Solid precursor vapor pressure stabilization and purification device and ALD deposition equipment

A purification device and precursor technology, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of evaporation sublimation speed difference, pollution, precursor vapor instability, etc., to avoid thermal decomposition, Effect of increasing steam pressure and stabilizing supply flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

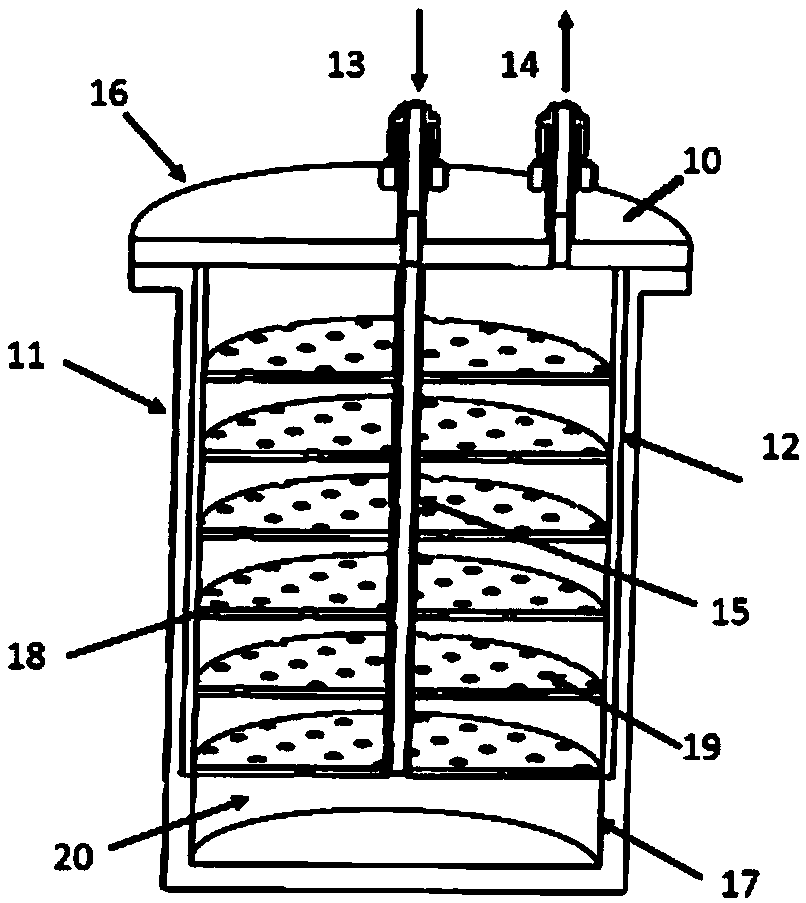

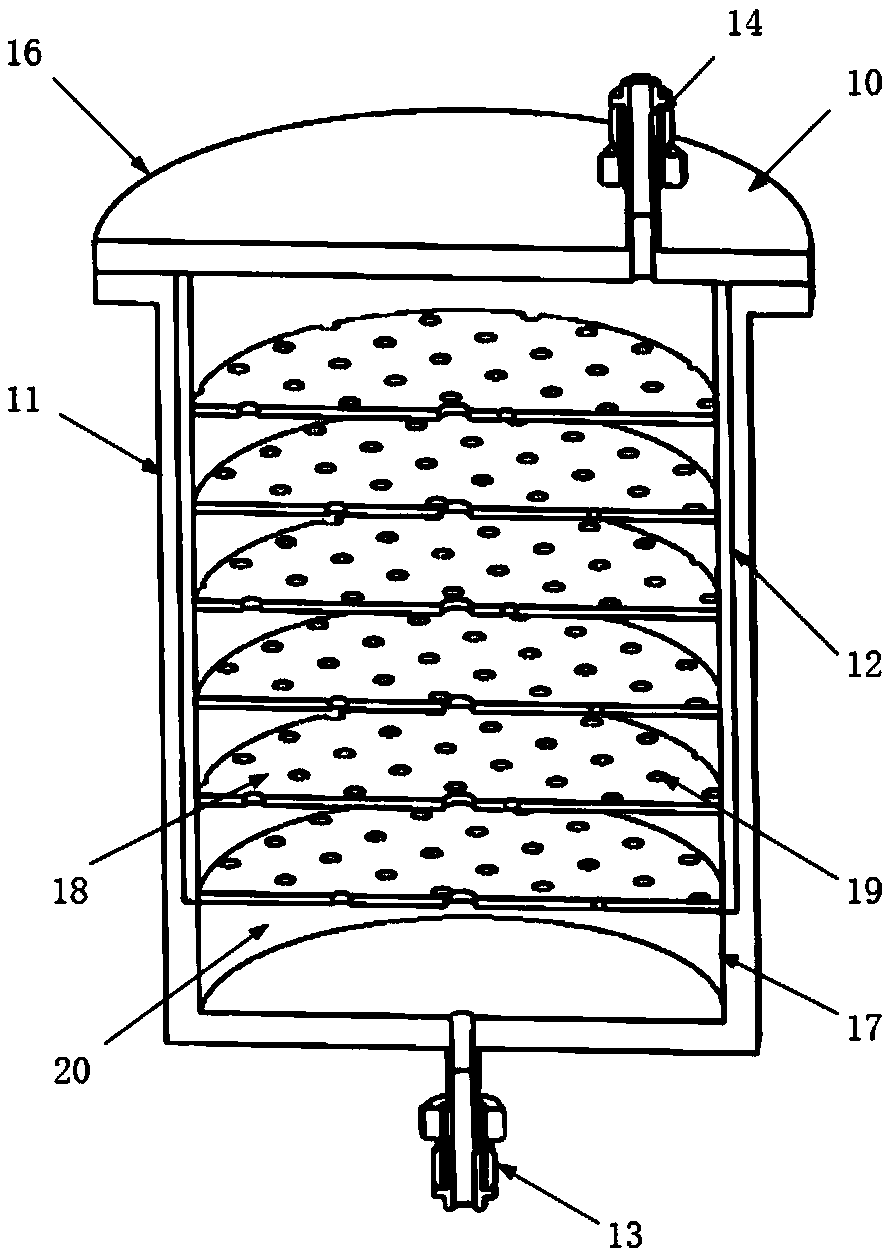

[0052] This embodiment provides a pressure-stabilizing and purifying device 9 for solid precursor vapor. For further reference Figure 3 to Figure 5 , image 3 Is a schematic diagram of the structure of the top cover part according to an embodiment of the present invention; Figure 4 Is a schematic diagram of the structure of the barrel 11 according to an embodiment of the present invention; Figure 5 It is a schematic diagram of the structure of the flow even component 12 according to an embodiment of the present invention. The casing of the device 9 for pressure stabilization and purification of solid precursor vapor includes a cylinder 11 and a top cover 16. The cylinder 11 has a cylindrical shape, the bottom of the cylinder 11 is closed, and the upper end is open. The disc-shaped top cover 16 is detachably connected to the top of the cylinder 11, and the air inlet 13 and the exhaust port 14 are both provided on the top cover 16. One end of the vent pipe 15 is connected to ...

Embodiment 2

