Patents

Literature

51results about How to "Accurate riveting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

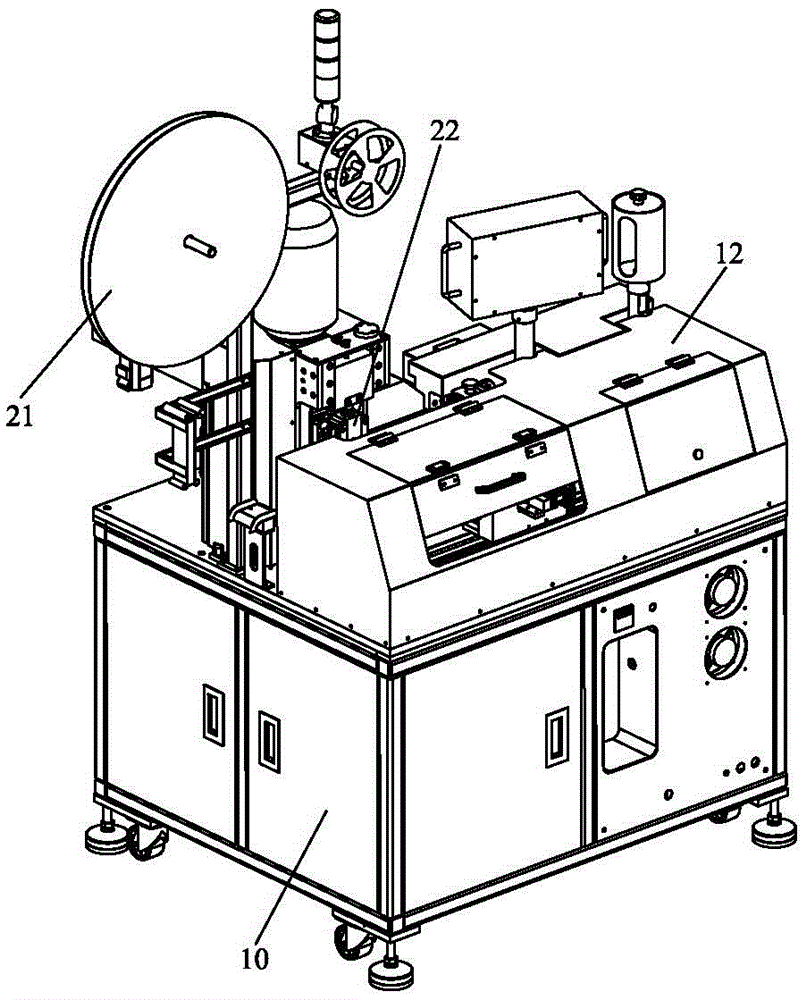

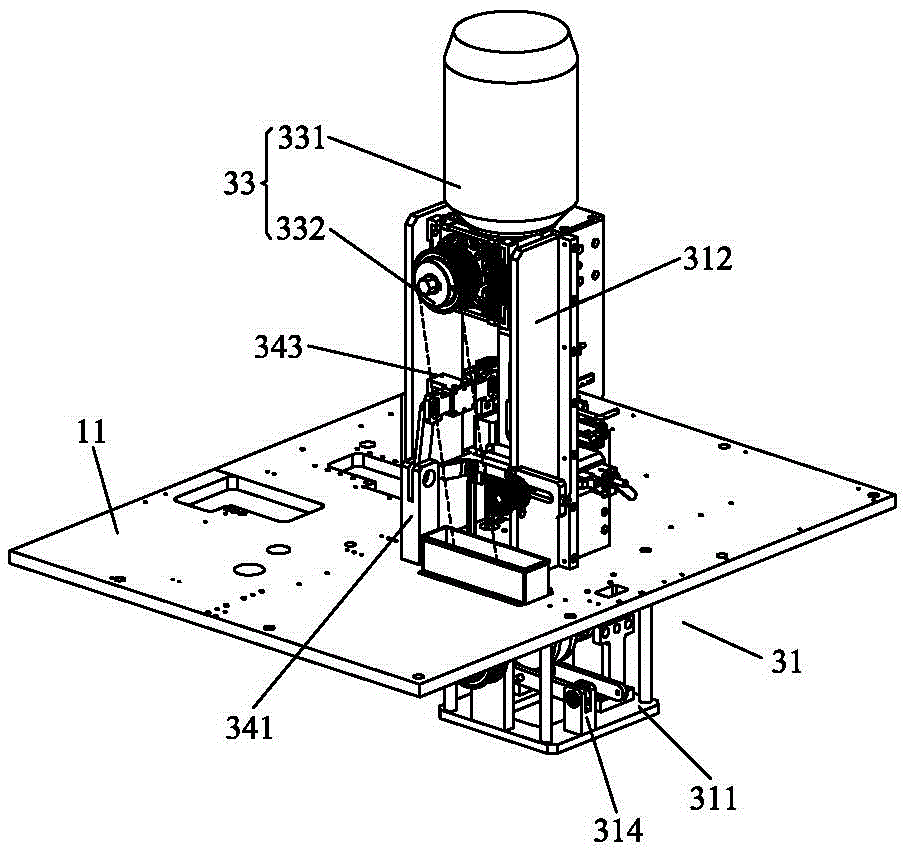

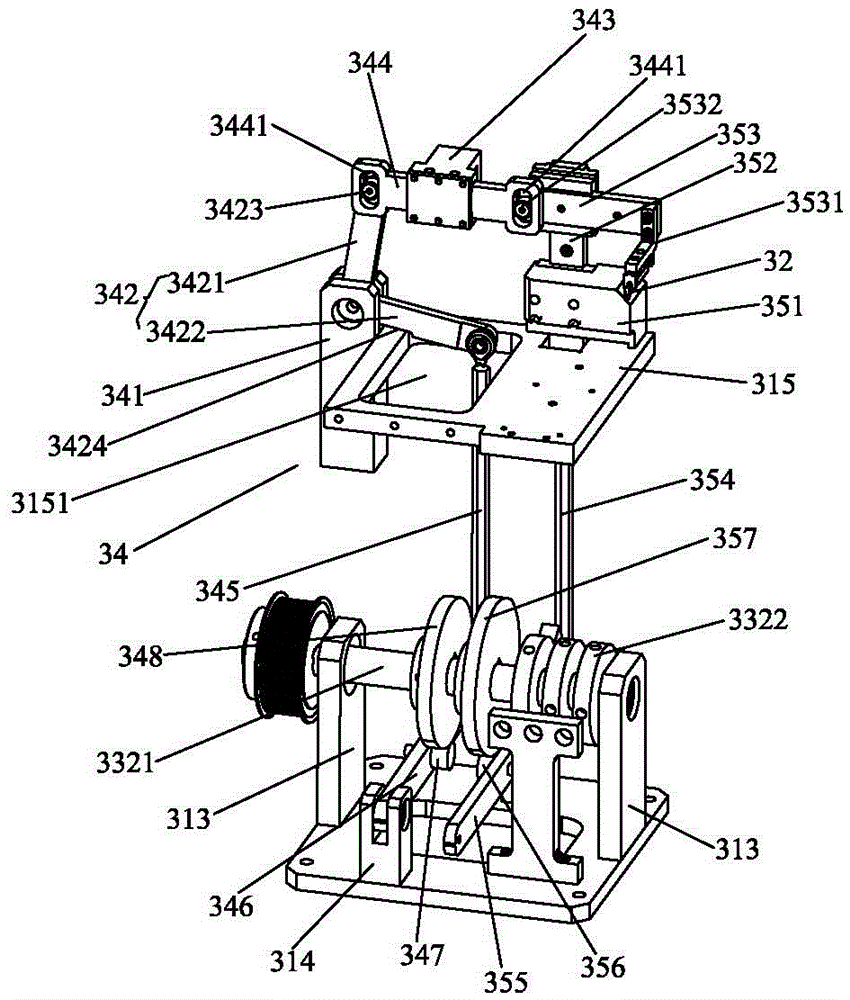

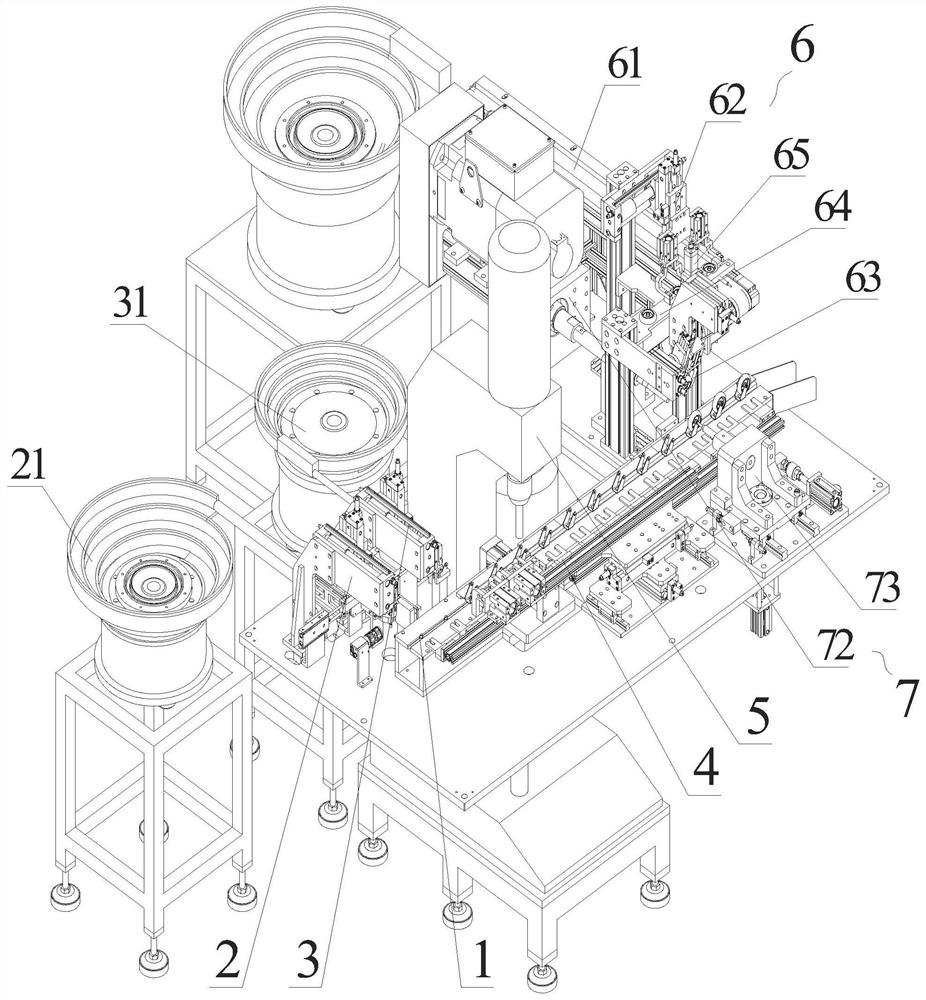

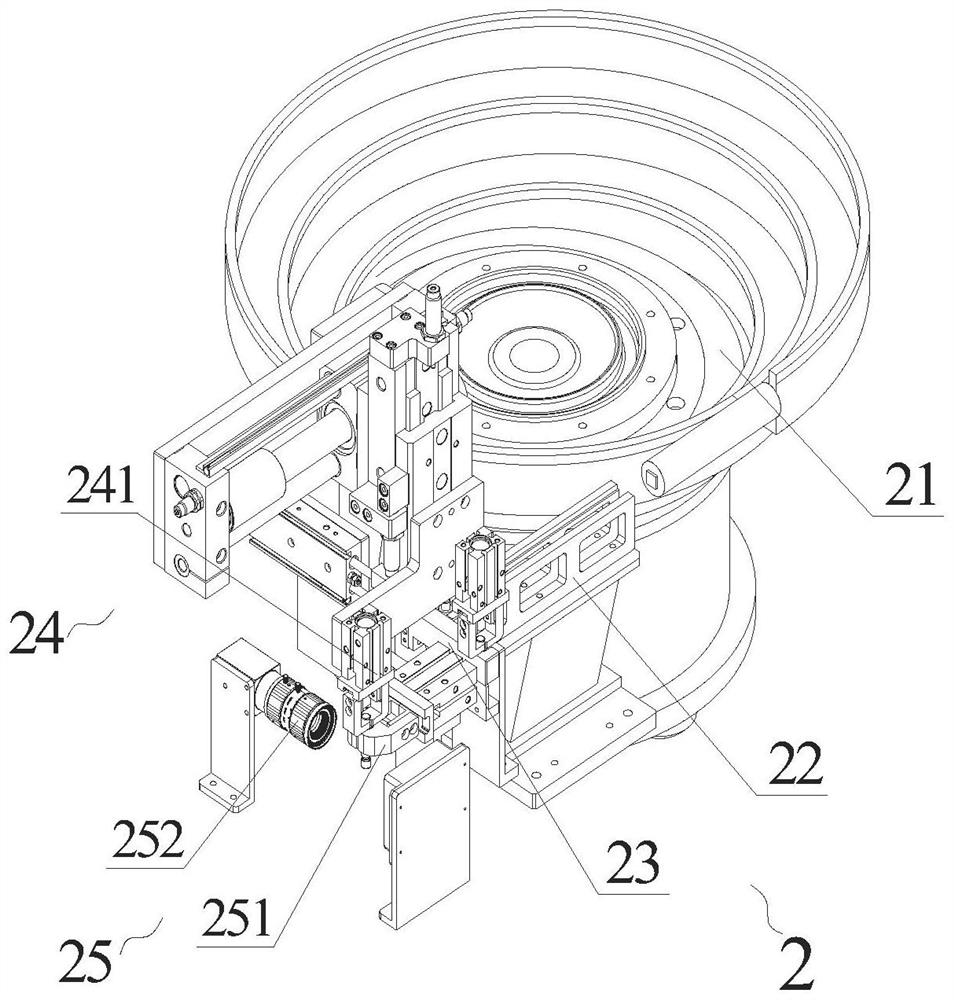

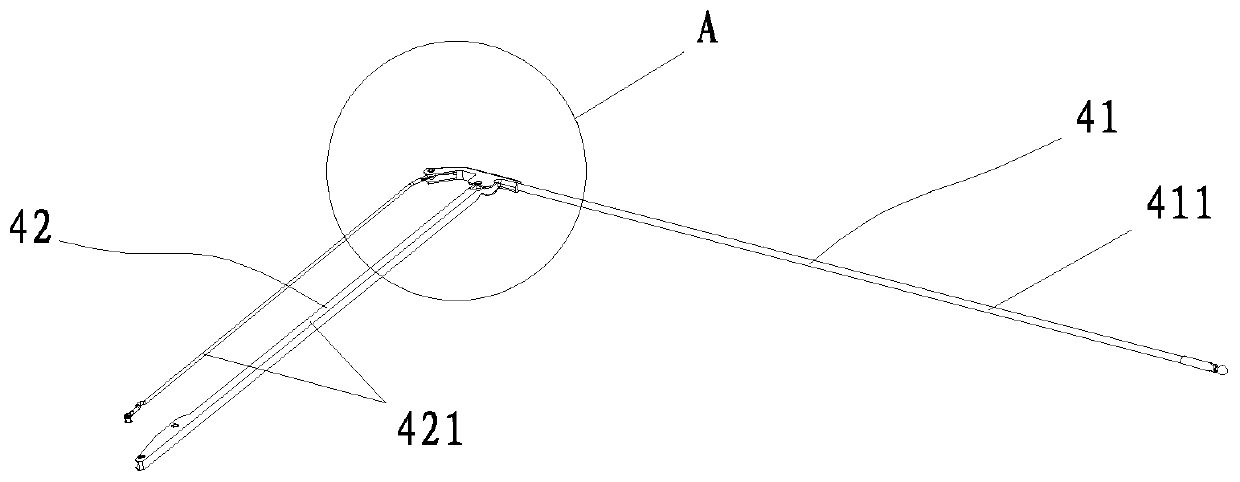

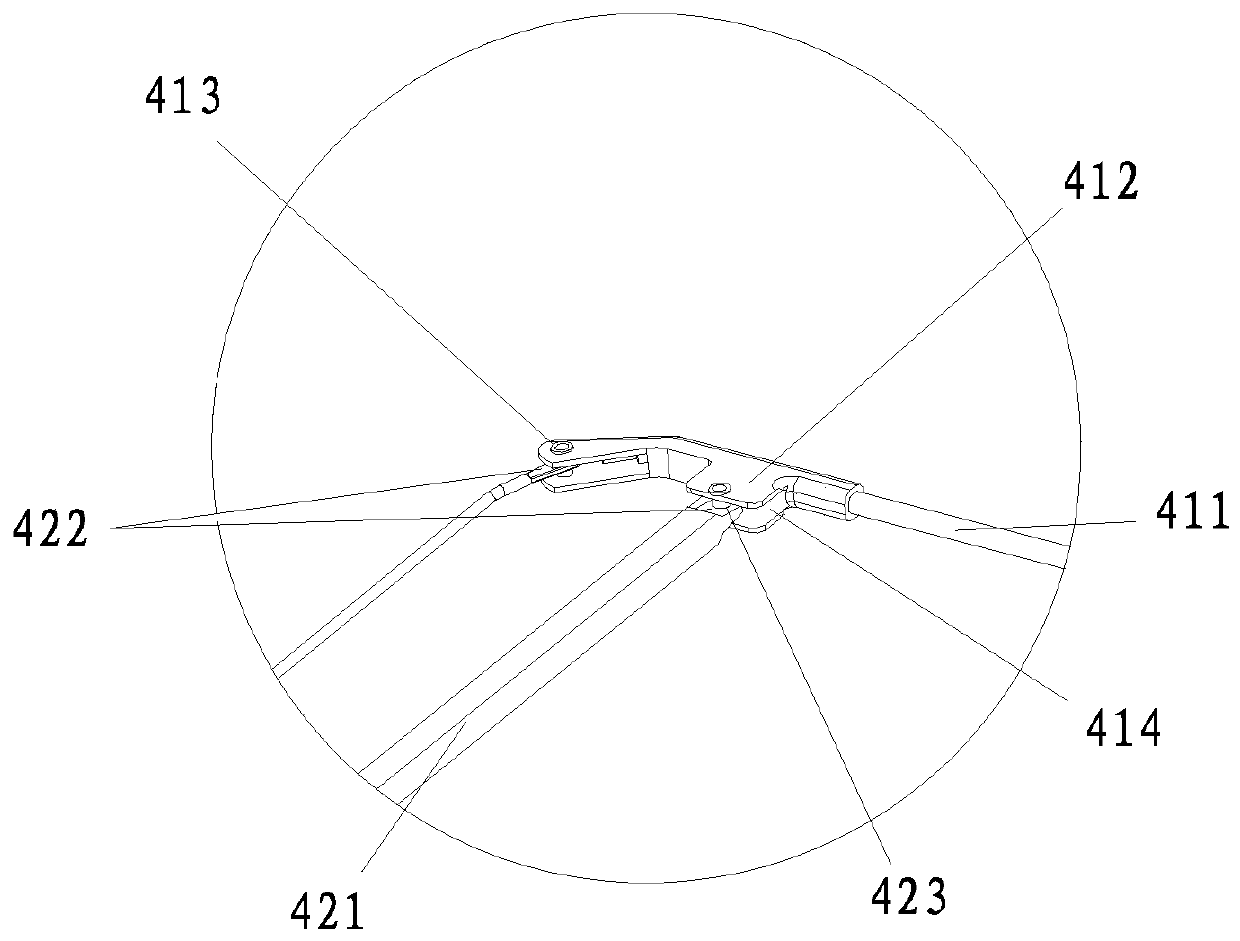

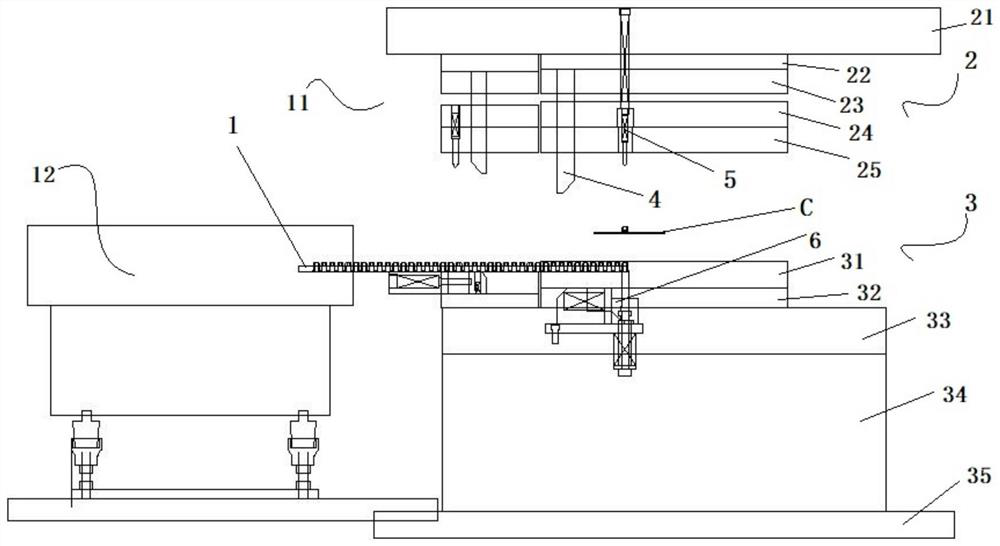

Full-automatic wire rod single-end terminal press fitting wetting machine

ActiveCN105790036AAccurate rivetingReduce error rateConnection formation by deformationPhysicsWire cutting

A full-automatic wire rod single-end terminal press fitting wetting machine disclosed by the present invention comprises a rack, a terminal conveying and press fitting mechanism, a branching mechanism, a wire rod moving mechanism, a wire cutting, peeling and twisting mechanism, a wire pulling and clamping mechanism and a wetting mechanism. The rack is equipped with a workbench, the wetting machine utilizes the wire rod moving mechanism to move the wire rods to the branching mechanism and the terminal conveying and press fitting mechanism to branch the wires and press fit the terminals, and then the wire rods are cut, peeled, twisted, wetted with the soldering flux and the tin, so that the above mechanisms are integrated on the rack, and all the wire rods can be separated and straightened before the terminals are press fitted, and accordingly, the terminals and the wire rods are riveted more accurately and firmly. The wire rods can be cut, peeled and twisted automatically, so that the wire rod processing efficiency is improved. Moreover, the wire rods are wetted with the soldering flux and the tin automatically, so that that the operations of branching, terminal press fitting, cutting, peeling, twisting, wetting with soldering flux and tin of the wire rods all can be finished automatically, the artificial workload and the production cost are reduced, and the production efficiency is improved.

Owner:东莞市超日自动化设备科技有限公司

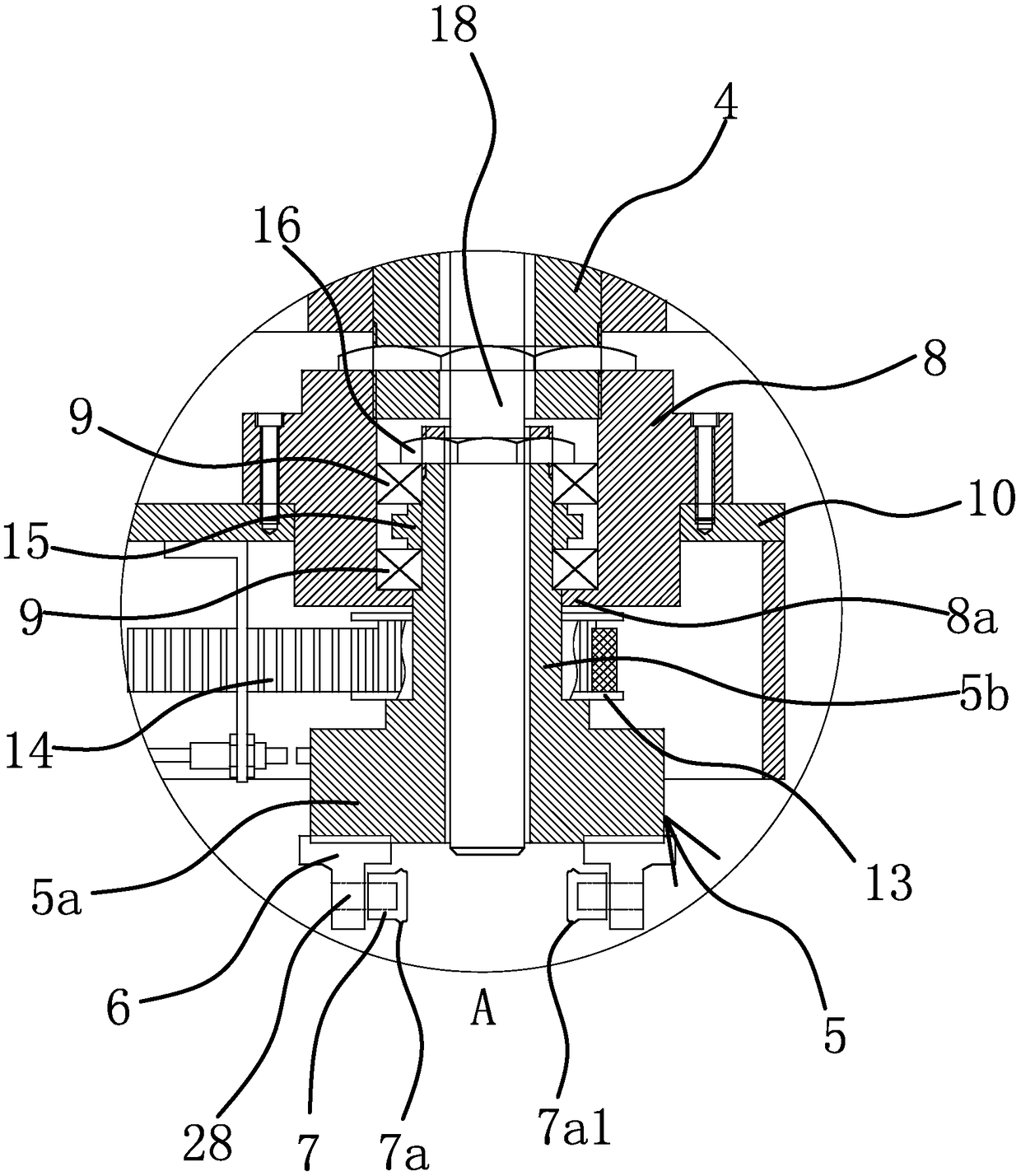

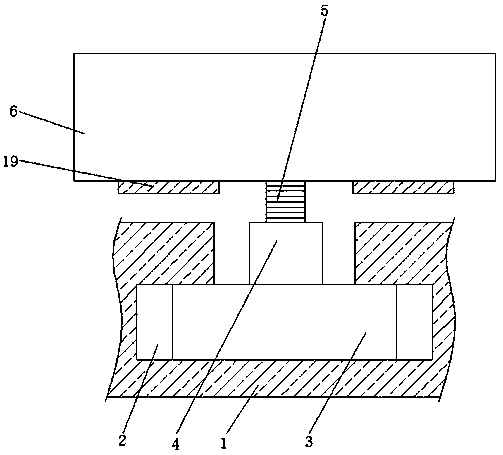

Riveting processing device of magnetron

The invention provides a riveting device of a magnetron, which comprises a machine body, a positioning seat which is used for fixing the magnetron and a riveting head which makes horizontal movement are arranged on the machine body, wherein the positioning seat is arranged on the surface of a lifting table, and the riveting head is arranged on worktables at both sides of the lifting table and always moves along the horizontal direction above the lifting table. The riveting head is provided with an outer riveting head and an inner riveting head, a gap is reserved between the two riveting heads, and a gap is also reserved between the outer riveting head and the inner edge of a mounting seat, and the size of each gap is slightly larger than the thickness of the magnetron outer shell. The riveting device uses a general structure filter box as a positioning object and a clearance is reserved between the riveting heads to make the device suitable for riveting magnetrons with various specifications. When the lifting table is lifted to a certain position and is delayed for a certain period, and cylinders at both sides push the riveting heads simultaneously during the delay to make an end cover buckle with the outer shell. The riveting device is simple and reasonable in the structure, stable and accurate in riveting, is low in rework and scrap.

