Technology for secondarily producing medium pressure steam during synthesizing chlorine and hydrogen into hydrogen chloride and equipment thereof

A hydrogen chloride and steam technology, applied in the direction of chlorine/hydrogen chloride, energy input, etc., can solve the problems of limited pressure bearing and pressure loss of equipment, and achieve the effect of extending service life and seamless connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment is a process embodiment.

[0047] The process of preheating the high-temperature water self-circulation heat exchange unit before starting the furnace is adopted: before starting the furnace, add enough water in the synthesis furnace, flash tank, and self-circulation pipeline, and then open the steam from the boundary area, and pass through the regulating valve TCV130 enters the steam-water mixer E130, mixes with pure water, and then enters the lower water collection tank of the steel medium-pressure steam synthesis furnace R140, until the temperature reaches the temperature controller TIC130 set value of 118°C, then the furnace can be turned on to start normal production.

[0048] After the steel medium-pressure steam synthesis furnace R140 is fired, hydrogen and chlorine gas are mixed and burned to generate a large amount of heat. The high-heat hydrogen chloride gas exchanges heat with the pure water in the inner coil of the steel medium-pressure steam ...

Embodiment 2

[0050] This embodiment is an embodiment of the device structure.

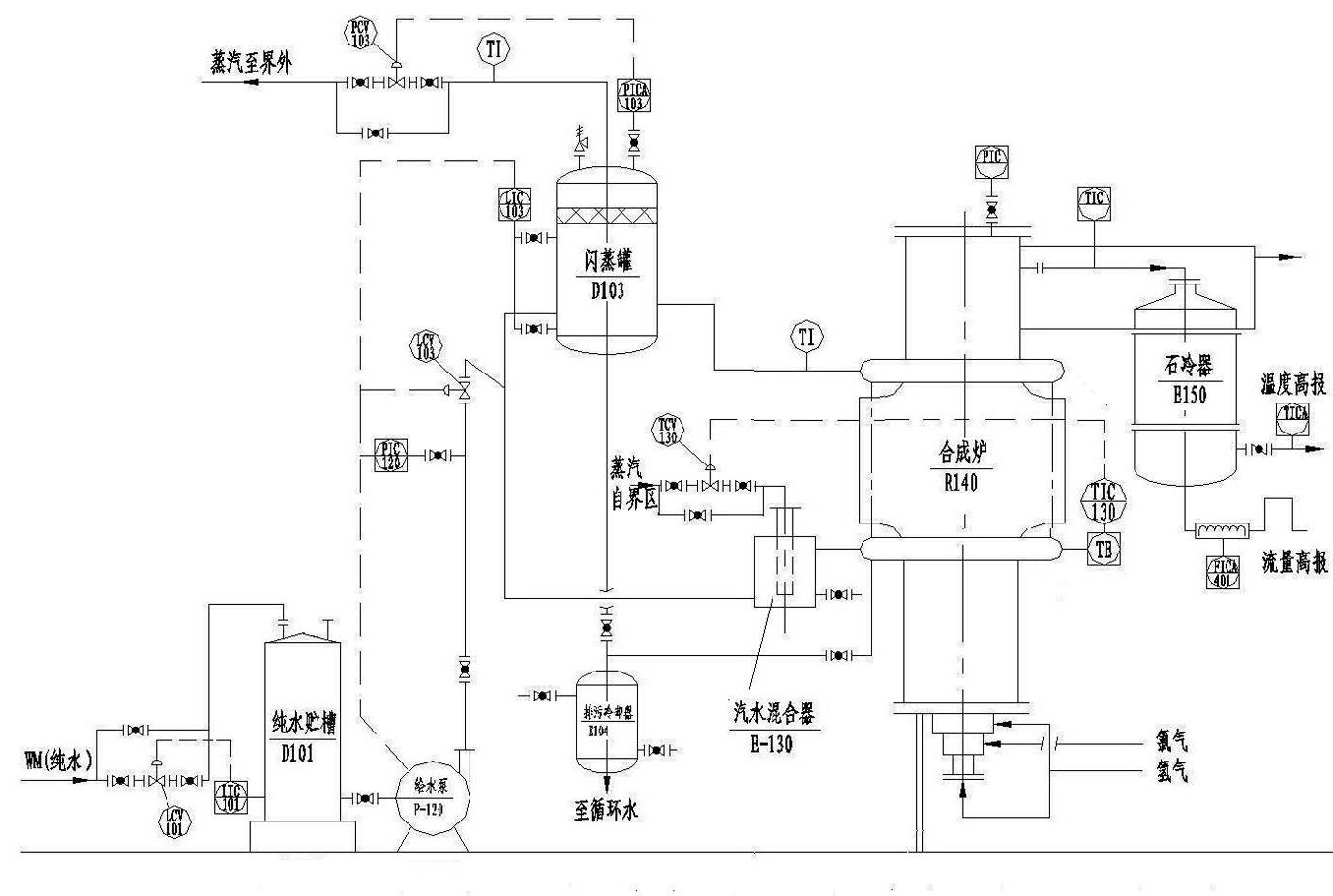

[0051] A device for synthesizing hydrogen chloride from chlorine and hydrogen to produce medium-pressure steam, including a water supply unit, a high-temperature water self-circulation heat exchange unit, and a hydrogen chloride synthesis cooling unit, wherein the water supply unit includes a pure water storage tank D101 and a feed water pump P-120, and the high-temperature water The self-circulating heat exchange unit includes a steam-water mixer E130, a synthesis furnace R140, a flash tank D103, and a blowdown cooler E104. The hydrogen chloride synthesis cooling unit includes a synthesis furnace R140 and a stone cooler E150. The flash tank D103 has a safety valve, pressure Transmitter PICA103 and pressure regulating valve PCV103;

