Patents

Literature

32results about How to "Stable joint strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

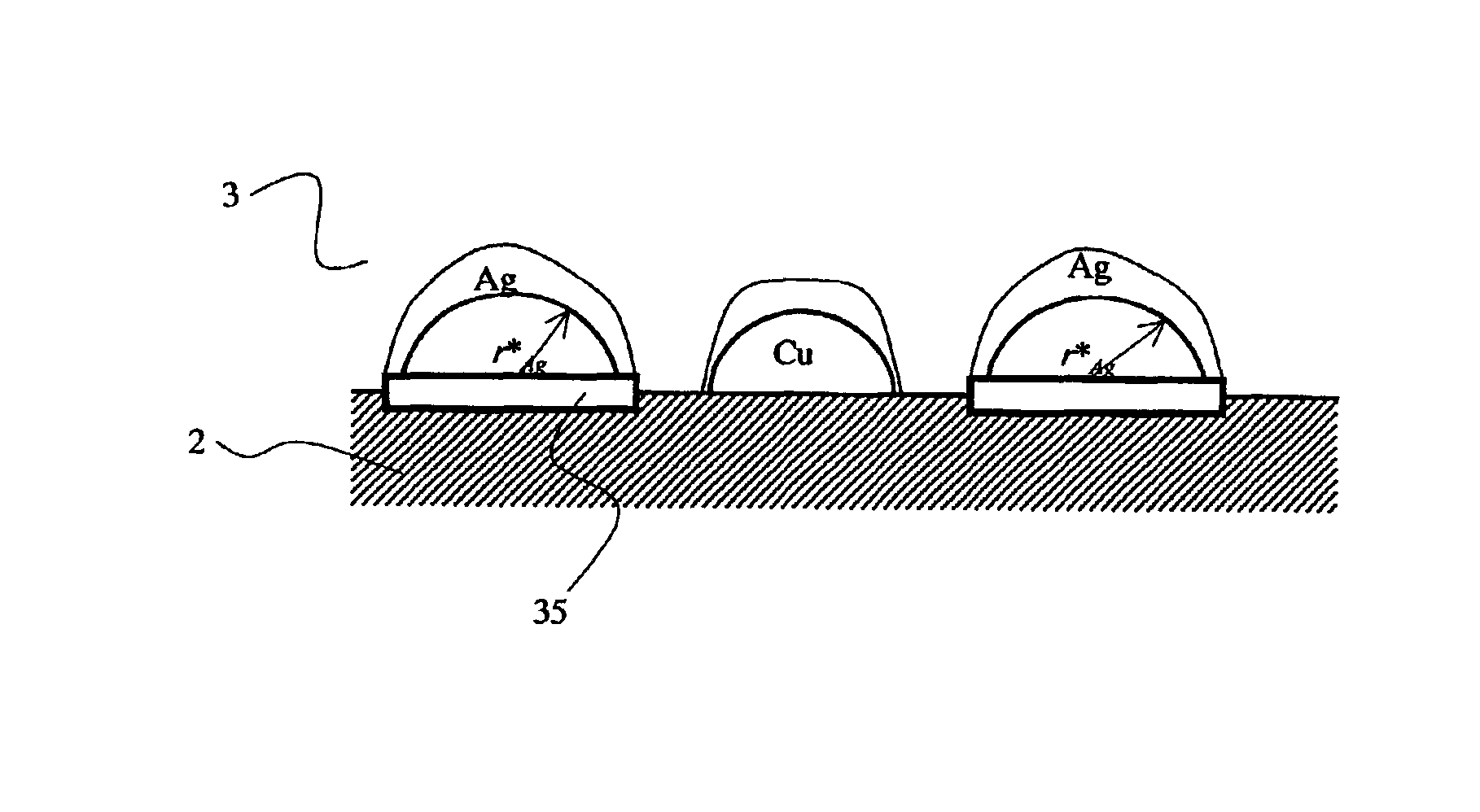

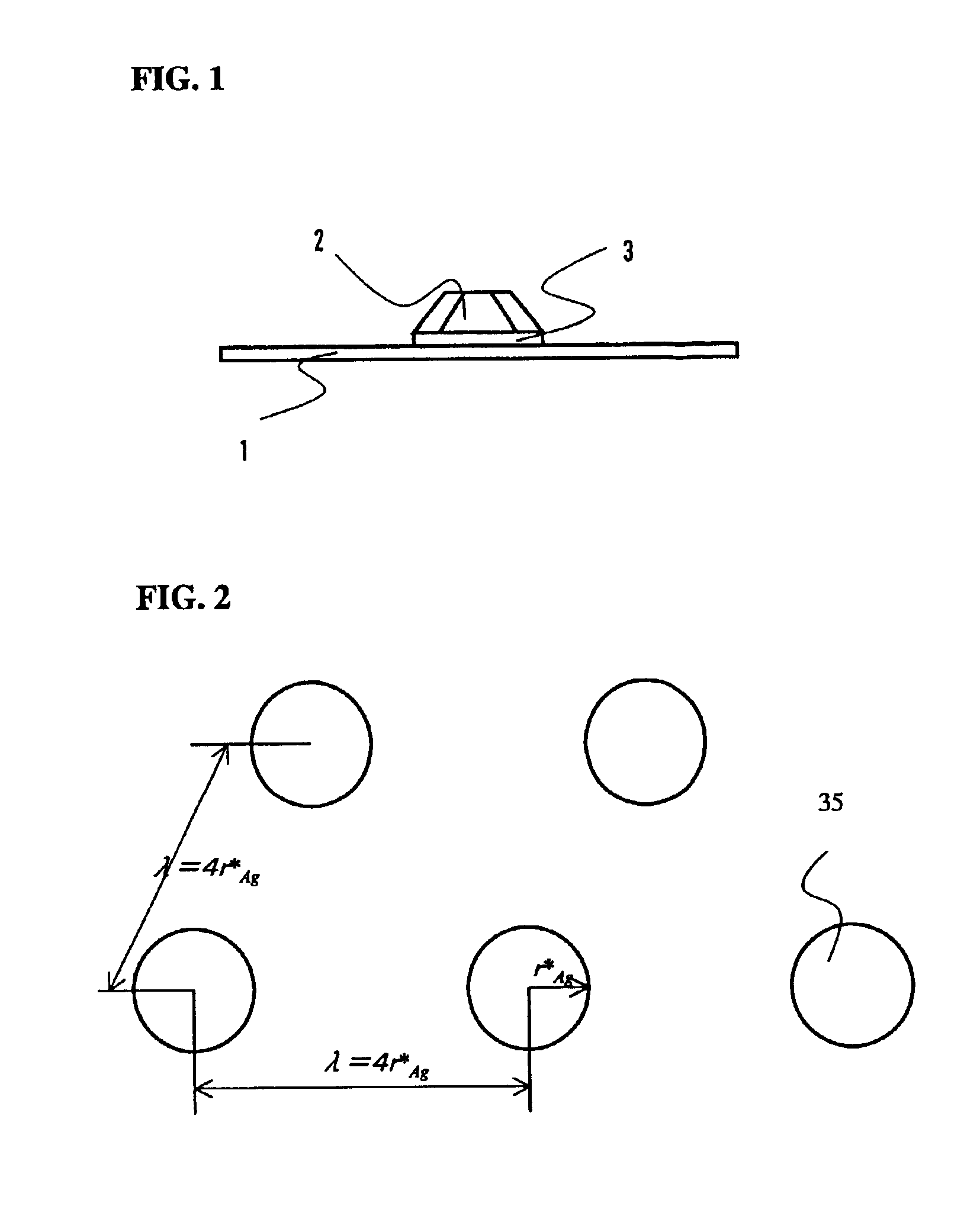

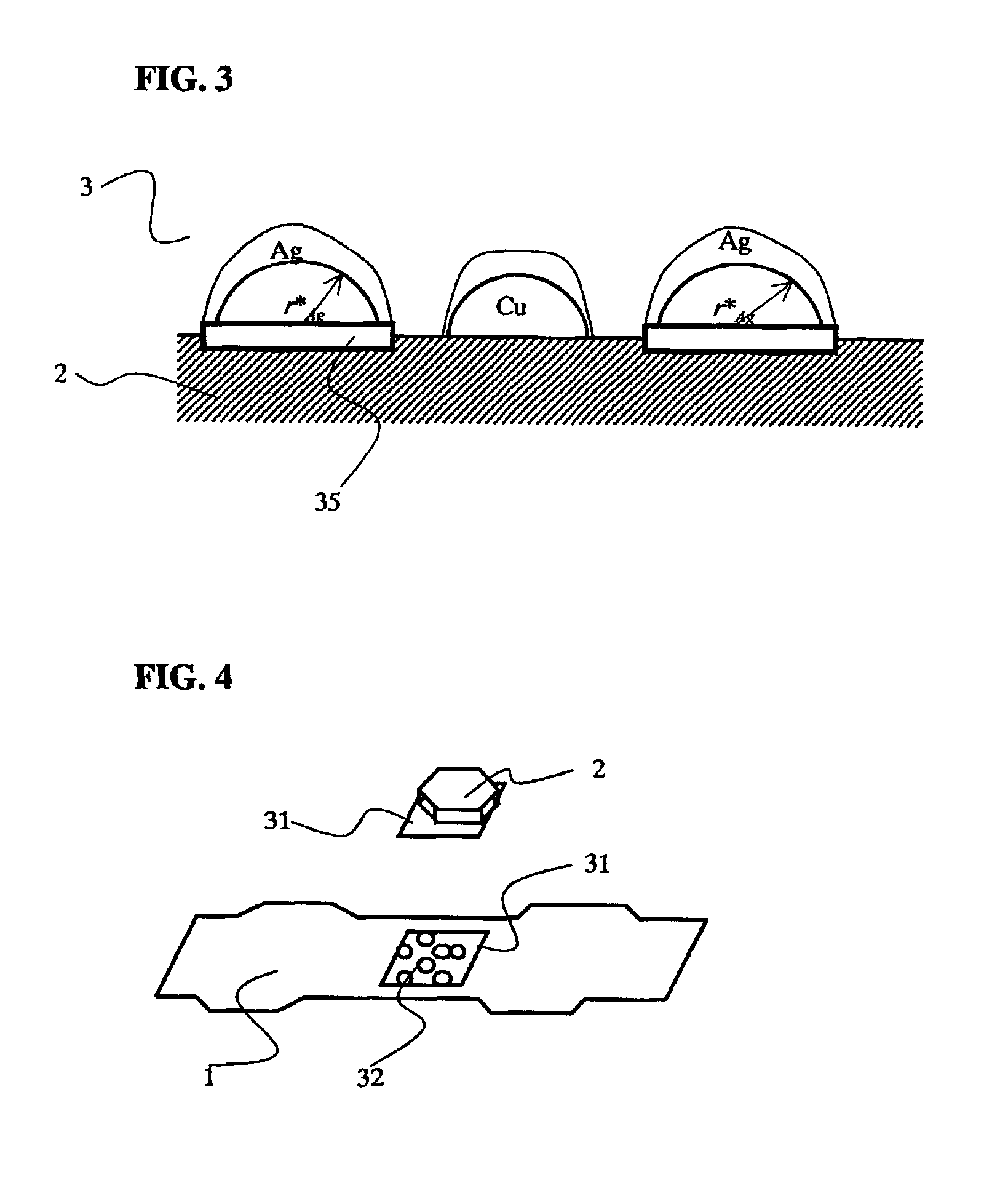

Brazing-filler material and method for brazing diamond

InactiveUS6889890B2Beautiful sceneryStable joint strengthLayered productsOther manufacturing equipments/toolsFilling materialsCopper

When a diamond is brazed to a metal substrate, while obtaining a stable joining strength, a joined interface of the diamond is not eroded to provide a good joint with a beautiful view. A brazing-filler material containing at least one selected from a group consisting of gold and silver, and copper as principal components, and further containing 0.001 to 5 mass % of vanadium is used. Preferably, a vanadium content is not more than 2.0 mass %, and more preferably not more than 0.5 mass %. Using this brazing-filler material, unidirectional solidification is performed from a side of diamond to form vanadium carbide in a joined interface in a shape of islands, and thereby an interface having a beautiful view with stable joining strength can be obtained. In addition, strong joining is possible also by a usual solidification method.