Owner:GUANGDONG GALANZ GRP CO LTD

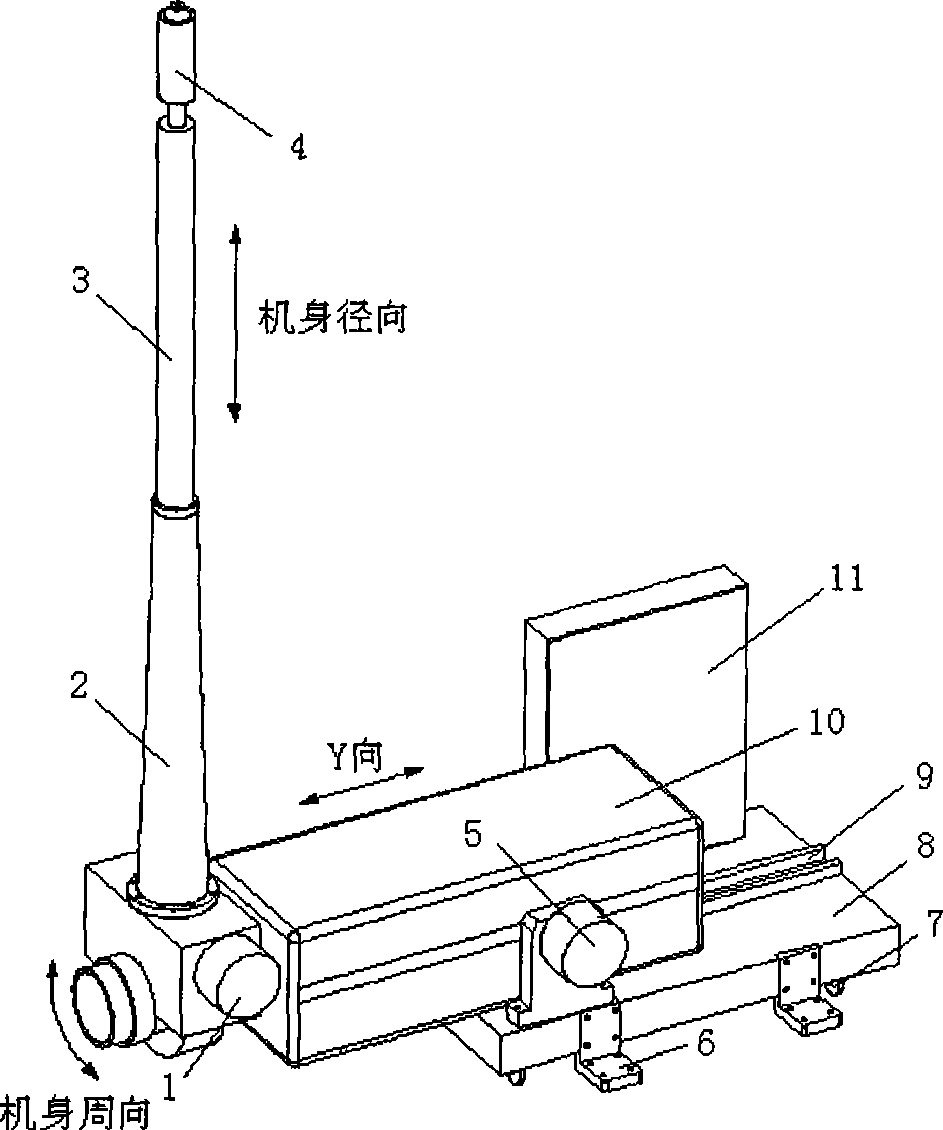

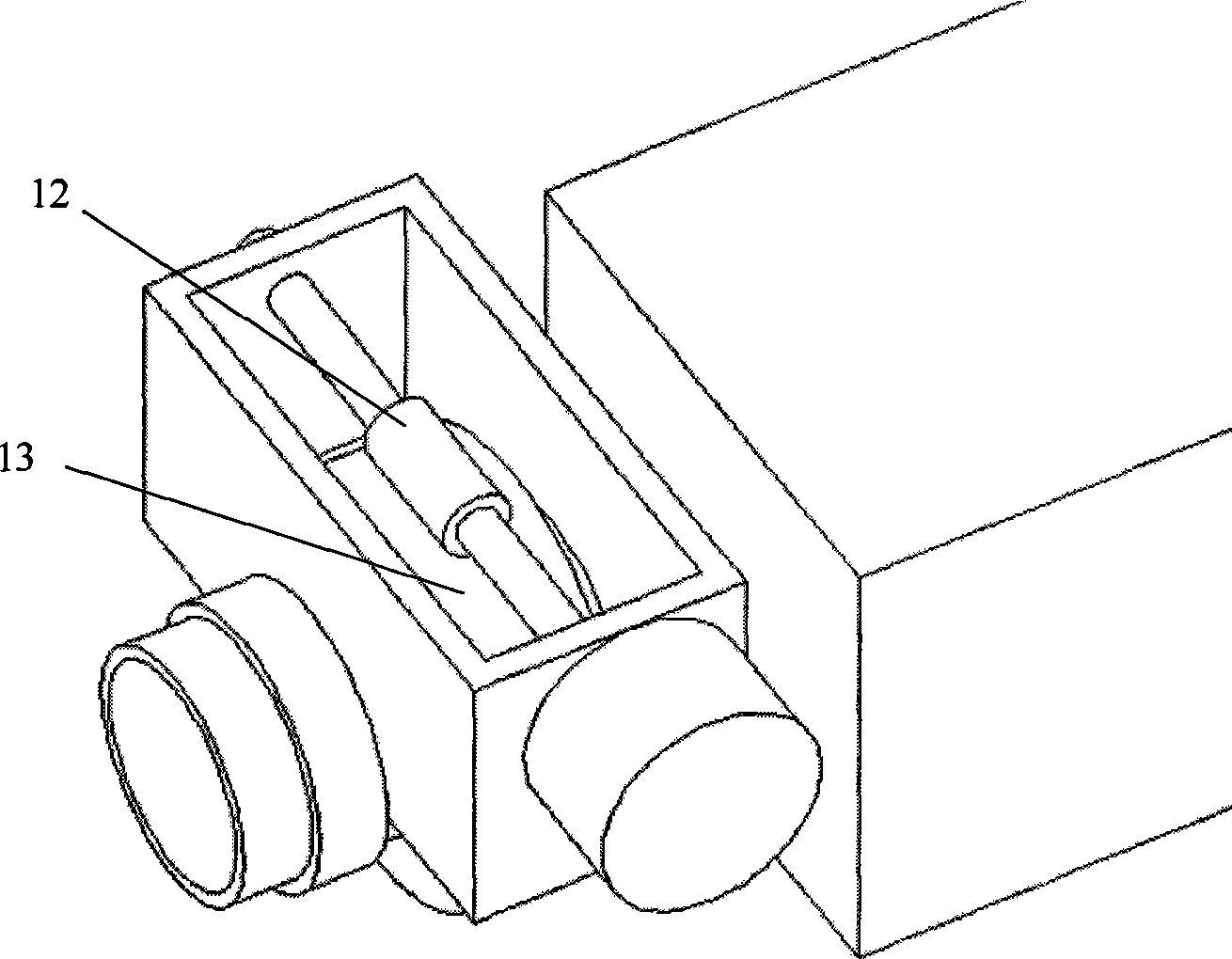

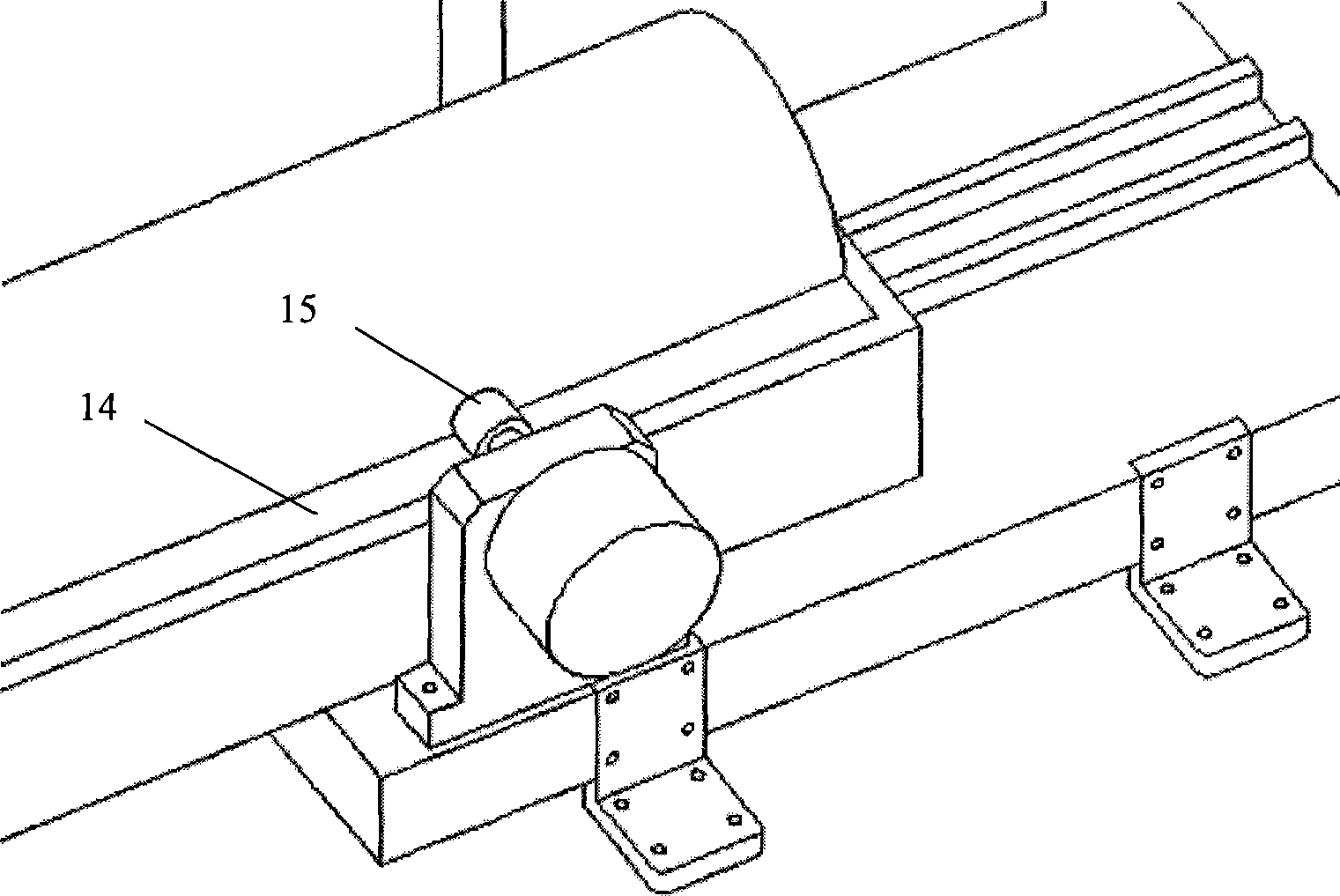

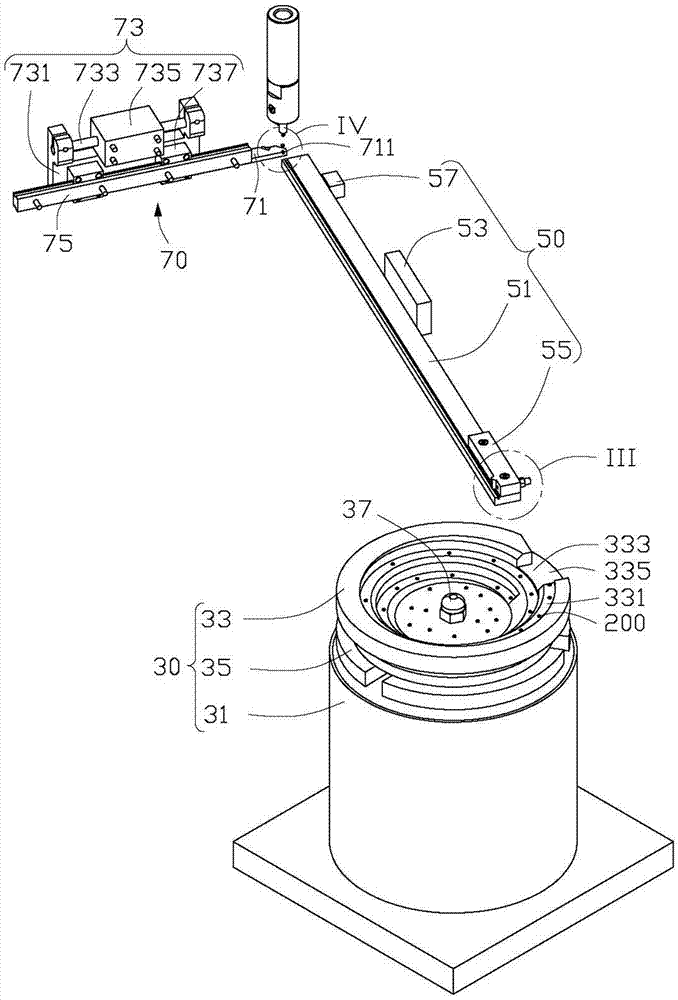

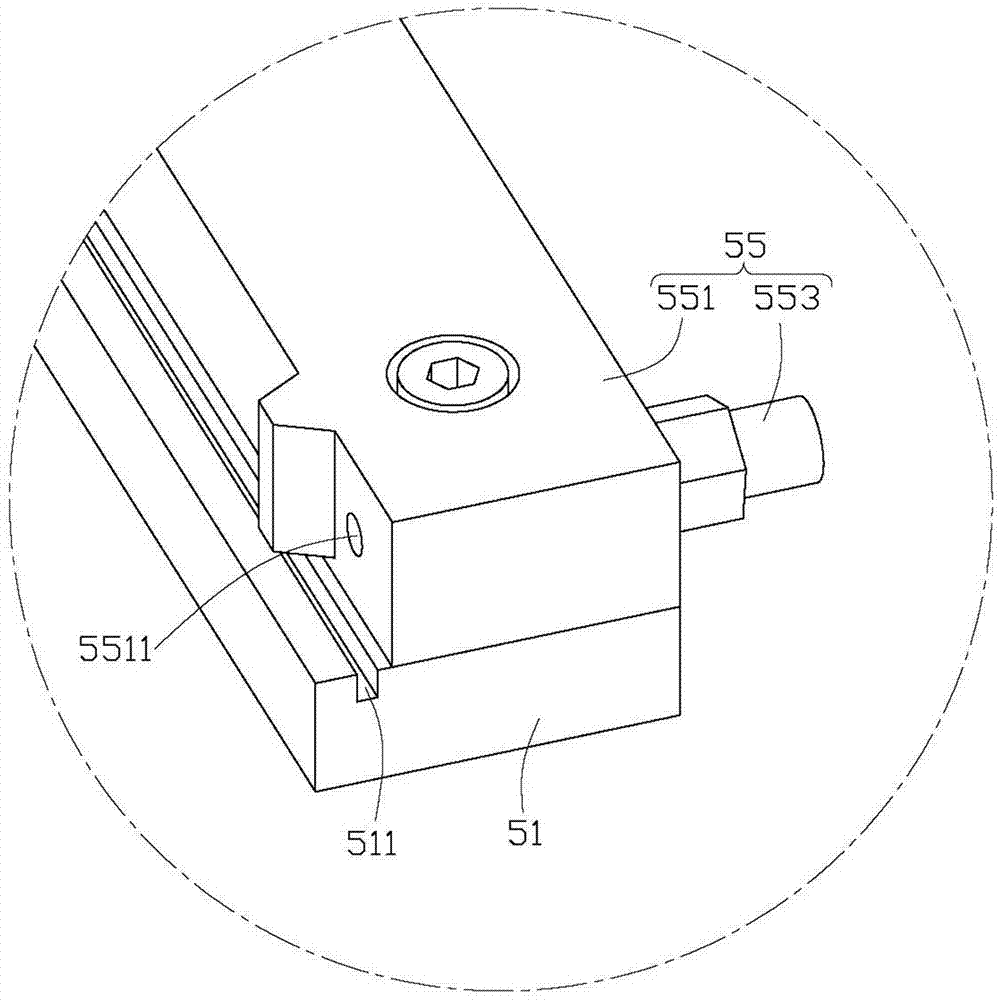

Rotary type automatic riveting machine hand and use method thereof

The invention discloses a structure of a rotary automatic riveting manipulator and an application method thereof. The rotary automatic riveting manipulator comprises a circumferential drive motor, a rotary bracket, a telescopic cylinder, a self-adaptive tool head, a Y-direction drive motor, a connecting piece, a wheelbarrow, a linear guide rail and a hollow sleeve. The connecting piece is arranged under the wheelbarrow, and the linear guide rail and a controller are arranged above the wheelbarrow; the linear guide rail is provided with the hollow sleeve; the end of the hollow sleeve is provided with the rotary bracket; the upper end of the rotary bracket is provided with the telescopic cylinder and the self-adaptive tool head. The application method comprises the following steps: (1) the manipulator is pushed to a riveting position to connect the connecting piece and a location hole by a bolt; (2) the hollow sleeve moves along the linear guide rail in Y direction, and the rotary bracket moves circumferentially along the body of the machine; (3) the self-adaptive tool head strikes a rivet to form a pier. The manipulator has the advantages that: (1) the manipulator can meet the riveting requirements of the straight sections of a large aircraft; (2) the rotary automatic riveting manipulator has simple structure, good rigidity and easy realization; (3) the circumferential riveting range is wide.

