Feeding system

A feeding system and material technology, used in conveyors, vibrating conveyors, metal processing, etc., can solve the problems of staple positioning, inaccuracy, affecting the riveting of the keyboard and the cover, and achieve stable feeding and accurate riveting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

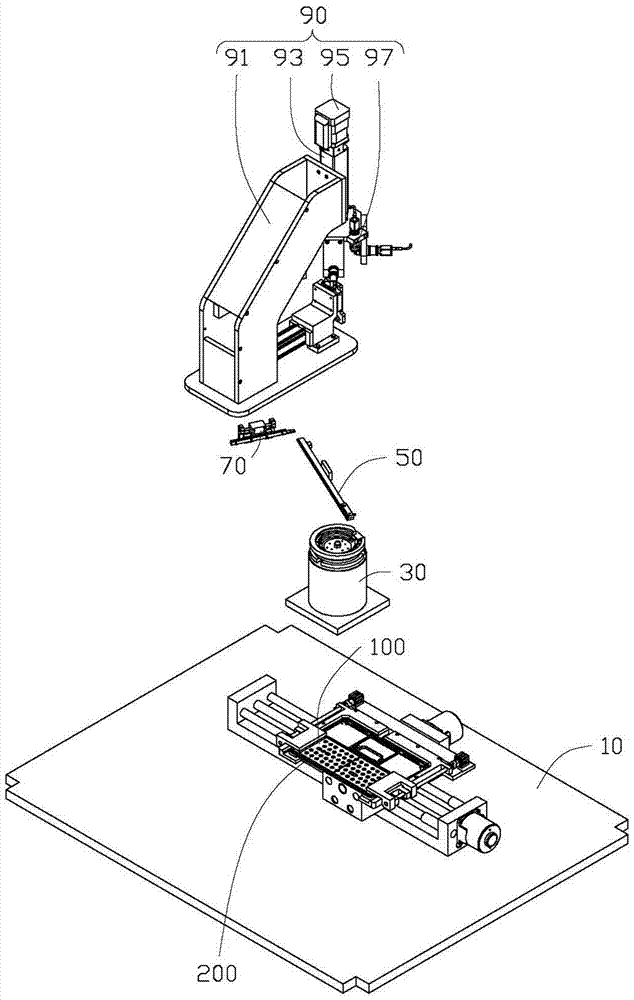

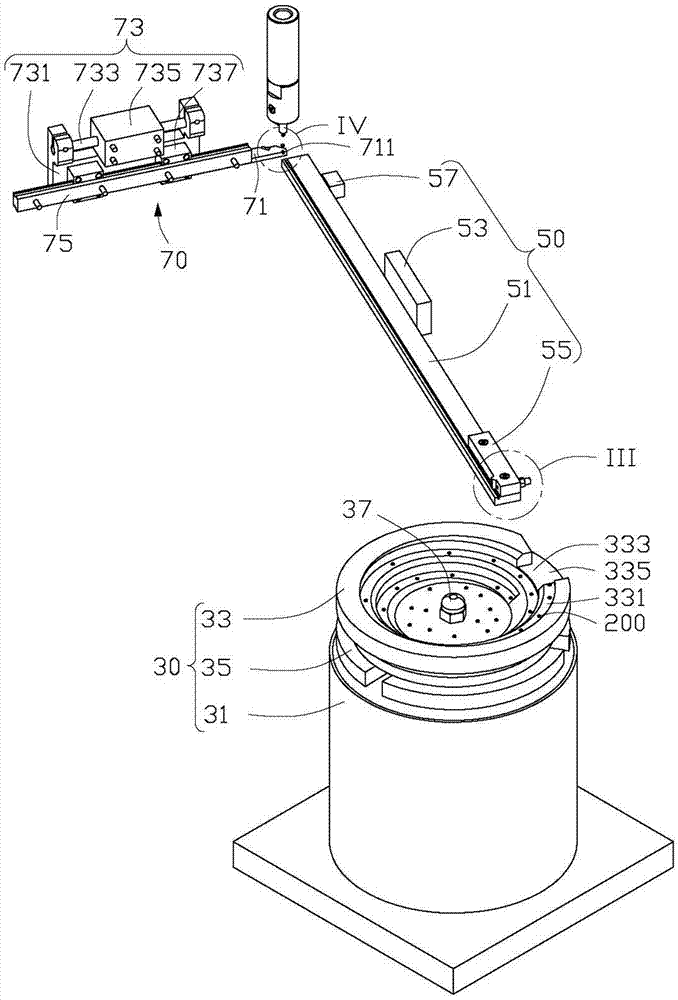

[0017] see figure 1 , the feeding system of the present invention is used to provide materials for an electronic device. In an embodiment, the material can be a screw, a rivet, a washer, etc., and this embodiment takes a rivet 200 as an example. The preferred embodiment of the feeding system includes a machine platform 10, a