Patents

Literature

284results about "Threaded closures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

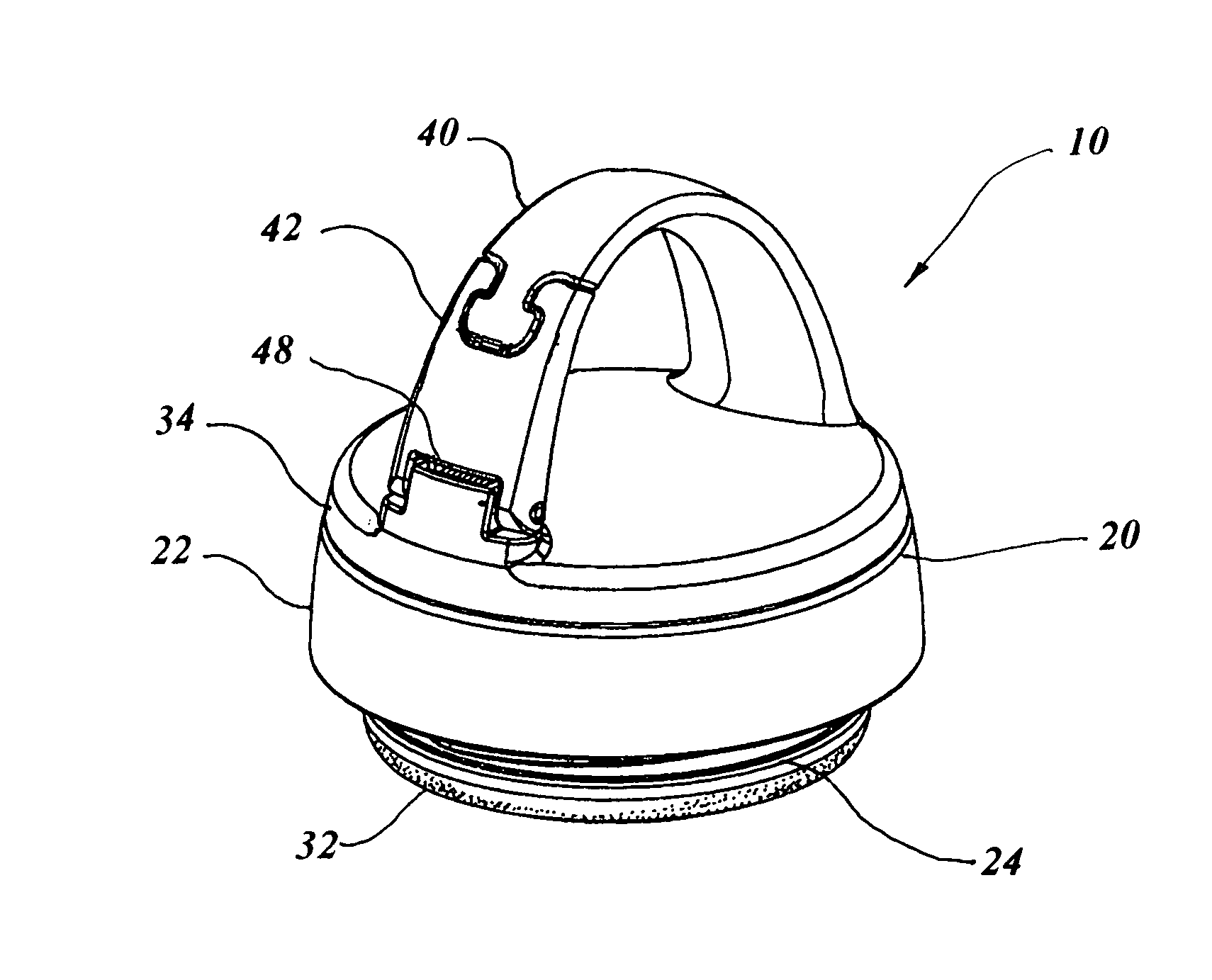

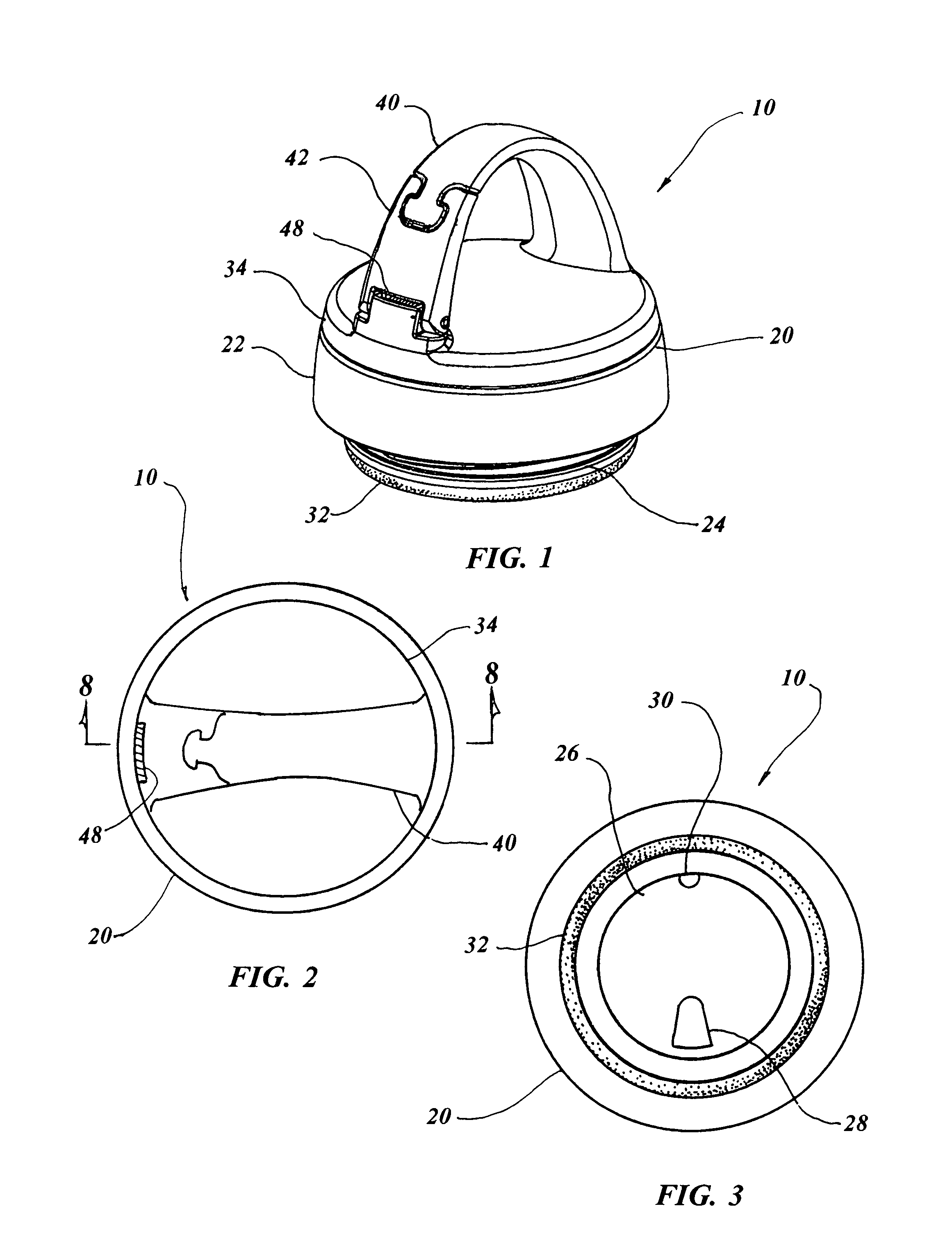

Latched handle container lid

A container lid with a latch handle is taught that incorporates a drinking lip, having a flared brim, configured to interface with a liquid container. A lip sealing ring is disposed on the drinking lip creating a watertight fit between the lip and the container. A lid body, having lid male threads, is configured to interface with container lid female threads, and the lid body includes a bottom cover which forms a dead air space for insulation purposes within the lid. The lid body incorporates a vertical arched handle with a snap-in hinged spring loaded latch for quick release attachment of the container lid and container securely to an object. A lid sealing ring is disposed on the lid body forming a watertight fit between the lid body and the container drinking lip.

