Metal bottle seal

a technology of metal bottles and seals, applied in the direction of caps, liquid handling, transportation and packaging, etc., can solve the problems of great difficulty encountered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

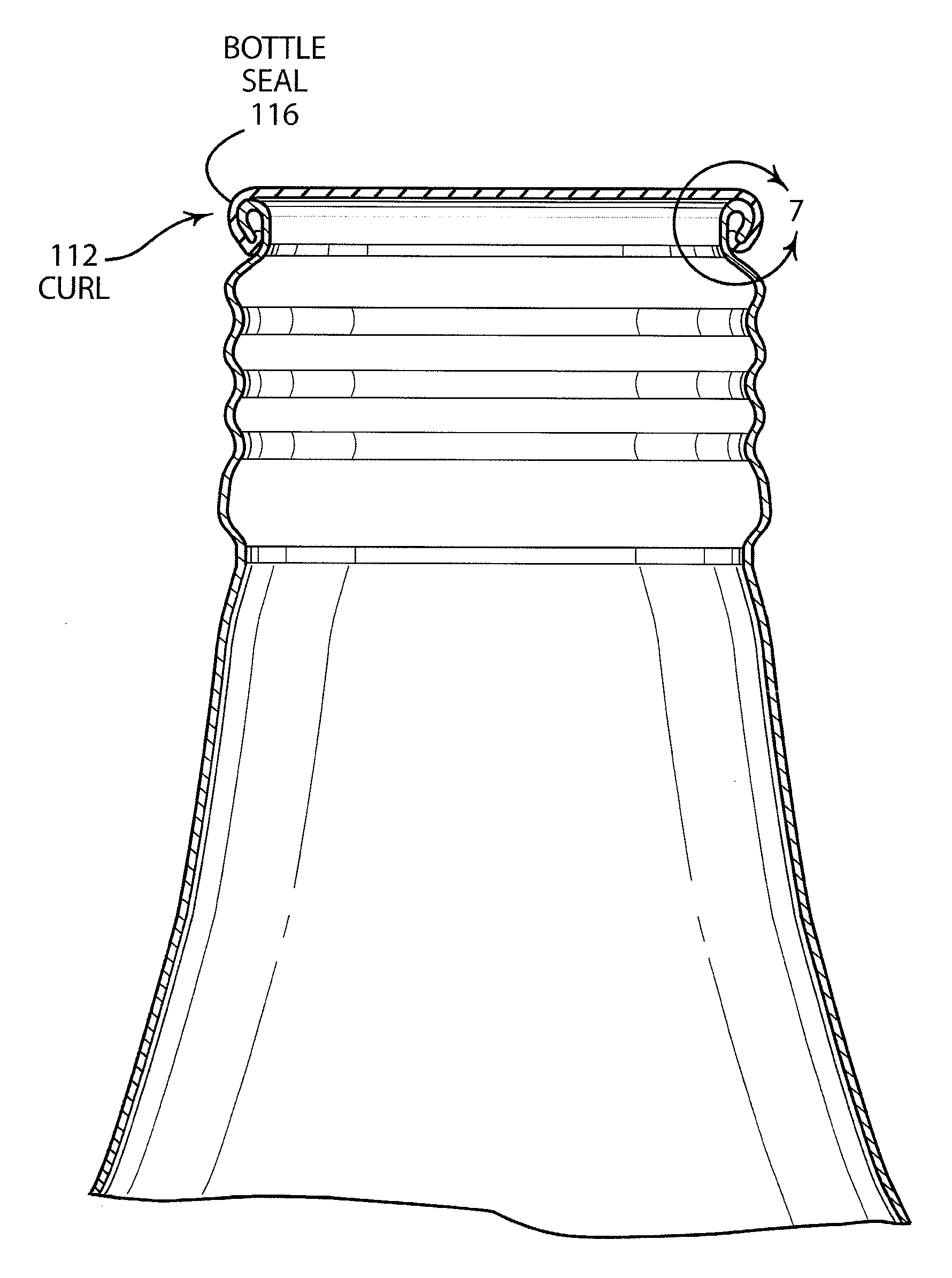

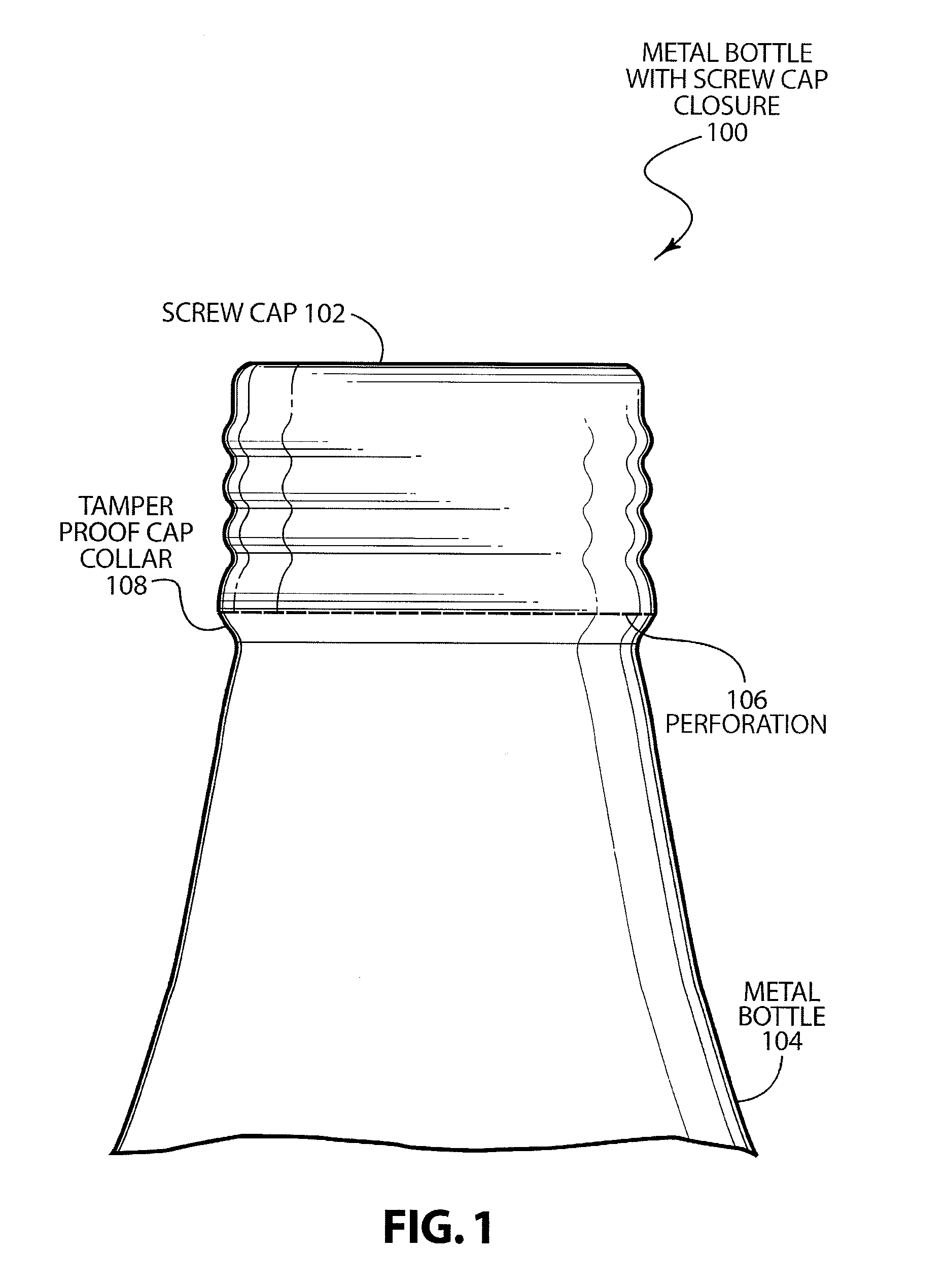

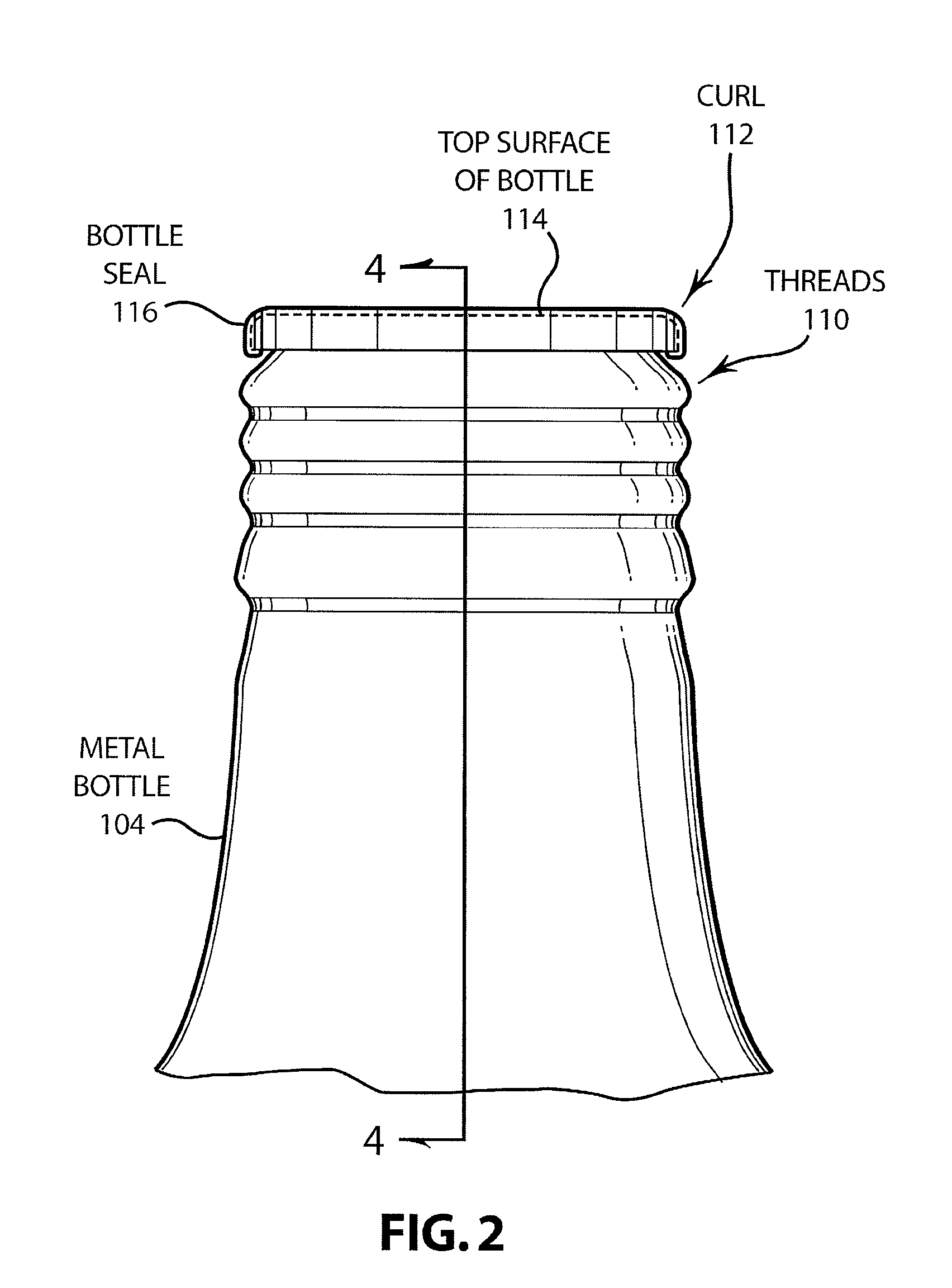

[0023]FIG. 1 is a schematic side view of a metal bottle having a closure such as a screw cap that incorporates the seal (not shown) of the present invention. As shown in FIG. 1, a screw cap 102, including a tamperproof cap collar 108 (roll on closure or pilfer-proof closure), is rolled onto and formed to the threads of metal bottle 104. In accordance with this process, a straight sidewall cap is slipped over the metal bottle 104. Screw threads are pre-formed in the metal bottle 104. A downward pressure is then placed on the top of the screw cap 102 which is sufficient to create pressure on the seal between the screw cap 102 and metal bottle 104. In conventional screw cap metal bottles, pressures of approximately 300 pounds per square inch are required to form an adequate seal.

[0024] In order to seal the cap, a roller then rotates around the outer surface of the metal screw cap 102 to force the straight sidewalls of the metal screw cap 102 to conform with the threads of the metal bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com