Owner:ZHEJIANG UNIV +1

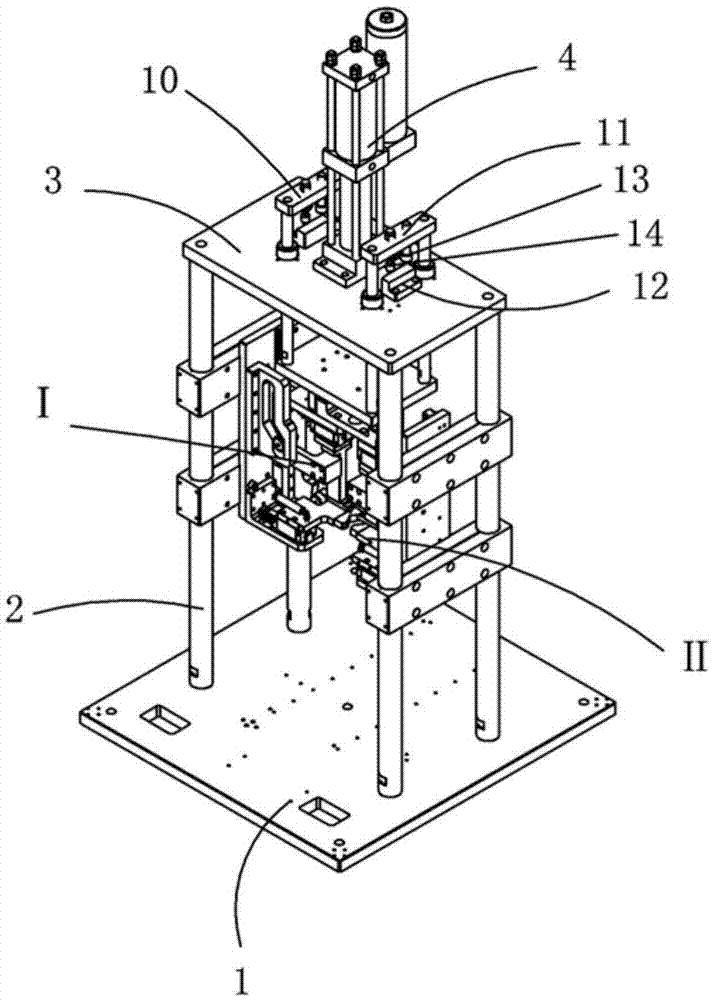

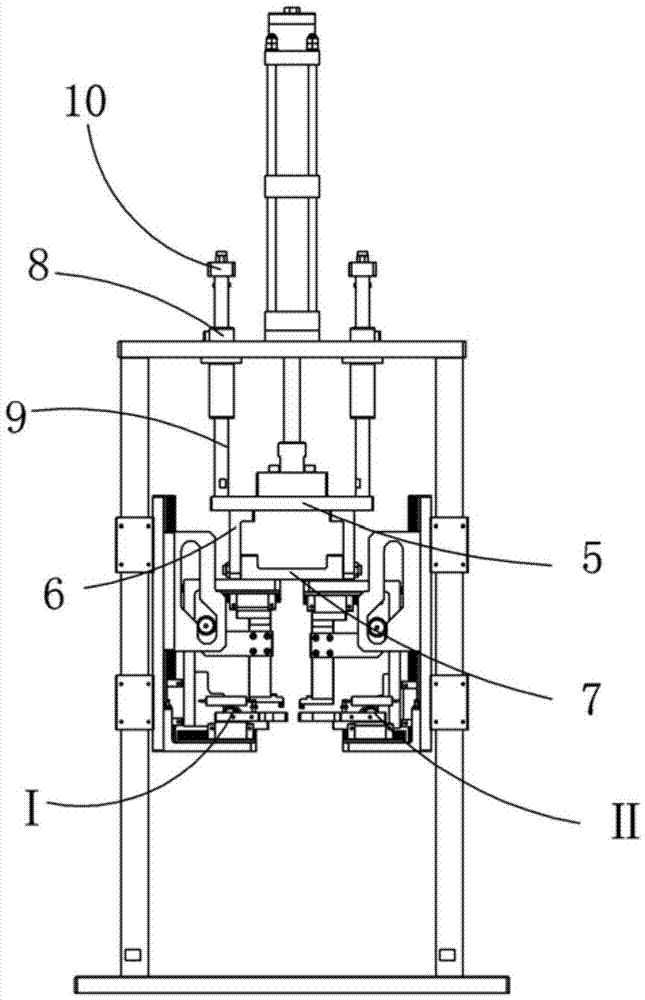

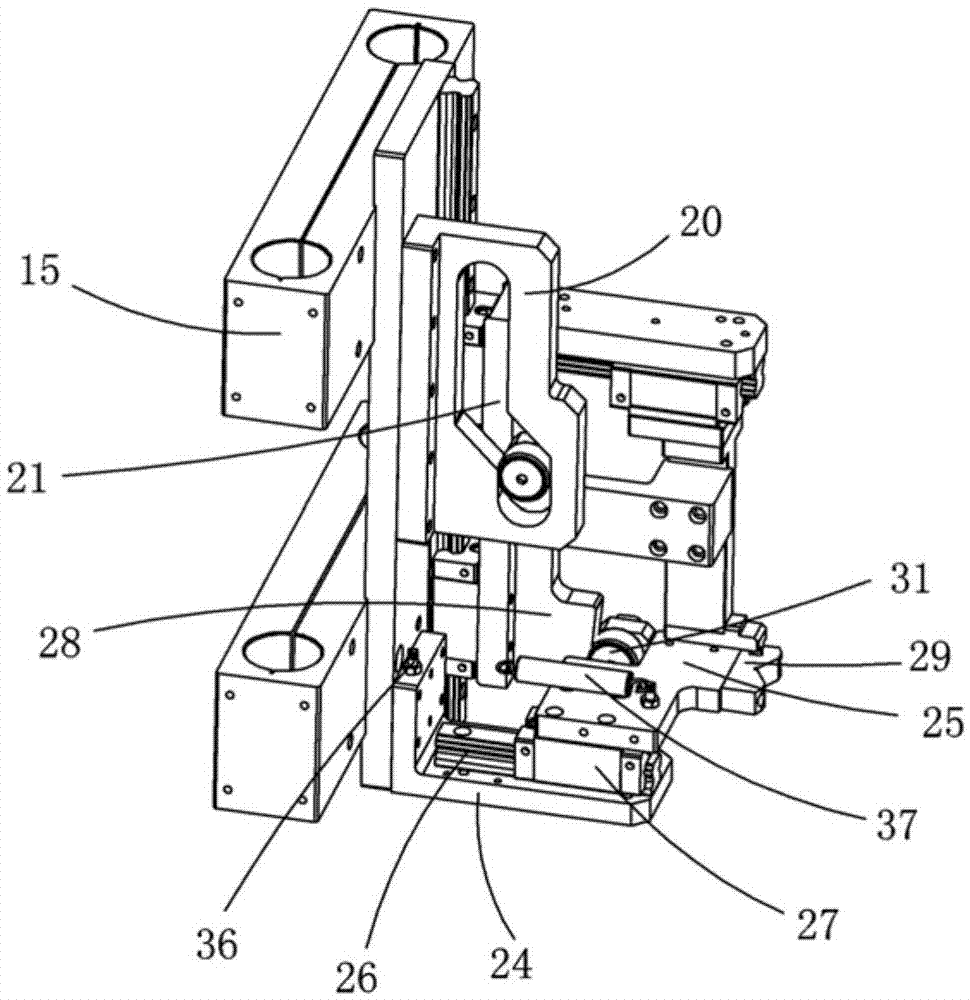

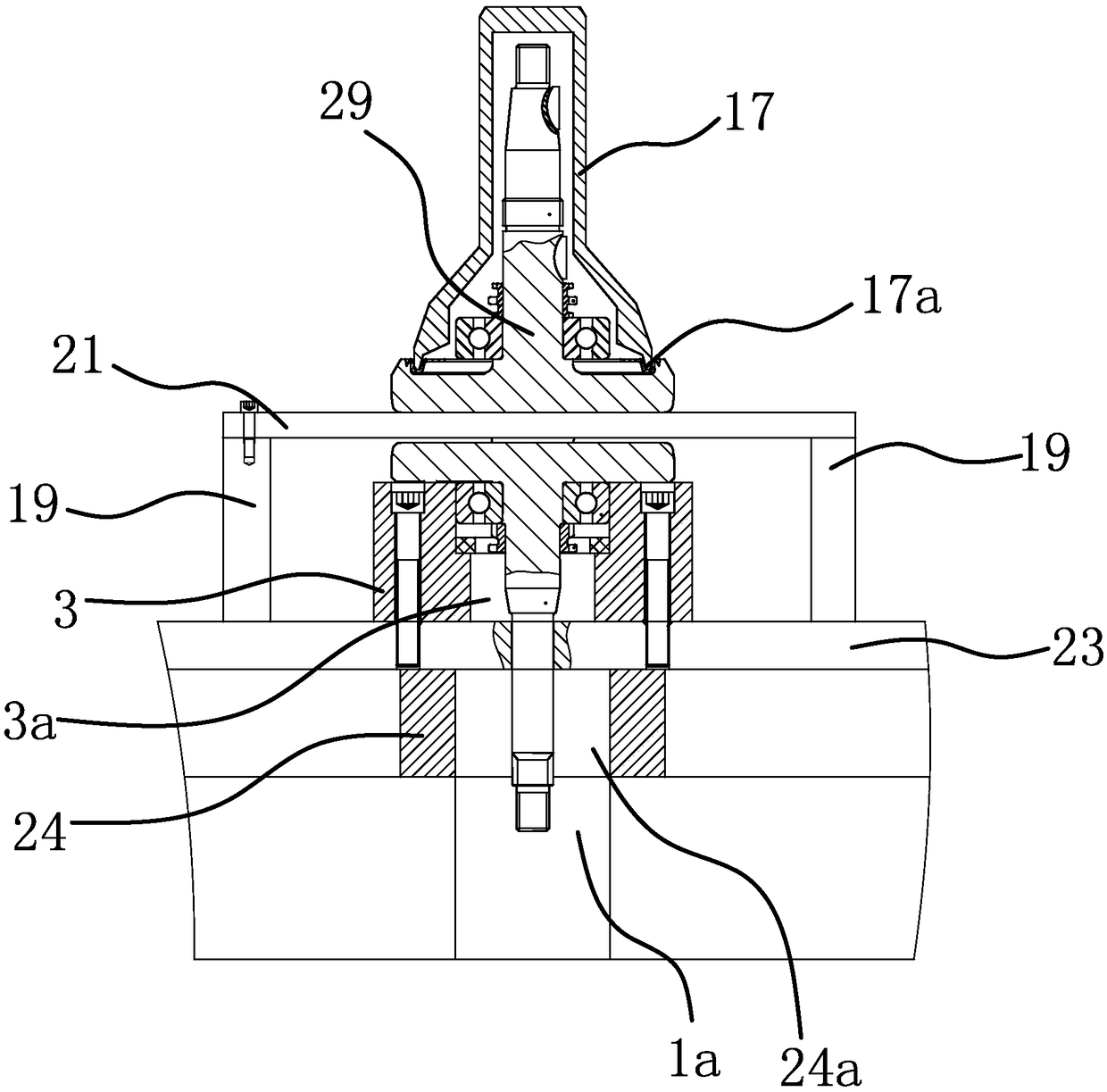

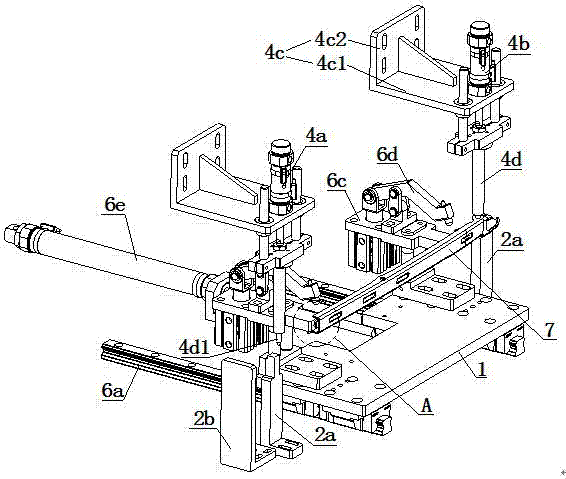

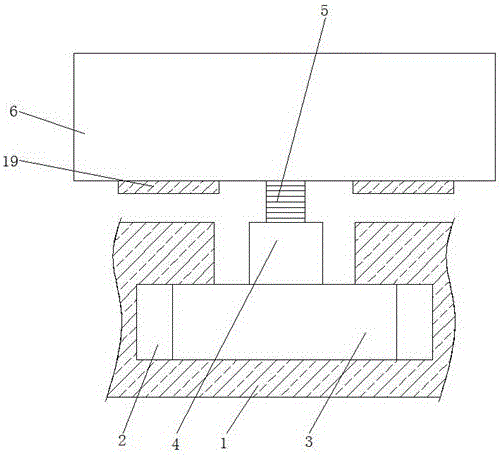

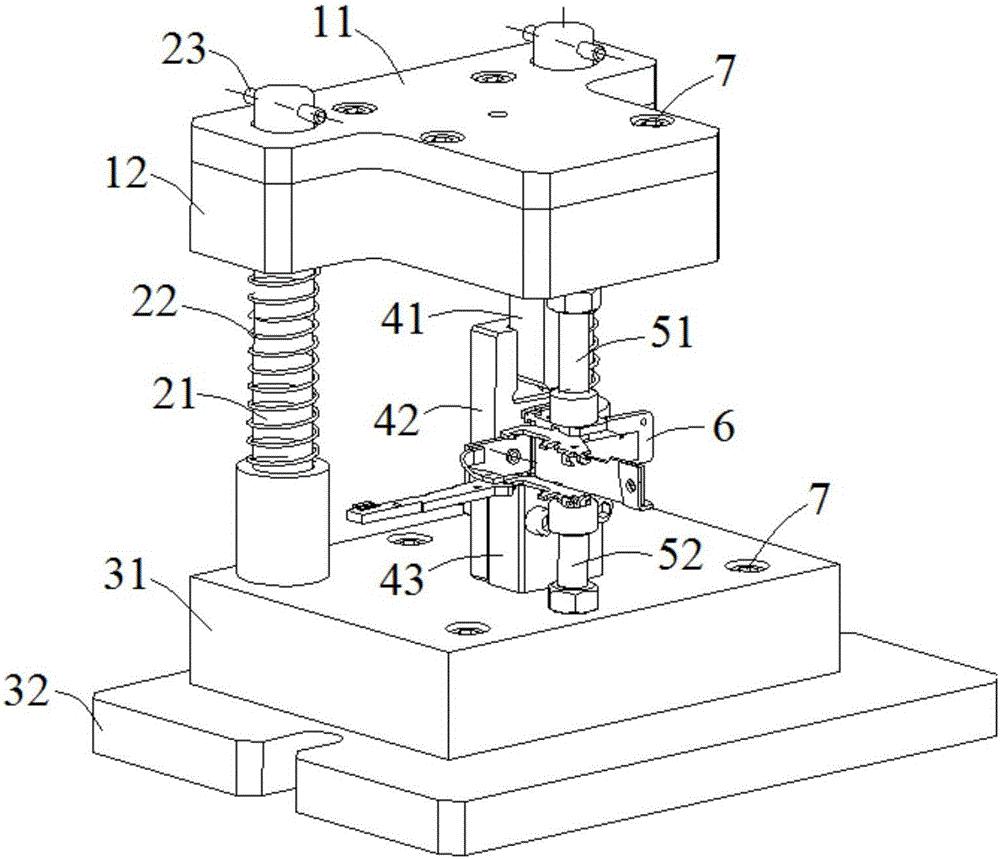

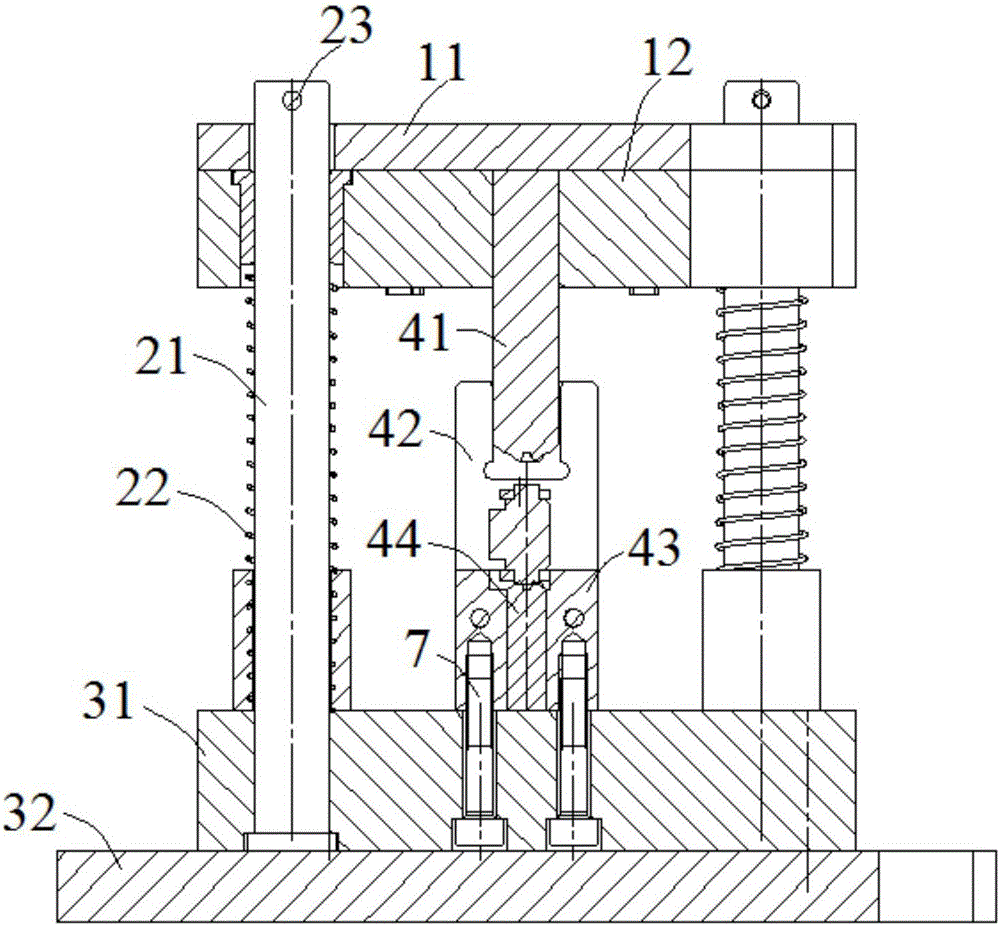

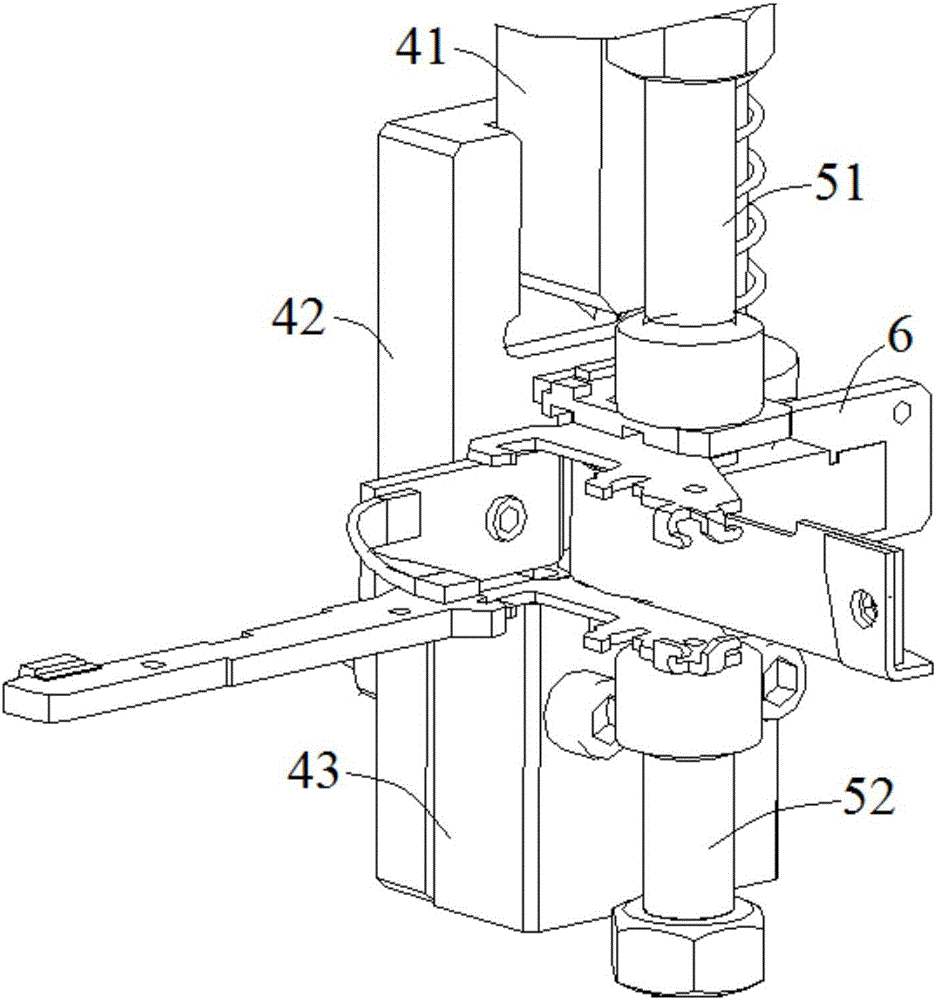

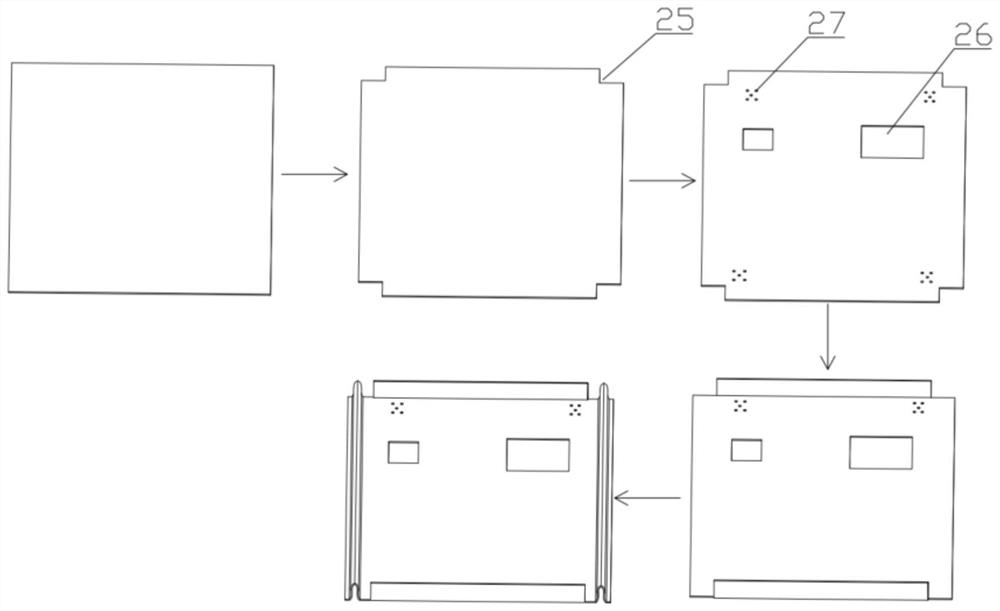

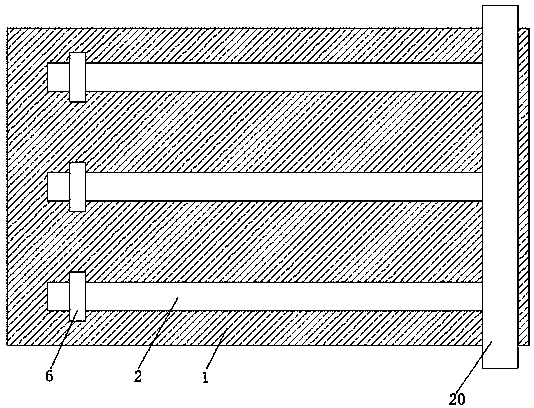

Positioning and riveting pressing mechanism

ActiveCN105436330AAccurate rivetingMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

The invention relates to a positioning and riveting pressing mechanism. The mechanism is characterized in that a lifting fixing plate is mounted on a bottom plate through four supporting columns, wherein a lifting cylinder is mounted on the lifting fixing plate; a movable plate is mounted at the lower end of a piston rod of the lifting cylinder through a lifting cylinder connector; a pressing plate is connected to the lower part of the movable plate through a connecting plate; left positioning and riveting pressing assemblies are arranged between two supporting columns at the left side and the pressing plate; right positioning and riveting pressing assemblies which are structured the same as the left positioning and riveting pressing assemblies are mounted between the rest two supporting columns at the right side and the pressing plate. According to the positioning riveting pressing mechanism, the tracks of guide slot plates, the contours of guide blocks, and the positions of the guide slot plates and the guide blocks are set, so that the left positioning and riveting pressing assemblies and the right positioning and riveting pressing assemblies can be driven by a single power source to realize the function of positioning firstly and riveting and pressing secondly or synchronously positioning, riveting and pressing, and as a result, the riveting pressing accuracy is improved.

Owner:BOZHON PRECISION IND TECH CO LTD

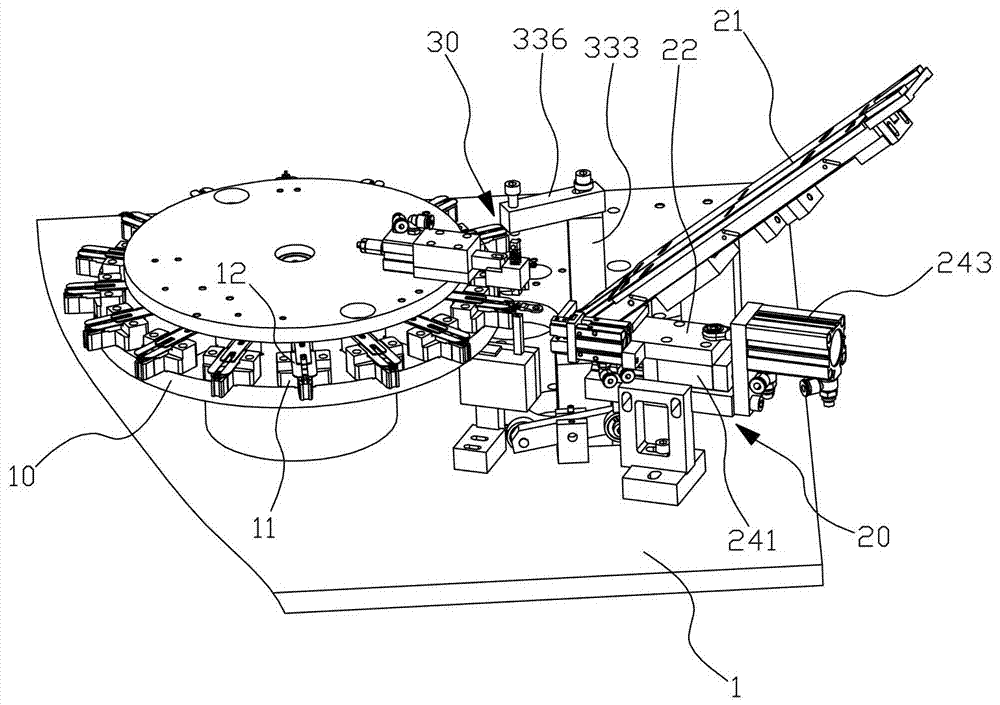

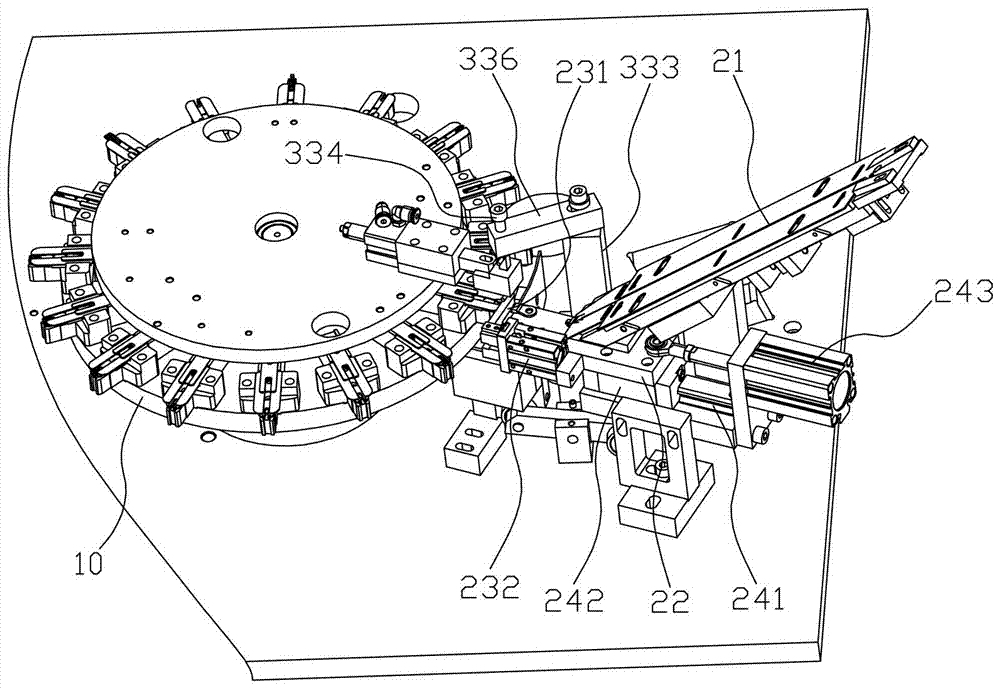

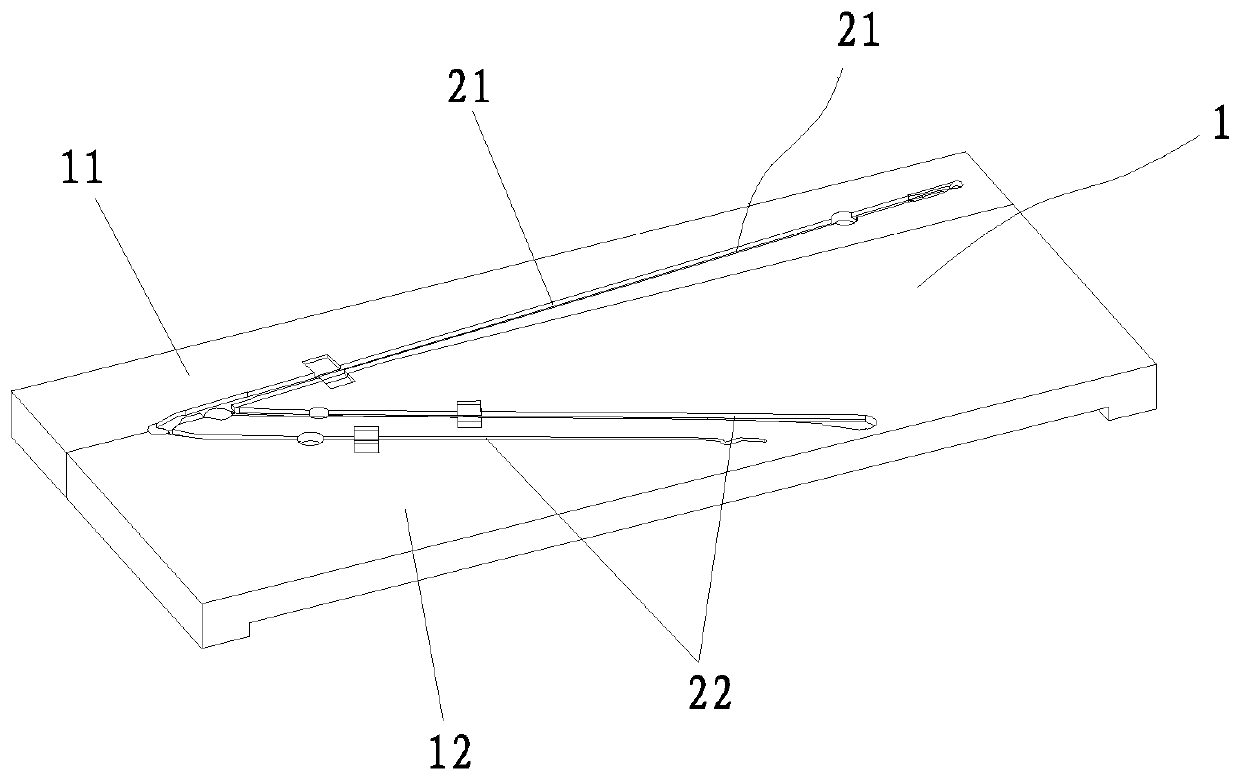

Automatic core drawing piece feeding assembling machine for pullers with rings in shape like Chinese character 'ri'

ActiveCN107052174AImprove riveting qualityImprove assembly efficiencySlide fastenersMetal-working feeding devicesEngineeringChinese characters

An automatic core drawing piece feeding assembling machine for pullers with rings in the shape like the Chinese character 'ri' comprises a rack and a circular rotary disc. A plurality of puller die cores are arranged on the circumferential face of the rotary disc. Each puller die core is provided with a U-shaped pressing sheet. A core drawing piece conveying device and a riveting device are arranged on the rack around the circular rotary disc. The core drawing piece conveying device comprises a pull piece track, a material distributing plate, a core drawing piece clamping mechanism and a core drawing piece pushing mechanism, wherein the pull piece track is obliquely and fixedly supported on the rack, the material distributing plate is arranged at the bottom of the discharging end of the puller track in a sliding manner, the core drawing piece clamping mechanism comprises a pair of clamping arms and a finger air cylinder, the clamping arms are arranged in front of the material distributing plate, the finger air cylinder is fixed to the side face of the material distributing plate, the clamping arms are fixed to the front end of the finger air cylinder, and the core drawing piece pushing mechanism comprises a sliding rail, a sliding block and an air cylinder. The assembling machine is simple in structure, core drawing pieces can be accurately clamped and conveyed to the corresponding positions of the rings in the shape like the Chinese character 'ri', and the assembling efficiency of the core drawing pieces and the rings in the shape like the Chinese character 'ri' and the quality and the qualification rate of puller products are greatly improved.

Owner:QUANZHOU LICHENG DISTRICT ZHAN AUTOMATION EQUIP

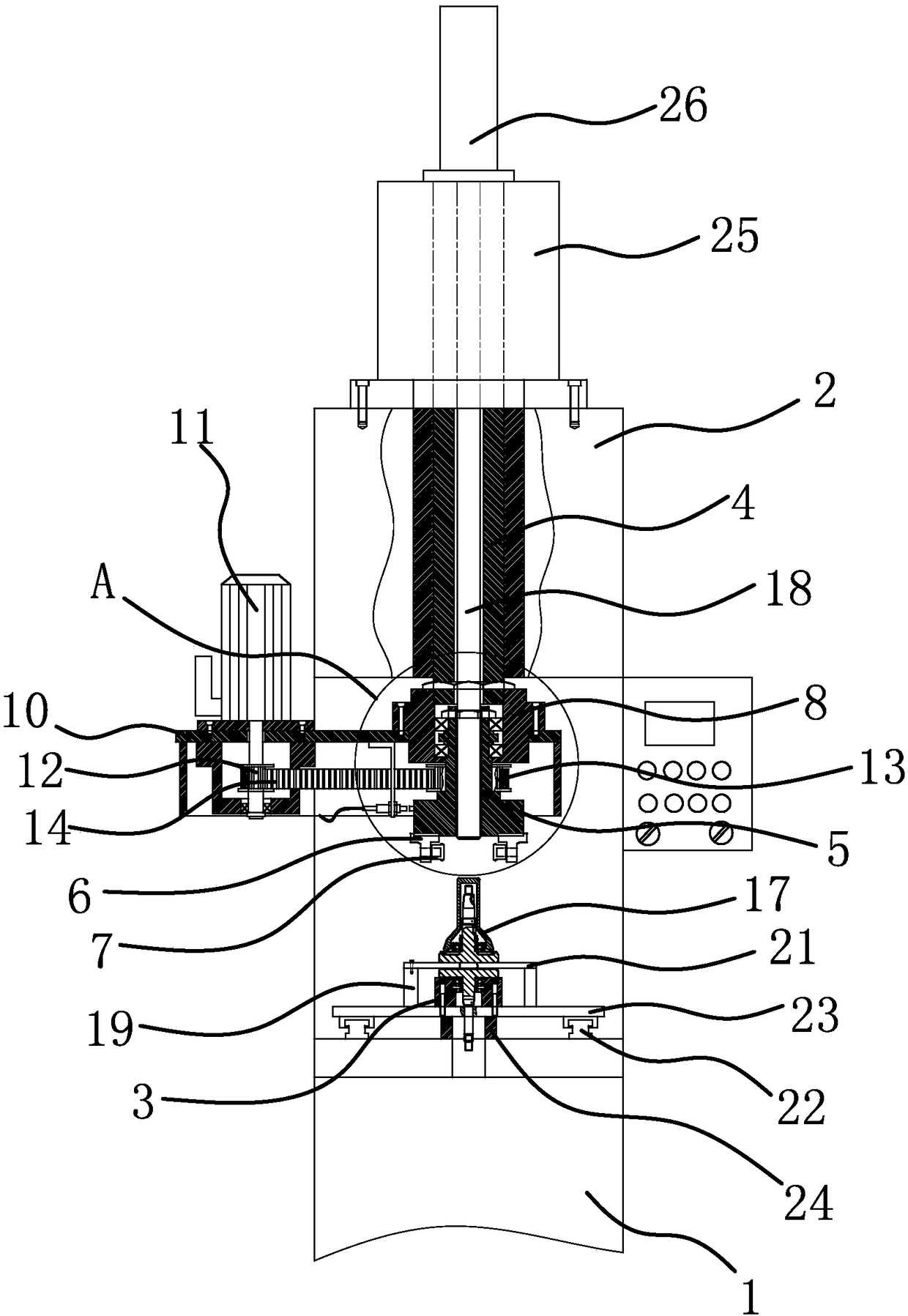

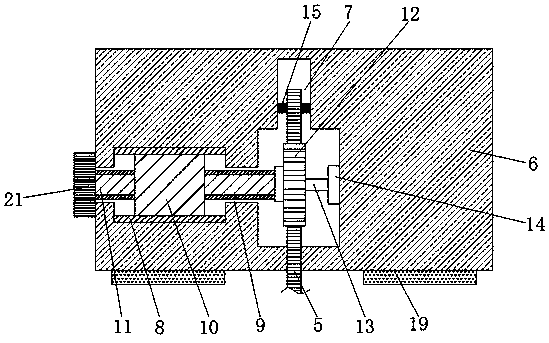

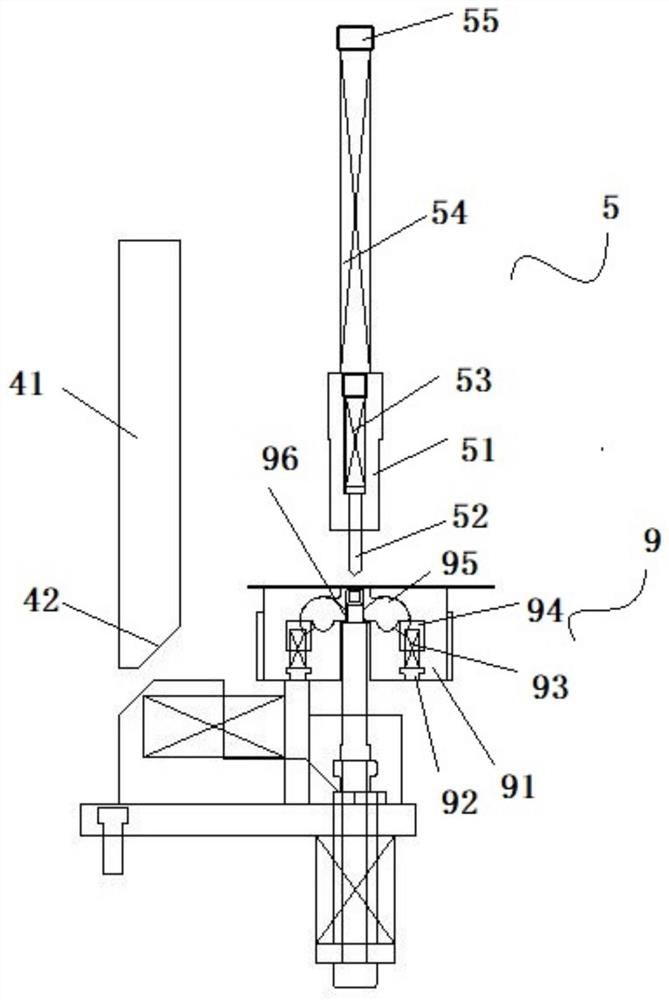

Spin riveting machine

The invention provides a spin riveting machine, and belongs to the technical field of machinery. The problem that the connection between an existing oil thrower and crankshaft is not firm enough is solved. The spin riveting machine comprises a machine frame, a mounting block and a spindle box, wherein the mounting block and the spindle box are arranged on the machine frame. The mounting block is provided with a mounting hole arranged in the vertical direction in a penetrating mode. The spindle box is internally provided with a spindle capable of moving up and down, and the lower end of the spindle extends outside the spindle box. A rotating head which can rotate is connected to the lower end of the spindle, and two positioning blocks are arranged at the lower end of the rotating head. Theinner sides of the two positioning blocks are separately connected with pressing wheels which can rotate, annular convex portions are arranged on the outer peripheral surfaces of the two pressing wheels, when the rotating head rotates, the movement trajectories of the two annular convex portions coincide, and extrusion faces inclined towards the outer sides of the positioning blocks are arranged on the inner sides of the two annular convex portions. The spin riveting machine has the advantages of high precision of spin riveting, simple operation, good connection fastness between the crankshaftand the oil thrower after riveting and the like.

Owner:TAIZHOU HONGXIN CRANKSHAFT

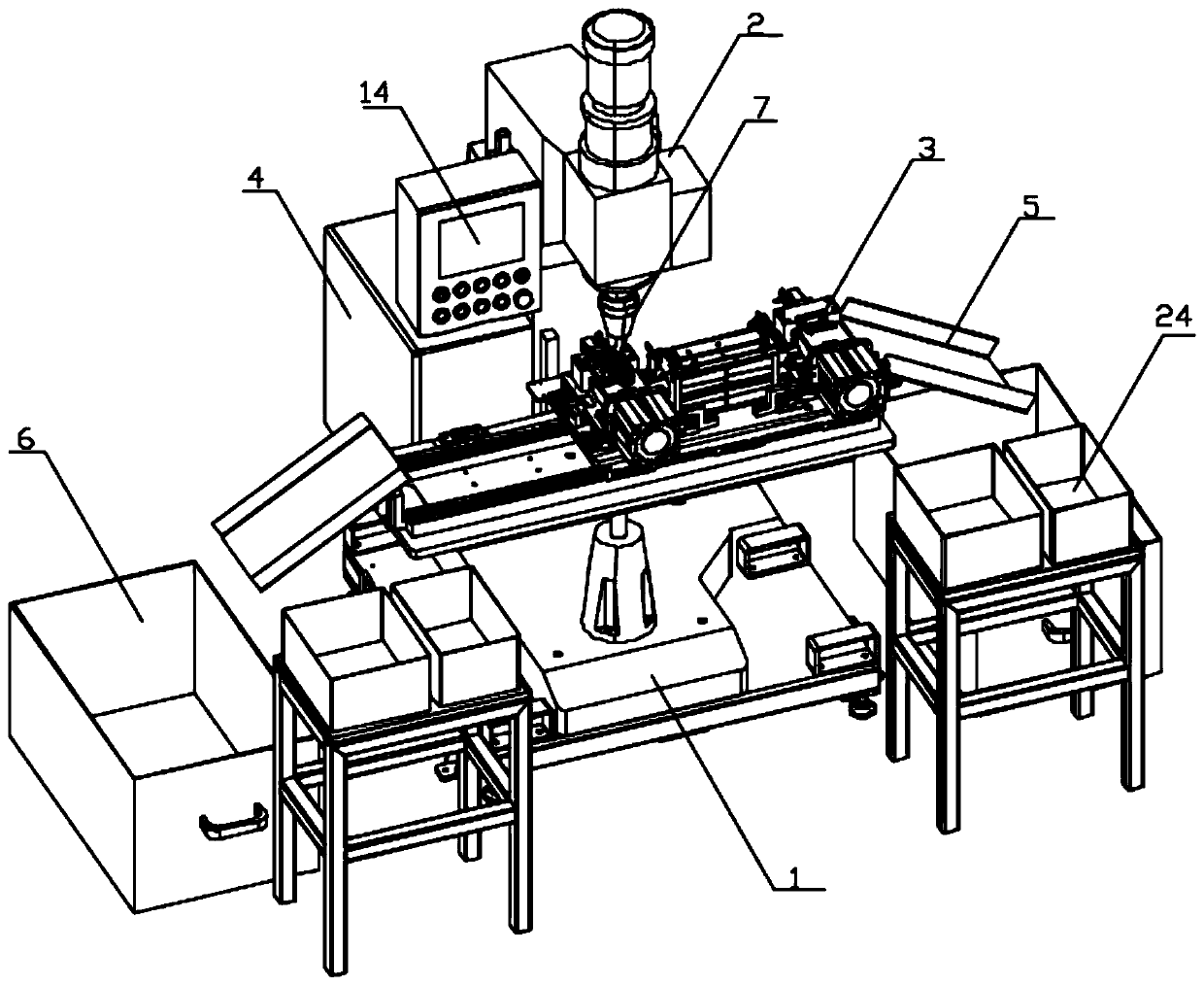

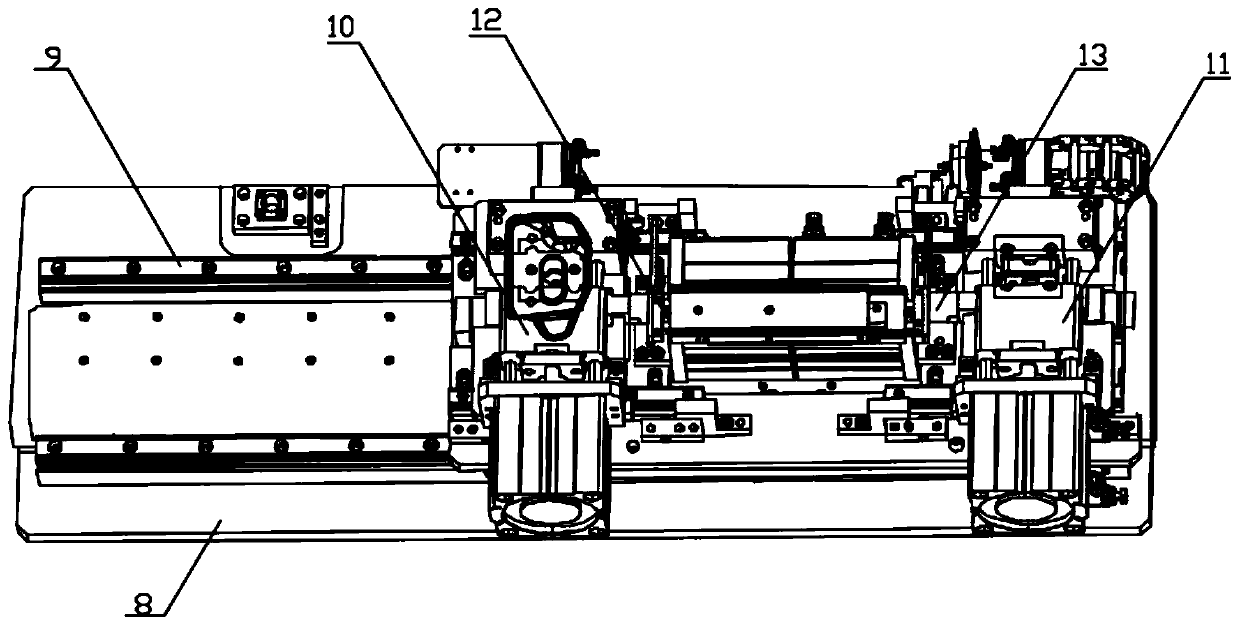

Automatic riveting machine

The invention relates to the technical field of riveting, in particular to an automatic riveting machine. The automatic riveting machine comprises a workbench, a positioning device, a rivet feeding device, a correcting device, pressing devices and a moving device; the positioning device and the rivet feeding device are mounted on the workbench at an interval, the positioning device is used for positioning a workpiece, the correcting device is arranged above the positioning device and used for correcting the positioned workpiece, the rivet feeding device 3 is used for arraying rivets well and outputting the same in sequence, the pressing device is arranged above the rivet feeding device 3, and the moving device is located between the positioning device and the rivet feeding device. The workpiece is manually placed on the positioning device to be automatically corrected and punched and riveted by placing the rivets to the preset position automatically through the correcting device, the rivet feeding device and the pressing device, the automatic riveting machine is high in operation efficiency, accurate and solid in riveting, suitable for mass production, free of manual operation in the whole process except workpiece loading and unloading and high in safety performance.