Owner:LIN SHIN SHUOH

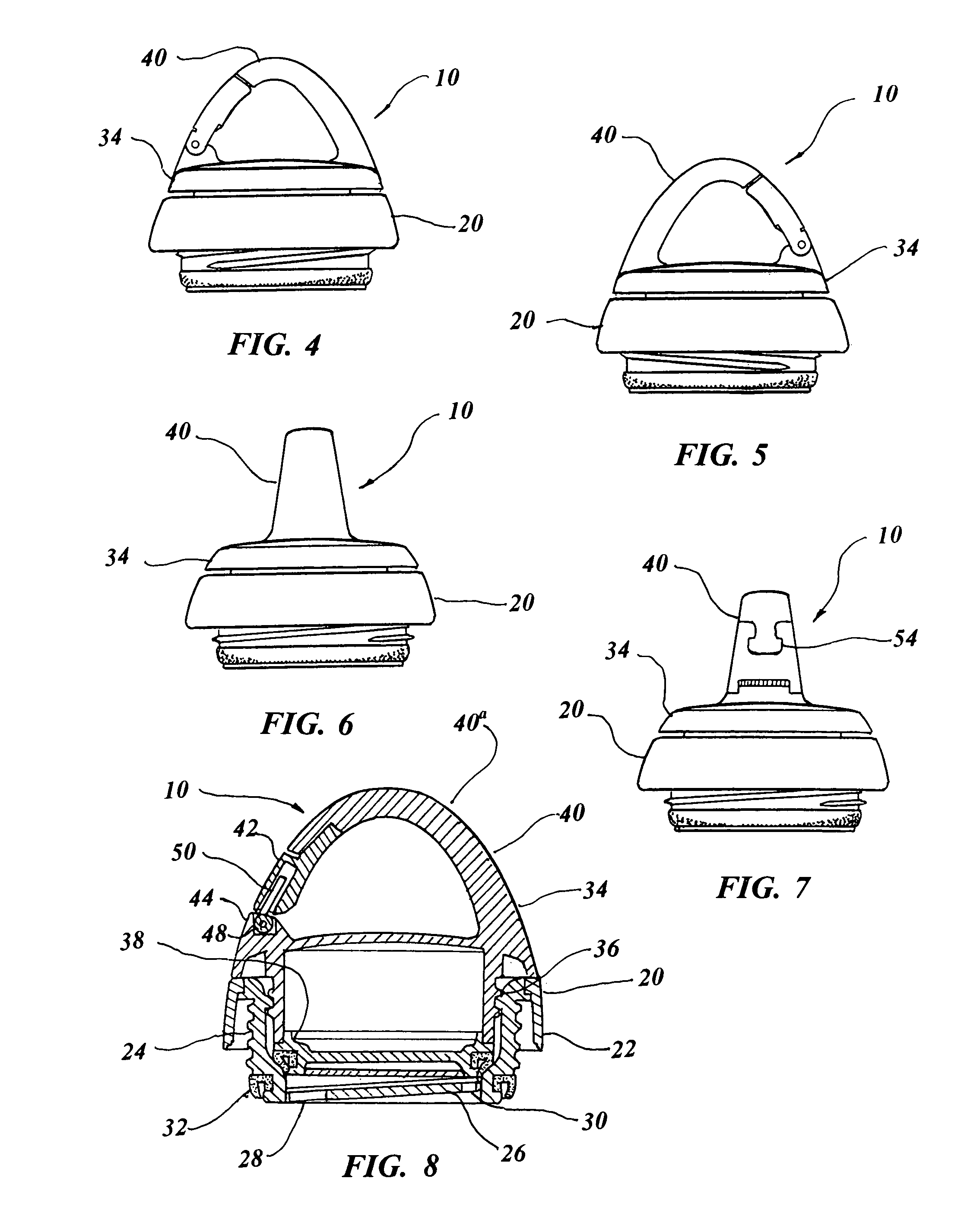

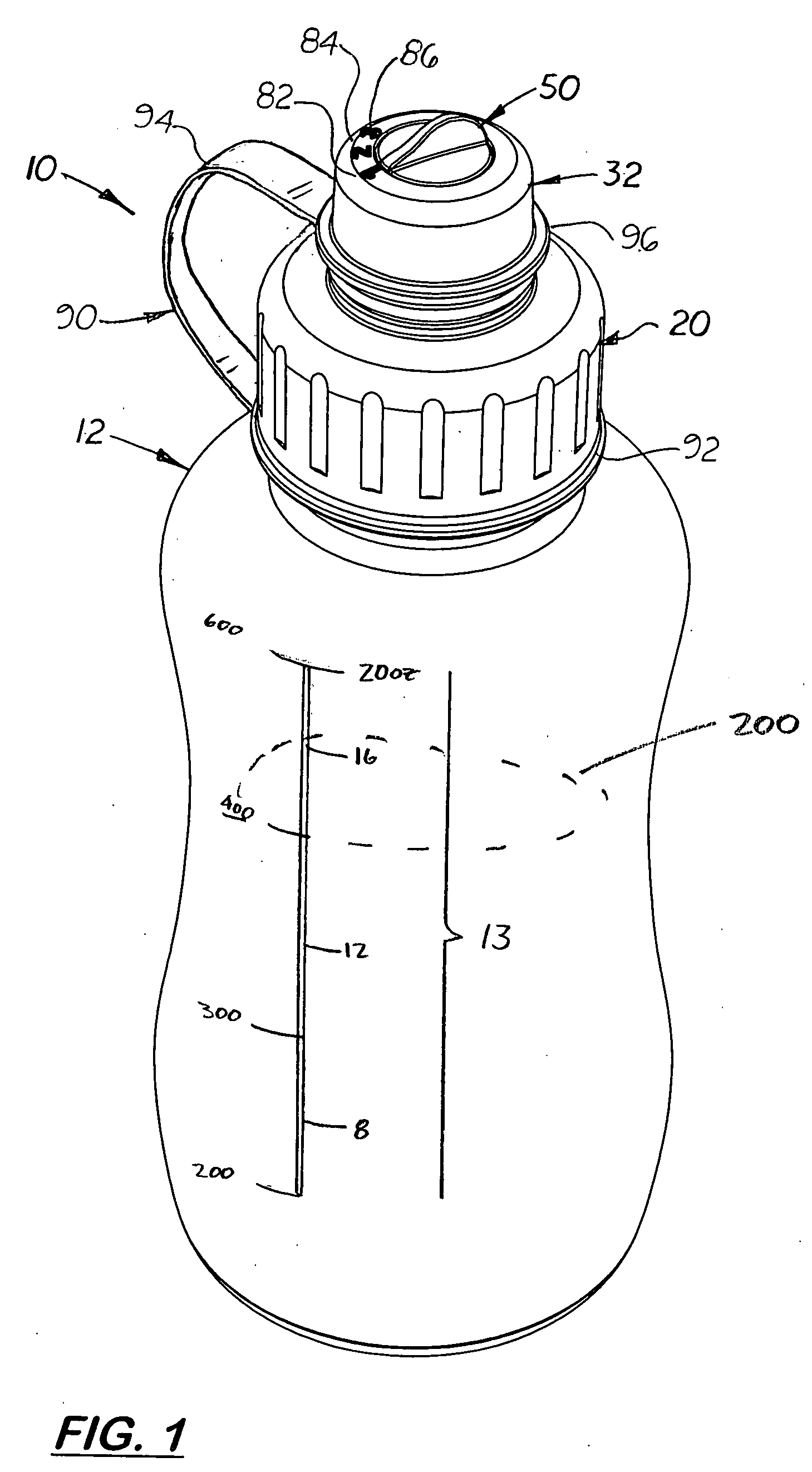

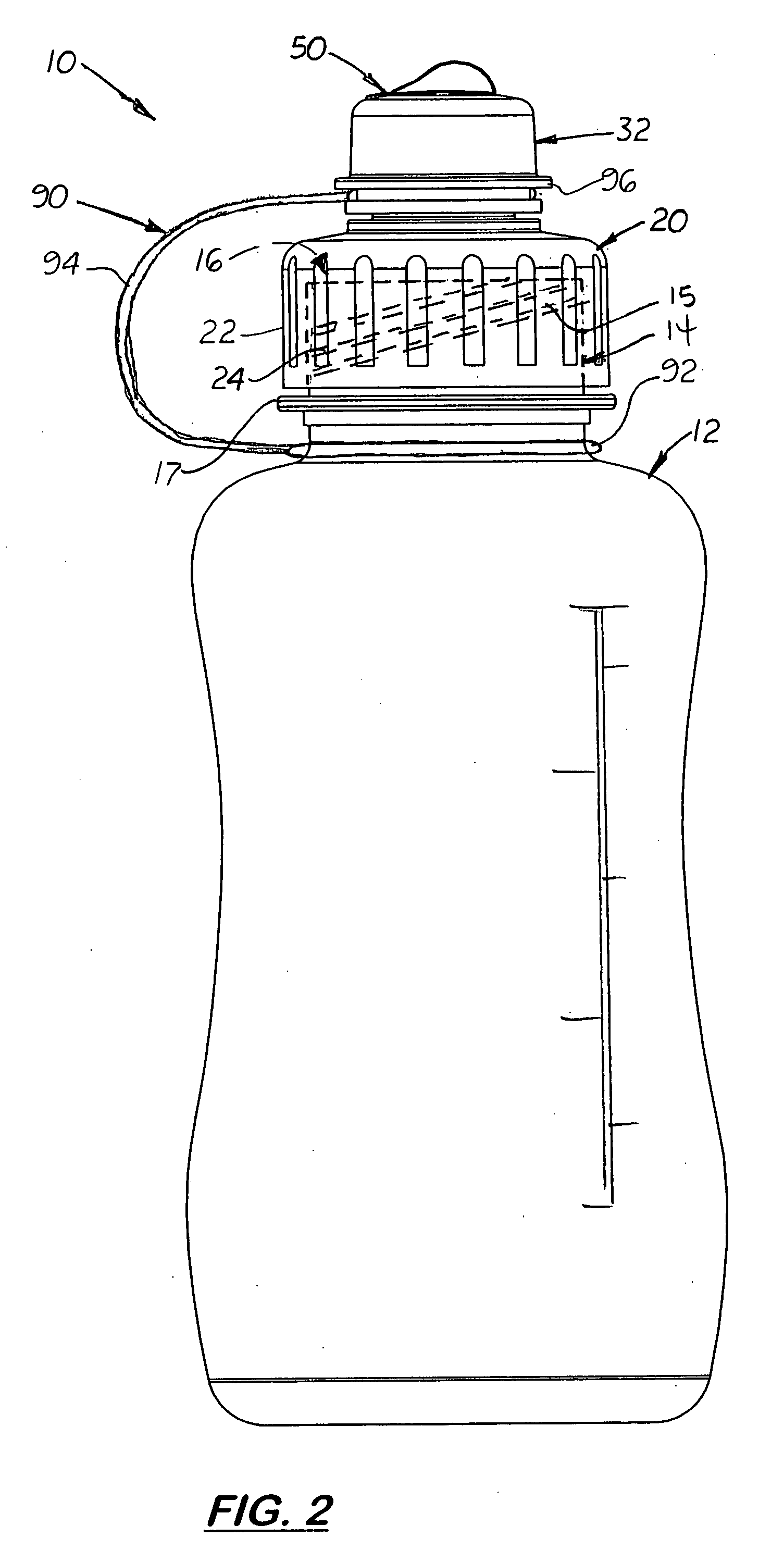

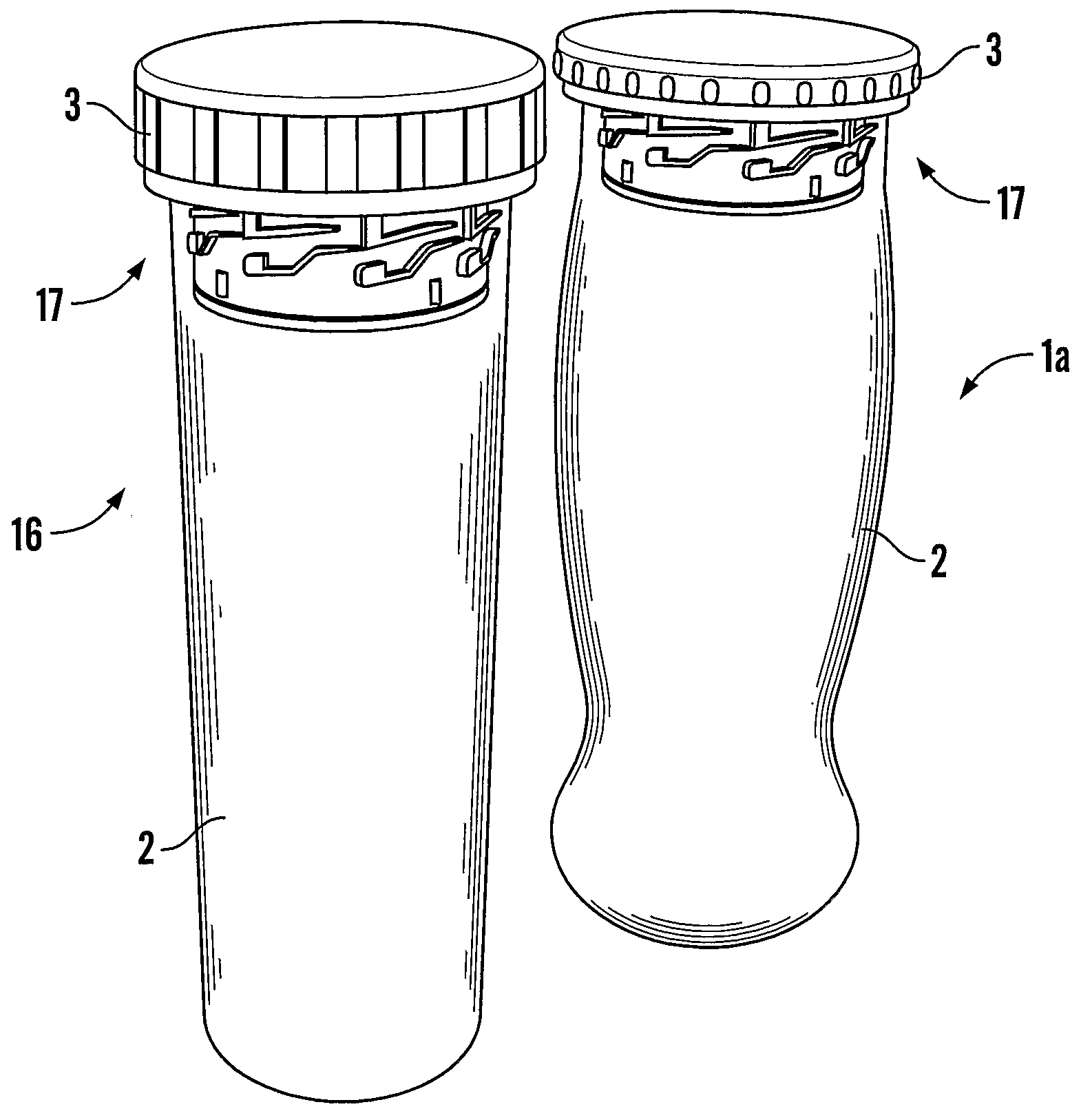

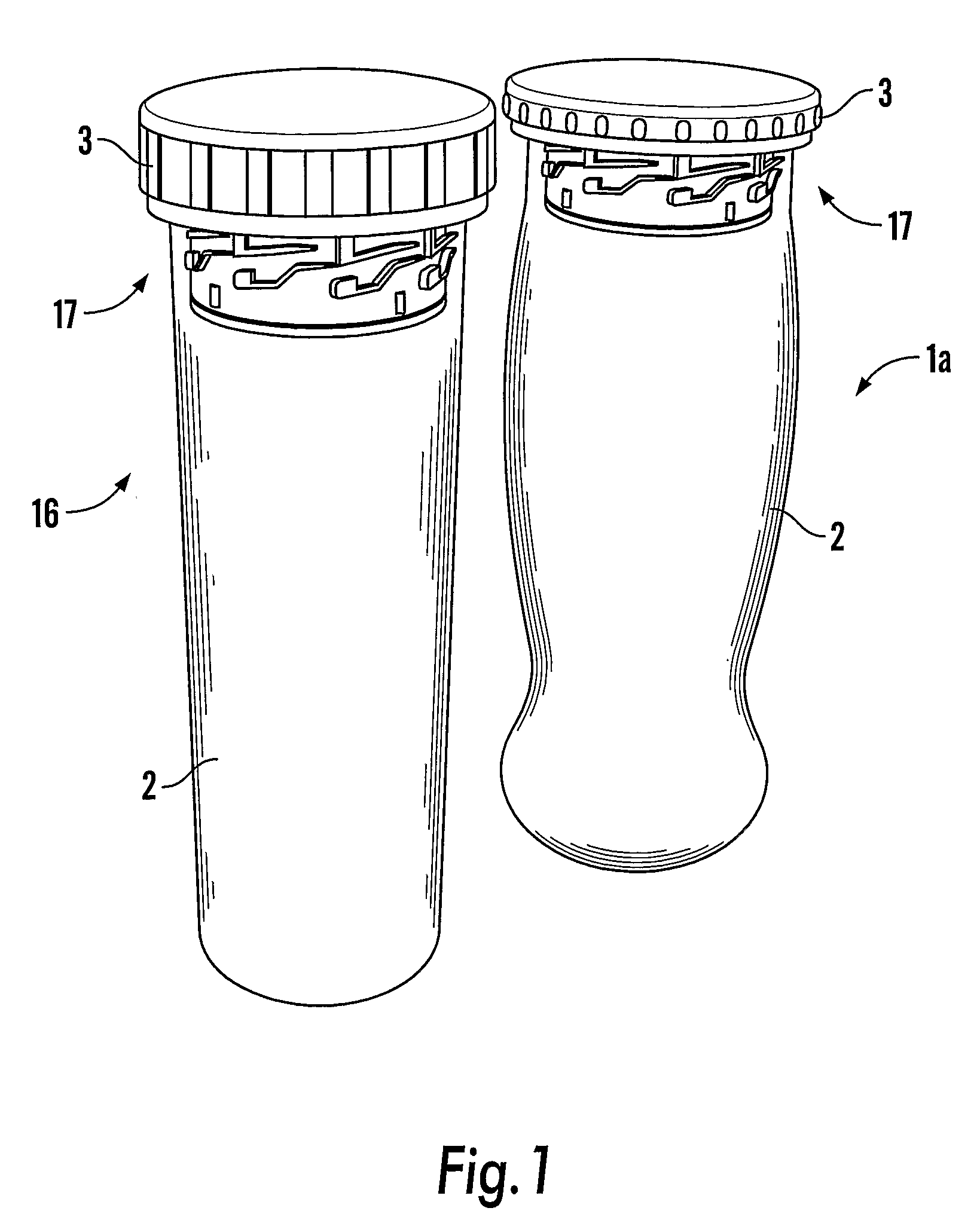

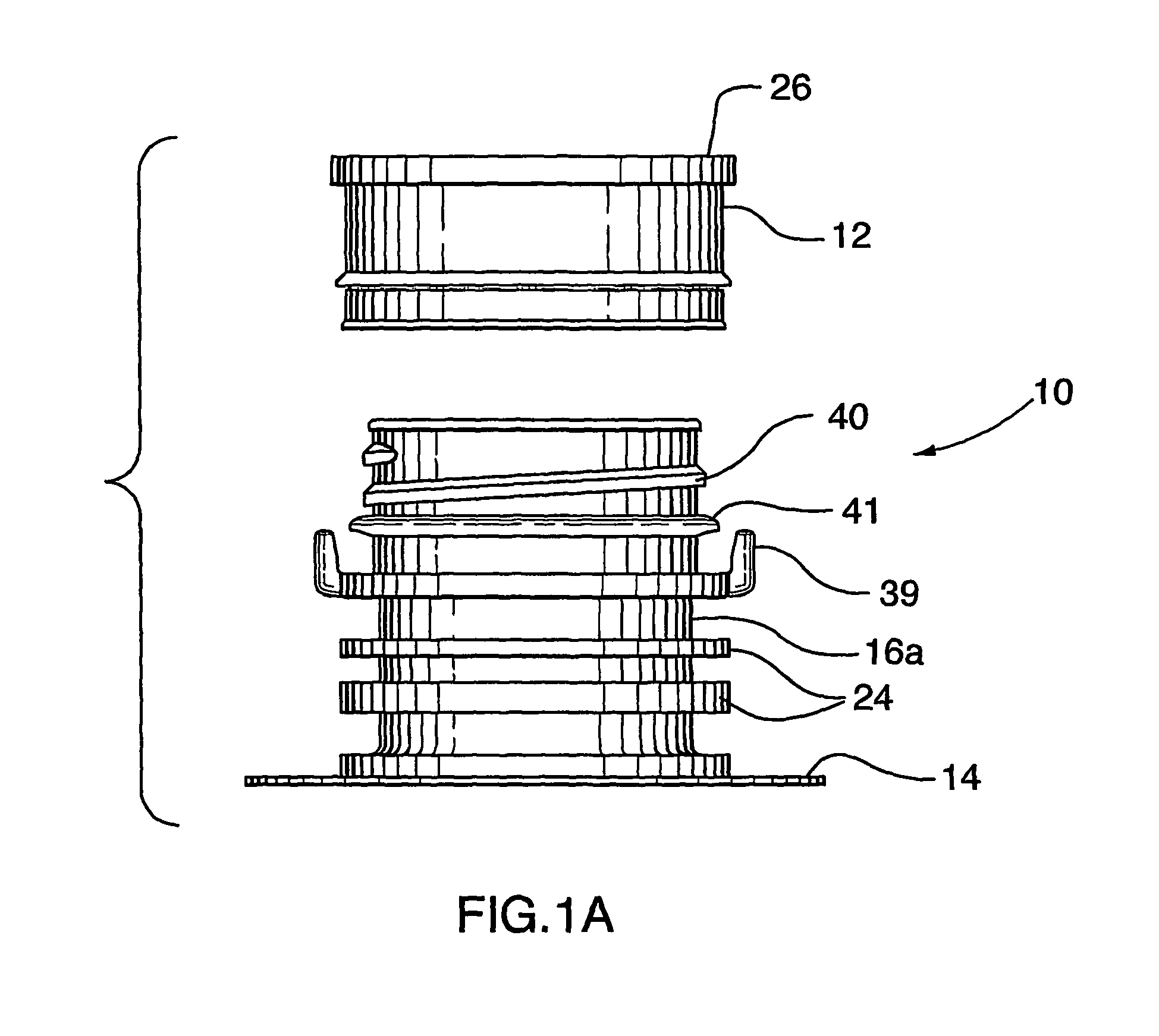

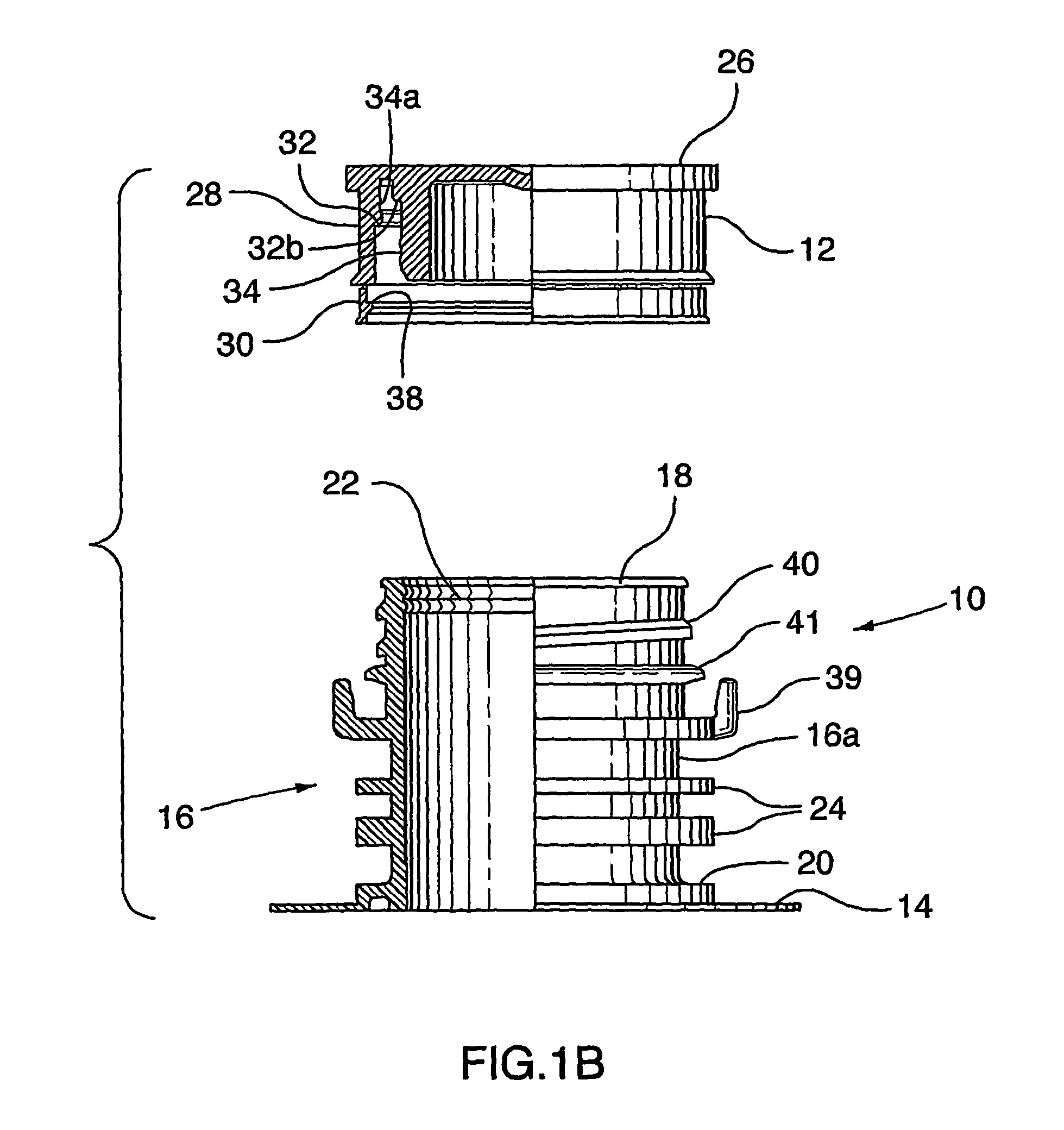

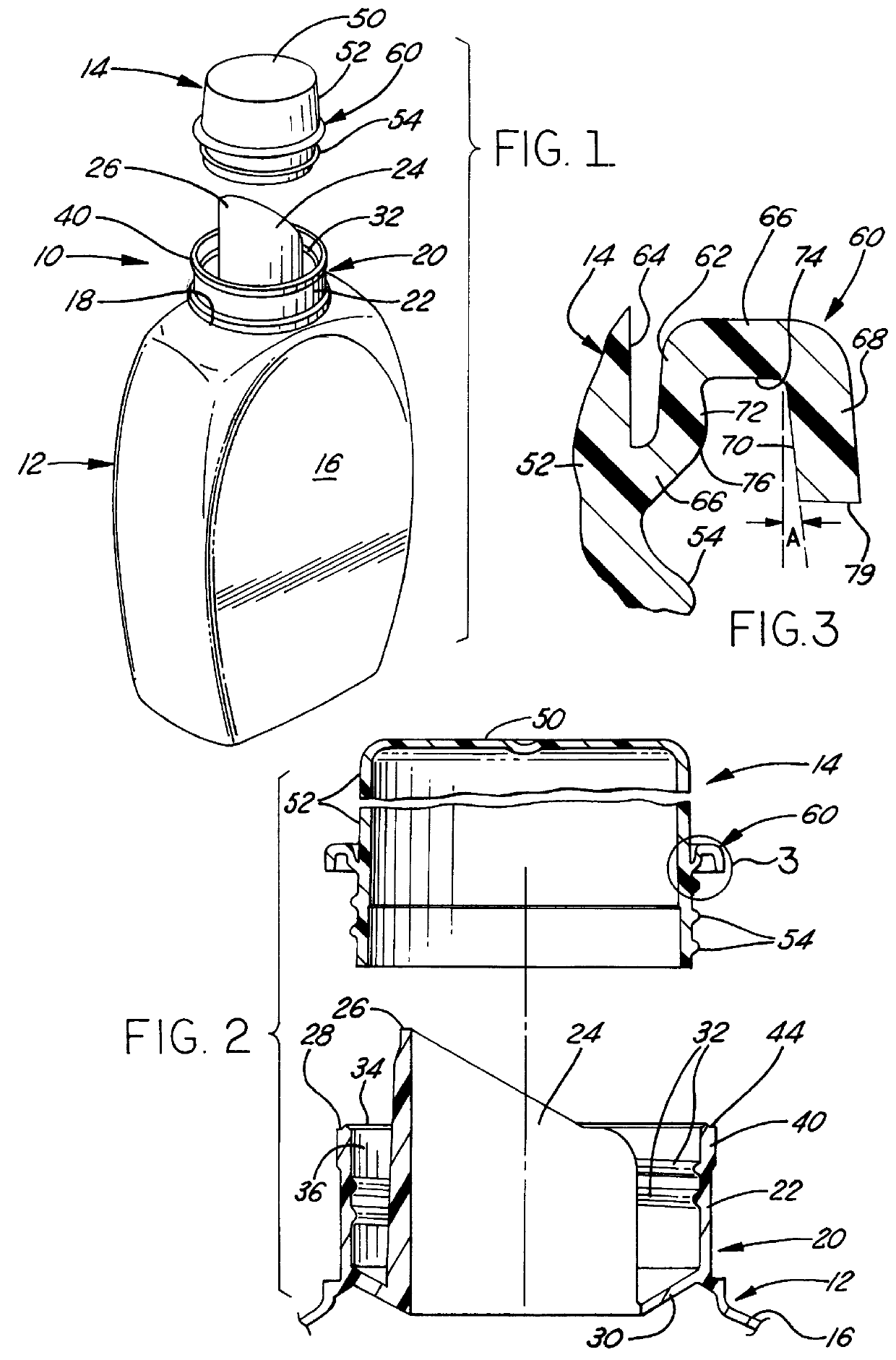

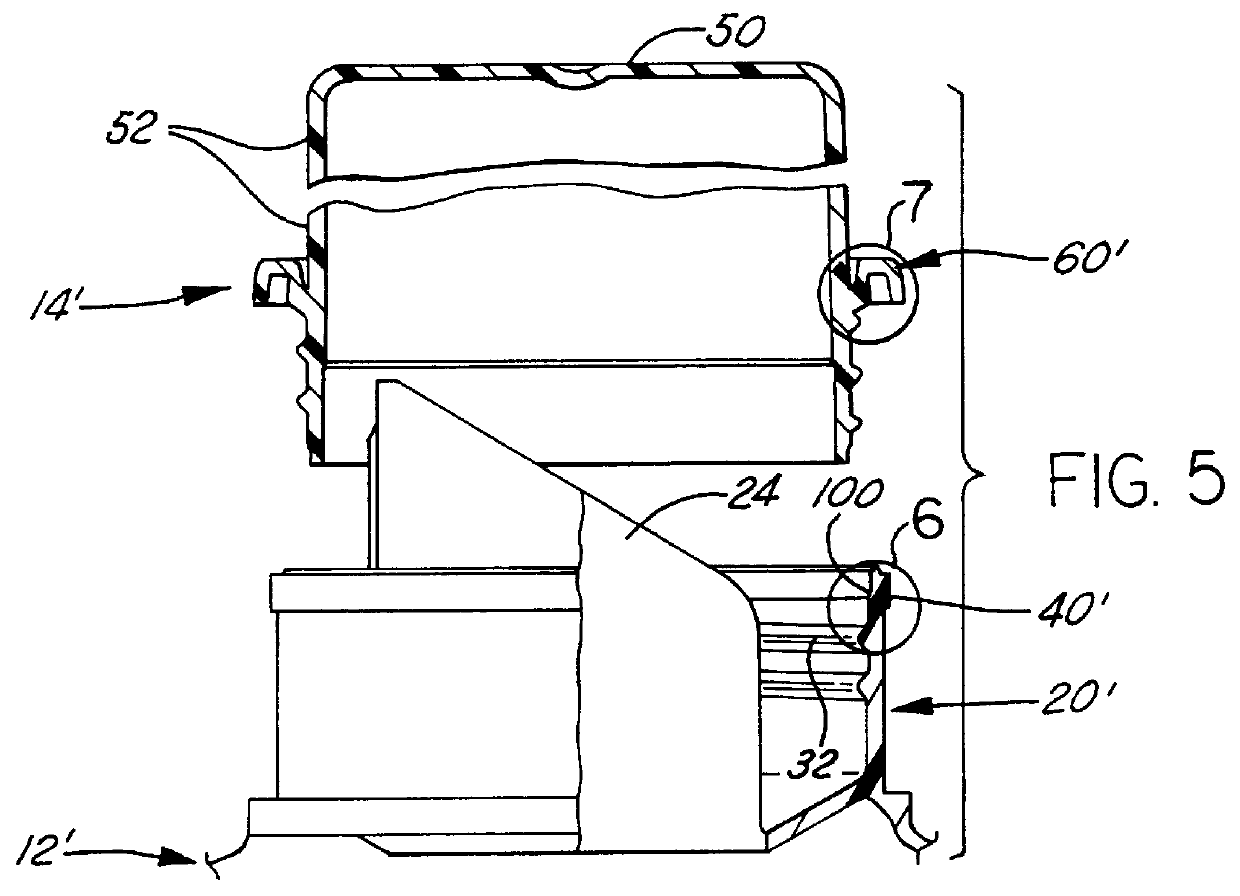

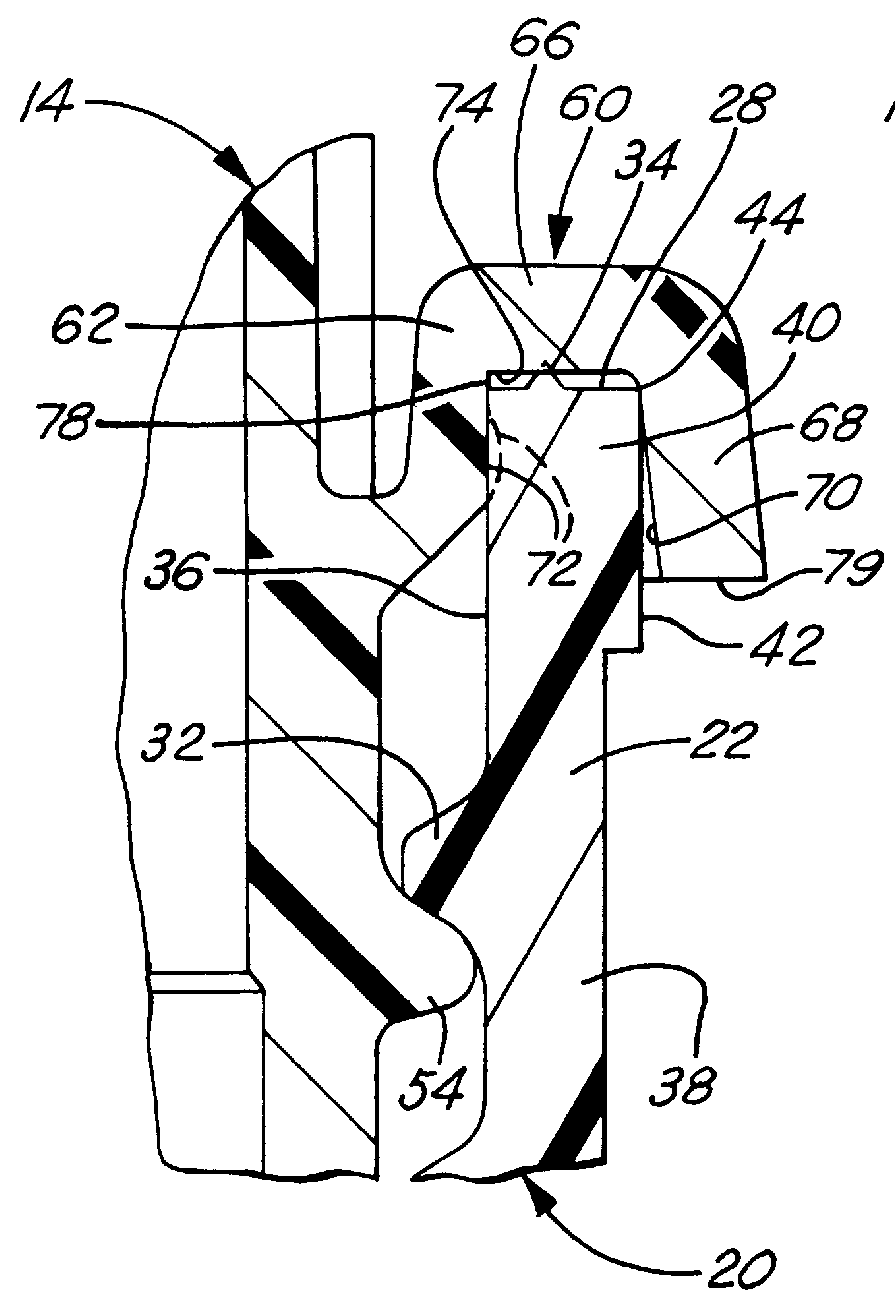

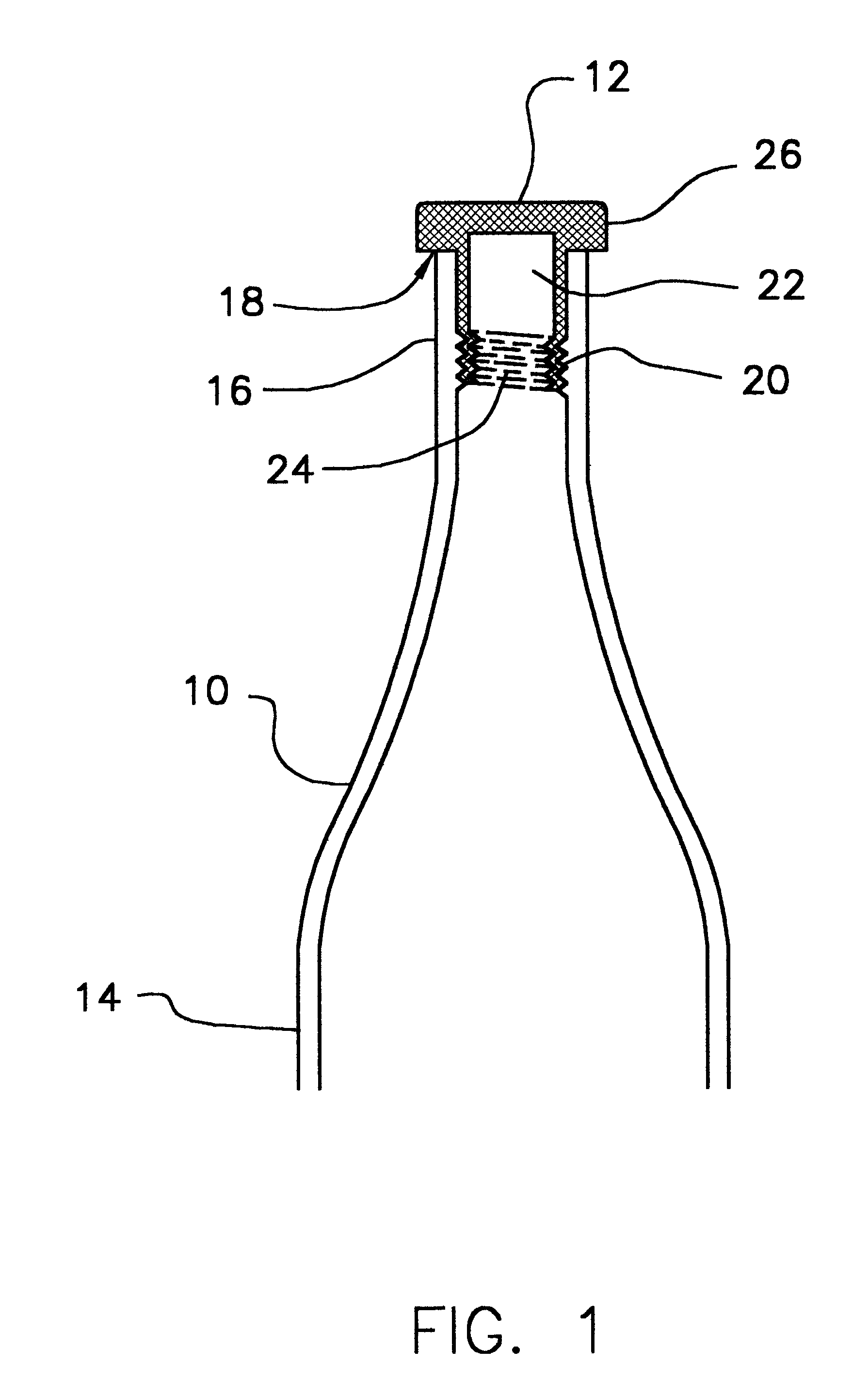

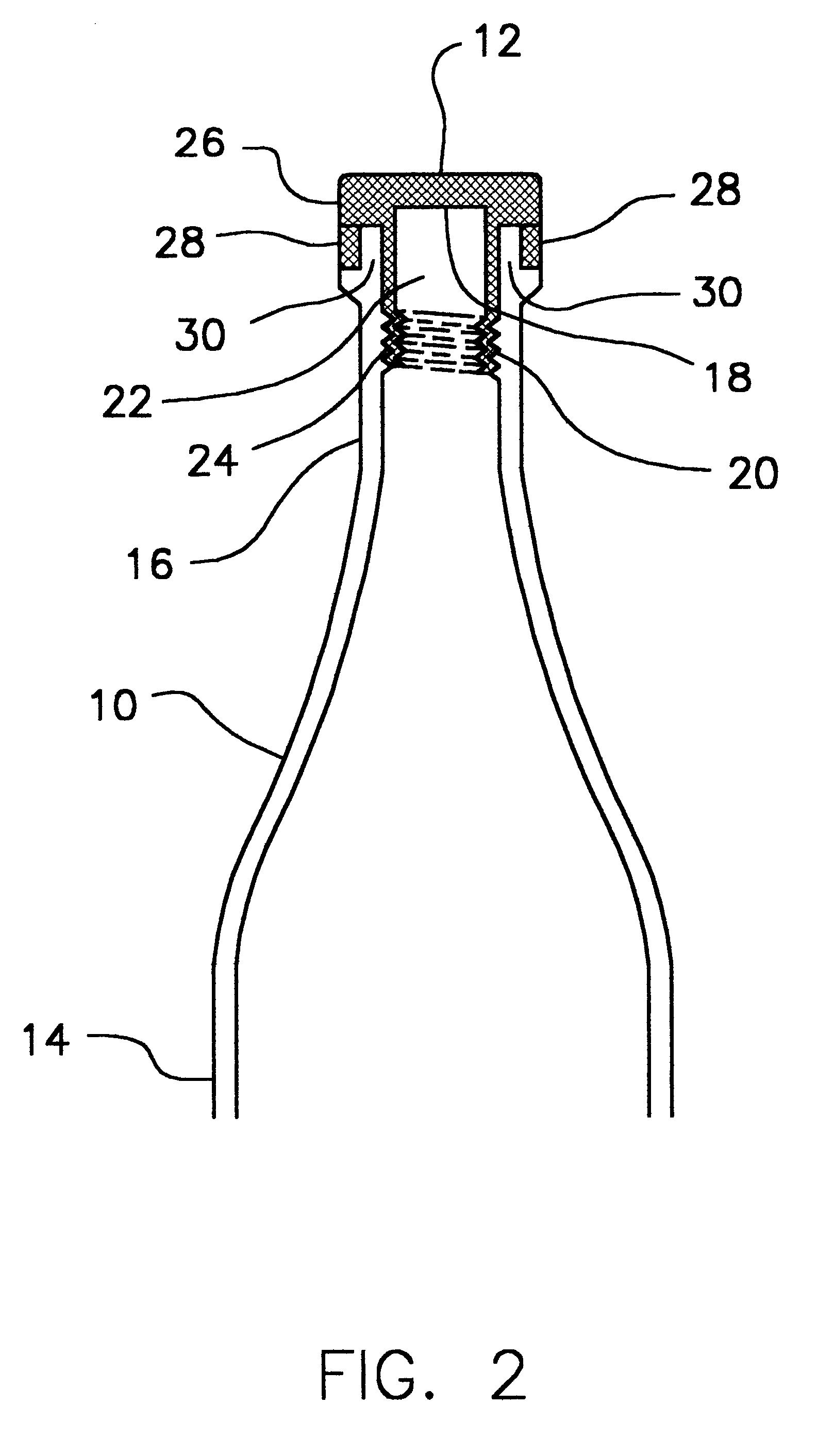

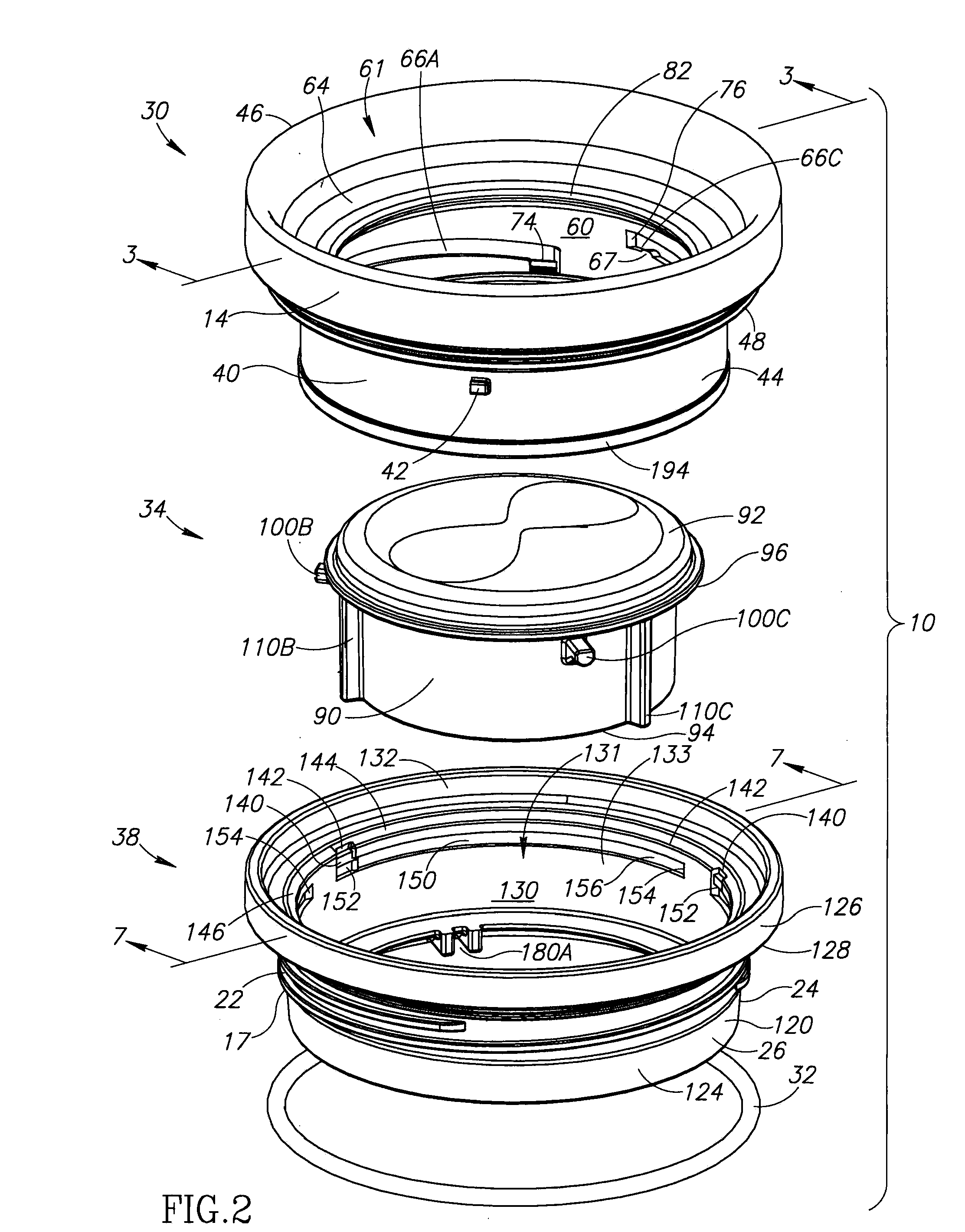

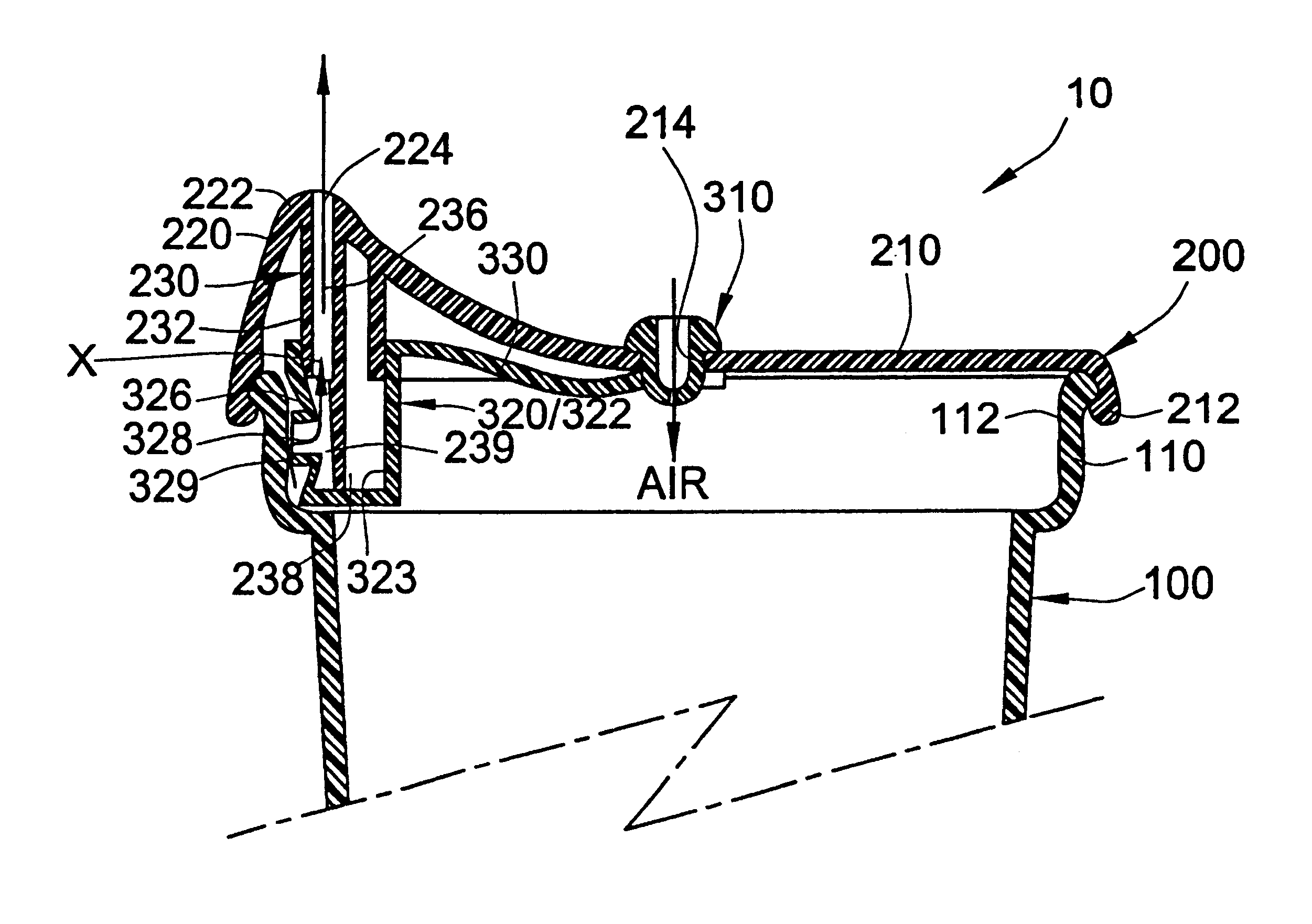

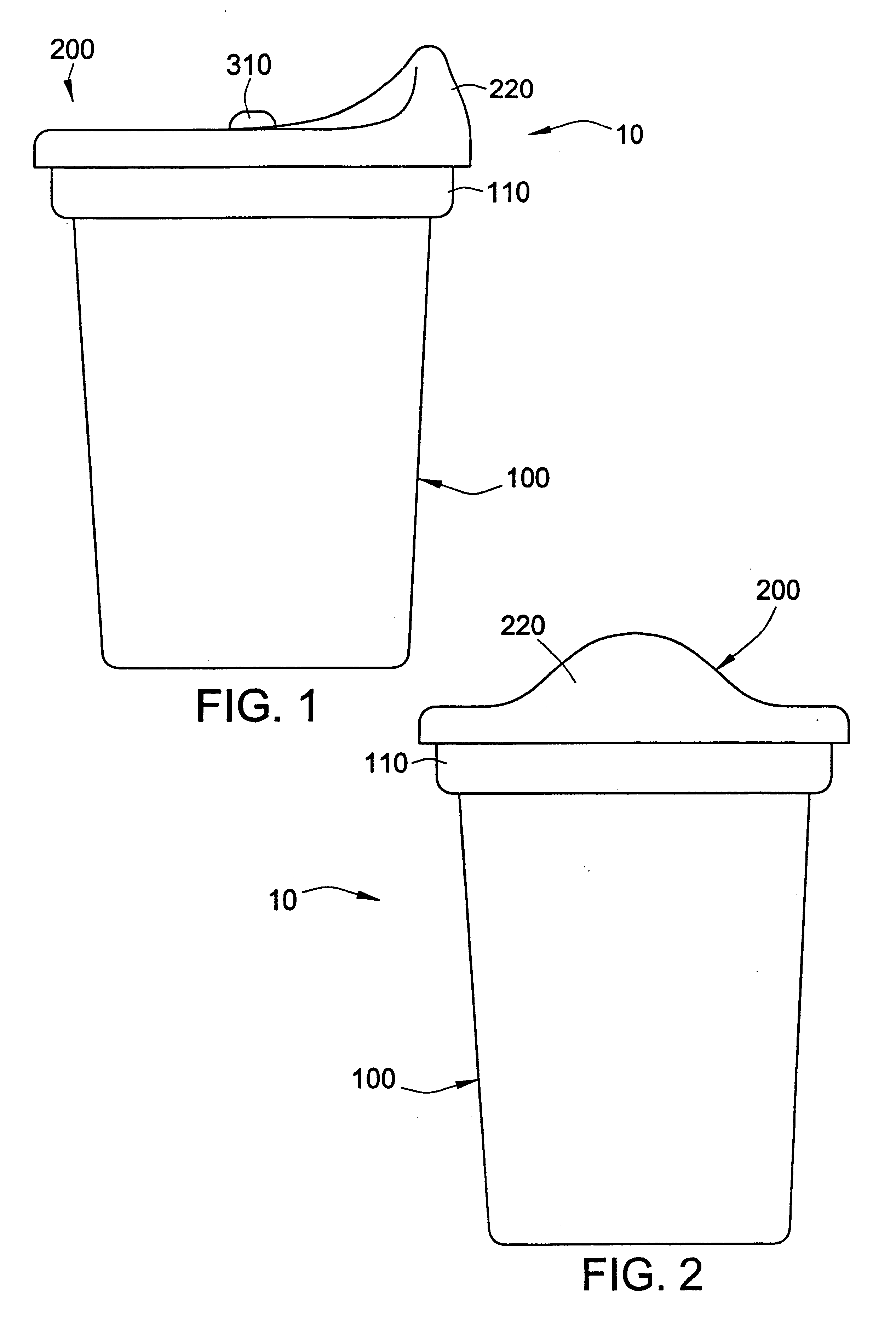

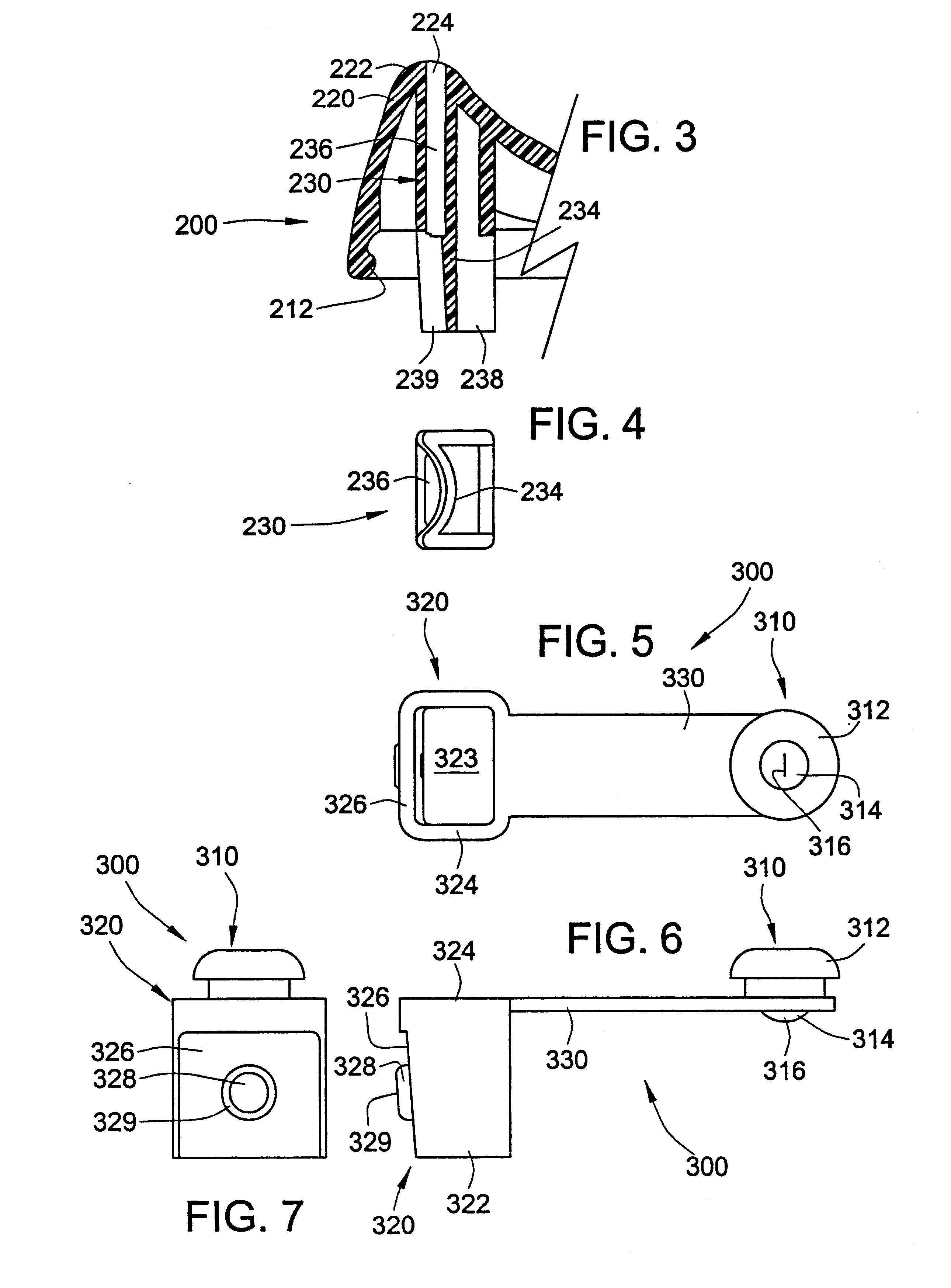

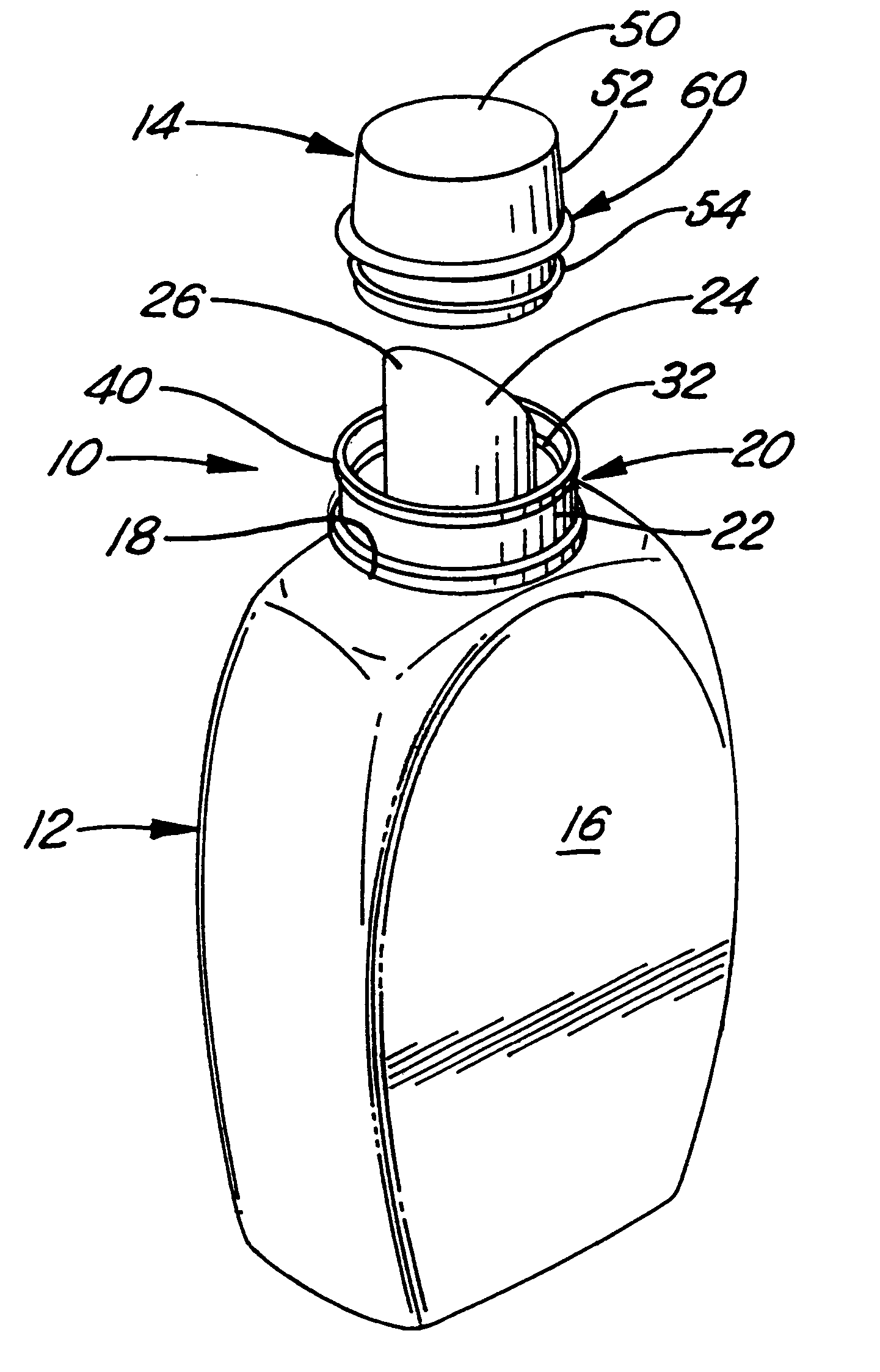

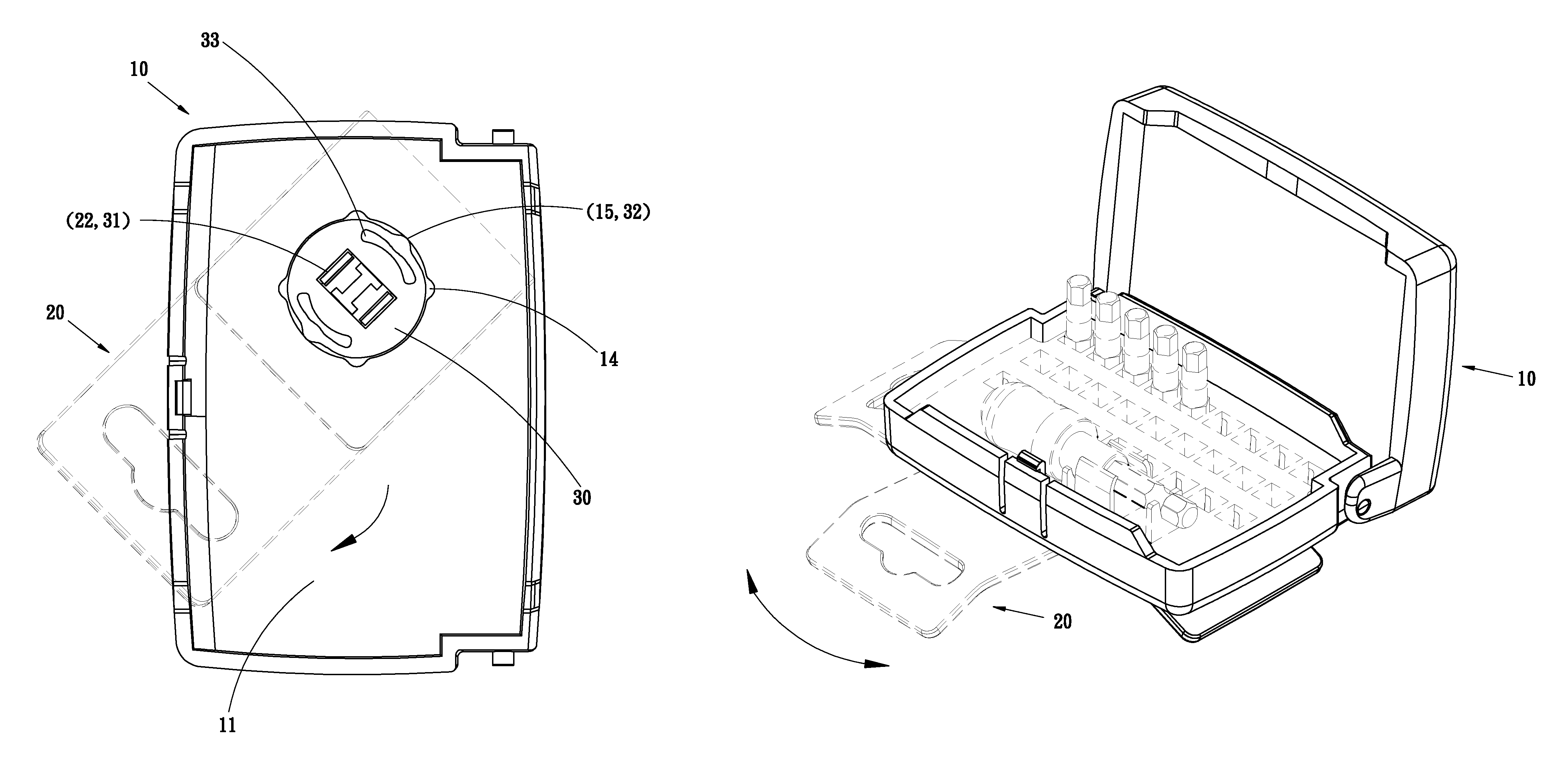

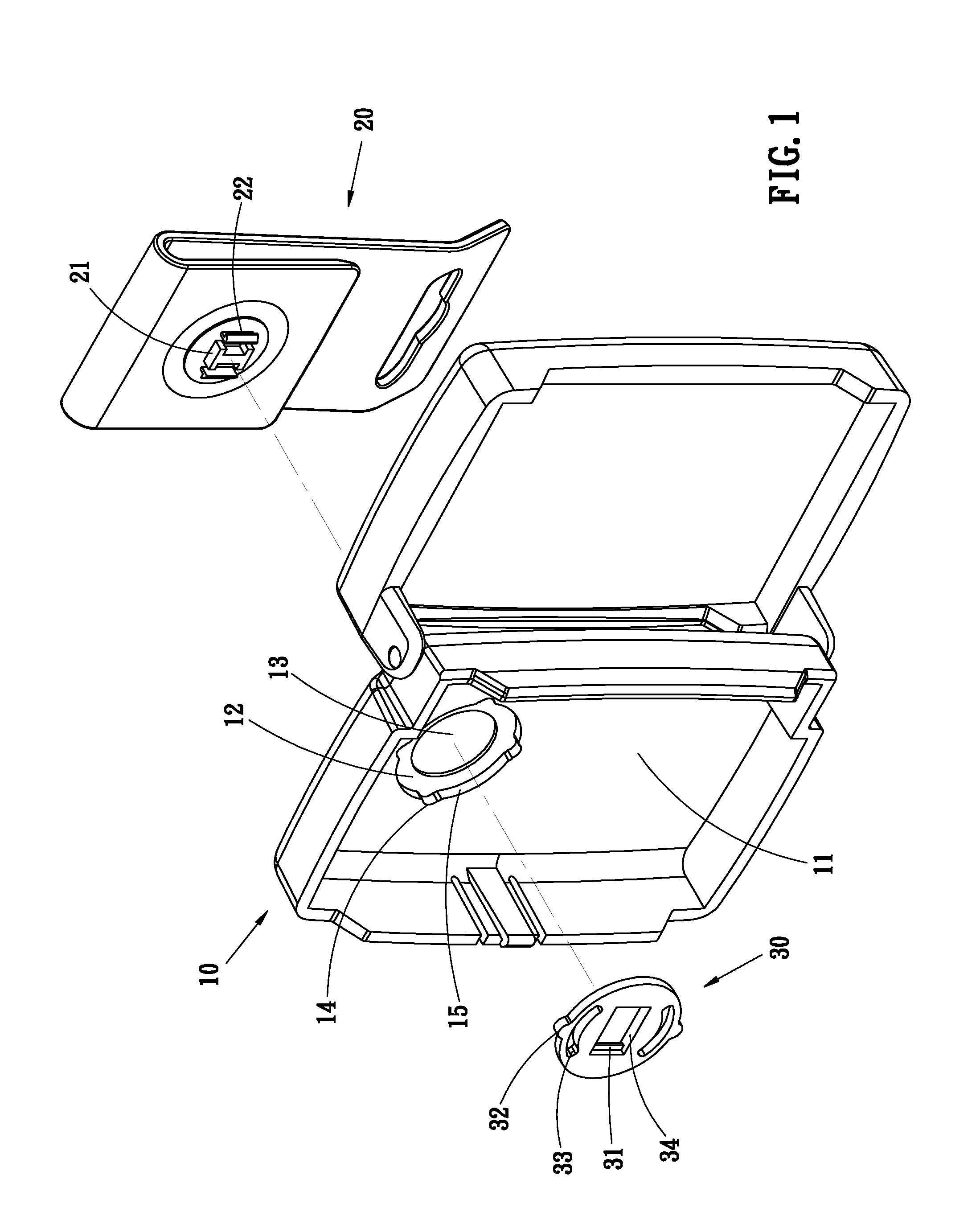

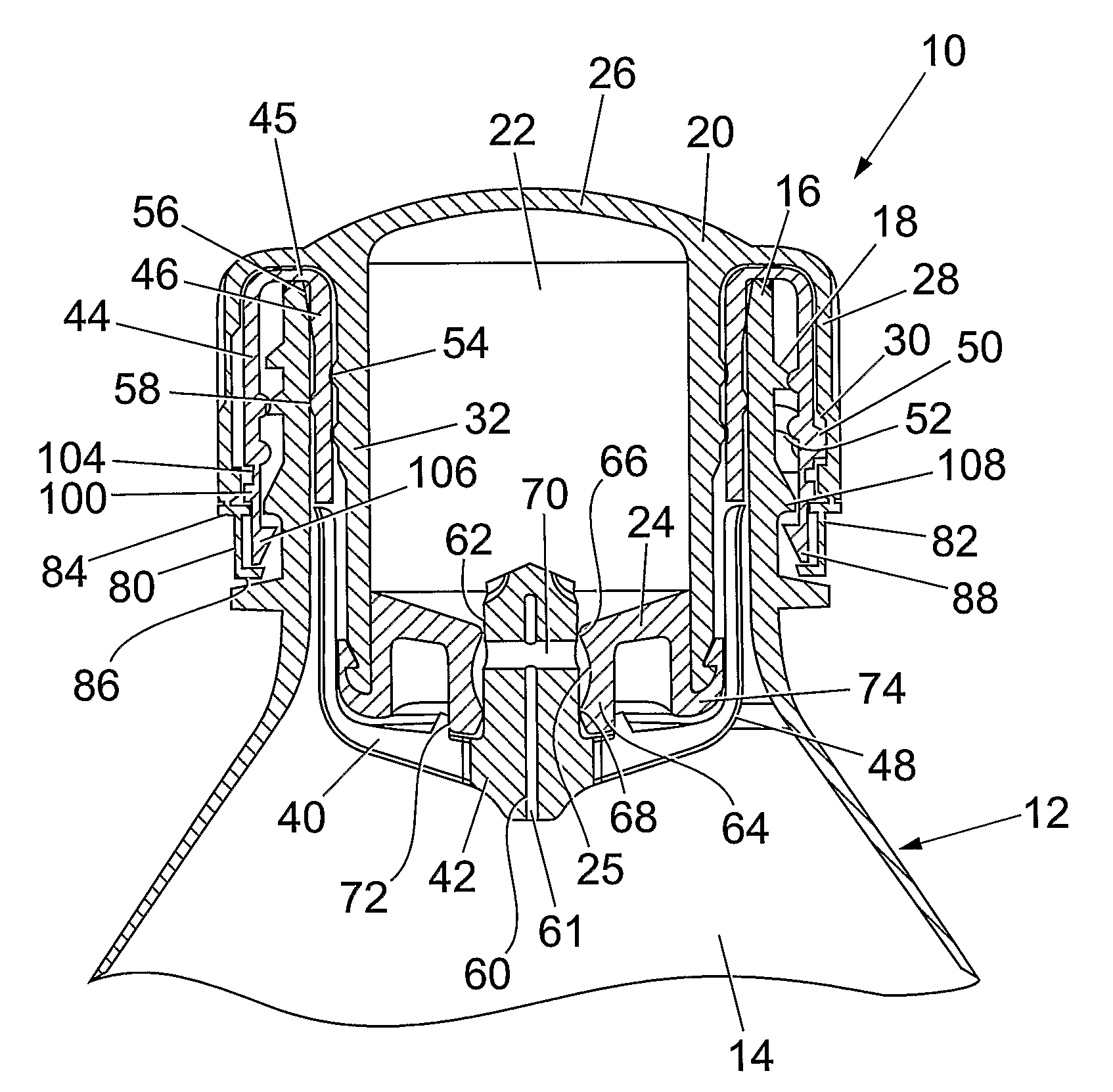

Daily water bottle consumption system

ActiveUS20080087624A1Promote hydrationLow costCapsDispensing apparatusWater bottleElectrical and Electronics engineering

A daily water bottle consumption system that includes a bottle with a threaded neck and a top opening. Attached to the neck is an intermediate cap with internal threads that selectively connect to the external threads on the bottle's neck. Formed on the intermediate cap is a threaded spout to which a removable lid is attached. The lid includes a cylindrical shaped lid body with a first recessed cavity in which a rotating turn dial is disposed. Disposed between the first recessed cavity and the turn dial is a snap ring that enables the turn dial to be manually turned and click into one of a plurality of coded positions. Formed on the turn dial is a handle which the user grasps and rotates to indicate the number of times the bottle has been filled with a desired liquid in a 24 hour period.