Owner:HOHOEMI BRAINS INC

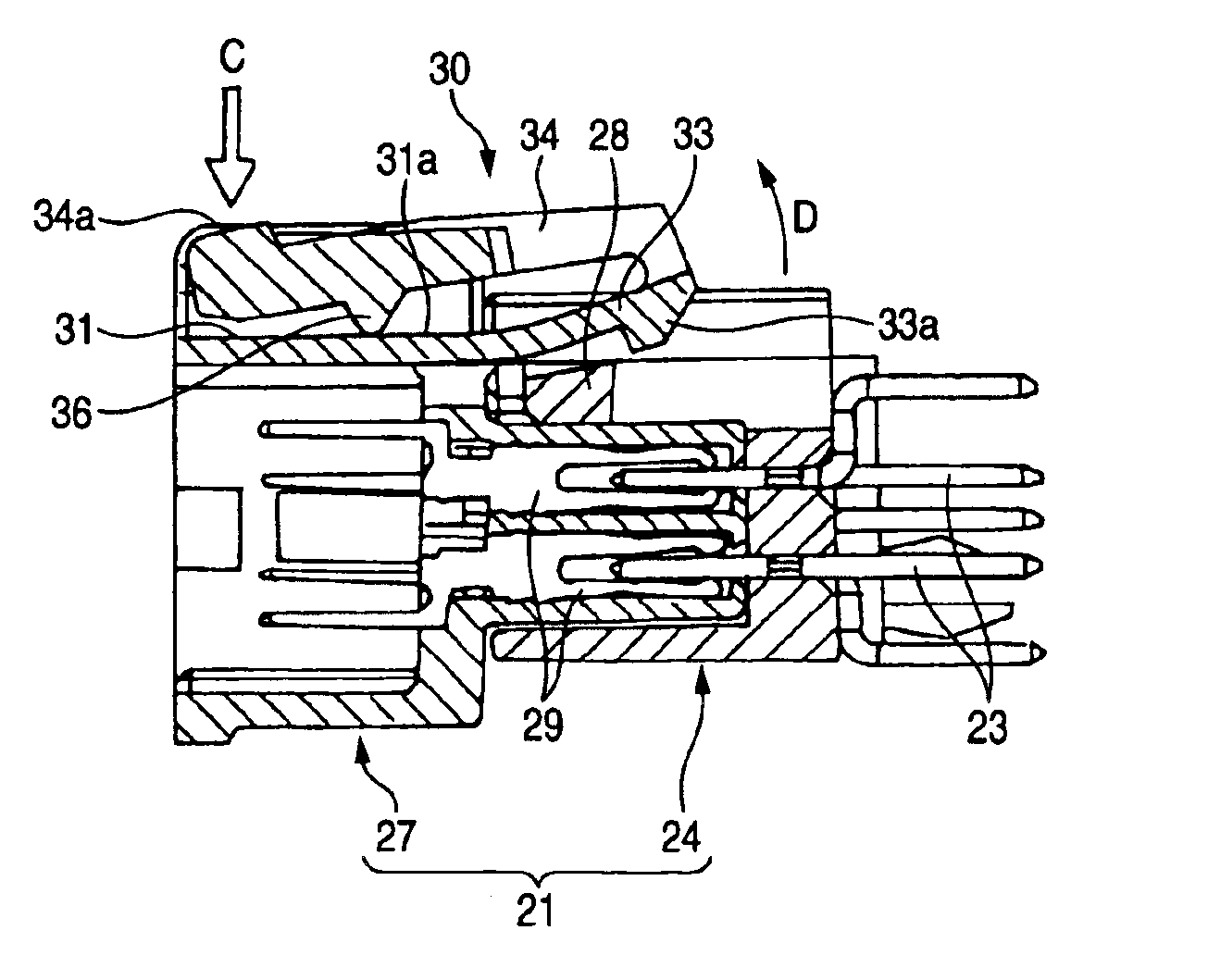

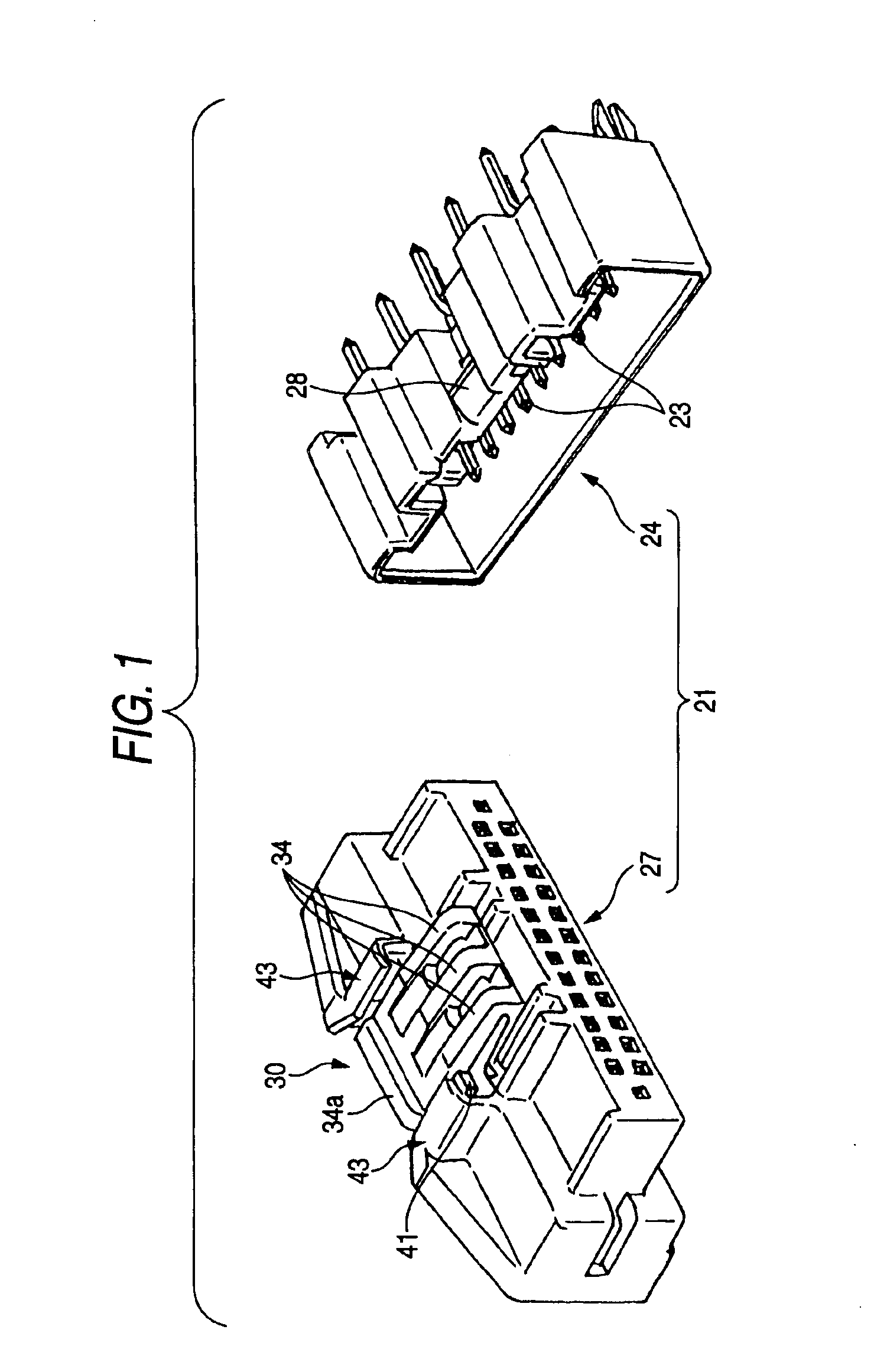

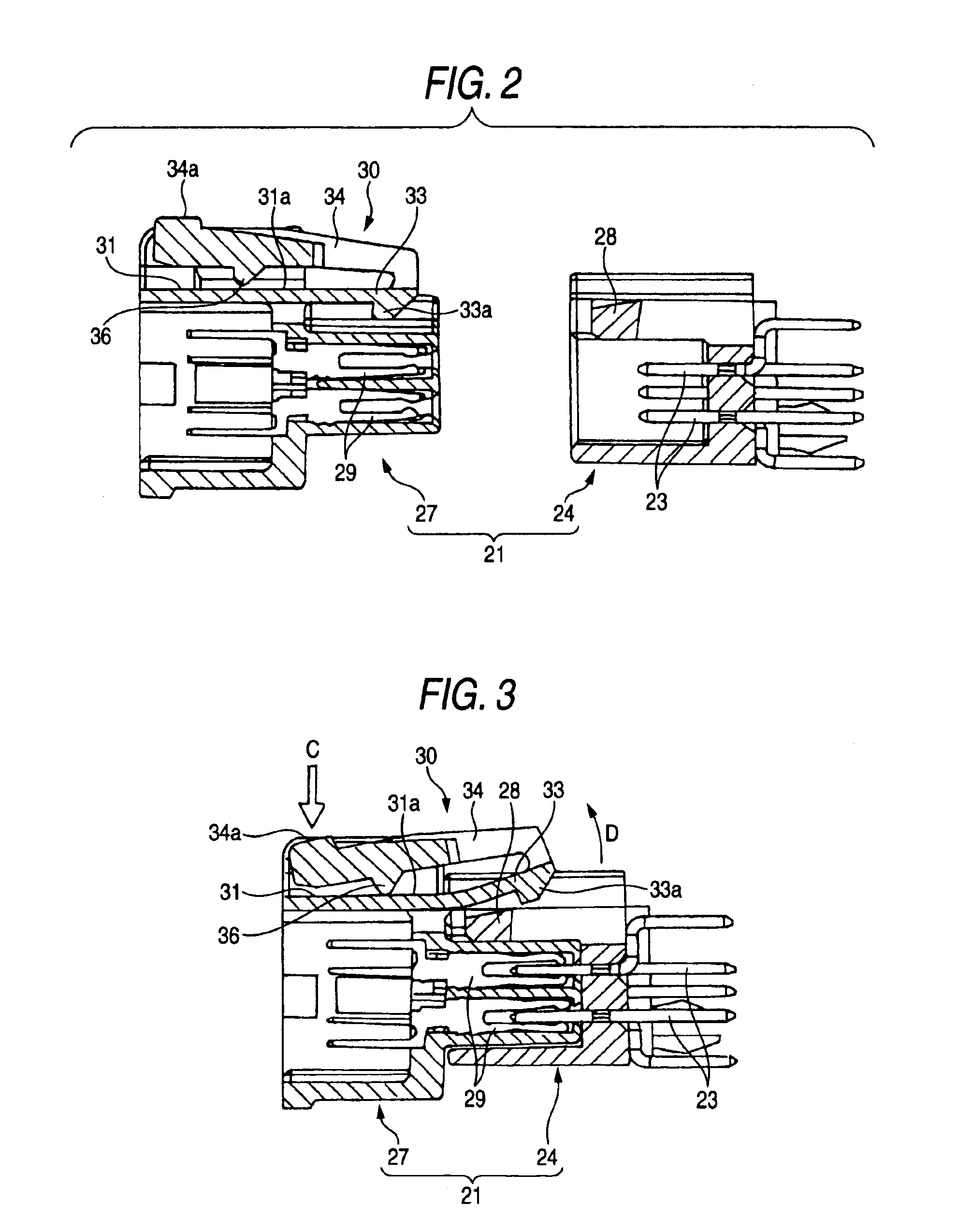

Connector lock structure

InactiveUS6902420B2MiniaturizationHigh strengthCoupling device detailsEngineeringMechanical engineering

