Automatic punching and riveting mechanism and full-automatic punching and riveting equipment for rivets

A rivet and punch riveting technology, applied in the field of automatic processing equipment, can solve the problems of strong manual dependence, low efficiency, poor product consistency, etc., and achieve the effect of reducing dependence, accurate feeding, and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

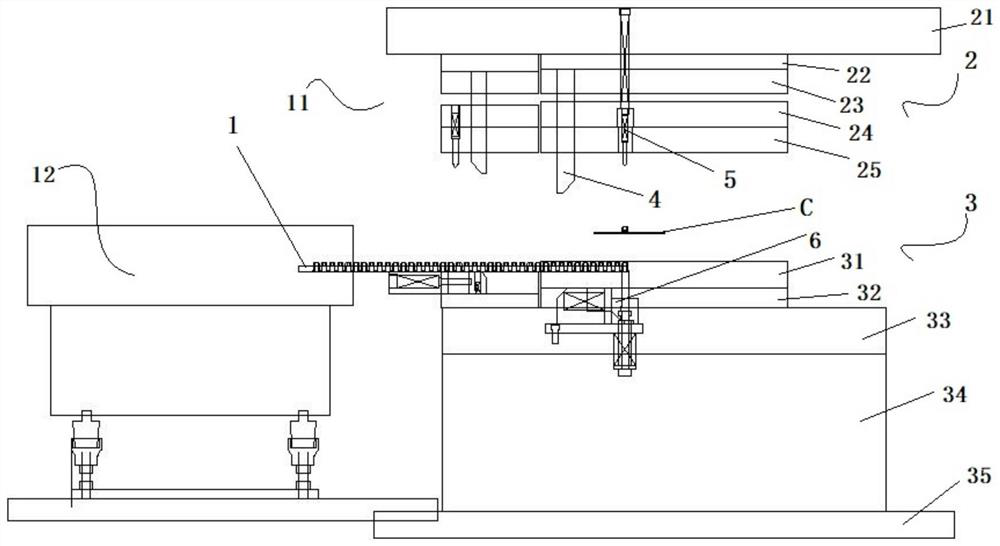

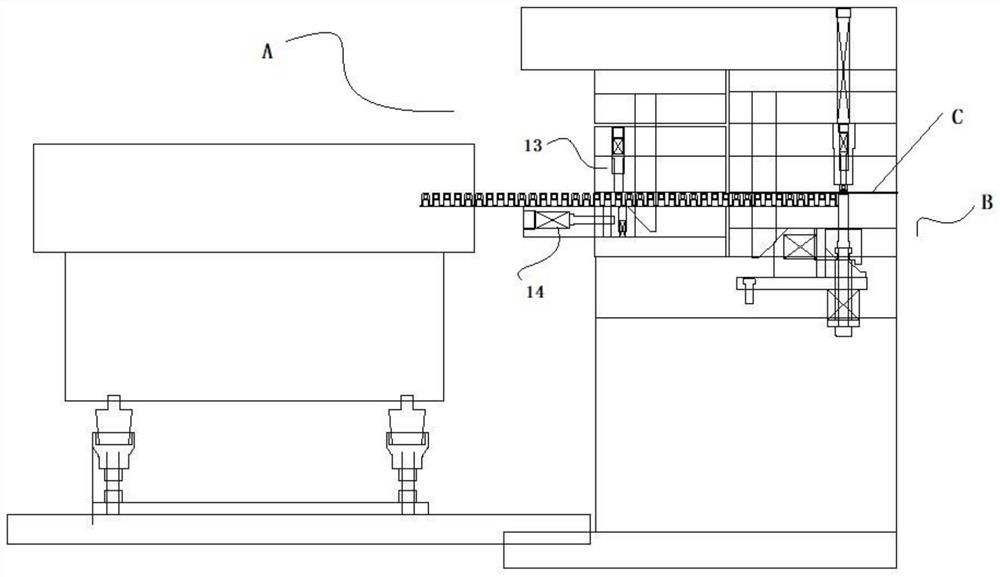

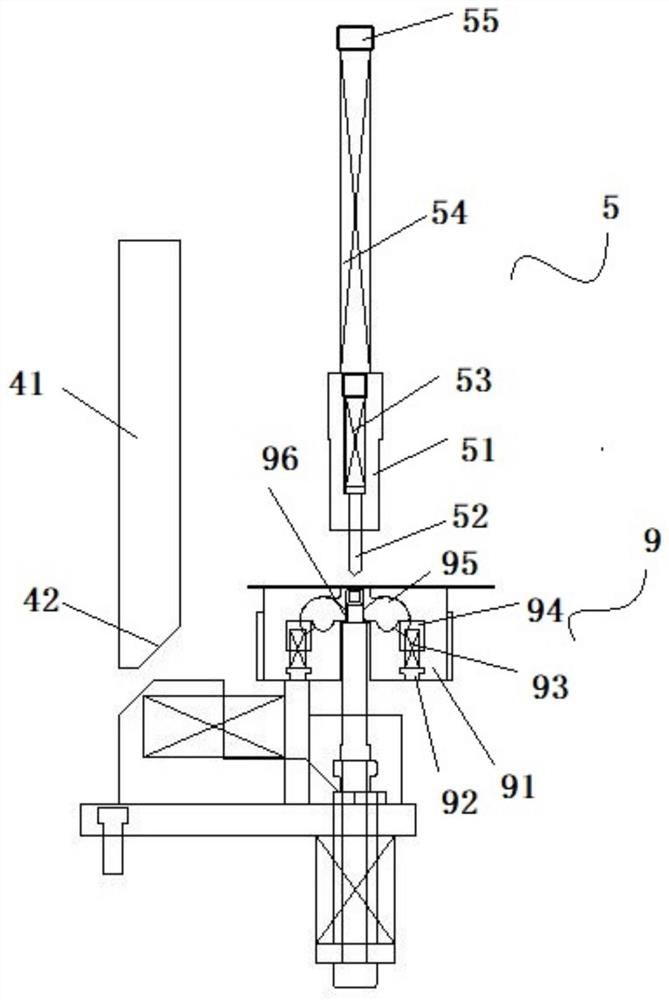

[0034] as attached Figure 1-5 As shown, the present invention provides a punching riveting mechanism for rivets, including a transfer rail 1 for conveying the rivet D, an upper die device 2 and a lower die device 3, the transfer rail is located on the lower die device 1, and on the upper die device 1 Device 1 is provided with riveting side push blade 4 and upper die riveting assembly 5, and lower die device 1 is provided with side push riveting device 6 for pushing the rivet to be punched upward, and said side push riveting device includes side push lateral movement Component 7 and the rivet jacking device 8 that is matched with the upper die riveting assembly to complete the punching riveting process, the riveting side pushing blade is located above the side pushing lateral movement assembly, and the upper die riveting assembly is located on the rivet upper jacking Above the device, a strip C is provided between the upper mold unit one and the lower mold unit one. The presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com