Owner:BUCKLEY MICHAEL

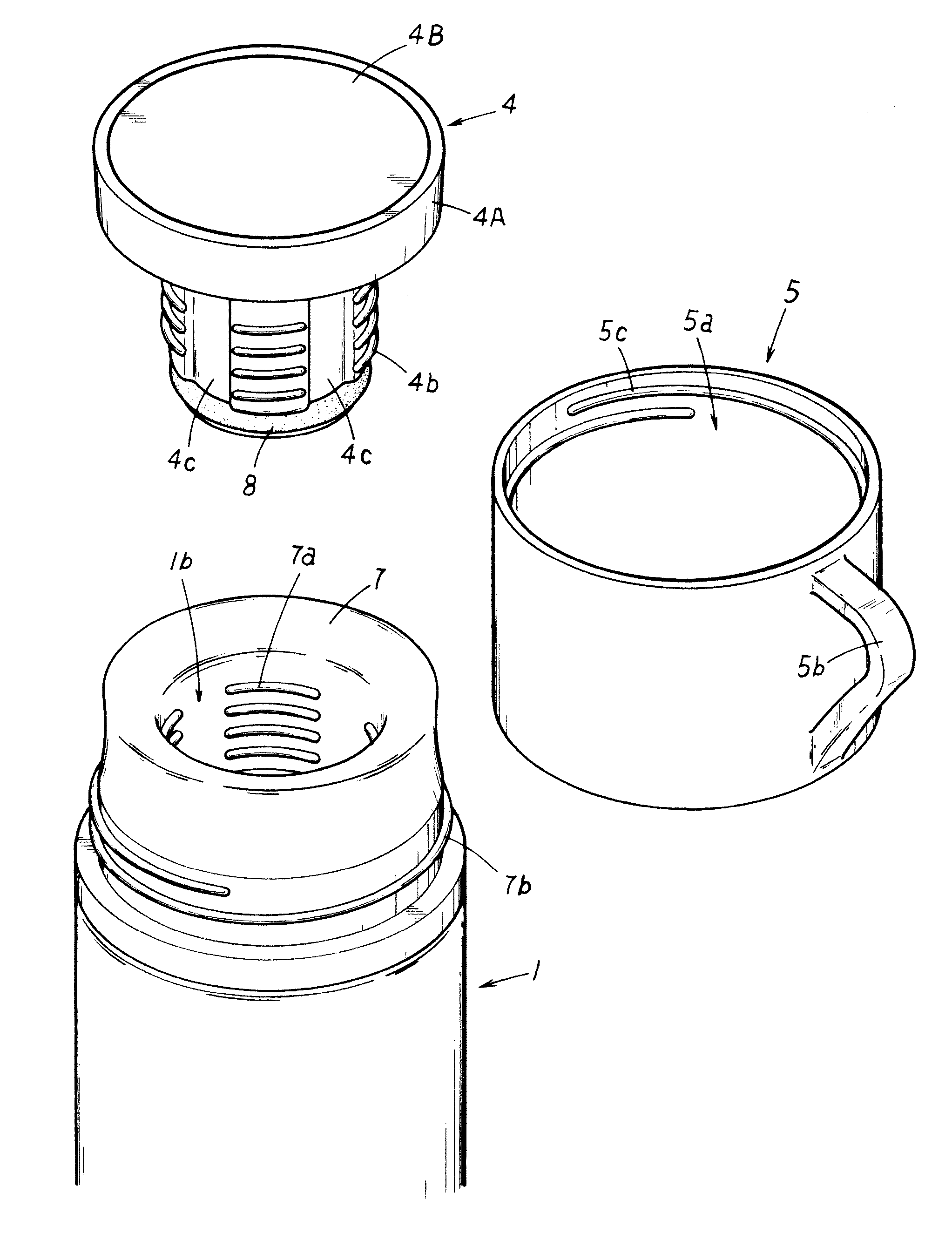

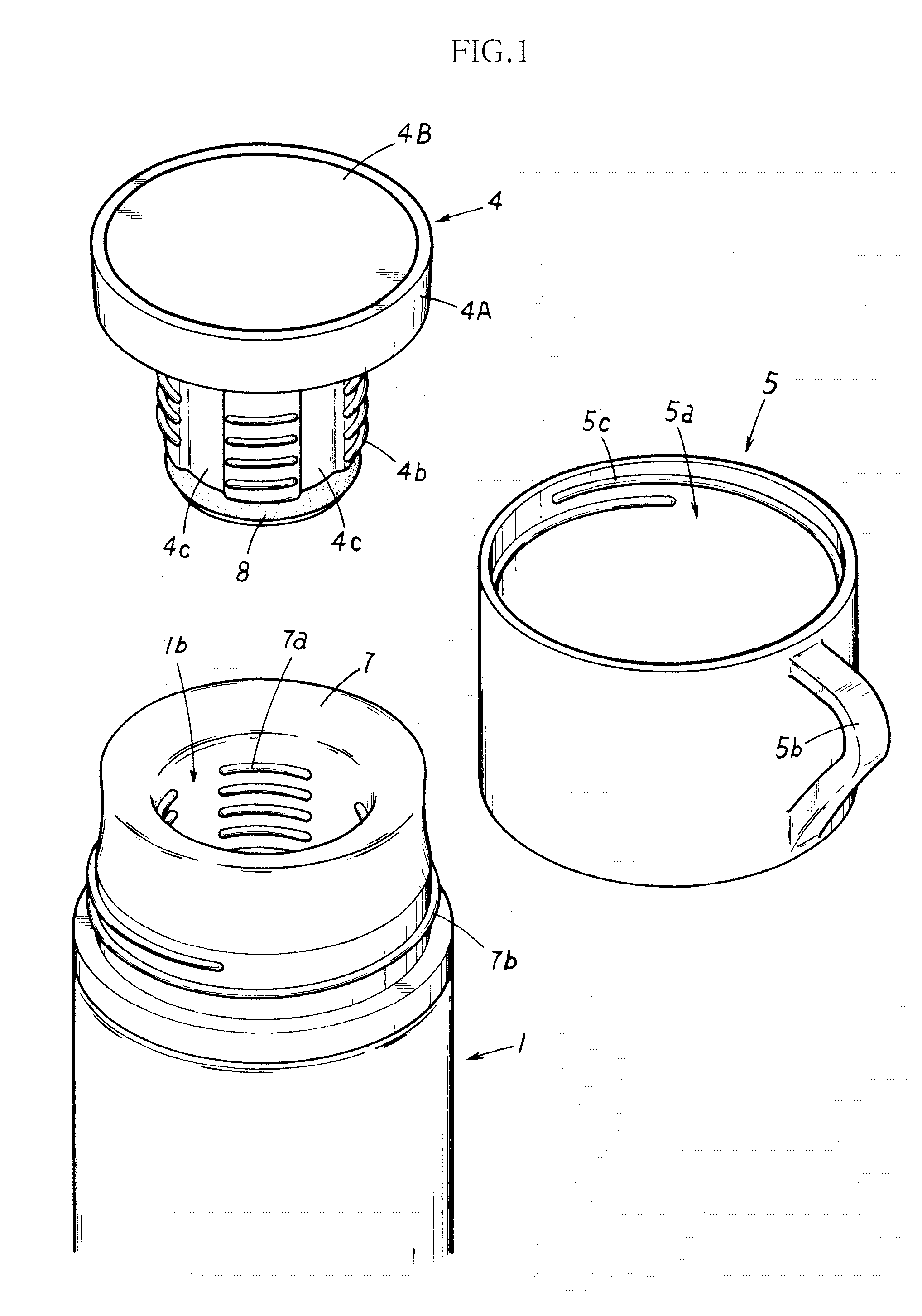

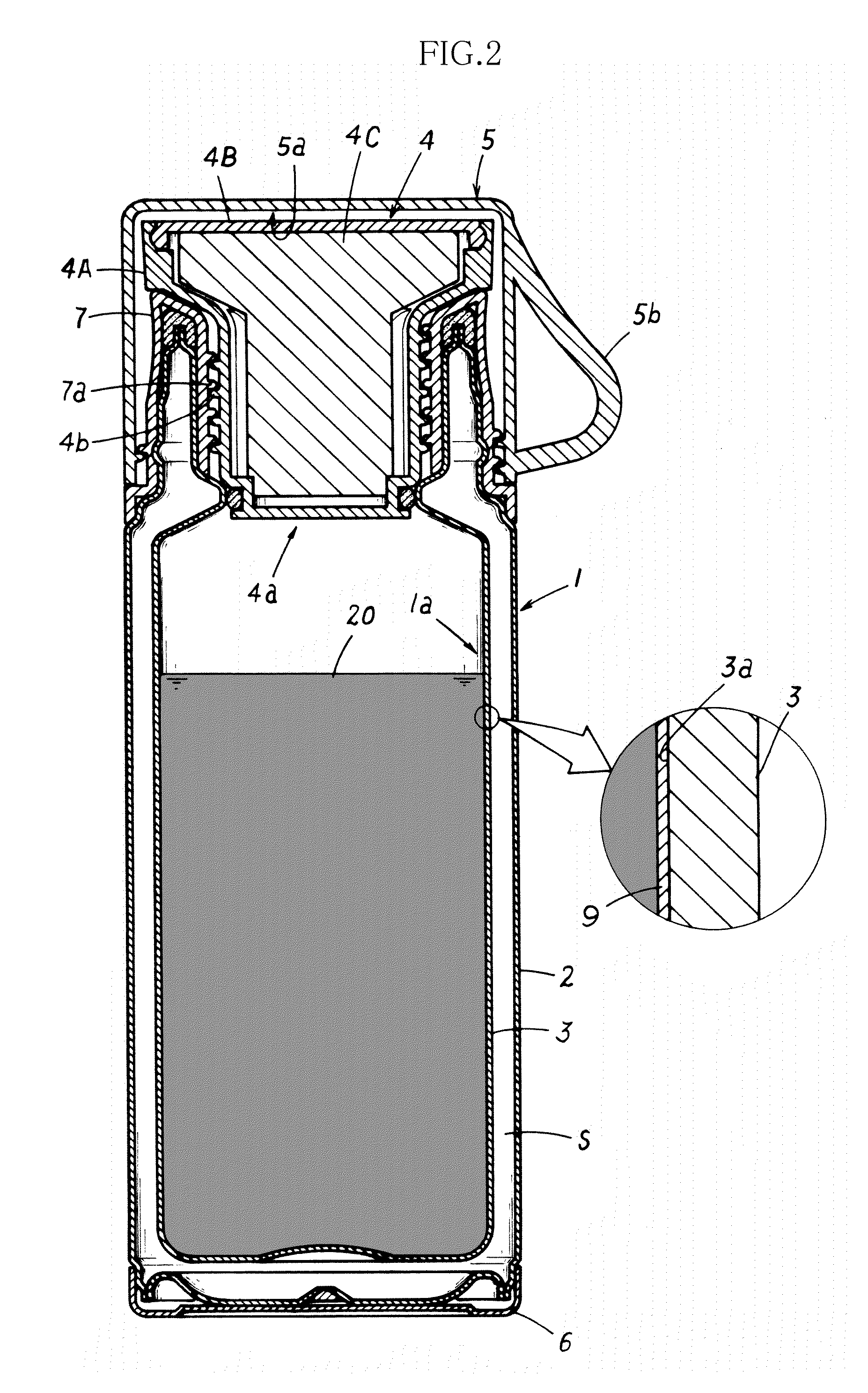

Coffee storage container

The purpose of the present invention is to provide a revolutionary coffee storage container of exceedingly high commercial value. This coffee storage container is designed for storing coffee (20), and has: a container body (1) in which an inner cylinder (3) made of metal is arranged within an outer cylinder (2) with a space (S) therebetween, the space (S) between the outer cylinder (2) and the inner cylinder (3) functioning as a vacuum insulation space; a closure body (4) for providing closure to an opening (1b) of the container body (1); and a coffee pouring cup body (5) that fits about the closure body (4) once the opening (1b) of the container body (1) has been closed by the closure body (4). An inner surface portion (1a) of the container body (1) that comes into contact with the coffee (20), a section of the closure body (4) that comes into contact with the coffee (20), and an inner surface portion (5a) of the coffee pouring cup body (5) are constituted by inert synthetic resin.

Owner:SEVEN SEVEN CO LTD

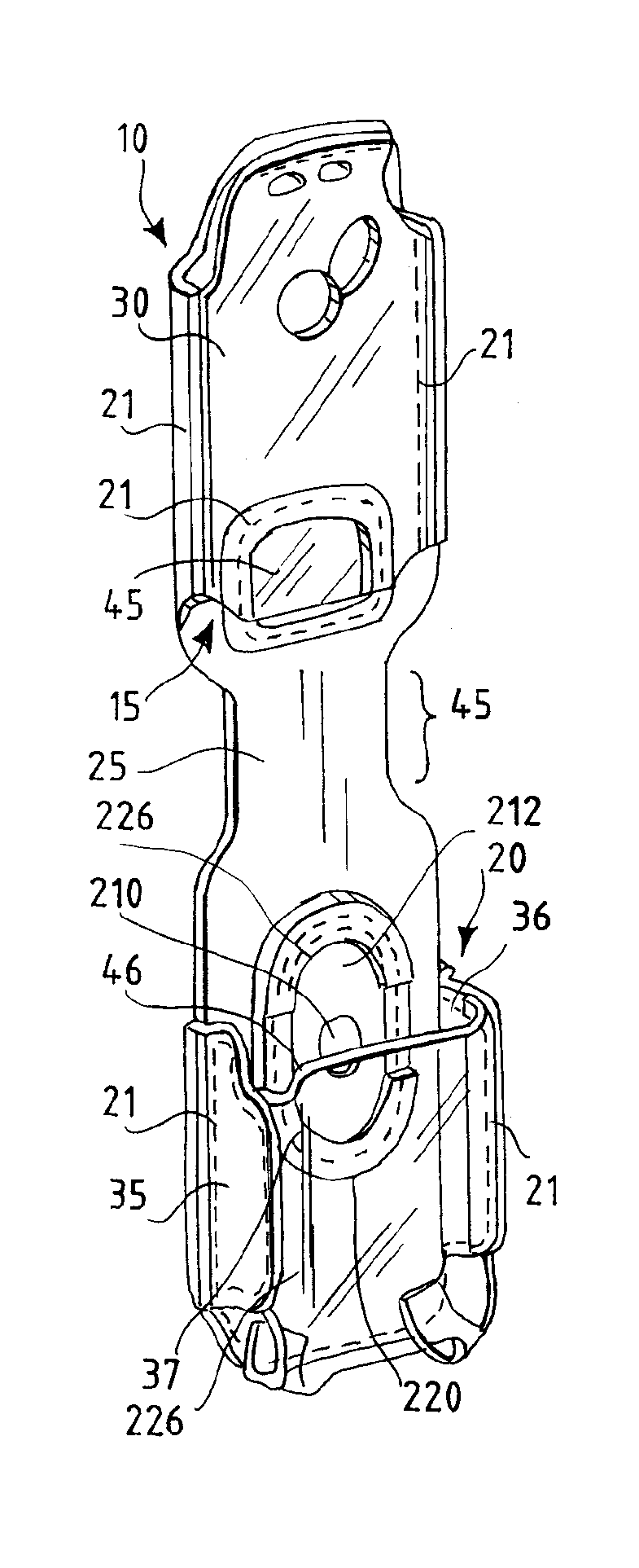

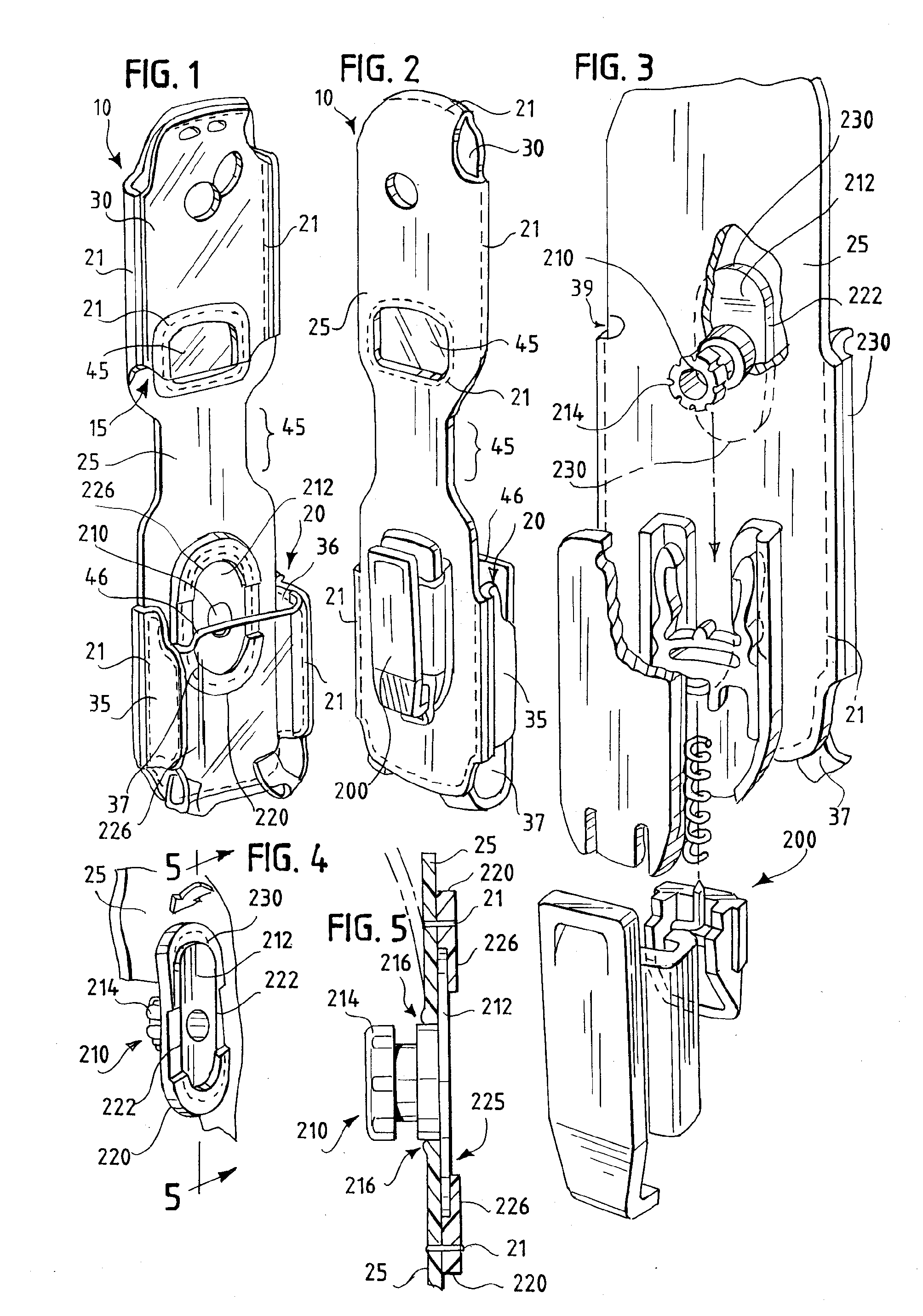

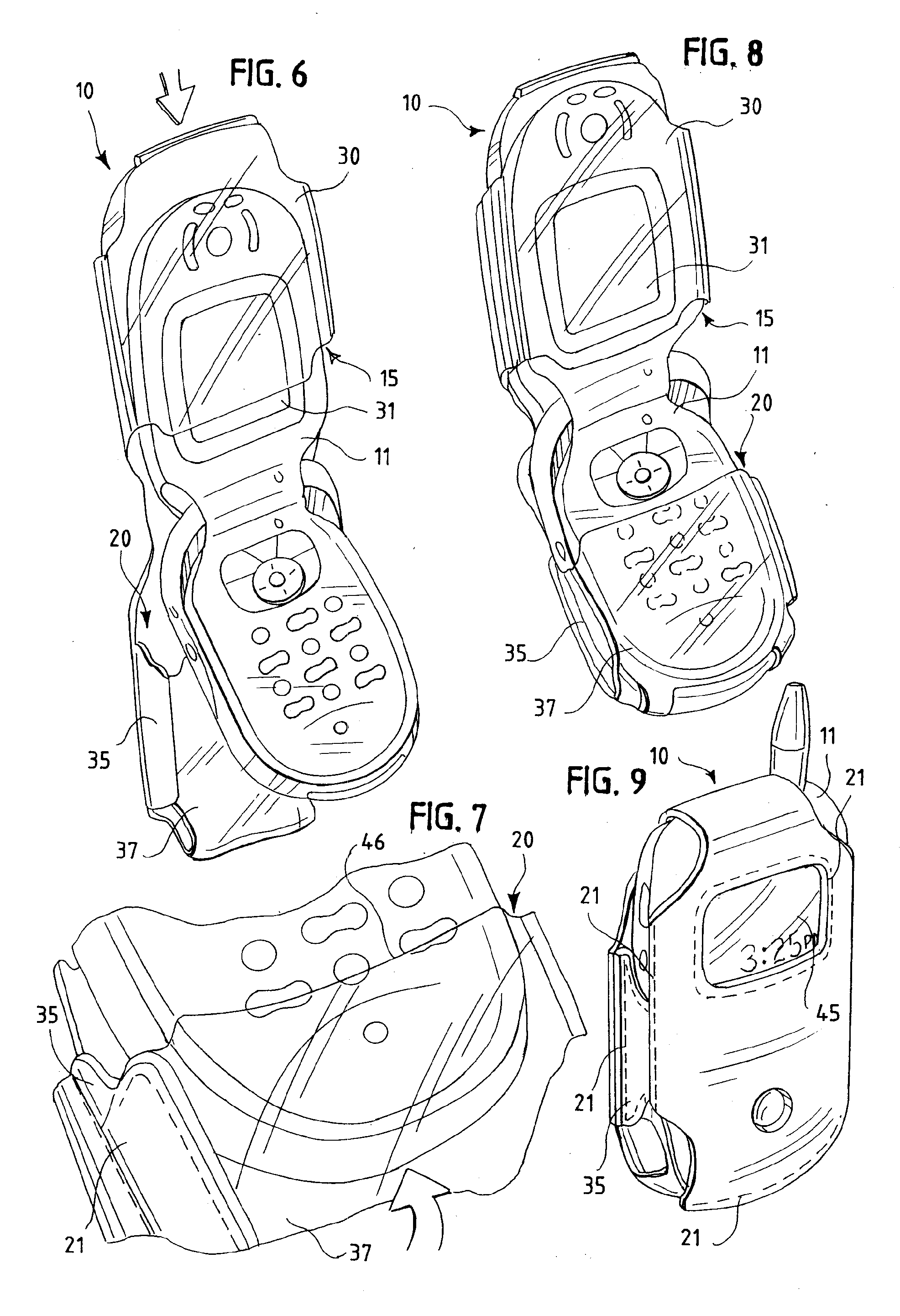

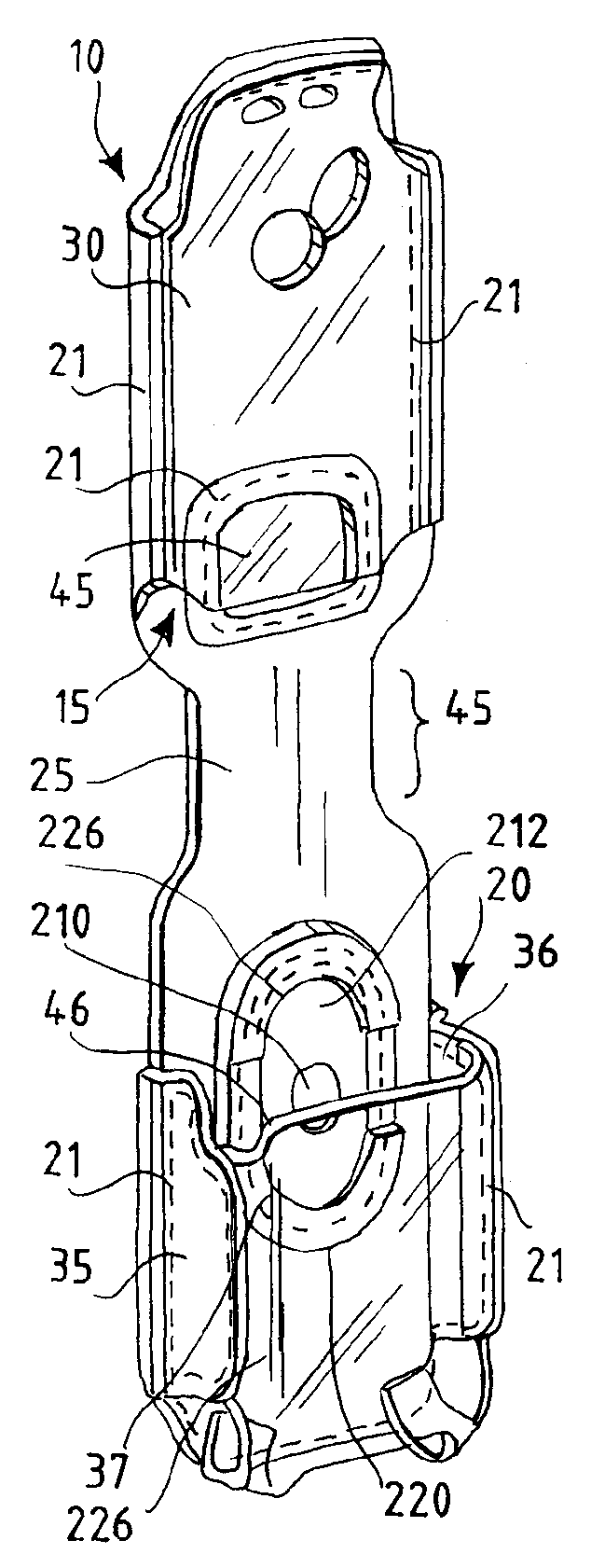

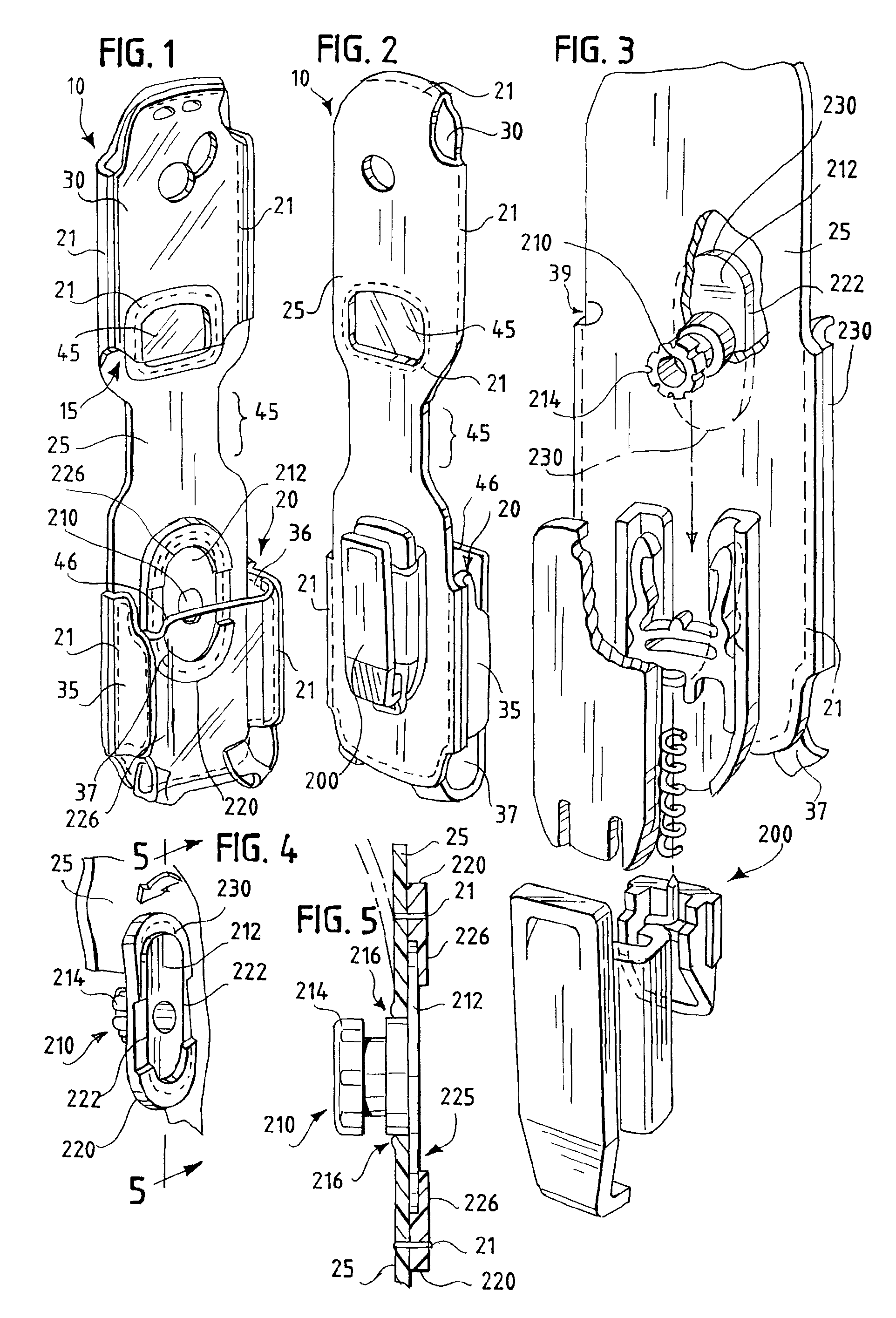

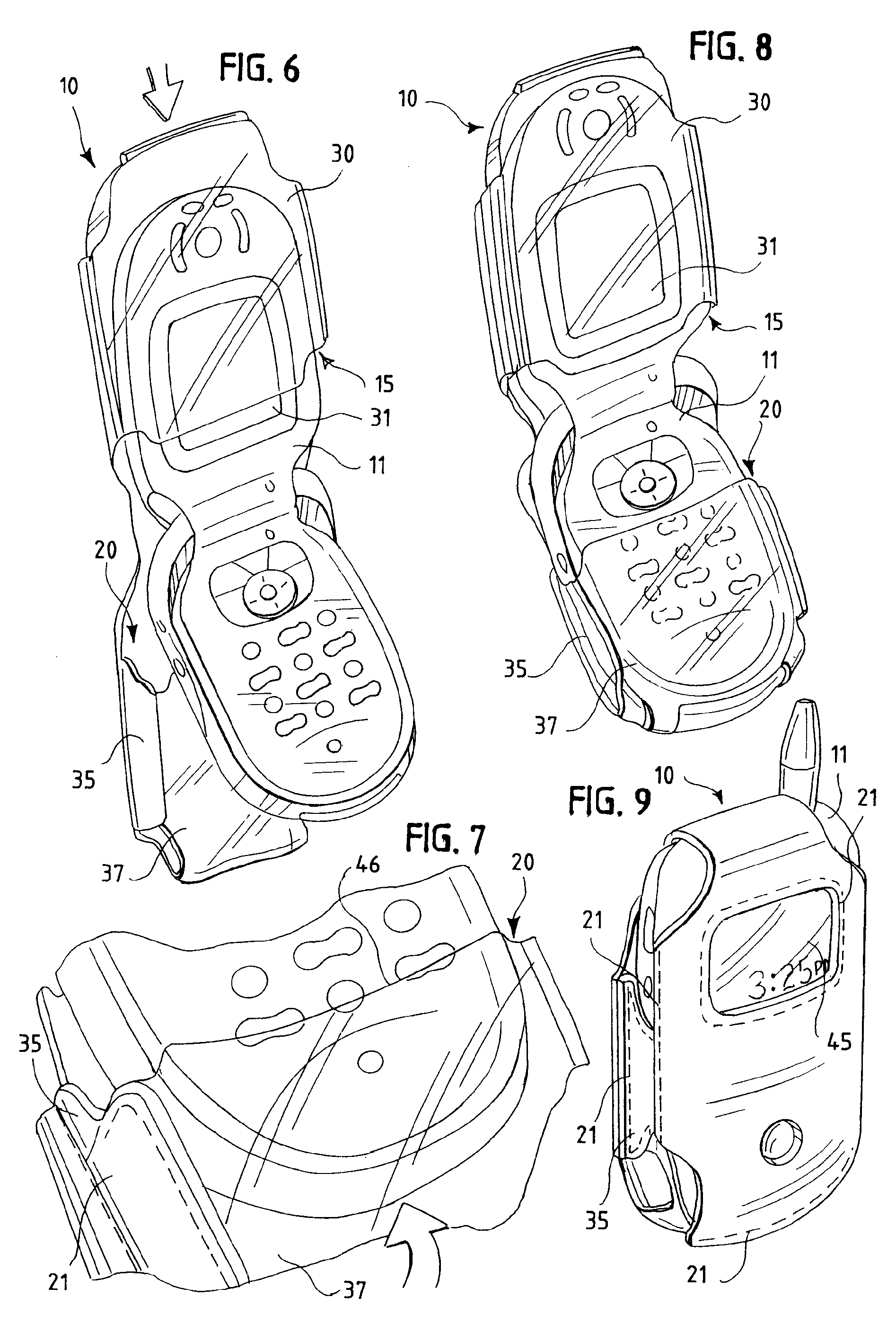

Portable device case with corner protector

ActiveUS20070225031A1Reduce thicknessReduce bulkTwo-way loud-speaking telephone systemsTravelling sacksElectronic equipmentMP3 player

A case for a portable electronic device such as cell phones, cameras, MP3 players and PDAs wherein said case includes material at the corners to provide protection to the electronic device. To reduce bulk at the corners and allow the material forming the case to conform with the contours of the device, the protection at the corners includes strips of material defining apertures there between. The apertures provide reduction in bulk and allow the case to conform to the corners of the device therein. Alternately, the protection at the corners can be provided by other structures co-molded into the corners of the cases. Such structures include material that is of a reduced thickness than other material used in the case, or structures that are formed to conform to the corners of the case. Such structures can be joined to the material forming the panels of the case by co-molding.

Owner:SAMSONITE IP HLDG SARL

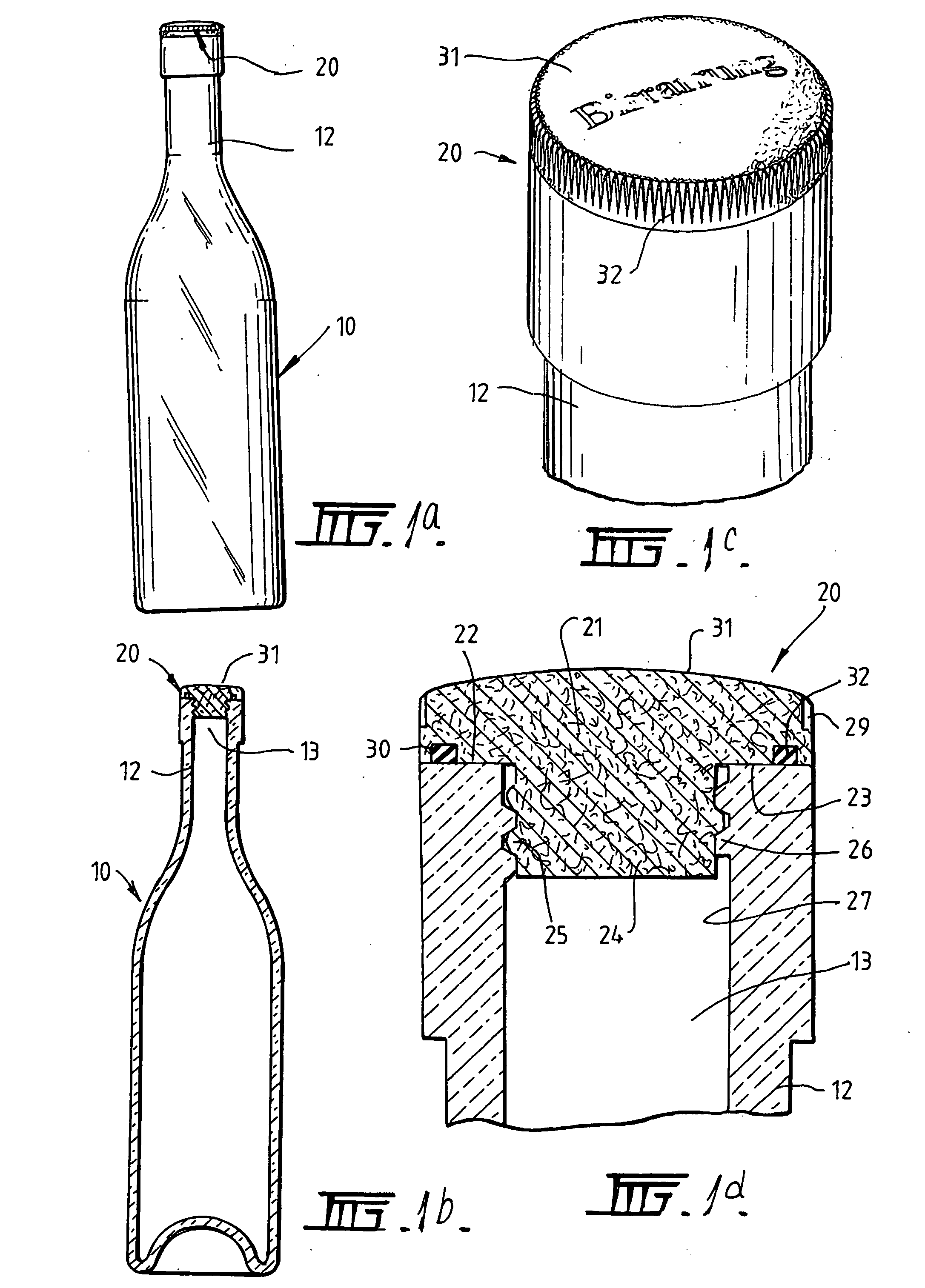

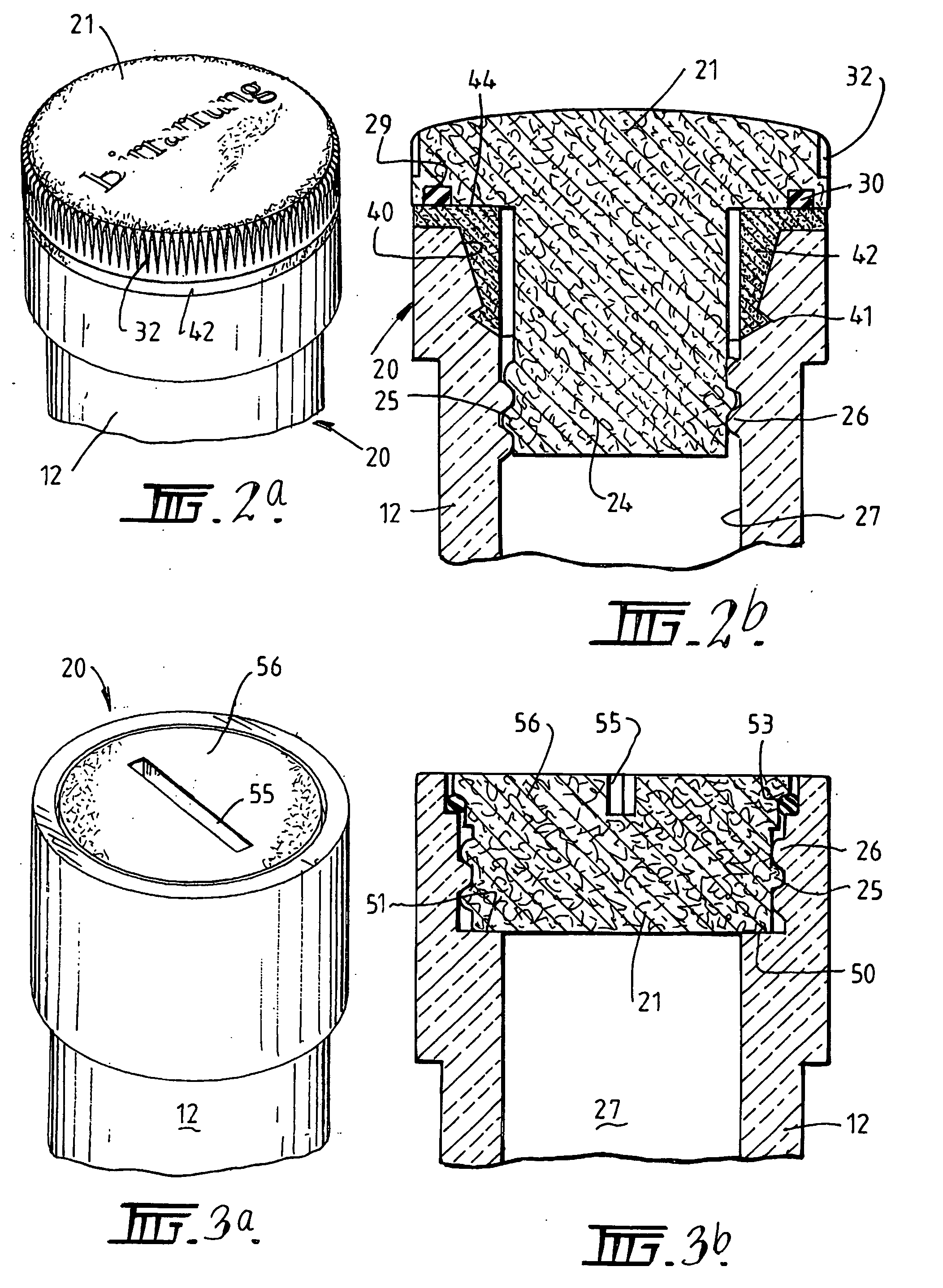

Twist closure means for a container

A twist closure for a container has a screw cap, which includes an inner cylinder and a cutting edge extending from the inner cylinder, and a supply container rotatably arrangeable on the inner cylinder. The supply container includes a supply container bottom and a pocket extending from the supply container bottom for accommodation of the cutting edge.

