Steam turbine structure

A steam turbine and cylinder technology, which is applied in the field of double reheat steam turbine structure, can solve the problems of high cost and inability to apply nickel-based alloy materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

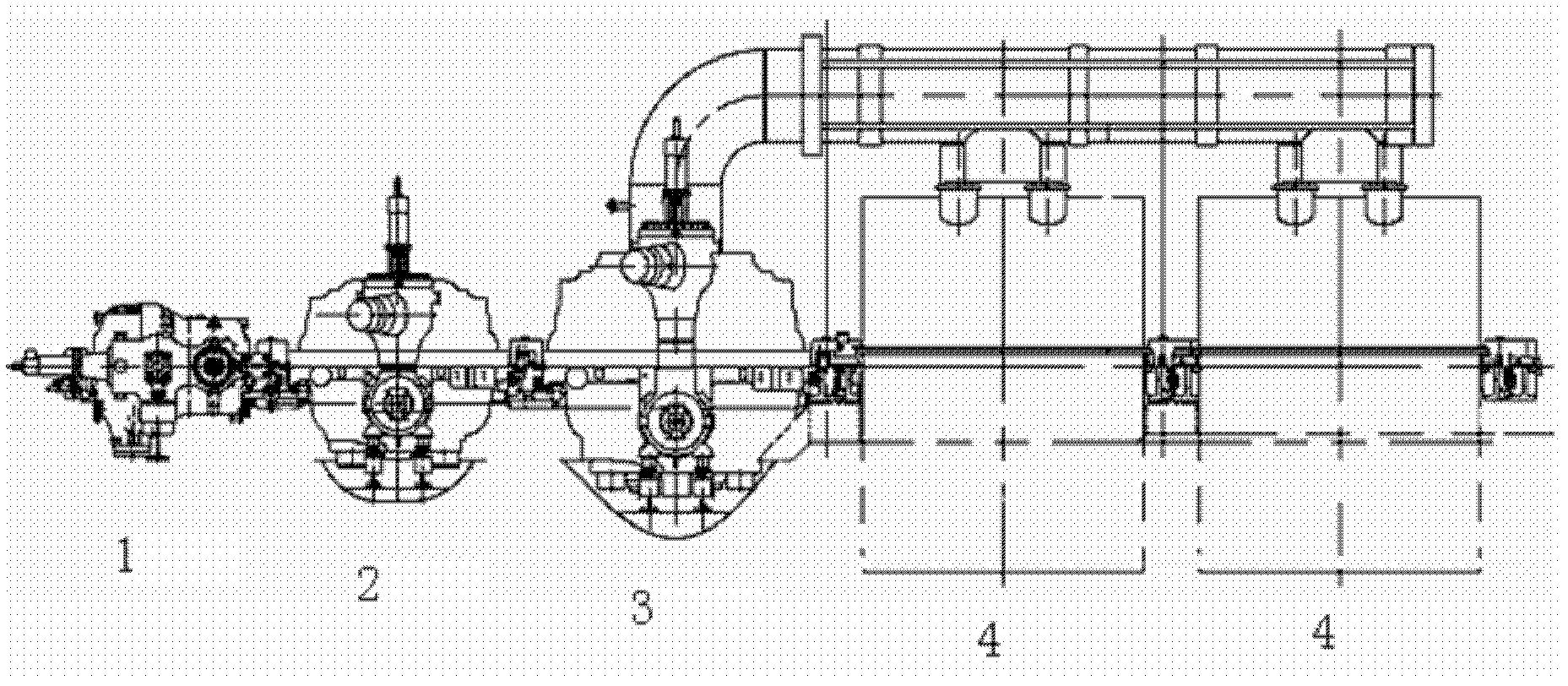

[0021] Such as figure 1 As shown, it is a steam turbine with a capacity of 660 MW with five cylinders and four rows. The steam turbine is configured as a single-flow ultra-high pressure cylinder 1, a single-flow reheat high-pressure cylinder 2, a double-flow reheat medium-pressure cylinder 3, and two standard exhaust areas The low pressure cylinder 4.