Owner:朱华习

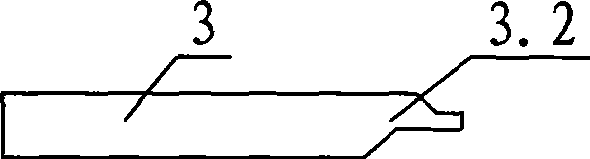

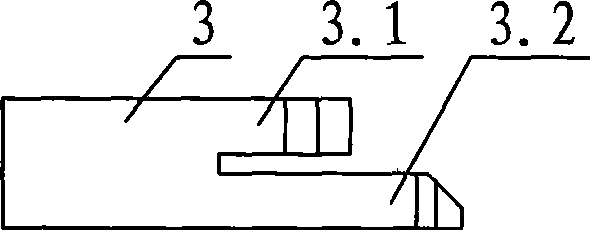

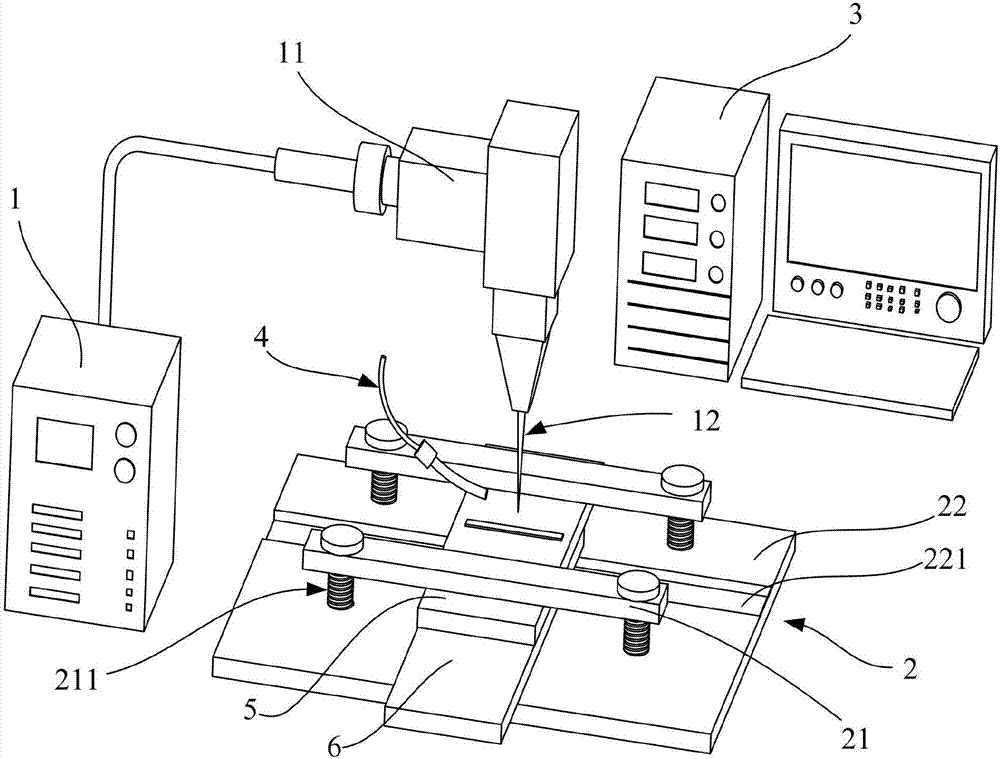

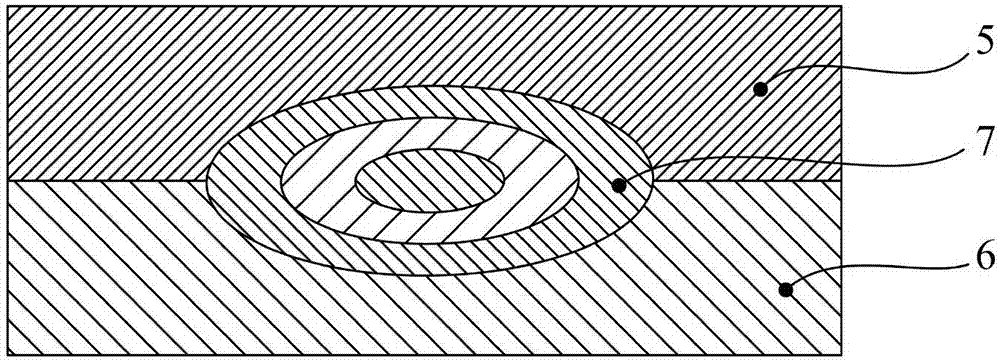

Polymethyl methacrylate and stainless steel laser welding system and welding method

The invention discloses a polymethyl methacrylate and stainless steel laser welding system. The polymethyl methacrylate and stainless steel laser welding system comprises a fiber laser, a laser head and an industrial computer, the laser head is electrically connected with the fiber laser and is capable of emitting a laser beam, and the industrial computer is electrically connected with the fiber laser and controls the fiber laser to conduct laser welding. The laser welding system further comprises a clamping device used for clamping a polymethyl methacrylate workpiece and a stainless steel workpiece. The clamping device comprises a lower pressing plate and upper pressing plates which are separated from each other and impact the two ends of each workpiece respectively, and the upper pressing plate can be used for adjusting the impacting degree for the workpieces through a screw rotation structure. The invention further puts forward a welding method using the polymethyl methacrylate and stainless steel laser welding system, so that the polymethyl methacrylate workpiece and the stainless steel workpiece can be tightly clamped so as to be effectively welded. Compared with the prior art, the polymethyl methacrylate and stainless steel laser welding system and the welding method have the advantages that the production yield is high, weld strength is high, welding deformation is small, precise welding is realized, and the like.

Owner:GUANGDONG UNIV OF TECH

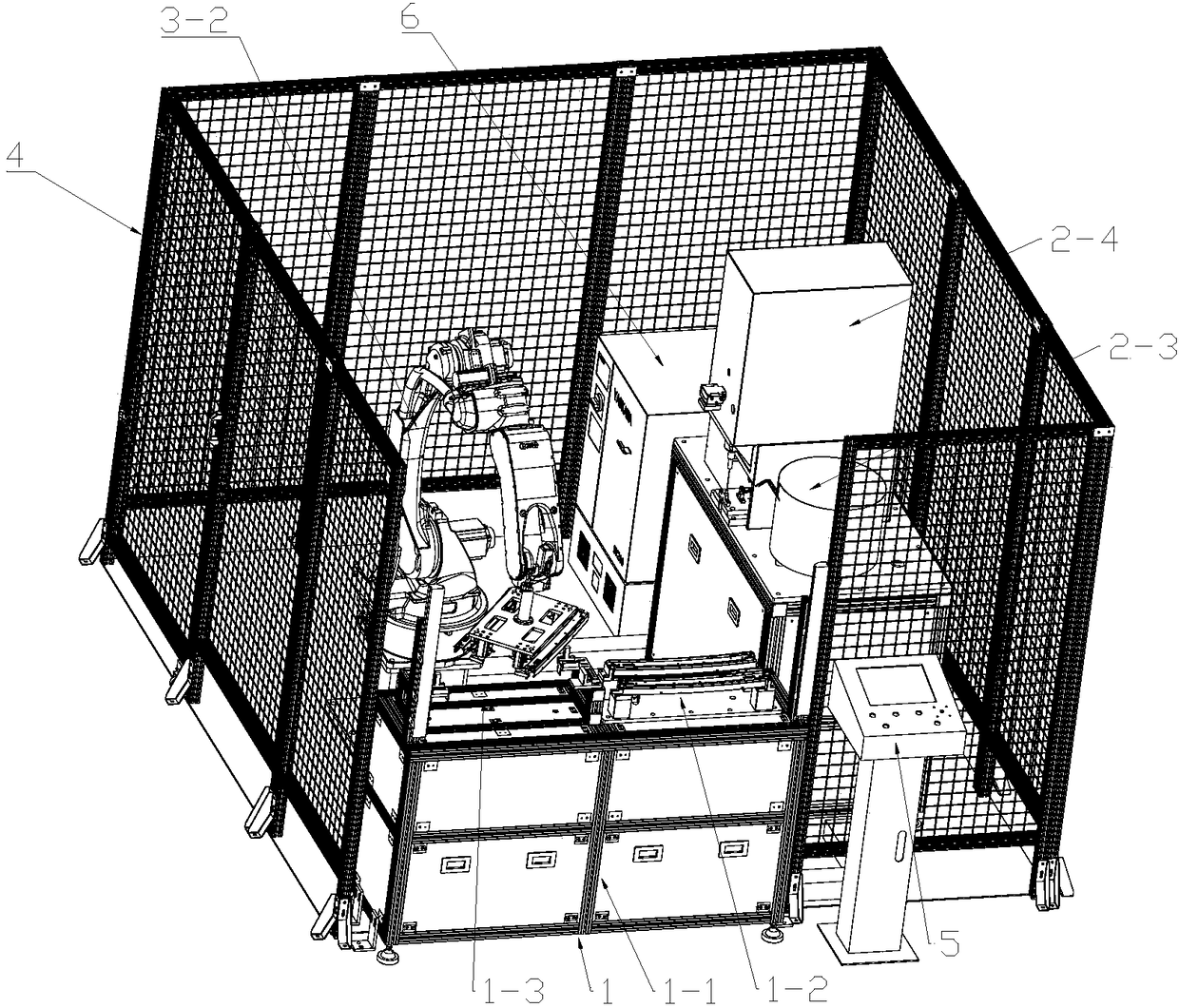

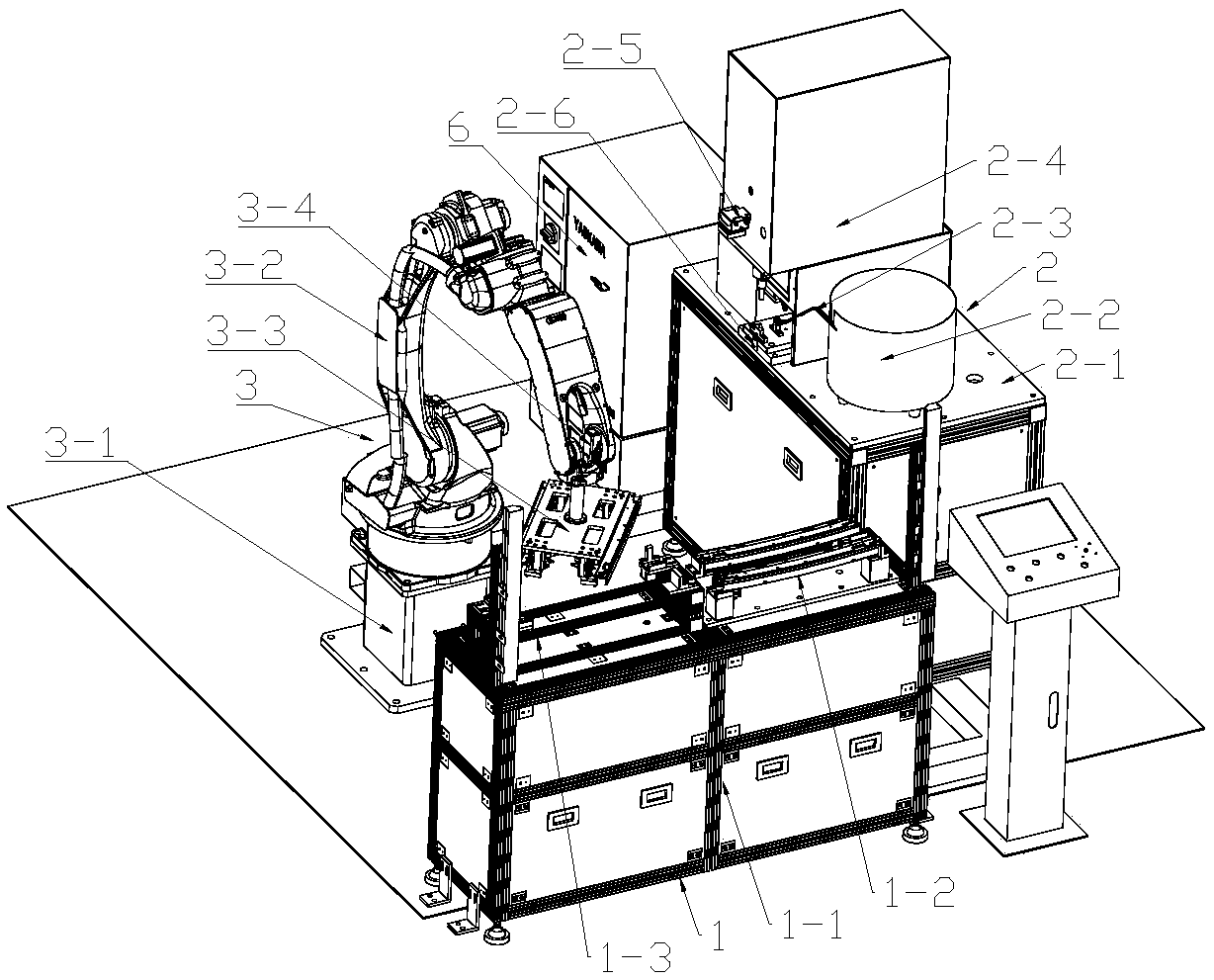

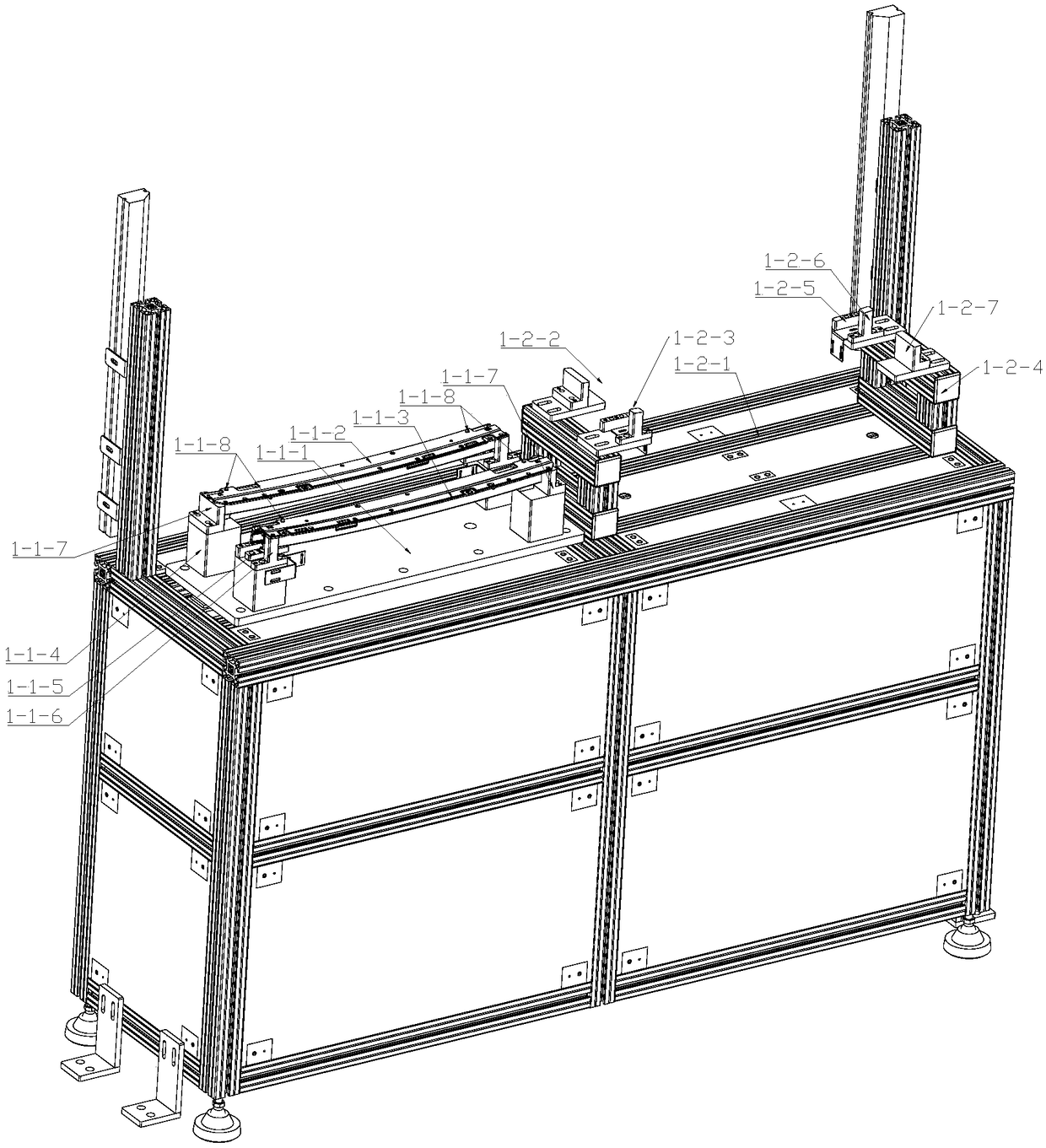

Flexible riveting device based on visual guidance and flexible riveting system thereof

The invention relates to a flexible riveting device based on visual guidance. The device comprises a feeing assembly, a riveting assembly, a feeding and riveting pressure assembly, an isolation net and an operation control table. An industrial camera, the visual guidance technology and the riveting system are combined, a riveting hole of a workpiece can accurately enter the riveting range and canbe subject to accurate riveting, the surface of a riveting part is not nicked, the flexible riveting effect is achieved, and the riveting work efficiency is improved.

Owner:NINGBO HUIZHIHENGDONG AUTOMATION TECH CO LTD

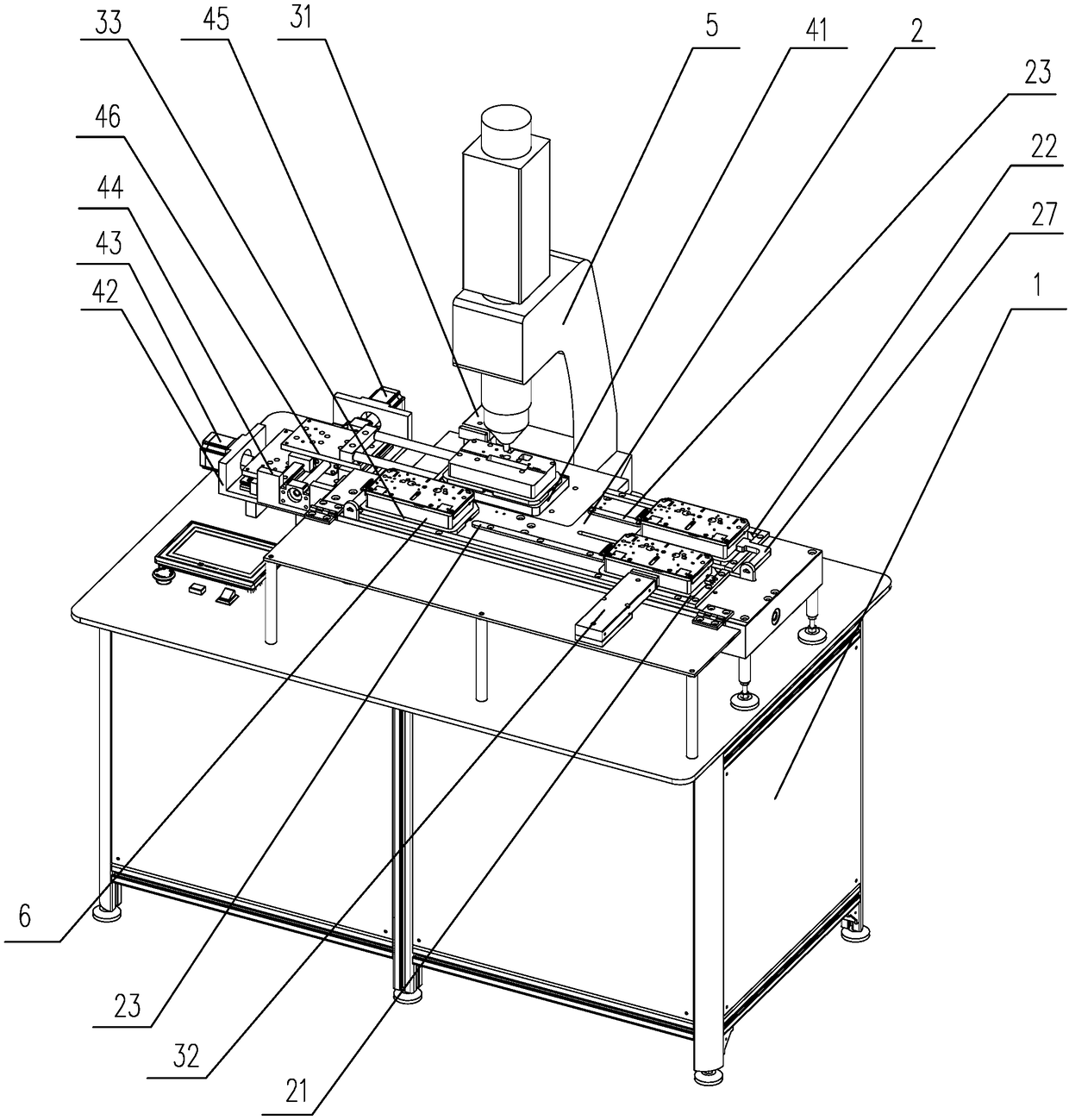

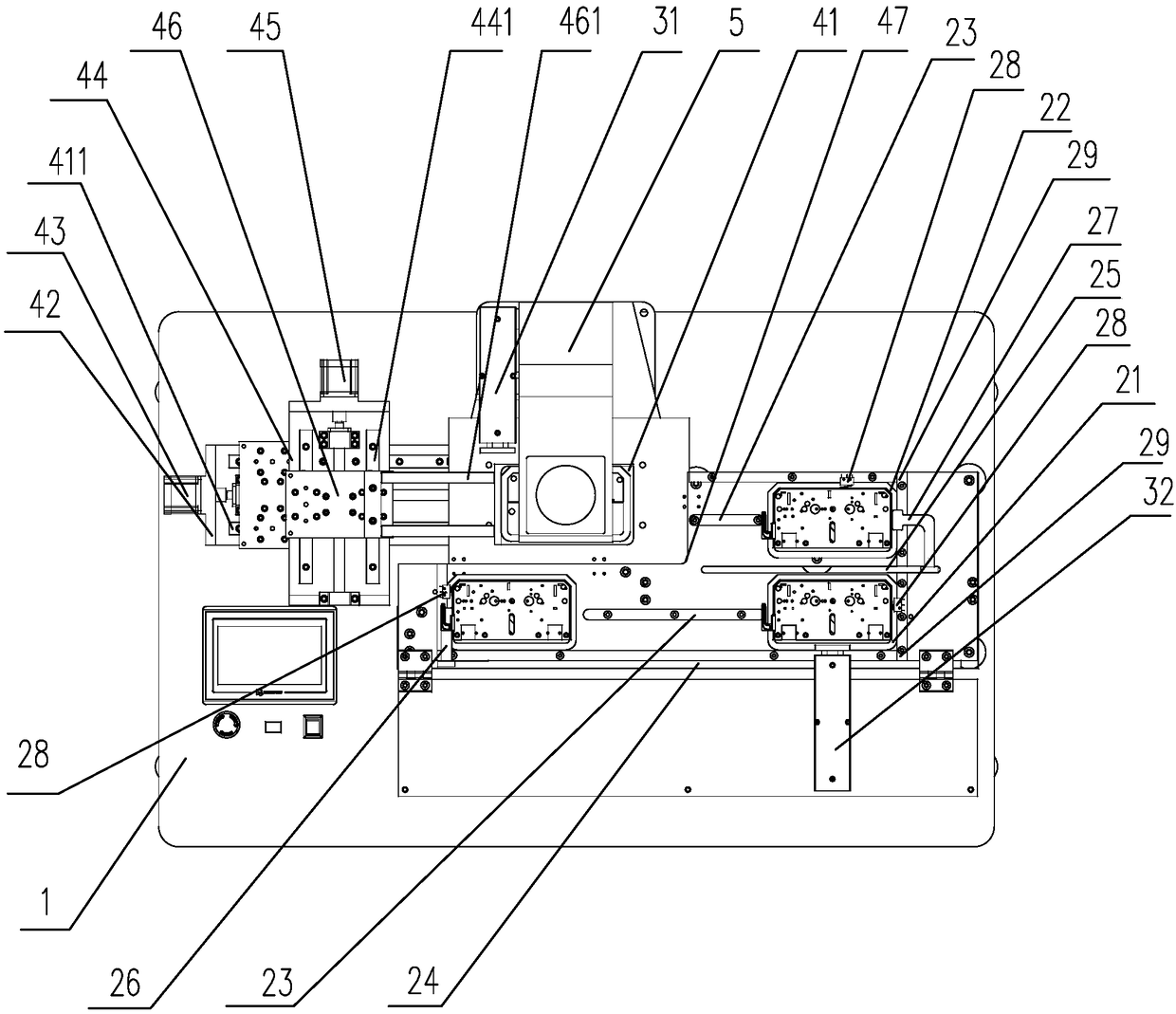

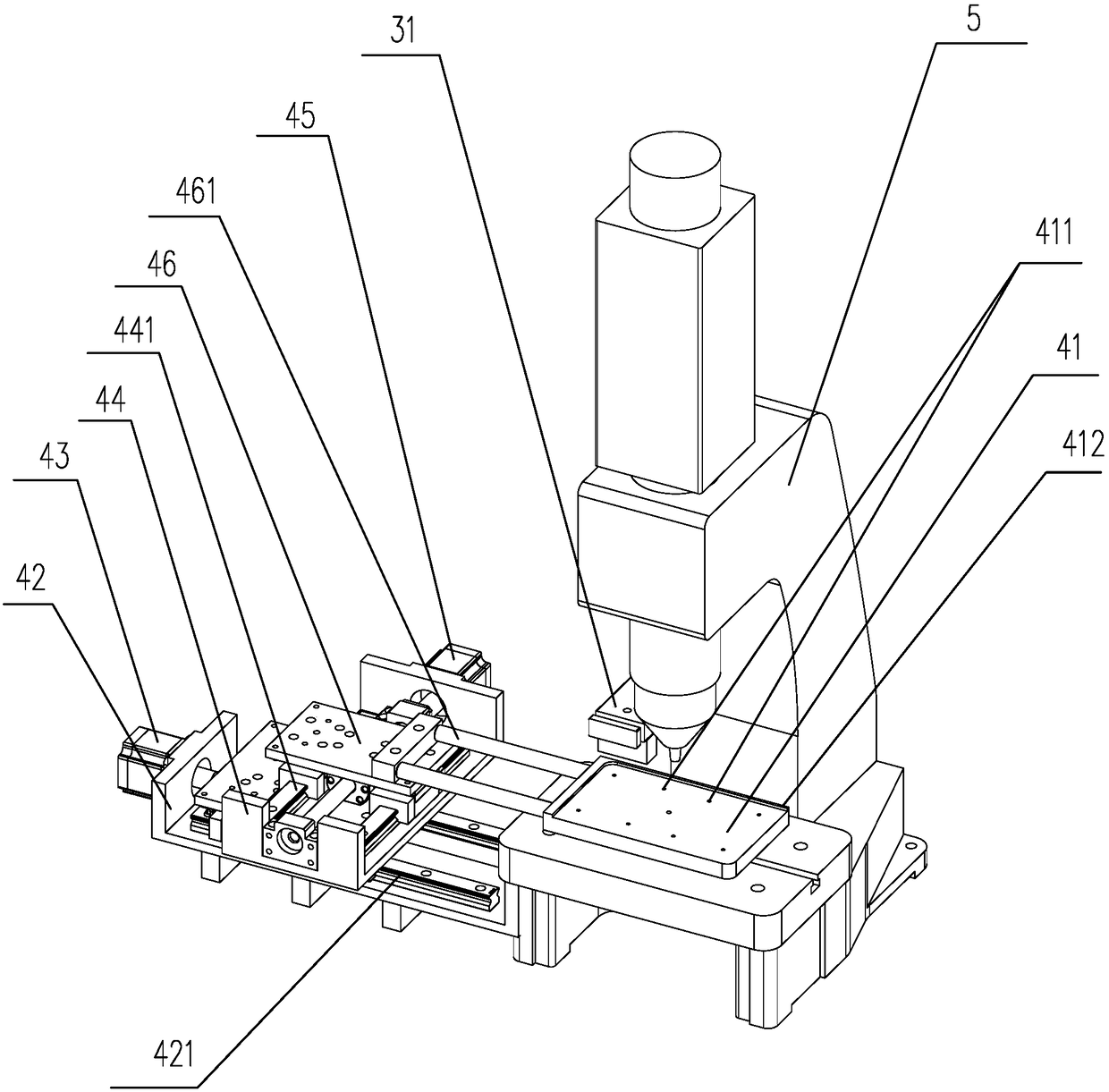

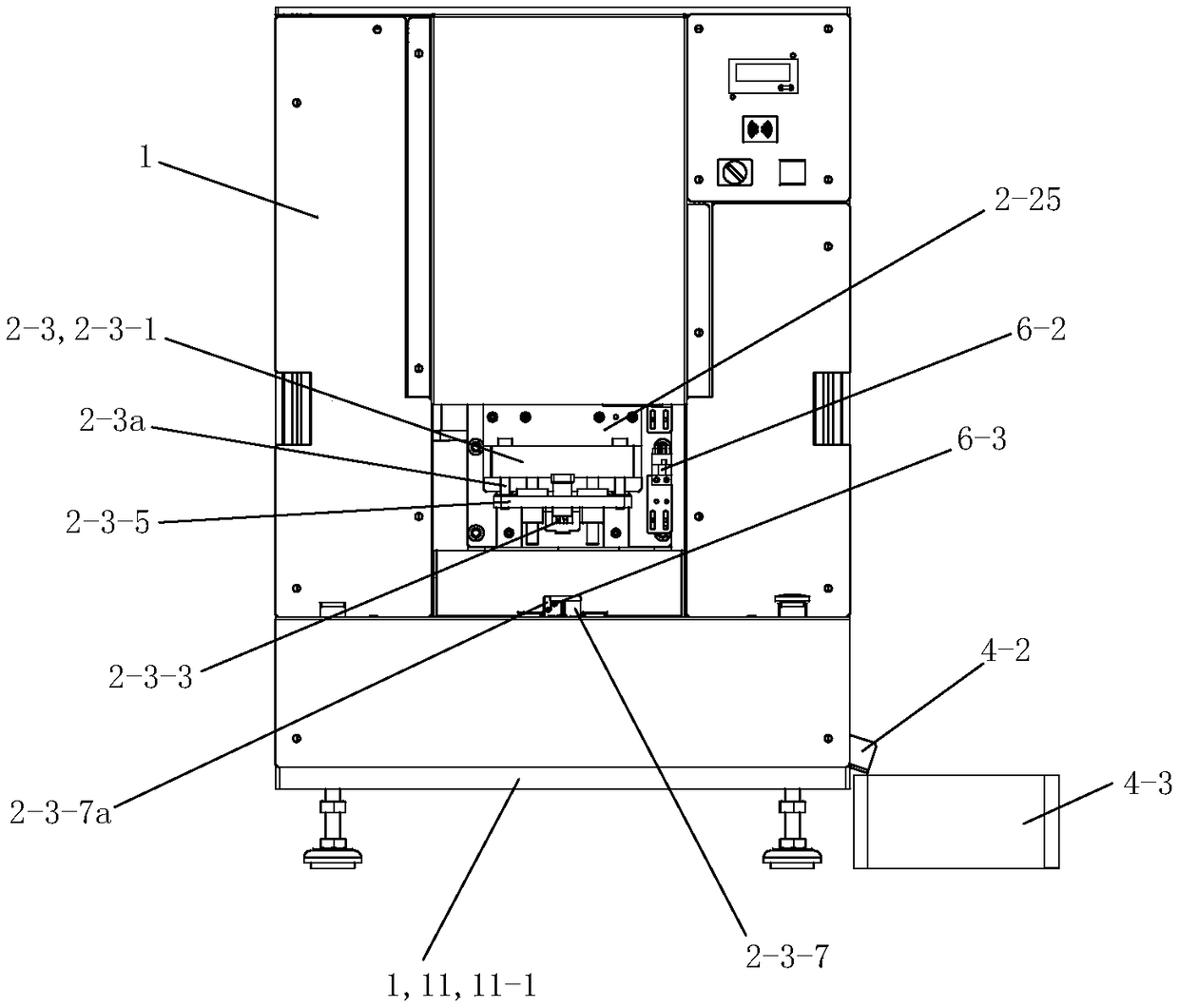

Double-station automatic blanking riveting equipment

The invention discloses double-station automatic blanking riveting equipment. The double-station automatic blanking riveting equipment comprises a machine seat, a riveting machine, a riveting clamp and a control cabinet; the riveting clamp is fixed on the machine base, and blanking sliding grooves are arranged at the two ends of the riveting clamp; and a finished product box is arranged below eachblanking sliding groove, the riveting machine and the machine base are oppositely fixed, and a riveting head of the riveting machine corresponds to the upper portion of the riveting clamp. The double-station automatic blanking riveting equipment is high in working efficiency, good in product consistency, good in equipment usability and high in safety.