Owner:PROF BIRKMAYER UNDHEITSPROD

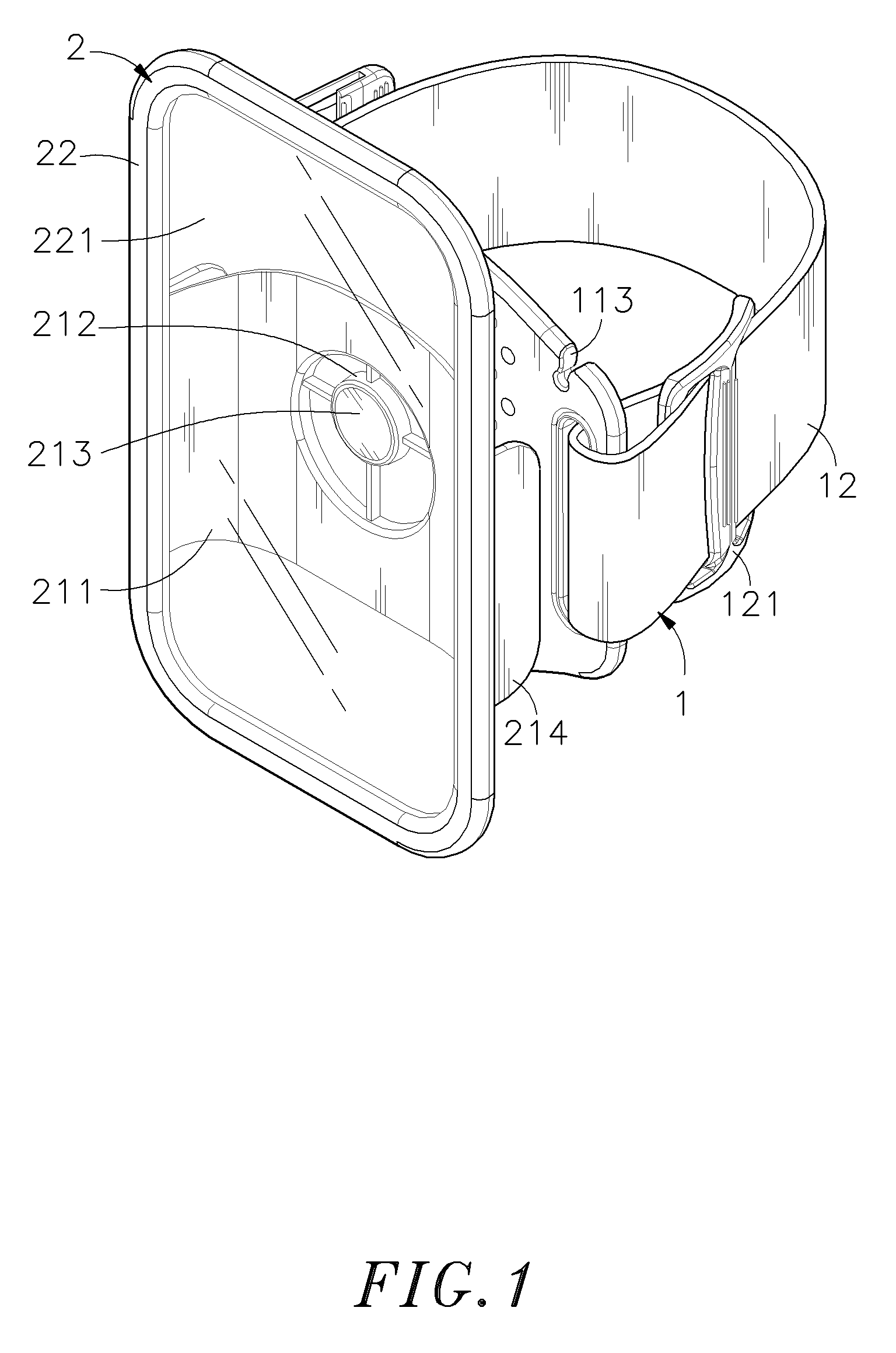

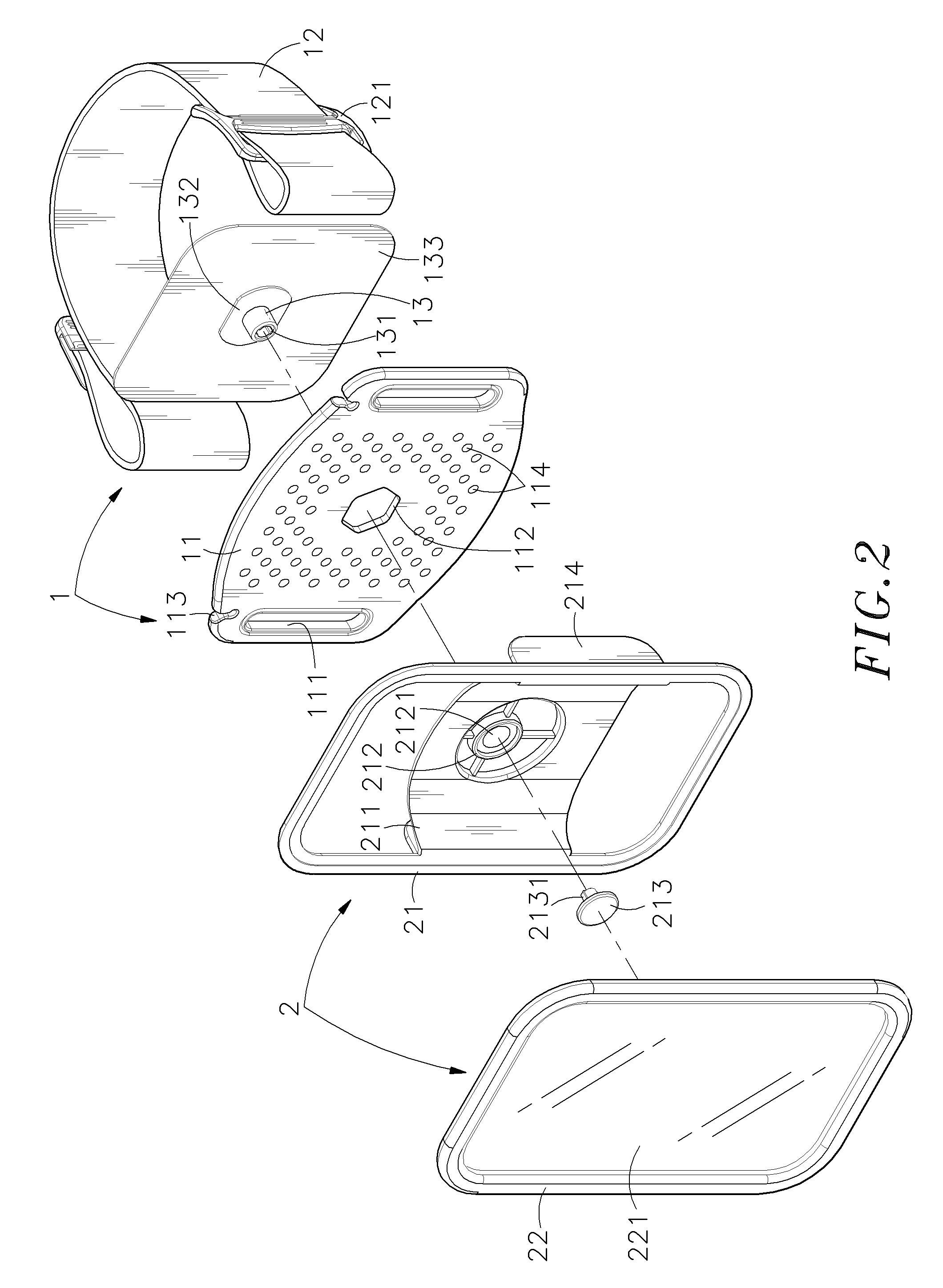

Portable binder with a rotating frame

InactiveUS20100327030A1Brought by users conveniently when theyEasy to useTravelling sacksTravelling carriersRotational axisEngineering

The present invention relates to a portable binder with a rotating frame, comprising a pedestal and a rotating frame, wherein the pedestal has a base and on both sides of the base, there is a lacing hole to be reeved by a binding tape, which can be used by tightening it around arms. An axle hole penetrates through the base to combine a coaxial connection shaft, and on the base, a supporting plate is established concavely on both sides to cover a proposed electronic device, while an axial part is established to interconnect the coaxial connection shaft on the supporting plate, and on the axial part, there is a rotation shaft that can be coaxially connected with the coaxial connection shaft. When the binding tape reeving the base is fastened around users' arms, the body of the rotating frame can be utilized to fix the electronic device, thus achieving the effect of making the electronic device portable when users go out. Besides, the design of adjusting the visual angle by using the rotating frame makes it convenient to use the portable binder disclosed in the present invention.

Owner:YANG SHANG WEN

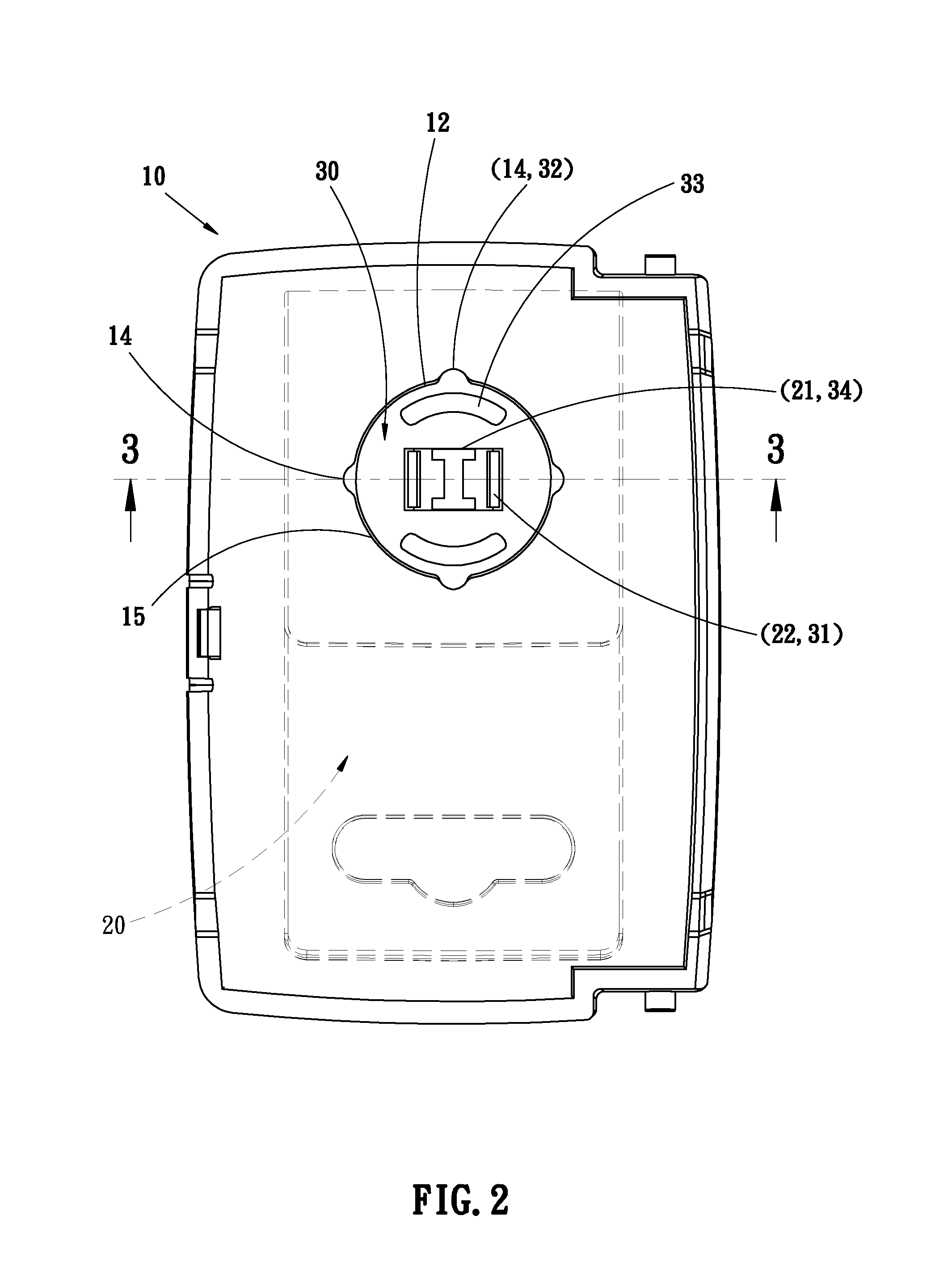

Bottle stopper

A stopper for an opening of a container such as a thermos. The stopper includes a pushbutton, a fluid flow channel extending between an inlet and an outlet, and a movable plug portion positioned adjacent the inlet. A biasing member biases the plug portion into sealing engagement with the inlet thereby preventing the contents of the container from flowing into the channel. A cam follower is disposed upon a cam surface opposing the biasing member. The cam follower is rotatable by the pushbutton relative to the cam surface from a closed position to an open position and when so rotated, exerts a biasing force on the cam surface sufficient to overcome the biasing force exerted by the biasing member on the plug portion and space the plug portion from the inlet allowing the contents of the container to flow into the channel and out the outlet.

Owner:PACIFIC MARKET INT

Closure or stopper forms a surface tension seal

InactiveUS20060151422A1Prevent escapePrevent lateral movementCapsClosure using stoppersEngineeringRelative motion

A closure or stopper for a container to contain liquid, powder or paste, the container having means to define a first extremely flat annular surface, the closure comprising a sealing member defining a second extremely flat surface, an annular groove that locates an O-ring, and means such as thread to urge the extremely flat surfaces into parallel abutting contact, the extremely flat surfaces adapted to form a surface tension seal when they are urged into parallel abutting contact and means to prevent lateral or shear relative movement. Another form of the closure is the sealing member being a disc that seats on the flat annular sealing surface defined by the top of the neck of a bottle to form a seal, and a metal cap to place the seal under axial load and protects the seal from vibration.

Owner:MANLEY DAVID WILLIAM

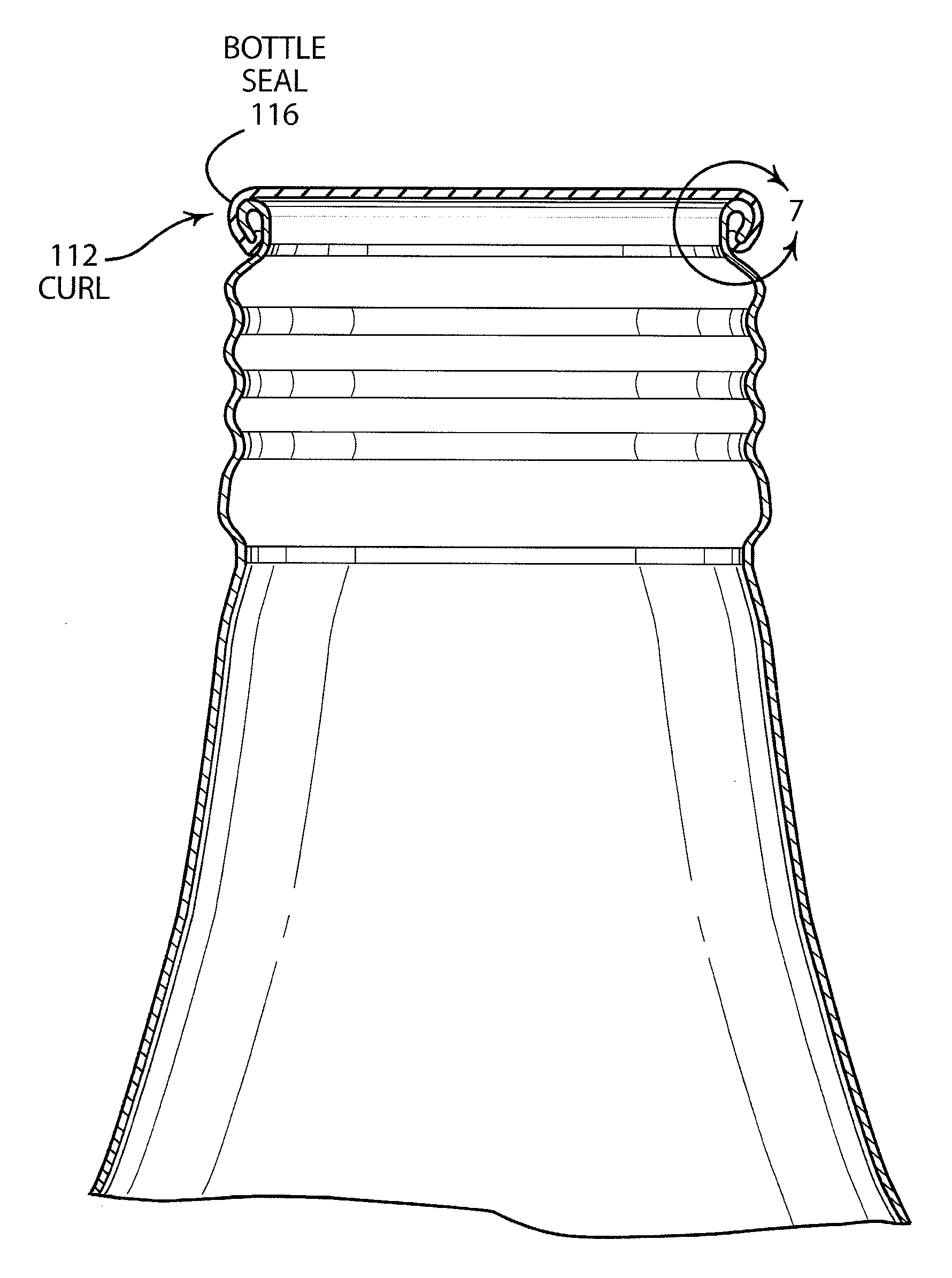

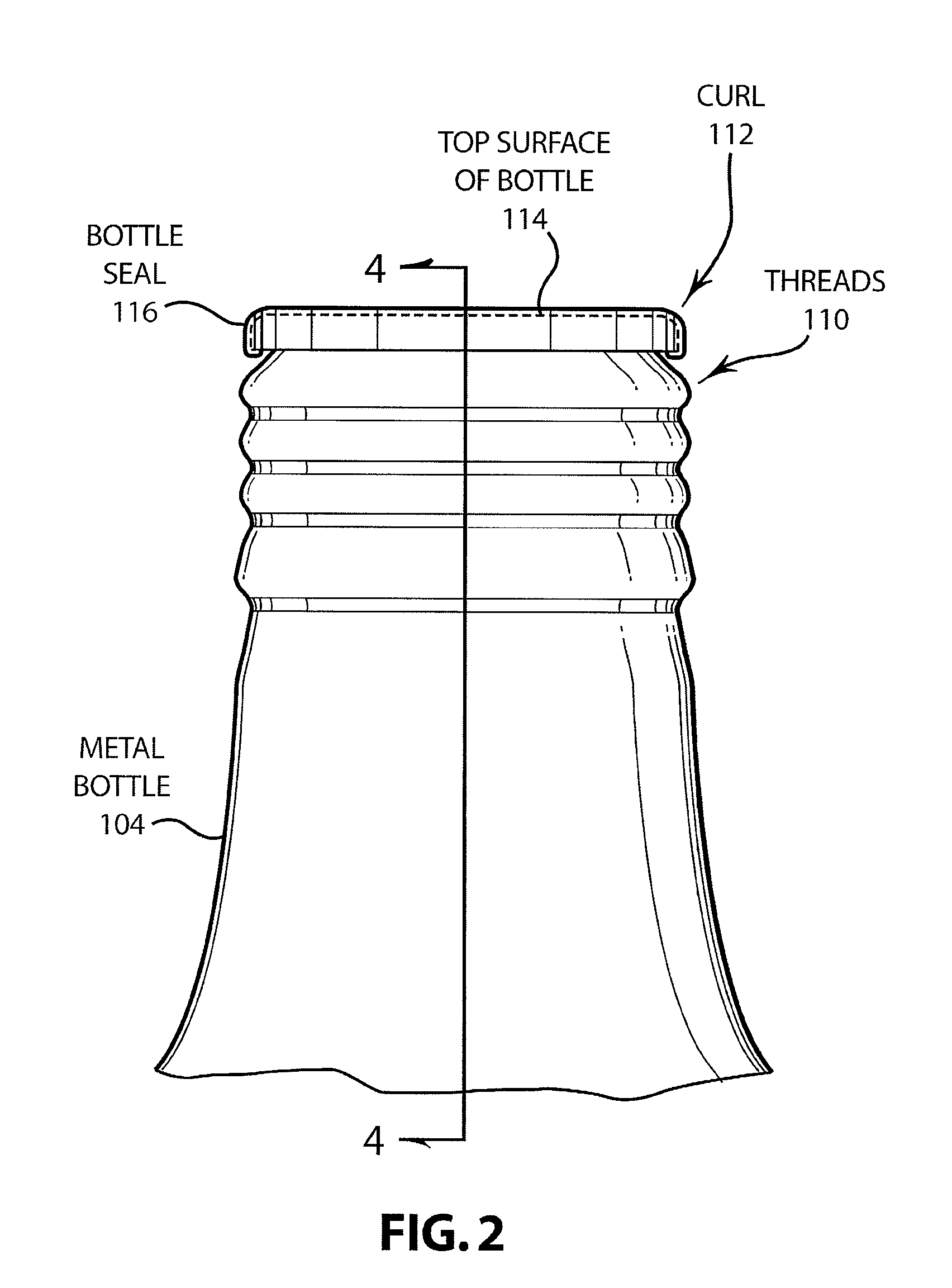

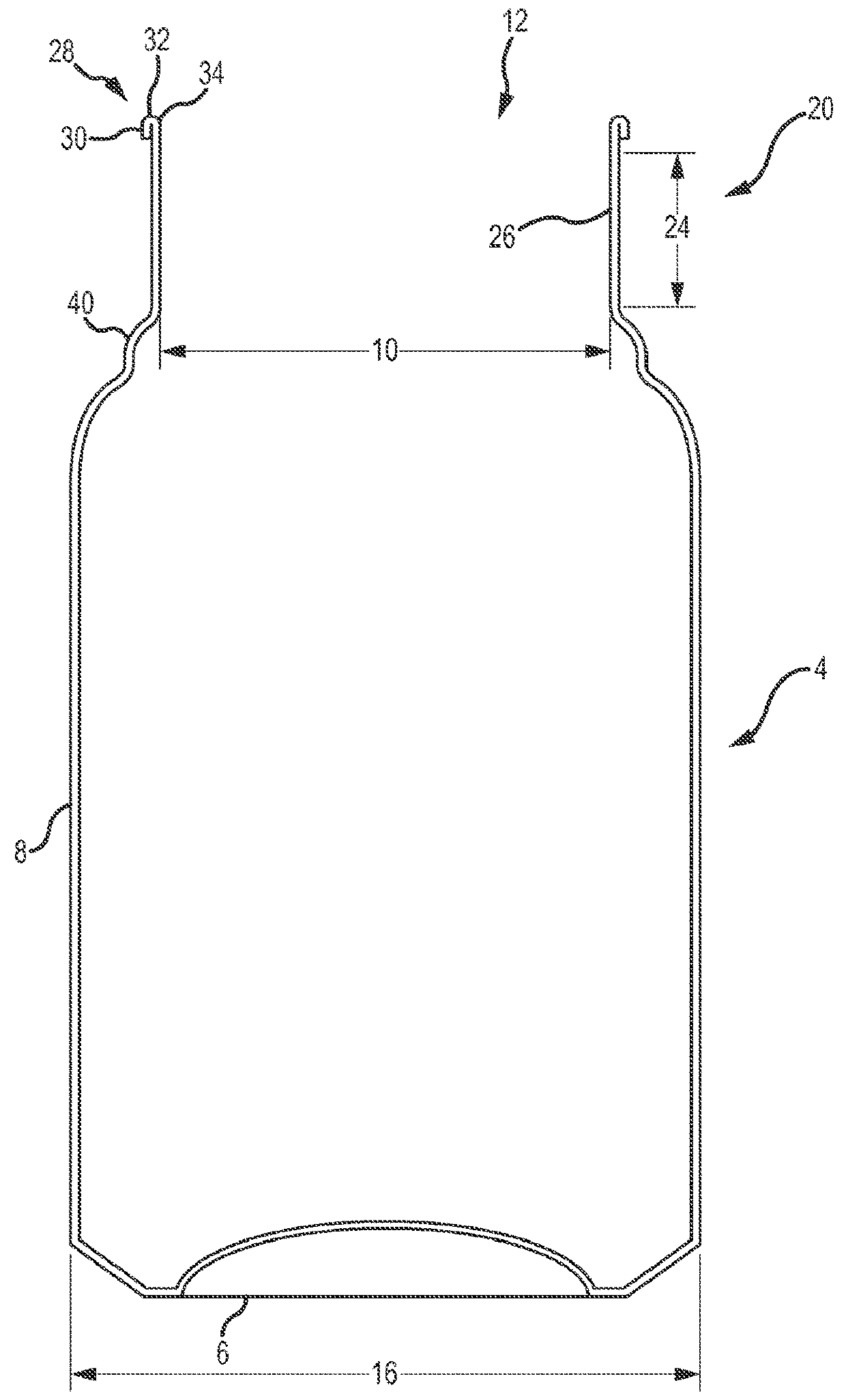

Metal bottle seal

Disclosed is a metal bottle seal that is disposed on the curl of the metal bottle. The bottle seal may be held in place by crimping of the curl. In addition, adhesive may be used to hold the bottle seal on the curl. Adhesives can be used that fill discontinuities that may exist in the curl as a result of substantial drawing and ironing of the metal. Further, the metal bottle seal can be made of a material or laminated with a material that is soft enough to fill the discontinuities. The seal can be preformed as a continuous annulus for easy application to the top of the metal bottle. The metal bottle seal can also be used in conjunction with a cap seal to ensure an adequate and reliable seal.

Owner:STOLLE MACHINERY +1

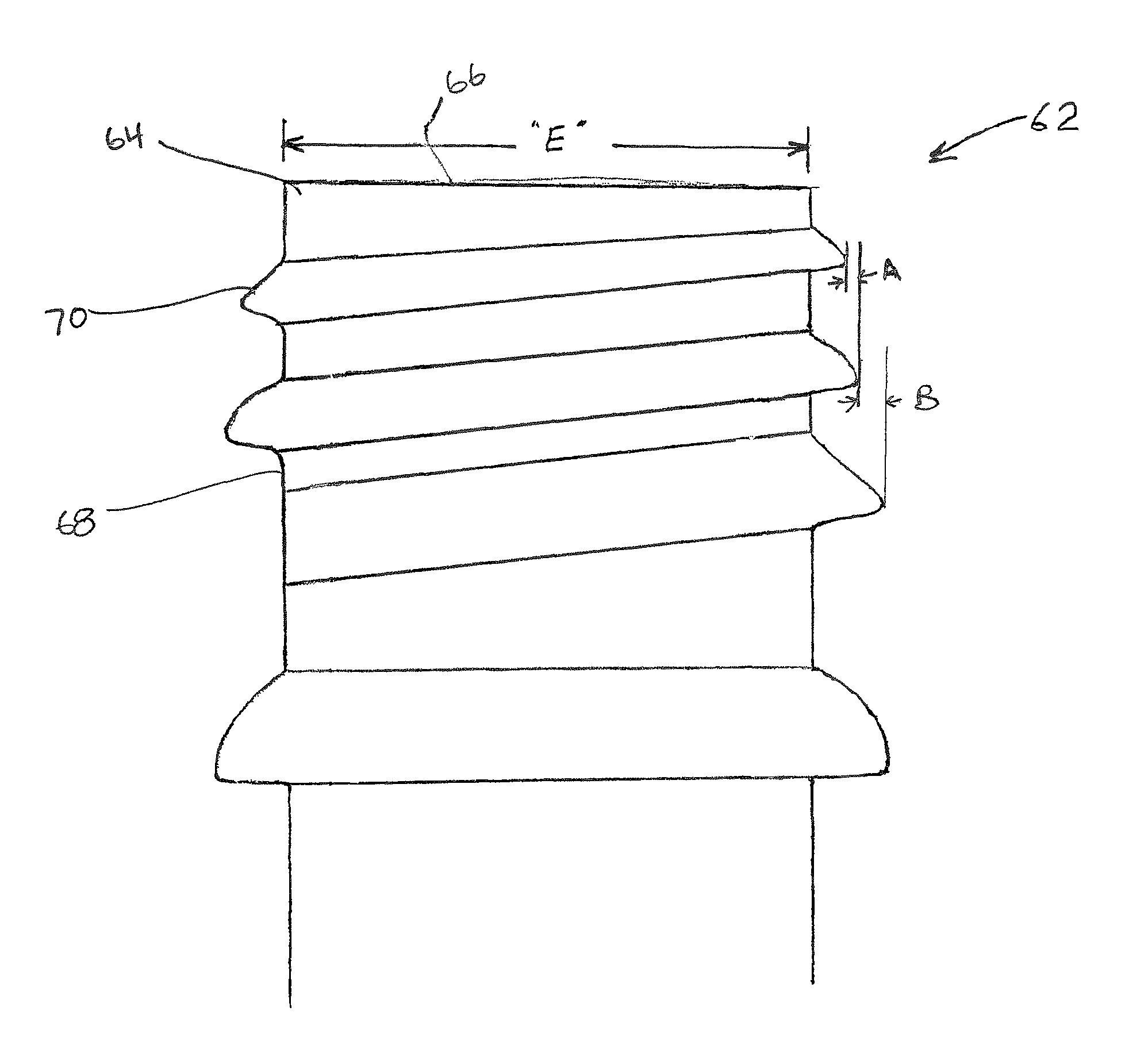

Tapered thread structure

ActiveUS7735664B1Improve integrityImprove sealingCapsClosure using stoppersMaximum diameterEngineering

In one embodiment there is provided a novel container neck finish having a substantially cylindrical exterior wall surface surrounding an orifice defined in the container and a thread structure positioned about the exterior wall surface. The thread structure has at least a first portion and a second portion. Each portion has a corresponding effective maximum diameter, wherein the effective maximum diameter of the first portion is less than the effective maximum diameter of the second portion.

Owner:PORTOLA PACKING INC

Container with Securement for a Cap

InactiveUS20080257849A1Excellent gas barrier performanceCapsClosure using stoppersEngineeringMechanical engineering

Owner:DUBOIS LIMITED (GB)