Owner:YAZAKI CORP

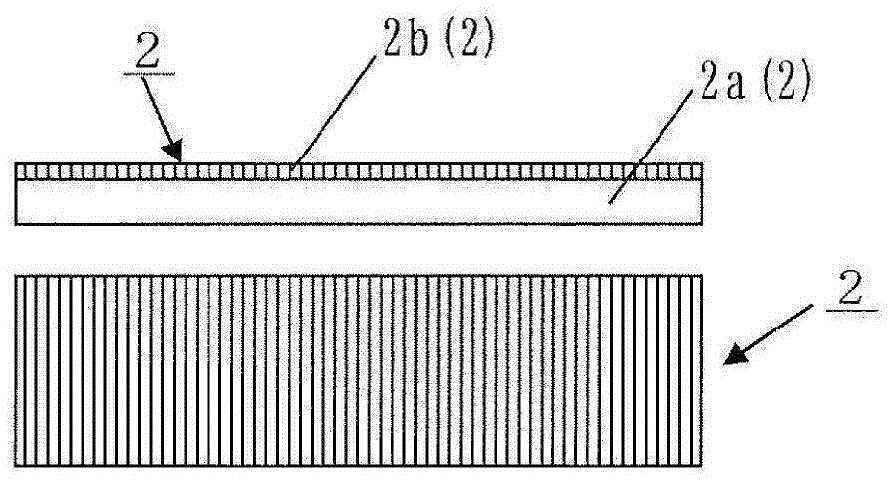

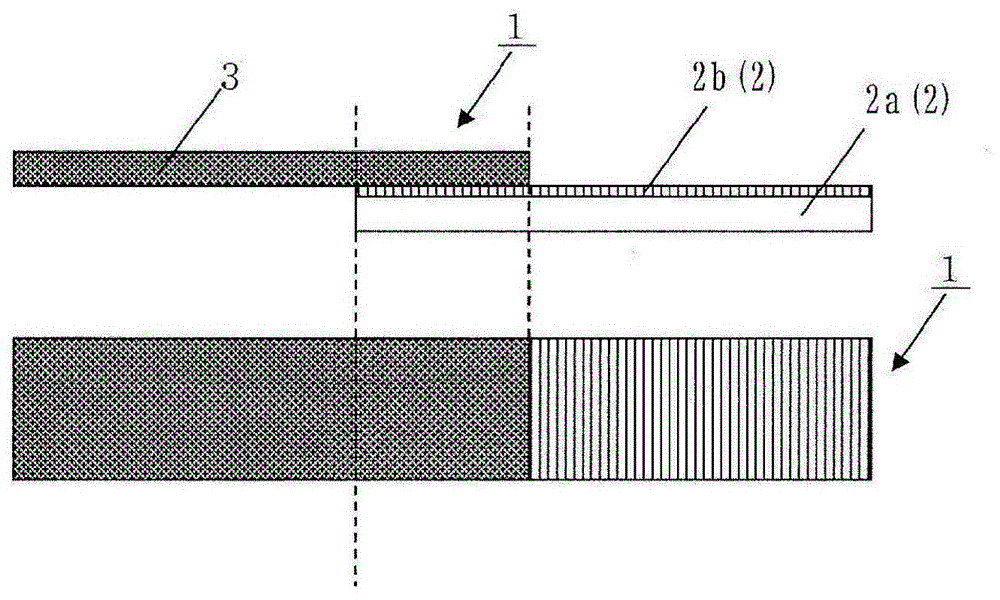

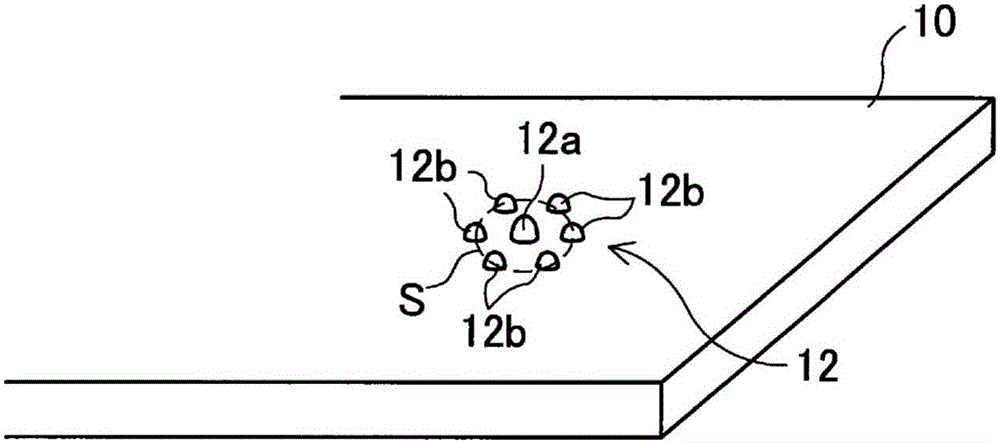

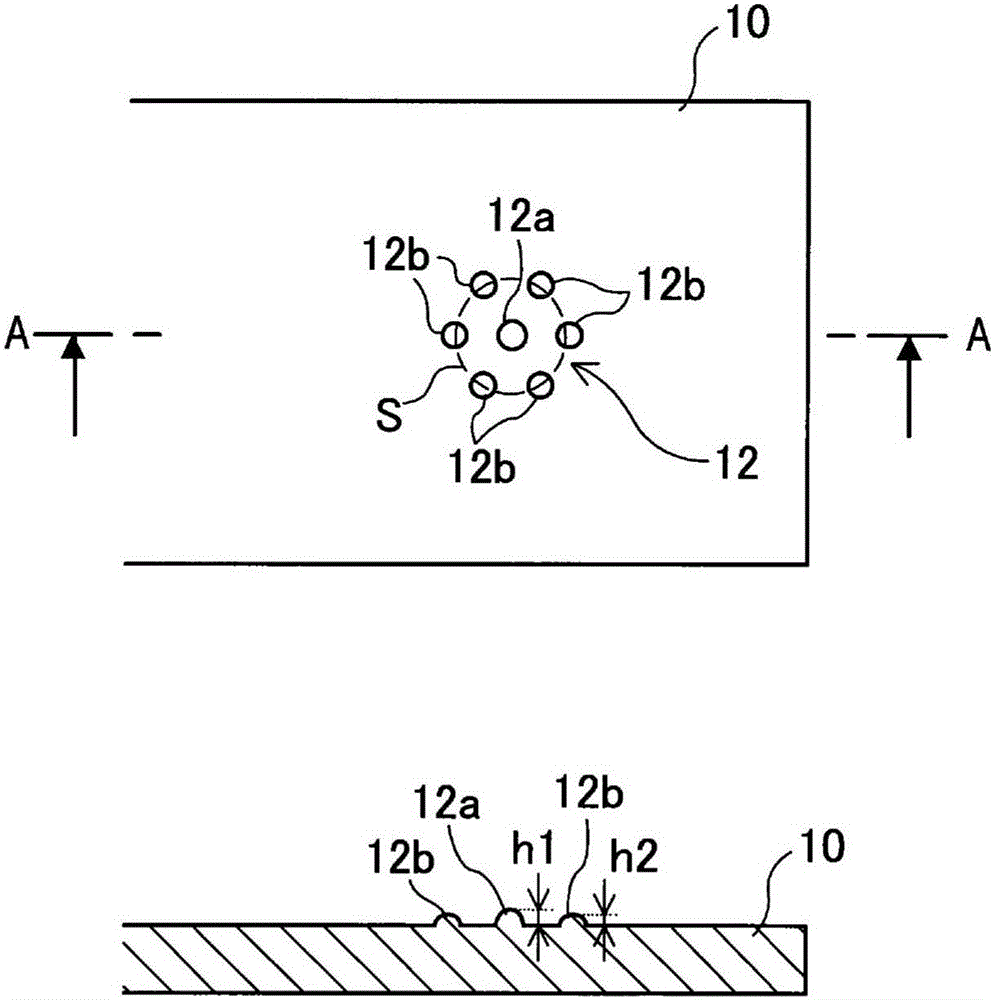

Process for producing metal-resin bonded object, and metal-resin bonded object

Provided is a process for producing a metal-resin bonded object in which the metal member has been untied with the resin member constituted of a thermoplastic resin, the process being easier and versatile, being capable of imparting stable bonding strength to the bonded surfaces of the metal member and resin member, and giving no damage, etc. to the metal member, etc. of the metal-resin bonded object. The process, which is for producing a metal-resin bonded object by bonding a metal member to a resin member constituted of a thermoplastic resin, comprises: superposing beforehand a resinous bonding layer that comprises a thermoplastic resin having compatibility with the resin member and has a thickness of 0.01-9 mm, on the surface of the metal member which is to be bonded; and heating the surfaces to be bonded of the resinous bonding layer of the metal member and the resin member to compatibilize and bond the resinous bonding layer and the resin member.

