Rotary type automatic riveting machine hand and use method thereof

A rotary and manipulator technology, applied in the field of rotary automatic riveting manipulator, can solve problems such as difficult to import in large quantities and high price, achieve accurate riveting, simple structure, and improve the quality and efficiency of aircraft riveting assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

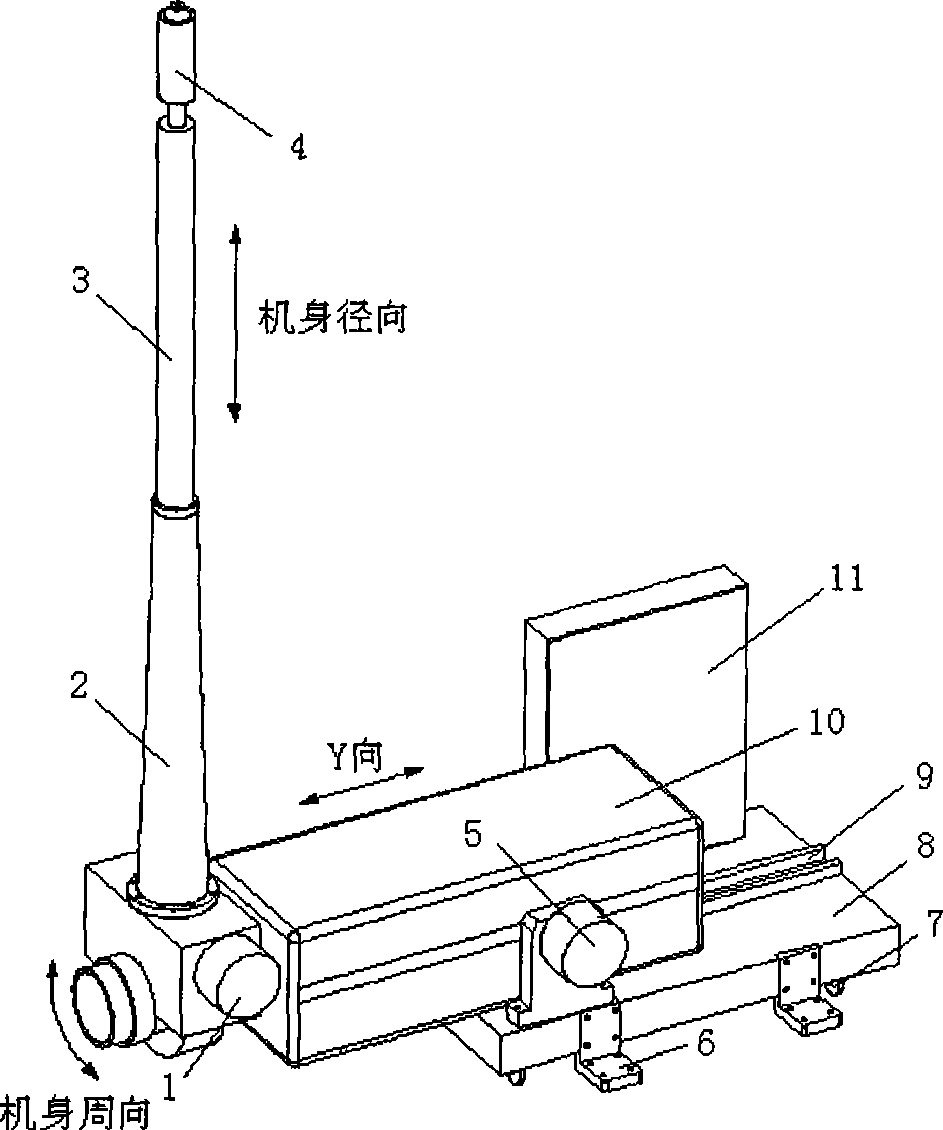

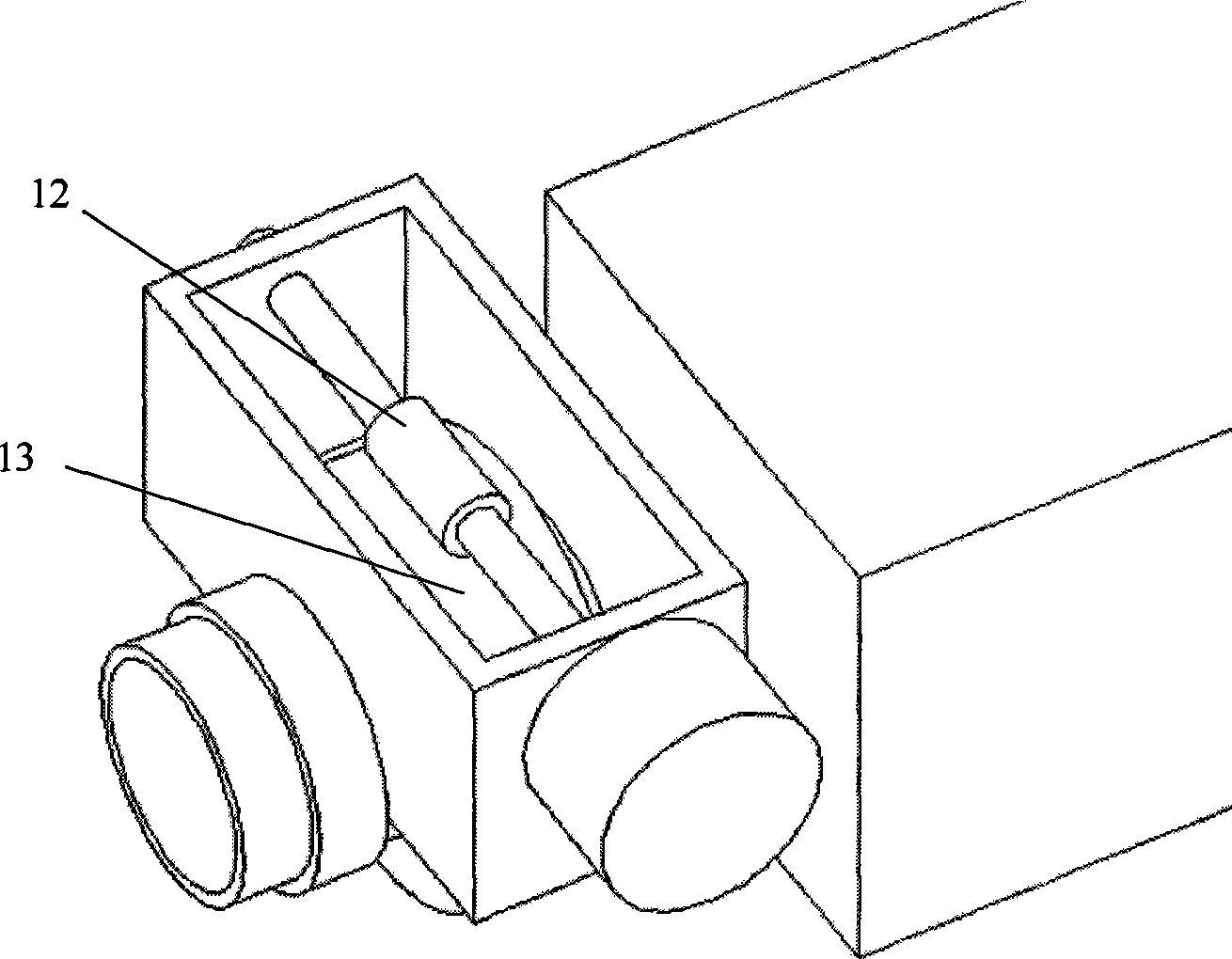

[0020] Such as figure 1 As shown, the rotary automatic riveting manipulator includes a circumferential driving motor 1, a rotating bracket 2, a telescopic cylinder 3, an adaptive tool head 4, a Y-direction driving motor 5, a connecting piece 6, a universal wheel 7, a trolley 8, and a linear guide rail 9 , a hollow sleeve 10, a controller 11, a connector 6 is provided under the trolley 8, a linear guide rail 9 and a controller 11 are provided on the trolley 8, a hollow sleeve 10 is provided on the linear guide rail 9, and it is connected with the Y-direction drive motor 5 The end of the hollow sleeve 10 is provided with a rotating bracket 2, the connection between the lower end of the rotating bracket 2 and the end of the hollow sleeve 10 is provided with a circumferential drive motor 1, and the upper end of the rotating bracket 2 is sequentially provided with a telescopic cylinder 3 and an adaptive tool. head 4.