Owner:武汉东焊汽车装备有限公司

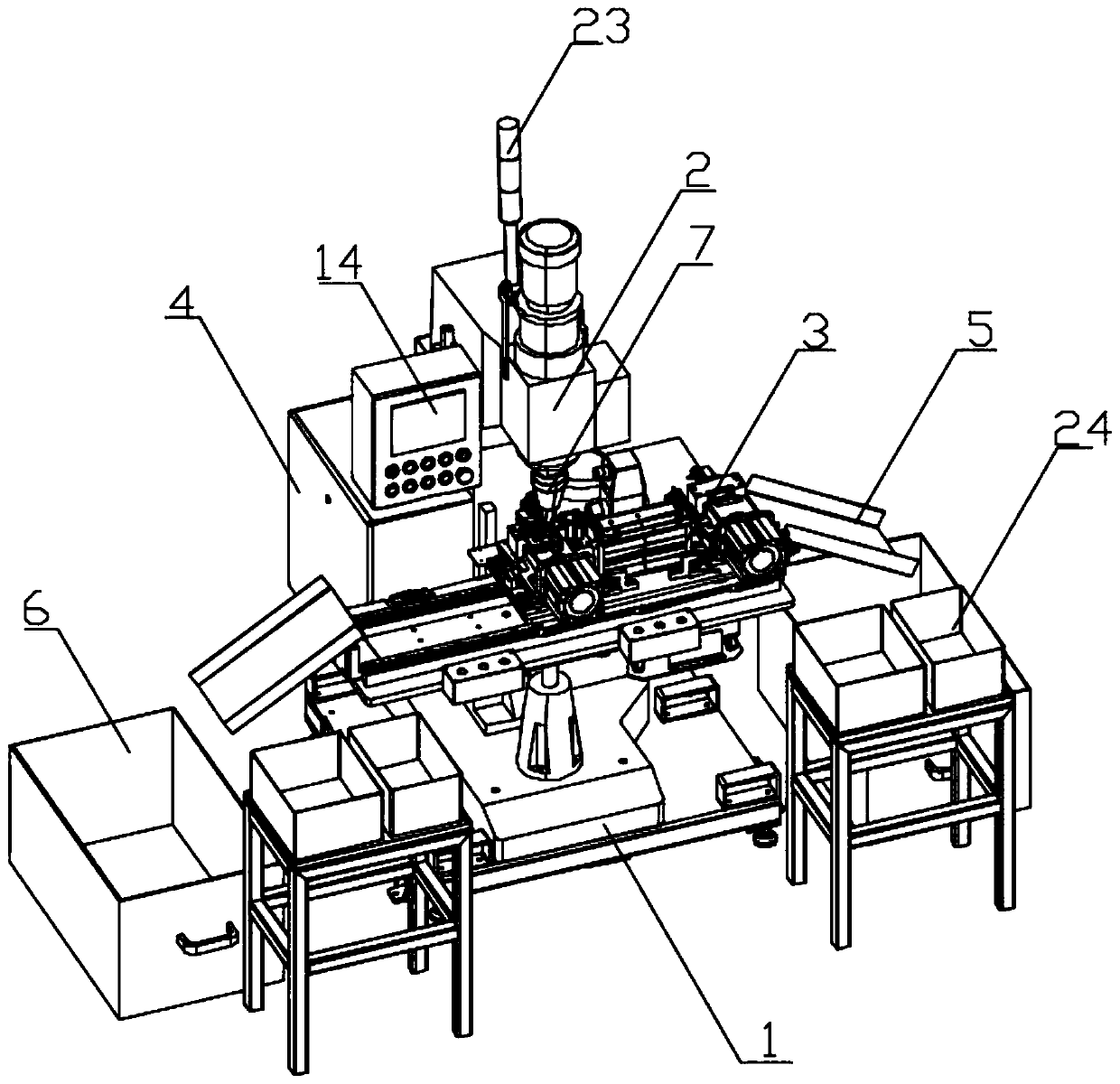

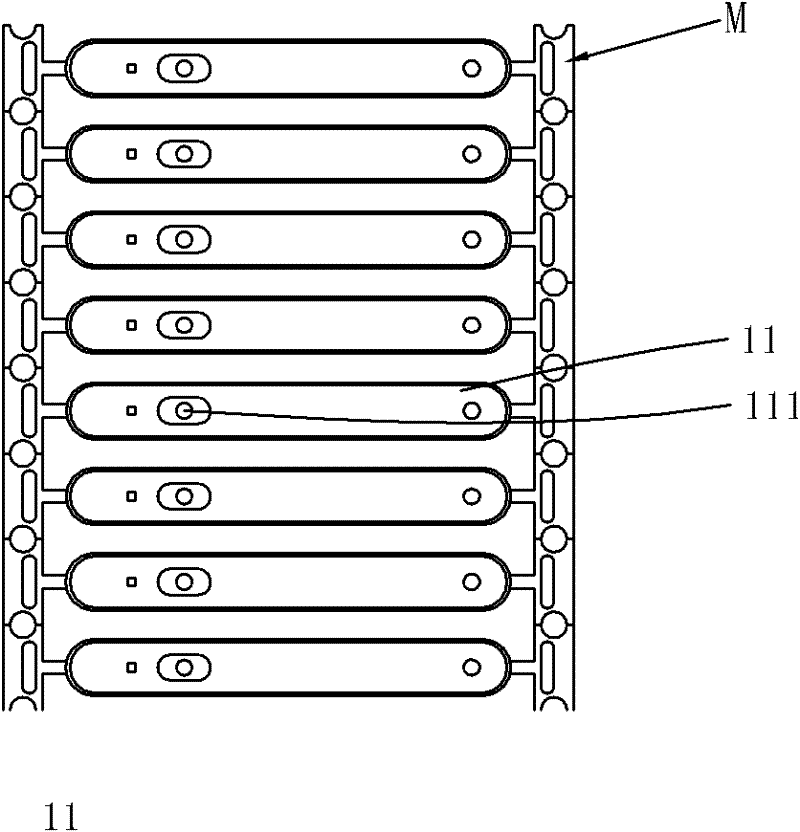

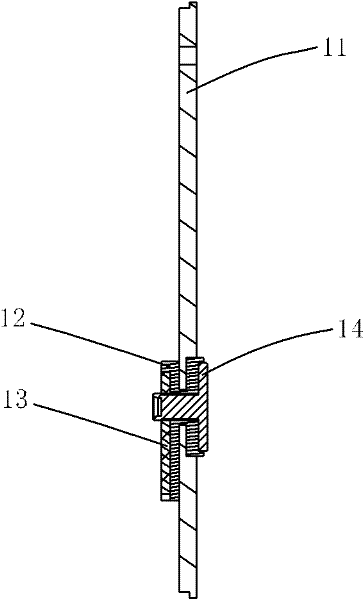

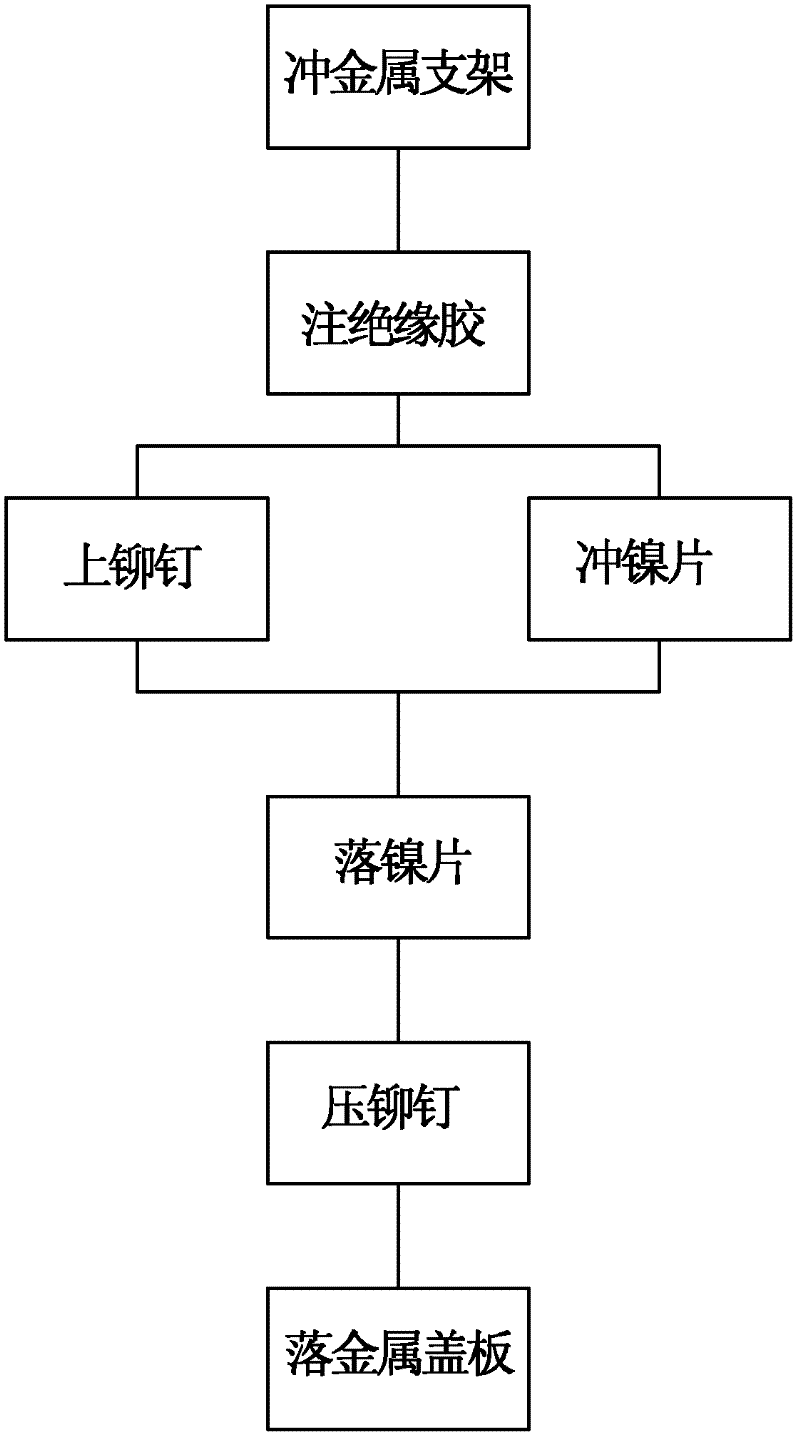

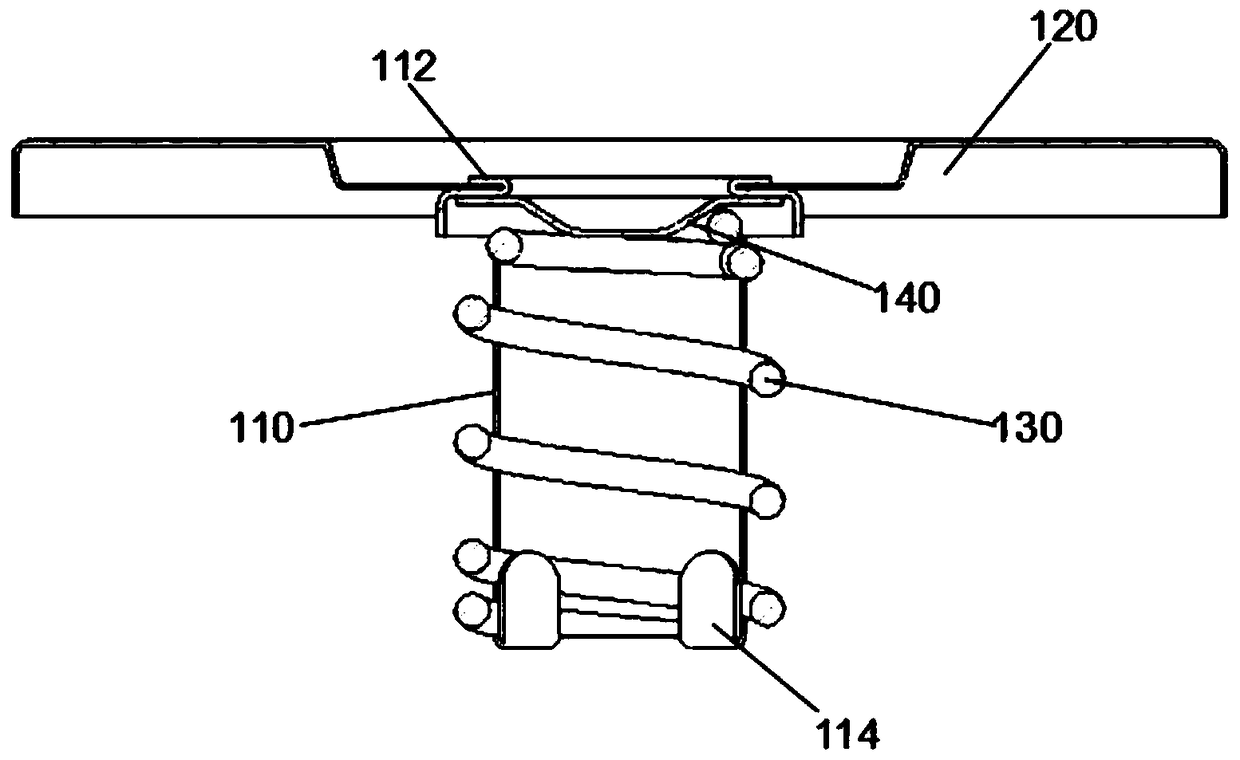

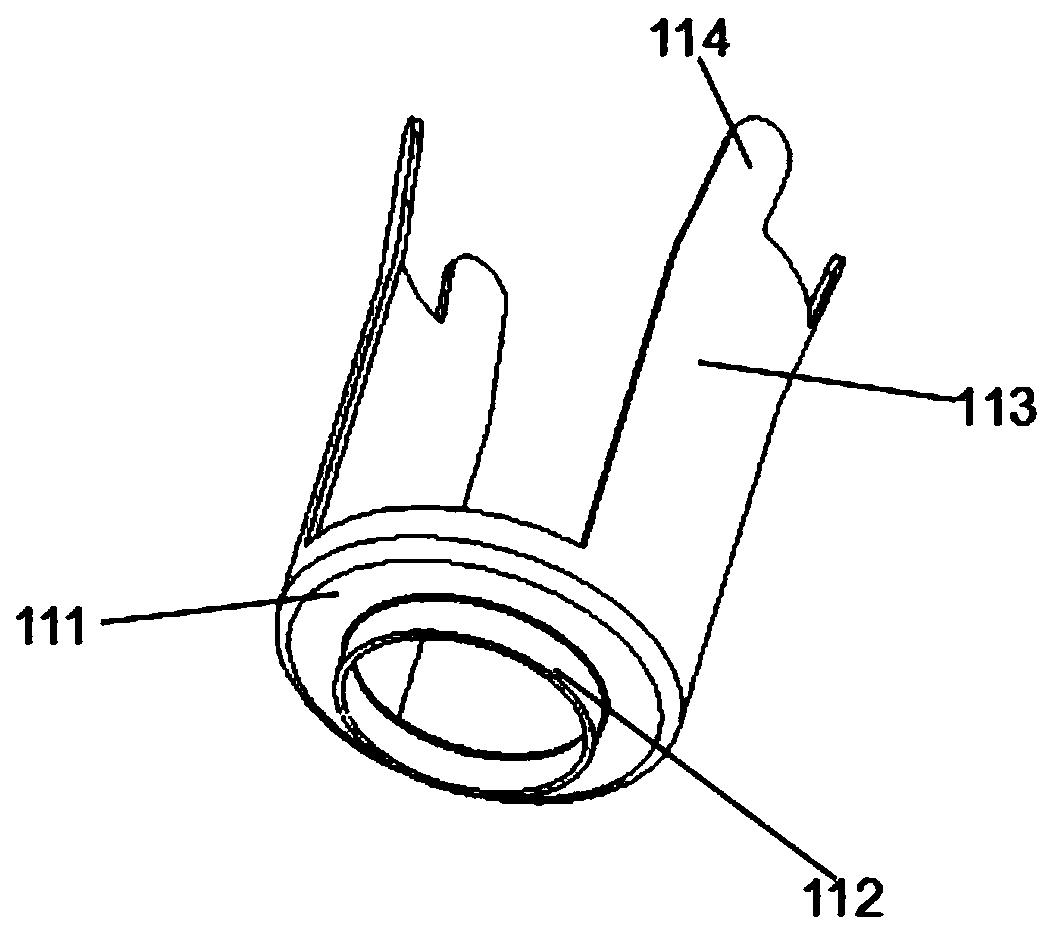

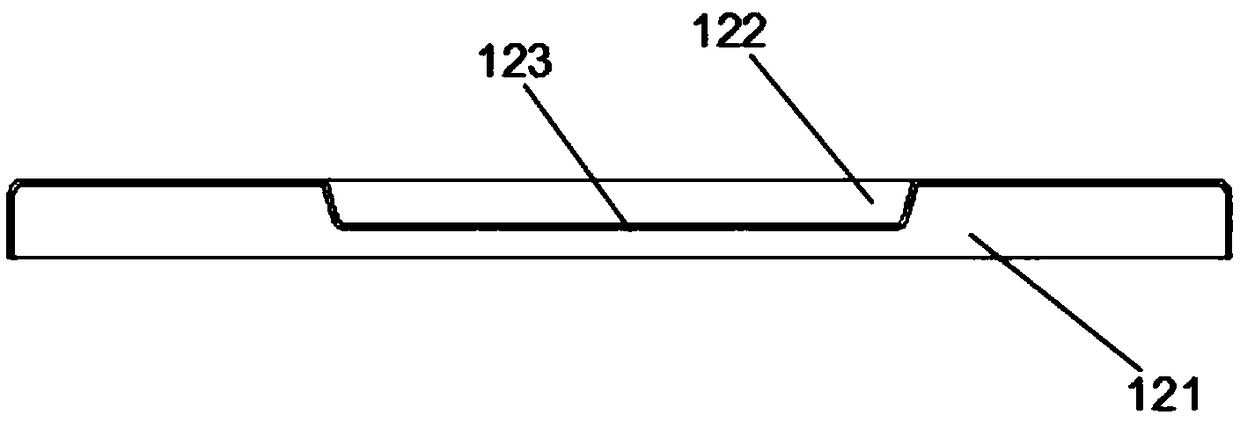

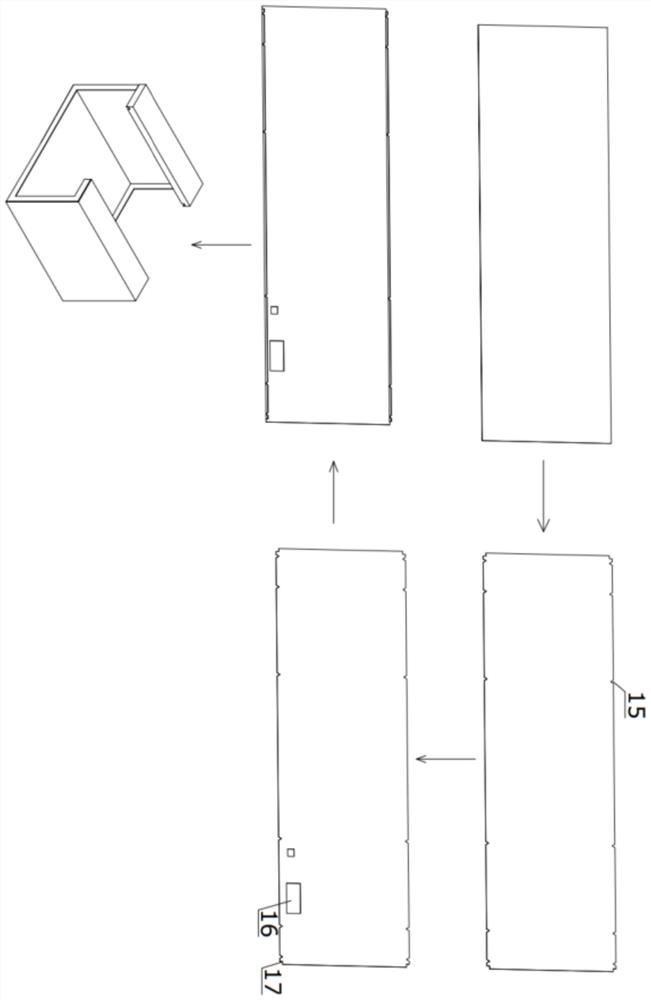

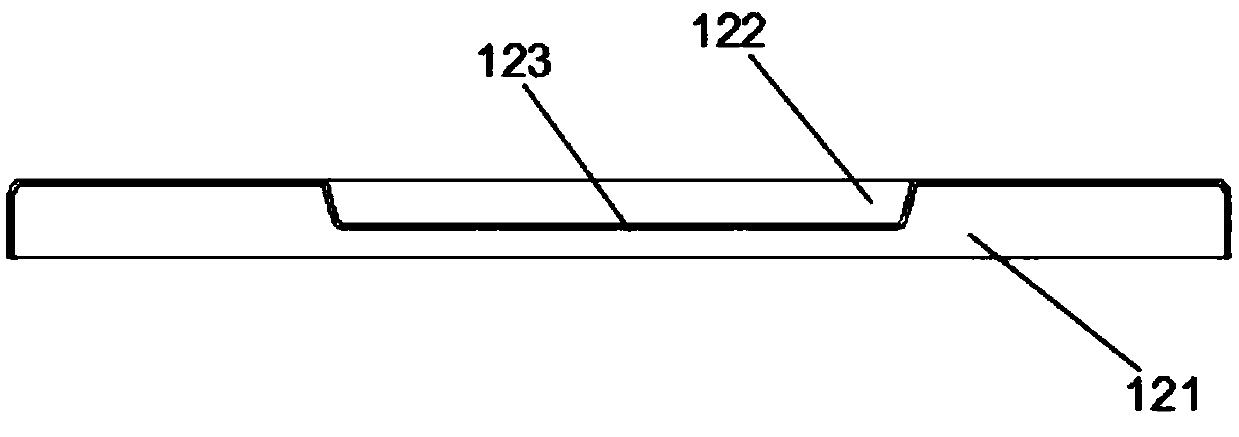

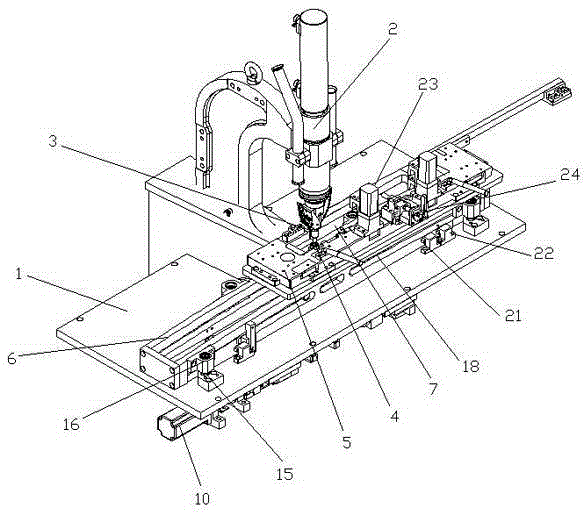

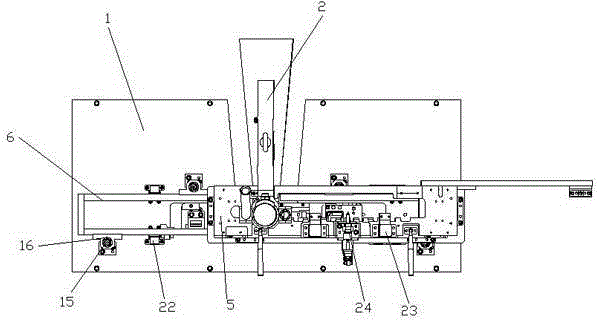

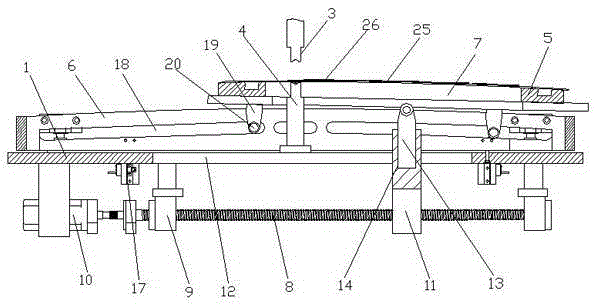

Manufacturing method and manufacturing equipment of battery metal cover plate

InactiveCN102299270AIncrease productivityImprove product qualification rateCell component detailsElectrical batteryStructural engineering

Embodiments of the present invention relate to a preparation method for a battery metal cover plate, and preparation equipment thereof. The battery metal cover plate is applicable for a sealing cover of a battery metal shell. The battery metal cover plate comprises a metal support connected through rivets, insulation glue and nickel plates. The preparation method for the battery metal cover plate comprises steps of metal support punching, insulating glue injecting, nickel plate punching, rivet installing, nickel plate blanking, rivet pressing and cover plate blanking. The steps of the nickel plate punching, the rivet installing, the nickel plate blanking, the rivet pressing and the cover plate blanking are performed in a set of composite progressive mold. The preparation equipment comprises a first punching machine provided with a support punching die, an injection molding machine provided with an injection mold, a second punching machine provided with the composite progressive mold, and a rivet transportation apparatus used through combination with the second punching machine. According to the embodiments of the present invention, the problems of low production efficiency and low product qualification rate of the metal cover plate are mainly solved, such that a purpose of great improvements of the production efficiency and the product qualification rate of the metal cover plate is achieved.

Owner:梅承寨 +1

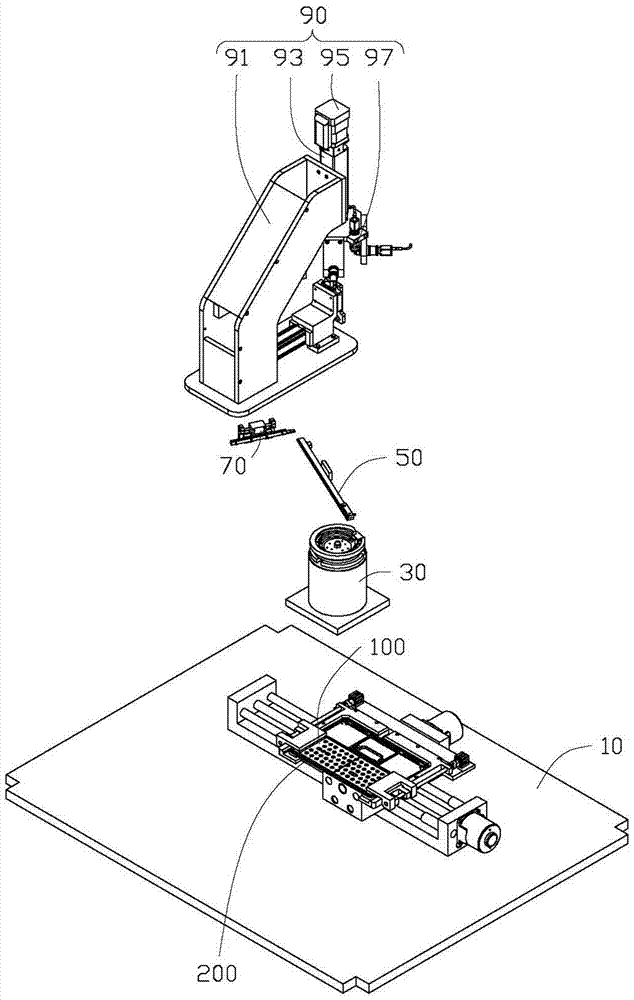

Continuous punch forming device of filter cleaner filtration safety valve gland

ActiveCN109201901ARealization of continuous stampingIncrease productivityMetal-working feeding devicesPositioning devicesFiltrationEngineering

The invention provides a continuous punch forming device of a filter cleaner filtration safety valve gland. The device comprises a rack, an annular caterpillar band arranged on the rack, a driving device arranged at the rear end of the rack and used for driving the annular caterpillar band to operate, multiple punch part putting columns fixed to the annular caterpillar band at intervals in parallel, a first punch mechanism, a second punch mechanism, a third punch mechanism and a fourth punch mechanism, punch part fixing discs are arranged between two adjacent punch part putting columns, and the first punch mechanism, the second punch mechanism, the third punch mechanism and the fourth punch mechanism are sequentially arranged on the rack at intervals side by side in the running direction of the caterpillar band. According to the continuous punch forming device of the filter cleaner filtration safety valve gland, continuous punch forming of the engine oil filter safety valve gland can be achieved, production efficiency of the engine oil filter safety valve gland can be greatly improved, the forming quality of the engine oil filter safety valve gland can be improved, and compared with traditional manual machining manner, the per capita production efficiency is improved by 226%, and the yield is improved by 20%.

