Continuous stamping and forming device for filter filter safety valve gland

A technology of stamping forming and safety valve, which is applied in the direction of storage device, feeding device, positioning device, etc., can solve the problems of easy production of defective products, low efficiency, breakage, etc., and achieve the improvement of production efficiency, production efficiency, and qualification rate improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

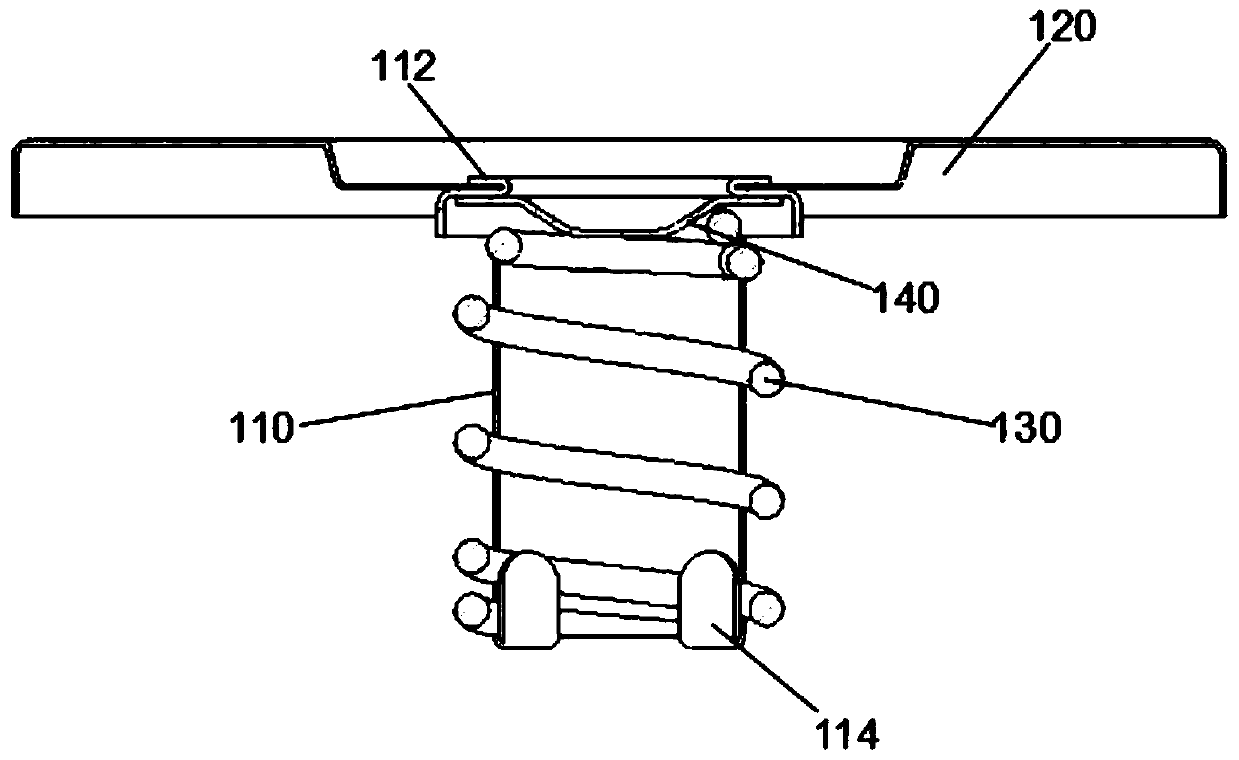

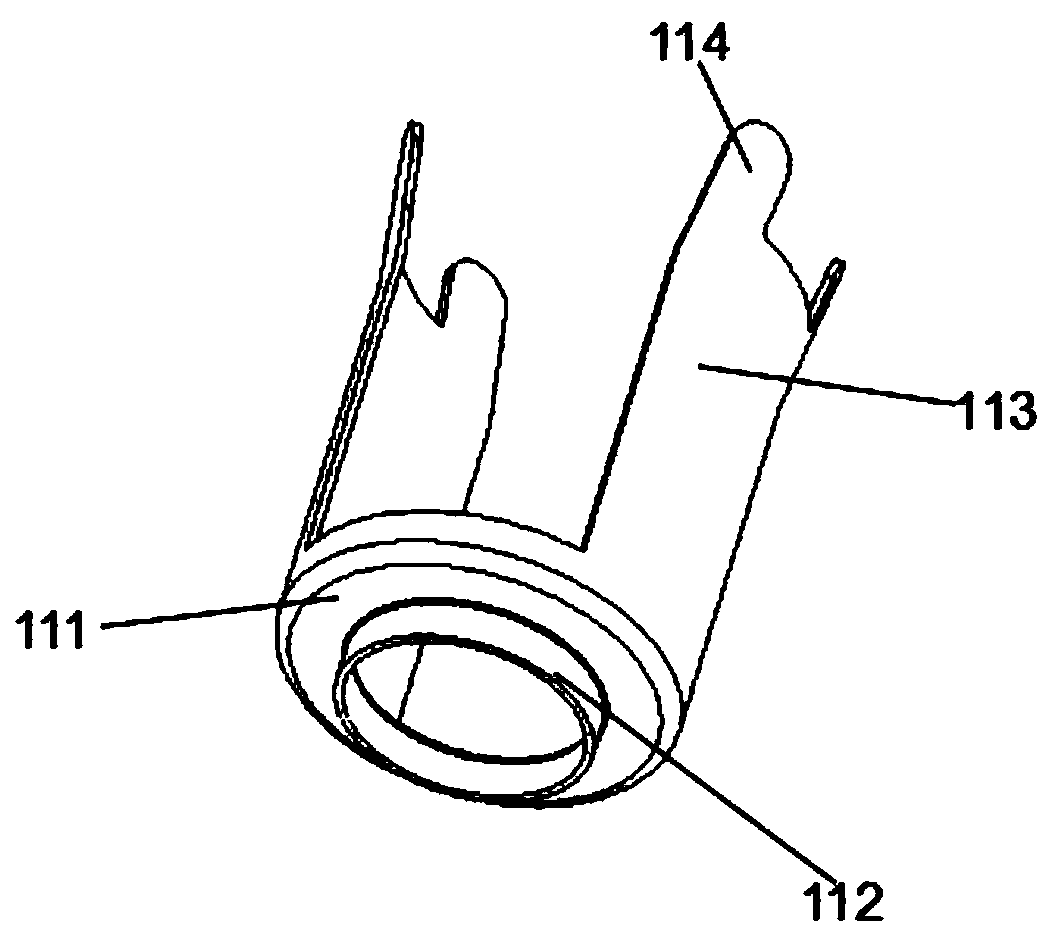

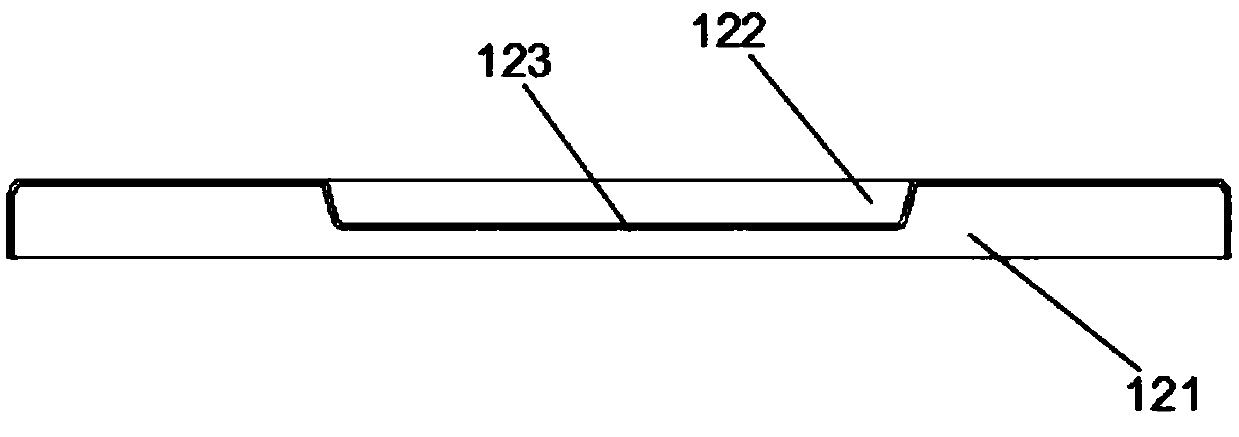

[0041] Embodiment: A continuous stamping and forming device for filter filter safety valve cover.

[0042] refer to Figure 1 to Figure 24 As shown, a filter filter safety valve gland continuous stamping forming device, including: frame 1; ring track 2 installed on frame 1; mounted on the rear end of frame 1 and used to drive ring track 2 The driving device of operation, described driving device comprises mounting base, drive motor 3, transmission gear 4 and coupling, described driving motor 3 is fixed on the mounting base, and driving motor 3 passes through the transmission of transmission gear 4 through coupling Shaft connection, the transmission gear 4 meshes with the crawler belt 2, and the drive motor 3 is a servo motor, which drives the transmission gear 4 to rotate and then drives the endless crawler belt 2 to continue running;

[0043] The continuous forming device also includes a plurality of stamping parts placement columns 5 fixed at intervals in parallel on the en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com