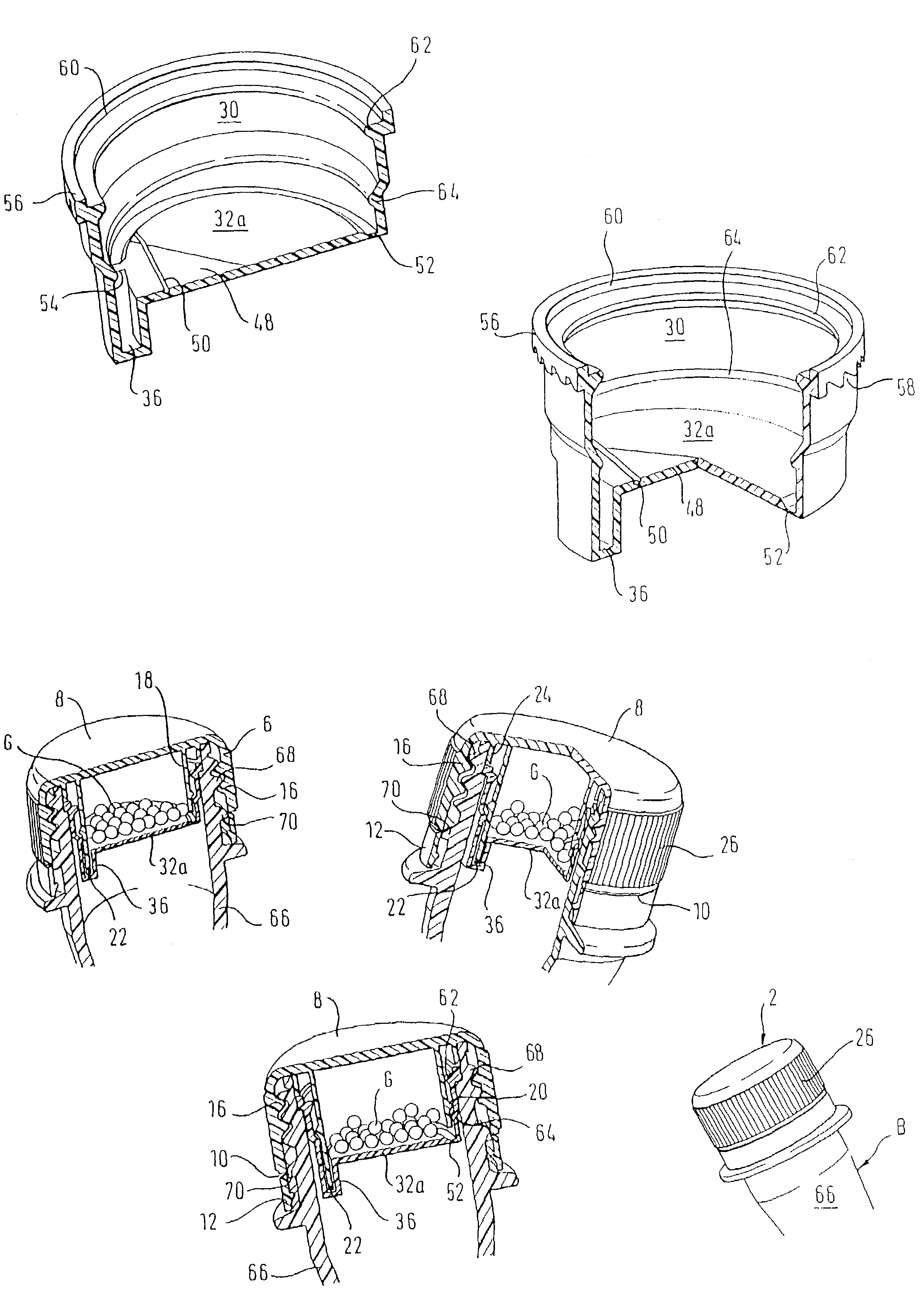

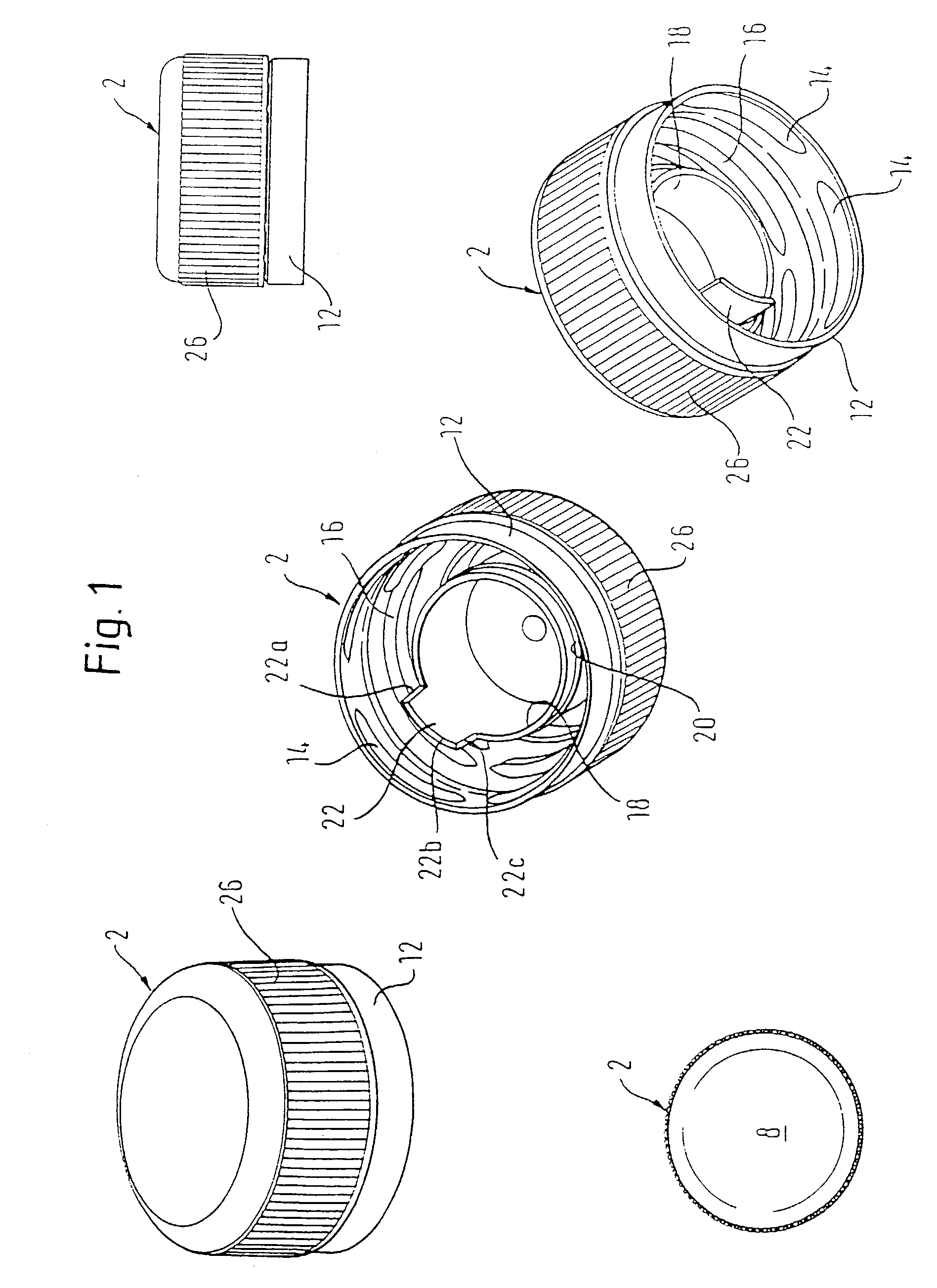

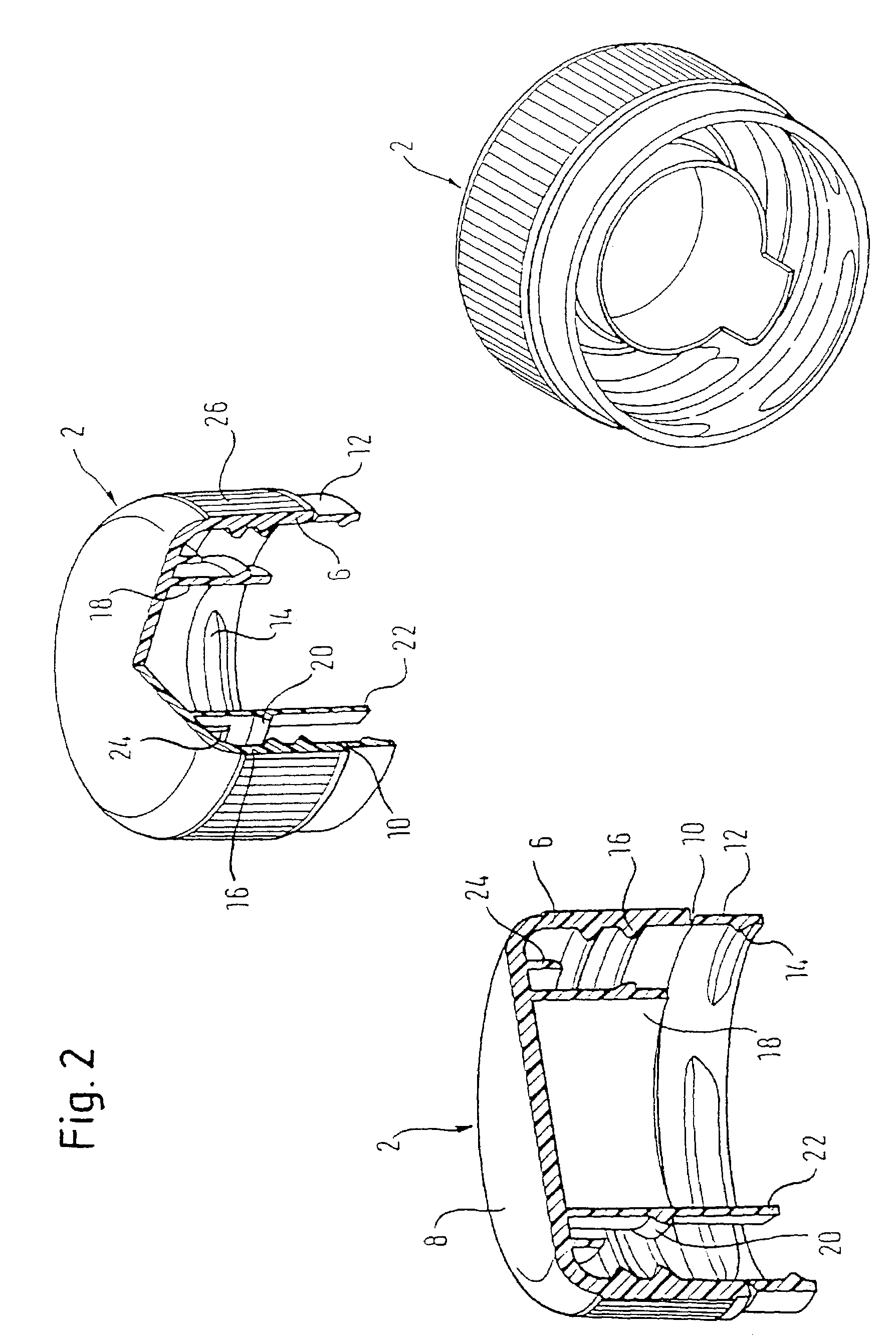

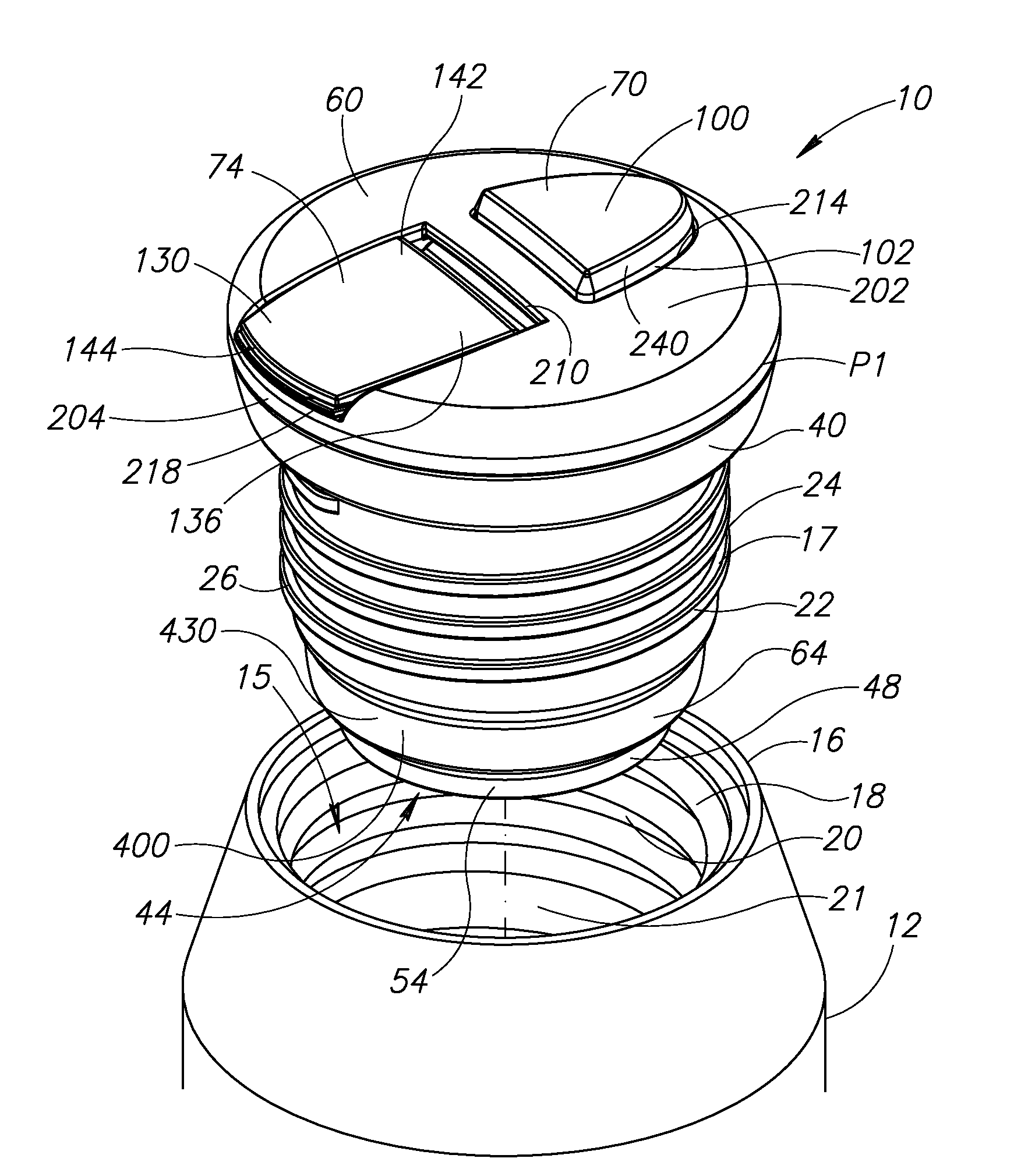

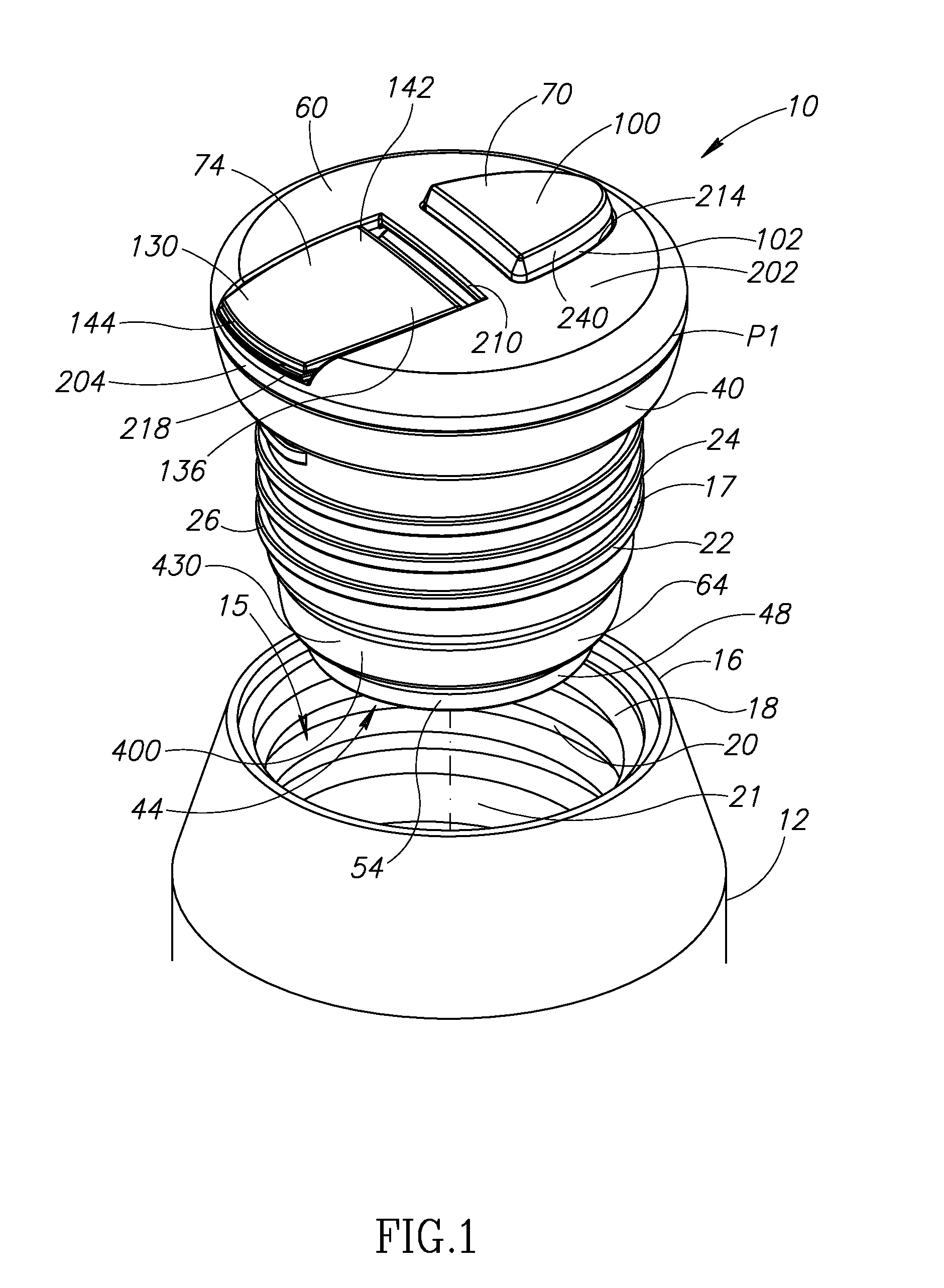

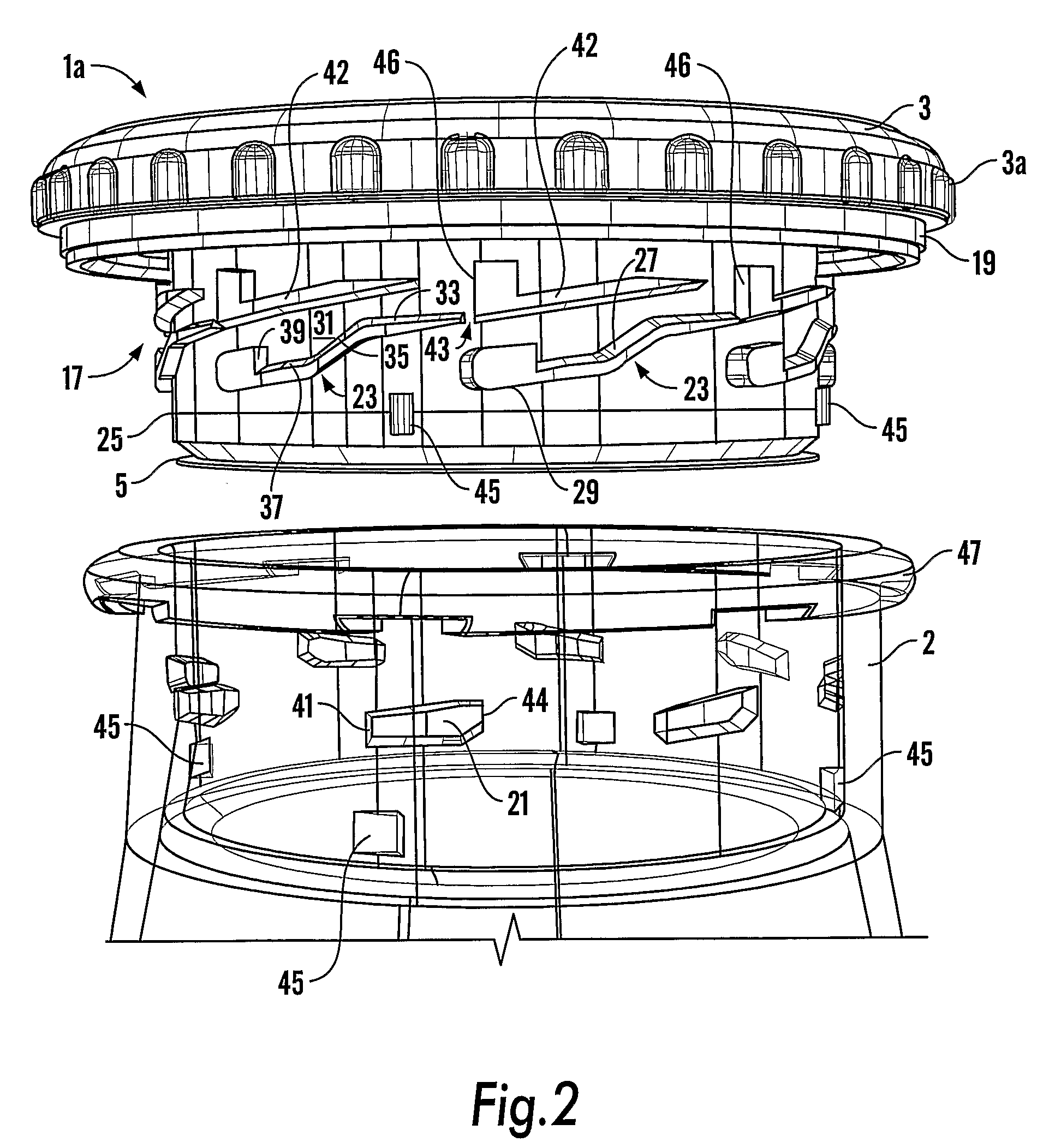

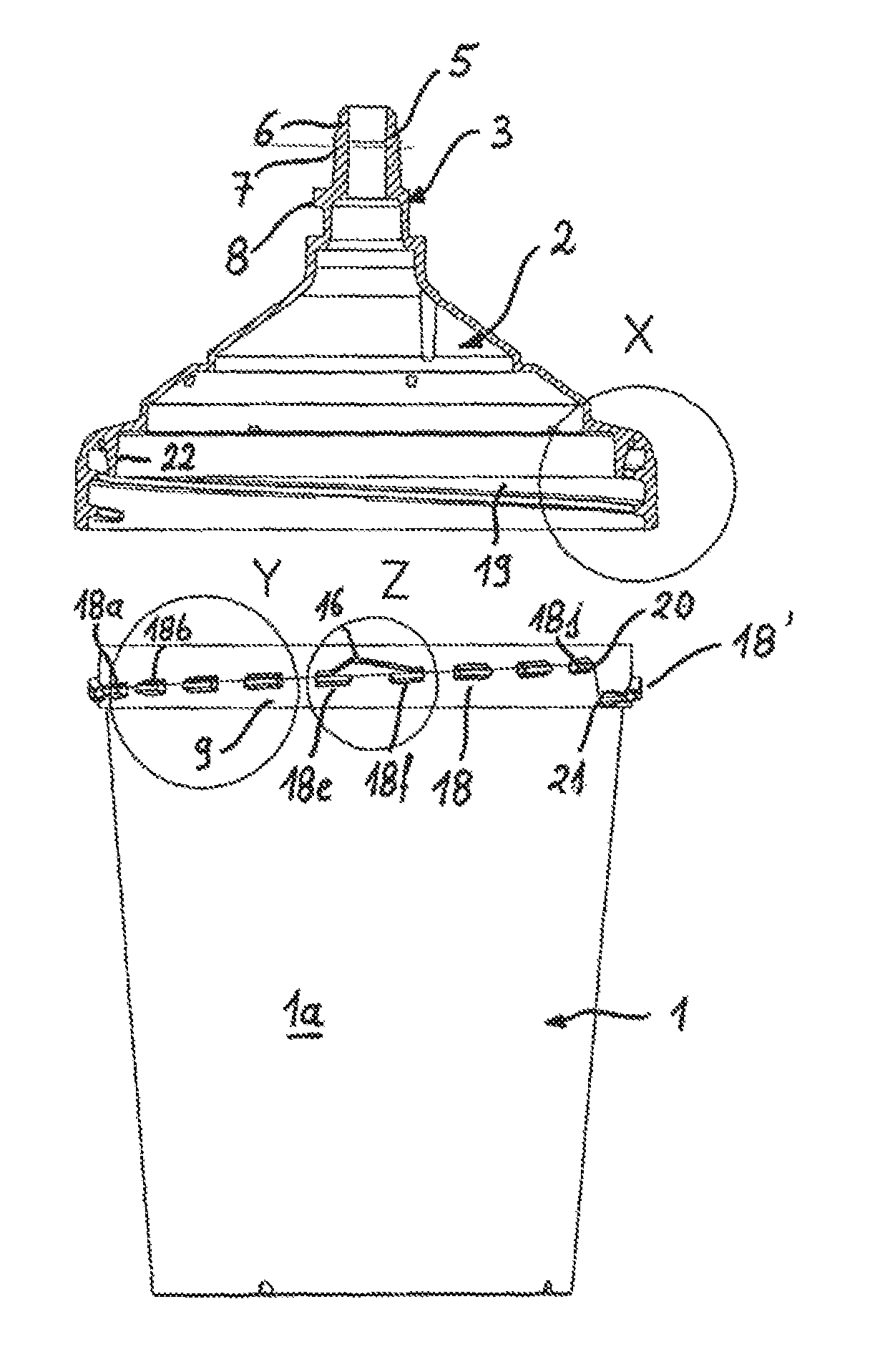

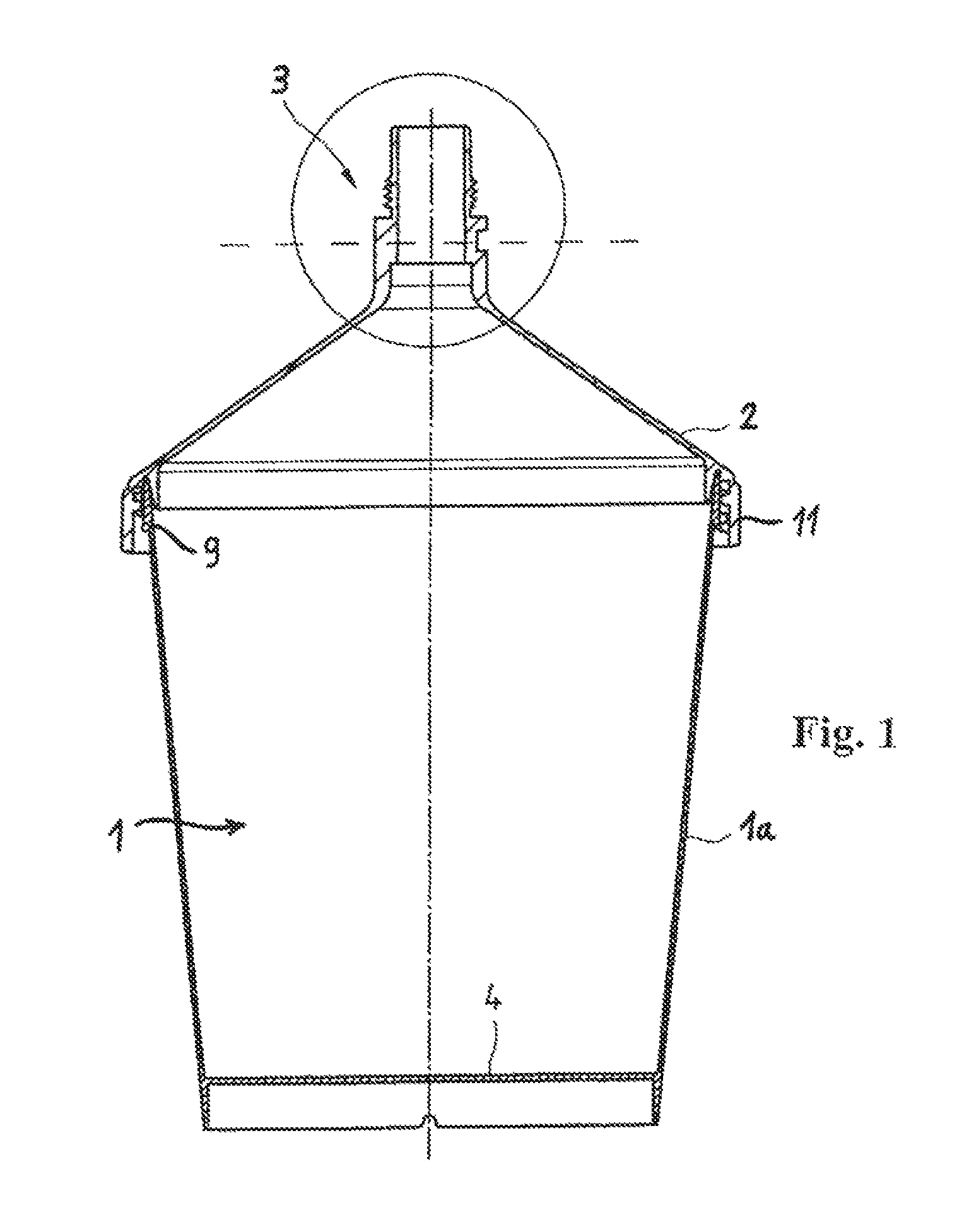

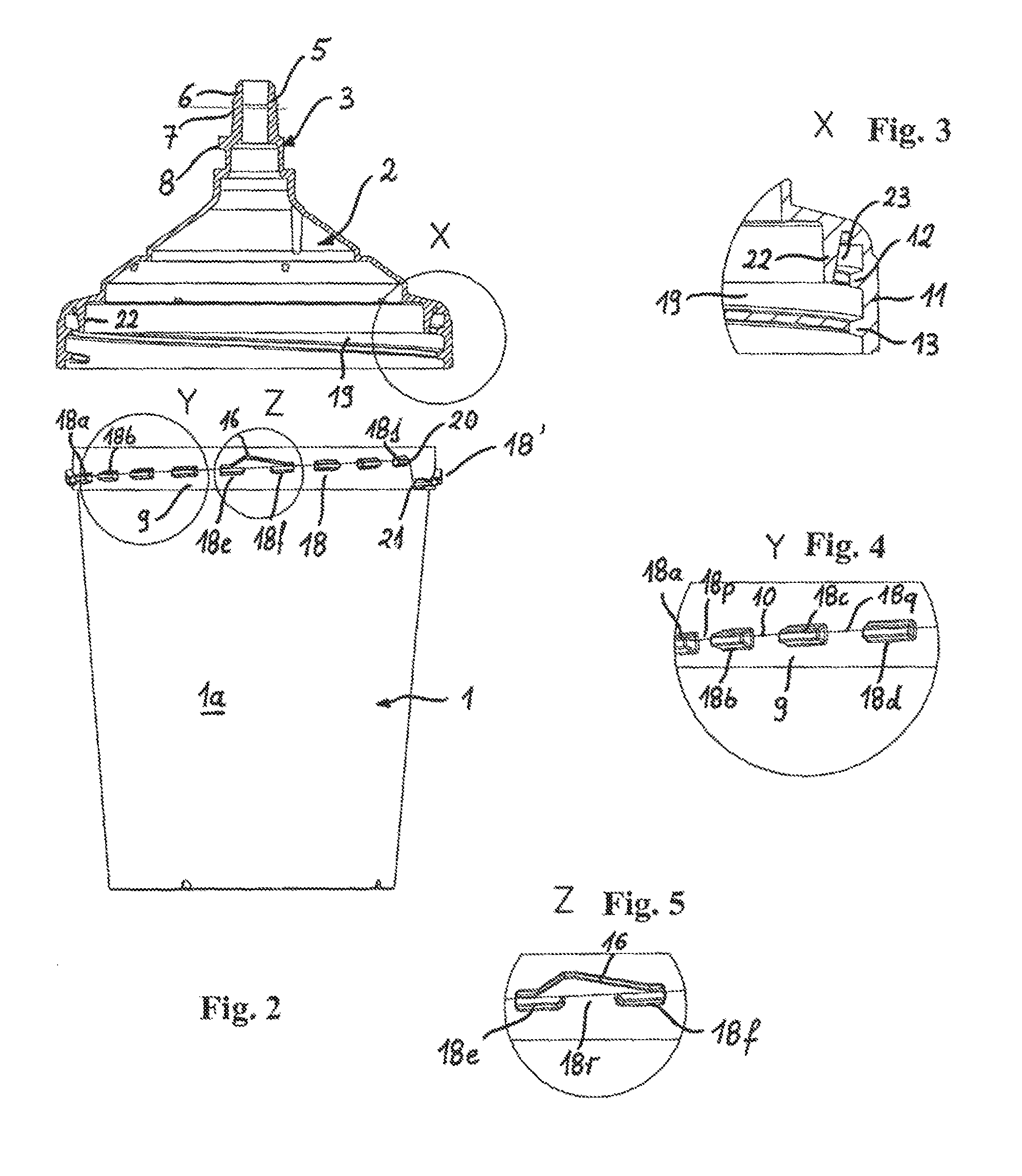

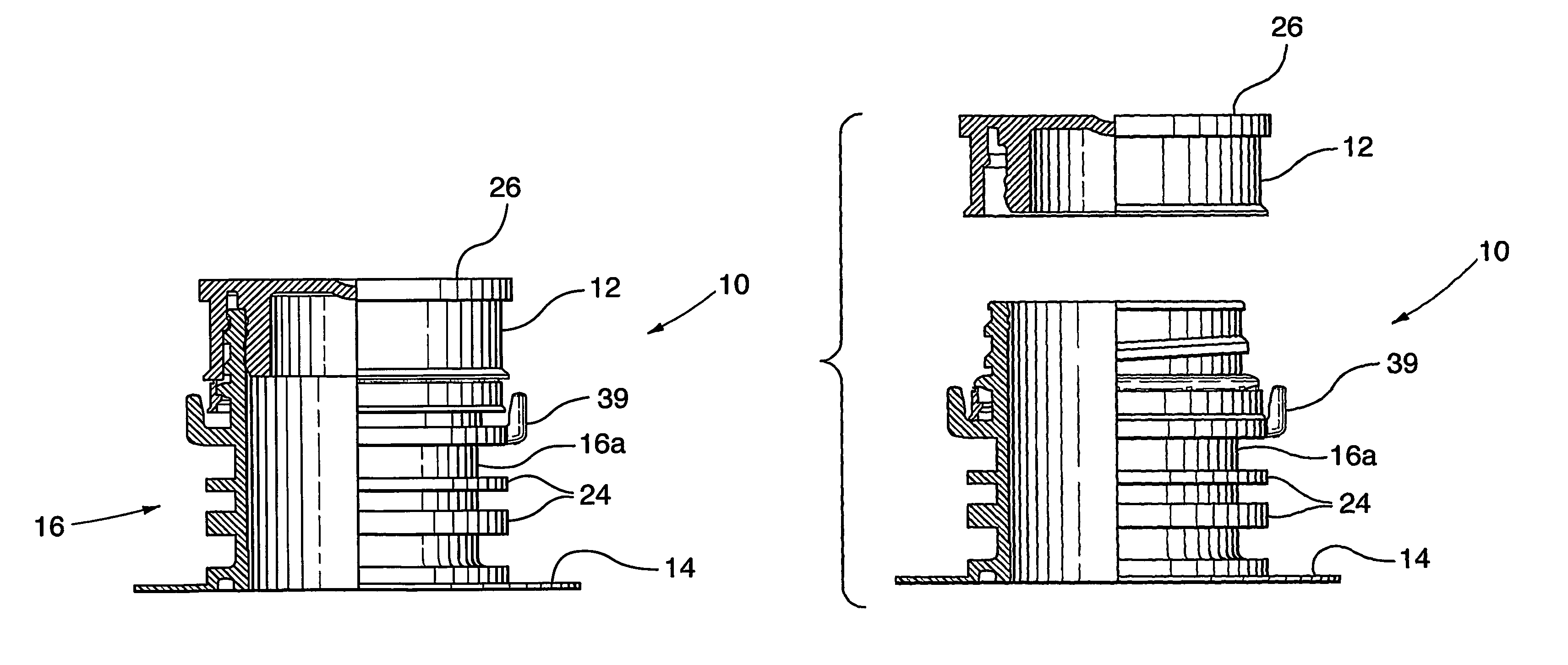

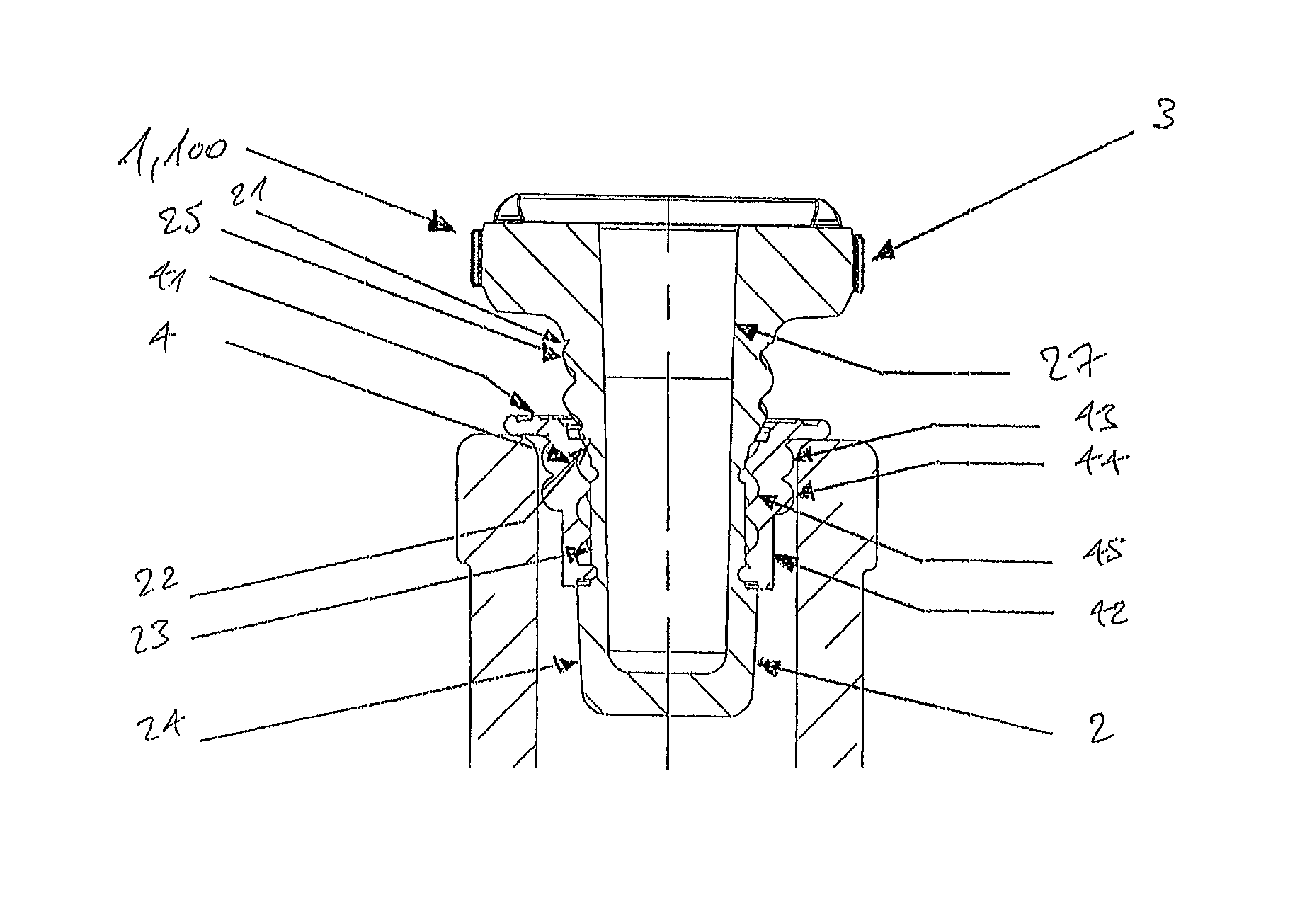

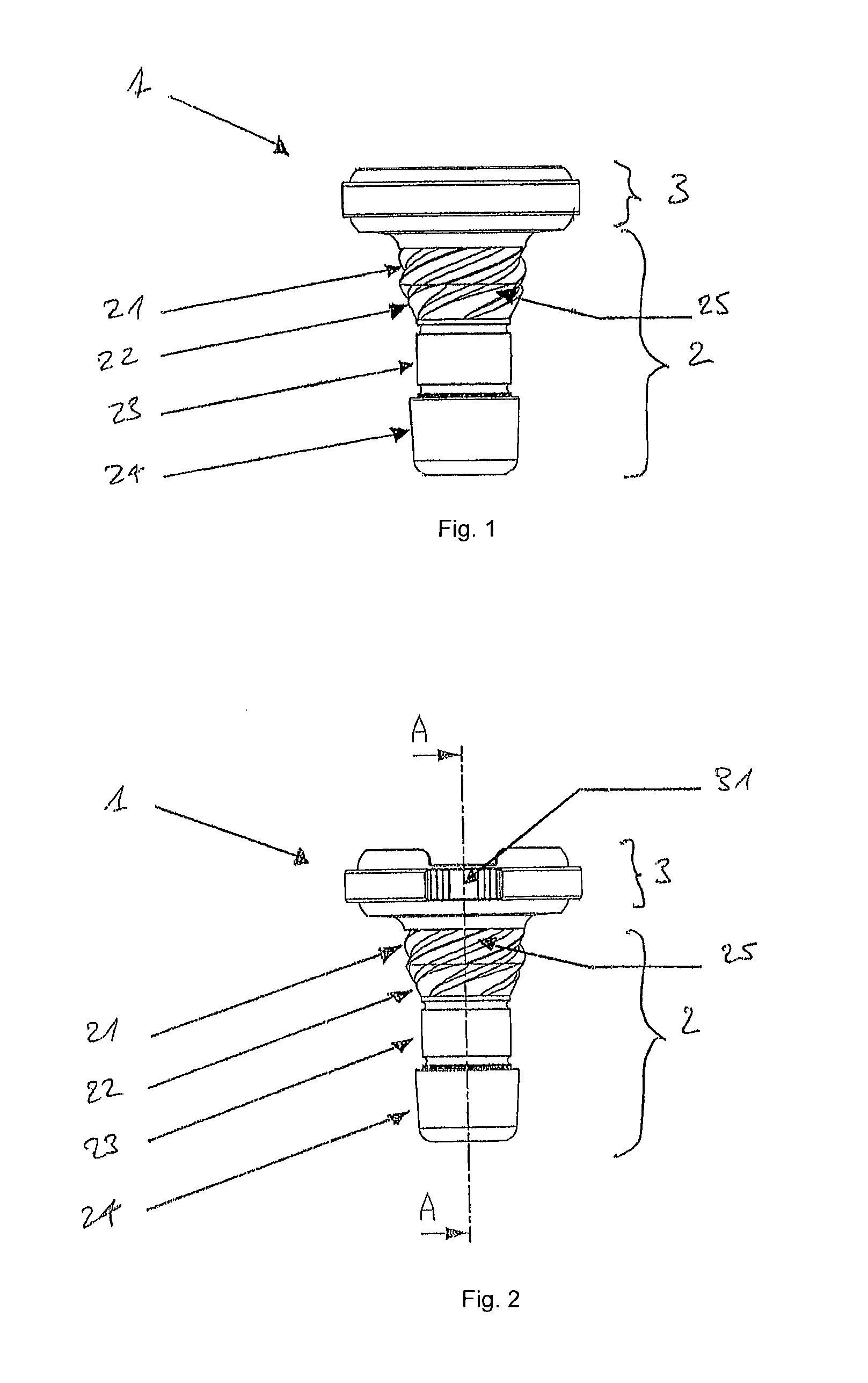

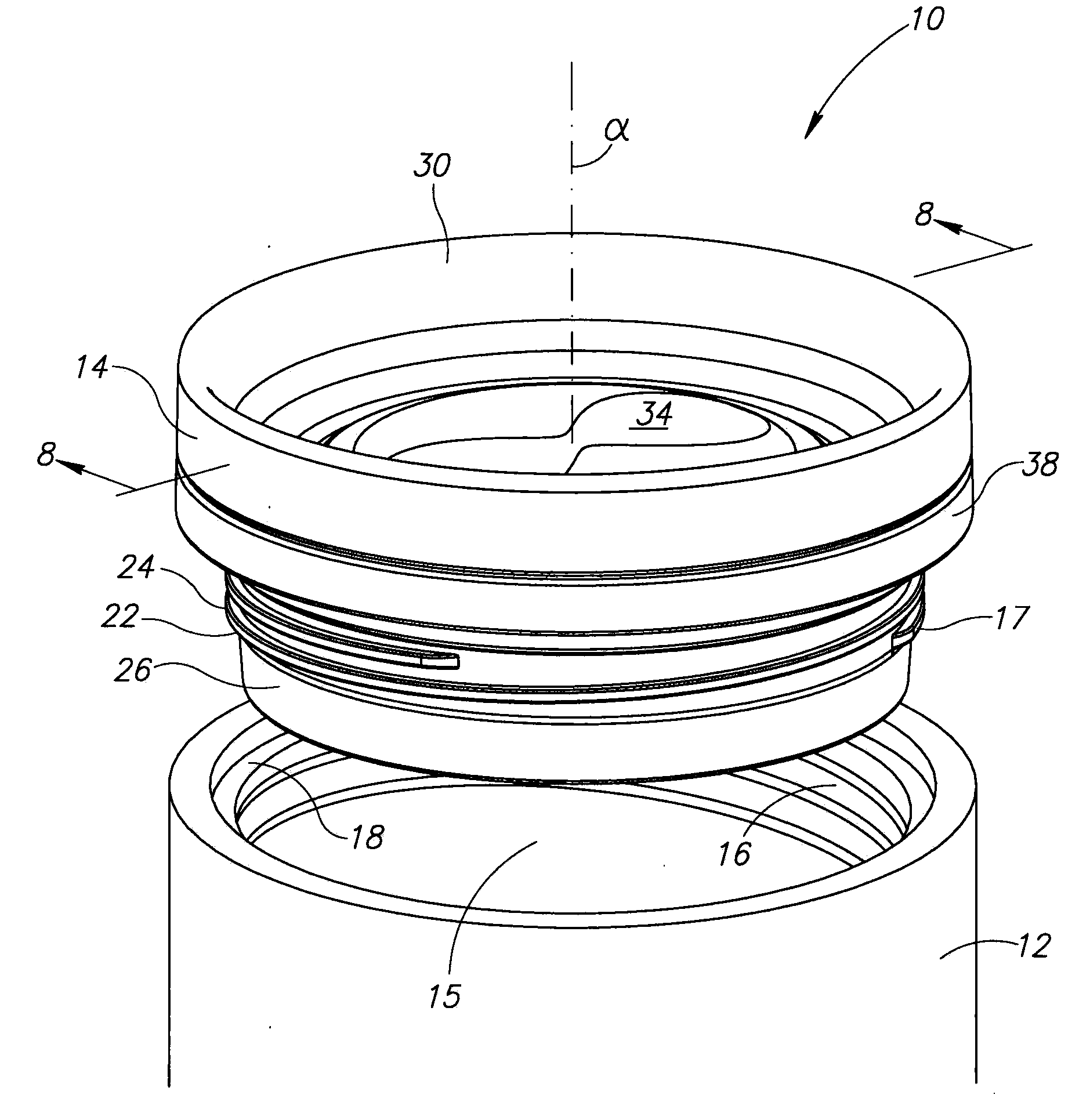

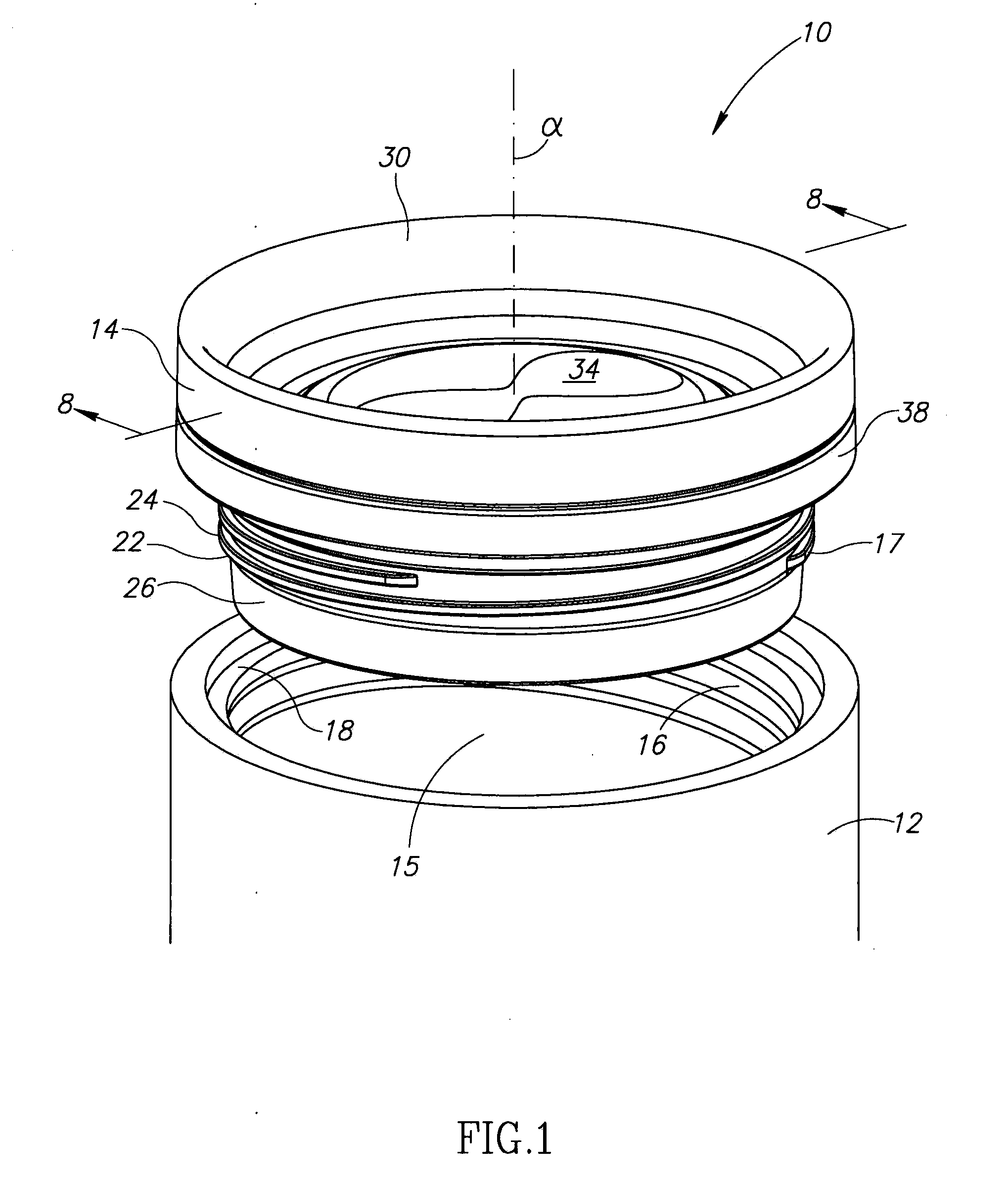

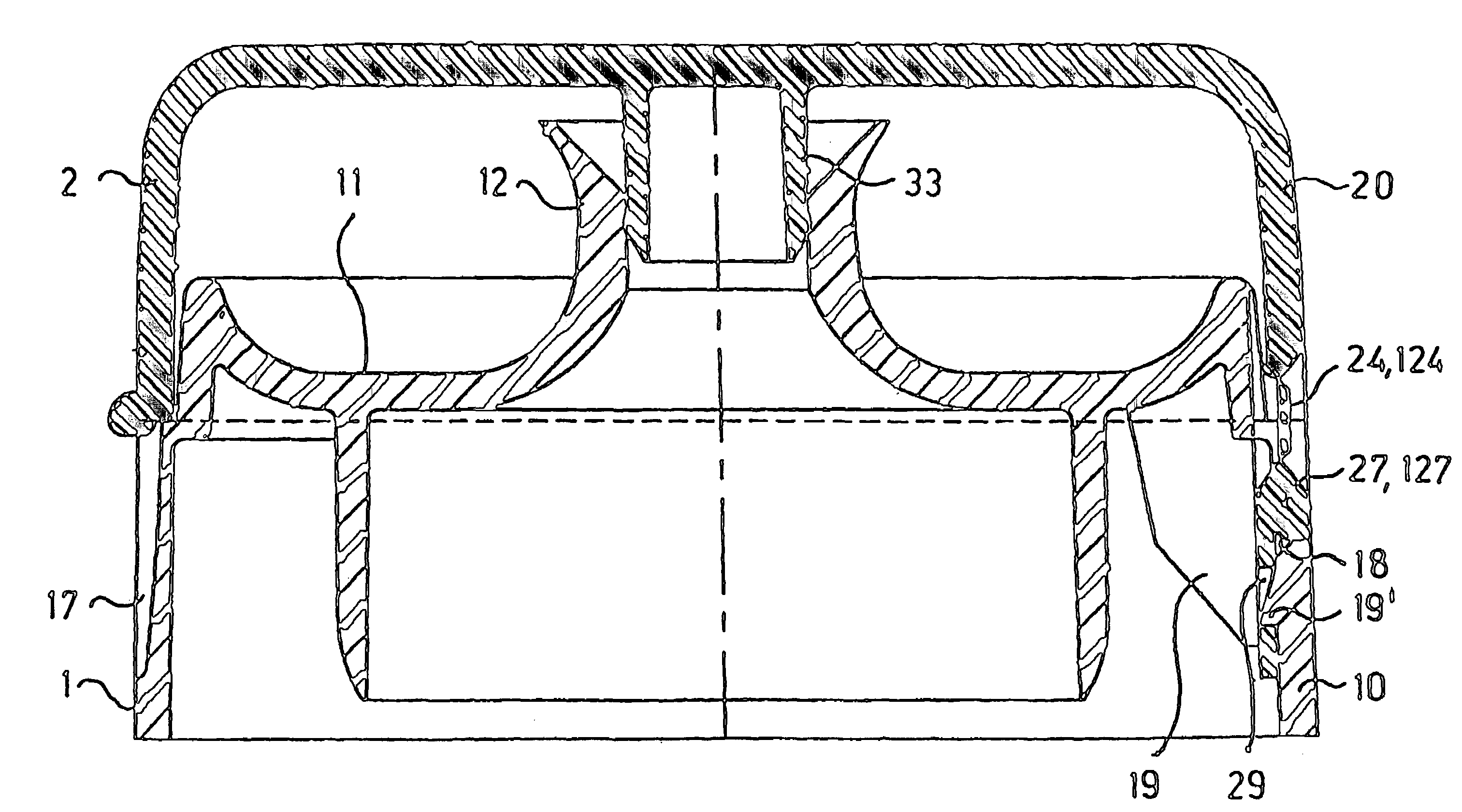

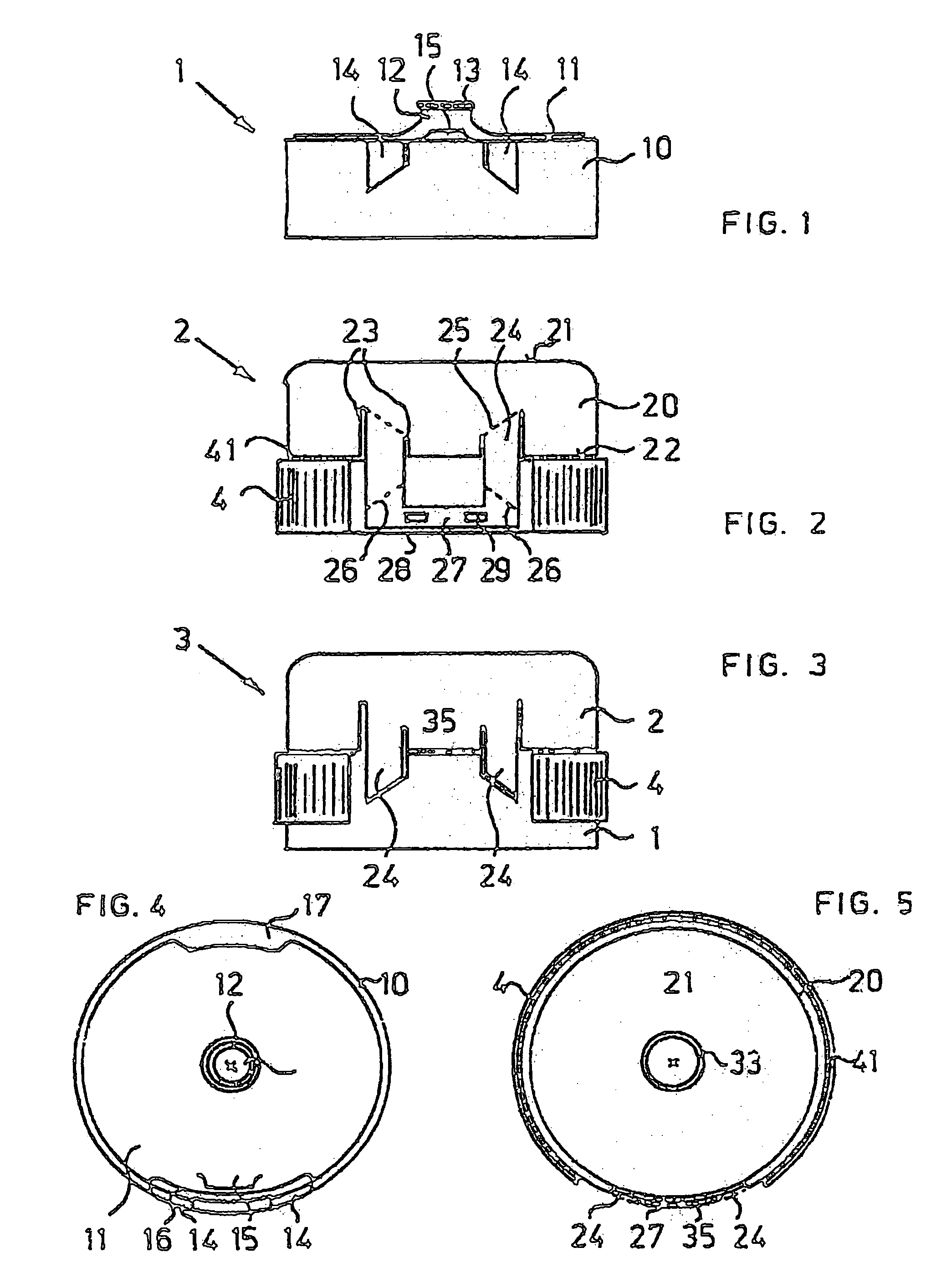

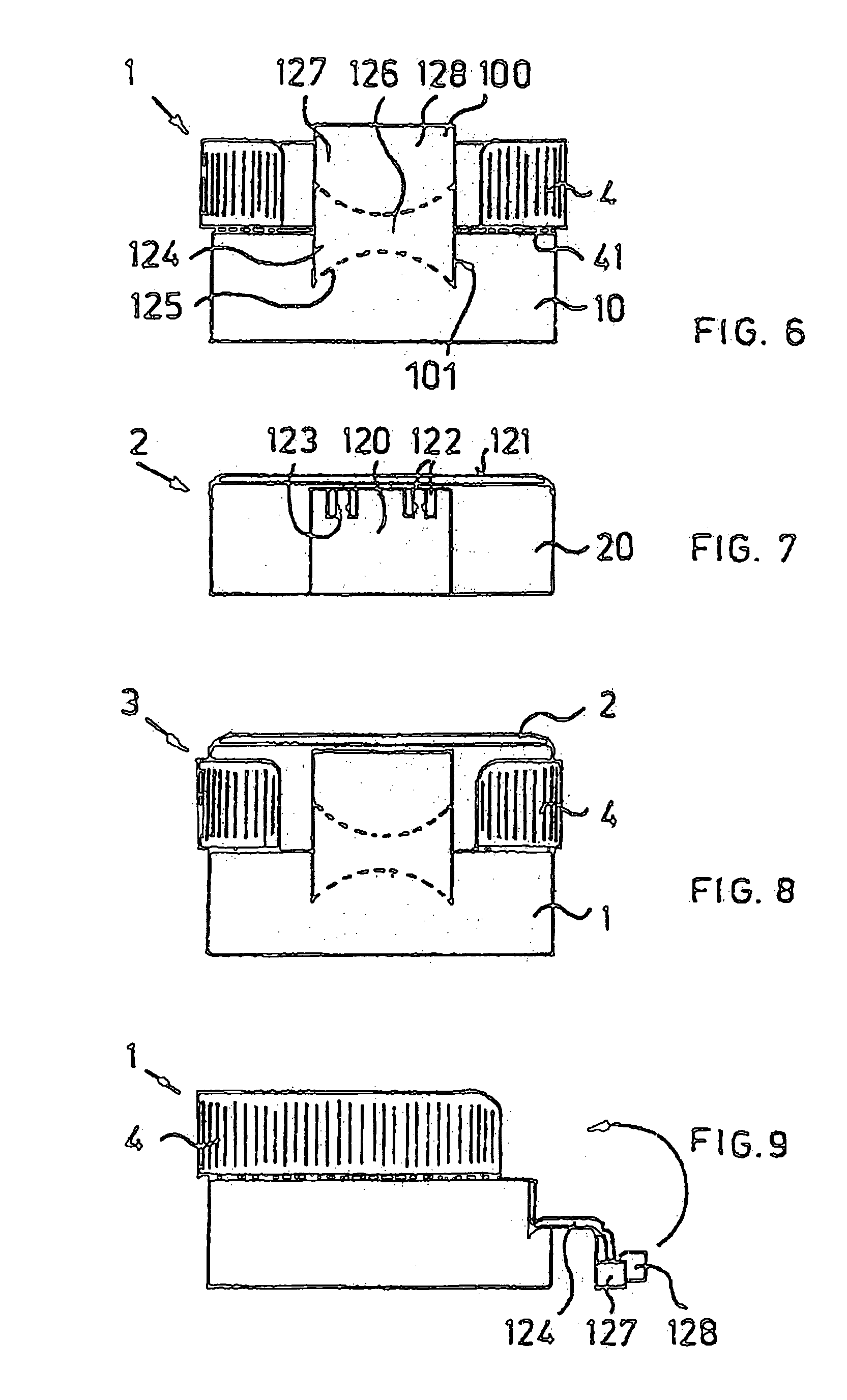

Gravity cup for a paint sprayer

ActiveUS8925836B2Improve tightnessConstant rigidityCapsClosure using stoppersGravitationWaste management

The invention relates to a gravity cup for a paint sprayer, having a cup-shaped tank (1) and a cover (2) that can be placed on the tank (1), a multiplex quick-connect thread having at least two external thread turns (18) and internal thread turns (19) engaging with the external thread turns (18) for connecting the tank (1) and the cover (2), characterized in that each external thread turn (18) is formed of a plurality of thread segments (18a, 18b, 18j) disposed along the pitch line of each external thread turn, wherein a gap (18p, 18q . . . 18w) is formed between adjacent thread segments.

Owner:SATA GMBH & CO KG

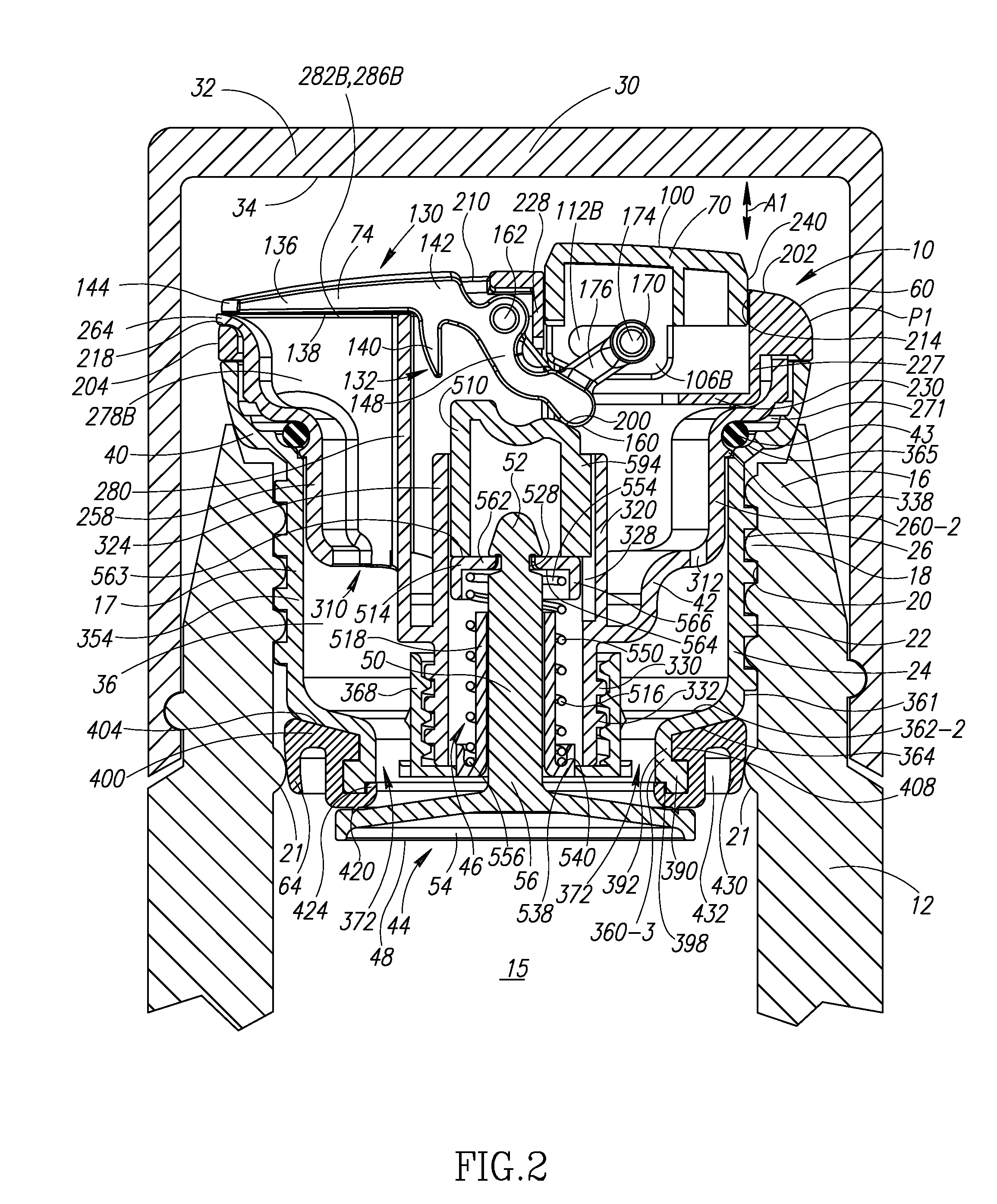

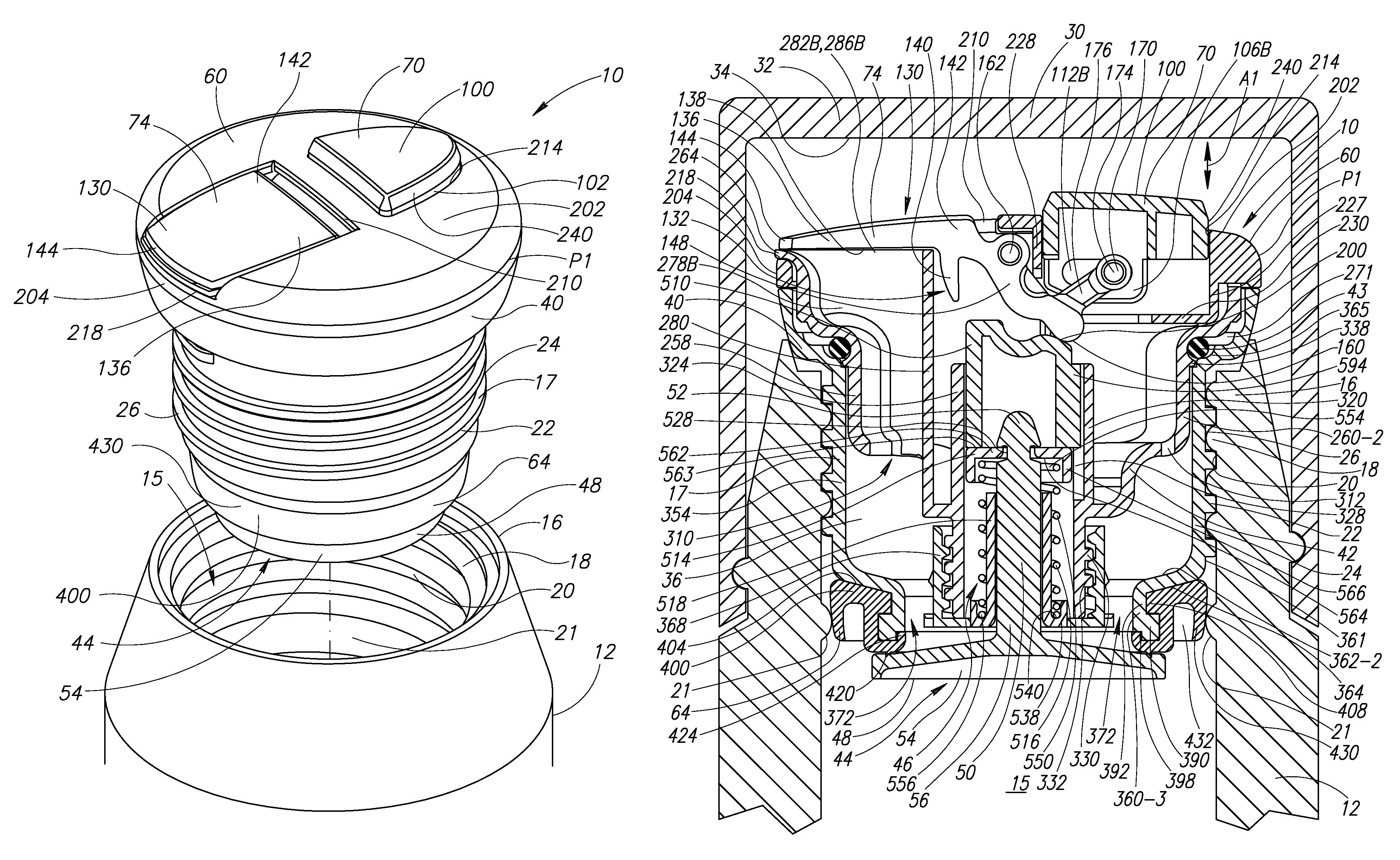

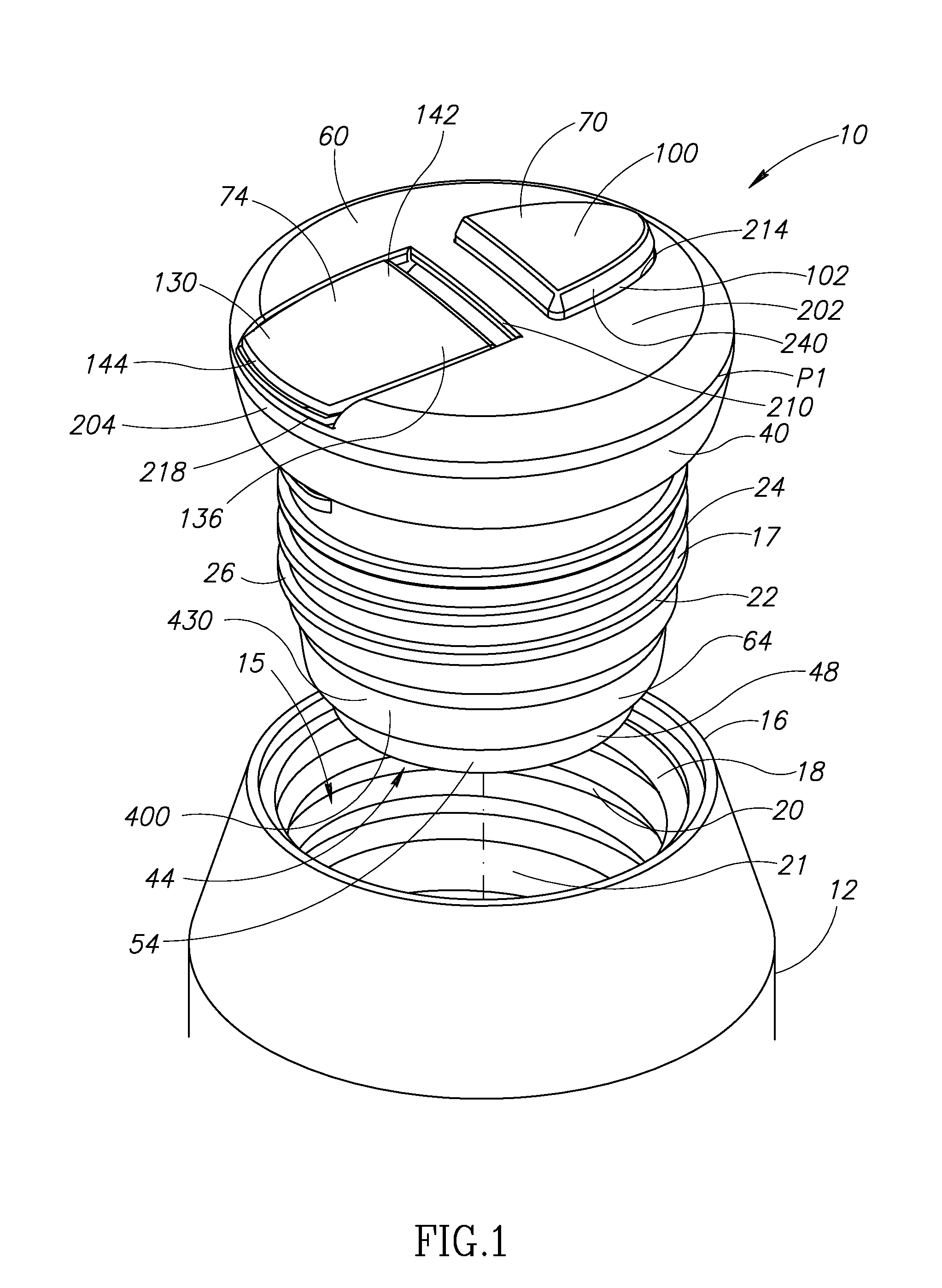

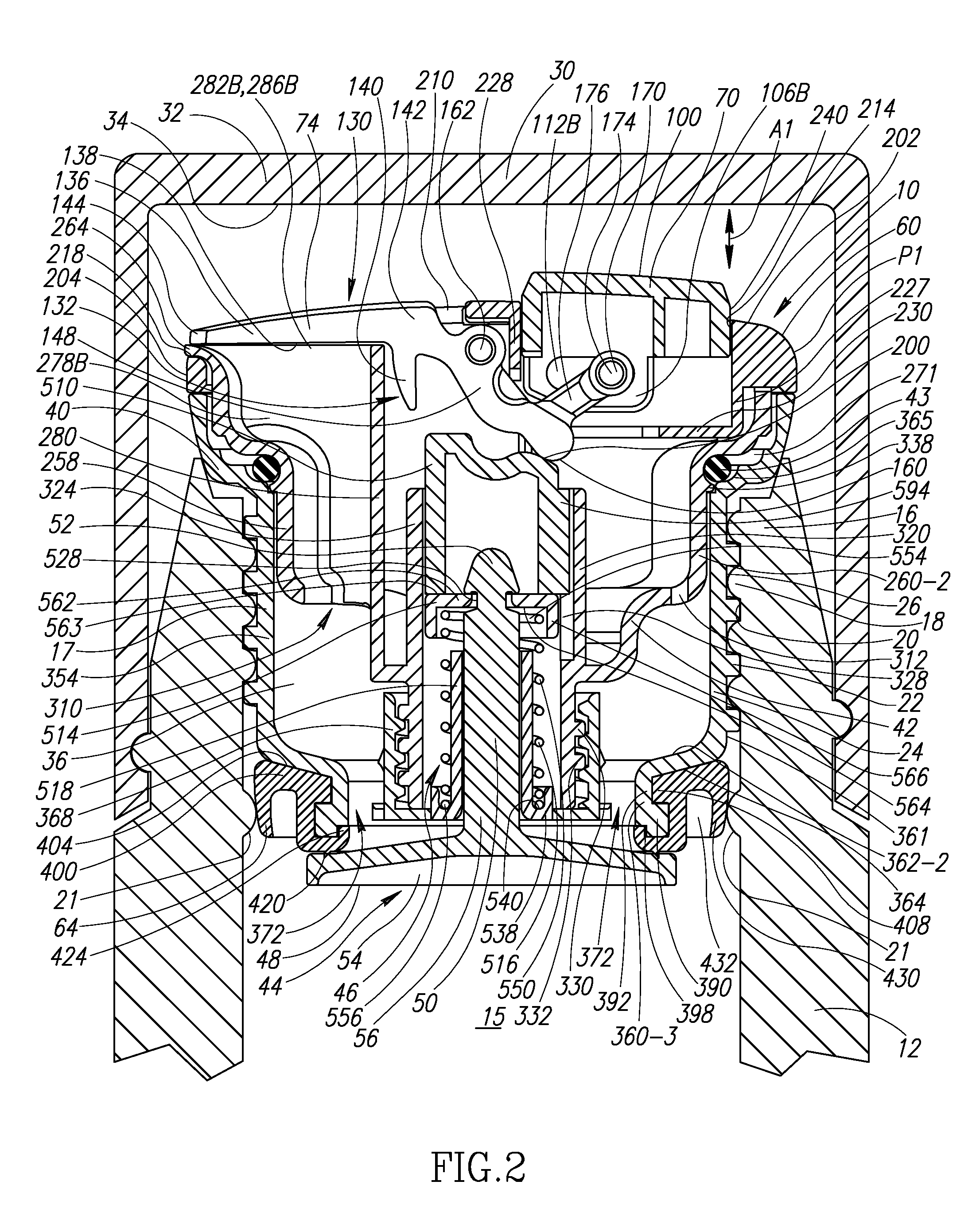

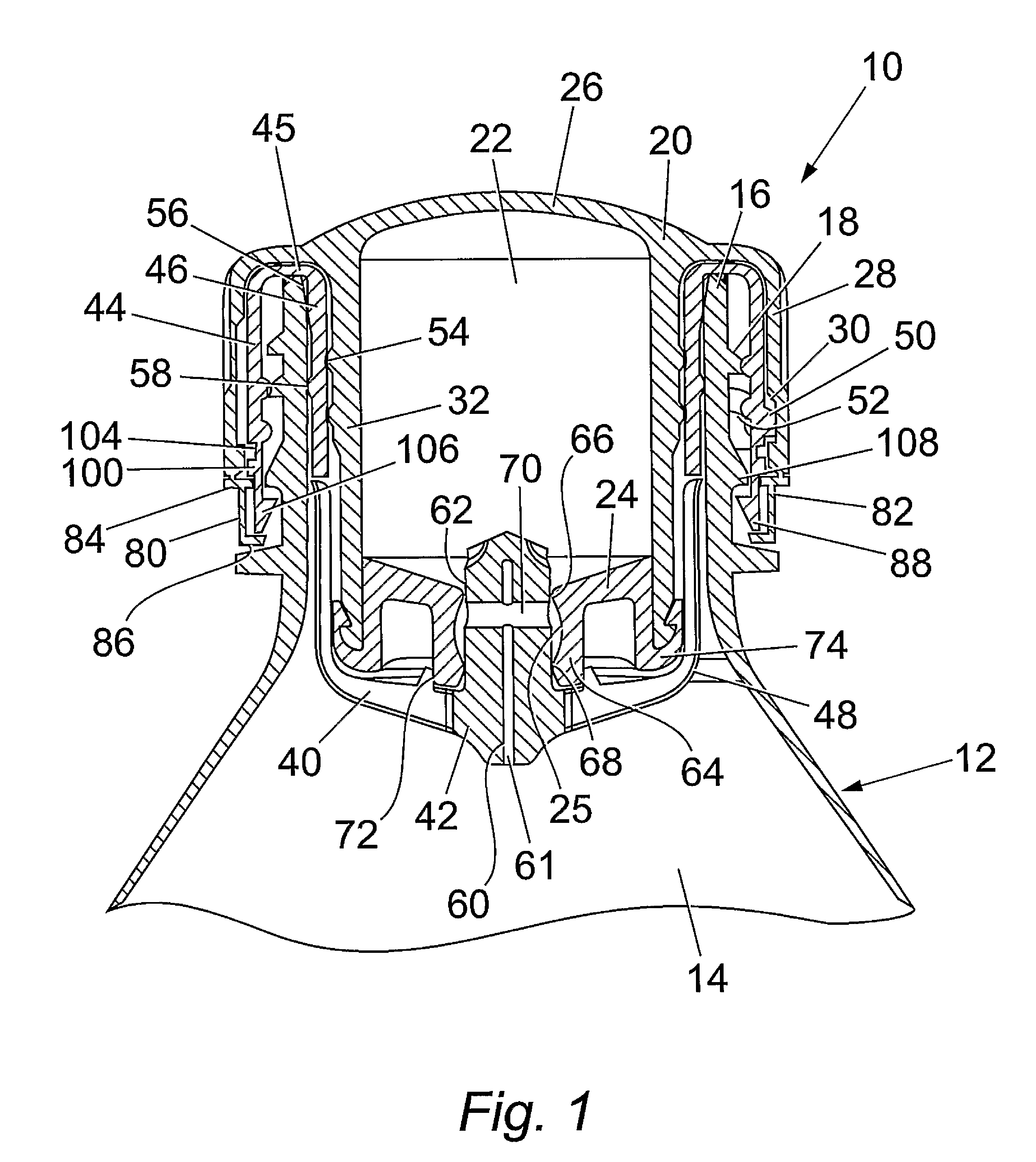

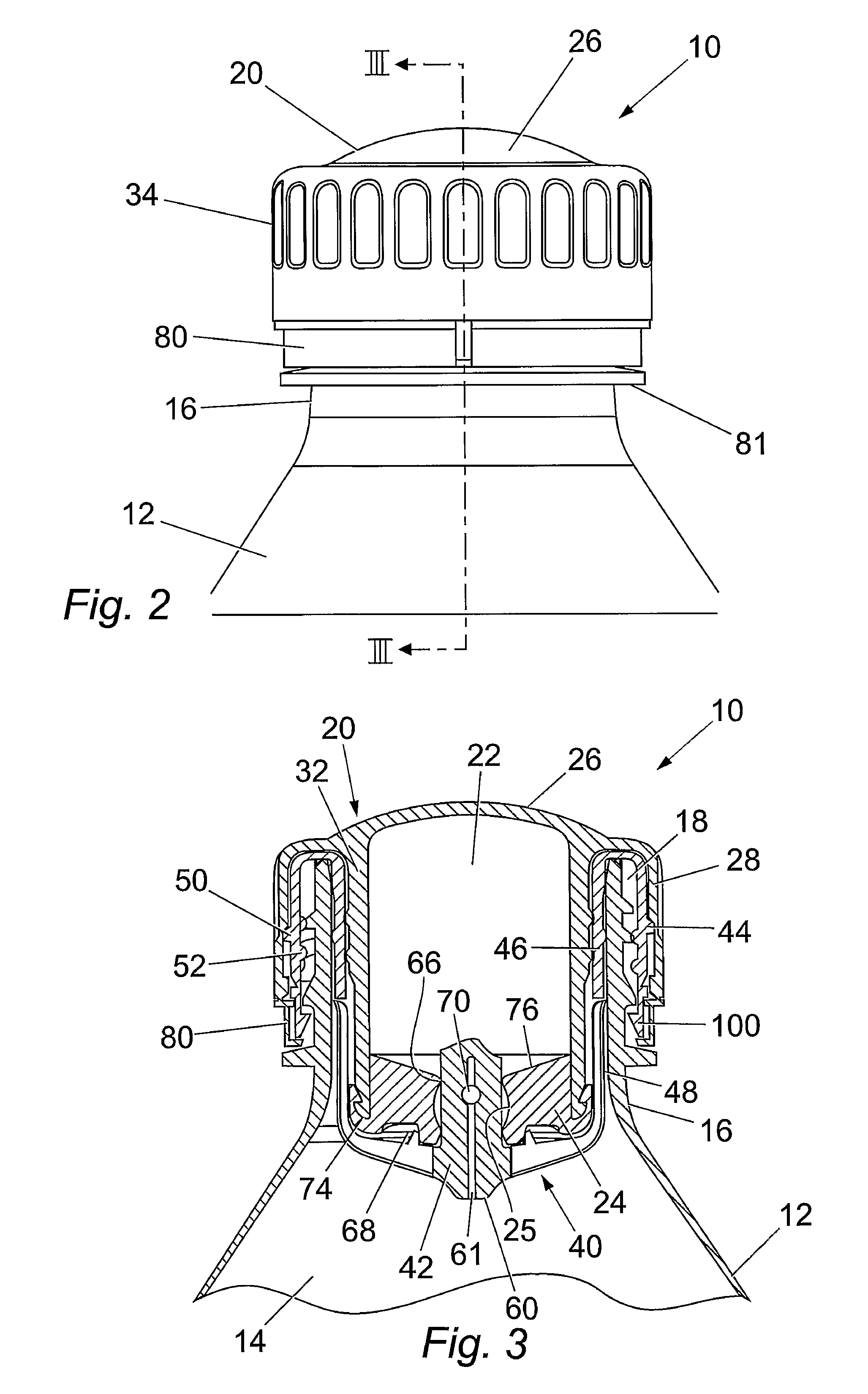

Bottle stopper having pushbutton and movable plug

A stopper for an opening of a container such as a thermos. The stopper includes a pushbutton, a fluid flow channel extending between an inlet and an outlet, and a movable plug portion positioned adjacent the inlet. A biasing member biases the plug portion into sealing engagement with the inlet thereby preventing the contents of the container from flowing into the channel. A cam follower is disposed upon a cam