Automatic riveting machine for lock body cover plate

A technology of riveting machine and cover plate, applied in the field of lock processing, can solve the problems of high labor cost, low efficiency, finger injury and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

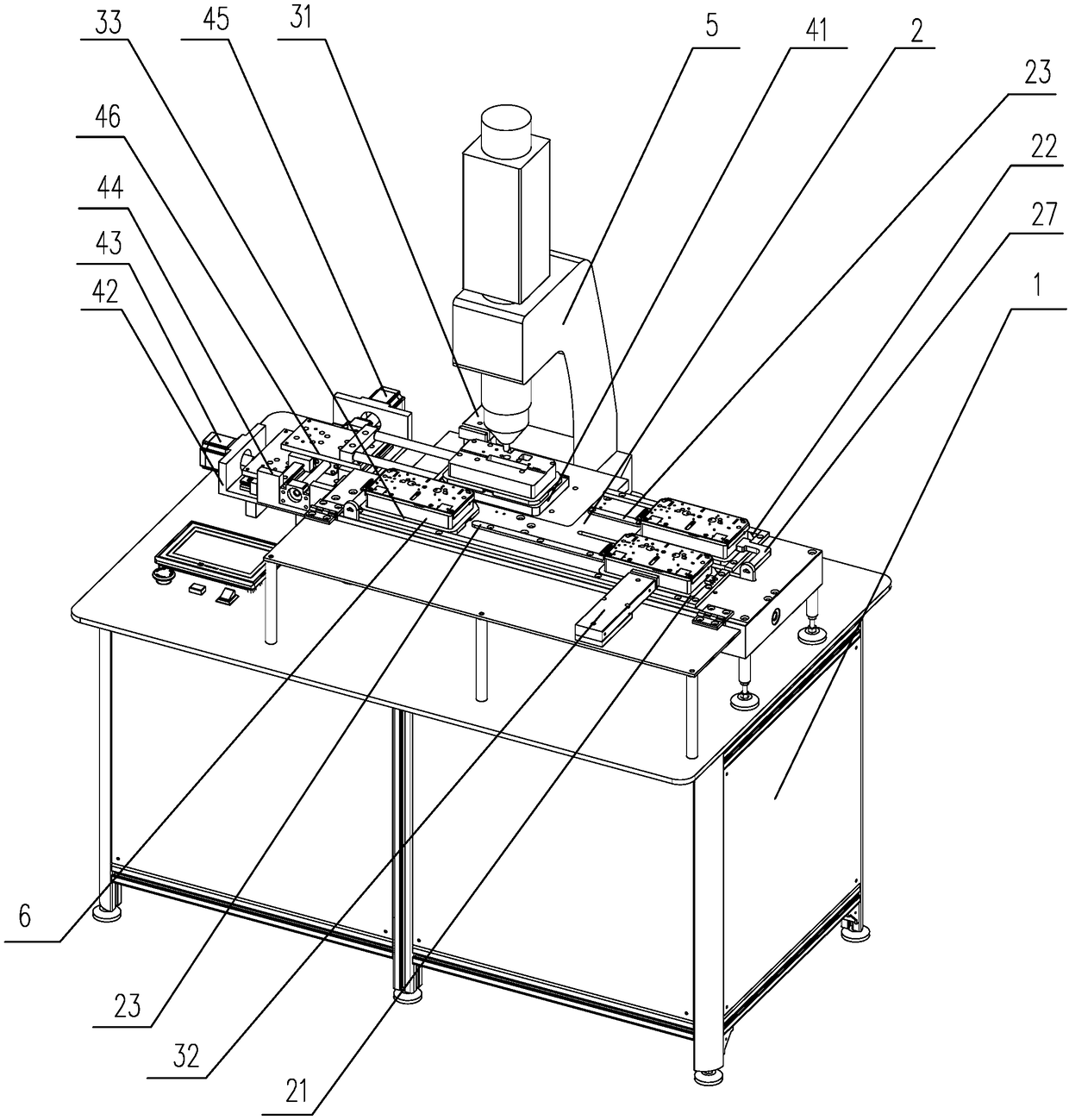

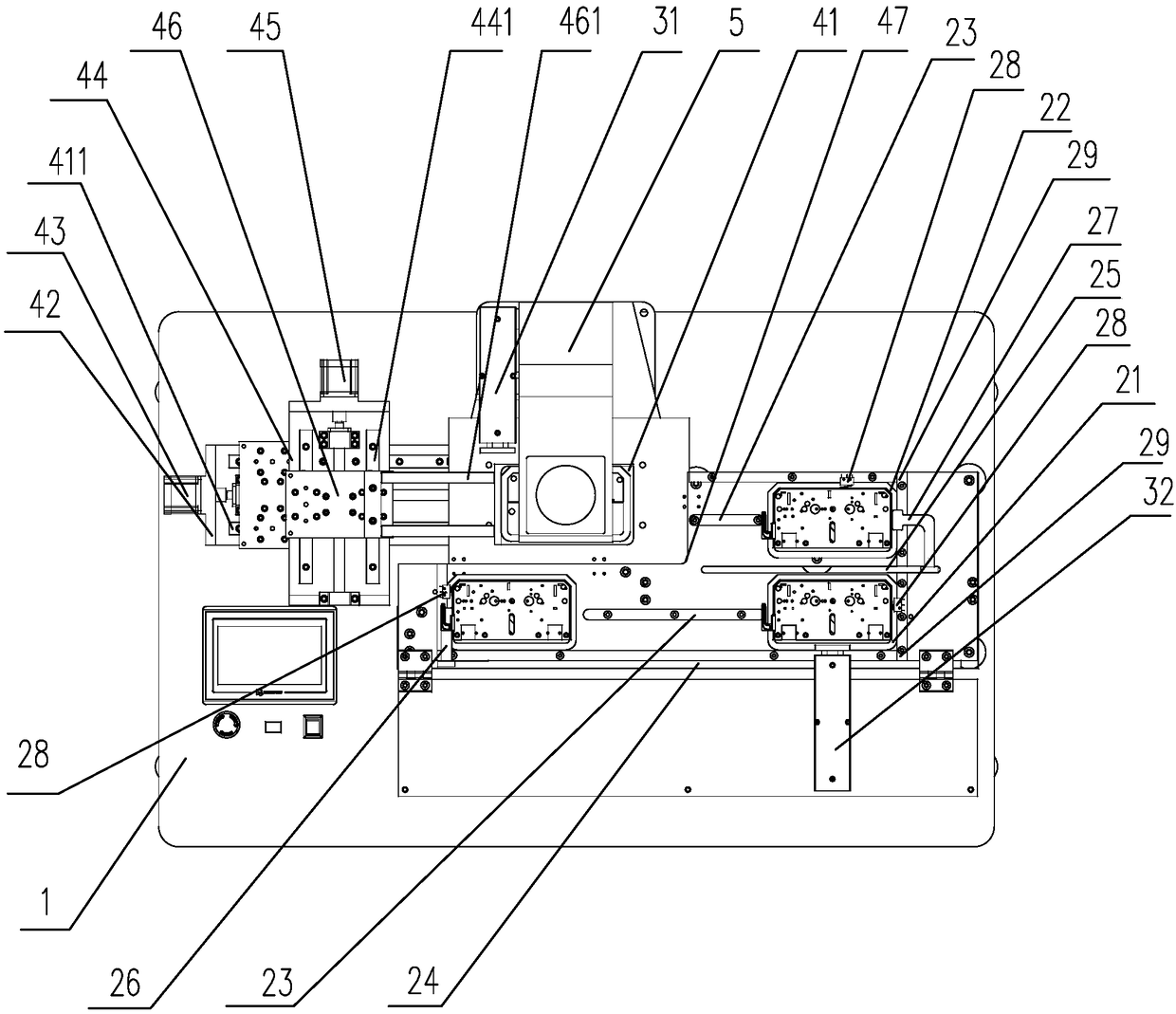

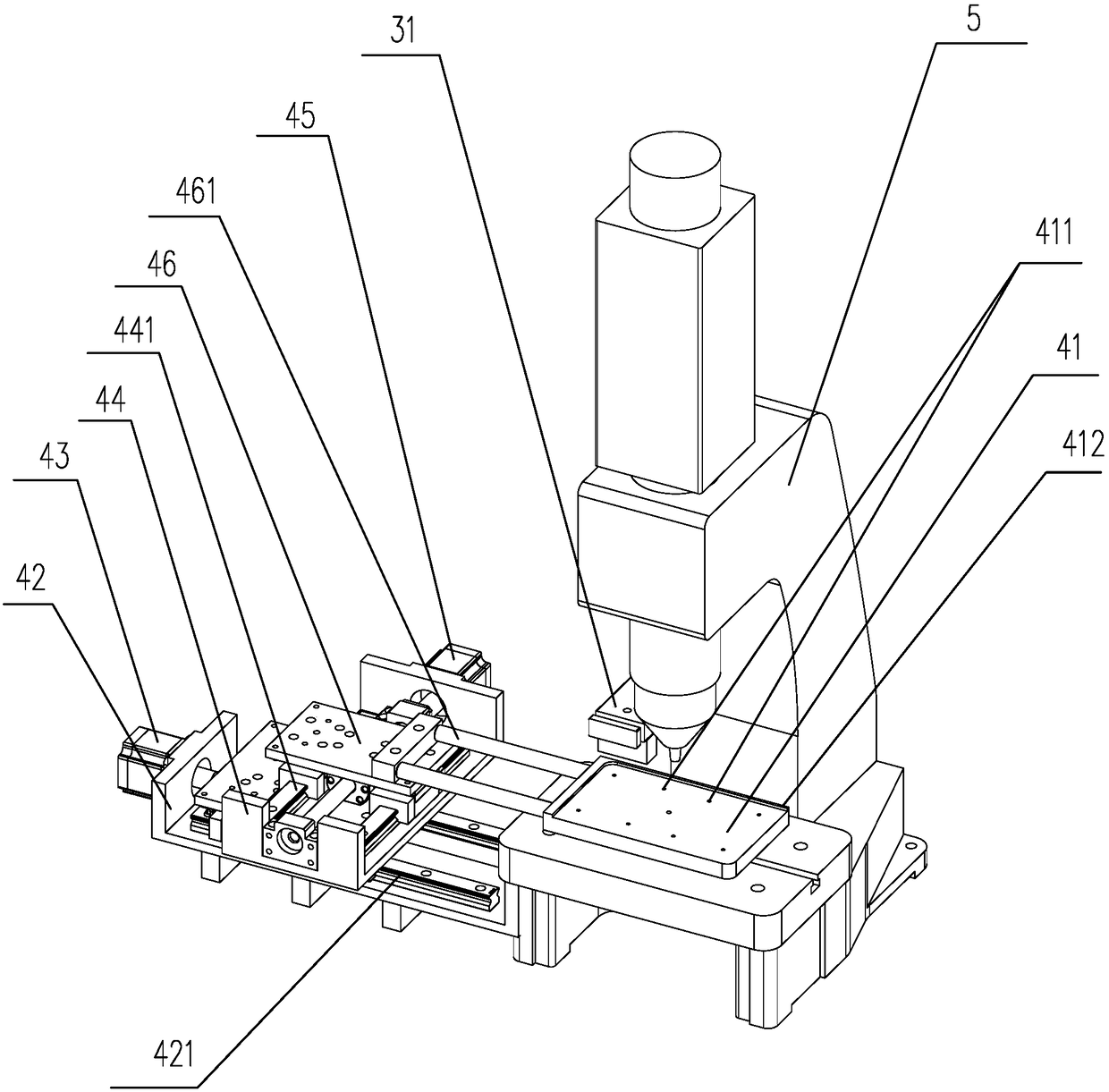

[0024] Depend on Figure 1 to Figure 4It can be seen that the present invention discloses an automatic riveting machine for lock body cover plates, including a workbench 1 and a punching machine 5, the punching machine 5 is arranged on the workbench 1, and the workbench 1 corresponds to the punching machine 5 The position is provided with stamping platform 41, and described workbench 1 is provided with loading platform 6 and is used for conveying device that the material on loading platform 6 is sent to stamping platform 41, and described loading platform 6 and stamping platform 41 pass U The U-shaped track 2 is connected, and the U-shaped track 2 includes a first corner 21 and a second corner 22. The conveying device includes a first feeding cylinder, a second feeding cylinder, a second pushing cylinder 32, and a slide for carrying materials. seat 33, the sliding seat 33 is slidably arranged on the workbench 1, a first sliding groove 24 is provided between the loading platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com