[0052] The synthesis furnace R140 has a temperature transmitter;

[0053] The stone cooler E150 has a temperature transmitter and a flow transmitter;

Embodiment 3

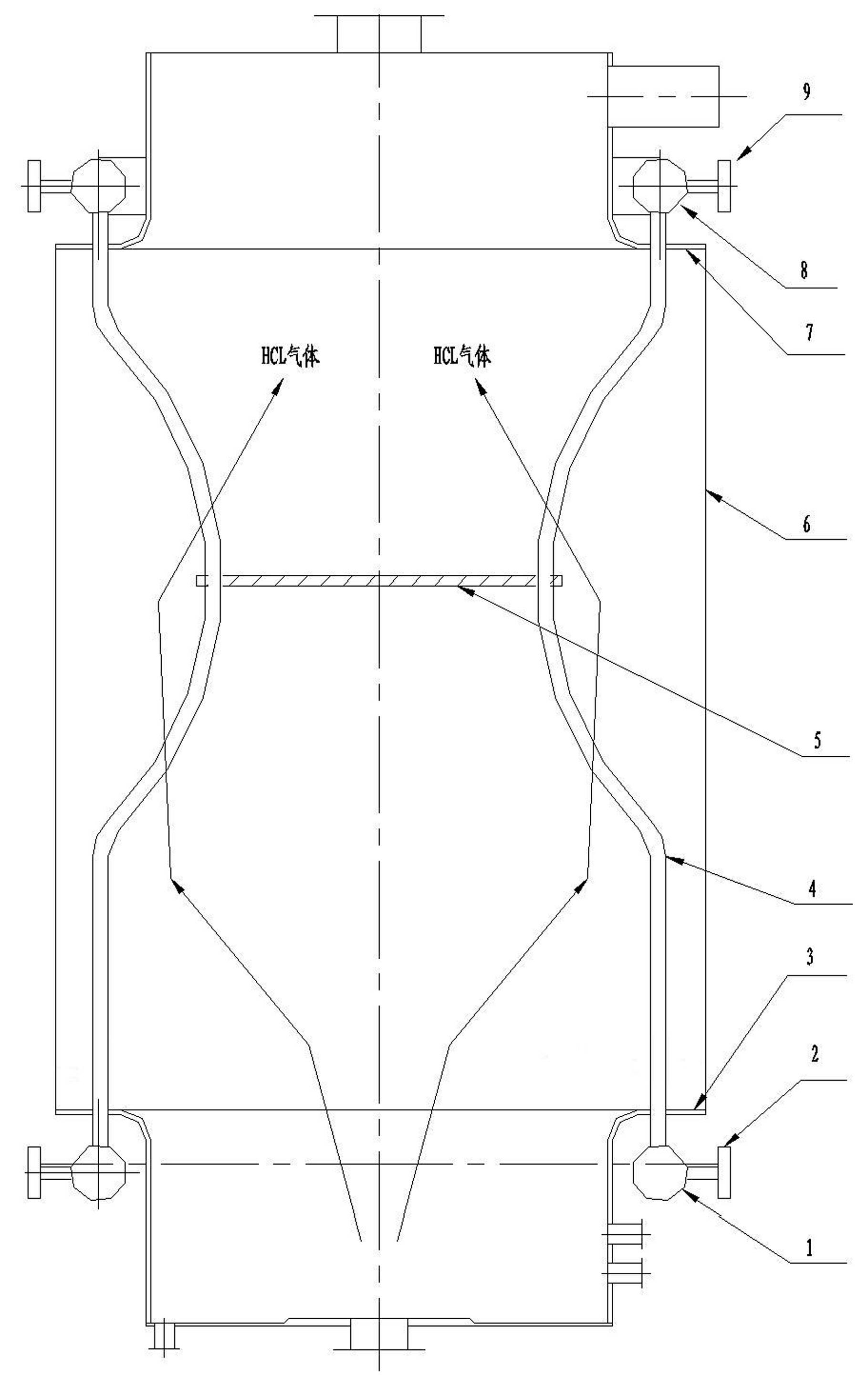

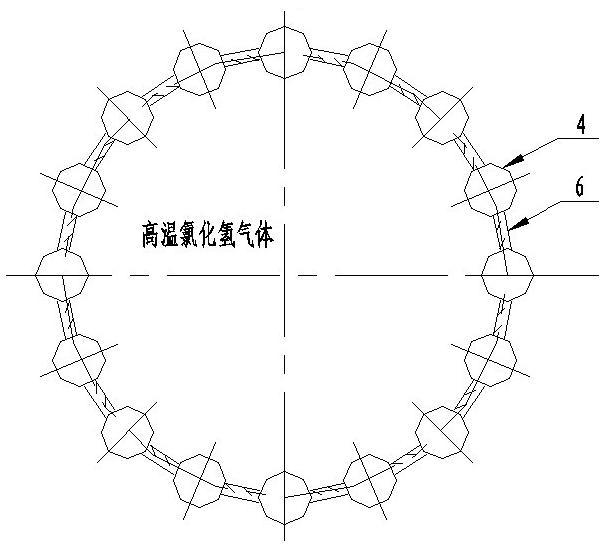

[0055] This embodiment is an embodiment for solving the problem of equipment corrosion.

[0056] Spray anti-corrosion paint AK07-4 on the inner surface of the furnace body 6 and the outer surface of the inner coil 4;

[0057] The present invention adopts AK07-4 high-temperature and corrosion-resistant coating of Beijing Aoyukexin Surface Engineering Technology Co., Ltd., which has a temperature resistance of 1100°C. It is proved by experiments that the coating has no chemical reaction with hydrogen chloride and hydrochloric acid.

[0058] At the same time, it also solves the problem of equipment parking and heat preservation to reduce energy consumption.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com