surface opposing the biasing member. The cam follower is rotatable by the pushbutton relative to the cam surface from a closed position to an open position and when so rotated, exerts a biasing force on the cam surface sufficient to overcome the biasing force exerted by the biasing member on the plug portion and space the plug portion from the inlet allowing the contents of the container to flow into the channel and out the outlet.

Owner:PACIFIC MARKET INT

Portable device case with corner protector

ActiveUS8073131B2Large thicknessEliminates reduces issueTwo-way loud-speaking telephone systemsTravelling sacksEngineeringMechanical engineering

A case for a portable electronic device such as cell phones, cameras, MP3 players and PDAs wherein said case includes material at the corners to provide protection to the electronic device. To reduce bulk at the corners and allow the material forming the case to conform with the contours of the device, the protection at the corners includes strips of material defining apertures there between. The apertures provide reduction in bulk and allow the case to conform to the corners of the device therein. Alternately, the protection at the corners can be provided by other structures co-molded into the corners of the cases. Such structures include material that is of a reduced thickness than other material used in the case, or structures that are formed to conform to the corners of the case. Such structures can be joined to the material forming the panels of the case by co-molding.

Owner:SAMSONITE IP HLDG SARL

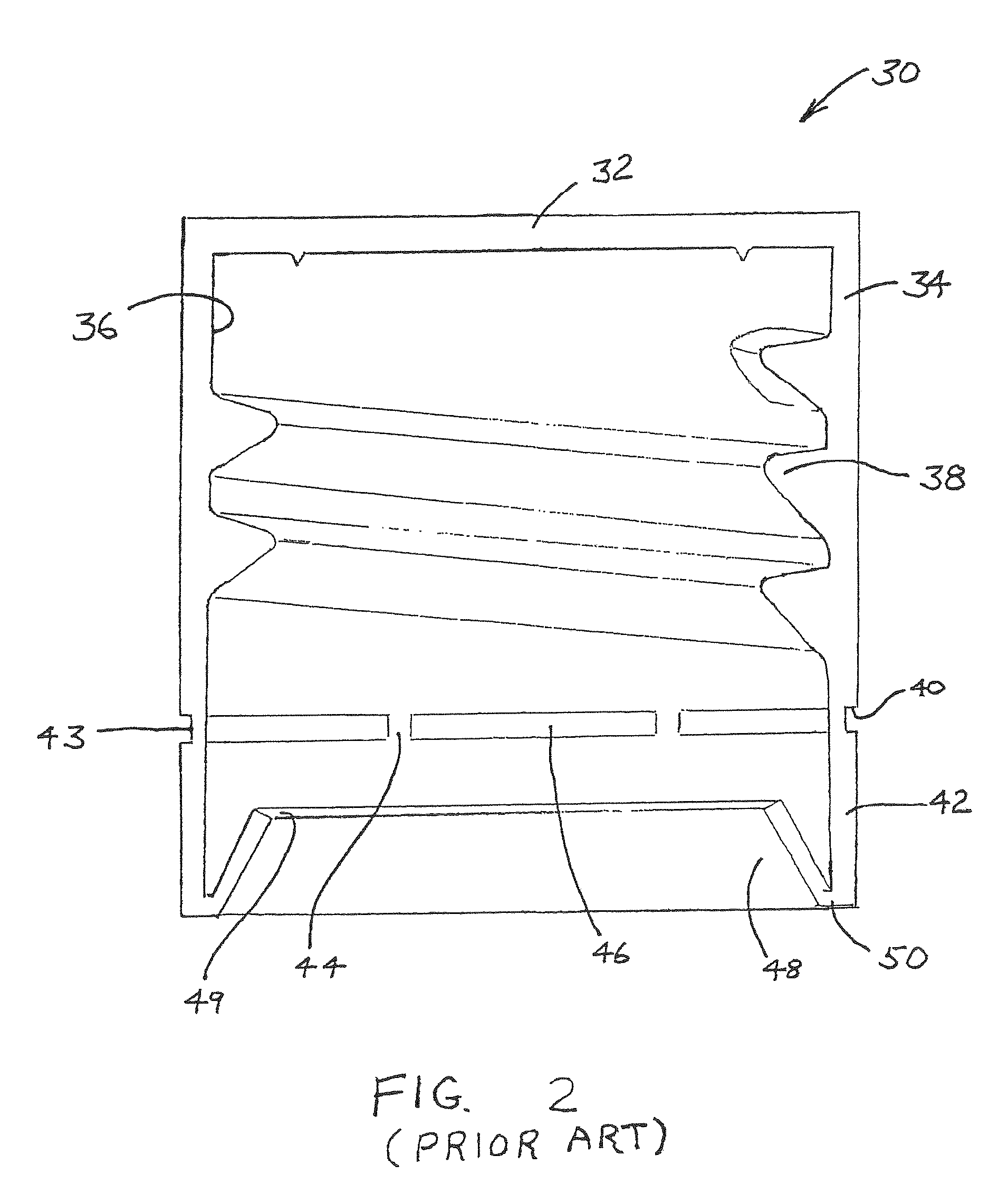

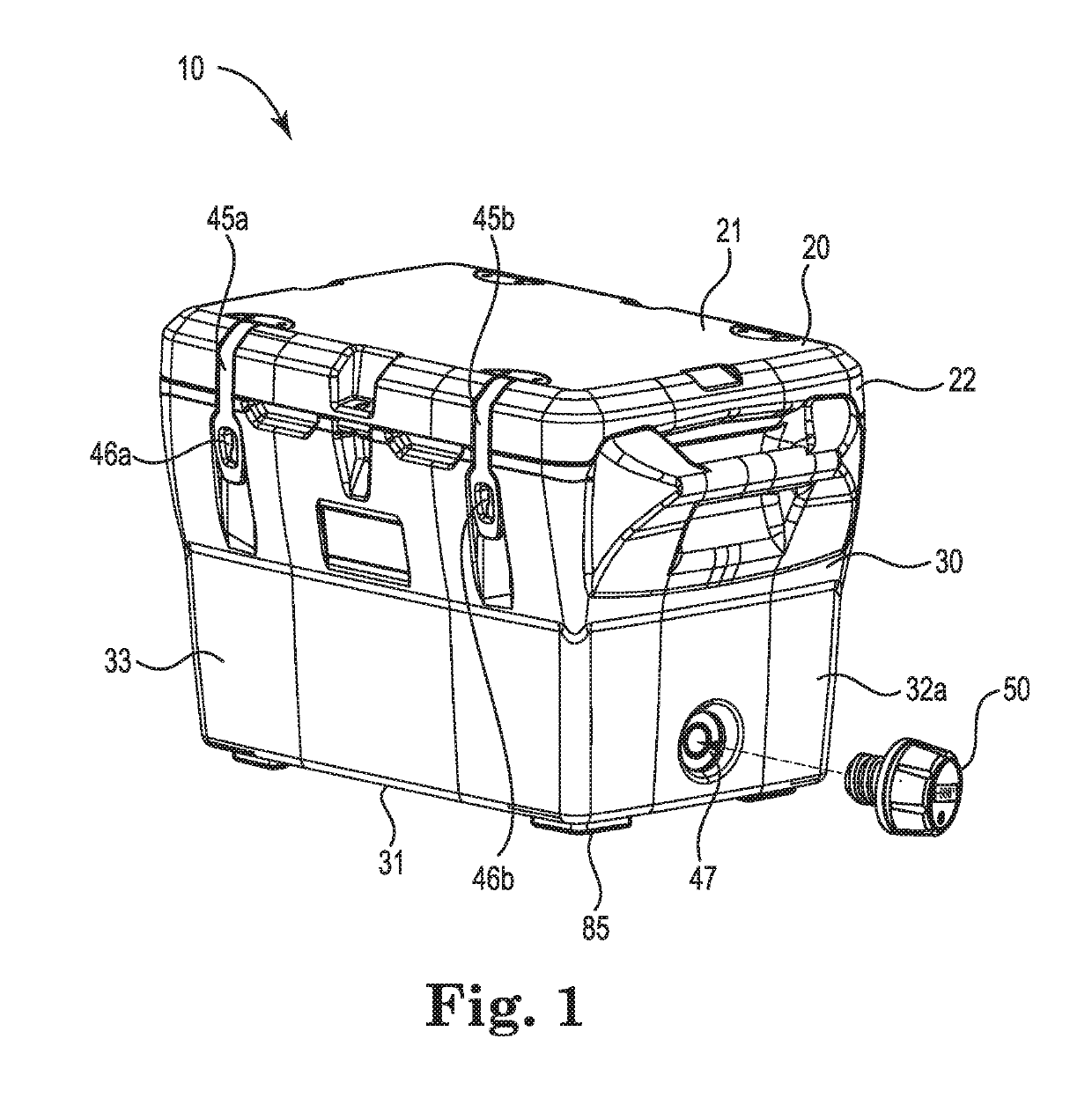

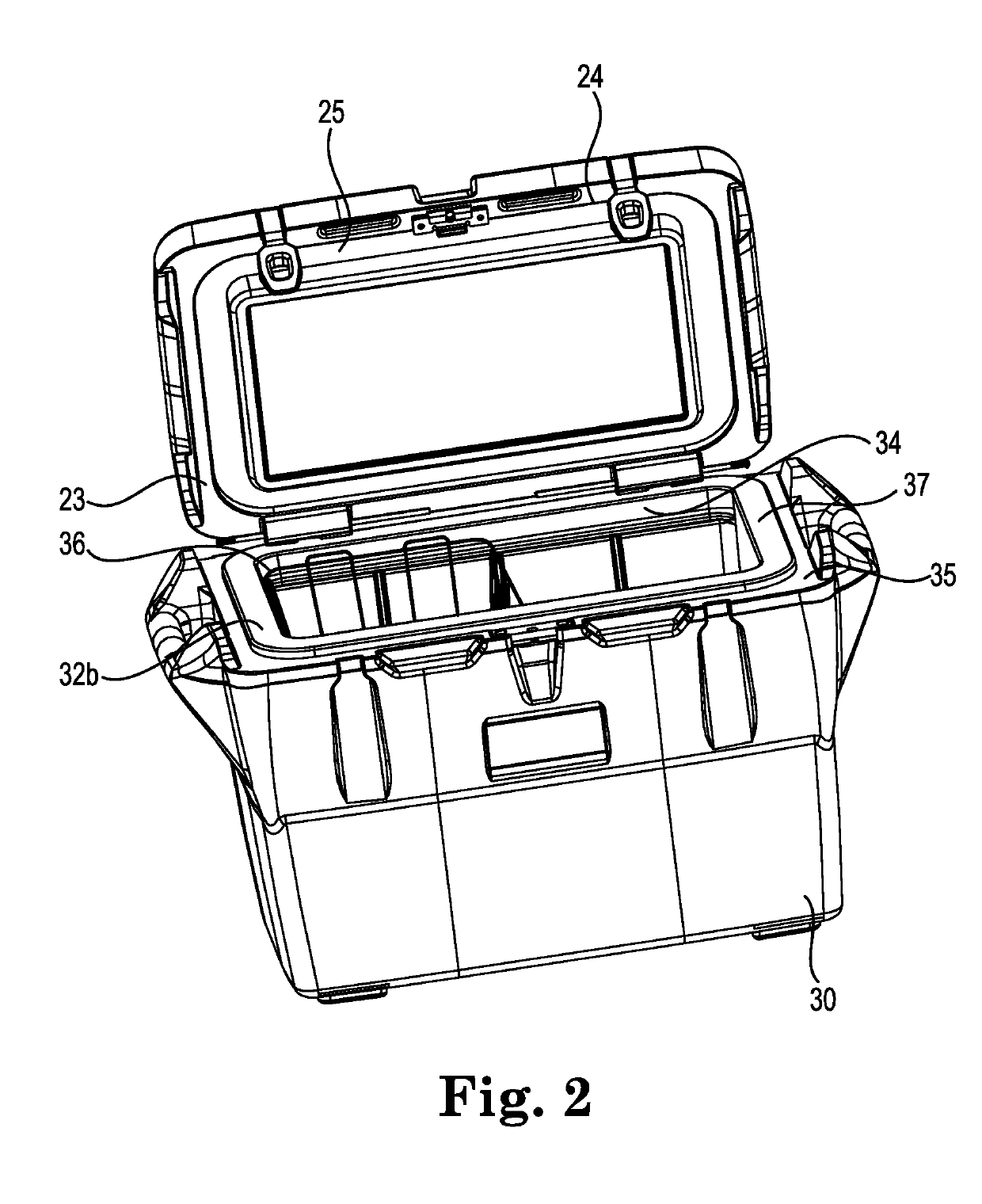

Container with closures

ActiveUS20190152677A1Thermometer detailsDomestic cooling apparatusDifferential pressurePressure regulator

A container having a full perimeter lid pressure or tensioning mechanism. The container can also have a removable temperature sensor to monitor an internal compartment temperature. A pressure regulator is also disclosed to regulate a pressure differential and vacuum of the container in order to control an amount of vacuum sealing of the lid to the container.