Owner:NIPPON LIGHT METAL CO LTD

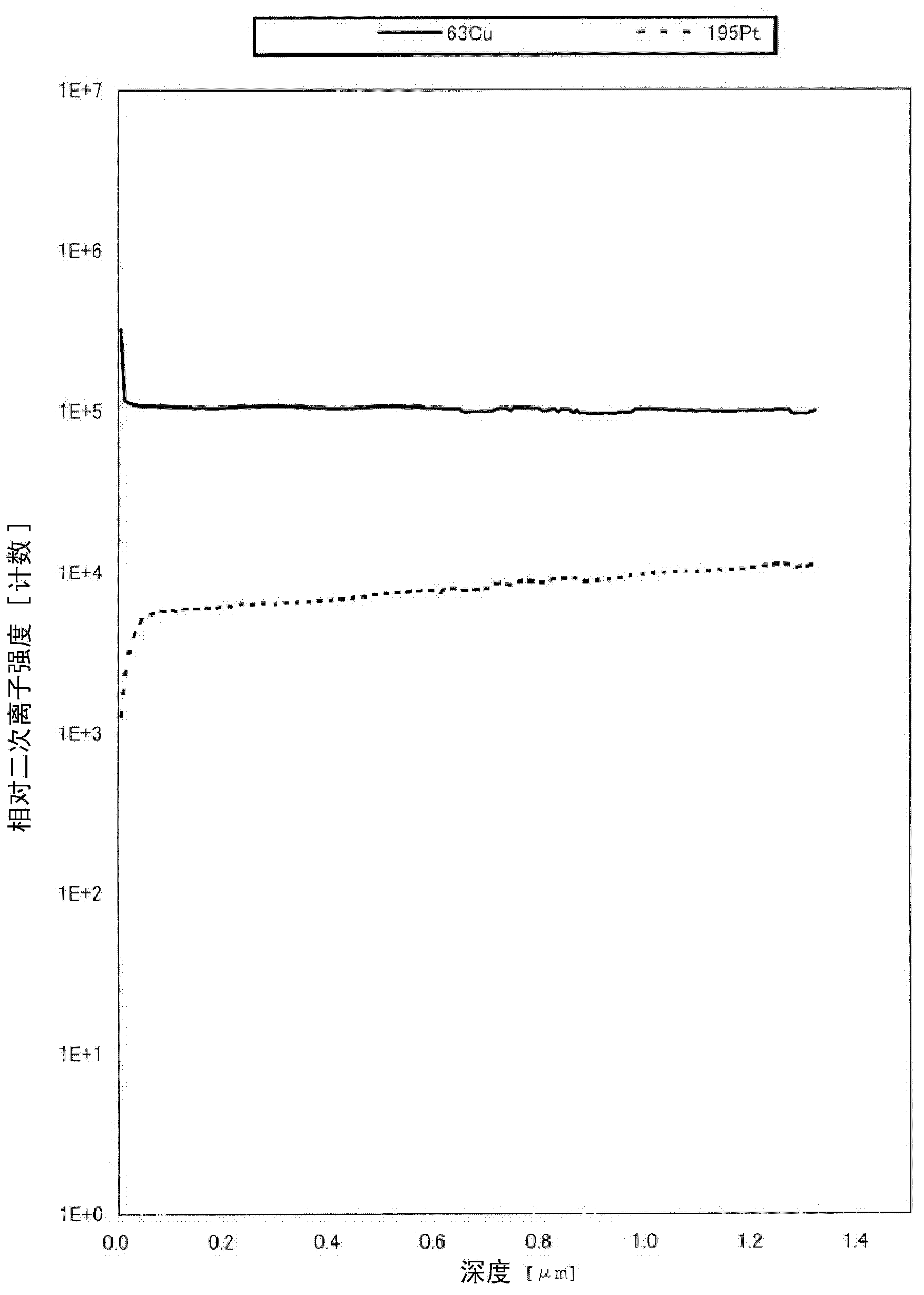

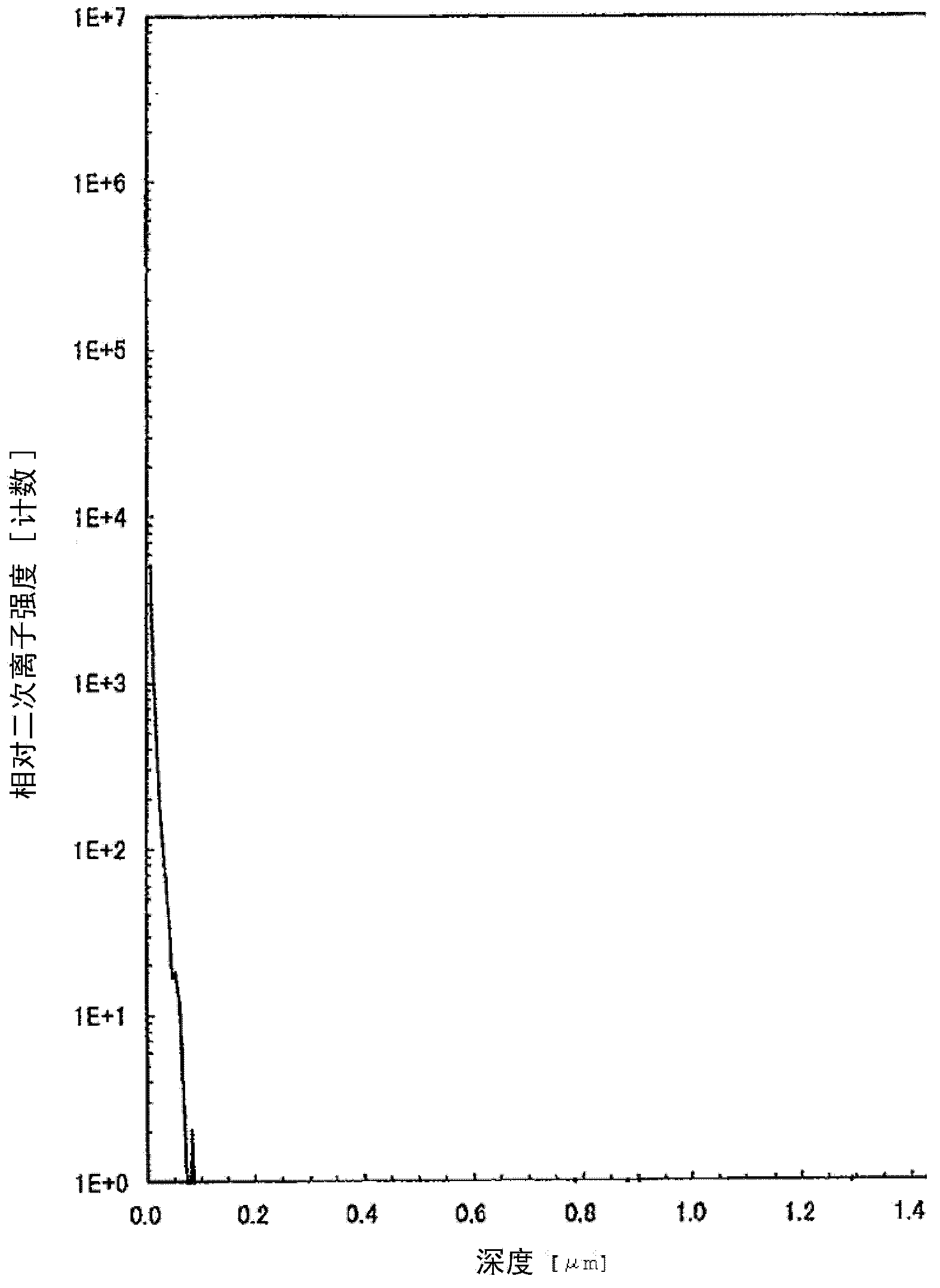

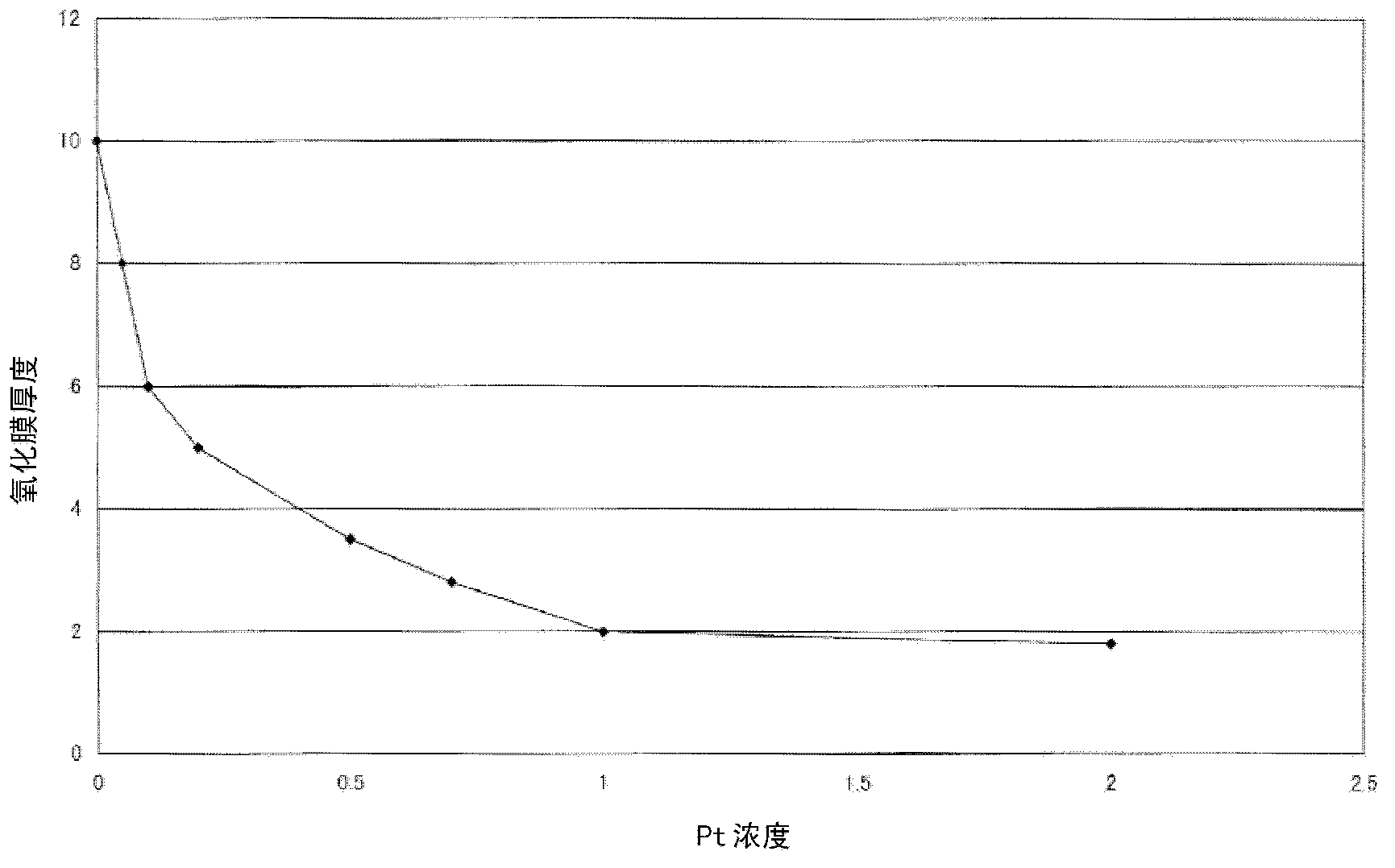

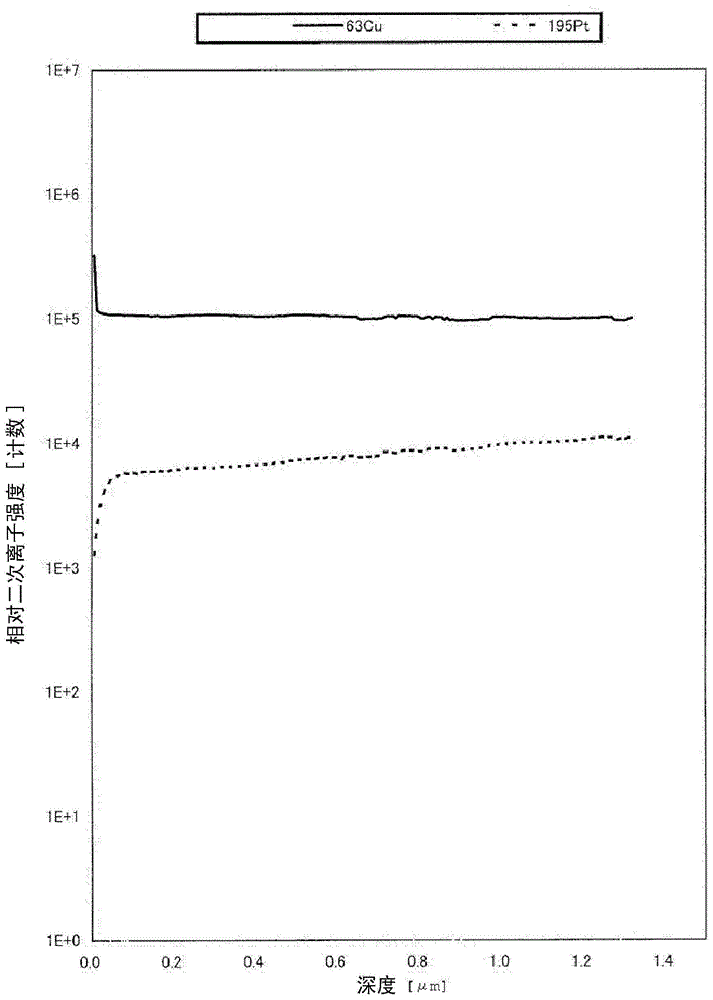

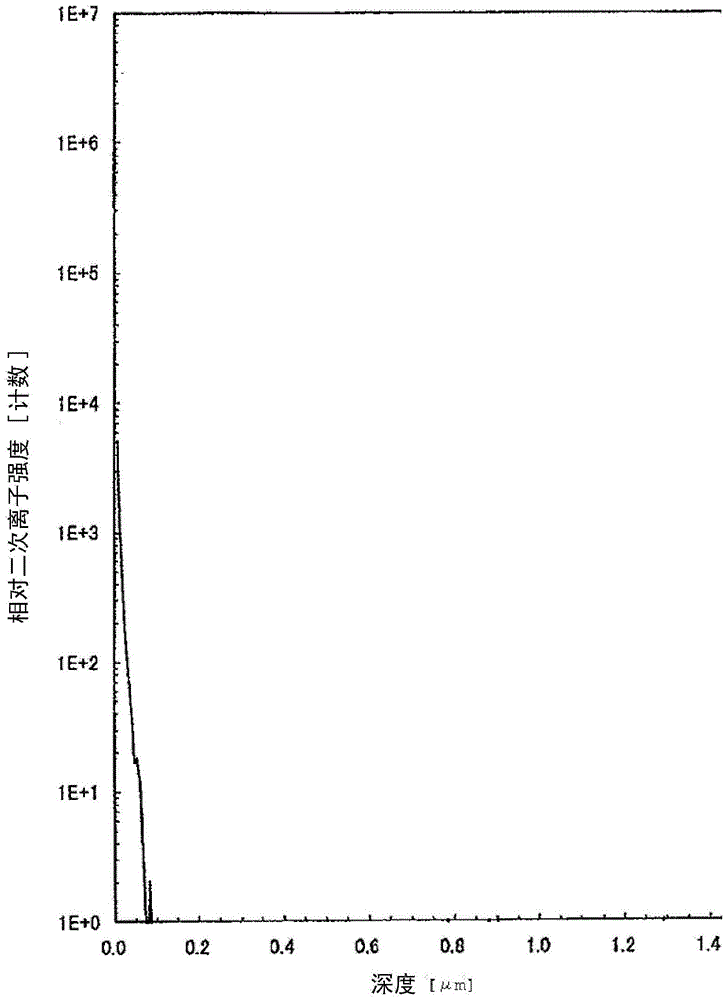