Owner:佛山市豹王滤芯制造有限公司

Automatic assembling machine for stem wheels

PendingCN113001178AEfficient and stable assemblyImprove assembly qualityAssembly machinesMetal working apparatusEngineeringMachine

The invention discloses an automatic assembling machine for stem wheels. The automatic assembling machine comprises an assembling slide way, an automatic stem feeding component, an automatic support feeding and assembling component, an automatic material moving component, a support spin riveting component, an automatic roller feeding component and an automatic roller riveting component. The automatic stem feeding component is used for grabbing and placing stem parts on the assembling slide way, the automatic support feeding and assembling component is used for grabbing and assembling support parts into the stem parts on the assembling slide way, and the automatic material moving component is used for sequentially moving the parts placed on the assembling slide way to the next step. The support spin riveting component is used for riveting a support and the stem parts together, the automatic roller feeding component is used for assembling a roller part conveyed by a conveying device to the support, the automatic roller riveting component is used for riveting the support and the roller part together, and the stem wheels after riveting are moved and output through the automatic material moving component. Assembly of the stem wheels can be efficiently and automatically completed through the machine, the assembly efficiency is high, and the assembly quality is stable and consistent.

Owner:福州品轮智能科技有限公司

Die structure capable of automatically positioning and embedding umbrella ribs

PendingCN111227462AImprove riveting efficiencyQuality improvementWalking sticksEngineeringStructural engineering

The invention discloses a die structure capable of automatically positioning and embedding umbrella ribs, which comprises a plurality of positioning modules, and each positioning module is provided with a positioning groove for fixing an umbrella rib section and a riveting through hole for giving way to a riveting machine. After the structure is adopted, the umbrella ribs are placed in the corresponding positioning grooves to be positioned, and then the positioning modules are oppositely combined, so that the umbrella rib sections in the positioning grooves are connected together in an inserted mode, and then the umbrella rib sections are fed into a riveting machine to be riveted. Compared with the prior art, the die structure has the beneficial effects that automatic embedding of the umbrella rib sections can be achieved, the umbrella rib riveting efficiency is improved, a large amount of manpower is not needed, the production cost is saved, the umbrella rib sections are accurately positioned through a mold, and the umbrella rib riveting quality is improved.

Owner:福建优安纳伞业科技有限公司

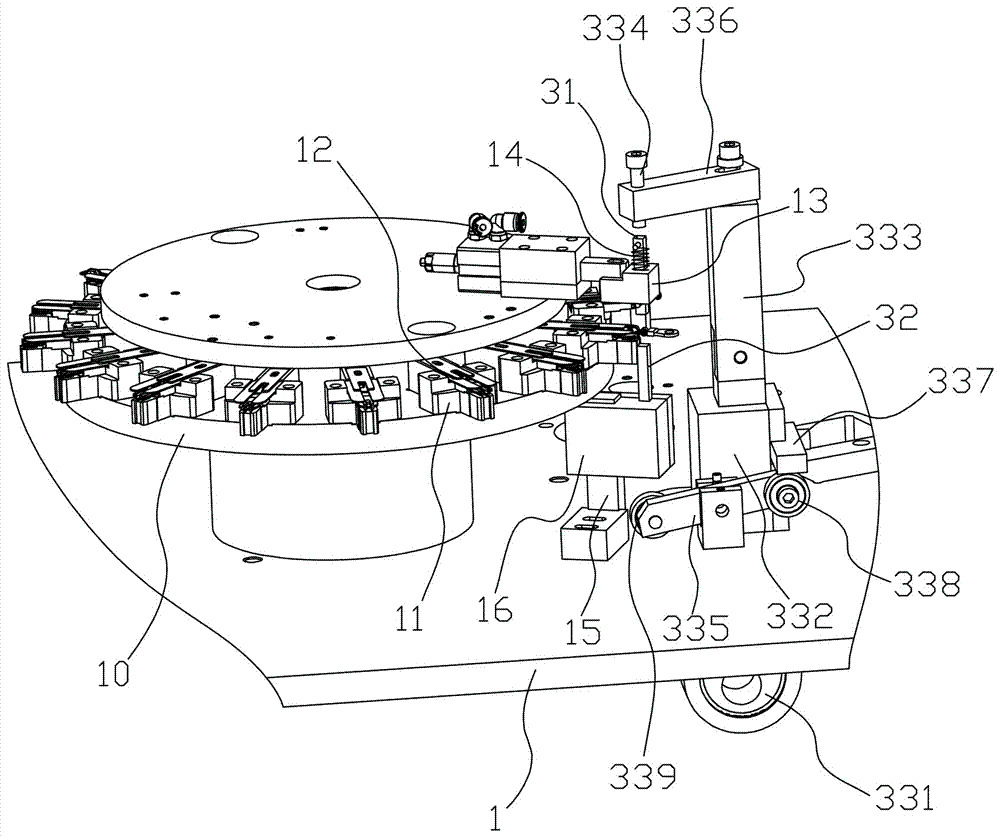

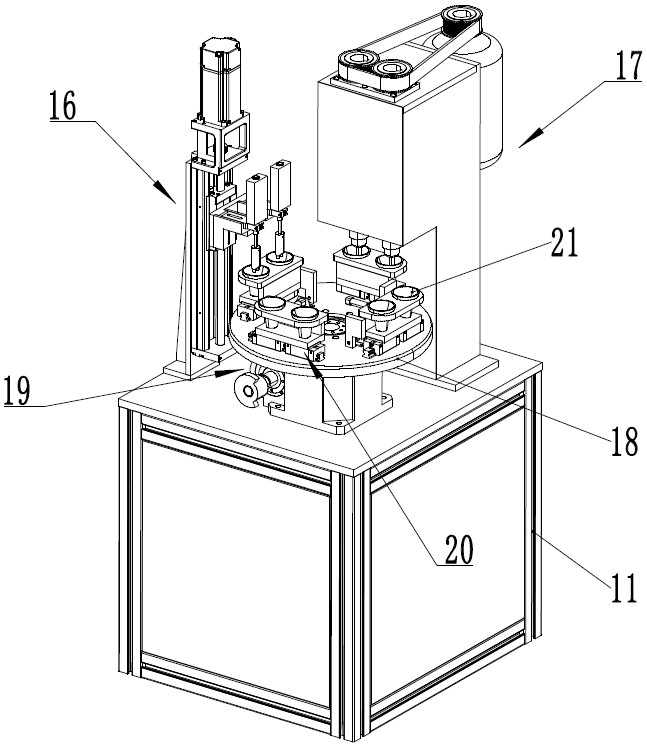

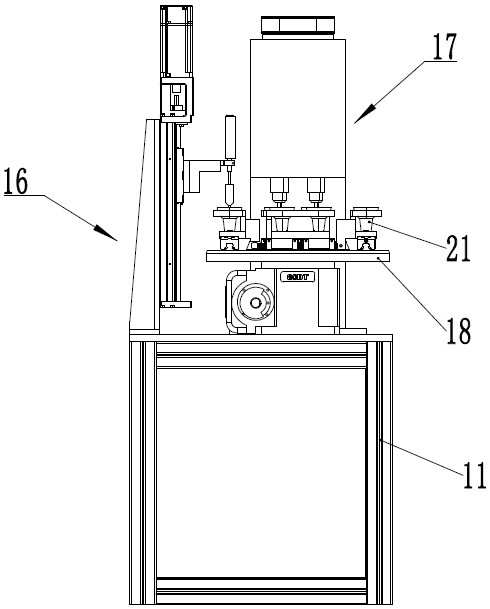

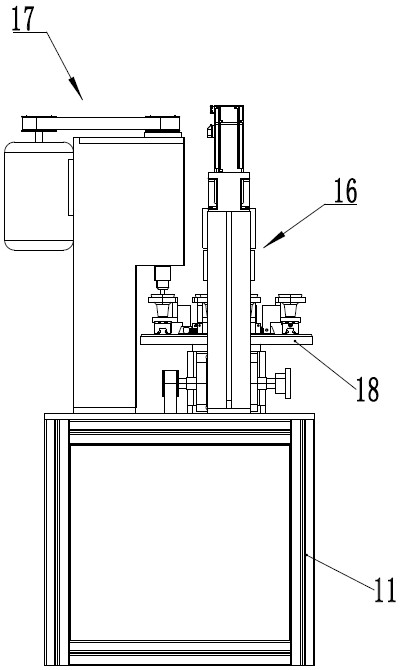

Riveting machine for riveting binding post of glass lamp cup and riveting method of riveting machine

ActiveCN114789222AAccurate rivetingGood riveting consistencyMetal-working feeding devicesMetal working apparatusEngineeringControl circuit

The invention belongs to the technical field of lighting lamp production equipment, and discloses a riveting machine for riveting binding posts of glass lamp cups and a riveting method thereof.The riveting machine comprises a rack and a control circuit, a rotatable rotary disc and a rotary disc driving mechanism are arranged on the rack, a plurality of positioning devices for positioning the glass lamp cups are arranged on the rotary disc, and the control circuit is connected with the control circuit. A feeding station, a measuring station, a riveting station and a discharging station are arranged on the machine frame, a height measuring device is arranged at the position of the measuring station on the machine frame, and a riveting device is arranged at the position of the riveting station on the machine frame. According to the riveting machine and the riveting method thereof, before the binding post is riveted, the height of the cup bottom is measured through the height measuring device, measured data are sent to the control circuit, then the control circuit controls the riveting device to rivet the binding post of the glass lamp cup according to the received measured data, riveting is more accurate, riveting consistency is very good, and the riveting efficiency is improved. The riveting quality is improved, the riveting reject ratio is reduced, the automation level is high, and the production efficiency is improved.

Owner:佛山市创大为聚氨酯制品有限公司

Automatic riveting machine for lock body cover plate

The invention discloses an automatic riveting machine for a lock body cover plate. The automatic riveting machine comprises a workbench and a punching machine, wherein the punching machine is arrangedon the workbench, a punching platform is arranged on the workbench at the corresponding position of the punching machine, the workbench is provided with an object carrying platform and a conveying device used for conveying materials on the object carrying platform to the punching platform, a second working air cylinder used for driving the punching platform to slide is connected to the punching platform, the second working air cylinder is further connected with a first working air cylinder used for driving the second working air cylinder to slide, the projection of the output shaft of the second working air cylinder are arranged perpendicular to the projection of the output shaft of the first working air cylinder on the end face of the workbench, a positioning device used for positioningthe object carrying platform is further arranged on the punching platform, and a first pushing air cylinder used for conveying materials back to the object carrying platform after riveting is completed is further arranged on the workbench and corresponds to the impact, so that the lock body cover plate can be accurately and efficiently riveted, and the production machining efficiency is improved.

Owner:浙江威欧希科技股份有限公司

High-safety riveting machine

The invention discloses a high-safety riveting machine. The high-safety riveting machine is structurally characterized by comprising a rack, a riveting device and a protection device. The riveting device is arranged on the rack and comprises a driving assembly, a transmission assembly, a riveting assembly and a guide assembly. The driving assembly drives a steel needle puncher pin of the rivetingassembly to move downwards along the guide assembly through the transmission assembly, and riveting work is carried out. The protection device comprises a protection sliding table air cylinder, a protection sheet and a speed regulating valve. The protection sheet is a U shape with a forward opening. The rear portion of the protection sheet is fixedly arranged on a sliding table of the protection sliding table air cylinder. The two ends of the U shape of the protection sheet correspond to two guide sleeves on a riveting seat correspondingly in the front-back direction. The protection sliding table air cylinder communicates with a corresponding air source through the speed regulating valve, and the stretching and retracting speed of the protection sheet are regulated through the speed regulating valve.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

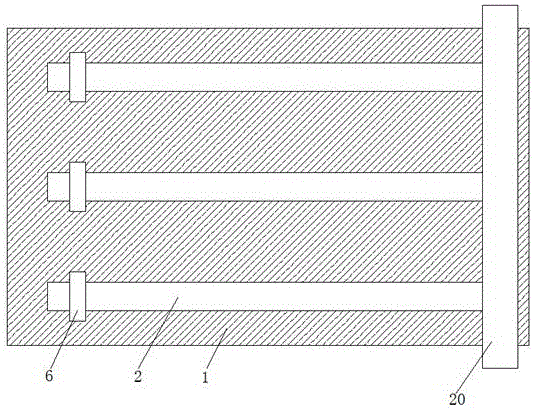

Rivet welding platform precise in machining

InactiveCN106826075AAccurate rivetingClamp firmlyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMachining

The invention discloses a rivet welding platform precise in machining. The rivet welding platform precise in machining comprises a bottom plate, the upper surface of the bottom plate is provided with T-shaped grooves, a stop plate is fixedly connected to the top of the bottom plate and one end of every T-shaped groove, a slider is slidably connected to the inner portion of every T-shaped groove, the top of every slider and the top of a connection block are formed integrally, the top of every connection block penetrates out of the corresponding T-shaped groove and is fixedly connected with the bottom of a rack, and the top of every rack is inserted into the inner portion of a clamping plate. The rivet welding platform precise in machining has the advantages that with the aid of coordination between the clamping plates and the stop plate, the connection blocks drive the clamping plates to slide on the surface of the bottom plate through sliding of the sliders, so that a workpiece requiring rivet welding is clamped between the stop plate and the clamping plates; when moving downwards, the clamping plates can match with the sliders to clamp the surface of the bottom plate, so that the workpiece requiring rivet welding can be fixed, rivet welding error due to movement of the workpiece is prevented and higher rivet welding precision is achieved.

Owner:嘉兴日昌汽车配件股份有限公司

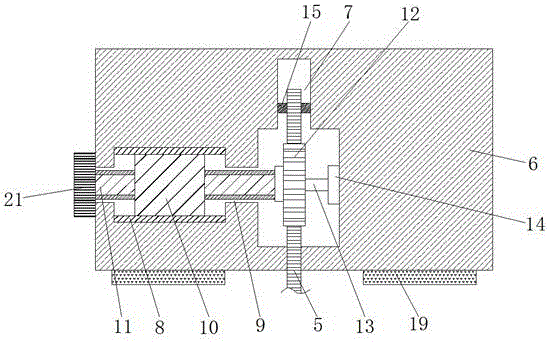

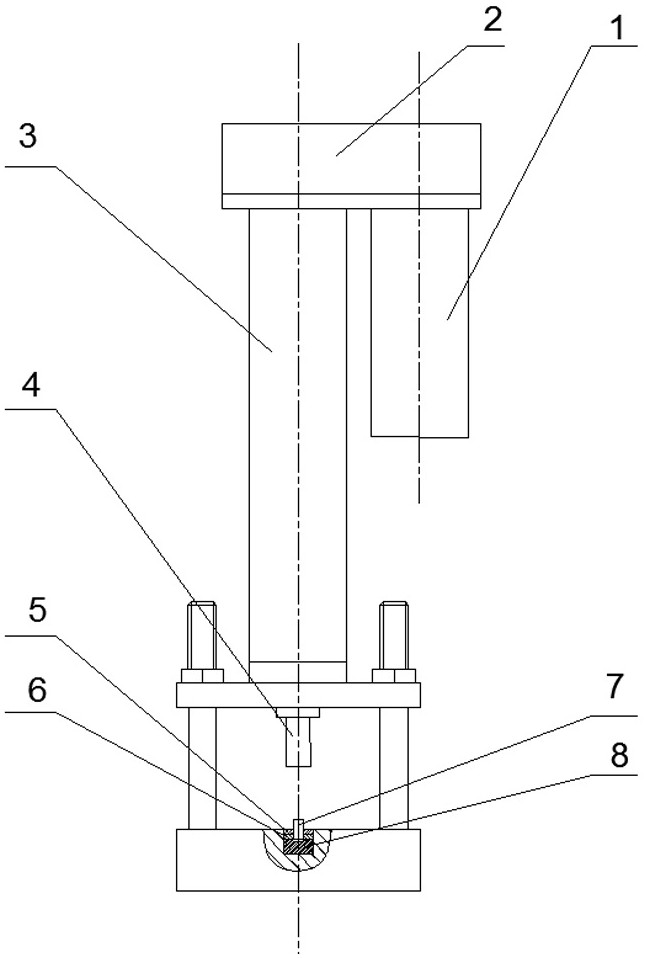

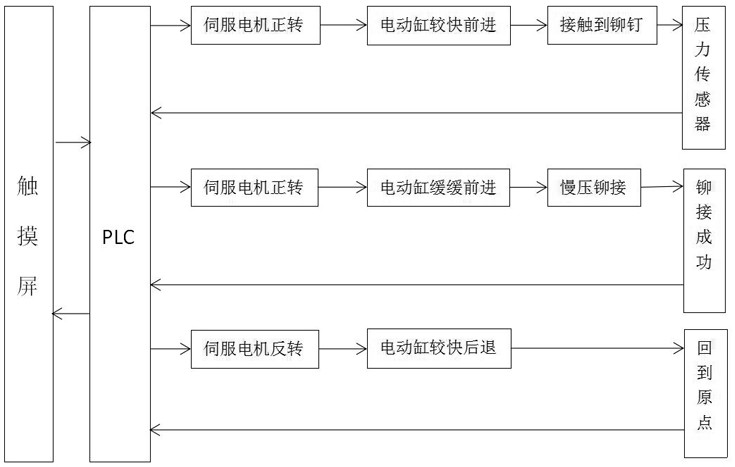

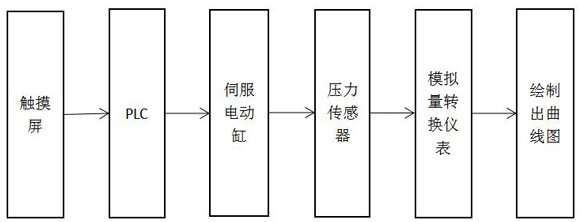

Rivet punching machine with complete servo driving system and working method thereof

The invention provides a rivet punching machine with a complete servo driving system and a working method thereof. The rivet punching machine is characterized by comprising a servo motor, a screw rodmechanism, a cylinder body, a pressed platform, a pressure sensor and a controller. The screw rod mechanism converts the rotation of an output shaft of the servo motor into the linear motion of a punch in the cylinder body; the pressed platform is located on the linear motion path of the punch; the pressure sensor is mounted at the bottom of the pressed platform; and the servo motor and the pressure sensor are electrically connected with the controller, and the pressure sensor serves as a trigger switch of the working state of the servo motor. When a rivet is punched, riveting is controlled bythe closed-loop servo driving system, riveting efficiency is guaranteed, the length of the punched rivet is accurately controlled, and therefore stable riveting and riveting quality are guaranteed, and a curve that pressure changes along with the length of the rivet can be generated.

Owner:FUZHOU UNIVERSITY

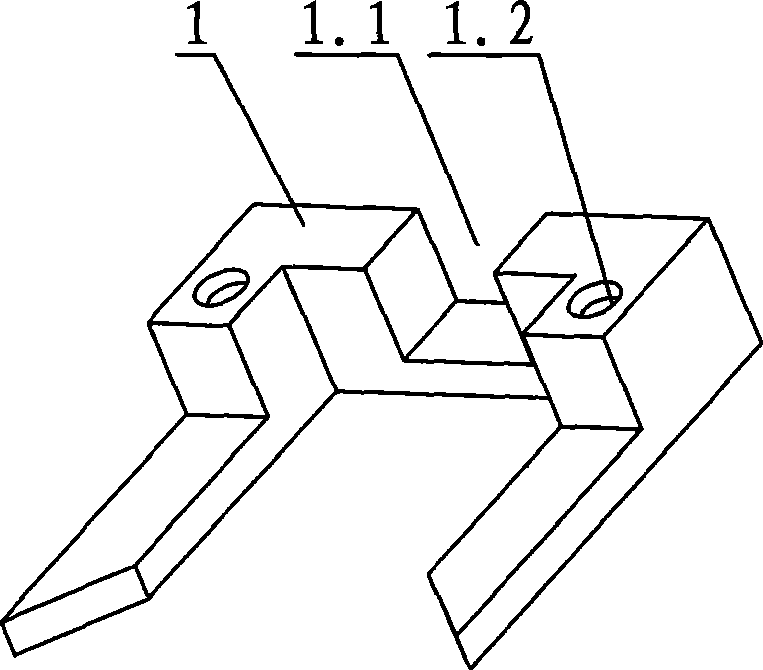

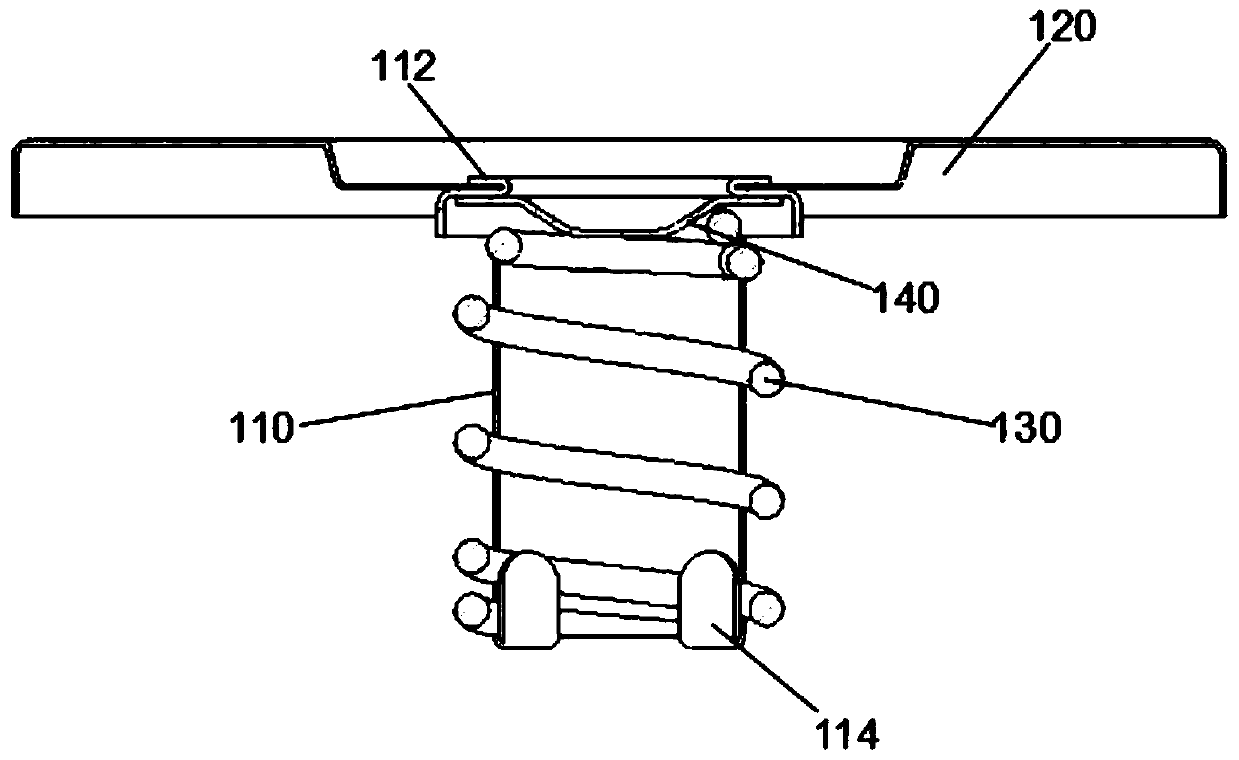

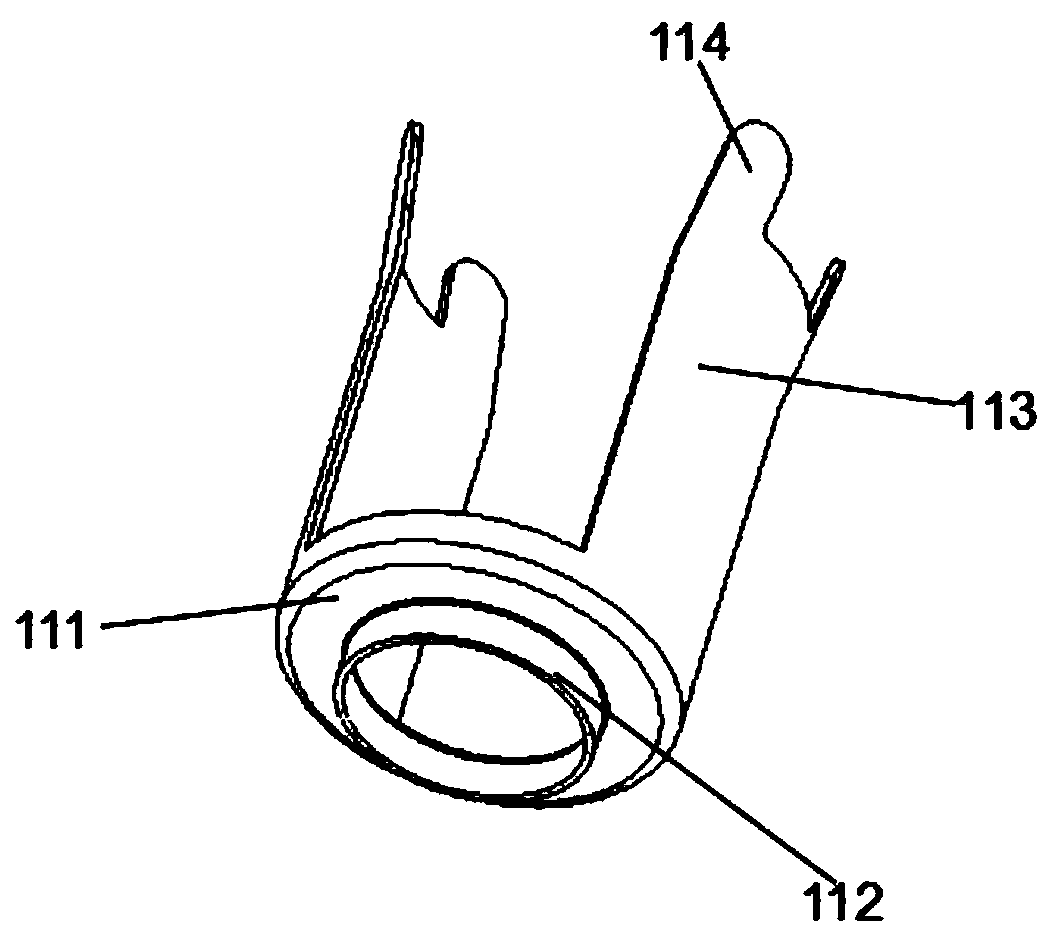

Tripping device chiseling and riveting fixture and riveting method thereof

ActiveCN106710970APrecise positioningAccurate rivetingEmergency protective device manufactureEngineering

The invention discloses a tripping device chiseling and riveting fixture and a riveting method thereof, which belong to the technical field of special fixtures. The tripping device chiseling and riveting fixture an upper mold, guide columns, reset springs, a lower mold, an upper punch, a rear baffle plate, a U-shaped positioning block and a lower punch, wherein the guide columns are arranged between the upper mold and the lower mold, each reset spring is connected on the corresponding guide column, the upper punch is connected with the upper mold, the U-shaped positioning block is fixed on the lower mold, a U-shaped groove is formed in the U-shaped positioning block, a lower punch fixing hole is formed in the groove bottom of the U-shaped groove, and the lower punch penetrates out of the lower punch fixing hole; and the rear baffle plate is arranged on one side of the U-shaped positioning block, a limiting groove is formed in the side wall on one side, close to the U-shaped positioning block, of the rear baffle plate, and the upper punch moves in the vertical direction along the limiting groove. The tripping device chiseling and riveting fixture can complete the riveting of a tripping device part in one step, is reliable in riveting quality, concise in structure, low in cost, and convenient in popularization and application.