Owner:EUFOURIC BRANDS LLC

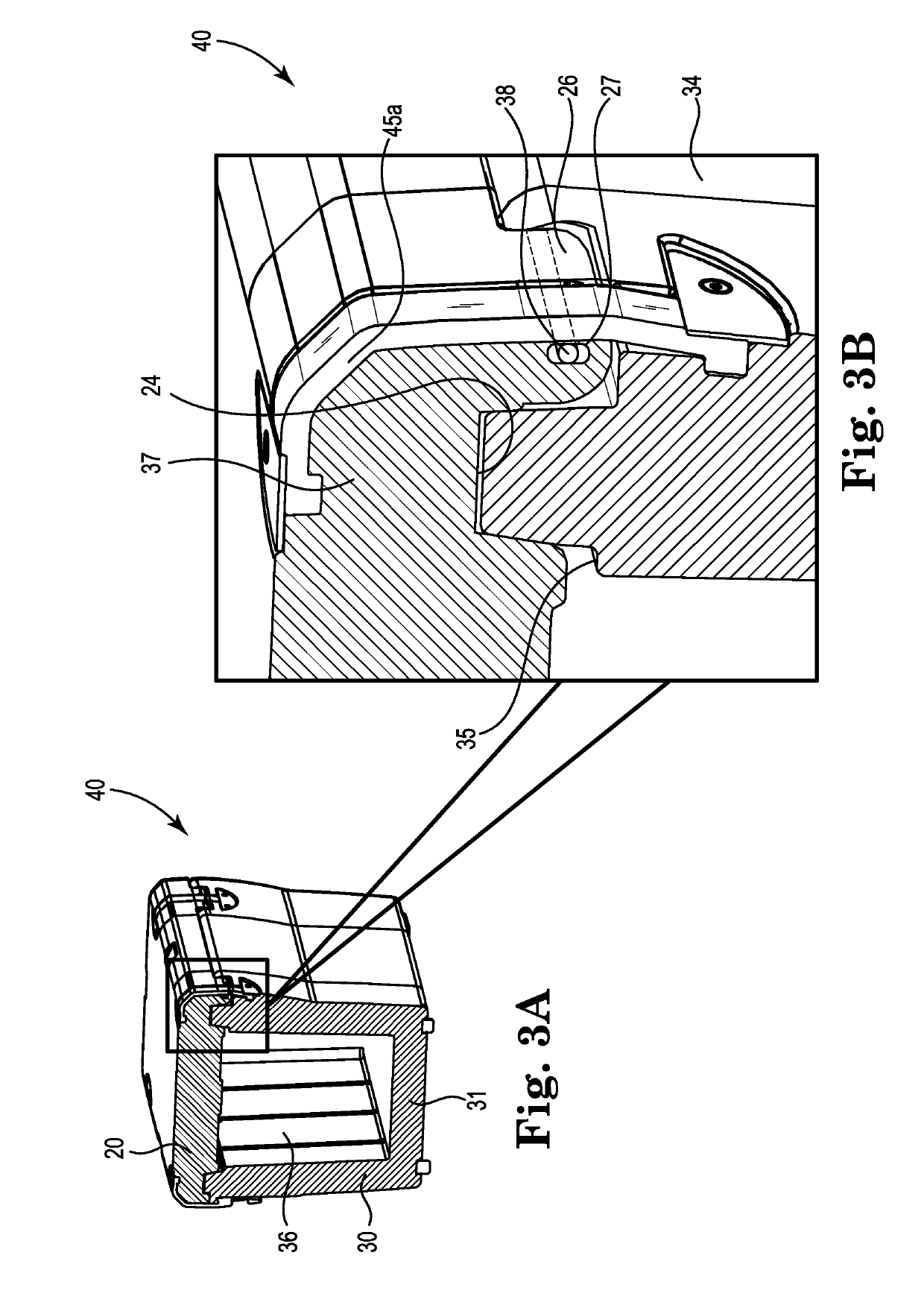

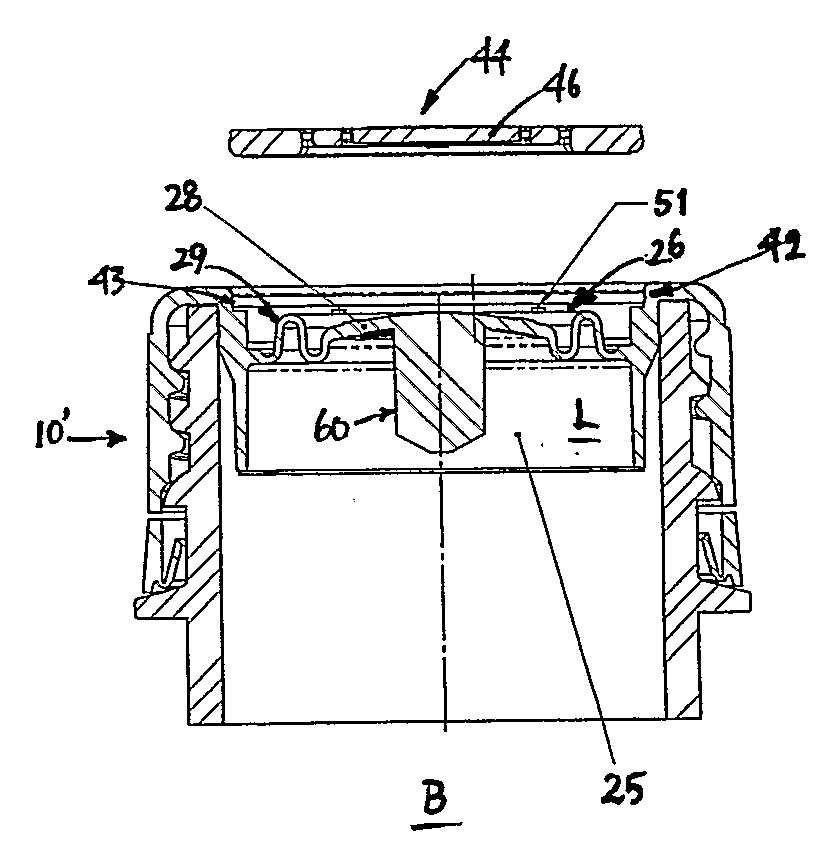

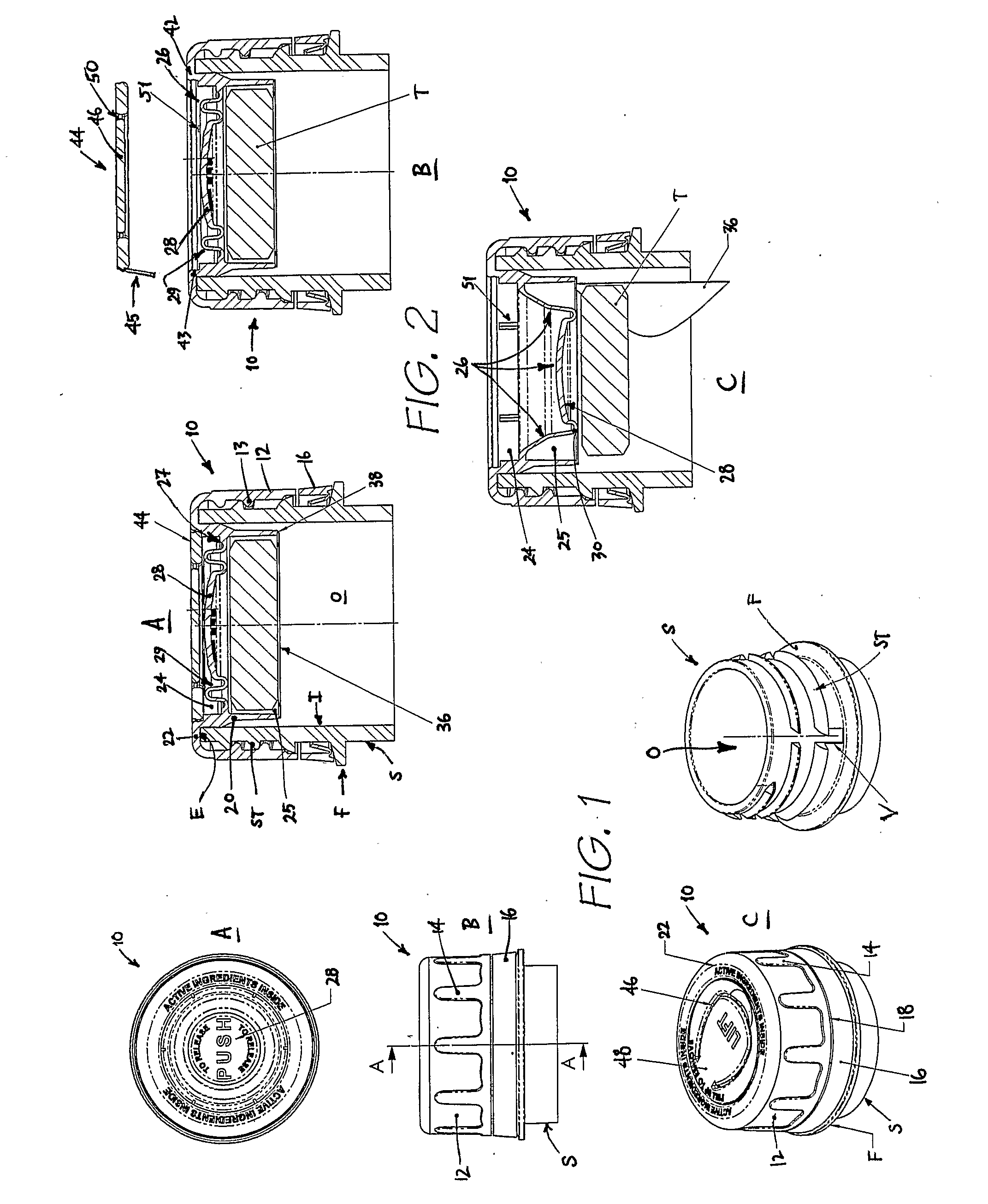

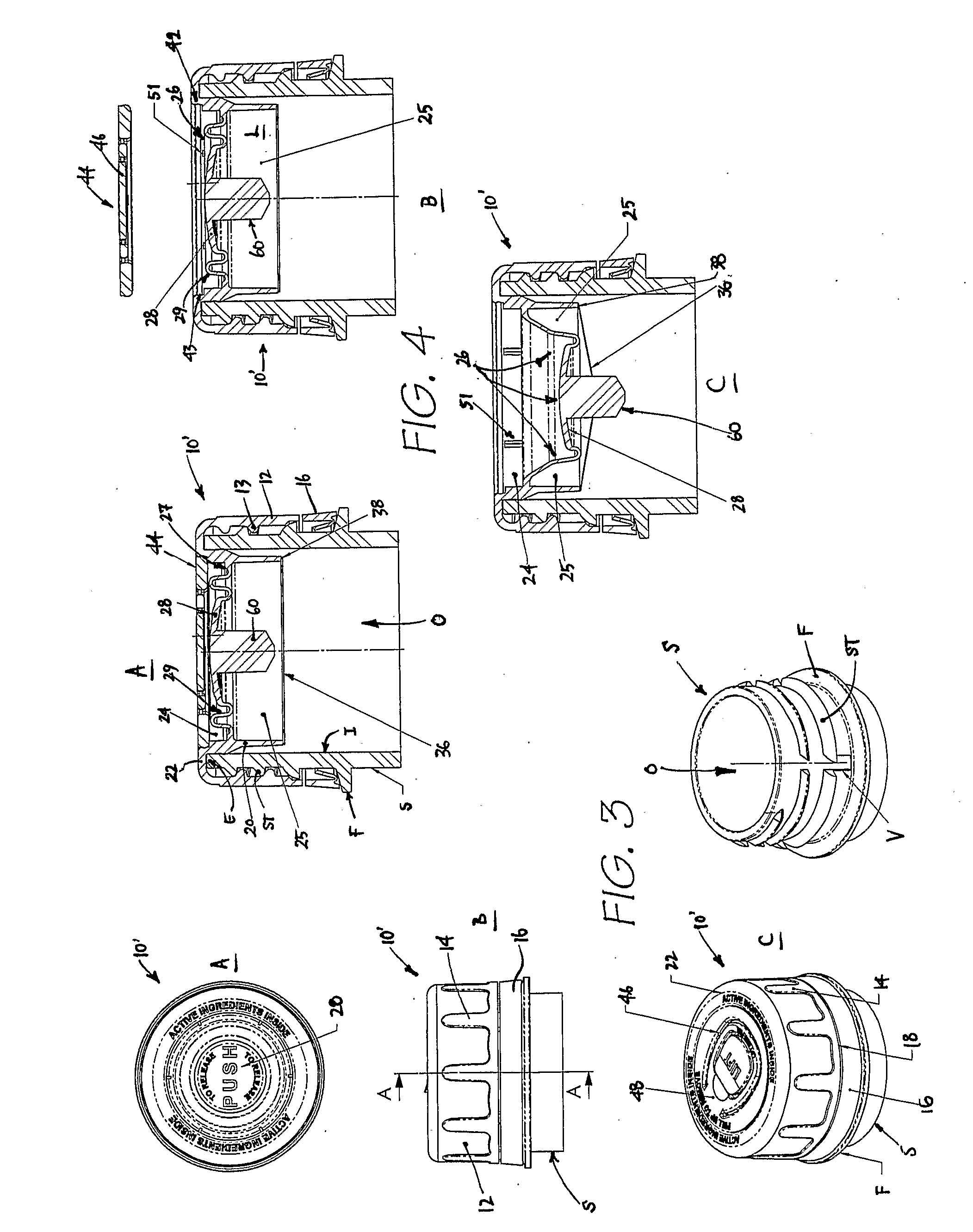

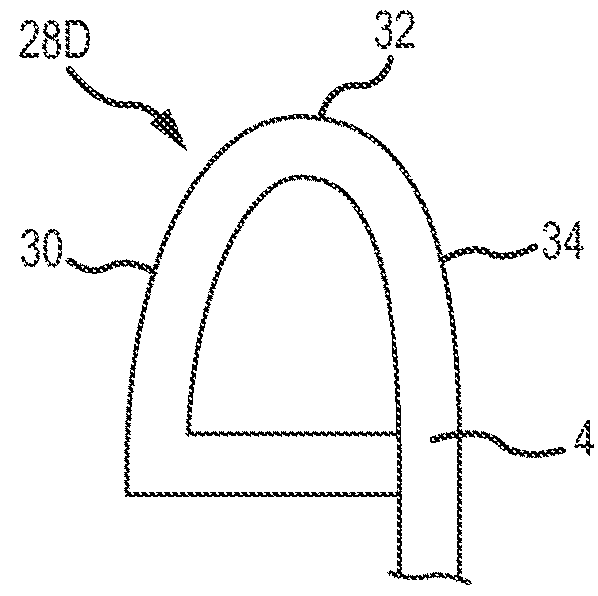

Closure

ActiveUS20090242561A1Considerable in operationEasy constructionCapsClosure using stoppersEngineeringBellows

A closure (10) for mounting at an opening (O) of a container spout (S) comprises a compartment (32) in which material such as a tablet (T) can be positioned. The compartment comprises a wall (26) that comprises a first region (28) that is surrounded by a second bellows-like region (30) that enables the first region to be displaced from a first position to a second position to cause the material to be released from the compartment. The wall can comprise a protrusion (X) that extends into the compartment such that, when the wall is displaced to the second position, the protrusion can cause the material to be released from the compartment. Also, when the wall is displaced to the second position the first region can act directly on the material to force it out of the compartment.

Owner:SOPHINITY PTY LTD (ATF WELLMAN CONSOLIDATED TRUST)

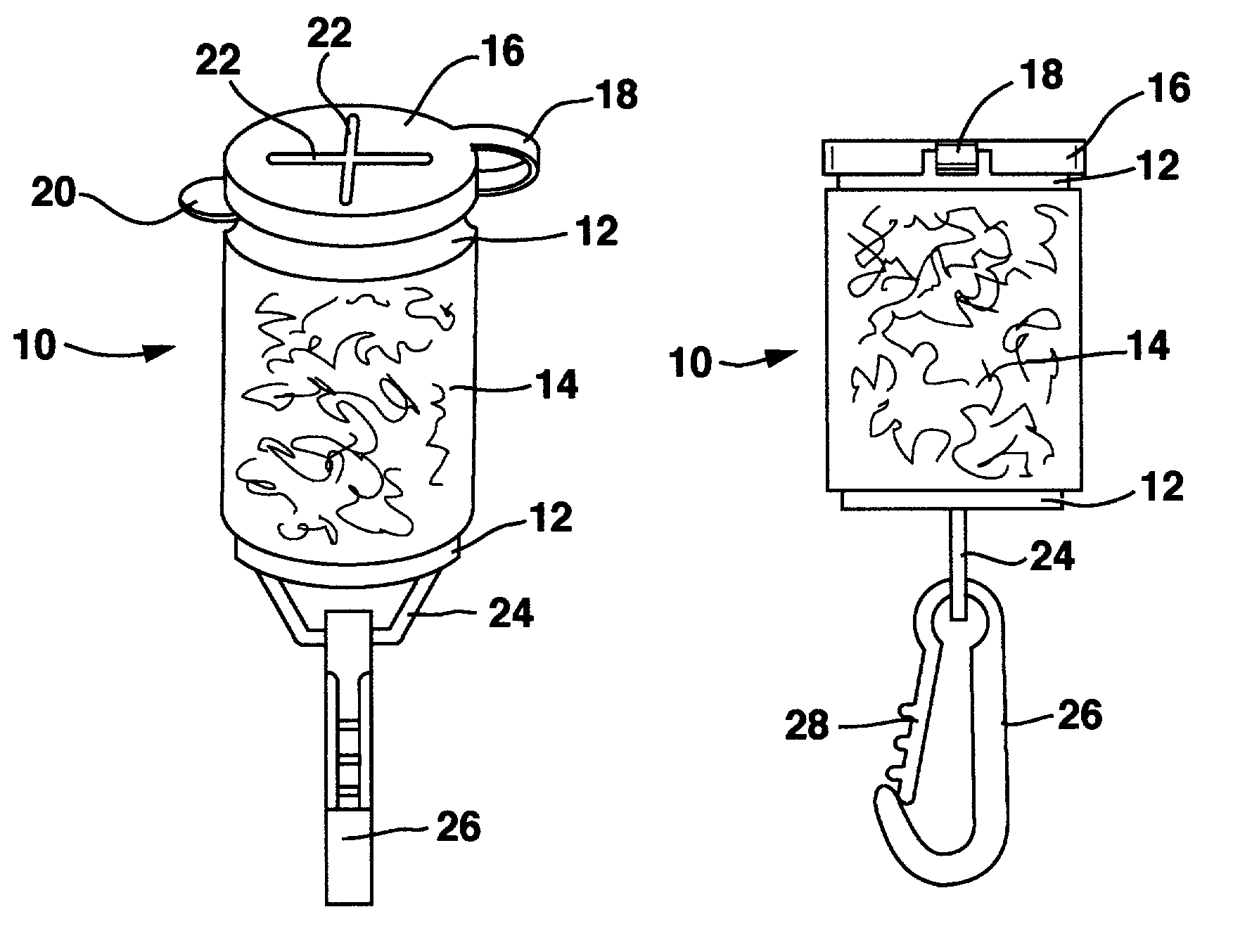

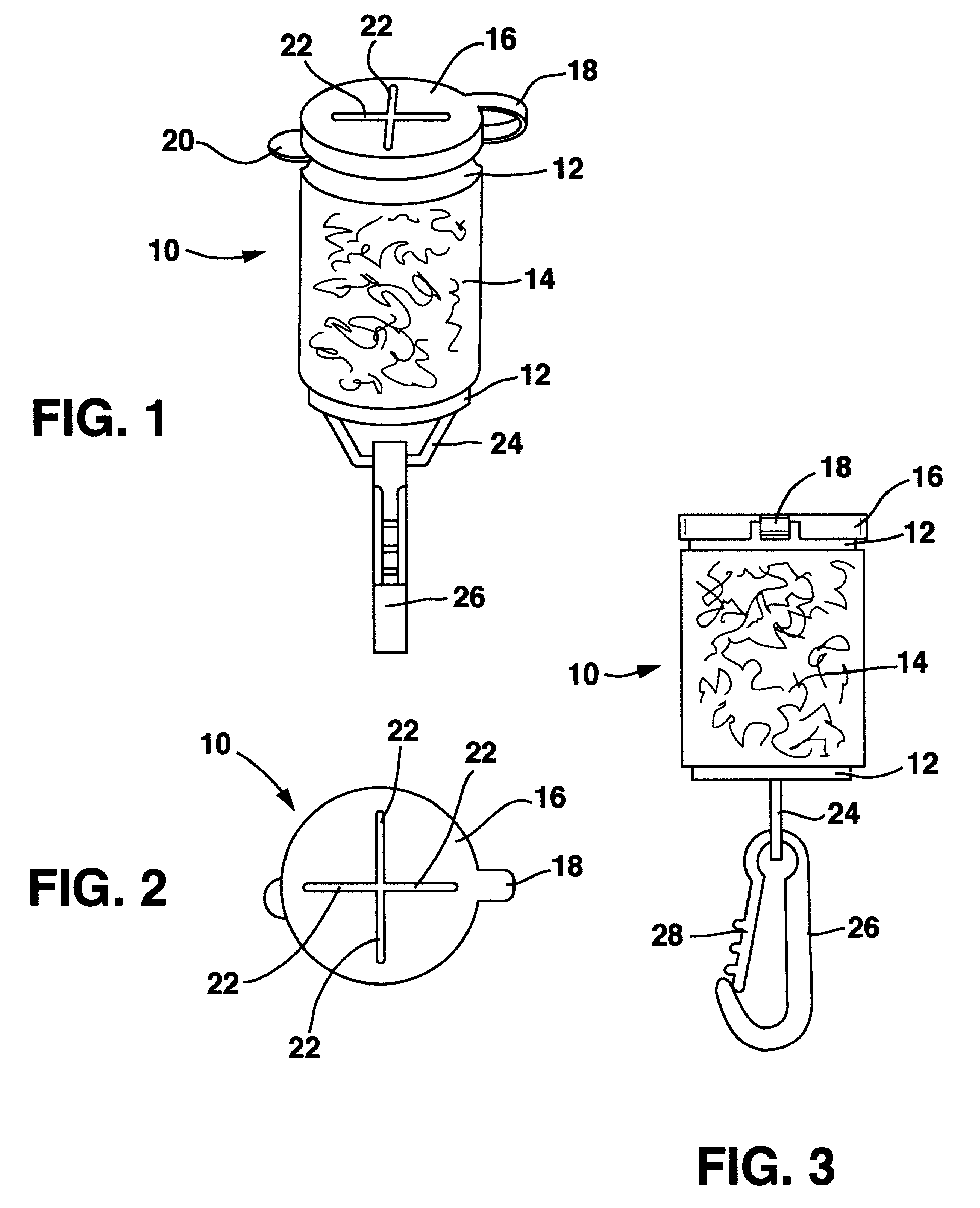

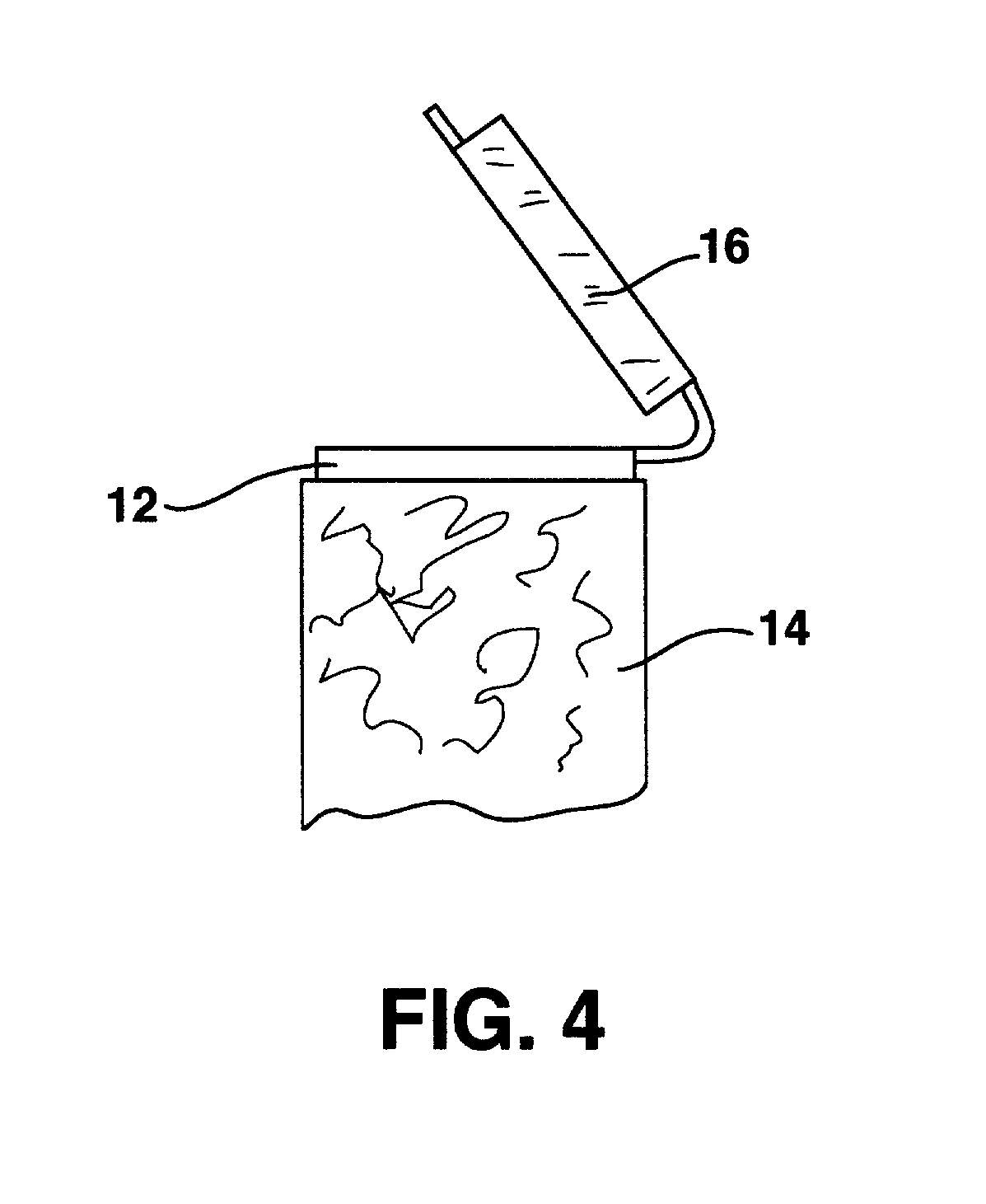

Fisherman's trash receptacle and fly rig holder

The present invention includes a cylindrical container closed at one end and opened at the other. The container is wrapped with Velcro material, or a foam material, to which leader and fly rigs can be easily wrapped and kept in place. A lid is provided to cover the open top of the container, the lid is hingedly attached to the container to prevent inadvertent loss of the lid. The lid is also provided with cross slits so that small items can be pushed through the slits for storage within the closed container. Further, a clip is fixed to the container so that the receptacle can be easily attached to a fly fisherman's vest.

Owner:CLEAN STREAM

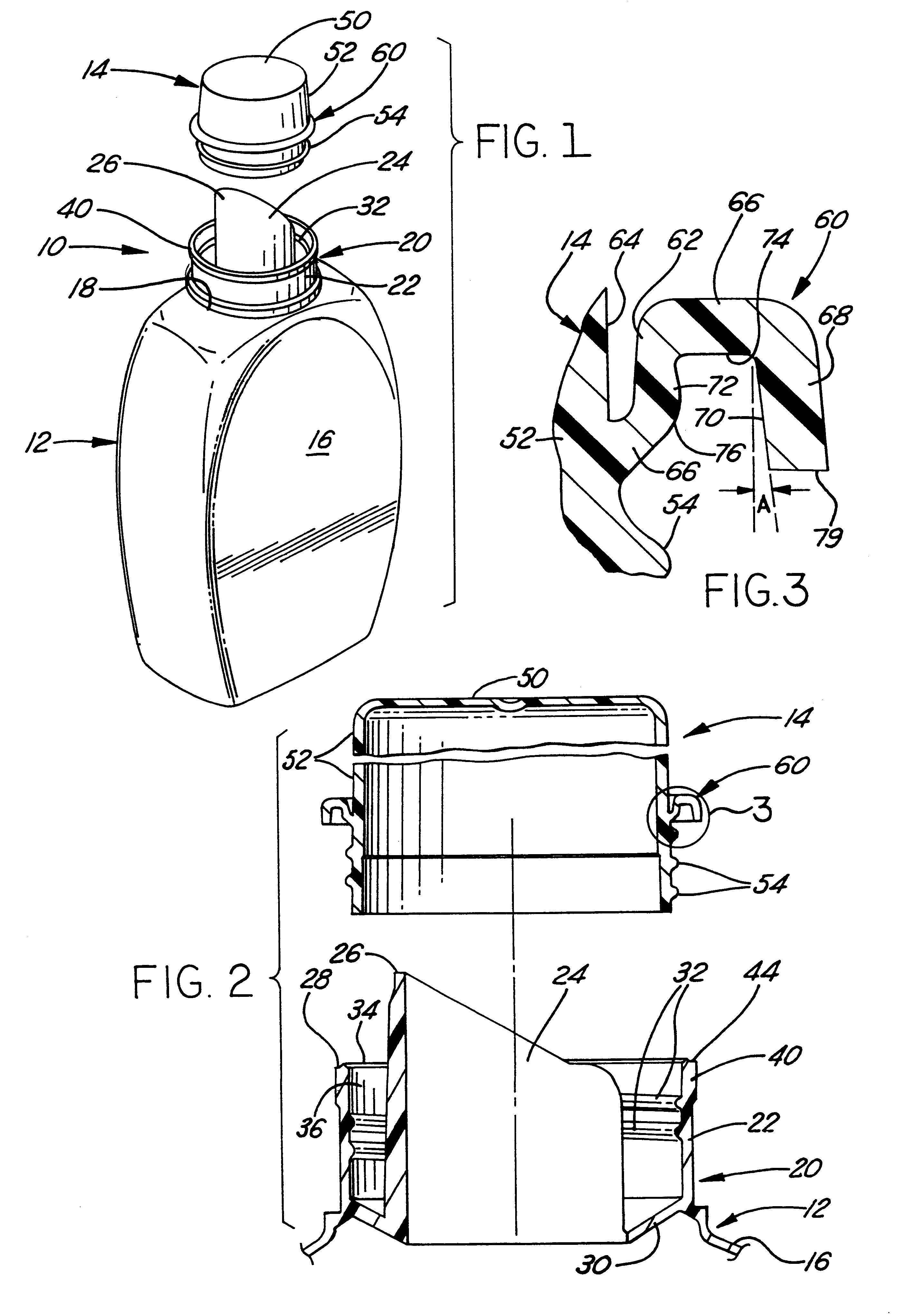

Fitment assembly for a container having a tamper indication band attached thereto

A tamper evident fitment assembly for use with a container for flowable material, the closure comprising a cap and a spout secured to the container, the cap having a frangible tamper evident band, the cap having an annular recess for frictionally engaging a top portion of the spout, the cap and spout having cooperating detent and locking elements so that the assembly in a first position where the cap is removably sealed to the spout and the tamper evident band is not broken when the cap is removed for filling may move to a second position when the cap is removably sealed to the spout and the tamper evident band is broken upon removal of the cap. An important feature of the present invention is that the cap frictionally engages a top portion of the spout. No screw threads or similar securing means are required to retain the cap on the spout.

Owner:LIQUI BOX

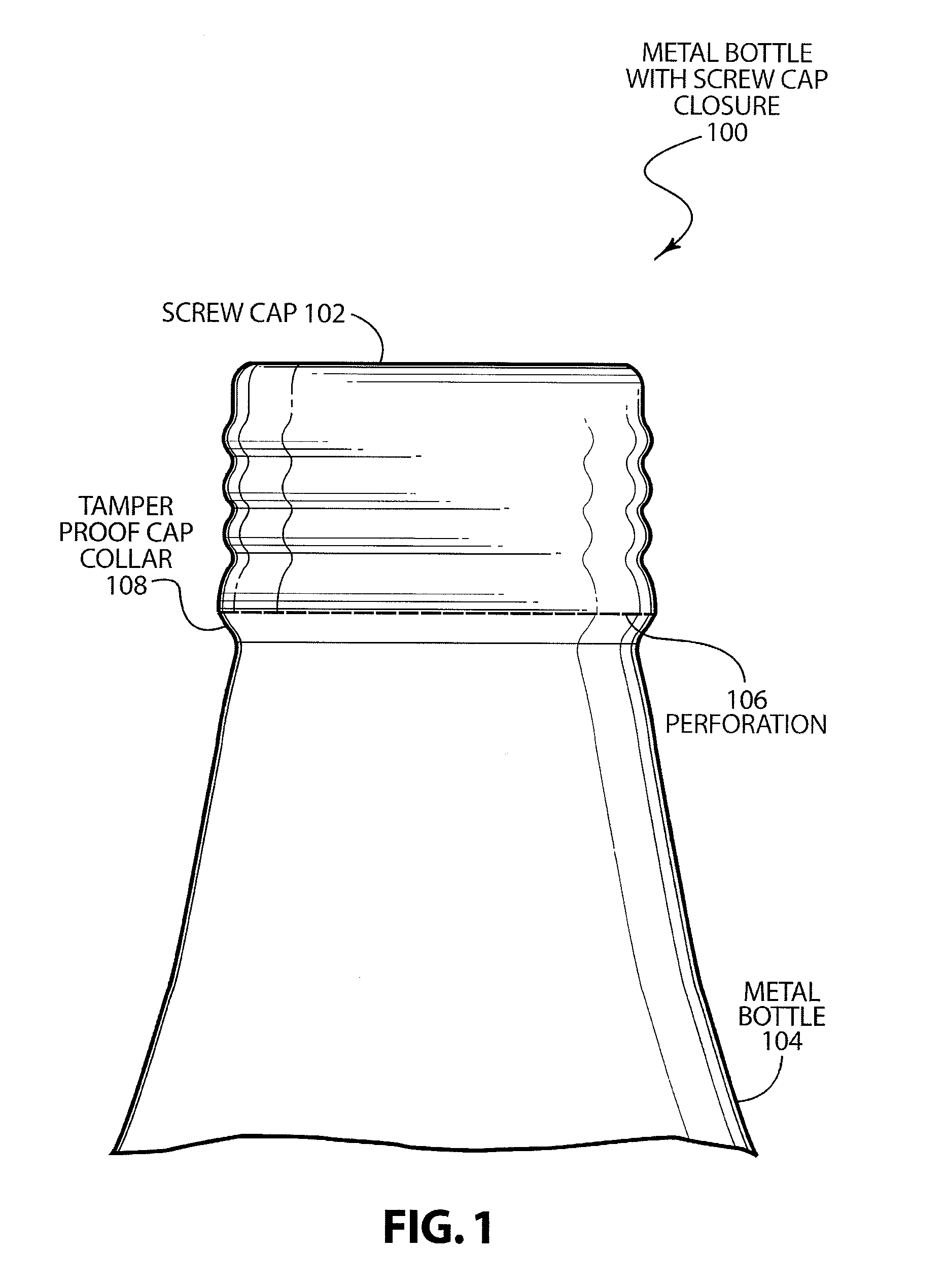

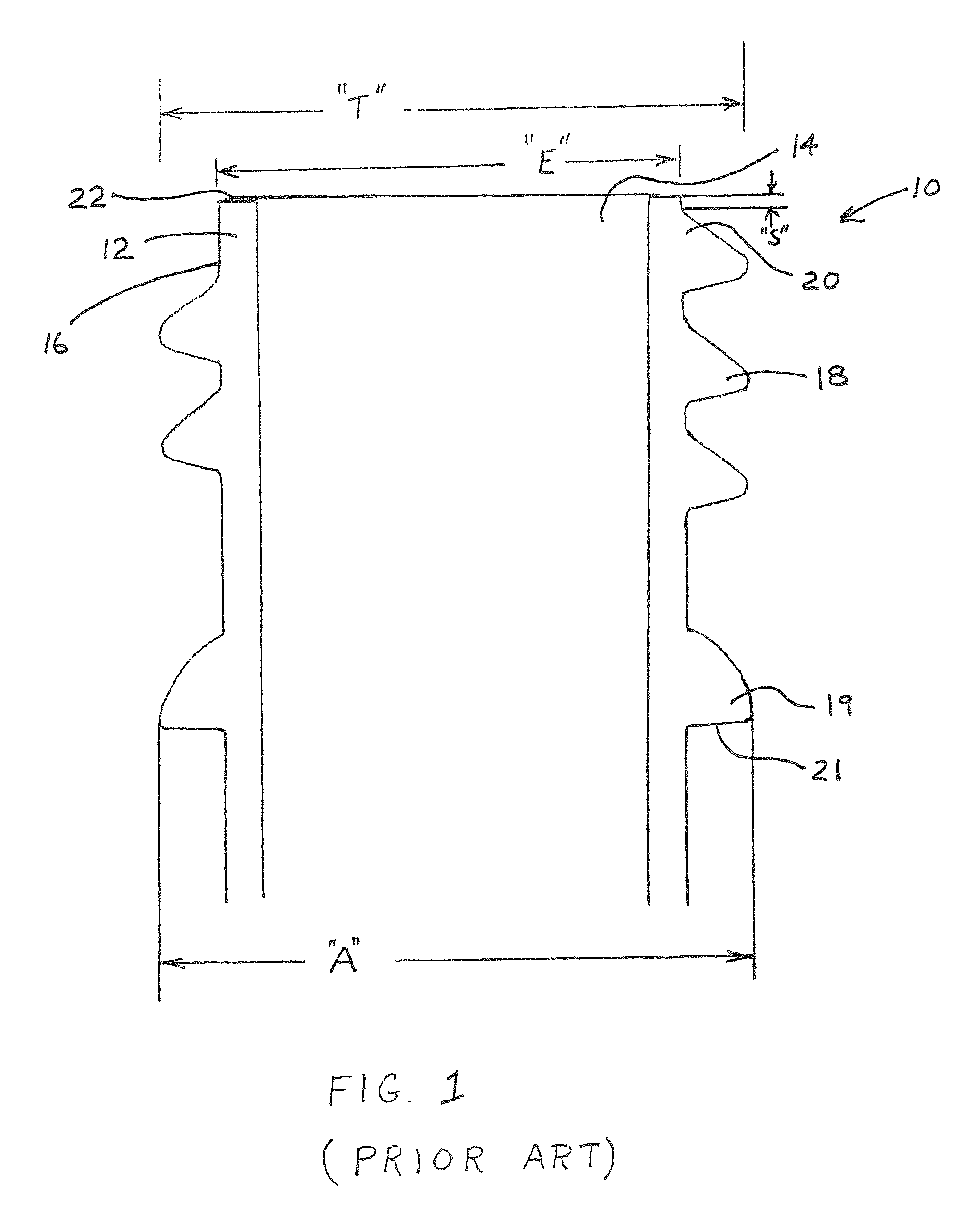

Metallic container with a threaded closure

ActiveUS10040593B2Prevent further rotationCompromise sealClosure using stoppersBottlesEngineeringMechanical engineering