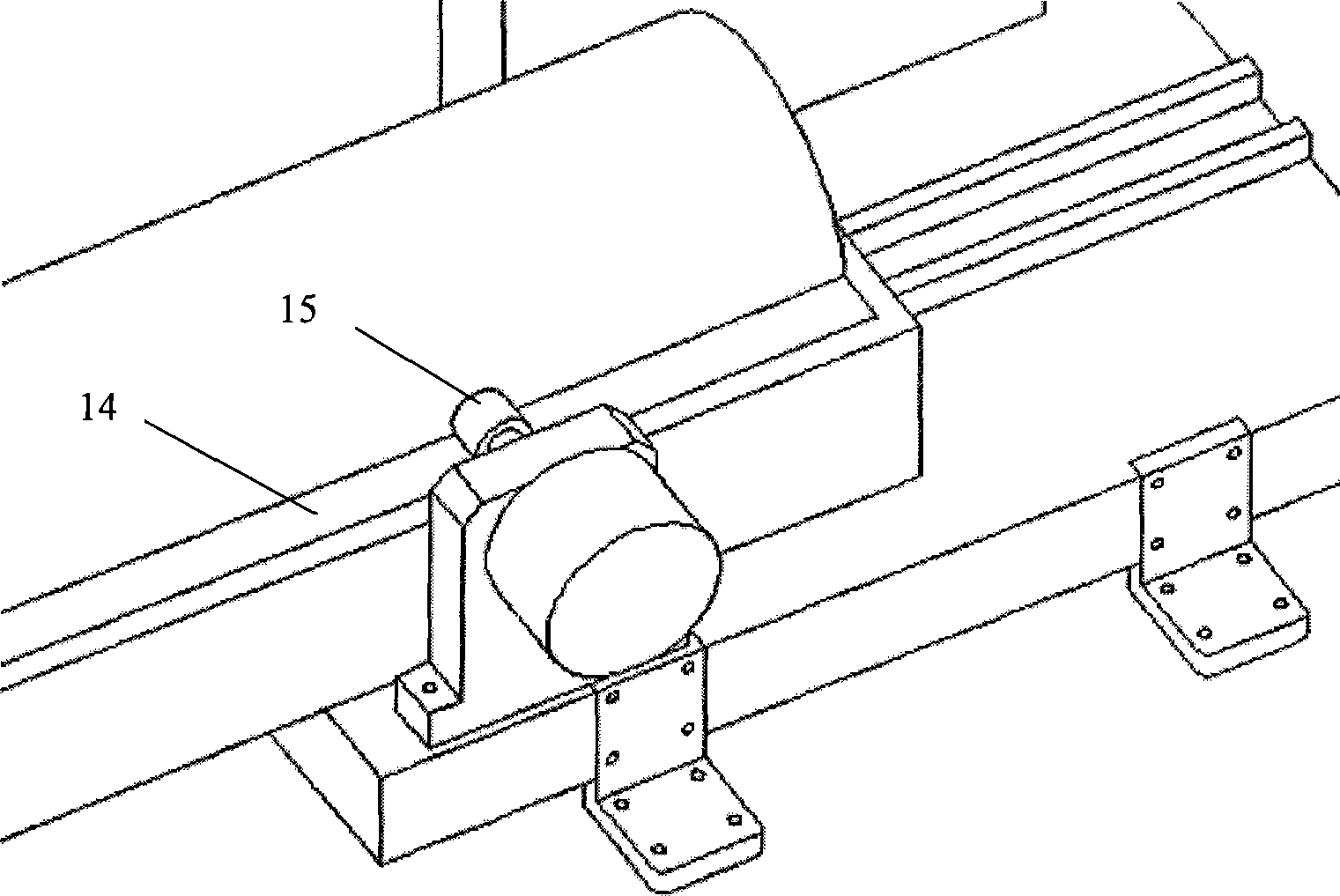

[0021] Two linear guide rails 9 on the trolley 8, the slider a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com