentration; switching on the emptying valve of the static pressure kettle, carrying out empty after the pressure in the static pressure kettle is decreased to a second specified vapor pressure. By improving a liquid sodium silicate production process by adopting the technical scheme provided by the invention, an energy-saving and environmental-friendly process for dissolving the solid sodium silicate is provided.

Owner:青岛东岳泡花碱有限公司

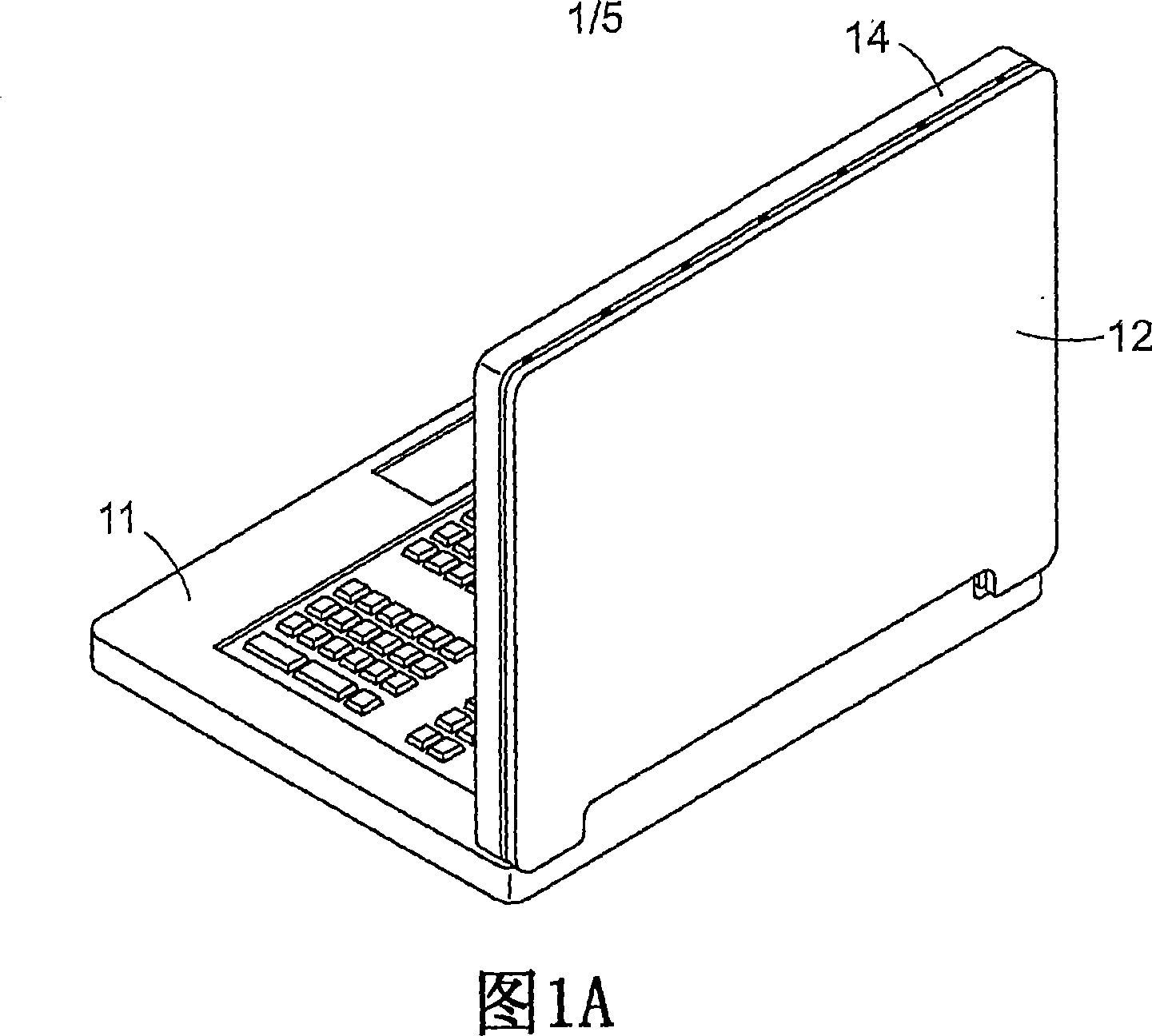

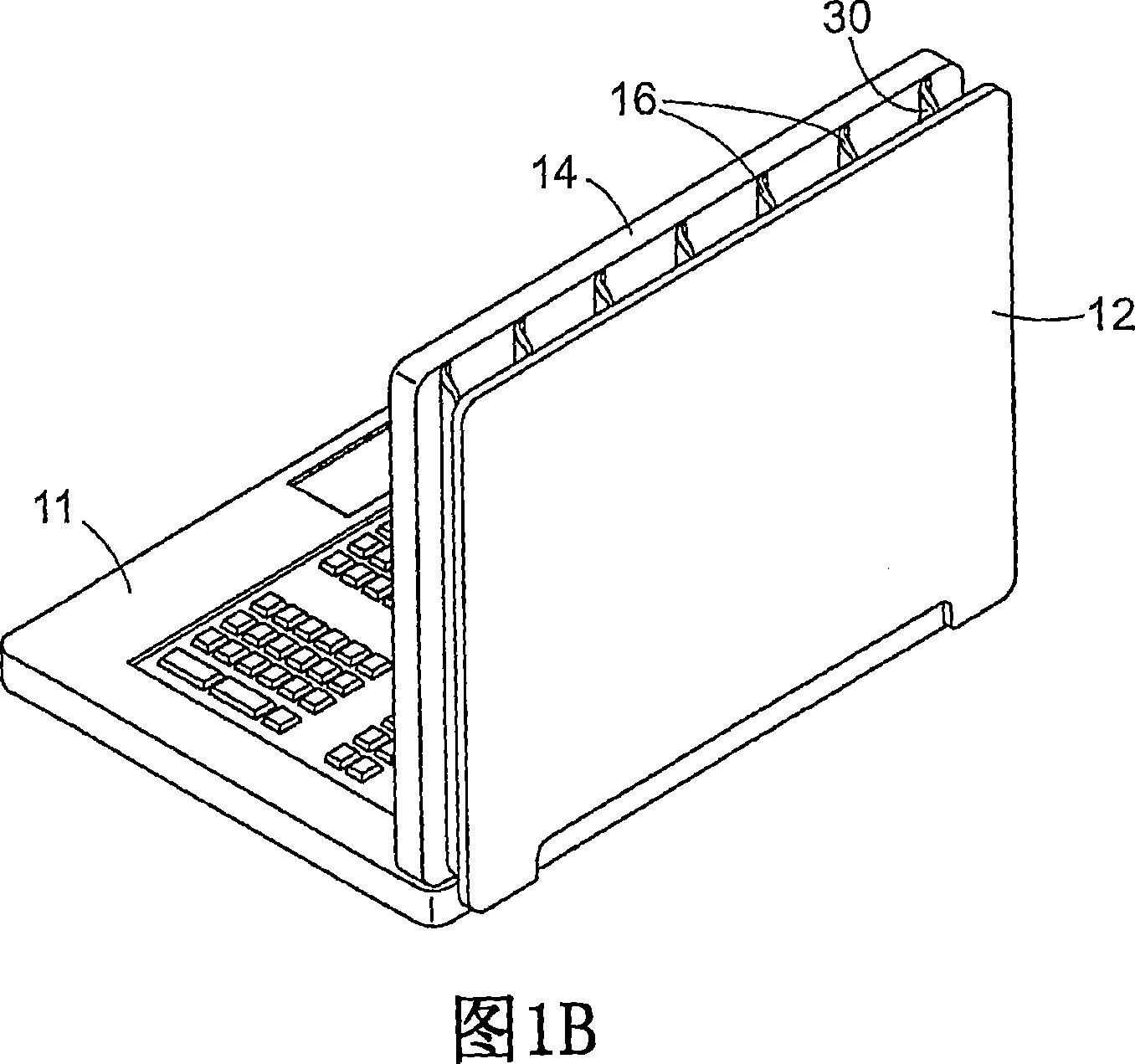

