Treatment method for concentration of strong brine

A treatment method and technology for concentrated brine, applied in heating water/sewage treatment and other directions, can solve the problems of easy scaling, not high enough temperature, and poor economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below by means of specific embodiments:

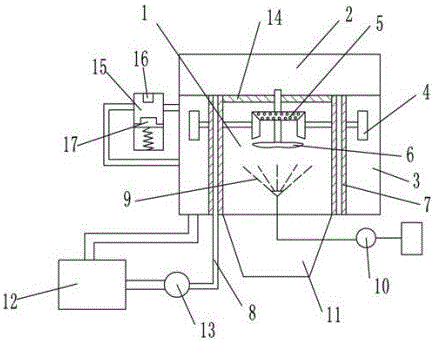

[0017] The reference signs in the accompanying drawings of the description include: high dispersion chamber 1, steam chamber 2, condensation chamber 3, turbine 4, bevel gear 5, negative pressure blade 6, heating insulation cover 7, steam pipe 8, high dispersion net 9, high pressure Water pump 10, concentration chamber 11, water storage tank 12, steam pump 13, mesh gas distributor 14, control box 15, switch 16, piston 17.

[0018] The processing method of concentrated brine concentration in this scheme comprises the following steps:

[0019] (1) The concentrated brine is sent to the high-dispersion net of the high-dispersion chamber through the water outlet of the high-pressure water pump. The high-dispersion net disperses the concentrated brine into tiny and fine liquid particles. Under the action of vapor pressure, the liquid particles become water vapor. The water in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com