Owner:JIANGSU DAQO KFINE ELECTRIC

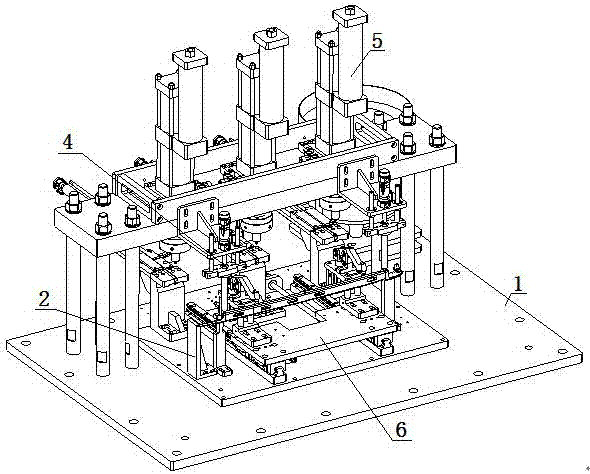

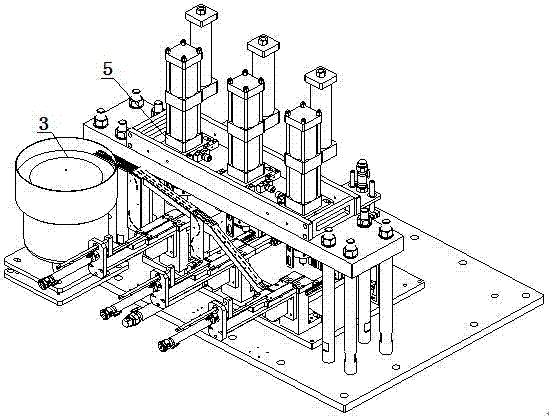

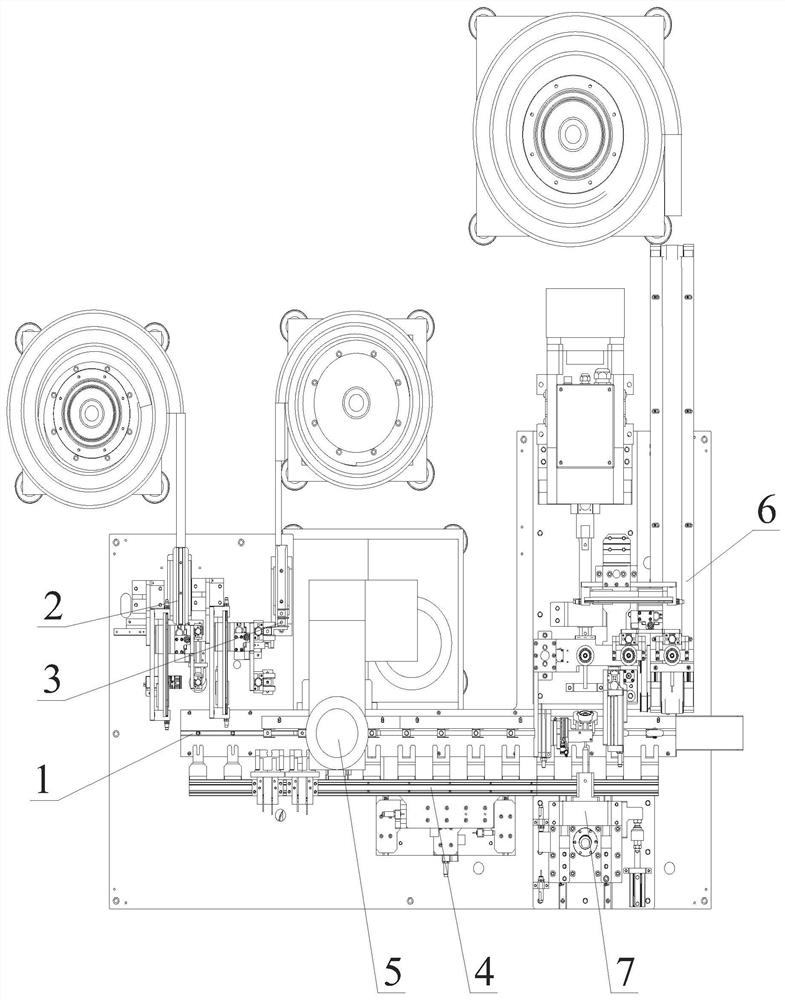

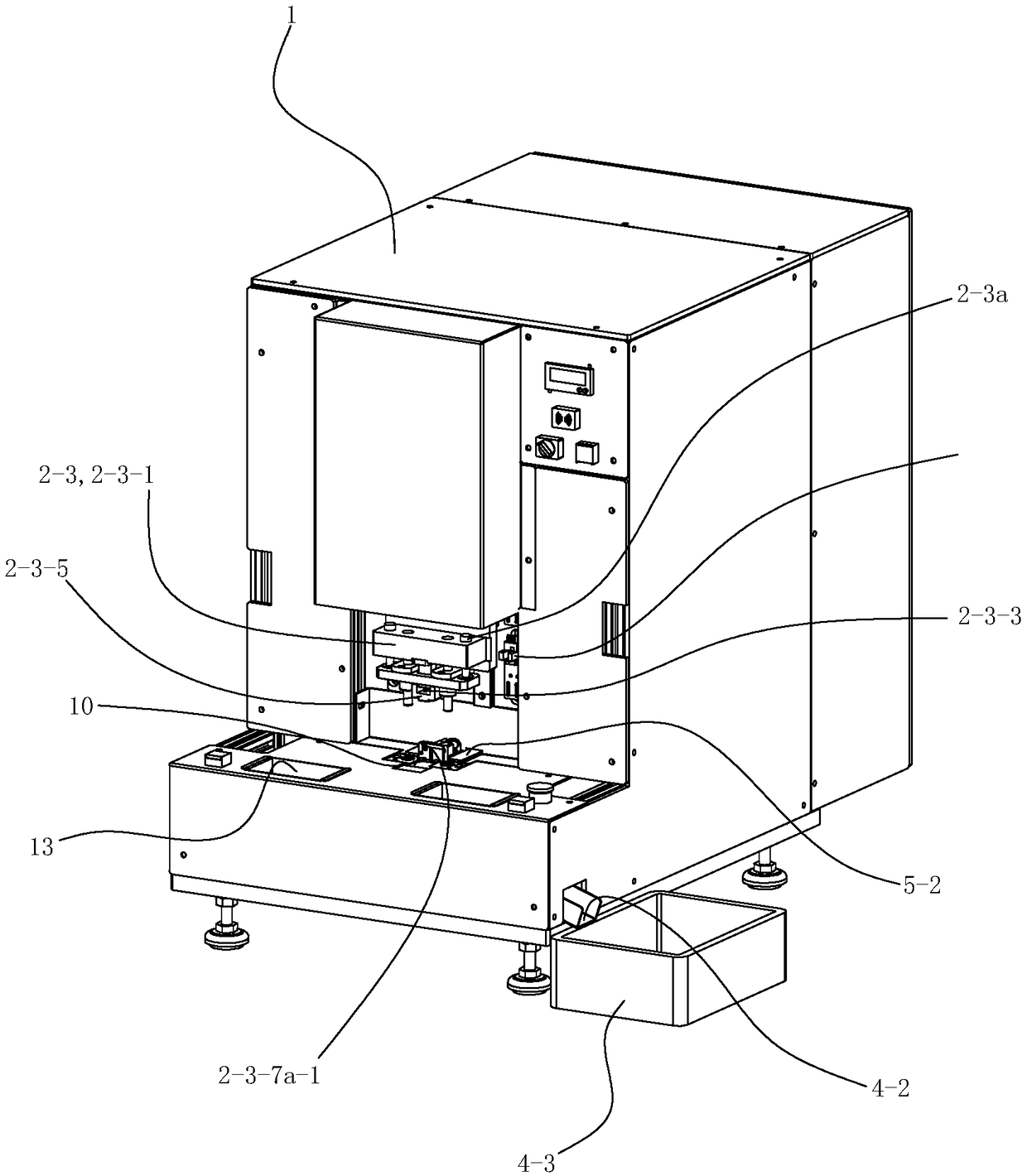

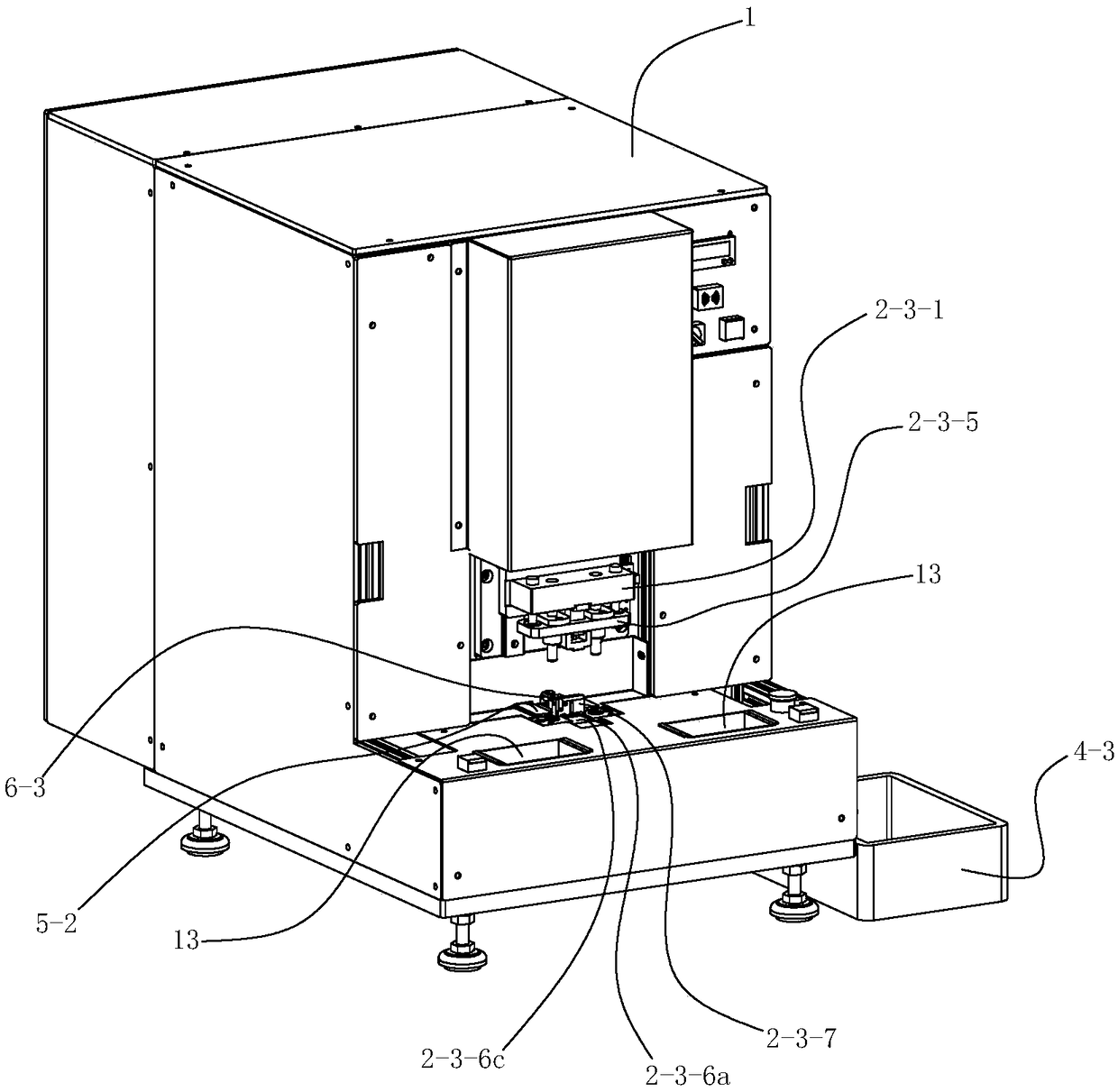

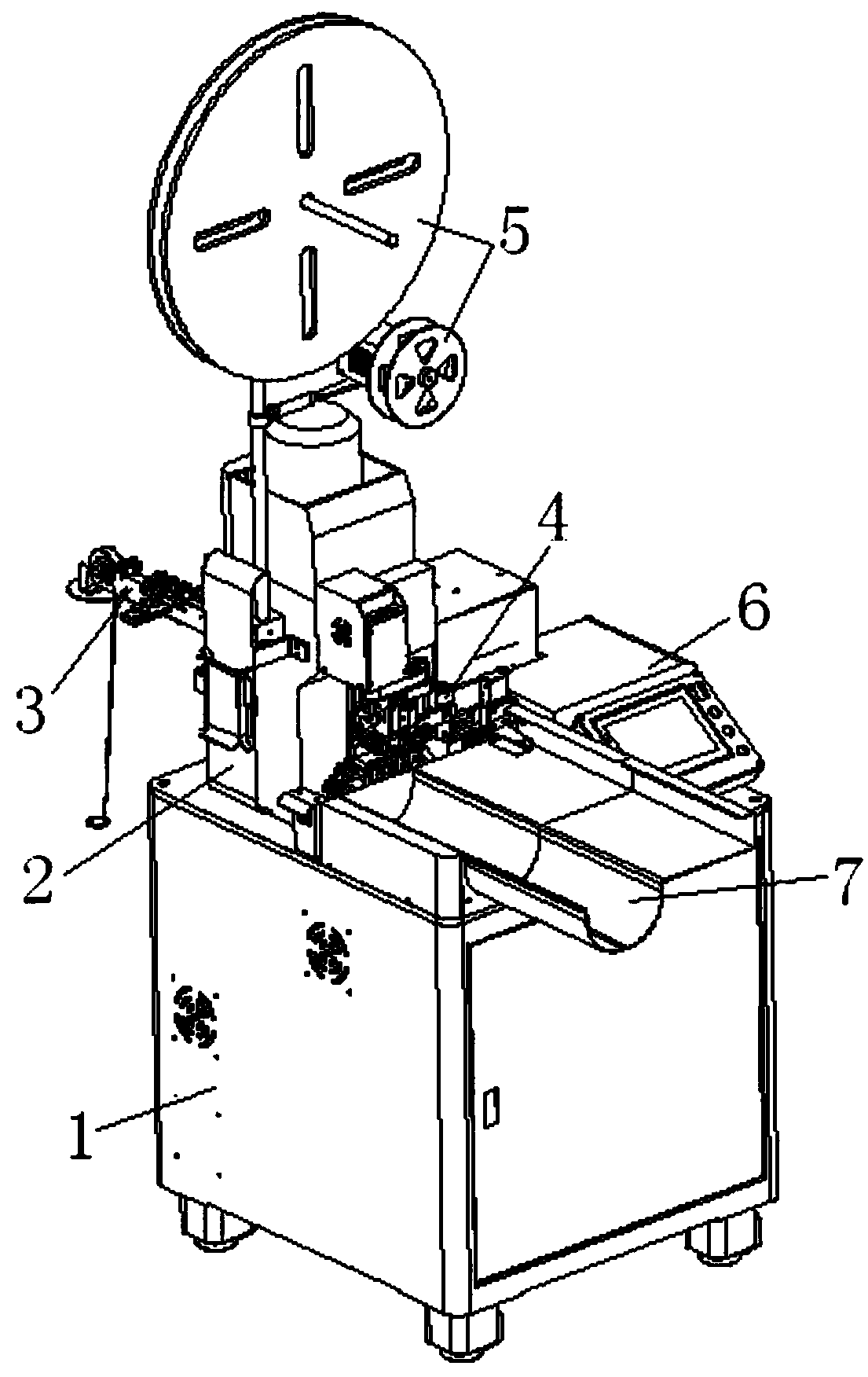

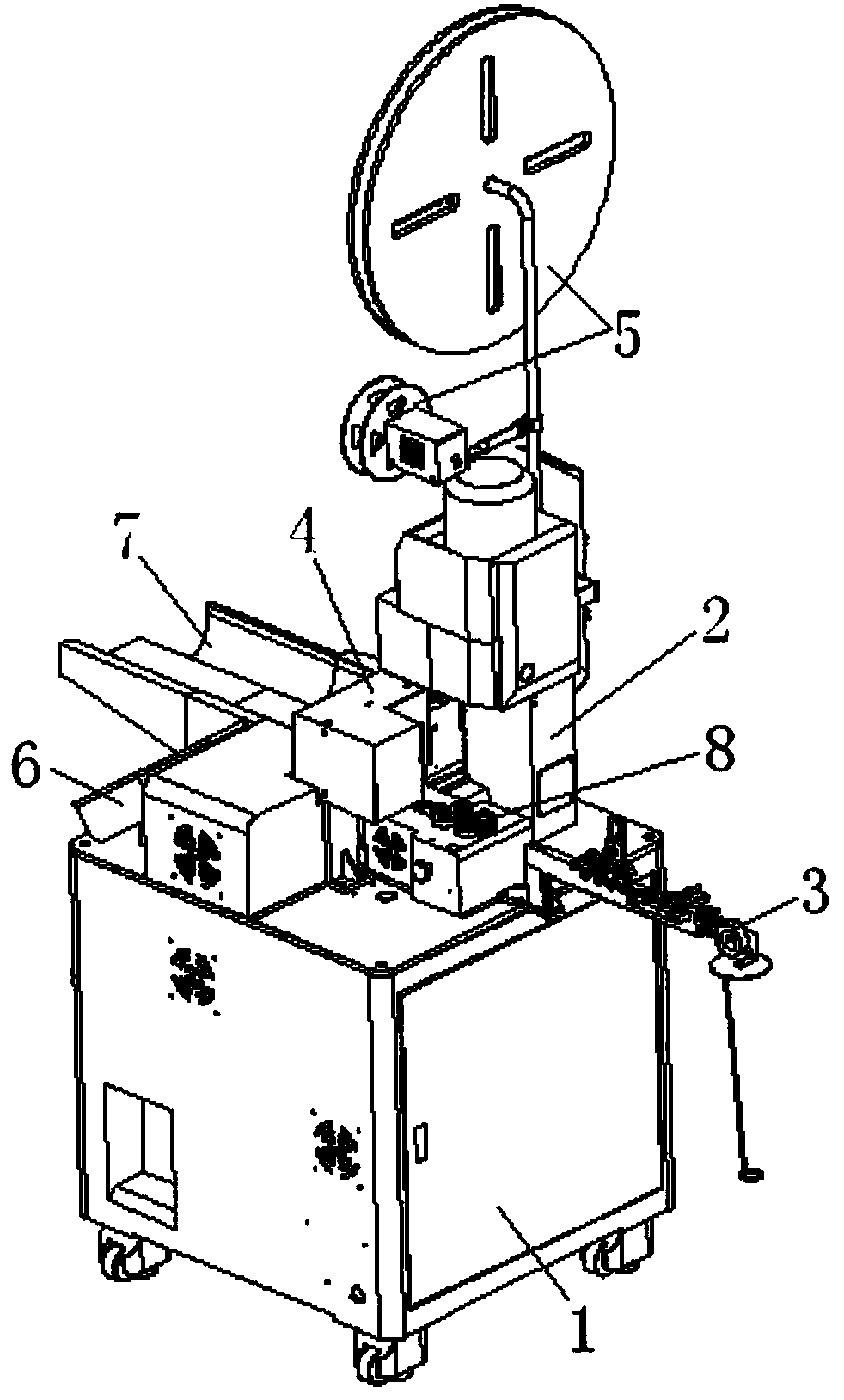

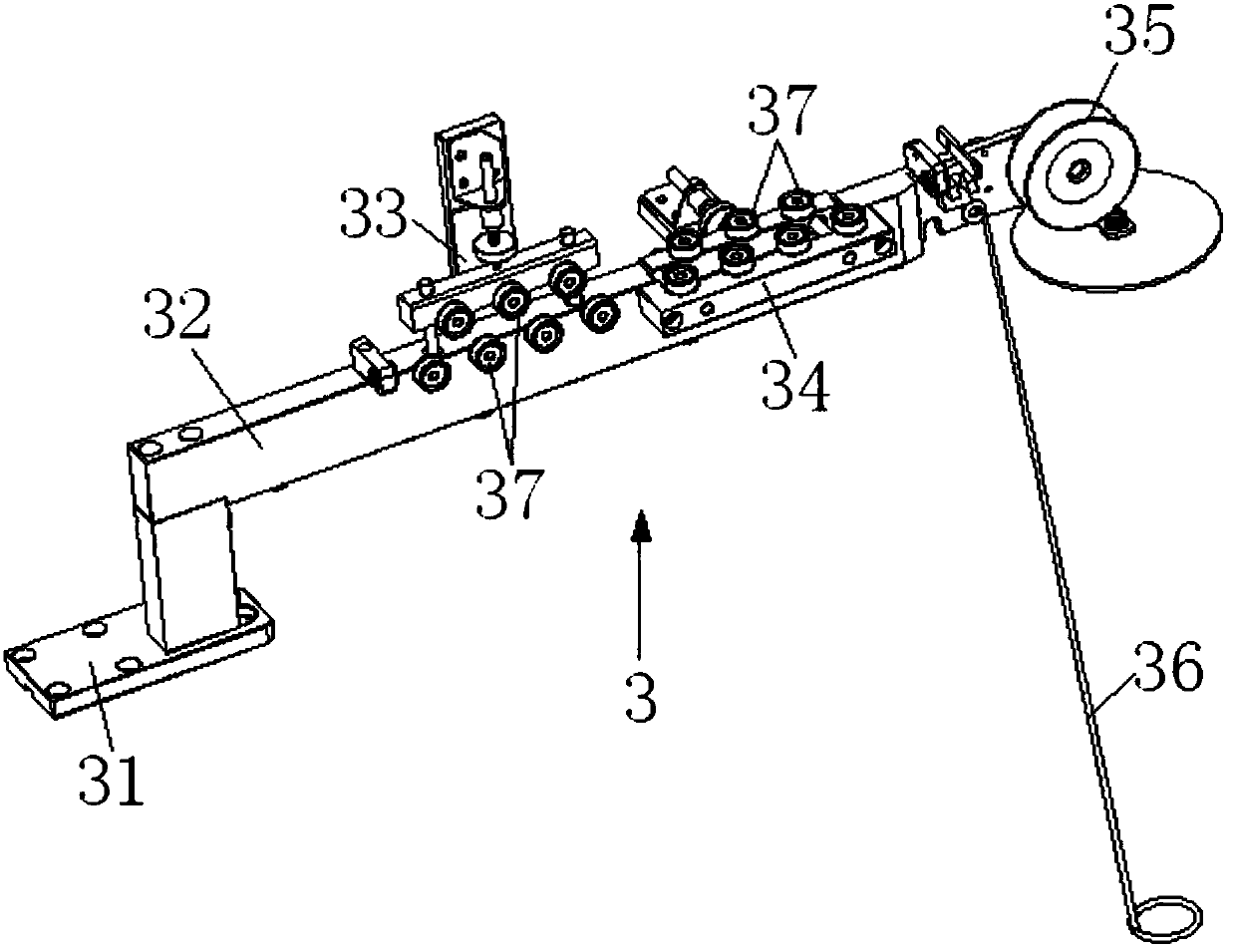

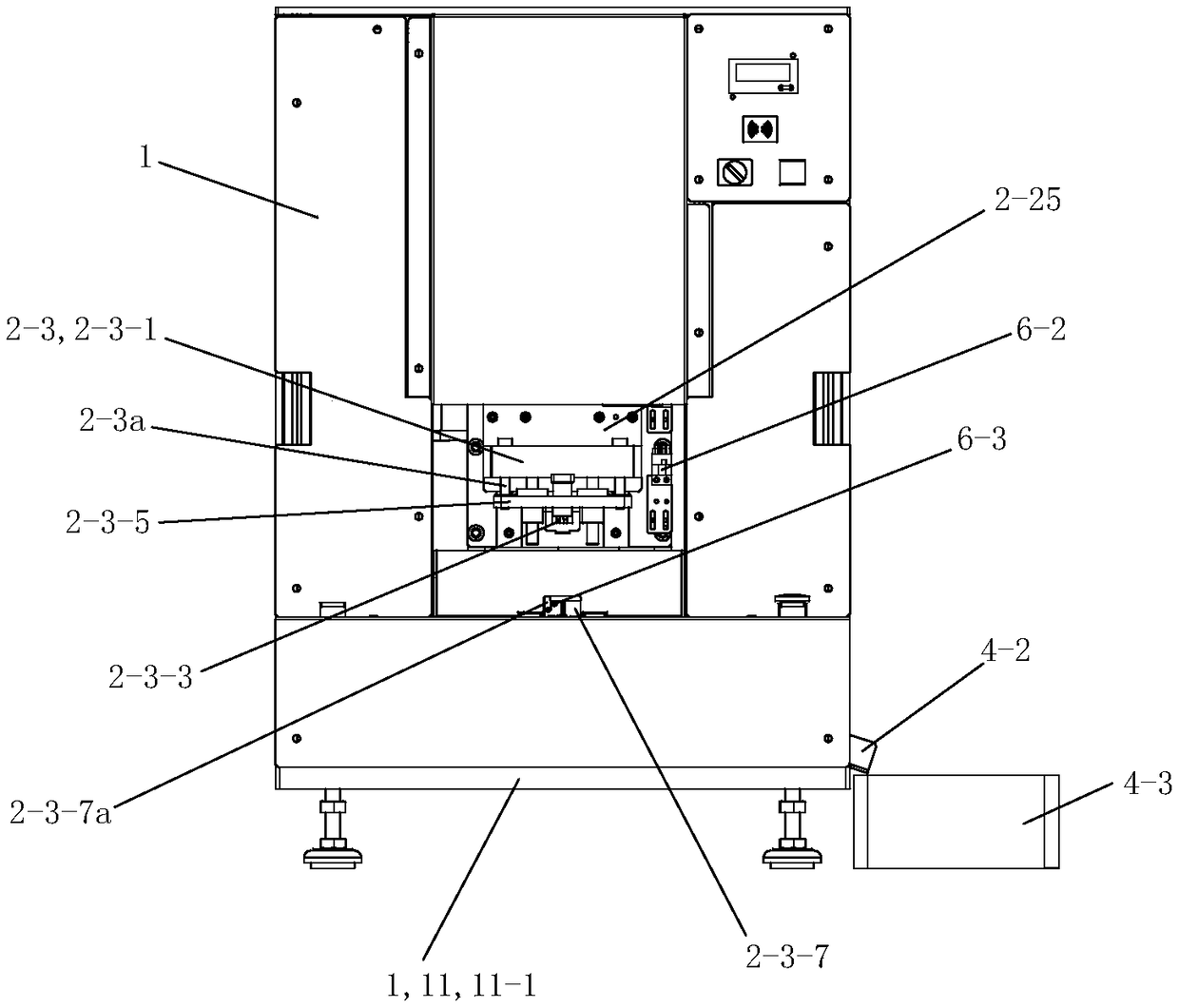

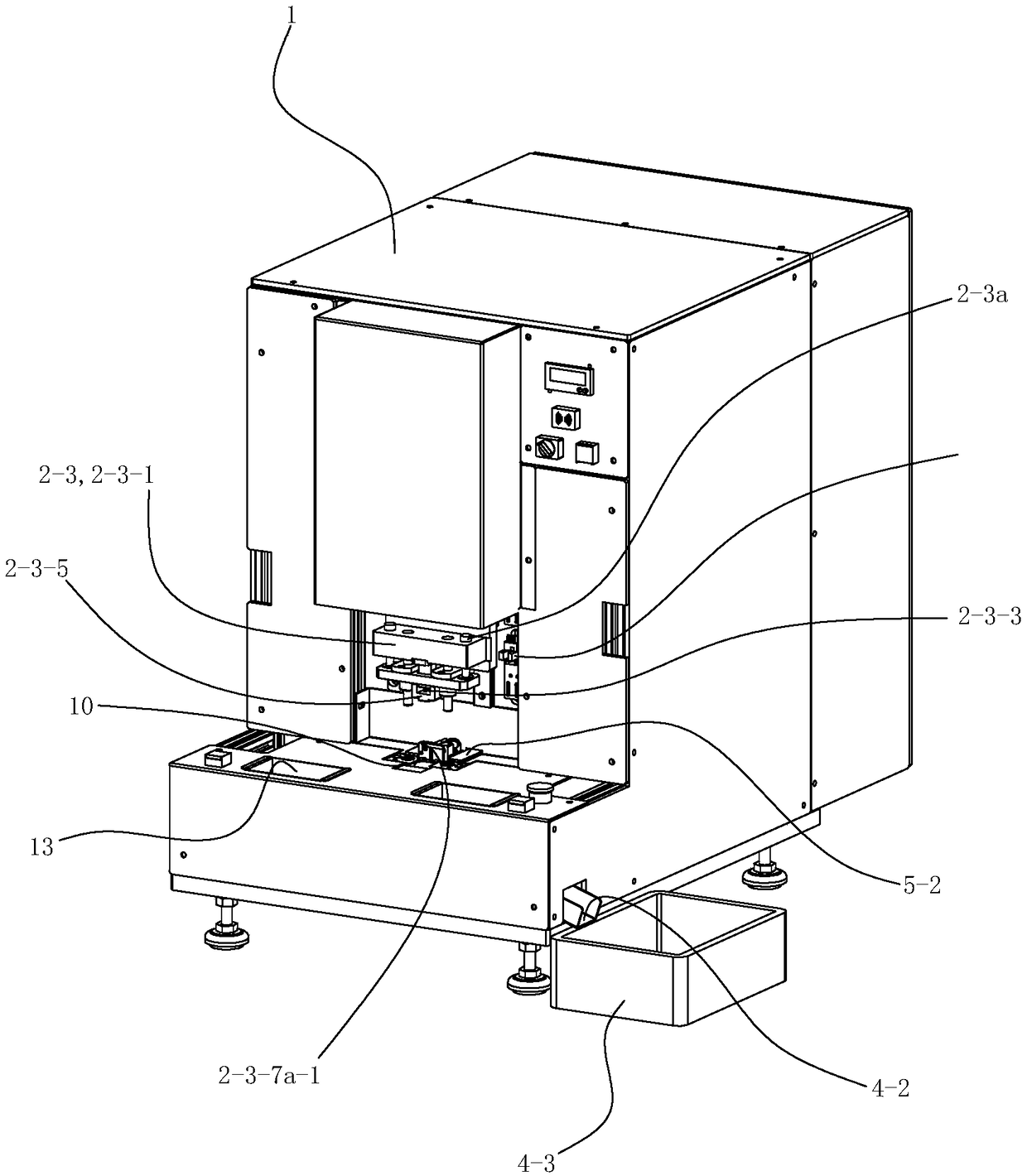

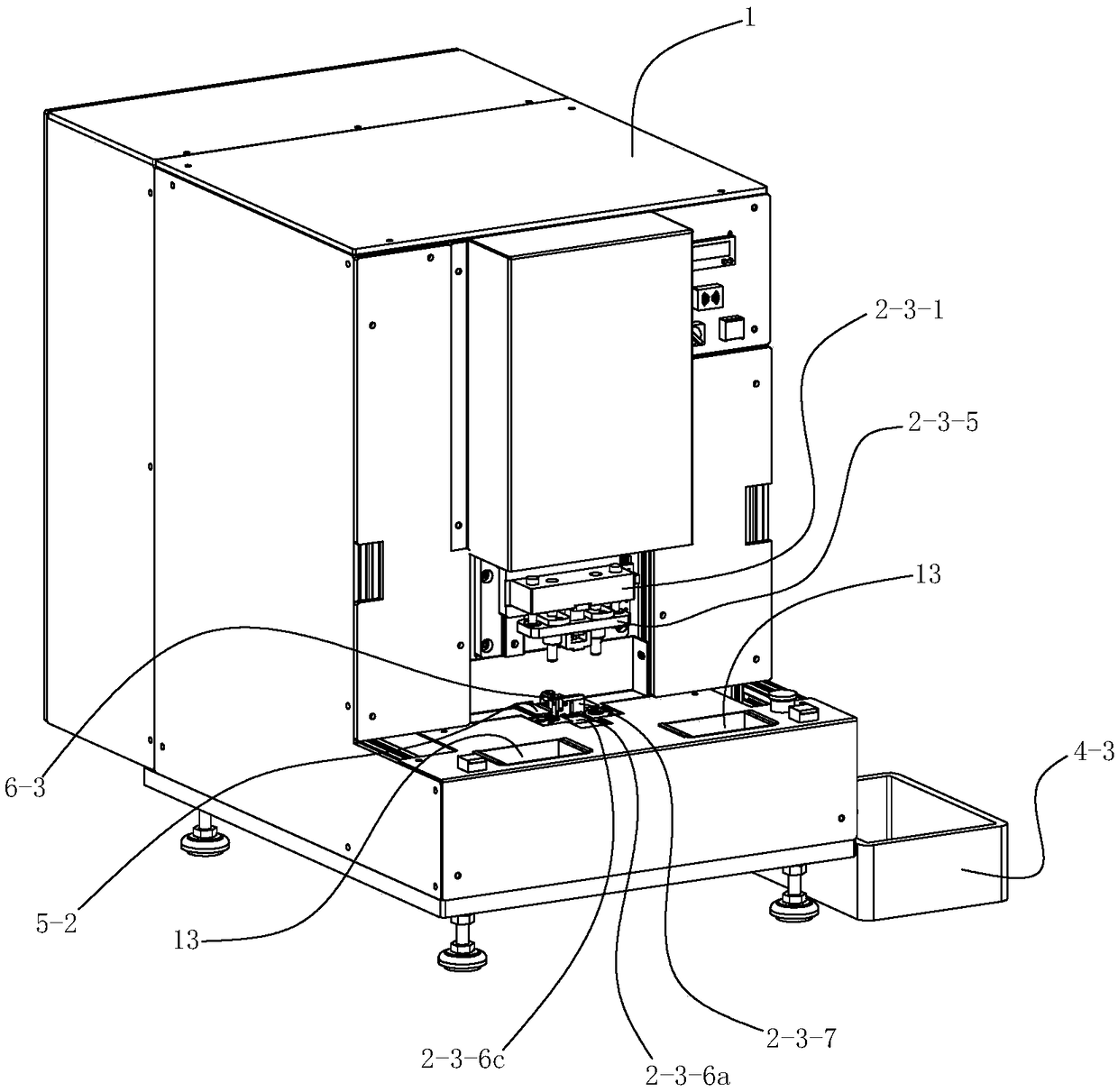

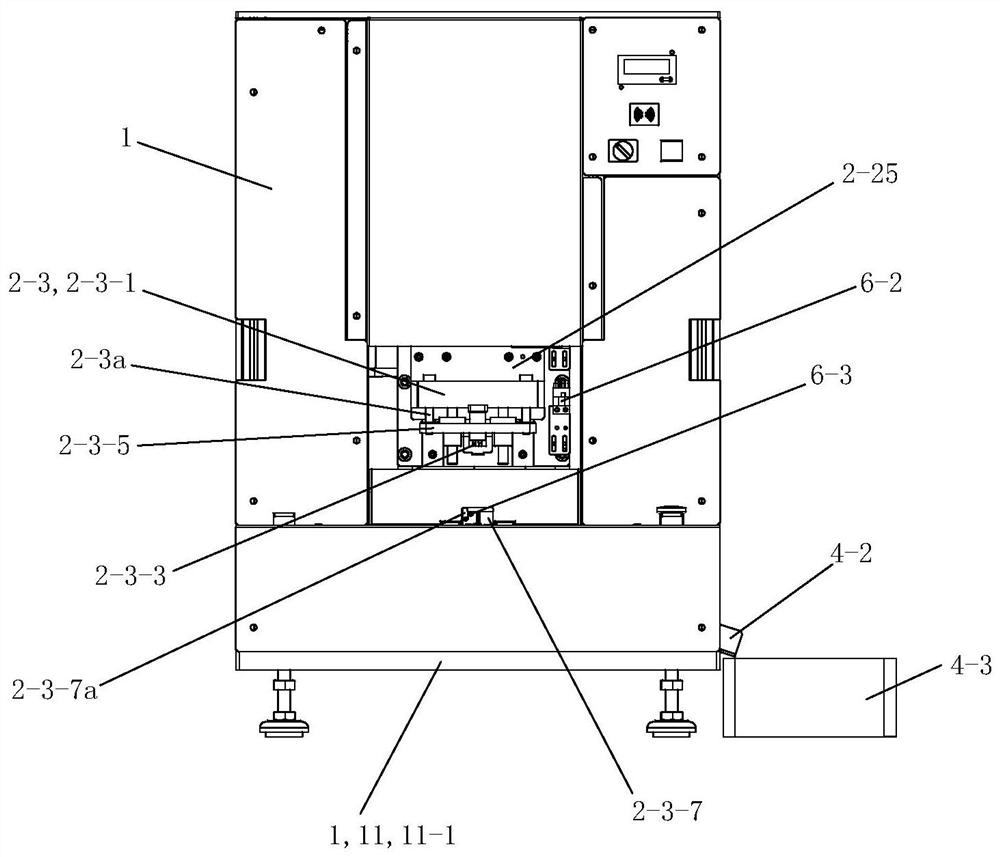

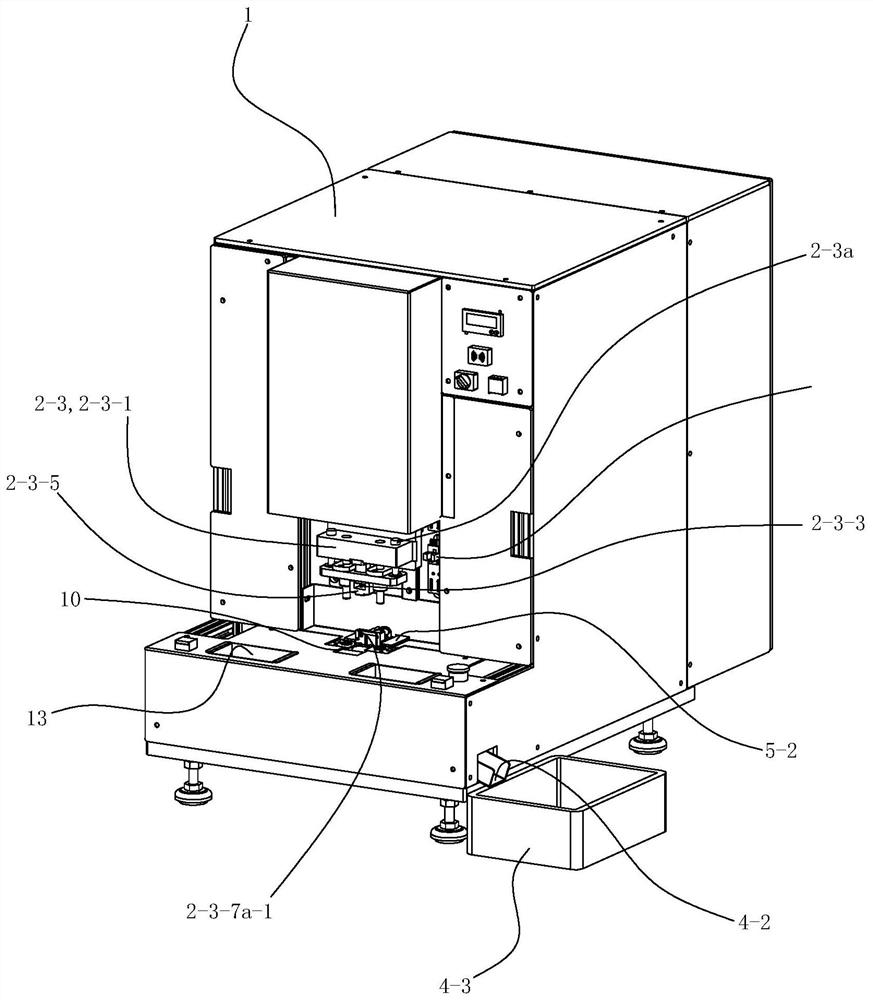

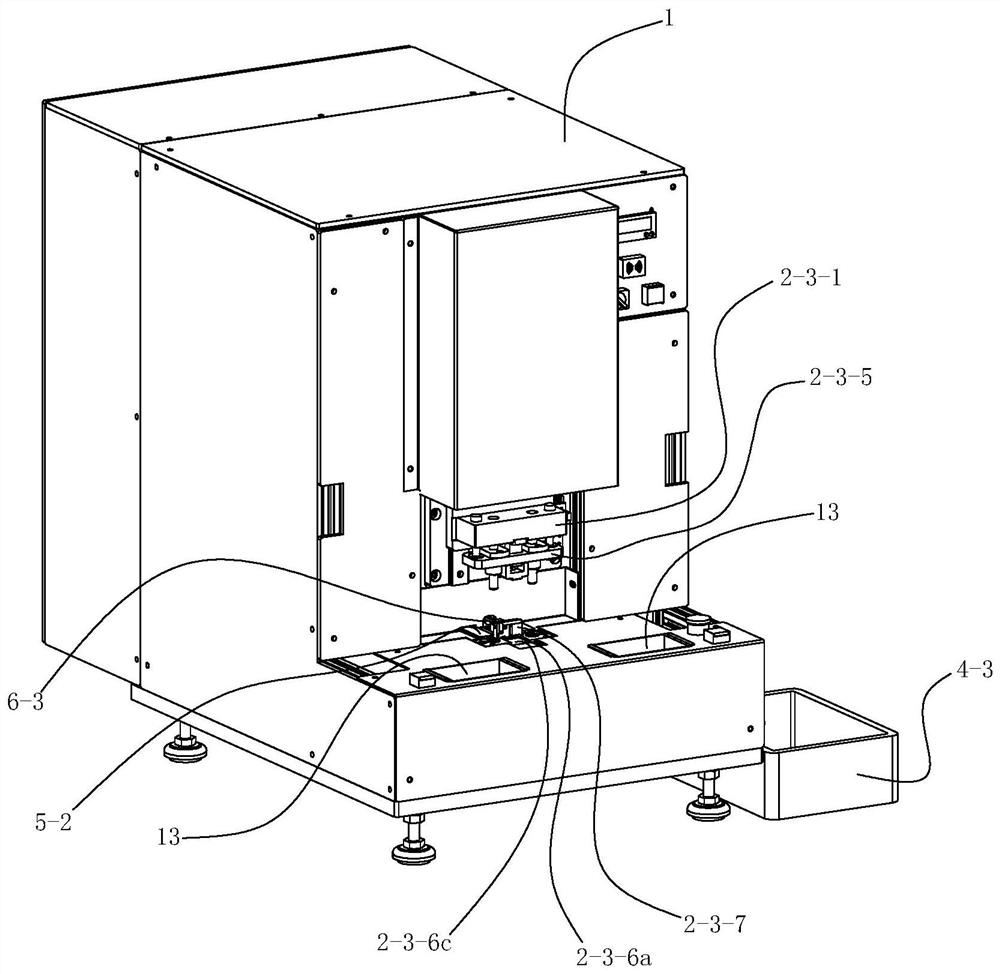

Dual-head and full-automatic terminal machine for harness

PendingCN107681408AImprove processing efficiencyStrong rivetingLine/current collector detailsElectronic waste recyclingMan machineEngineering

A dual-head and full-automatic terminal machine for a harness comprises a case and a fixed bottom rack, wherein the fixed bottom rack is fixedly arranged at the top of the case, a rotation round discis arranged at the top of the fixed bottom rack, a transmission device is arranged on an end surface of one side of the fixed bottom rack, a line cutting and terminal punching mechanism is fixedly arranged at the top of the transmission device, a loading device is arranged on an end surface of an outer side of the transmission device, a receiving device is arranged on an end surface of one side ofthe line cutting and terminal punching mechanism, and a human-machine interaction device is arranged on an end surface of the other side of the line cutting and terminal punching mechanism. Under control of the human-machine interaction device, the loading device, the transmission device and the line cutting and terminal punching mechanism are jointly coordinated and matched to work, so that twoends of the harness are separated and straightened at an extruded terminal, the terminal and the hardness are more stably and accurately riveted, and the finished rate is improved; and meanwhile, operation such as line cutting and line twisting can be automatically completed by the harness, the processing efficiency of the harness is improved, the labor capacity of a worker is reduced, the production efficiency is improved, and the production cost is reduced.

Owner:苏州正兆机械有限公司

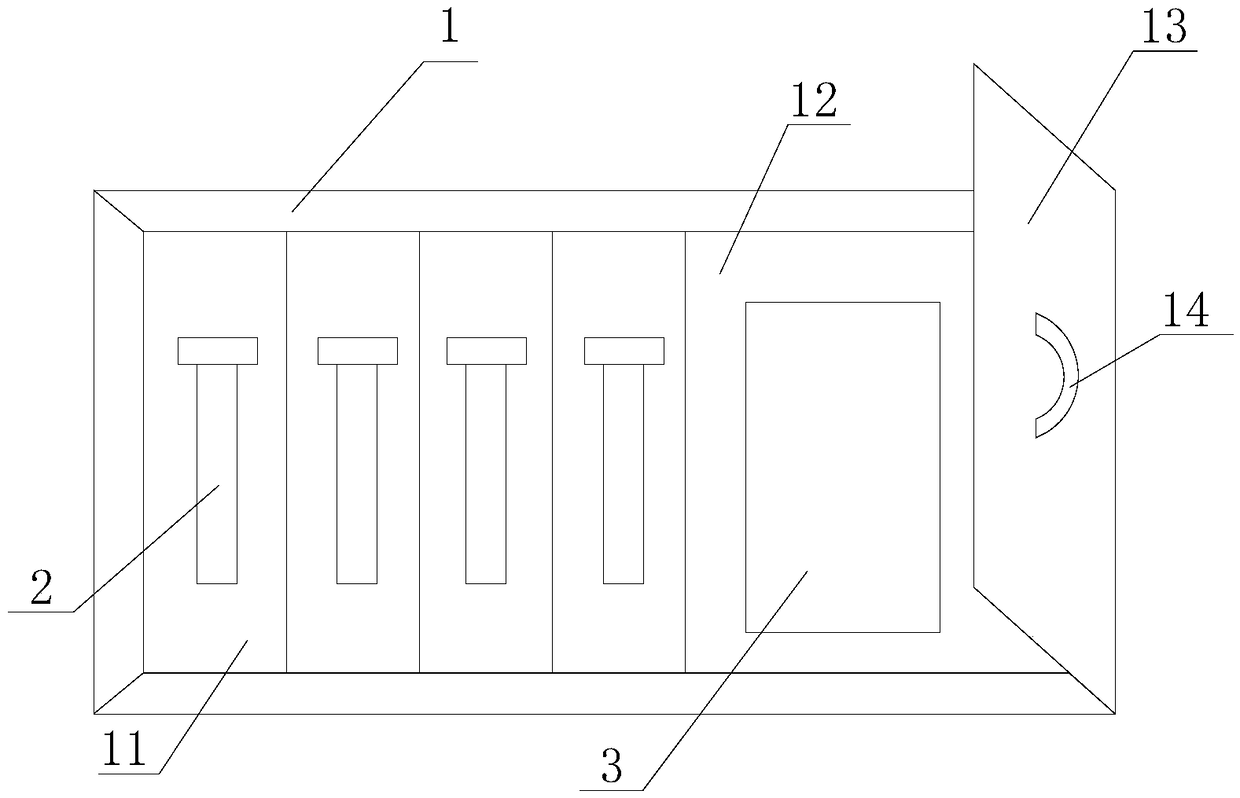

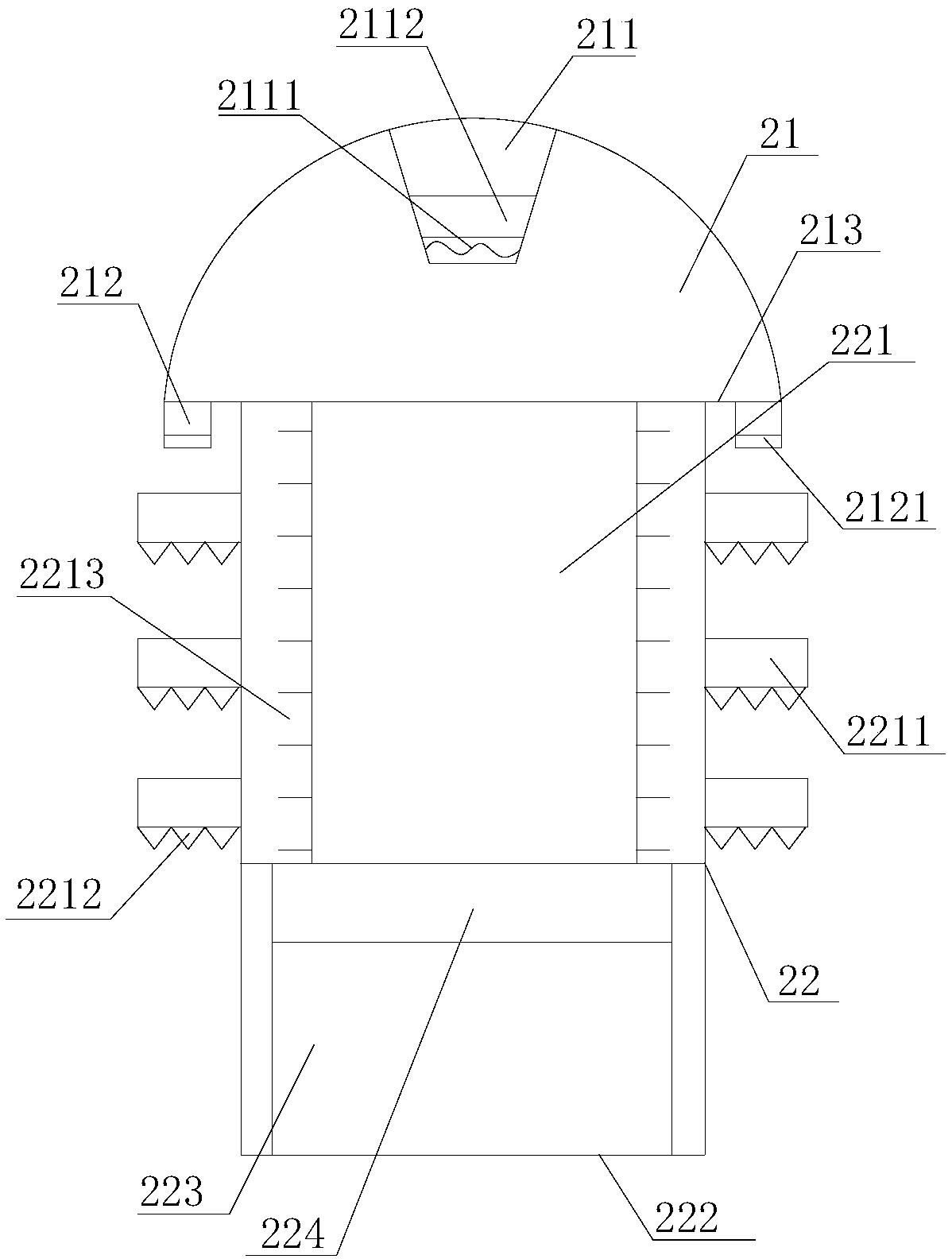

Hollow rivet combination convenient to use

The invention provides a hollow rivet combination convenient to use. The hollow rivet combination convenient to use comprises a storage box, hollow rivet bodies and a simple knocking machine, whereina plurality of first storage cells and a second storage cell are arranged in the storage box, and the hollow rivet bodies are arranged in the first storage cells; each hollow rivet body comprises a rivet cap and a rivet rod; the upper end of each rivet cap is provided with a knocking base; fixing parts are arranged on the two sides of the lower end of each rivet cap; each rivet rod comprises a solid part and a hollow part; the simple knocking machine is arranged in the second storage cell and comprises a base, an extension block, a knocking block and a towing rope; a storage cover is arrangedon the upper portion of the storage box; and a lifting handle is arranged at the upper end of the storage box. The hollow rivet combination convenient to use has the characteristics of being firm in connection and not prone to breaking, the service life is prolonged, the usage cost is reduced, meanwhile, usage is convenient, the pressing and riveting efficiency is high, and the riveting time is shortened.

Owner:ZHEJIANG TIANYUAN METAL PROD

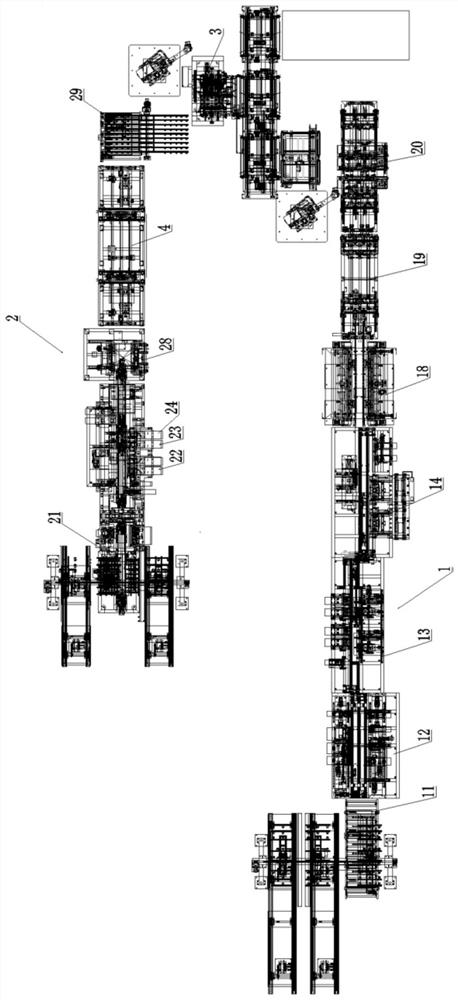

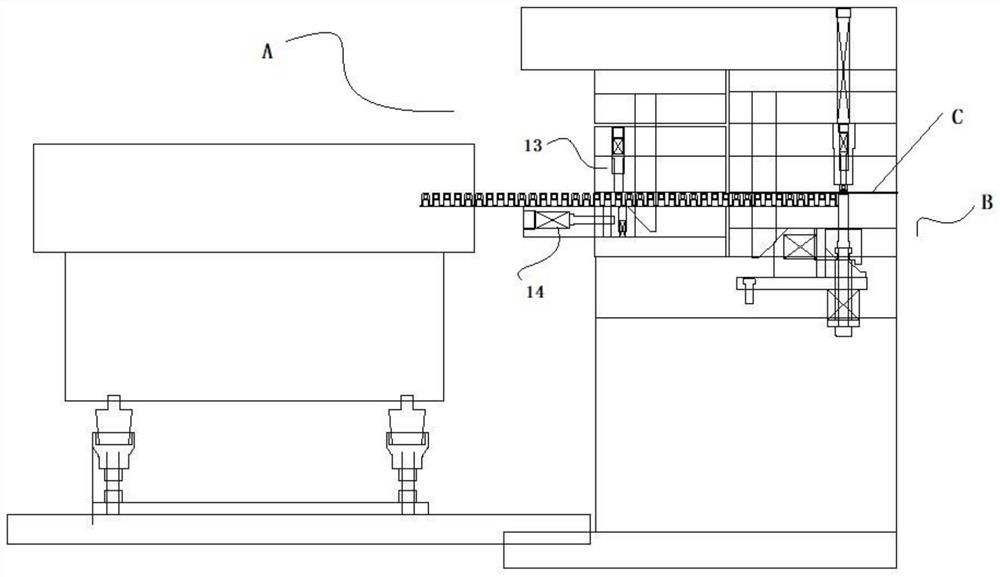

Refrigerator outer box puncturing and riveting production line

ActiveCN113560424ALow costImprove work efficiencyMetal-working feeding devicesPositioning devicesManual handlingManufacturing line

The invention discloses a refrigerator outer box puncturing and riveting production line, which comprises a U-shell coaming production line, a back plate production line and a riveting production line. The U-shell coaming production line comprises the steps that (S11) feeding; (S12) carrying out punching; (S13) carrying out side bending; (S14) carrying out L-shaped bending; (S15) folding a U shape; the back plate production line process comprises the following steps: (S21) feeding; (S22) carrying out punching; (S23) carrying out side bending; (S24) clamping groove forming; (S25) carrying out overturning; the riveting production line process comprises the steps that (S31) a back plate turned over in the step (S25) is transferred to a riveting device; (S32) conveying the U-shaped coaming of step (S15) to the riveting device below the back plate; and (S33) enabling the riveting device to operate, and completing riveting work. According to the refrigerator outer box puncturing and riveting production line provided by the invention, the procedures of punching, bending, riveting and the like of the U-shaped coaming and the back plate are automatically completed, a traditional manual operation mode is replaced, the riveting working efficiency is improved, the personnel cost is reduced, and automatic production is promoted.

Owner:青岛科博尔智能装备有限公司

Riveting machine

The invention discloses a riveting machine which comprises a rack and a riveting device. The riveting device is arranged on the rack and comprises a drive assembly, a transmission assembly, a rivetingassembly and a guiding assembly. The riveting assembly comprises a punch connecting seat, a punch installing seat, steel needle punches, a riveting and guiding assembly, a guiding seat, a riveting seat and a positioning backup plate. The punch connecting seat is fixedly arranged on the transmission assembly. The two steel needle punches are limited and fixedly arranged in the punch installing seat from the upper part through the punch connecting seat. Two riveting holes penetrating through a positioning part of the guiding seat up and down are formed in the positioning part of the guiding seat. A positioning groove corresponding to the positioning part of the guiding seat is formed in the rear part of the middle part of the riveting seat; the positioning groove is provided with two contact placement blind holes for placing relay contacts; and the positions of the two contact placement blind holes correspond to the riveting holes of the positioning part. The drive assembly drives the steel needle punches of the riveting assembly to downwards move along the guiding assembly through the transmission assembly so as to carry out riveting operation.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

Feeding system

InactiveCN106976687ASmooth feedingAccurate rivetingMetal working apparatusJigging conveyorsShock waveEngineering

A feeding system, including a machine and a feeding device, the feeding system also includes a transmission device, a transport device and an adsorption device, the feeding device includes a storage tray and a first shock wave generator connection block, the transmission The device includes a guide rod and a connecting block of the second shock wave generator. An adsorption hole is provided on the conveying device. The connecting block of the first shock wave generator is used to transfer the material to the guide rod. The guide rod is connected to the second shock wave generator. Under the vibration of the connecting block, the material is transferred to the adsorption hole, and the adsorption device absorbs the material so that the material is fixed on the electronic device. Compared with the prior art, the feeding system of the present invention continuously transports the material in the storage tray to the guide rod through the connecting block of the first shock wave generator, and the guide rod transports the material to the adsorption hole through the connecting block of the second shock wave generator. The delivery device transports the material in the adsorption hole to the adsorption device, and the adsorption device fixes the material to the electronic equipment, with stable feeding and accurate riveting.