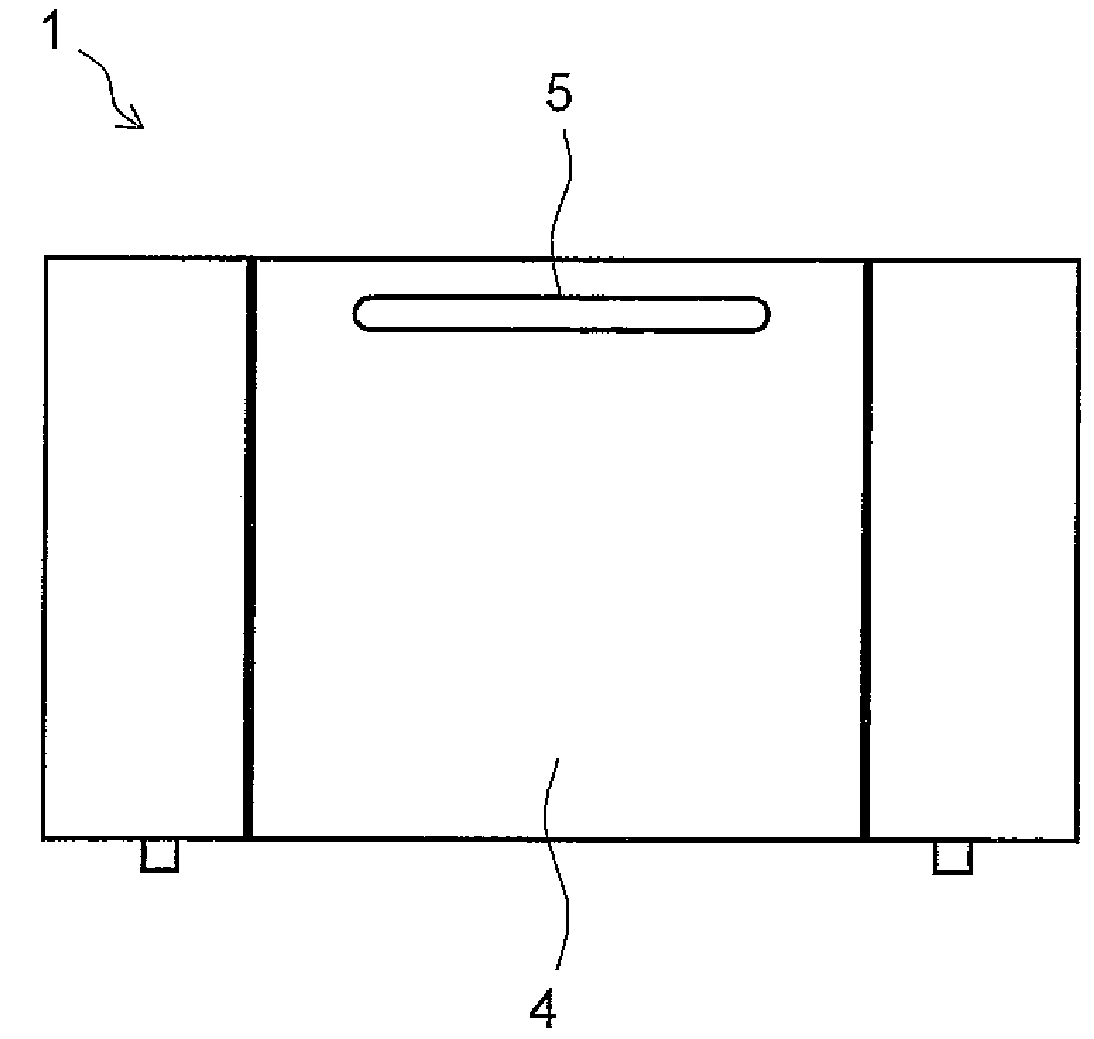

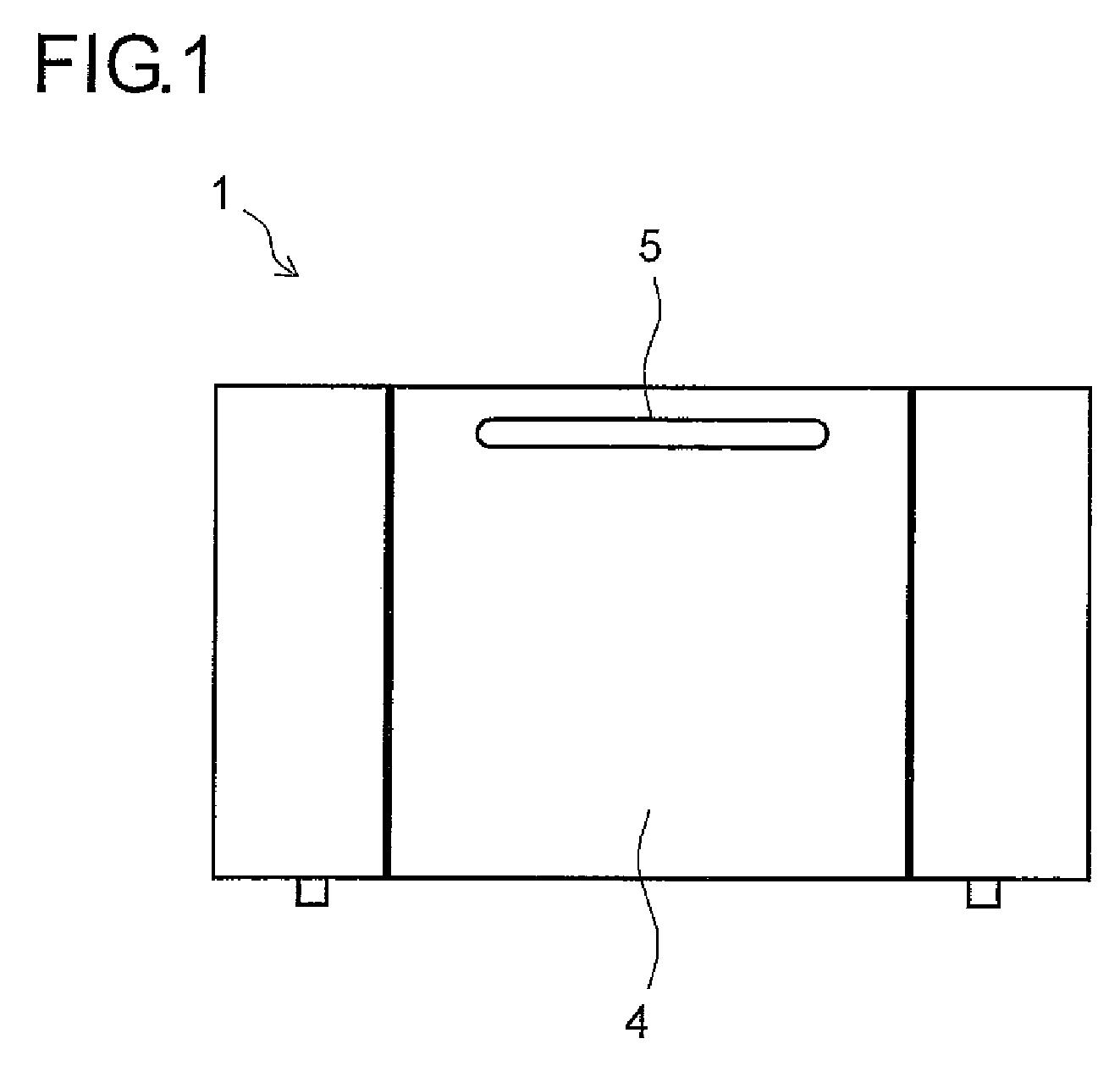

Cooking device

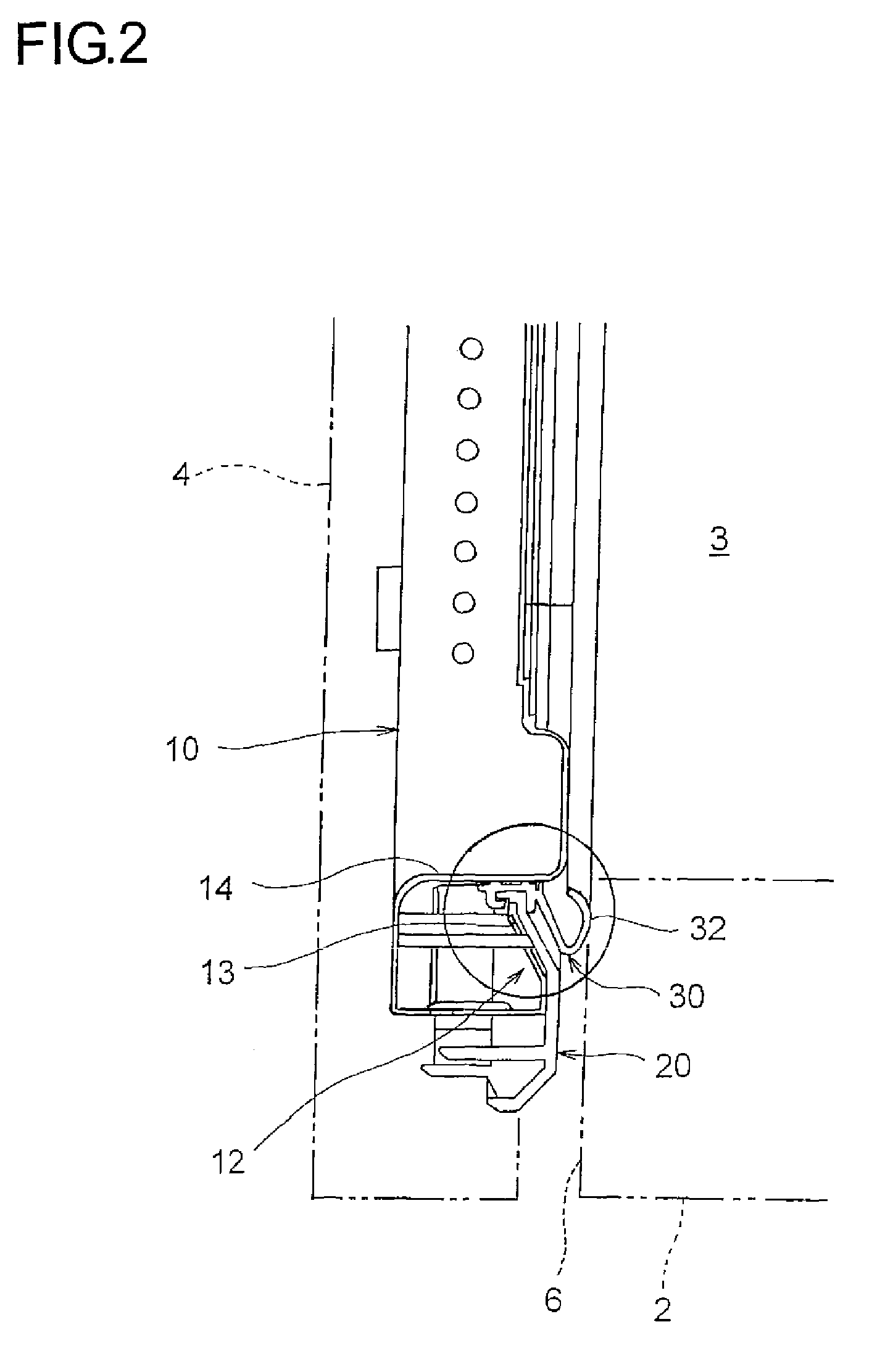

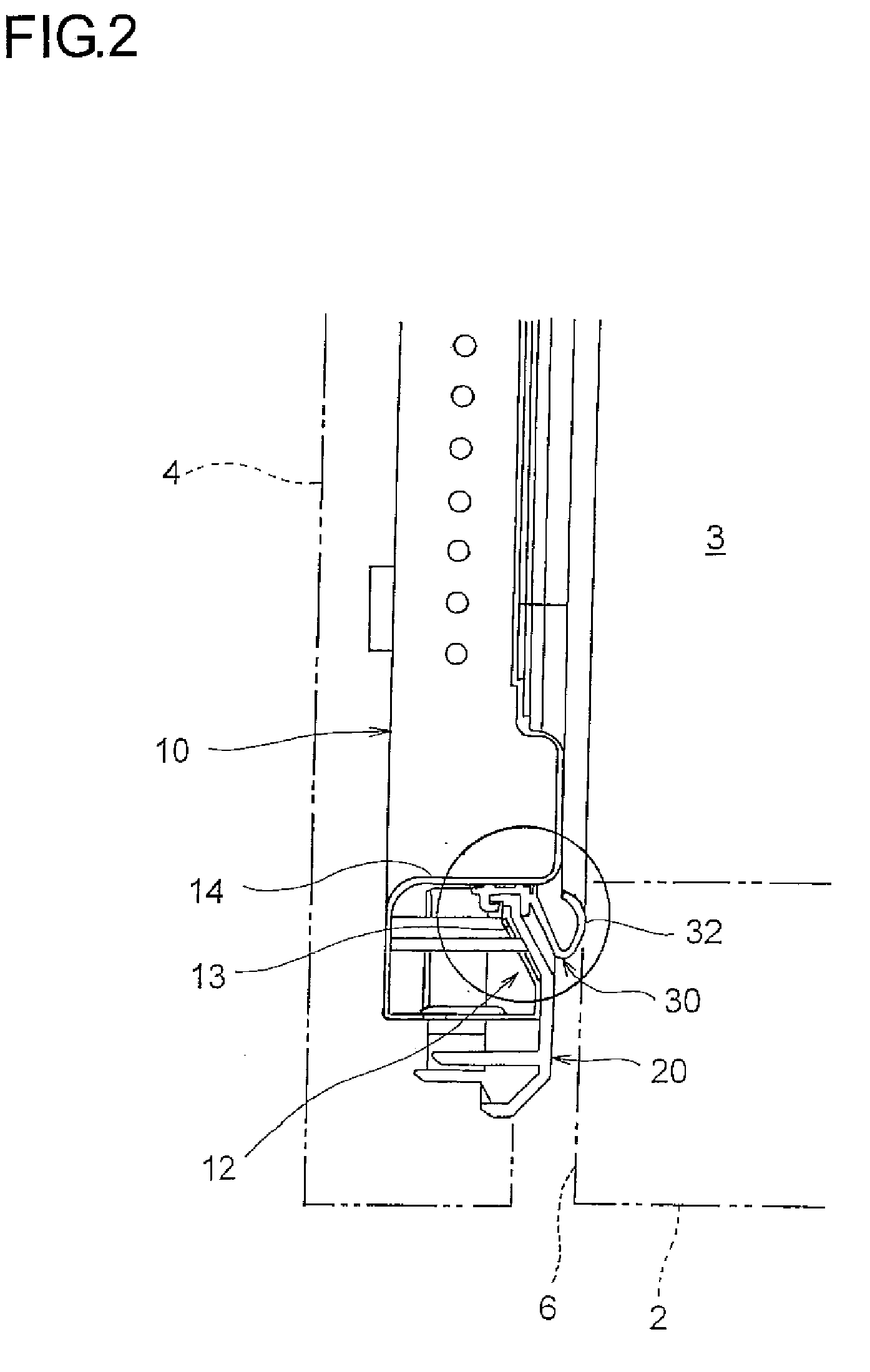

ActiveUS8288695B2Improve sealingPrevent leakageDomestic stoves or rangesOven air-treatment devicesMicrowaveGasket

A cooking device for performing cooking using a microwave and steam, in which a door of a heating chamber includes, as constituting components, an inner frame, a choke cover, and a gasket. The inner frame is made of metal and has at its periphery a choke structure constructed from a large number of comb teeth. The gasket is installed in the door with a base section of the gasket held between the inner frame and the choke cover. A lip section of the gasket has a bag-like cross-section whose side that faces the inside of the heating chamber is an entrance. The forward end of the lip section is bent to the door side. The comb teeth, except those positioned at the corners of the door, are bent at a larger angle than in a case in which the gasket is not installed.