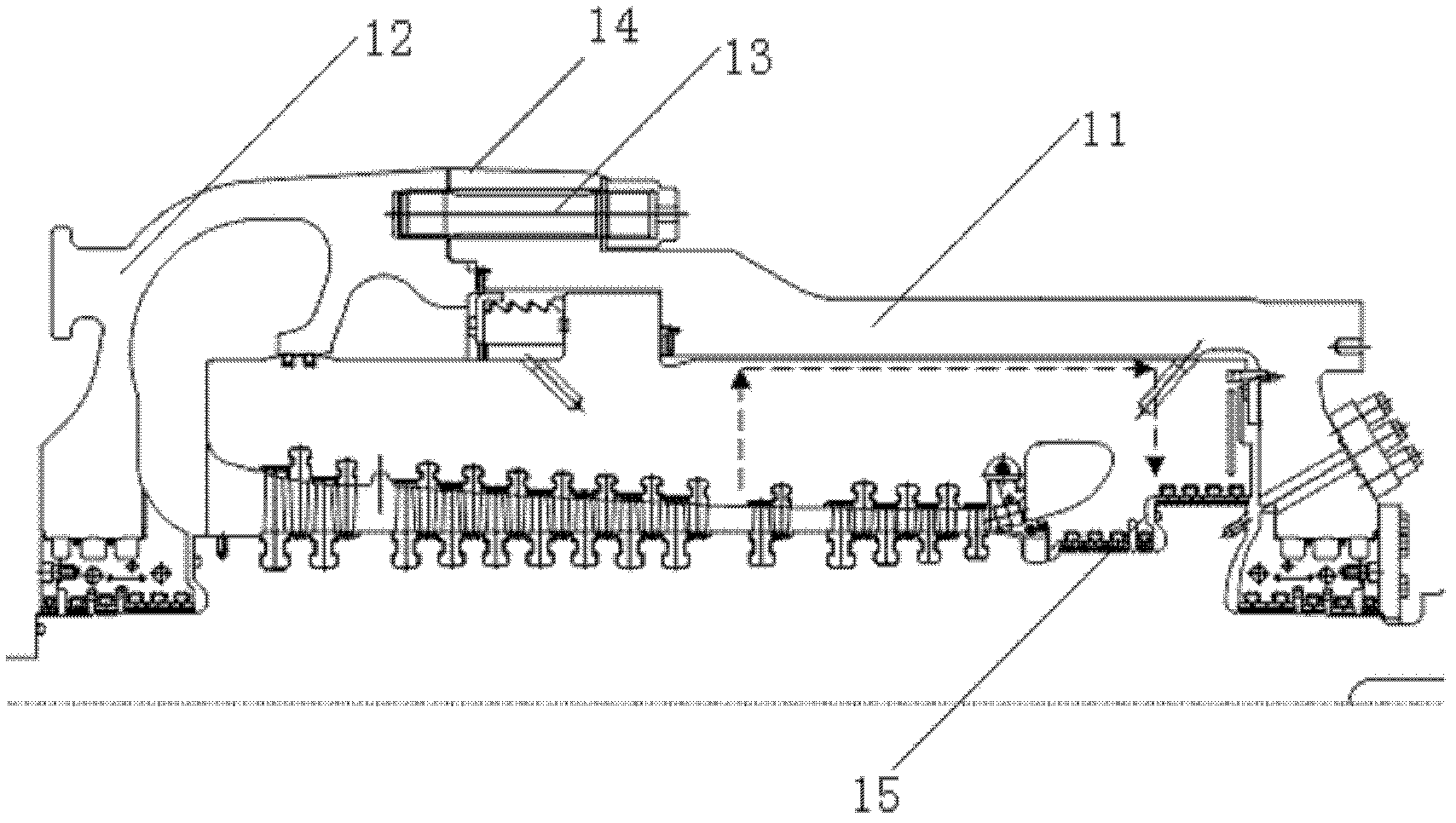

[0022] Such as figure 2 As shown, the ultra-high pressure cylinder 1 is a double-layer cylinder, and its outer cylinder is composed of two cylindrical cylinder blocks 11 and 12 connected by axial bolts 13. The axial flange at the joint of the two cylindrical cylinder blocks 14 is located in an area with low working pressure. Since the axial action area of the cylinder is much smaller than the area of the horizontal mid-section, the cylinder with this structure has a stronger pressure-b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com