Owner:FU TAI HUA IND SHENZHEN +1

Continuous stamping and forming device for filter filter safety valve gland

ActiveCN109201901BRealization of continuous stampingIncrease productivityMetal-working feeding devicesPositioning devicesFiltrationEngineering

The invention provides a continuous punch forming device of a filter cleaner filtration safety valve gland. The device comprises a rack, an annular caterpillar band arranged on the rack, a driving device arranged at the rear end of the rack and used for driving the annular caterpillar band to operate, multiple punch part putting columns fixed to the annular caterpillar band at intervals in parallel, a first punch mechanism, a second punch mechanism, a third punch mechanism and a fourth punch mechanism, punch part fixing discs are arranged between two adjacent punch part putting columns, and the first punch mechanism, the second punch mechanism, the third punch mechanism and the fourth punch mechanism are sequentially arranged on the rack at intervals side by side in the running direction of the caterpillar band. According to the continuous punch forming device of the filter cleaner filtration safety valve gland, continuous punch forming of the engine oil filter safety valve gland can be achieved, production efficiency of the engine oil filter safety valve gland can be greatly improved, the forming quality of the engine oil filter safety valve gland can be improved, and compared with traditional manual machining manner, the per capita production efficiency is improved by 226%, and the yield is improved by 20%.

Owner:佛山市豹王滤芯制造有限公司

Automobile sunroof guide rail automatic riveting device

The invention relates to the technical field of riveting devices, and discloses an automatic riveting device for an automobile skylight guide rail. The automatic riveting device comprises a workbench and a riveting machine mounted above the workbench, wherein an upper vertical riveting head is arranged on the riveting machine; a lower riveting head coaxial with the upper riveting head is arranged on the workbench; a skylight guide rail fixing seat is arranged on the workbench; a sliding rail is arranged between the skylight guide rail fixing seat and the workbench; a riveting head avoiding slot distributed along the sliding rail is formed in the skylight guide rail fixing seat, so that the skylight guide rail fixing seat can slide along the sliding rail; a screw rod distributed along the sliding rail is arranged below the workbench; two ends of the screw rod are respectively fixed on the lower side of the workbench through a rotating connection seat; a servo motor is arranged at one end of the screw rod; a sliding block is arranged on the screw rod and is in threaded connection with the screw rod; a sliding block avoiding slot distributed along the sliding rail is formed in the workbench; the upper end of the sliding block penetrates through the sliding block avoiding slot and is connected with the skylight guide rail fixing seat. Therefore the automobile riveting device has the beneficial effects of high riveting efficiency and high riveting quality.

Owner:宁波裕民机械工业有限公司

Rivet welding platform capable of precise processing

InactiveCN108555508APrevent errors in rivet weldingAccurate rivetingWelding/cutting auxillary devicesAuxillary welding devicesRivetWelding

The invention discloses a rivet welding platform capable of precise processing. The rivet welding platform capable of precise processing comprises a base board, T-shaped grooves are formed in the upper surface of the base board, a baffle is fixedly connected with the part, on the top of the base board, located at one ends of the T-shaped grooves, sliding blocks are connected into the T-shaped grooves in a sliding mode, the tops of the sliding blocks and the tops of connecting blocks are integrated, the tops of the connecting blocks penetrate out of the T-shaped grooves, the tops of the connecting blocks are fixedly connected with the bottoms of racks, and the tops of the racks are inserted into clamping boards. According to the rivet welding platform capable of precise processing, throughcooperation of the clamping boards and the baffle, by sliding the sliding blocks, the connecting blocks drive the clamping boards to side on the surface of the base board, so that a workpiece which needs to be subjected to rivet welding is clamped among the baffle and the clamping boards; when the clamping boards move downwards, the clamping boards matched with the sliding blocks are clamped on the surface of the base board, thus the position of the workpiece which needs to be subjected to rivet welding is fixed, and it is prevented that the workpiece moves to cause rivet welding errors, so that the effect of making rivet welding more accurate is achieved.

Owner:赵学明

Automatic punching and riveting mechanism and full-automatic punching and riveting equipment for rivets

The invention provides full-automatic punching and riveting equipment, a feeding mechanism and a punching and riveting mechanism for rivets. The punching and riveting mechanism comprises a transfer track for conveying rivets, a first upper die device and a first lower die device, the transfer track is located on the first lower die device, a riveting side pushing scraper knife and an upper die riveting and punching assembly are arranged on the first upper die device, a lateral pushing riveting device for pushing a to-be-punched rivet to move upwards is arranged on the first lower die device, the lateral pushing riveting device comprises a lateral pushing transverse moving assembly and a rivet jacking device matched with the upper die riveting and punching assembly to complete the punching and riveting process, a riveting lateral pushing scraper knife is located above the lateral pushing transverse moving assembly, and the upper die riveting and punching assembly is located above the rivet jacking device. By means of the equipment, full-automatic rivet feeding and automatic punching and riveting can be achieved, full-automatic control over the rivet from the feeding process to the punching and riveting process is achieved, the full-automatic process of automatic continuous punching and riveting in a die can be met, the degree of dependence on manpower is reduced, the production efficiency is improved, and the product performance is improved.

Owner:惠州市锐俊科技有限公司

Riveting machine

The invention discloses a riveting machine which comprises a rack and a riveting device. The riveting device is arranged on the rack and comprises a drive assembly, a transmission assembly, a rivetingassembly and a guiding assembly. The riveting assembly comprises a punch connecting seat, a punch installing seat, steel needle punches, a riveting and guiding assembly, a guiding seat, a riveting seat and a positioning backup plate. The punch connecting seat is fixedly arranged on the transmission assembly. The two steel needle punches are limited and fixedly arranged in the punch installing seat from the upper part through the punch connecting seat. Two riveting holes penetrating through a positioning part of the guiding seat up and down are formed in the positioning part of the guiding seat. A positioning groove corresponding to the positioning part of the guiding seat is formed in the rear part of the middle part of the riveting seat; the positioning groove is provided with two contact placement blind holes for placing relay contacts; and the positions of the two contact placement blind holes correspond to the riveting holes of the positioning part. The drive assembly drives the steel needle punches of the riveting assembly to downwards move along the guiding assembly through the transmission assembly so as to carry out riveting operation.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com