Owner:SHARP KK

Ceramic halogen lamp

InactiveCN104183466AIncrease vapor pressureIncrease steam pressureGas discharge lamp detailsNoble gasSodium iodide

Provided is a ceramic halogen lamp which comprises a ceramic electric arc tube filled with a rare gas, first metal halides, second metal halides, and zinc. The first metal halides comprise sodium iodide, thallium iodide, dysprosium iodide, and thulium iodide. The second metal halides comprise zinc iodide and gallium iodide. The ceramic halogen lamp is environmentally friendly.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

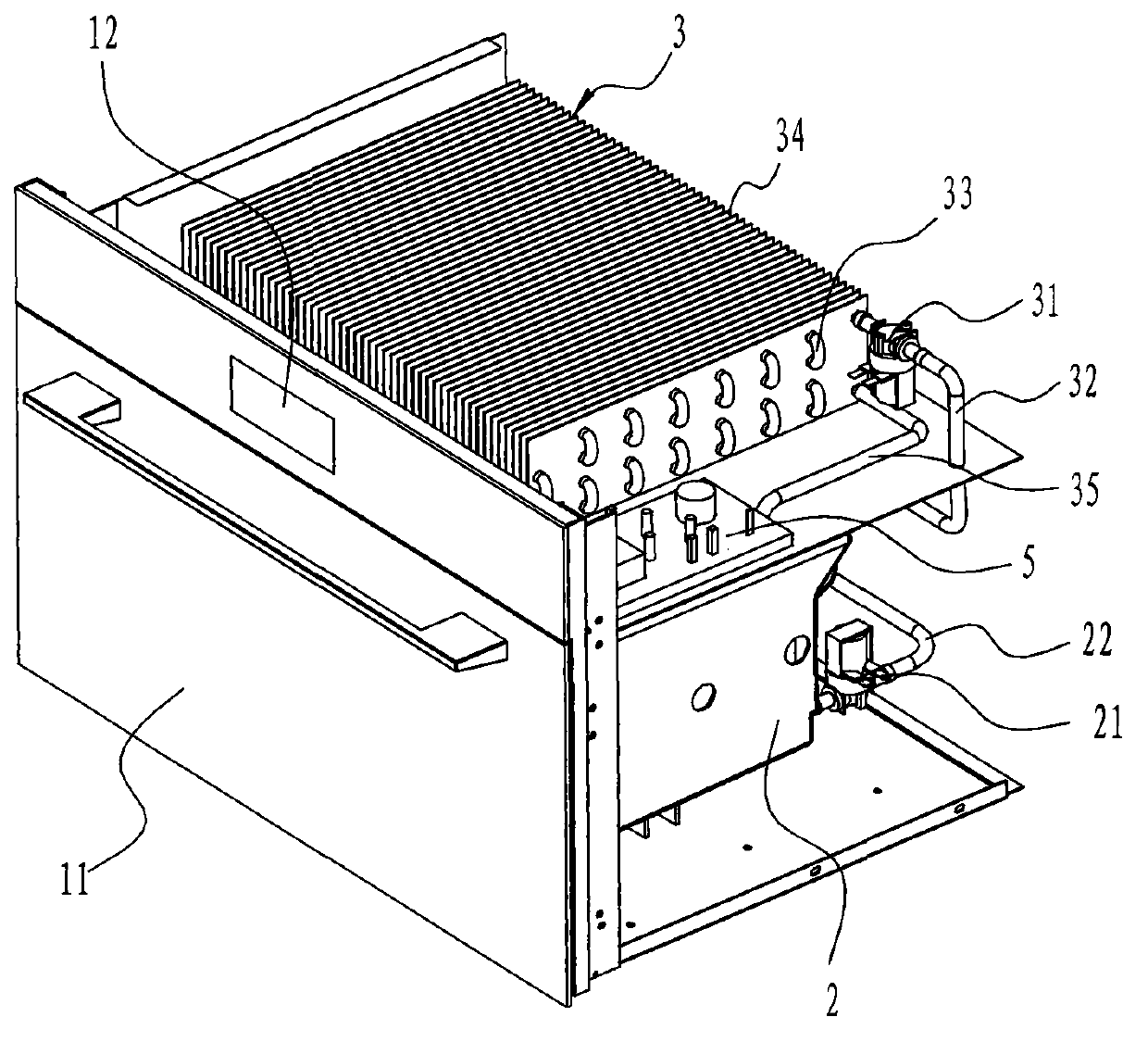

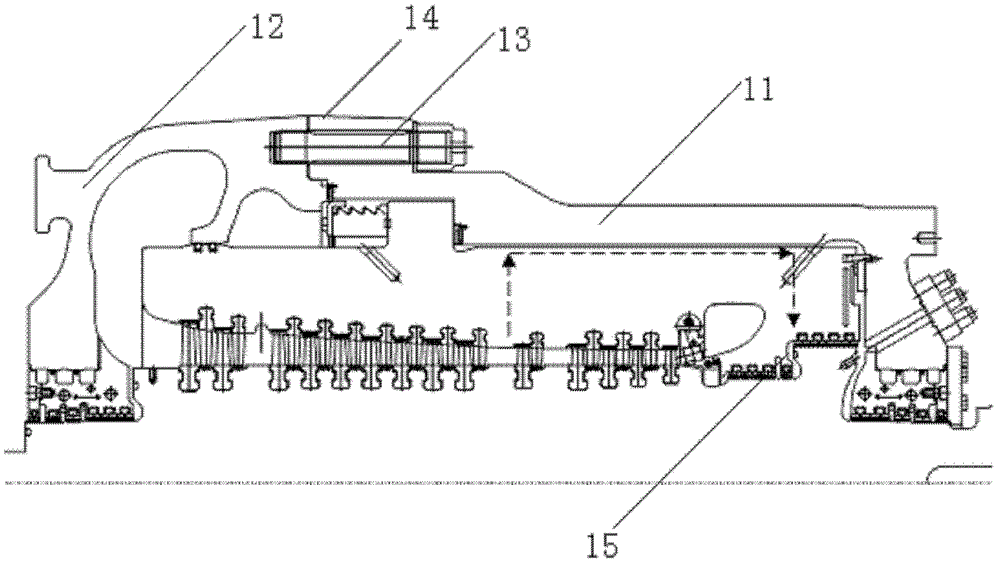

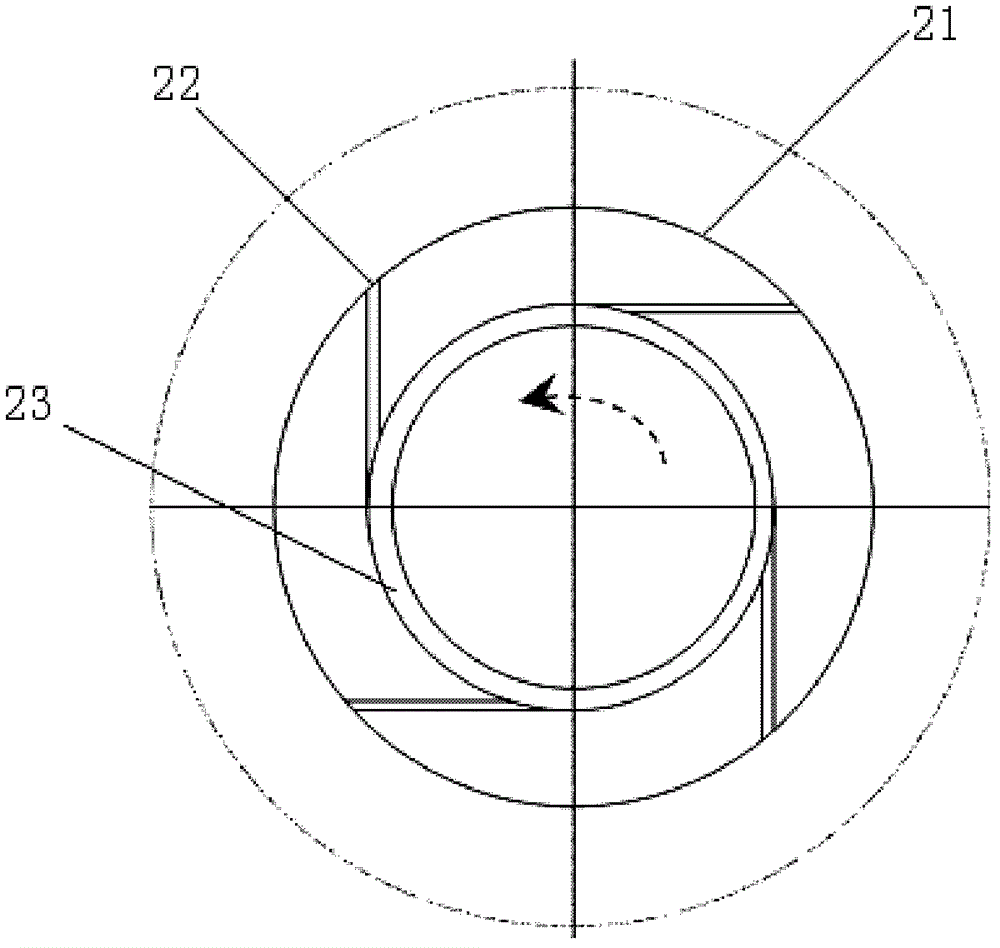

