Full-automatic wire rod single-end terminal press fitting wetting machine

A tin dipping machine, fully automatic technology, applied in the direction of circuit/collector parts, electrical components, circuits, etc., can solve the problems of inability to arrange and straighten the lines, high energy consumption, difficult to operate, etc., to reduce labor The effect of labor volume, production cost reduction, and production efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

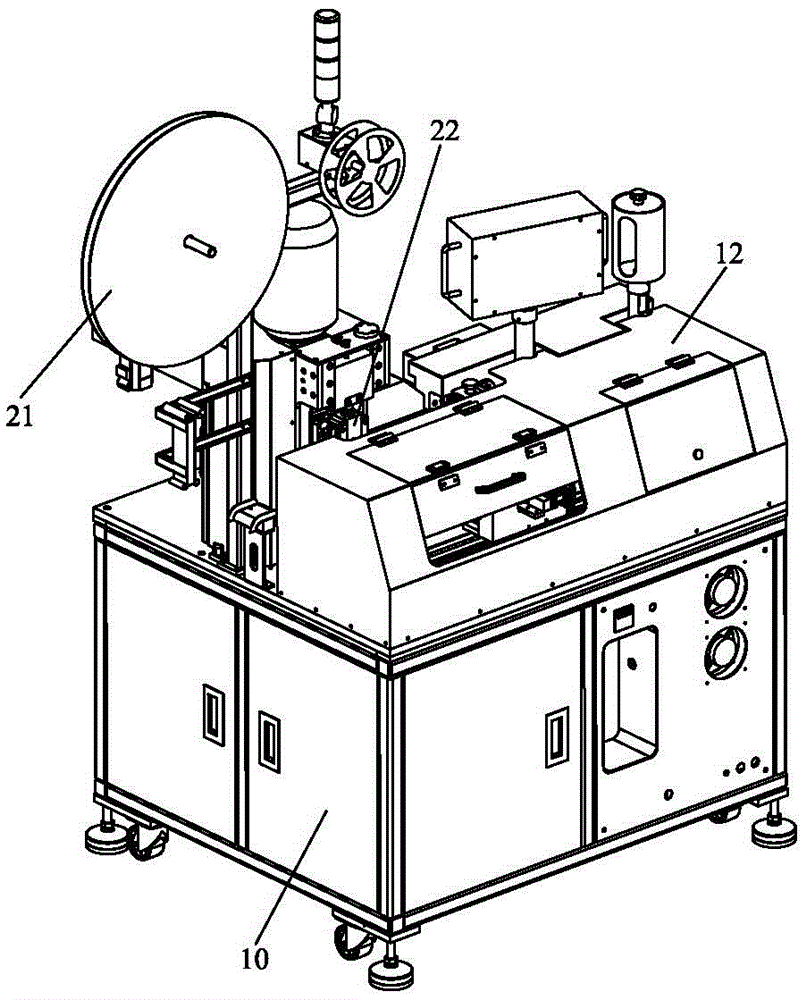

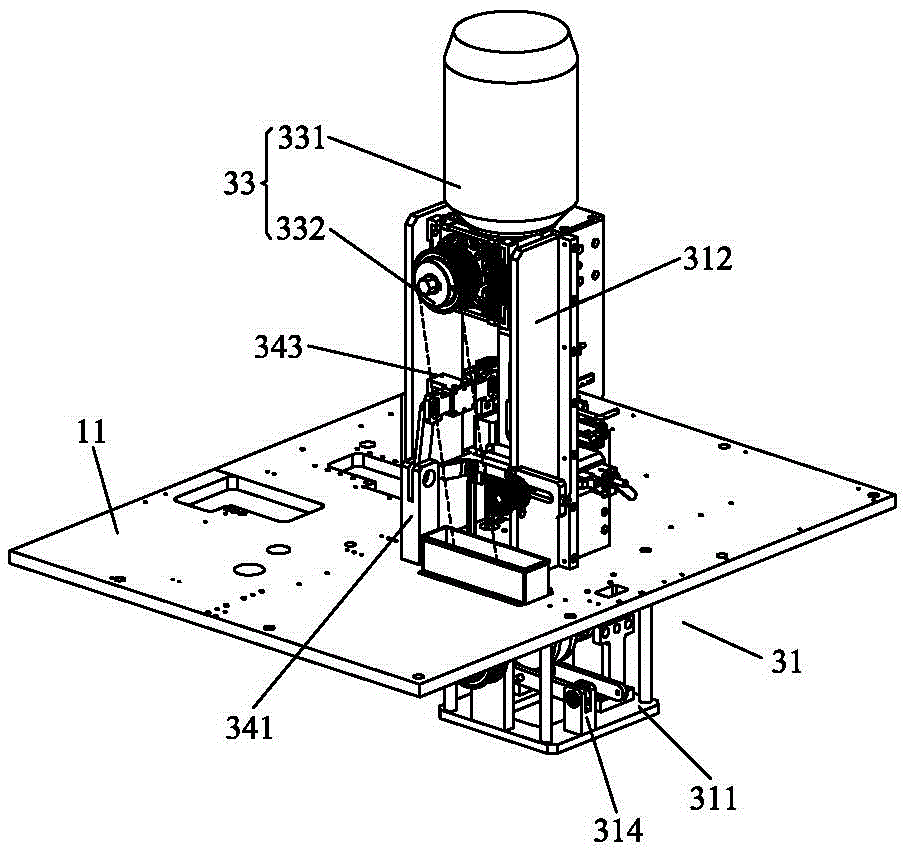

[0100] The present invention as Figure 1 to Figure 12 As shown, a fully automatic wire single-end pressing end tin dipping machine includes a frame 10, a terminal conveying pressing end mechanism 20, a wire dividing mechanism 30, a wire moving mechanism 