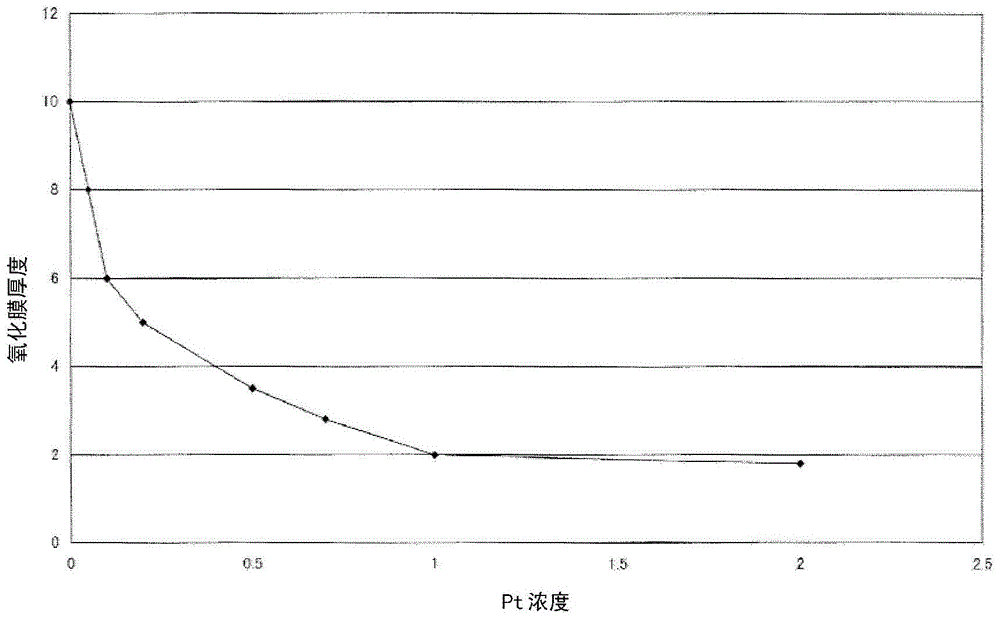

Copper-platinum alloy wire for connecting in semiconductor apparatus

ActiveCN103295993ADynamic strength does not increaseAvoid chip breakageSemiconductor/solid-state device detailsSolid-state devicesStatic strengthOxide