feeding device 30 placed on the machine platform 10, a transport device 50 connected to the feeding device 30, a transport device 70 and an adsorption place The adsorption device 90 of the rivet 200 is described. In this embodiment, the electronic device is a keyboard 100 .

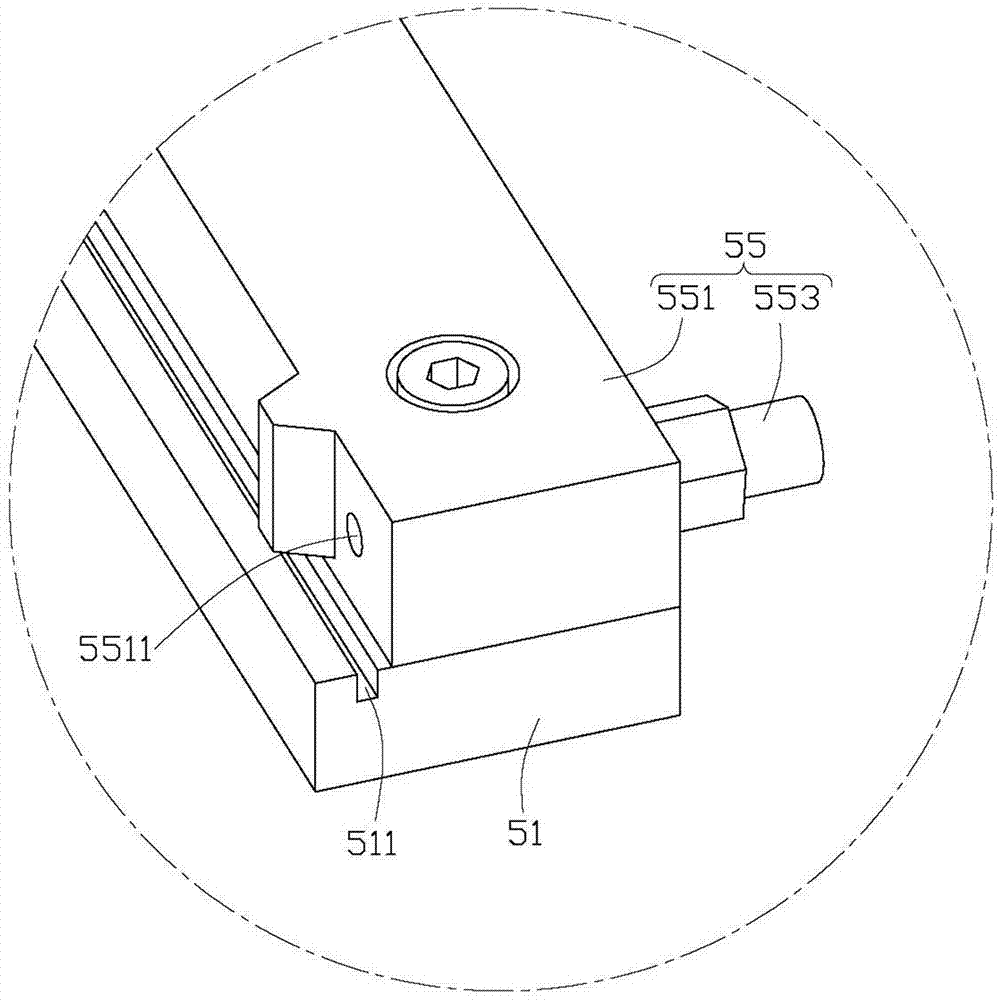

[0018] see figure 2 The feeding device 30 includes a support column 31 , a circular storage tray 33 and a first shock wave generator connection block 35 connected between the storage tray 33 and the support column 31 . The first shock wave generator connection block 35 is used to transmit the shock wave generated by the shock wave generator (not shown in the figure) to the storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com