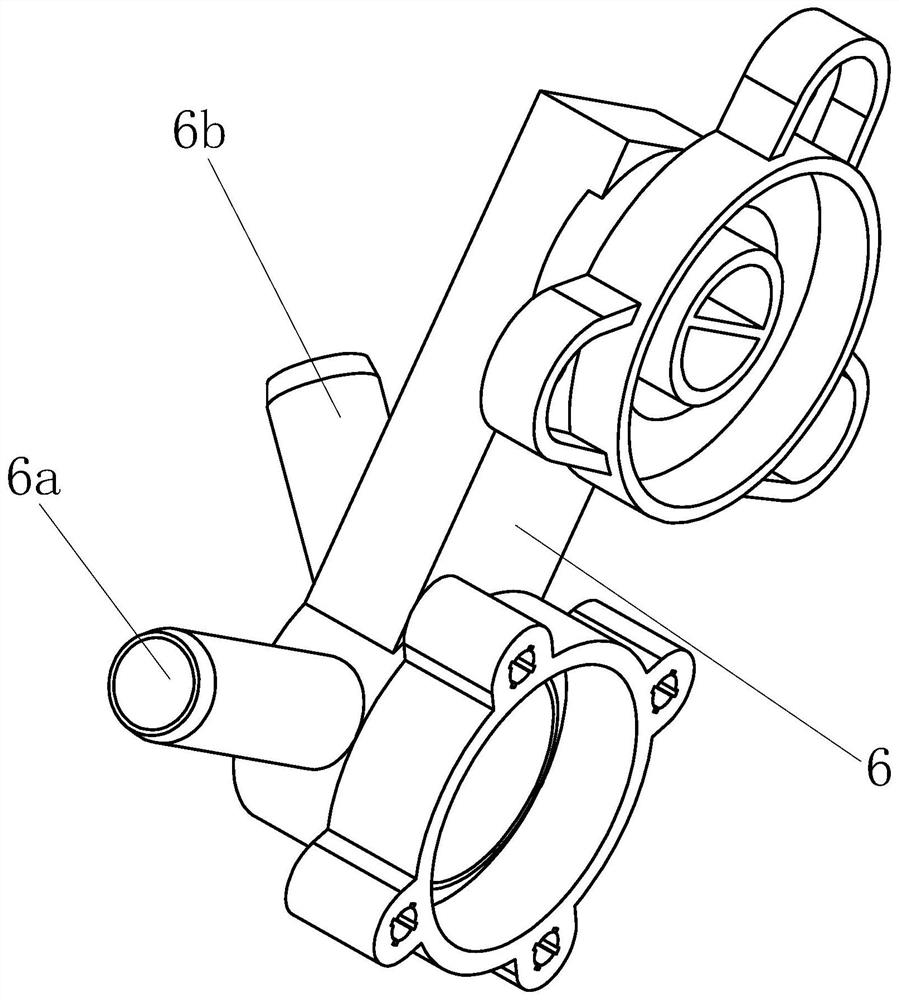

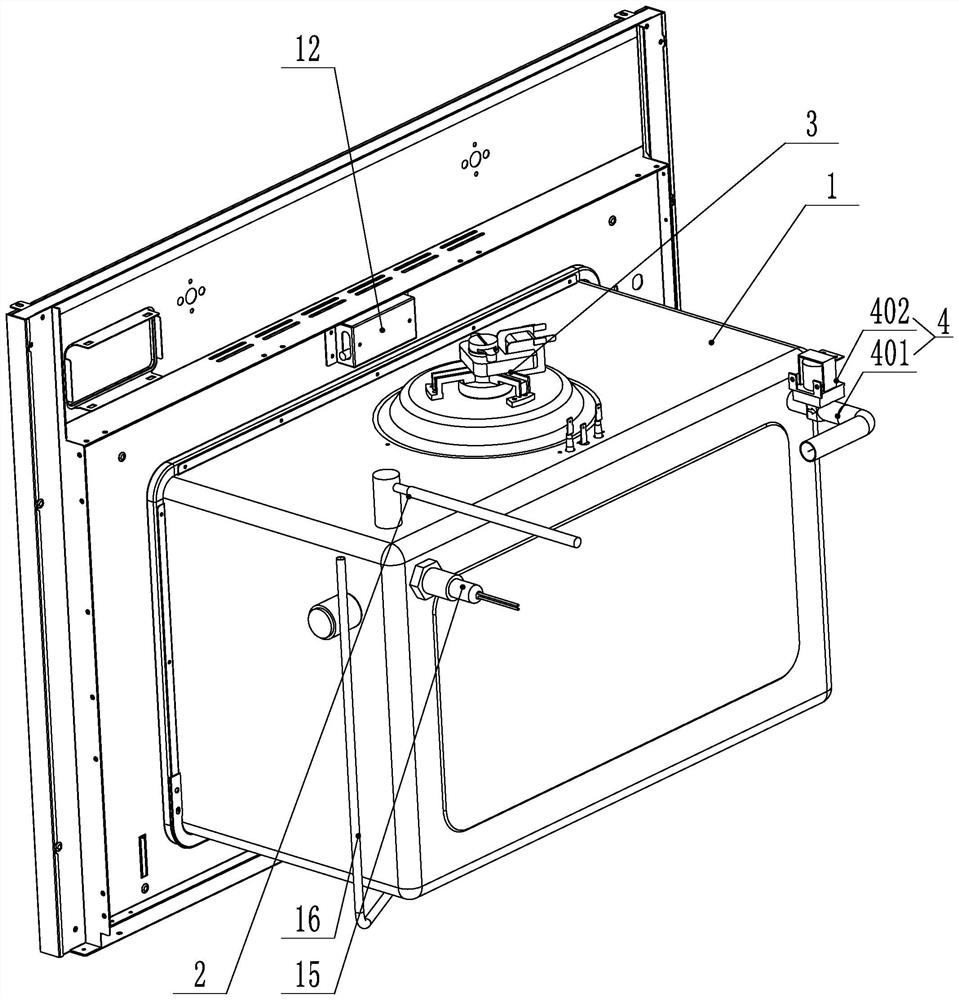

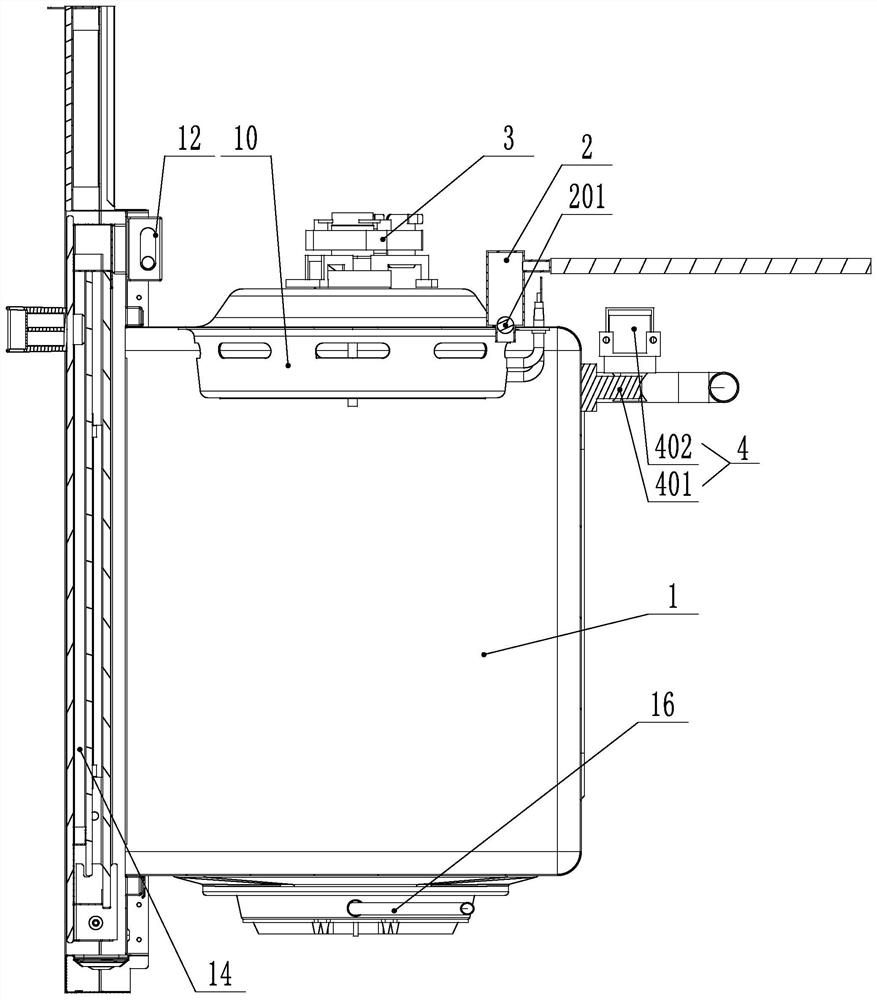

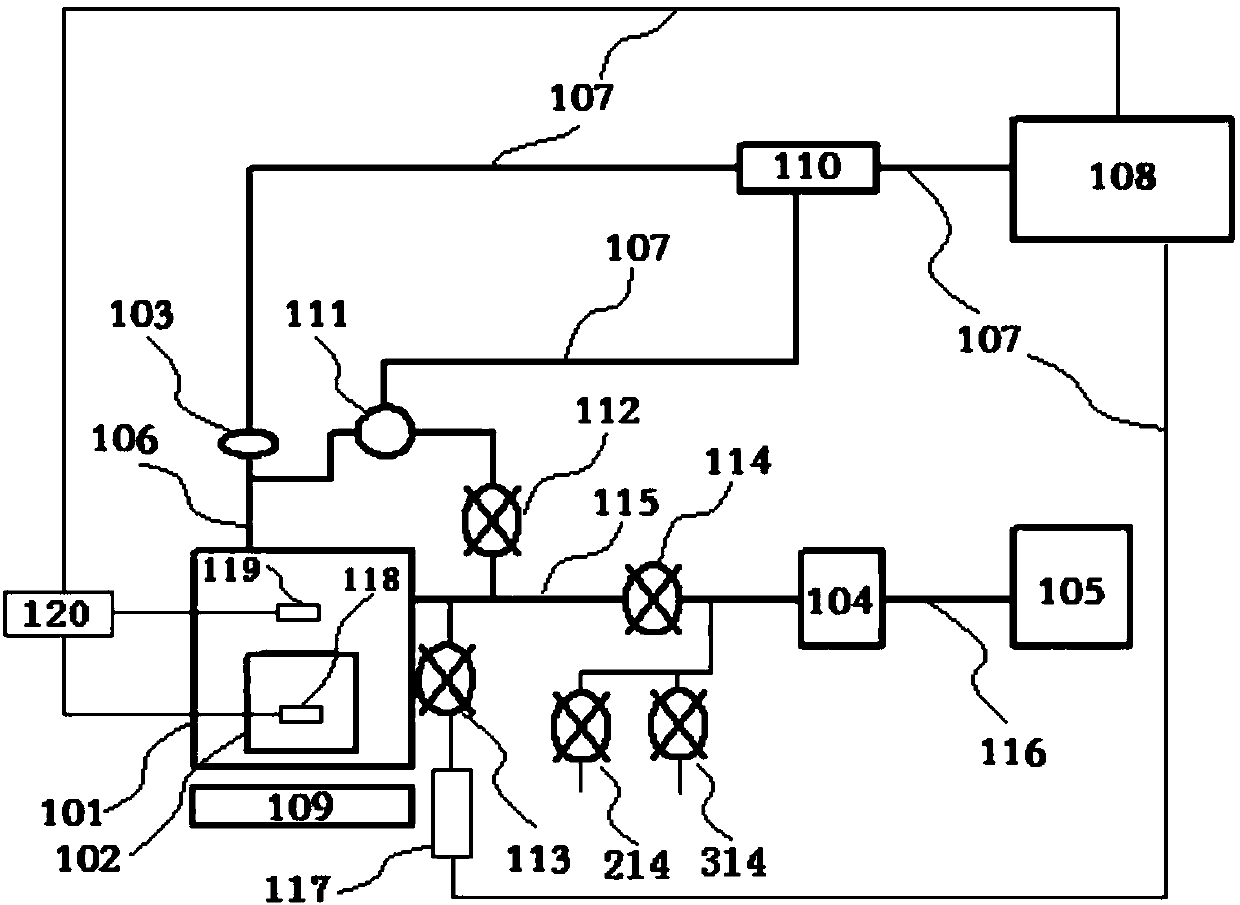

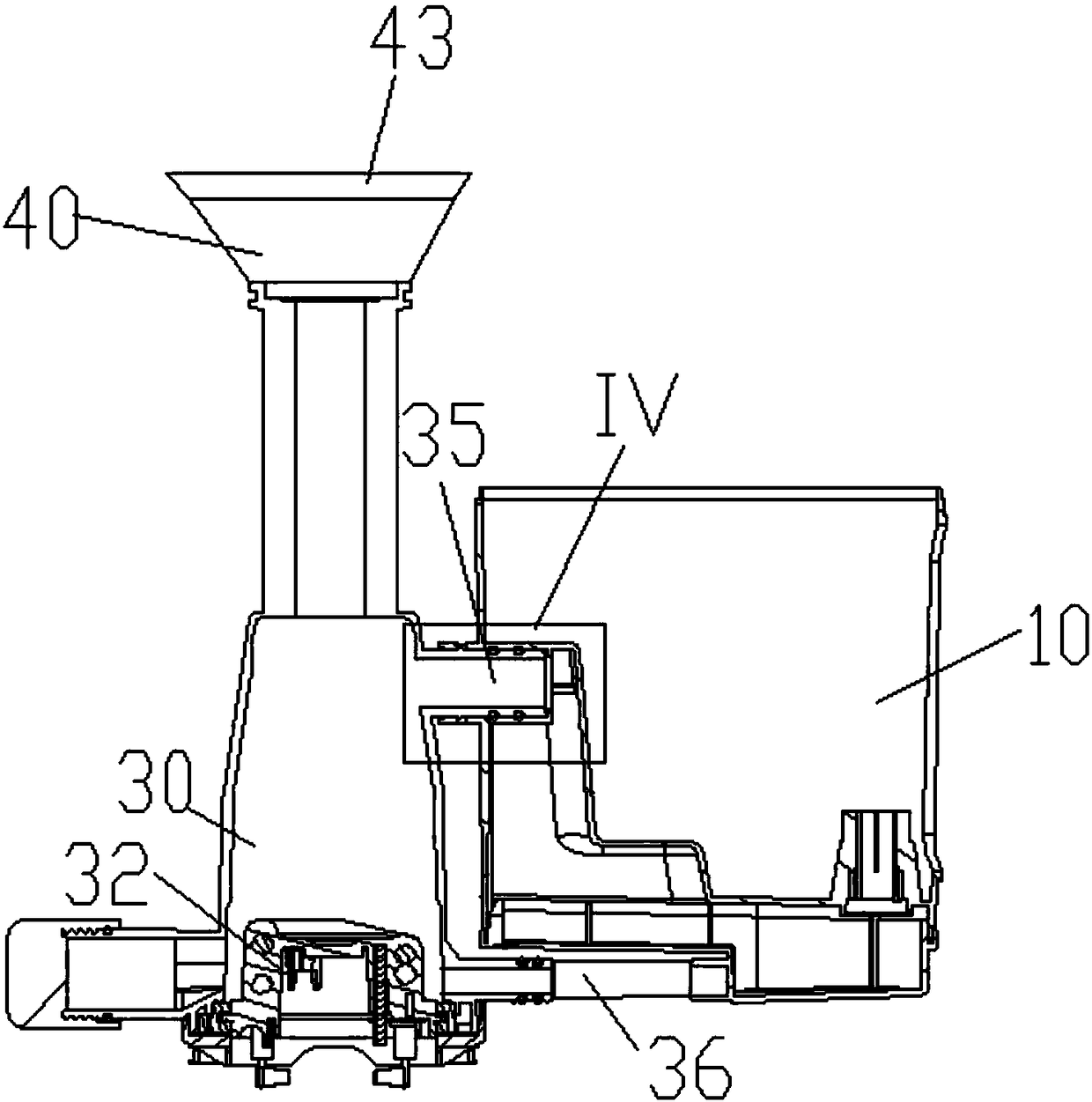

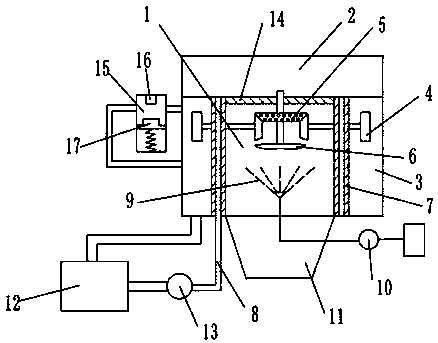

Integrated cooker steam box capable of circularly pressurizing and injecting water and operation method thereof

