Hydraulic control system in working machine

A technology for hydraulic control and work machinery, which is applied to fluid pressure actuation system components, mechanical equipment, earth movers/shovels, etc. Reduced discharge flow rate, stable supply flow rate, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

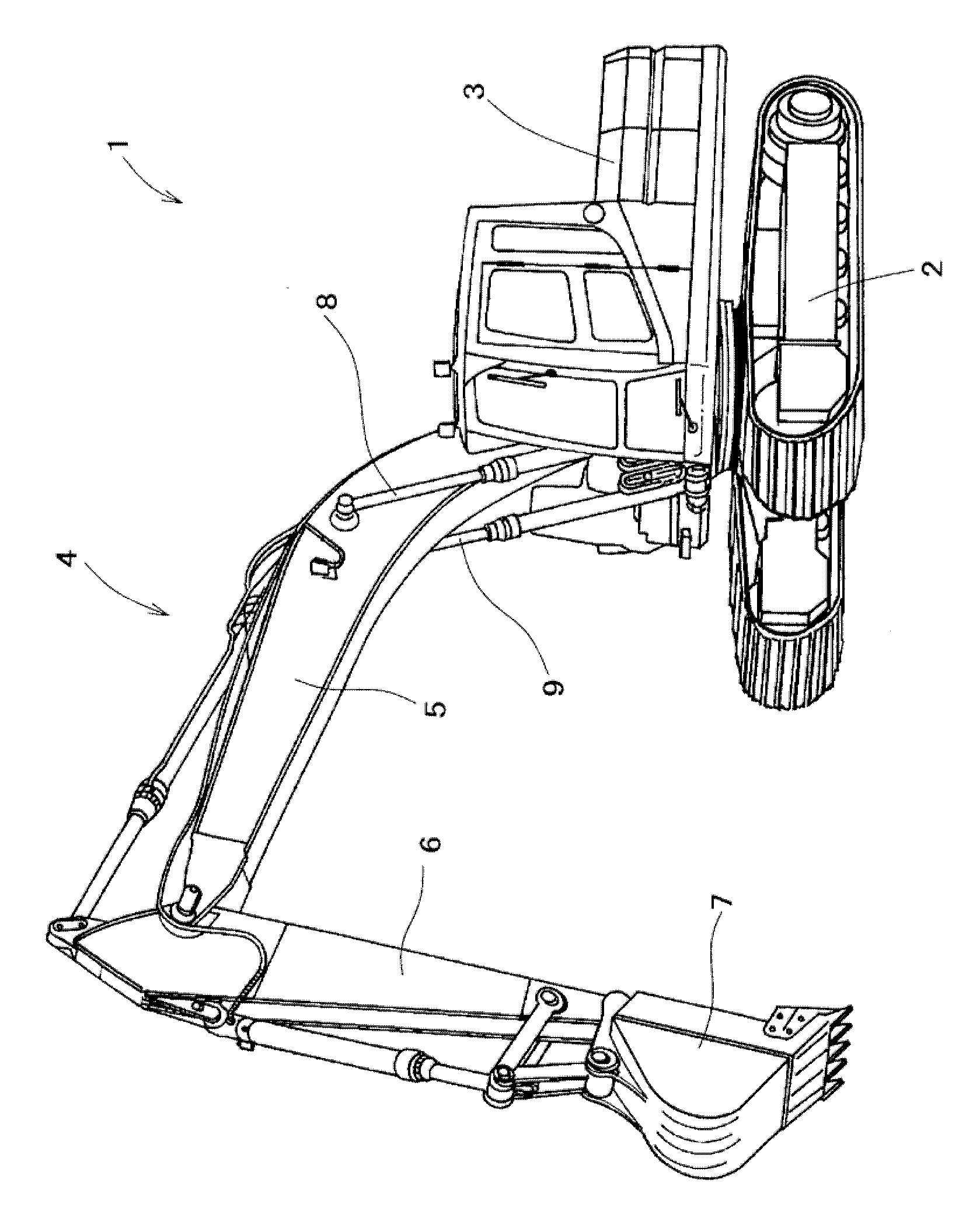

[0019] Embodiments of the present invention will be described below based on the drawings. exist figure 1 Among them, 1 is a hydraulic excavator as an example of a working machine. This hydraulic excavator 1 is composed of a crawler-type lower traveling body 2, an upper revolving body 3 rotatably supported above the lower traveling body 2, and The work section 4 installed in front of the upper swing body 3 is composed of various parts, and further, the work section 4 is supported by the boom 5 which is vertically swingable at the base end of the upper swing body 3 , and is freely swingable back and forth. An arm 6 at the front end of the boom 5 , a bucket 7 attached to the front end of the arm 6 , and the like are configured.

