Riveting processing device of magnetron

A processing device and magnetron technology, which is applied in the field of riveting processing devices, can solve the problems of magnetron rework, poor versatility, positioning block and shell misalignment, etc., and achieve the effect of low rework and scrap, simple and reasonable structure, and stable riveting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

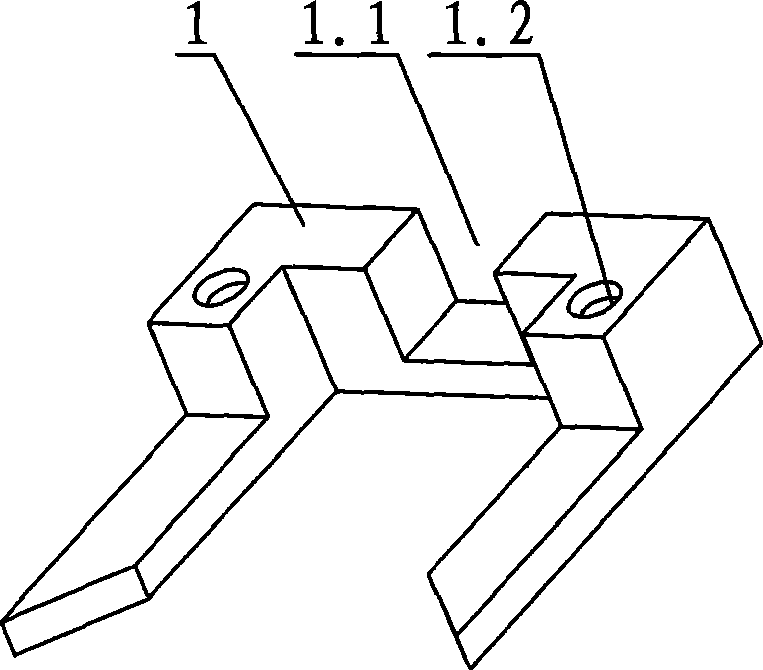

[0024] see figure 1 , figure 2 , Figure 4 and Figure 7 , the riveting processing device of the magnetron, including a fuselage, the fuselage is provided with a positioning seat 1 for fixing the magnetron and a riveting head 3 for horizontal movement, the positioning seat 1 is arranged on the surface of a lifting platform 5, and the riveting head 3 is set On the workbench 6 on both sides of the lifting platform 5, a slide rail is provided inside the workbench 6, and a U-shaped mounting seat 2 reciprocating along the slide rail is provided. The riveting head 3 is installed on the mounting seat 2 and is always located The top of the lifting platform 5 moves horizontally.

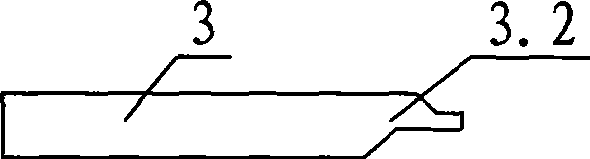

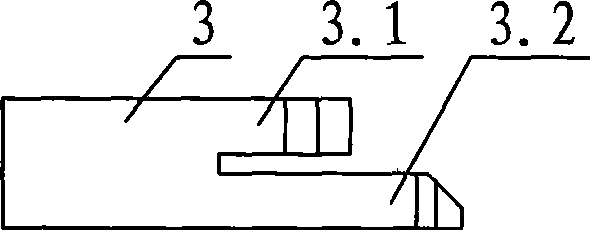

[0025] There are through holes 2.1 at both ends of the inner bottom of the mounting seat 2, see image 3 , The riveting head 3 is installed in the through hole 2.1 through the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com