PendingCN111700491AIncrease steam pressureExtended service lifeCheck valvesSteam cooking vesselsCookerEngineering

The invention provides an integrated cooker steam box capable of circularly pressurizing and injecting water and an operation method of the integrated cooker steam box. The integrated cooker comprisesa steam box shell, an evaporation cavity is formed in the steam box shell, a heating disc is fixedly arranged at the bottom of the evaporation cavity; the bottom of the heating disc is fixedly connected with heating wires; the bottom of one side of the steam box shell is connected with a water inlet pipe; the outer end of the water inlet pipe is connected with the bottom of a water box; small airoutlet holes are formed in the top of the same side of the steam box shell; the small air outlet holes are communicated with the water box through an air inlet pipe; an exhaust large hole is furtherformed in the top of the other side of the steam box shell and connected with an exhaust pipe, the exhaust pipe is connected with a pressure retaining valve in series, the pressure retaining valve comprises a valve body shell, an inlet communicated with the inner cavity is formed in one side of the valve body shell, an outlet communicated with the inner cavity is formed in the other side of the valve body shell, and a one-way valve element is arranged on the inner side of the inlet. The pressure retaining valve is additionally arranged at the exhaust hole, so that the pressure of the steam boxis in a dynamic change process, and the pressure is always kept in a high state while the steam pressure of the steam box is increased.

Owner:MARSSENGER KITCHENWARE CO LTD

Variable position cooling apparatus

InactiveCN101053289AIncrease steam pressureDigital data processing detailsCooling/ventilation/heating modificationsEngineeringExpansion chamber

Owner:3M INNOVATIVE PROPERTIES CO

Concentrated brine treatment method

ActiveCN106745422BImprove processing efficiencyLow boiling pointWater/sewage treatment by heatingWastewaterEngineering

Owner:BEIJING UNITY BENEFICIAL TECH CO LTD

Cooking device

ActiveUS20090134150A1Improve sealingPrevent microwave leakageDomestic stoves or rangesOven air-treatment devicesMicrowaveThe chokes

A cooking device for performing cooking using a microwave and steam, in which a door of a heating chamber includes, as constituting components, an inner frame, a choke cover, and a gasket. The inner frame is made of metal and has at its periphery a choke structure constructed from a large number of comb teeth. The gasket is installed in the door with a base section of the gasket held between the inner frame and the choke cover. A lip section of the gasket has a bag-like cross-section whose side that faces the inside of the heating chamber is an entrance. The forward end of the lip section is bent to the door side. The comb teeth, except those positioned at the corners of the door, are bent at a larger angle than in a case in which the gasket is not installed.

Owner:SHARP KK

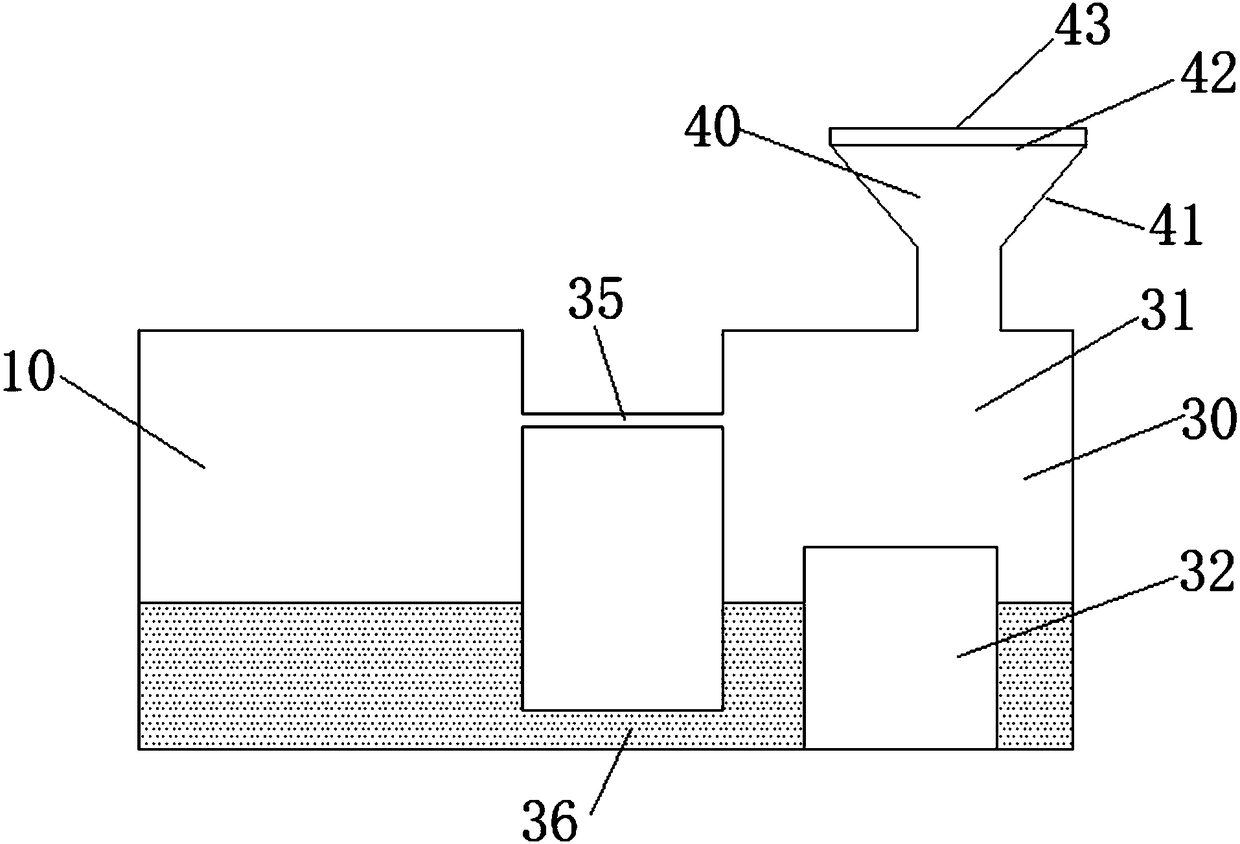

High-pressure steaming oven and integrated cooker using same

PendingCN114176389AImprove securityFast cookingSteam cooking vesselsRoasters/grillsSteam pressureExhaust valve

The invention discloses a high-pressure steaming oven and an integrated cooker using the same, and relates to the field of steam heating. In order to improve safety and heating uniformity, the steam generator comprises an inner container, a steam generator, a controller, a pressure release valve, an exhaust valve and an electric heating assembly located at the top of the inner container. The electric heating assembly comprises an electric heating pipe, fan blades located above the electric heating pipe, a motor driving the fan blades to work and a ventilation hood located on the outer side of the electric heating pipe and the outer sides of the fan blades. A plurality of ventilation holes are formed in the peripheral side of the ventilation hood, and the positions of the ventilation holes are higher than the positions of the electric heating pipes. According to the technical scheme, the pressure release valve and the exhaust valve are arranged, the working safety is high, improvement of steam pressure is guaranteed, fan blades rotate, air flows in order, hot air is continuously blown into a food cooking area, the heating efficiency is improved, and the heating time is shortened; meanwhile, due to stirring of air in the inner cavity, the temperature difference in the inner cavity can be reduced, and the temperature in the inner container cavity is uniform.