Owner:BALL CORP

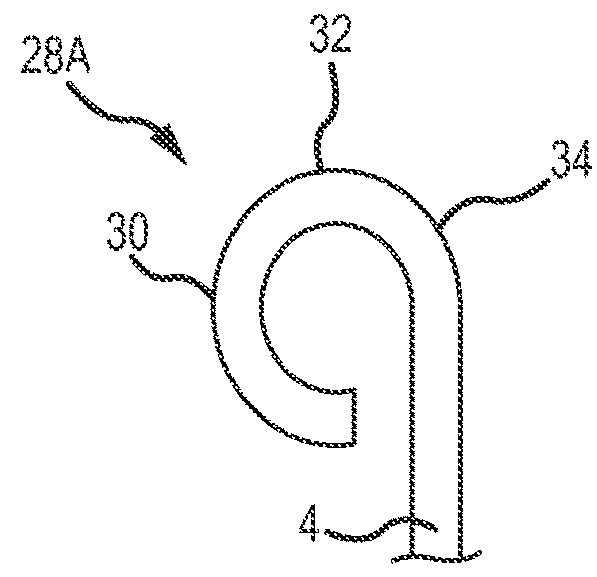

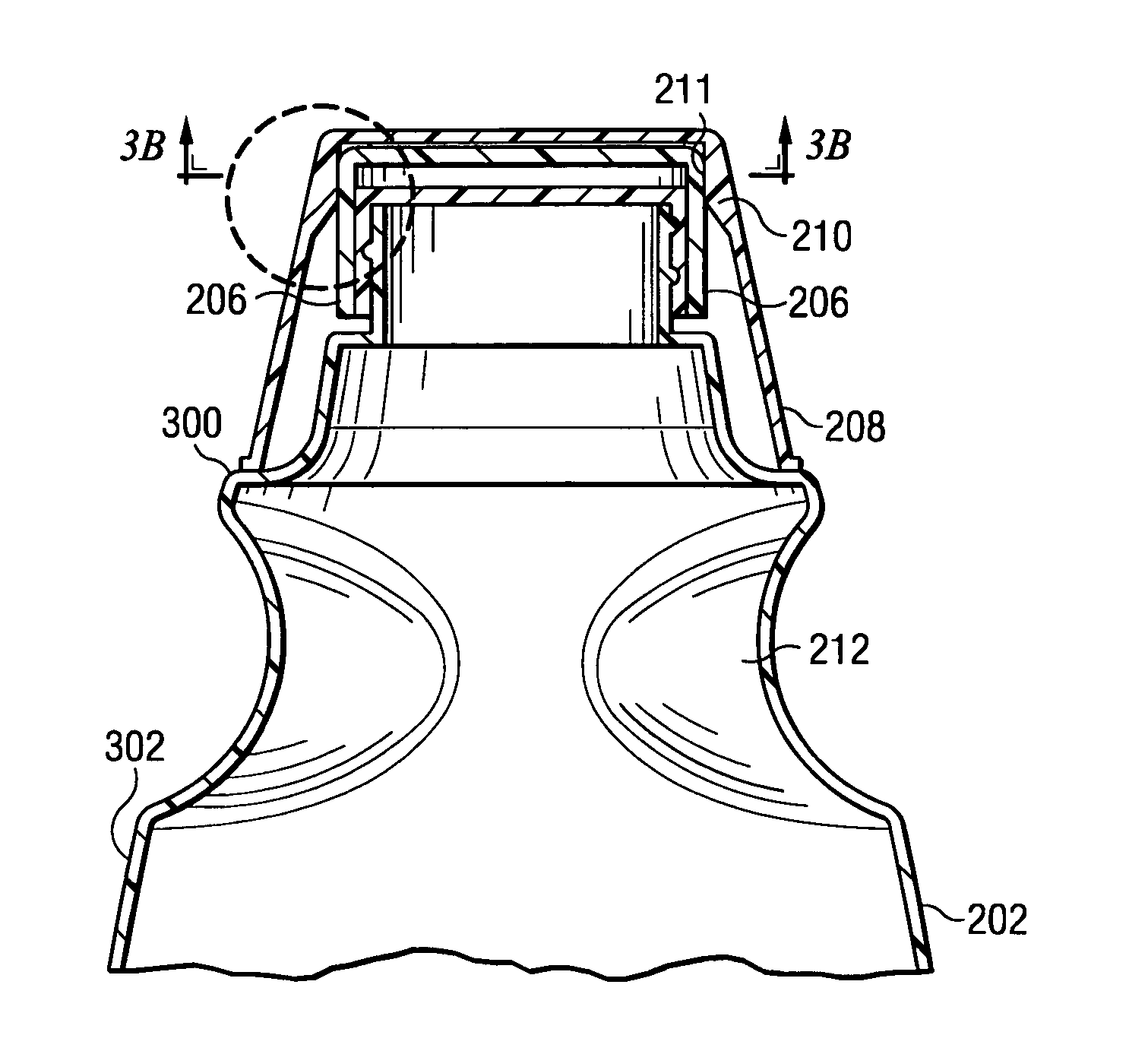

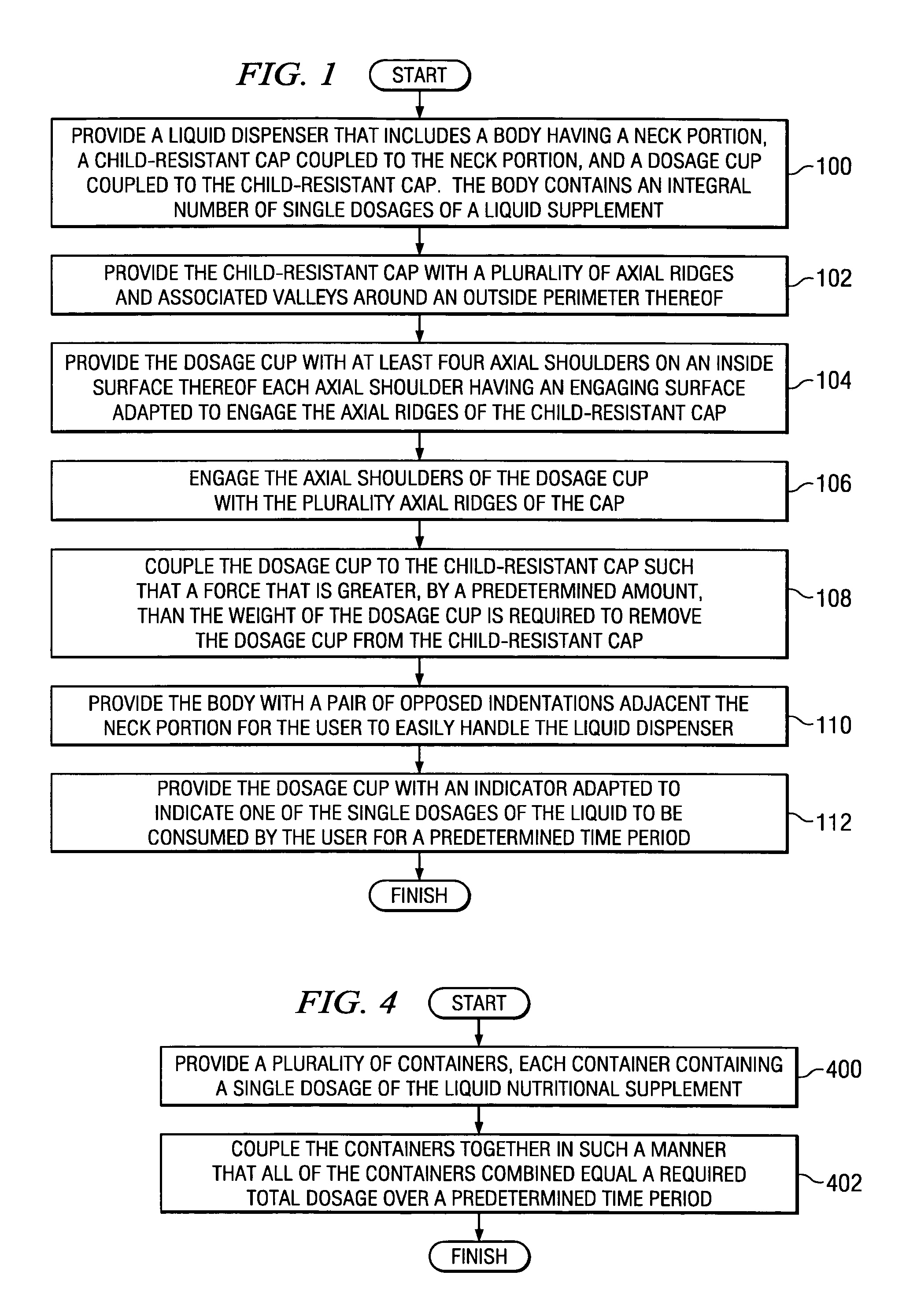

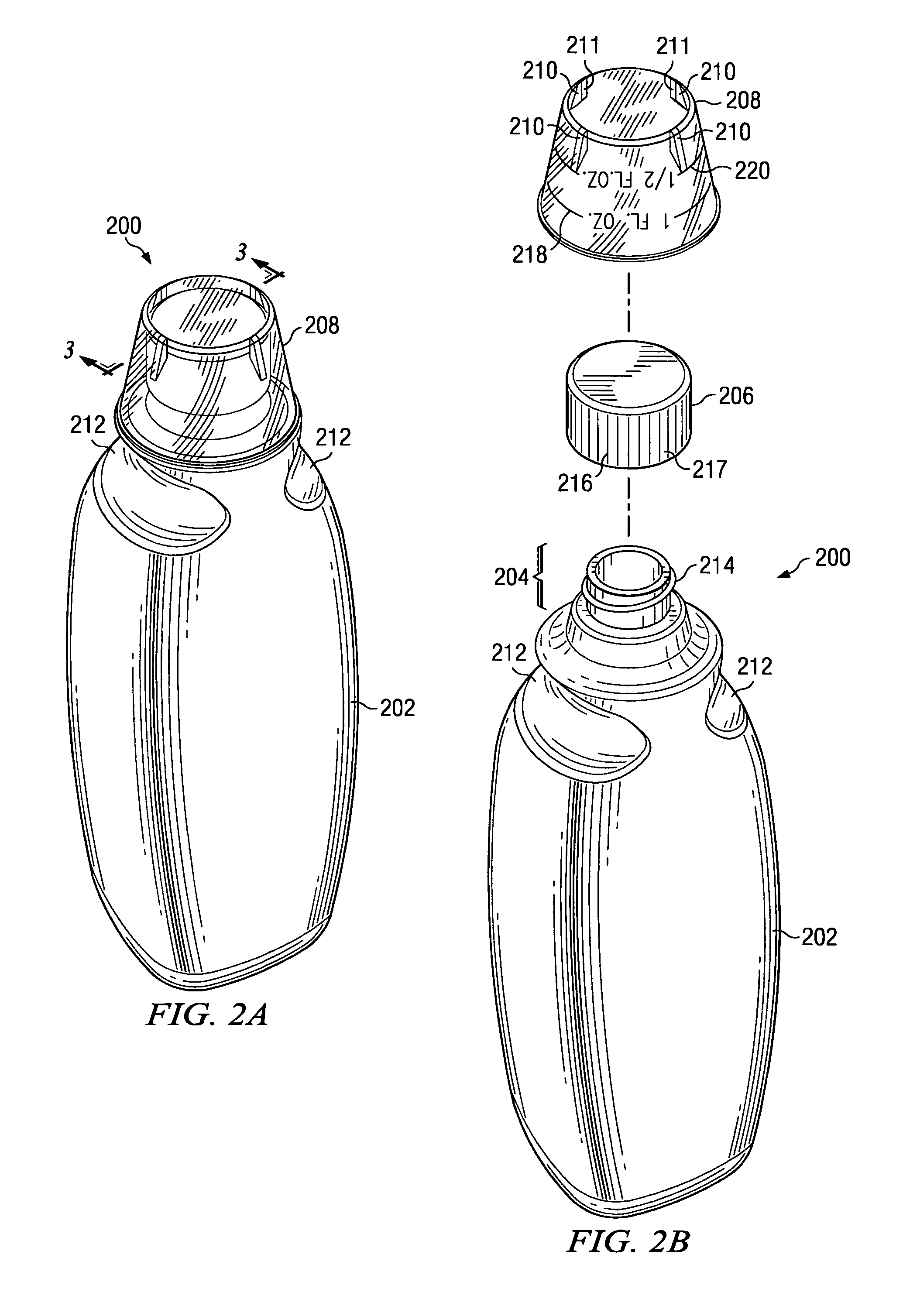

Method and apparatus for metering liquid nutritional supplements

Owner:REMINGTON HEALTH PRODS

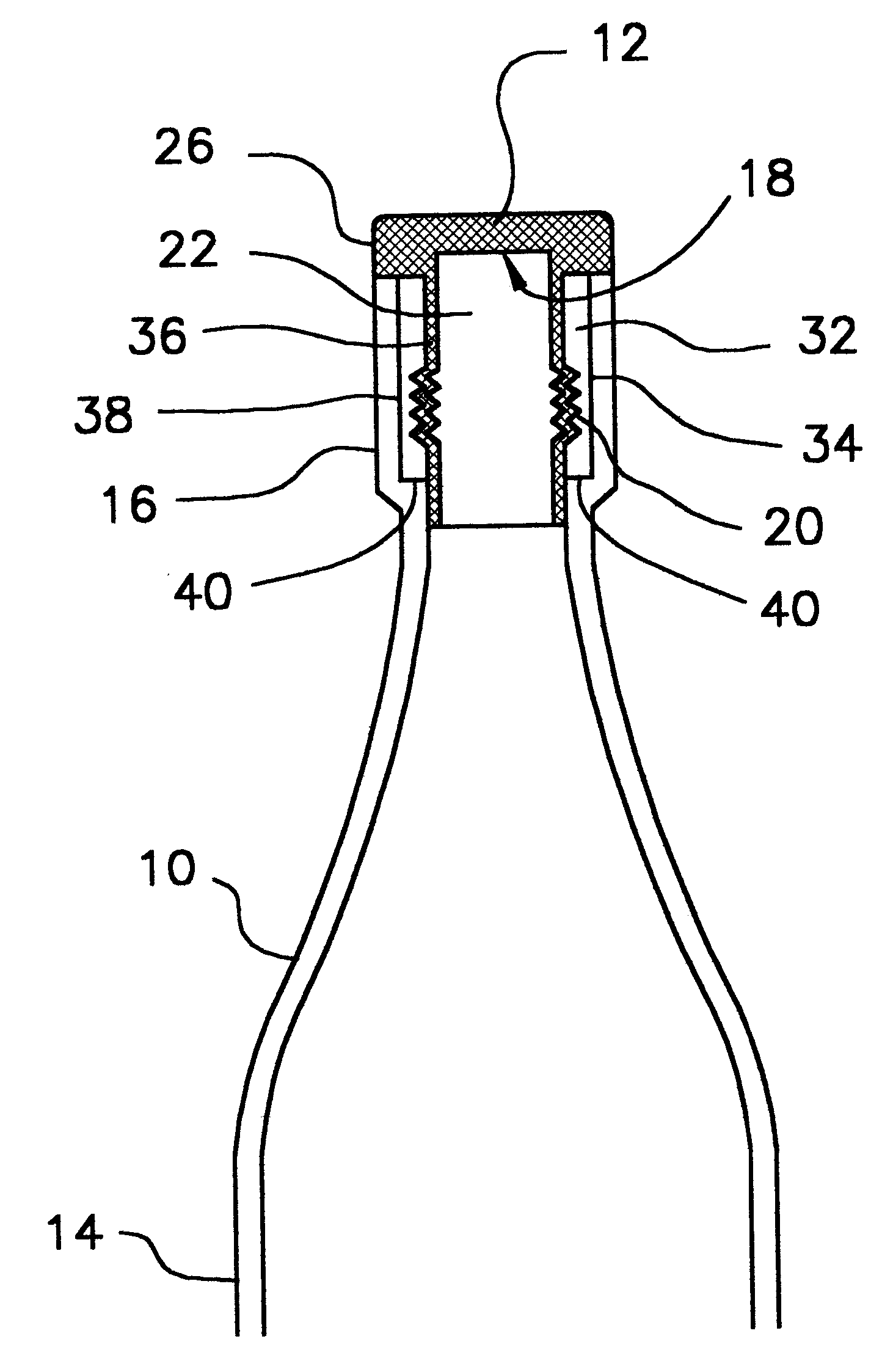

Container and closure package and method of making same

A container-and-closure sealing system embodied in a container and closure package, and method of making the same. The container has an open mouth surrounded by a cylindrical neck wall having internal threads and an open upper edge. The closure is a cap / dispensing cup type and has a skirt with external threads for threaded receipt within the container neck wall. A circumferentially continuous flange projects outwardly from the skirt and has a conical portion for cam engaging, trapping and sealing with the open upper edge of the neck wall as the closure is threaded into this wall. The closure skirt also has a circumferentially continuous plug-type sealing surface that extends radially outwardly from the skirt between the trapping flange and closure external threads for interference sealing engagement with the neck wall, as the closure is threaded thereinto. The materials of the closure and container may differ in hardness relative to another so that either the plug seal rib of the juxtaposed neck wall surface deforms under closure / container engaging forces to thereby enhance the sealing capability and life. The flange has a conical skirt wall portion integrally dependent from a flange radial wall portion that sealing cam wedge embraces the neck open upper edge and creates increasing squeeze force as the closure is threaded into the neck wall. A concentrically intermediate annular seal is also provided in the form of V-rib or liner material interposed in assembly between the container upper edge and the flange radial wall portion. The container neck wall may have a circumferentially continuous internal groove disposed between the neck internal threads and open upper edge for receiving the closure plug seal rub by interference snap fit when said closure is threaded into the wall and reaches closed position thereon to thereby enhance removal torque capability.

Owner:KUBETECH CUSTOM MOLDING INC

Flange screw closure and bottle with insert having threads

Owner:WAGNER DAVID C

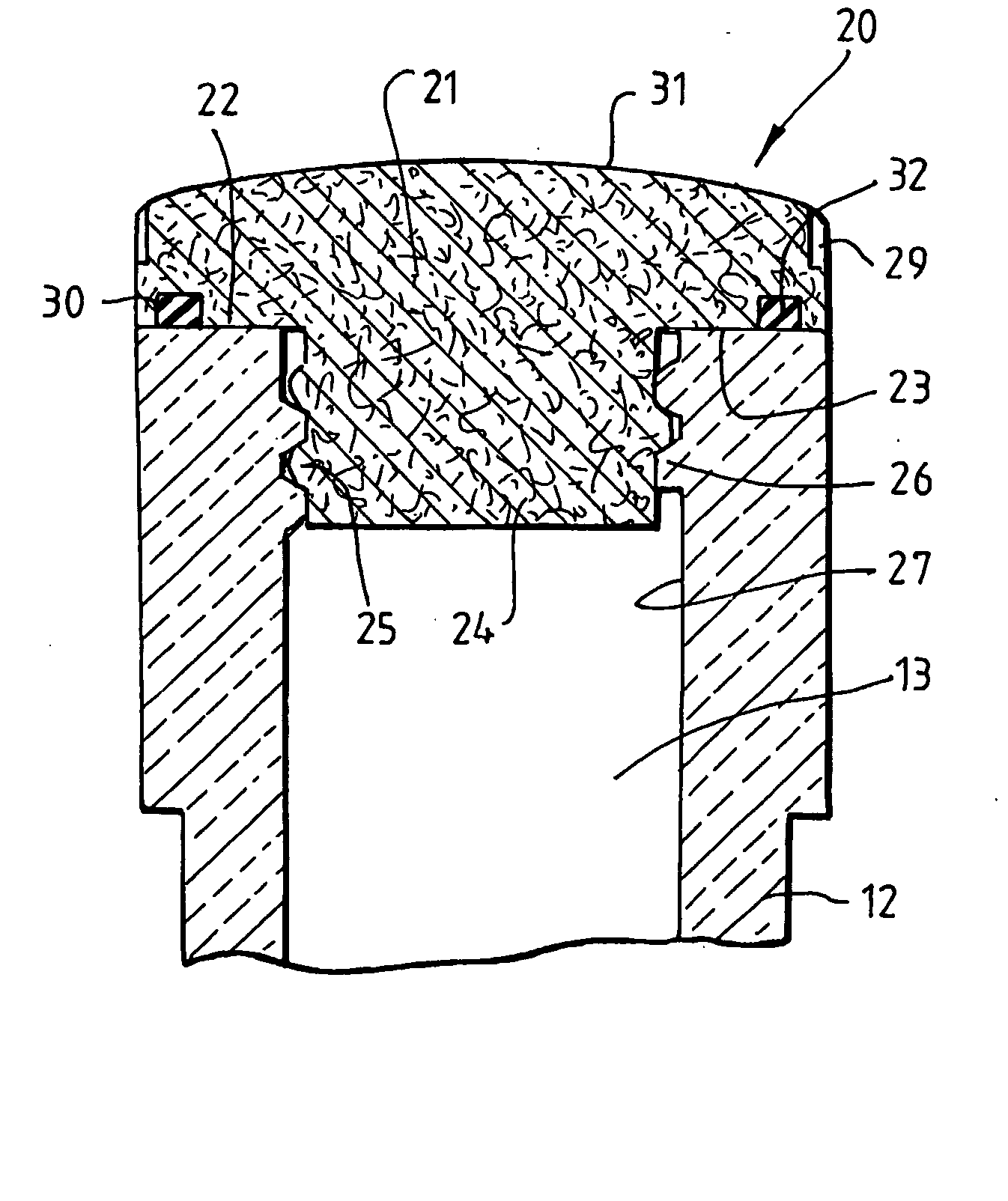

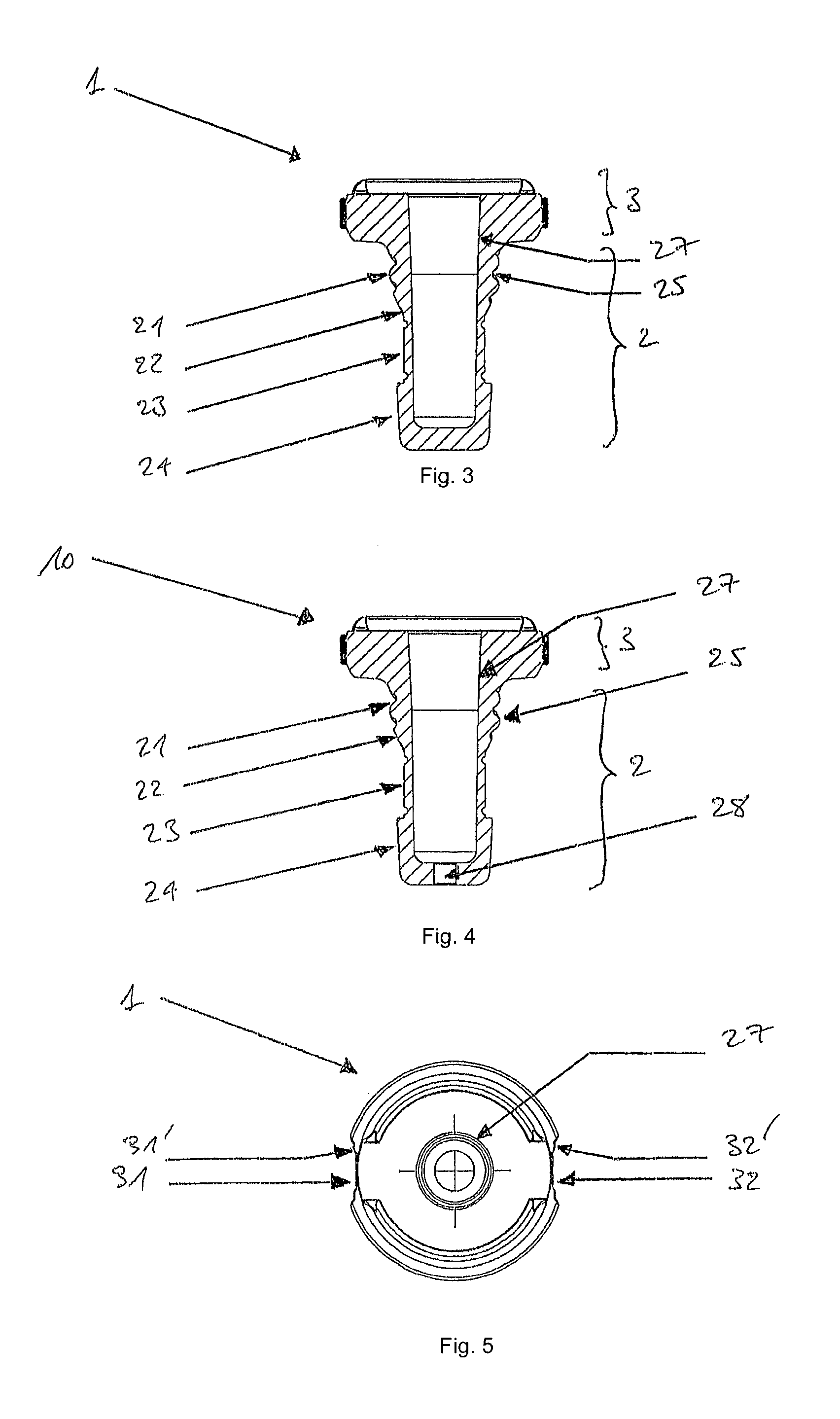

Stopper for a bottle and sealing element for said stopper

InactiveUS9493274B2Improve sealingProcess economyClosure with auxillary devicesRotating screw stopper insertionEngineeringBottle

A stopper for a bottle and a sealing element for sealing the stopper in the mouth of the bottle, which is separate from the bottle. The stopper comprises a stopper part for introduction into a mouth of the bottle, and a head part for remaining outside the mouth of the bottle, the head part having a diameter that is larger than that of the stopper part, wherein the stopper part comprises a an interlocking mechanism for engaging with a counterpart interlocking mechanism of the sealing element. The sealing element is forced against an inner wall of the mouth, thereby being brought into a sealed position, upon introducing the stopper part into the mouth, in which sealed position the stopper is held on the bottle. The interlocking mechanisms permit bringing the sealing element into an unsealed position by an unsealing action which comprises rotating the stopper with respect to the bottle.

Owner:PATENT ROOM P5 S A R L

Twist lid

A lid including a positionable stopper nested inside an upper body that is nested inside a lower body. A user applies a rotational force to the upper body, which rotates about an axis of rotation relative to the lower body to translate the rotational movement of the upper body into linear movement of the stopper along the axis of rotation. The stopper is configured to move axially along the axis of rotation relative to the upper body toward and away from the vessel based upon the direction in which the upper body is rotated. When the stopper is farthest from the vessel along the axis of rotation, the stopper abuts the upper body and seals the liquid inside the vessel. When the stopper is sufficiently near the vessel, an opening is defined between the stopper and the upper body through which the contents of the vessel may exit.

Owner:PACIFIC MARKET INT

Drinking device

InactiveUSRE38692E1Reduce decreaseClosure using stoppersFeeding-bottlesInternal pressureBiomedical engineering

A drinking device including a body having an open end and for containing a liquid, and a lid for sealingly closing the open end of the body. The lid has an outlet incorporating a first one-way valve for dispensing liquid from the body upon the application of suction at the outlet and an inlet incorporating a second one-way valve for air intake to automatically balance the internal pressure within the body with external pressure outside the body while liquid is being dispensed. The first valve includes a chamber having a resiliently deformable wall including a hole in communication with the outlet. The hole is normally closed by being pressed against an internal surface of the body by the resilience of the wall and is openable upon the application of suction.

Owner:FU HONG INDS

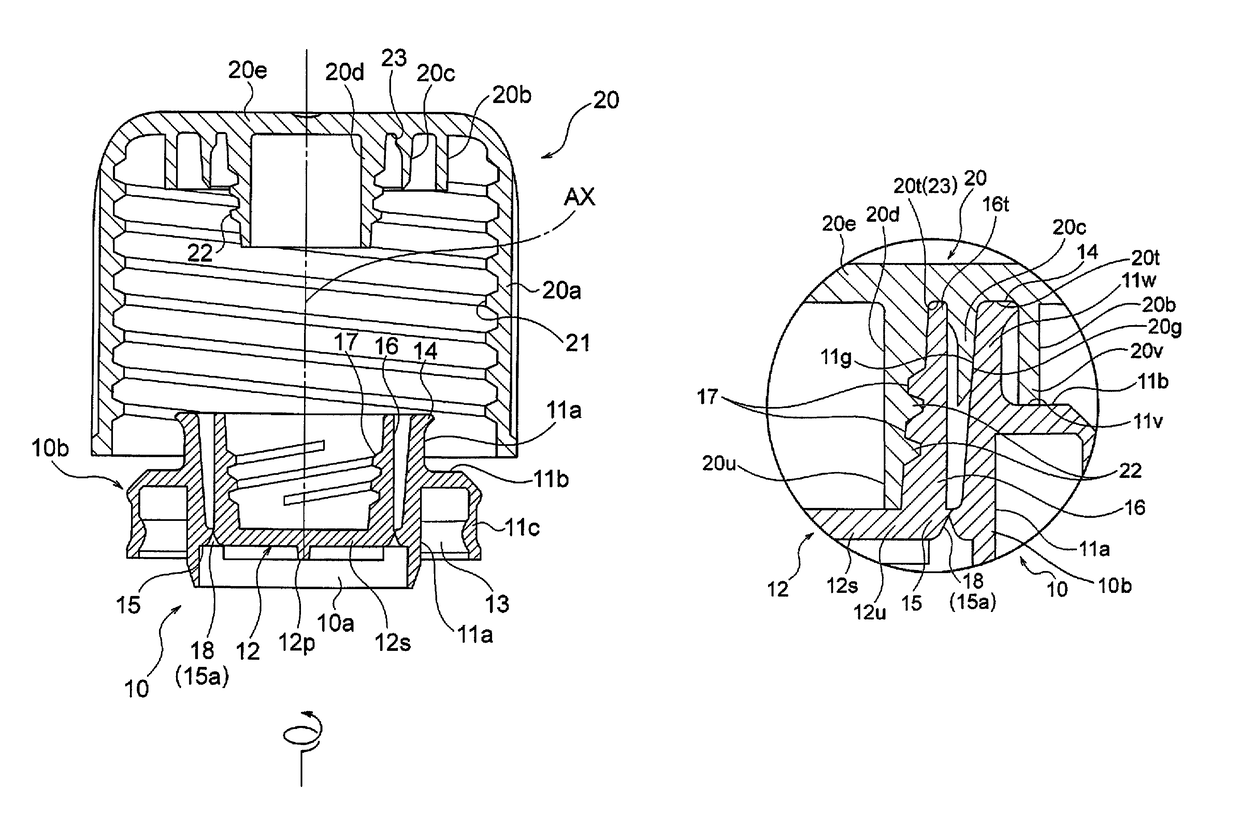

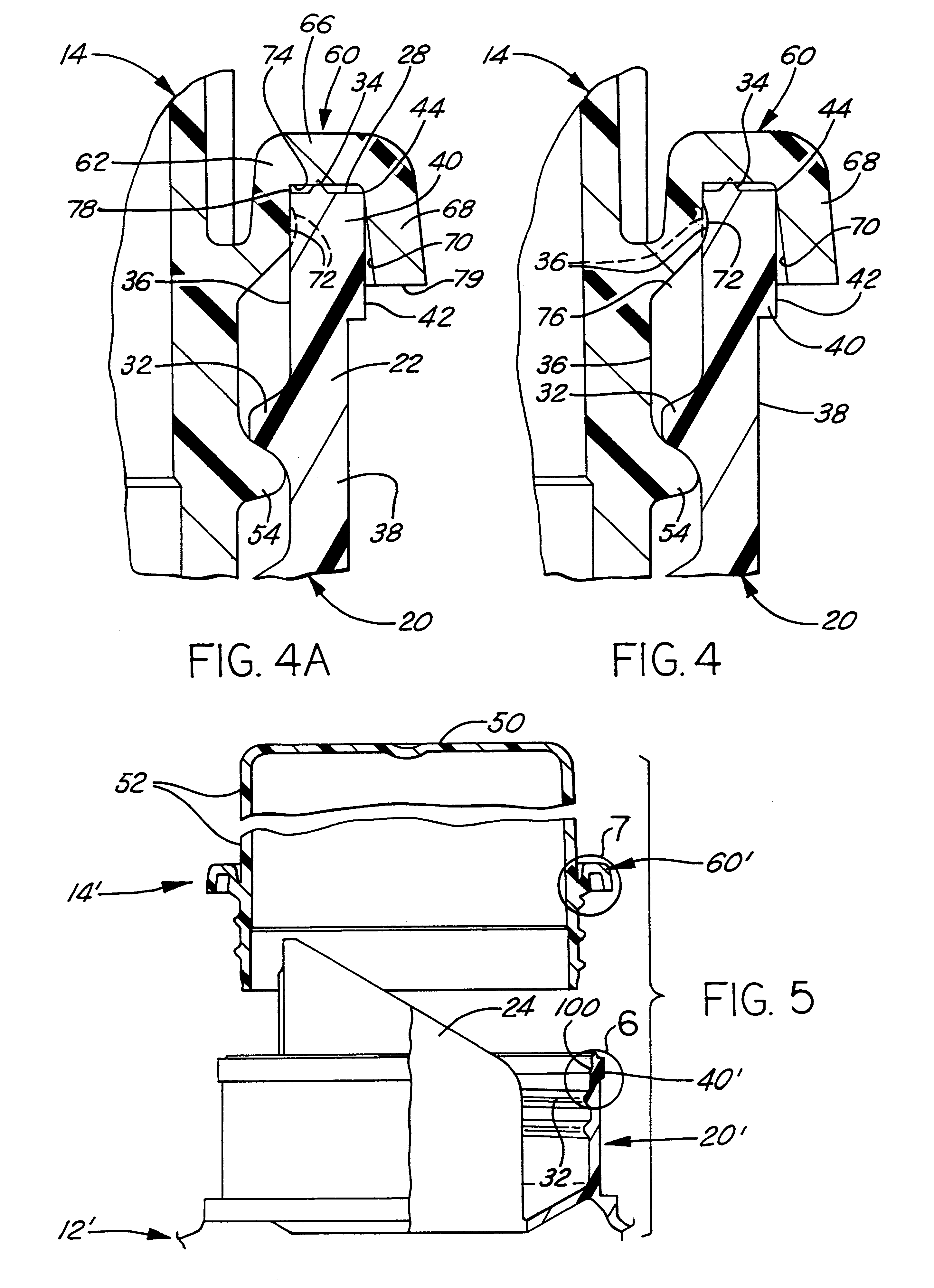

Container sealing device

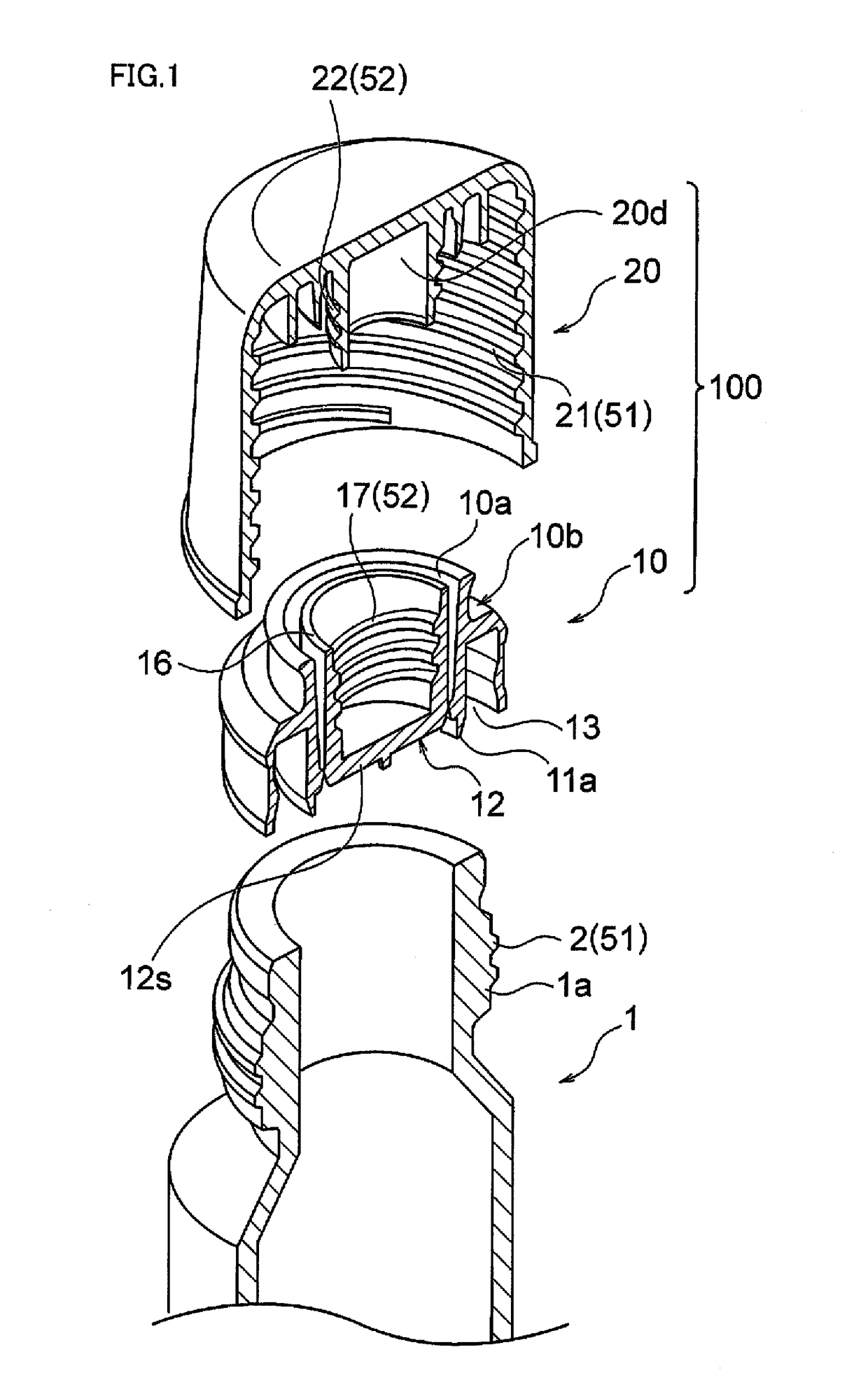

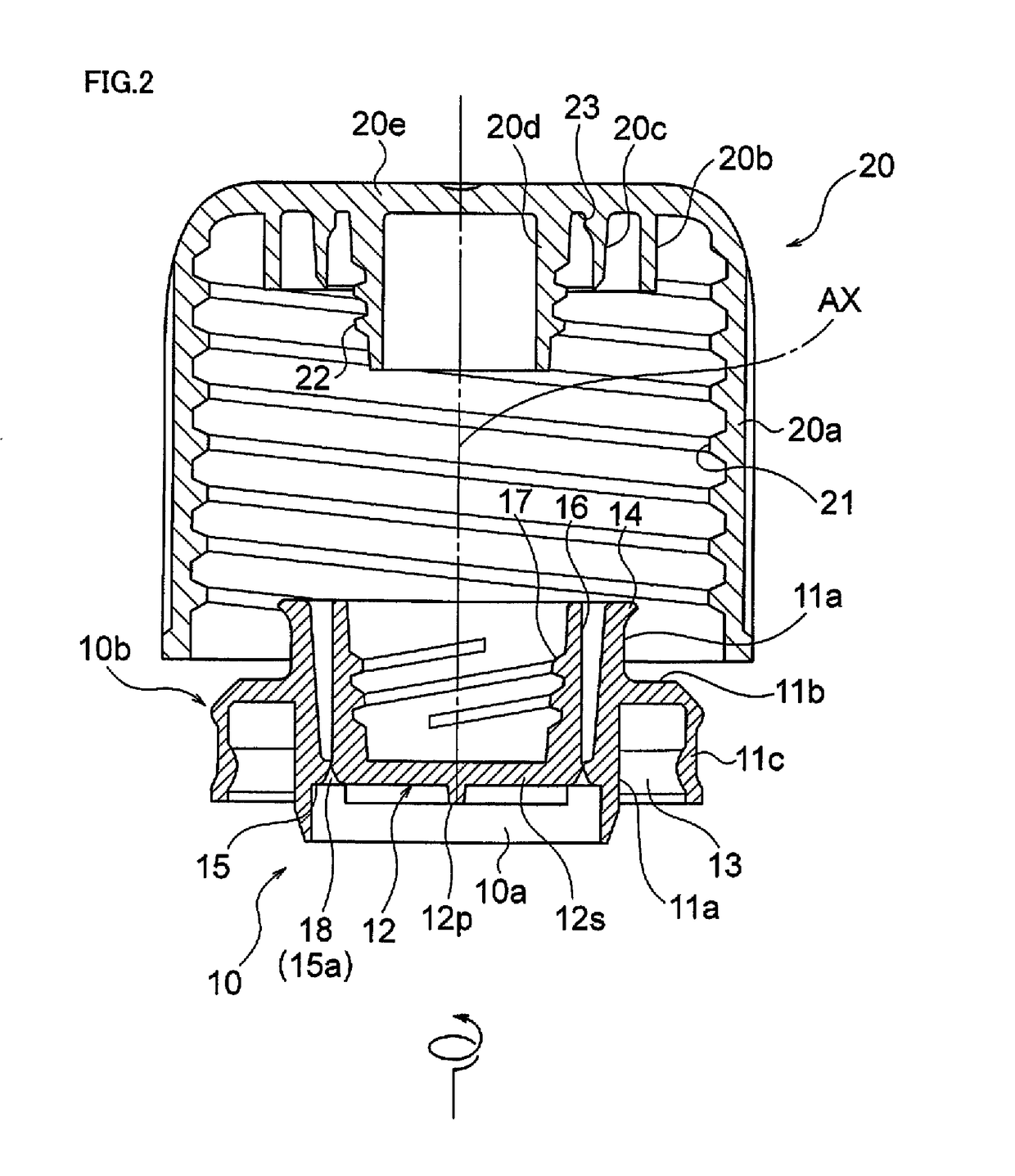

ActiveUS10086980B2Easy to separateReliable holdClosure using stoppersThreaded closuresMechanical engineering

An object is to provide a container sealing device which can perform an opening of an inner plug with a clear opening feeling. An inner plug 10 is assembled in advance to an upper closure 20 by using a second screwing part 52. At this time, since an assembling interval between a separation part 12 and the upper closure 20 can be adjusted by tip end parts 16t and 20u of a cylindrical part 16 which are first stoppers and the small-diameter cylinder part 20d, the second screwing part 52 can be brought into a lock state of being screwed to the deepest position or a state close to that. In opening the plug, the first screwing part 51 is loosened the second screwing part 52 is tightened, and the separation part 12 can be rapidly and reliably separated from a body part 10b of the inner plug 10.

Owner:TOKAN KOGYO CO LTD

Two-part plastic snap hinge closure

InactiveUS6971531B1Prevent large amount of plasticCheap productionCapsClosure using stoppersEngineeringClosed state

A two-part hinge closure having a lower part which has a surrounding outer wall and which can be placed on a container, and has a cap which has an outer wall and which can be joined to the lower part in a hinged manner. The lower part and the cap are separately produced and can be assembled together. In an assembled and closed state, the outer walls are situated above each other in an aligned manner, at least in the hinge area of both hinge closure parts. Both closure parts can be joined to one another by a snap hinge having at least one spring element and at least one coupling piece. When the closure is in a closed state, the at least one spring element and the at least one coupling piece are at least almost aligned with the outer wall of the closure part on which they are formed as one piece.

Owner:TERXO

Closure for container and closure package and method of making same

InactiveUS6223946B1Improve rendering capabilitiesProlong lifeClosure using stoppersLiquid flow controllersHardnessEngineering

Owner:KUBETECH CUSTOM MOLDING INC

Rotatable securing device

InactiveUS8584916B1Smooth rotationStable positionTravelling sacksTravelling carriersEngineeringSupport surface

Owner:INNO DESIGNER INT

Container closure having means for introducing an additive into the contents of the container

A closure device with a fluid chamber containing an additive. The additive can be introduced and mixed into a liquid on the container by the closure device. The closure device includes a cap member having a fluid chamber and a housing having a plug member. The cap member is provided with a primary engagement member which engages with a corresponding primary engagement member provided on the housing to allow the cap member to be lifted relative to the housing from a closed position in which the plug member closes an aperture in the fluid chamber to an open position in which the plug member is at least partially withdrawn from the aperture, thereby allowing the additive to pass from the fluid chamber to the liquid in the bottle. The closure device enables mixing of the additive and liquid in the bottle without opening the closure.

Owner:GIZMO PACKAGING LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com