Closure or stopper forms a surface tension seal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

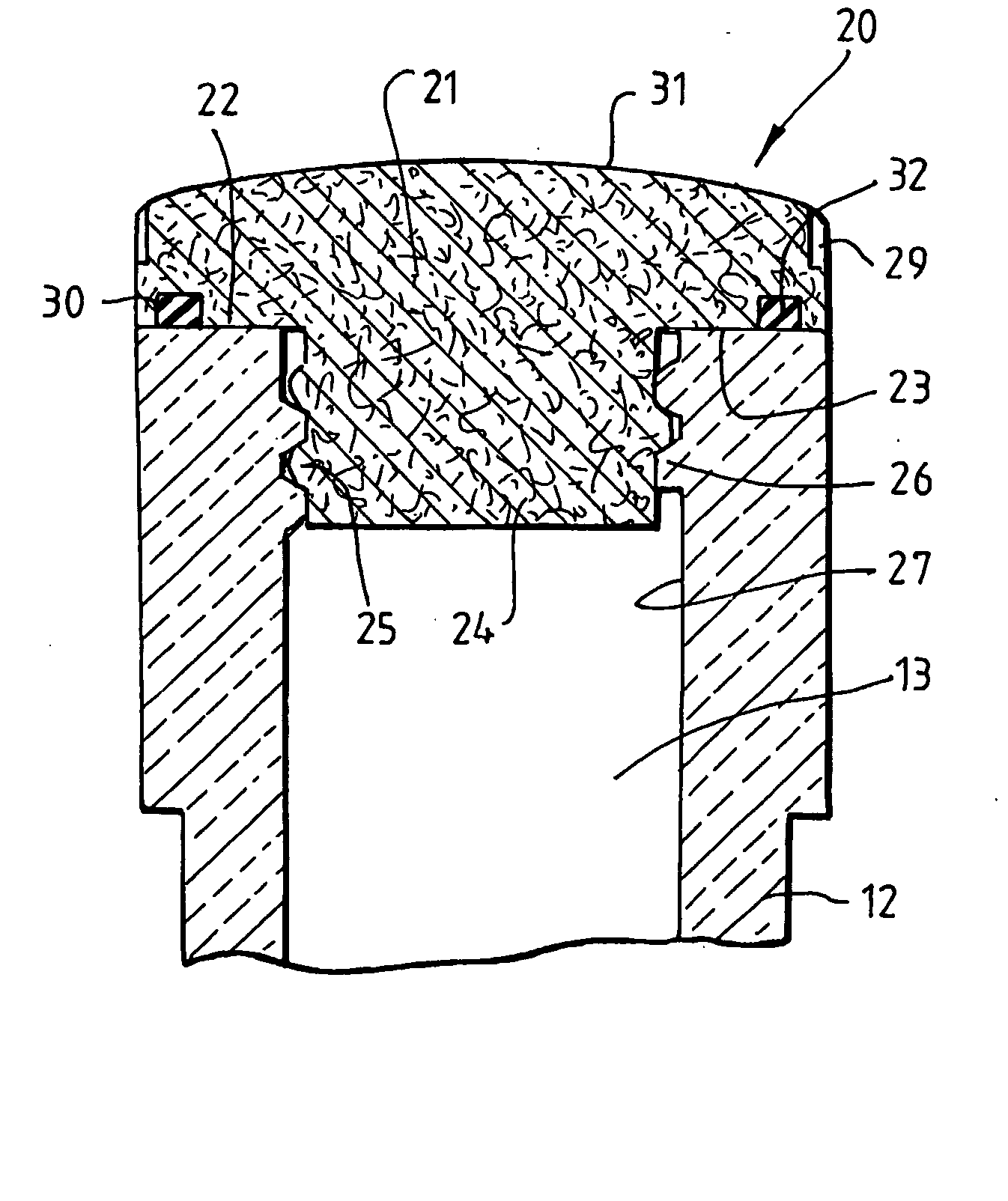

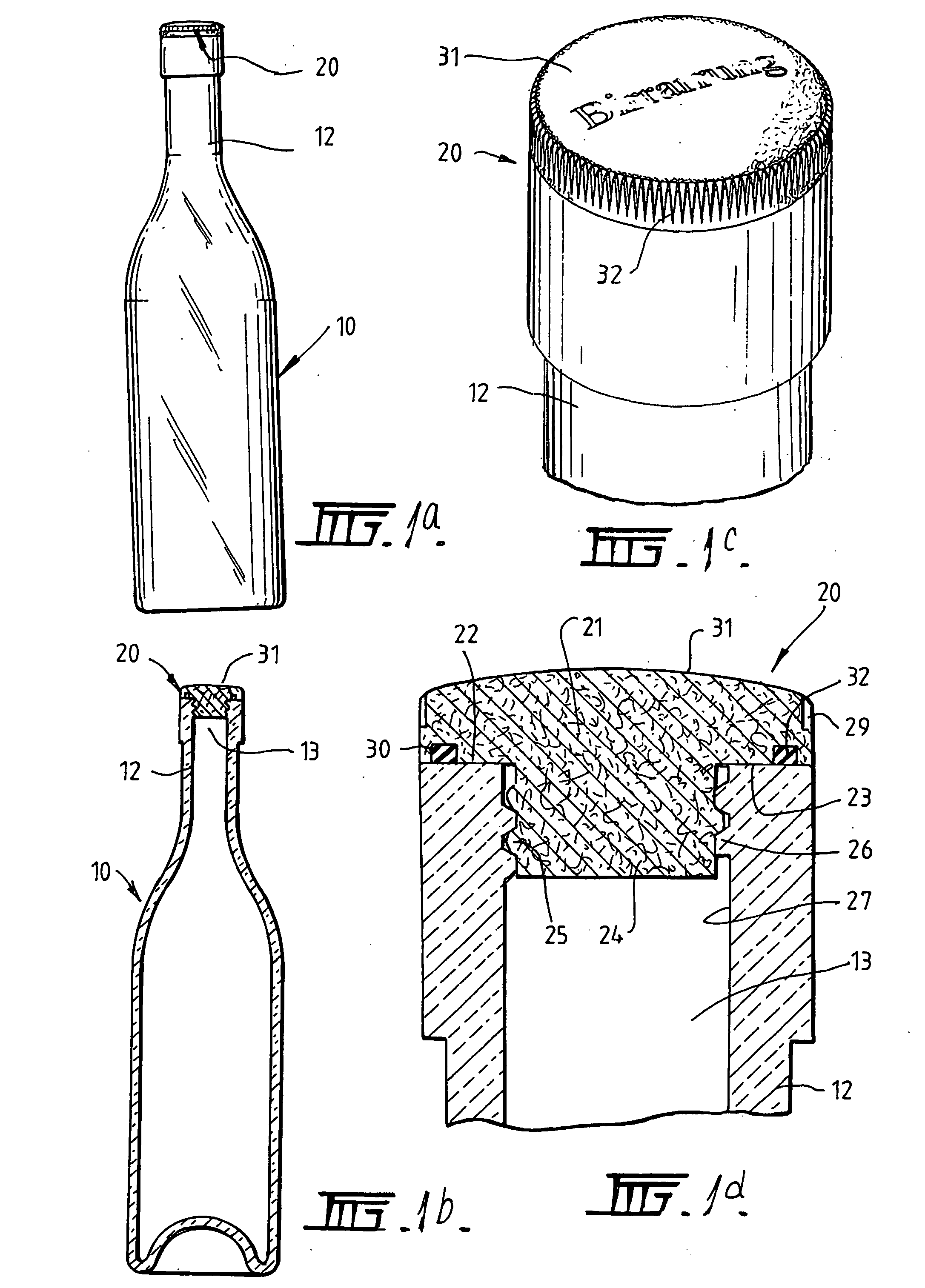

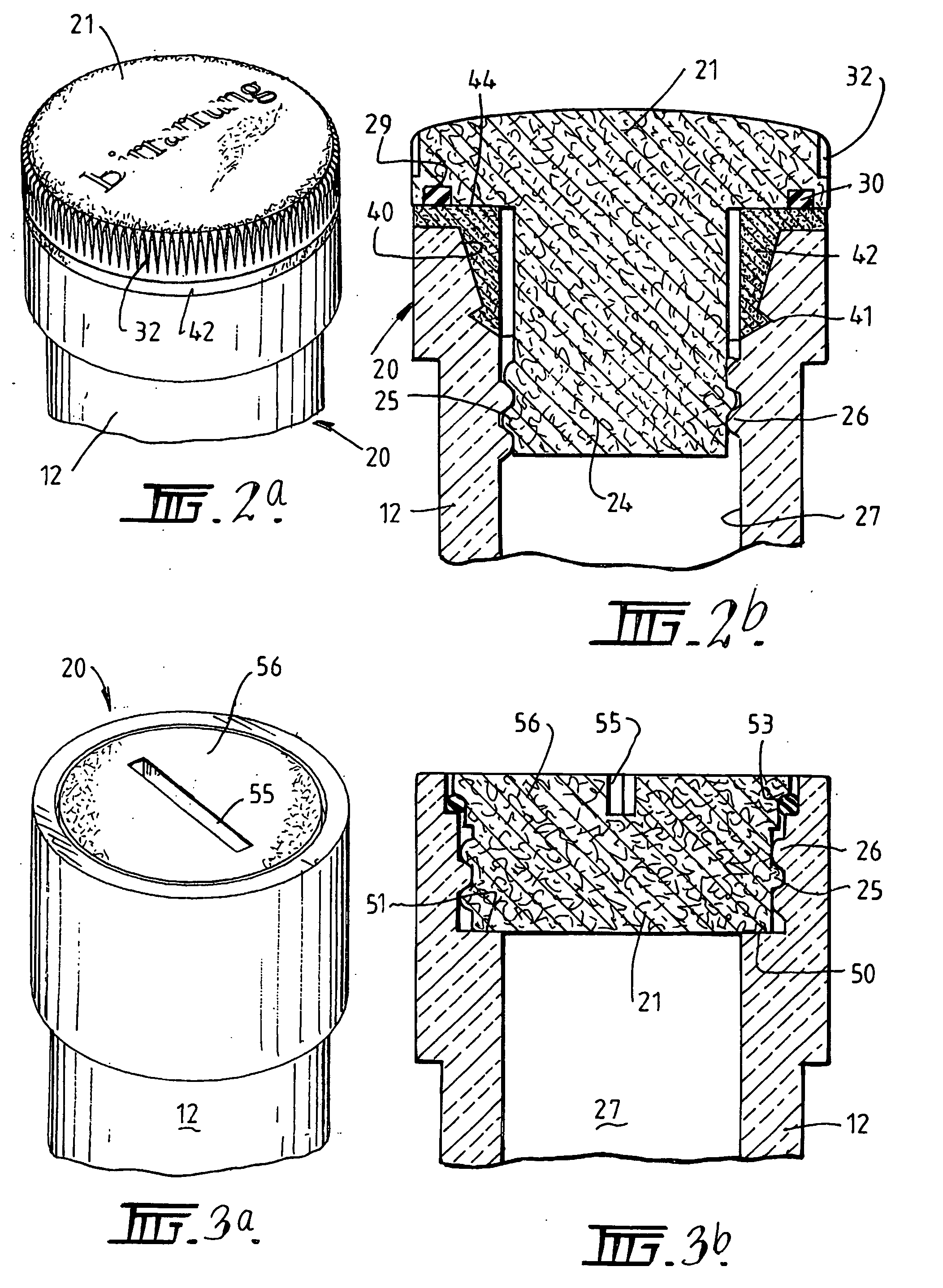

[0034] The embodiments of the invention described hereunder with reference to the accompanying drawings, all relate to closures for liquid containers and especially wine bottles. In essence the sealed closure is performed by the abutting contact between two extremely flat and smooth surfaces that are pressed into engagement to form a shear seal. All the embodiments include means to urge the surfaces into parallel abutting contact and to laterally locate the flat surfaces to prevent the seal being broken.

[0035] The abutting flat surfaces are extremely flat with the flatness being in the order of a few wavelengths of light. The wavelength of light in the visible spectrum range is between about 400 nanometres for deep violet and about 700 nanometres for deep red. A nanometre is a billionth of a metre. The flat surfaces that form the shear seals may be formed in glass with one portion defined by a hardened coating on the bottle itself and the other portion being defined by a glass or o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Content | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com