[0057] This embodiment provides a device 9 for pressure stabilization and purification of solid precursor steam. The difference between the structure and the first embodiment is that there is no bushing, and no annular shoulder 17 is required in the cylinder 11. The disc-shaped uniform flow plates 18 are arranged at intervals in the vertical direction inside the cylinder 11, and the edges of the uniform flow plates 18 are connected to the side walls of the cylinder 11. The edge of the flow plate 18 can be fixedly connected from the outside of the side wall of the cylinder 11 by screws, or the edge of the flow plate 18 can be directly welded to the side wall of the cylinder 11.

Embodiment 3

[0059] This embodiment provides a device 9 for stabilizing and purifying solid precursor steam. The difference between the structure and the first embodiment is that the disc-shaped uniform flow plates 18 are arranged at intervals in the vertical direction inside the cylinder 11 , The vent pipe 15 passes through the perforation of the uniform flow plate 18, and each uniform flow plate 18 is fixedly connected with the vent pipe 15 at the perforation. A bushing or no bushing may be provided in the cylinder 11, if no bushing is provided, the diameter of the flow plate 18 is slightly smaller than the inner diameter of the cylinder 11, and there is no need to provide an annular shoulder 17 in the cylinder 11; A bush is provided, and the diameter of the flow plate 18 is slightly smaller than the inner diameter of the bush. When disassembling, the uniformity plate 18 can be removed at the same time as the top cover assembly 10 is removed. The uniform flow plate 18 can be connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com