Ceramic tile seam filling device

A filling device and ceramic tile technology, which can be used in construction, building construction, etc., can solve the problems of color pollution, affecting filling effect, and mixing impurities into fillers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

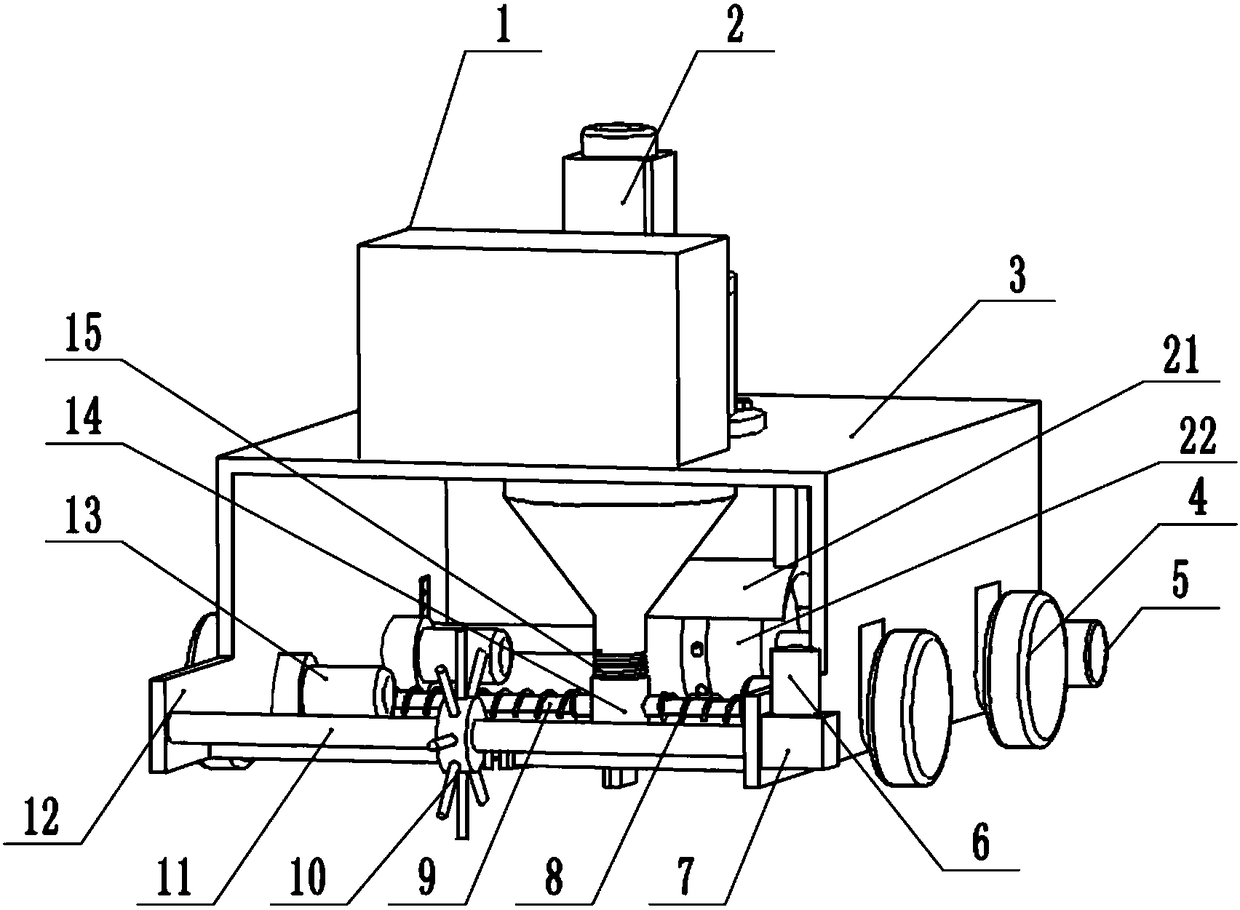

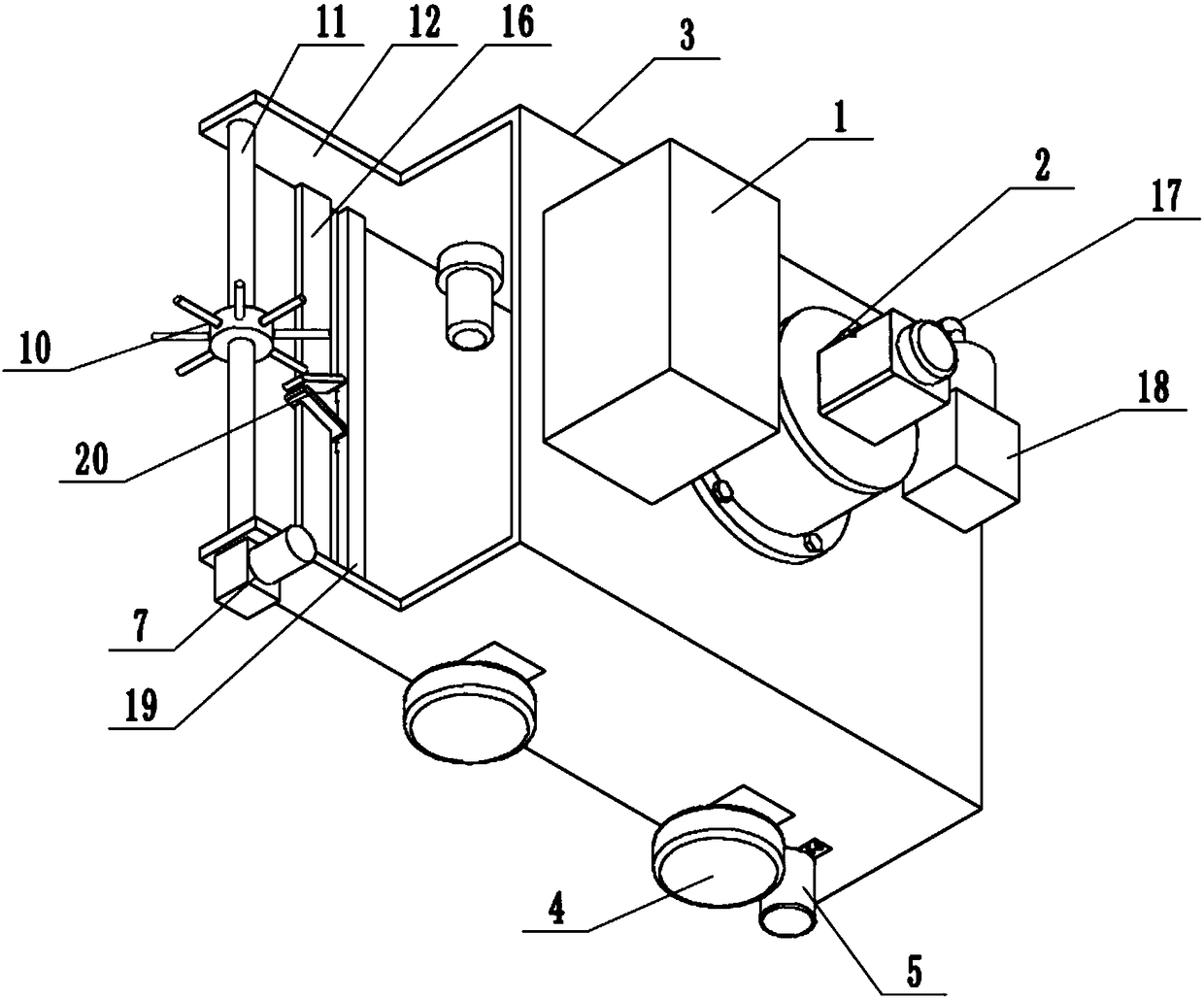

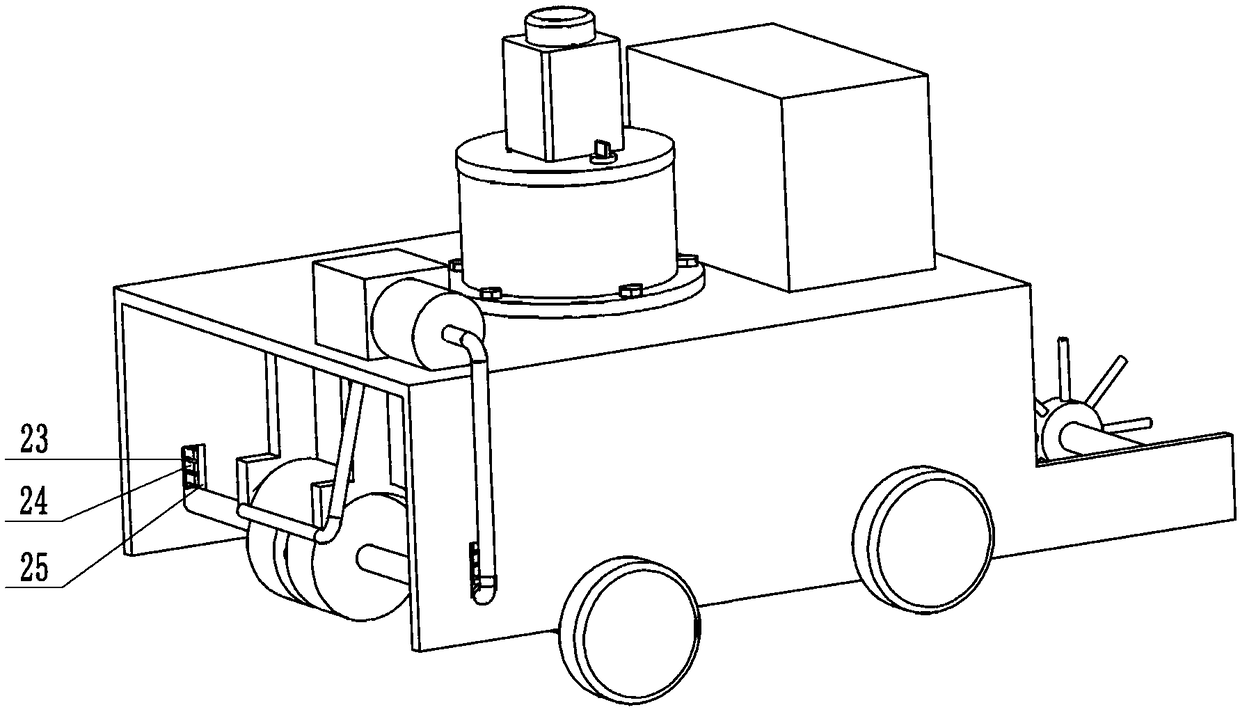

[0021] A ceramic tile seam filling device is composed of a battery 1, a pressing assembly 2, a casing 3, a wheel 4, a driving motor 5, a driving motor 6, a transmission box 7, a spring 8, a sliding rod 9, a brush roller 10, and a transmission Axis 11, front extension plate 12, driving motor 3 13, injection assembly 14, hose 15, horizontal plate 16, conduit 17, peristaltic pump 18, horizontal plate 2 19, guide plate 20, scraping assembly 21 and wiper Composed of material assembly 22, the pressure material assembly 2 is arranged in the middle of the housing 3, the battery 1 and the peristaltic pump 18 are installed on the upper surface of the housing 2, and the lower part of the pressure material assembly 2 is connected with a hose 15 Injection assembly 14, a slide bar 9 runs through the middle position of the injection assembly 14, two springs one 8 are arranged on the slide bar 9, and the injection assembly 14 is arranged at the middle position of the two springs one 8 , one e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com