Owner:ZHEJIANG SANFER ELECTRIC

Method for measuring moisture content of objects to be dried, vacuum drying device and control method thereof

ActiveCN107014156BEasy to implementLarge measuring rangeDrying using combination processesDrying solid materials without heatEvaporationPulp and paper industry

The invention provides a method for measuring the water content of a dried object, a vacuum drying device and a control method of the vacuum drying device. The method for measuring the water content of the dried object is used for calculating the water content of the dried object in a drying container in the vacuum drying process. The method calculates the water evaporation amount of the dried object at the drying temperature according to the system parameter values of the drying container in the closed state and calculates the current water content of the dried object according to the water evaporation amount. The method for measuring the water content of the dried object is simple, convenient to use and easy to achieve, efficient in the measuring process, and wide in measuring range and reliable in measuring result. The invention further provides the vacuum drying device and the control method of the vacuum drying device. The vacuum drying device controls the drying process by conducting real-time measurement on the water content of the dried object, the control method can meet the requirements for rapidness and continuity, manual intervention is not required, and the preset target water content of the dried object can be accurately and rapidly achieved.

Owner:常州广建仪器科技有限公司

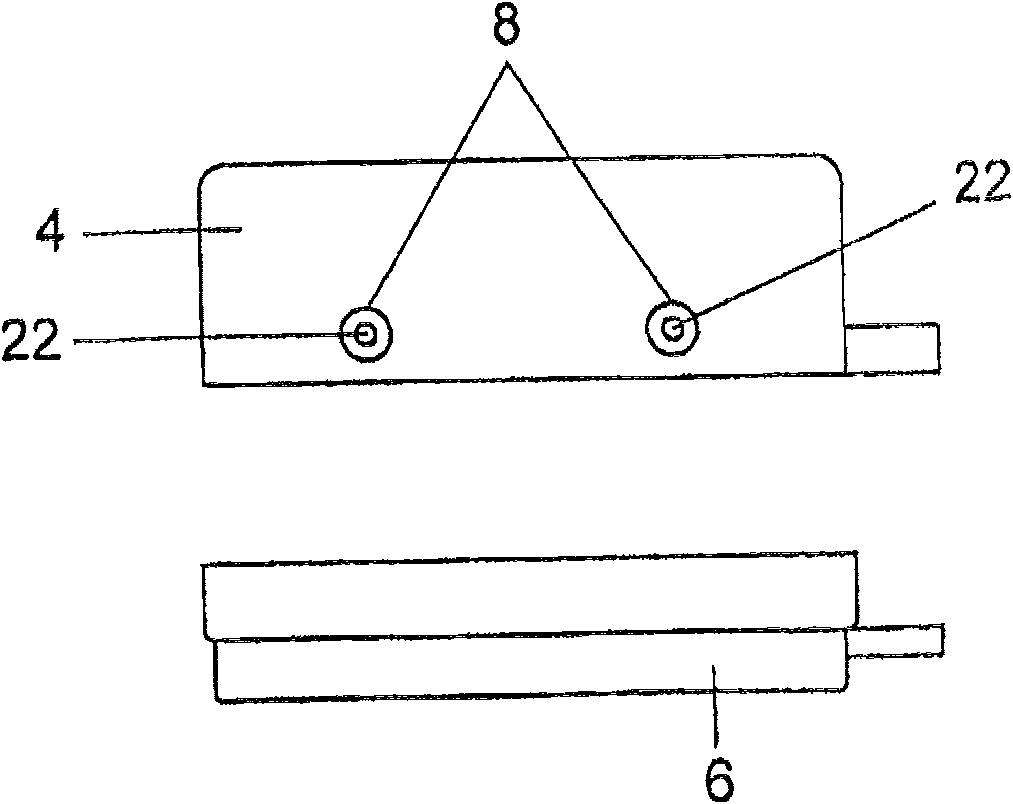

Water level adjusting mechanism and hanging ironing machine

PendingCN108252066AIncrease steam pressureAdjustable steam pressureIroning apparatusTextiles and paperInlet channelEngineering

The invention discloses a water level adjusting mechanism. The water level adjusting mechanism comprises a steam generation device, a water tank and an ironing head, wherein the steam generation device is internally provided with a water heating cavity and a heater, the heater is accommodated in the water heating cavity; an air pressure channel and a water inlet channel are formed between the water tank and the steam generation device, and the air pressure channel is higher than the water inlet channel; and the ironing head is connected with the steam generation device and comprises a steam surface and an adjusting assembly, the steam surface is provided with a plurality of air outlets, and the adjusting assembly is used for adjusting the total area of the air outlets. The invention further discloses a hanging ironing machine.

Owner:GD MIDEA ENVIRONMENT APPLIANCES MFG +1

Component with a weld projection having a projection and lamp housing part comprising a component with a weld projection

InactiveCN100591457CIncrease steam pressureAvoid accessCoupling device connectionsElectric discharge tubesEngineeringLaser

Owner:PATENT TREUHAND GESELLSCHAFT FUER ELECTRIC GLUEHLAMPEN M B H

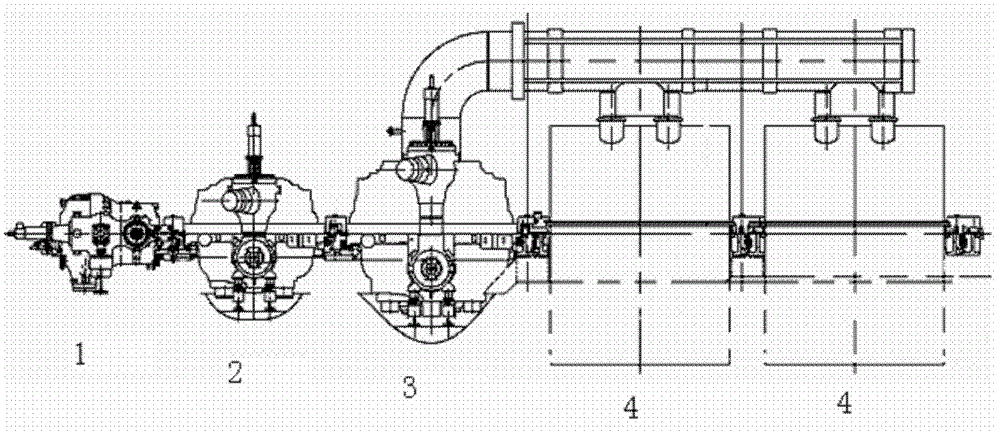

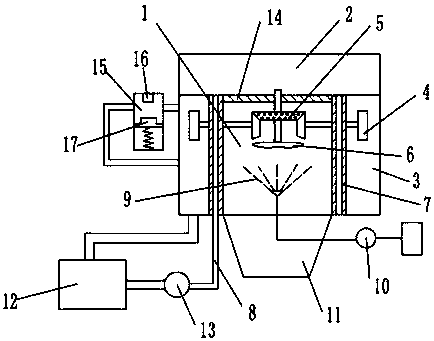

Concentrated brine high dispersion dehydration equipment

ActiveCN106693418BImprove processing efficiencyLow boiling pointEvaporation by sprayingElectricityWater storage tank

The invention belongs to the field of industrial wastewater treatment equipment and in particular discloses strong brine high dispersion and dehydration equipment. According to the equipment, a turbine is arranged in a condensing chamber; a bevel gear is arranged in a high dispersion chamber; a rotating shaft is arranged on the bevel gear; a plurality of negative pressure blades are arranged on the rotating shaft; a steam pipe is arranged in a heating insulation jacket; a gas guide pipe is arranged on one side of the condensing chamber; a control box is arranged on the gas guide pipe; a spring is arranged at the bottom in the control box; a piston is arranged on the spring; a piston-contactable switch is arranged on the top of the control box; a water storage tank is arranged below the condensing chamber and connected with the condensing chamber through a water inlet pipe; a drainage pipe is arranged on one side of the water storage tank; a steam pump is arranged on the drainage pipe and electrically connected with the switch; one end of the steam pump is connected with the steam pipe. According to the strong brine high dispersion and dehydration equipment provided by the scheme, a high dispersion chamber is kept at a high temperature.

Owner:连云港中星能源有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com