40, a wire tangential stripping and twisting mechanism 50, and a wire pulling and clamping mechanism 60 and tin dipping mechanism 70, wherein:

[0101] The frame 10 is provided with a workbench 11, the workbench 11 has a front side and a rear side, a protective cover 12 is arranged on the front side, and a flux bath 13 and a tin bath 14 are arranged on the rear side.

[0102] The terminal conveying crimping mechanism 20 includes a terminal conveying plate 21 and a terminal crimping device 22 connected thereto, and the crimping device 22 has a crimping head 221 for riveting wires and terminals.

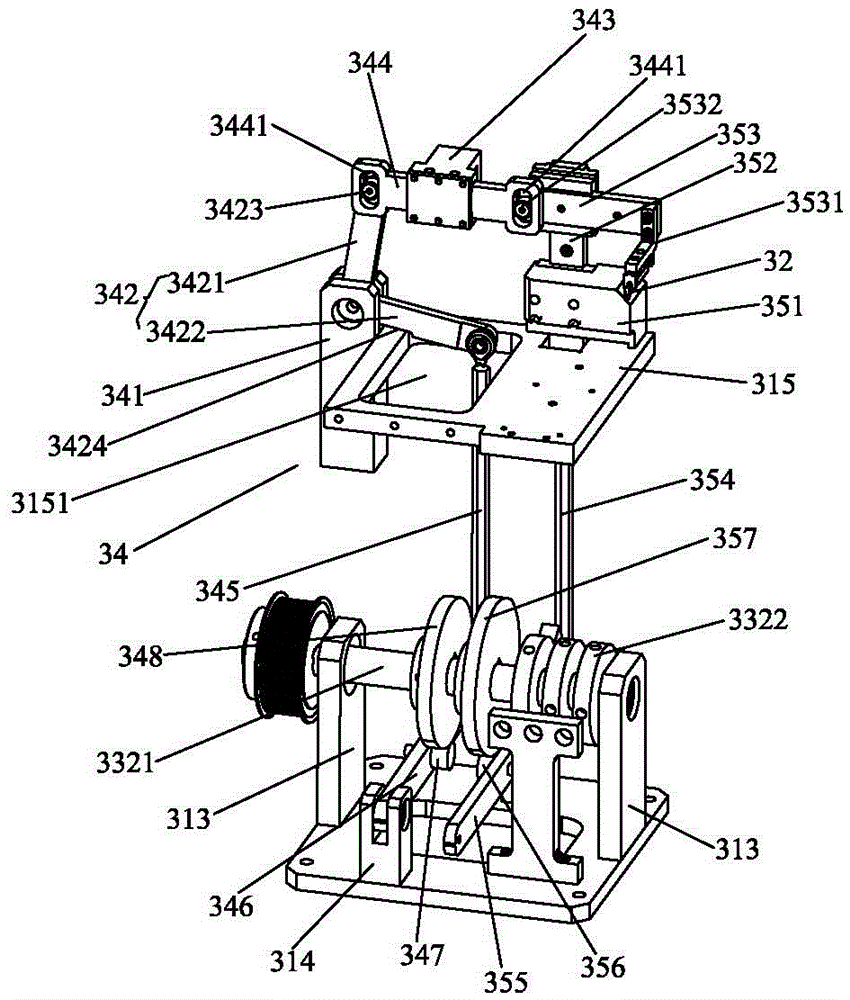

[0103] The wire distribution mechanism 30 includes a wire distribution frame 31, a wire distribution frame 32, a driving device 33, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com