Flexible riveting device based on visual guidance and flexible riveting system thereof

A technology of visual guidance and riveting device is applied in the field of workpiece riveting technology, which can solve the problems that the accuracy requirements cannot meet the requirements, affect the production efficiency, and the product surface is uneven, and achieve the effect of reasonable design and improved riveting work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

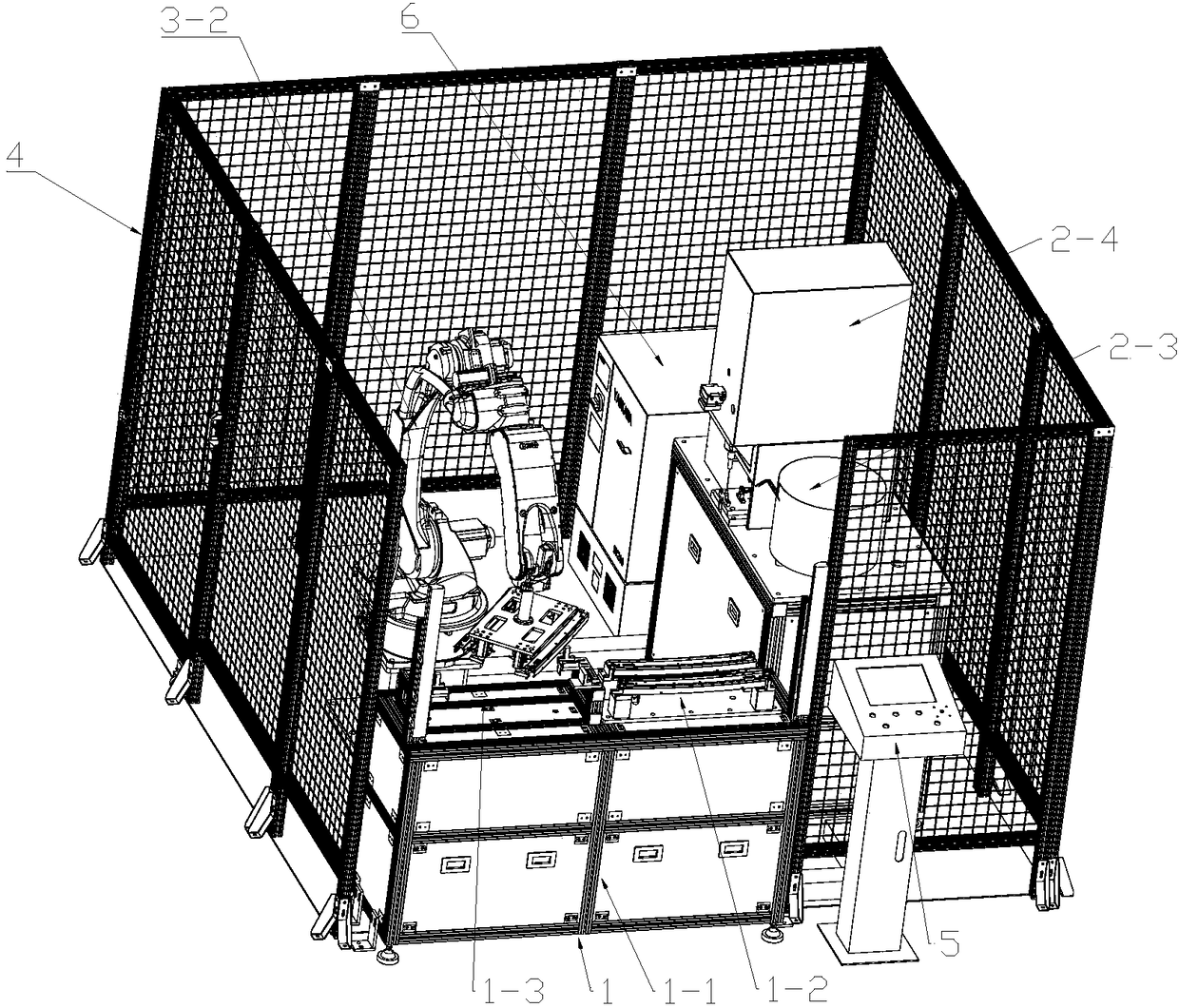

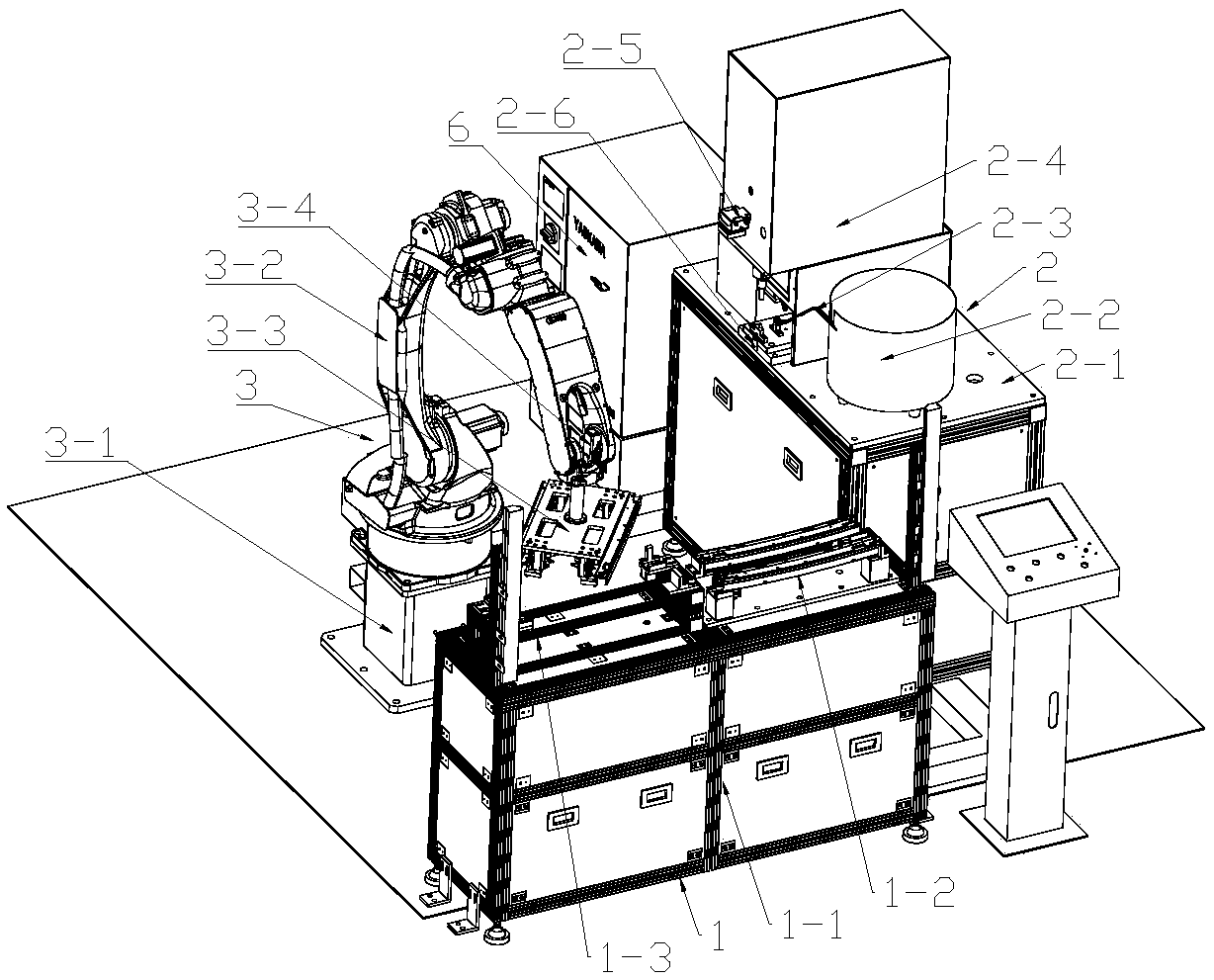

[0037] Such as Figure 1-8 As shown, a vision-guided flexible riveting device includes:

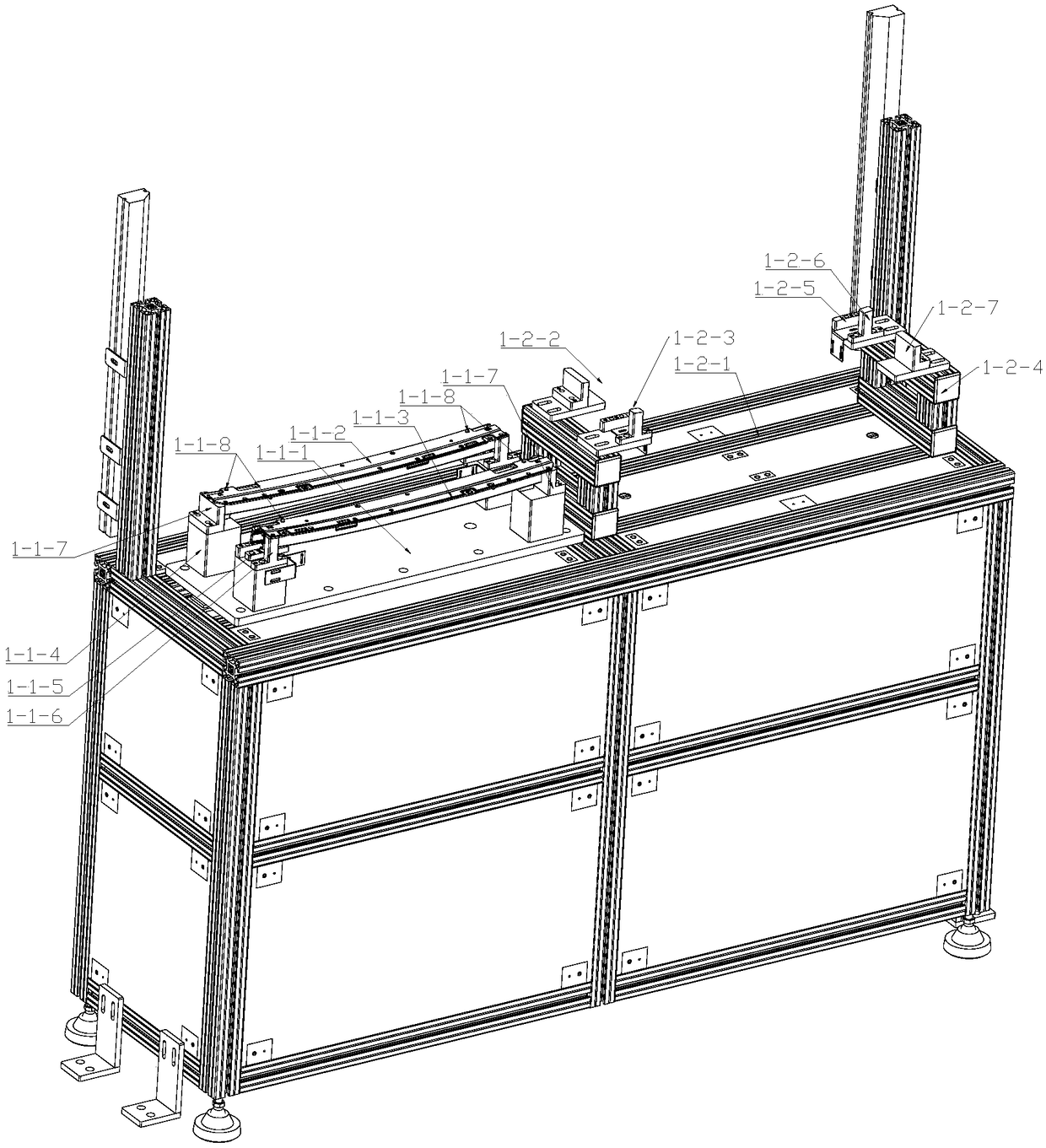

[0038]Feeding assembly 1: the feeding assembly 1 is used to provide and position the workpiece with riveting holes, the feeding assembly 1 includes a feeding table 1-1 and a feeding mechanism 1-1 arranged on the feeding table 1-1 2 and a blanking mechanism 1-3, the loading mechanism 1-1 includes a loading platen 1-1-1, a left feeding group 1-1-2 and a The right feeding group 1-1-3, and the directions of the left feeding group 1-1-2 and the right feeding group 1-1-3 are oppositely set, the left feeding group 1-1-2 and the right feeding group 1-1 -3 all include a symmetrically arranged feeding table 1-1-4, wherein, on the feeding table 1-1-4 at one end, a square top block 1-1-5 and a T-shaped top block 1- are arranged in parallel on the left and right 1-6, the loading table 1-1-4 at the other end is provided with an L-shaped top block 1-1-7, and the feeding table 1-1-4 corresponds to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com