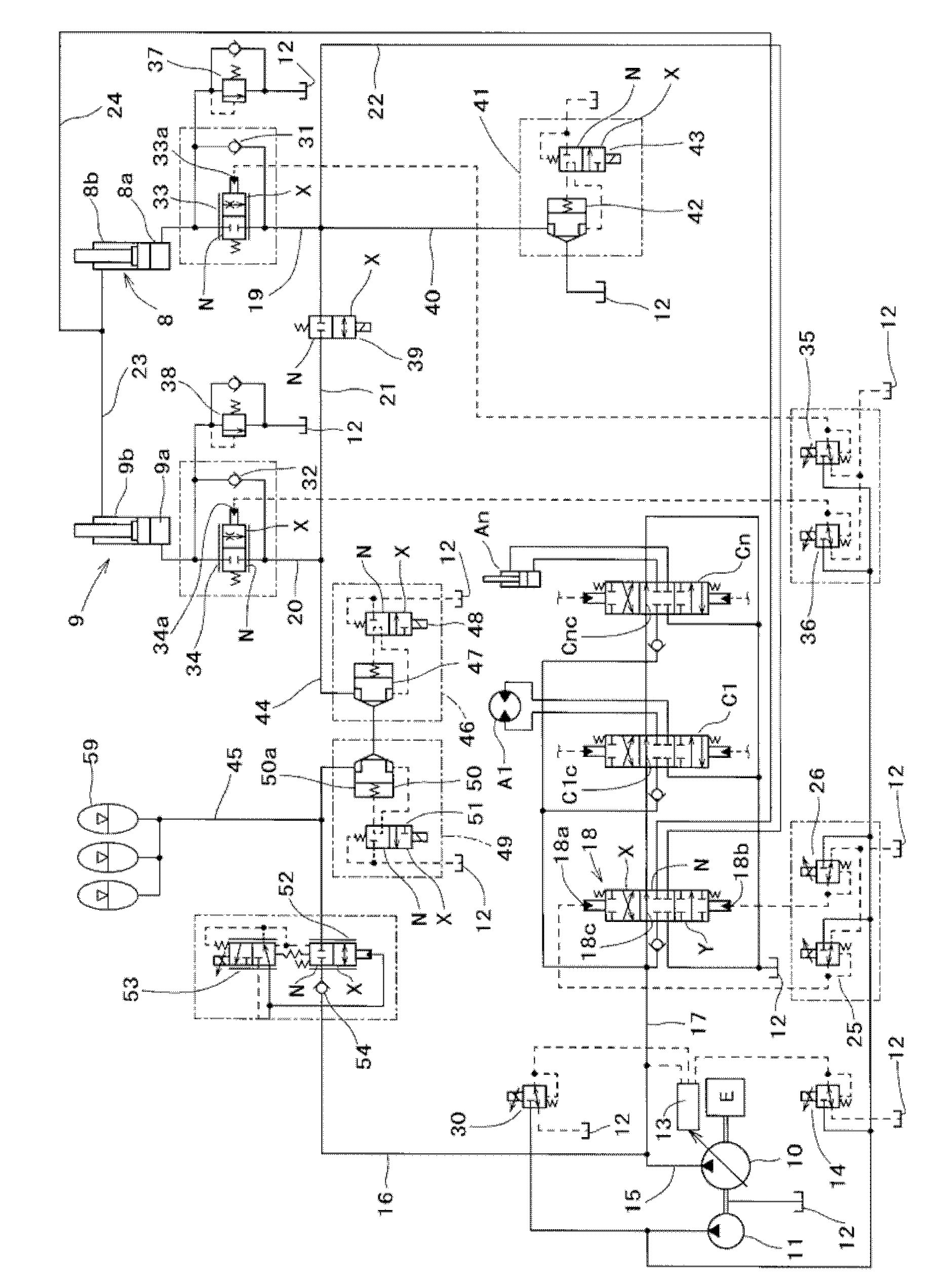

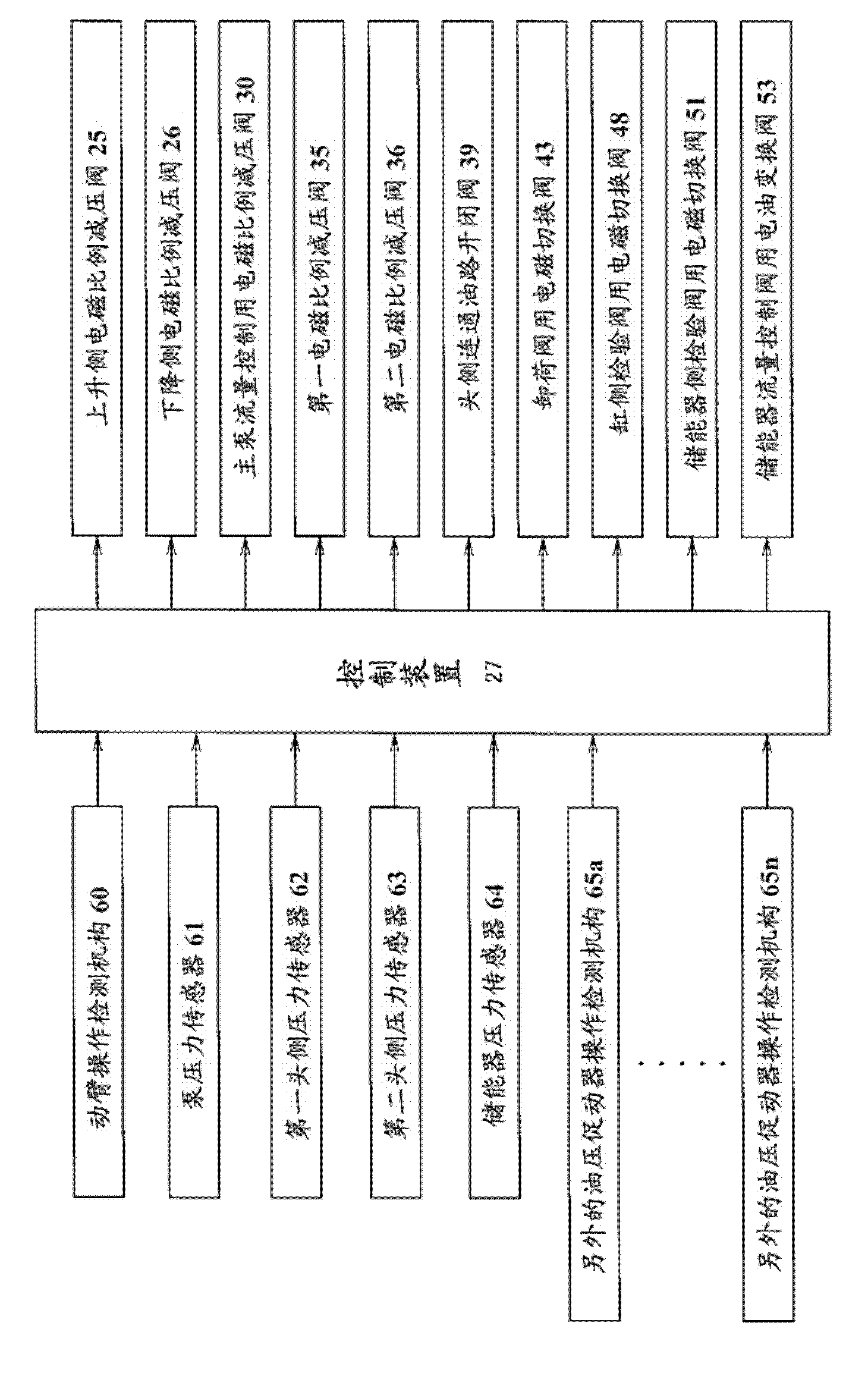

[0020] Furthermore, 8 and 9 are a pair of left and right first and second boom cylinders for swinging the above-mentioned boom 5 up and down, and these first and second boom cylinders 8 and 9 are constituted as follows: The pressure of 9a maintains t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com