The invention relates to a copper-platinum alloy wire for connecting in a semiconductor apparatus. The copper-platinum alloy wire can improve a secondary joining property, prevent chip crack in ball bonding and improve ring formation performance in copper wires for the ball bonding. During preparing element wires of continuous casting of a fusing copper-platinum alloy containing high-purity copper (Cu), by mass, 0.1-2.0 % of platinum (Pt), 1-10 ppm sulphur (S) as a non-metal element, 10-150 ppm oxygen (O), optionally together with 1-5 ppm phosphorus (P), a very thin copper layer without the platinum is formed because of segregation, is subsequently oxidized in the atmosphere and a 6-2 nm oxide film is formed on a surface layer of the wires after continuous wire drawing is carried out. According to the joining wires of 77-105 Hv Vickers hardness, the uniform oxide film improves the secondary joining property, the elements added to a matrix restrain dynamic strength during ball bonding, so that aluminum splash is prevented and static strength incapable of leading to inclination is maintained.

Owner:TANAKA DENSHI KOGYO

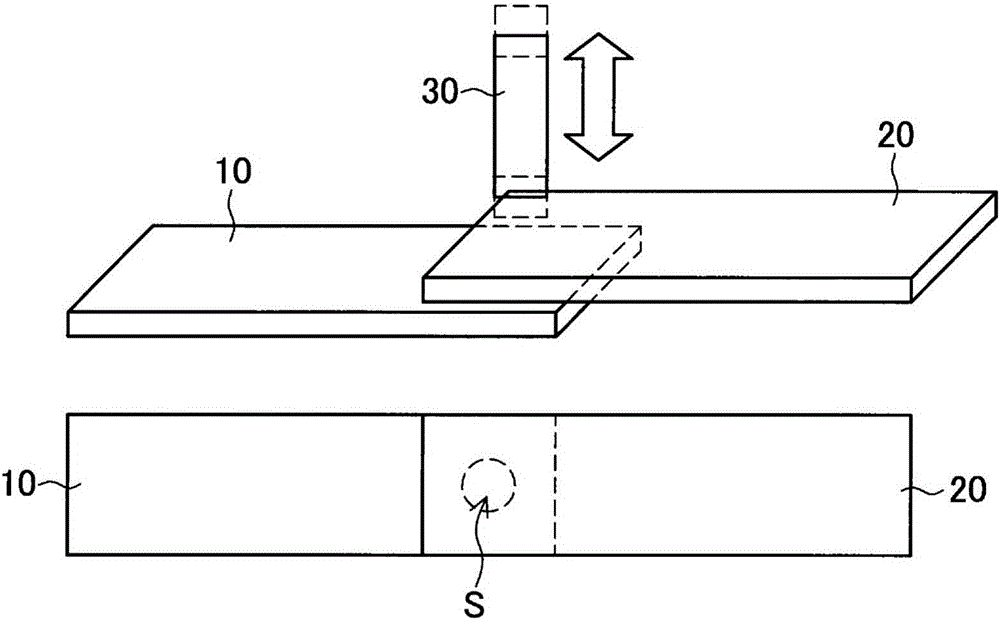

Bonding method and members to be bonded

InactiveCN103260808AStable joint strengthCylinder headsCylindersElectrical resistance and conductanceConductive materials

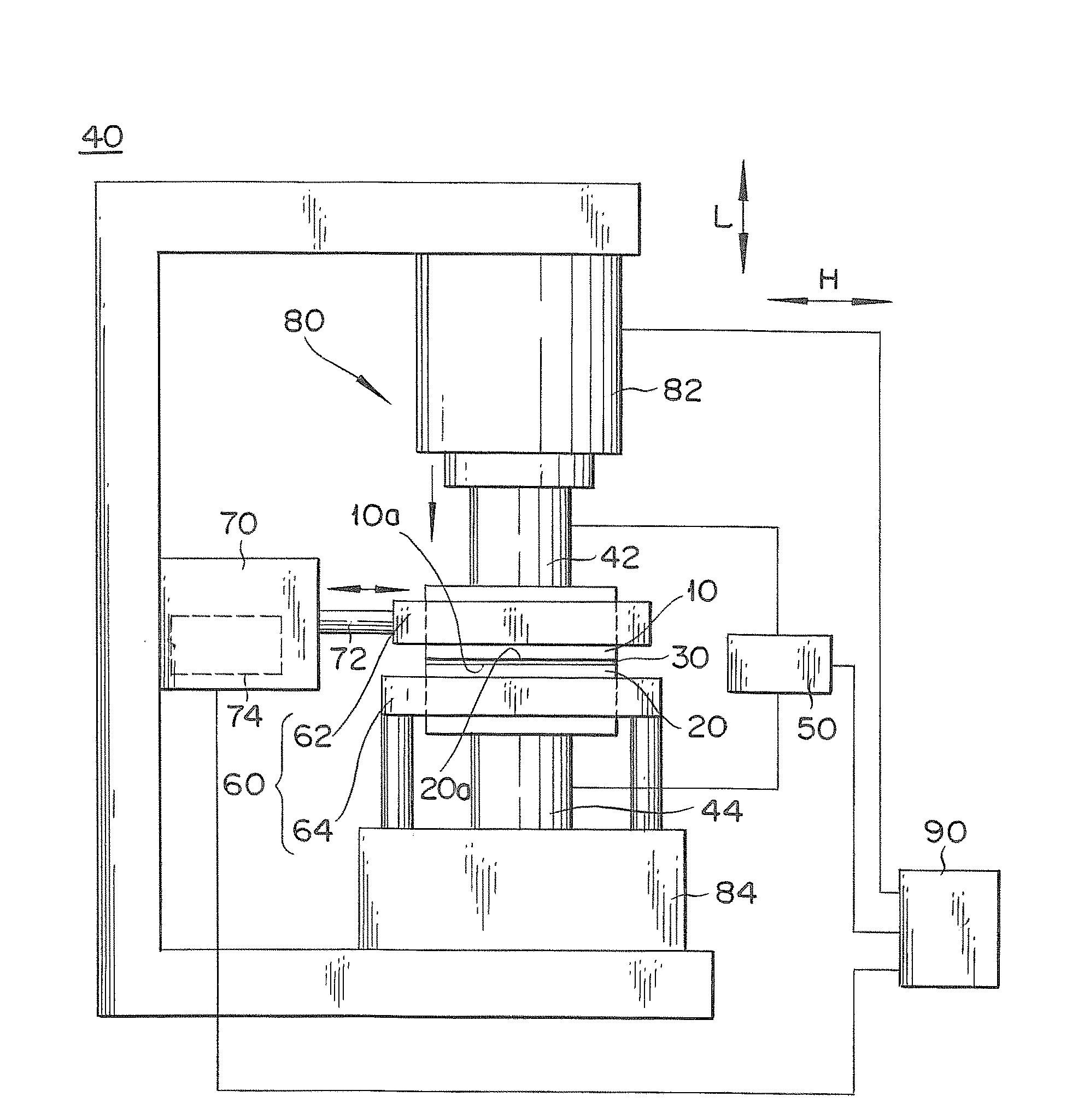

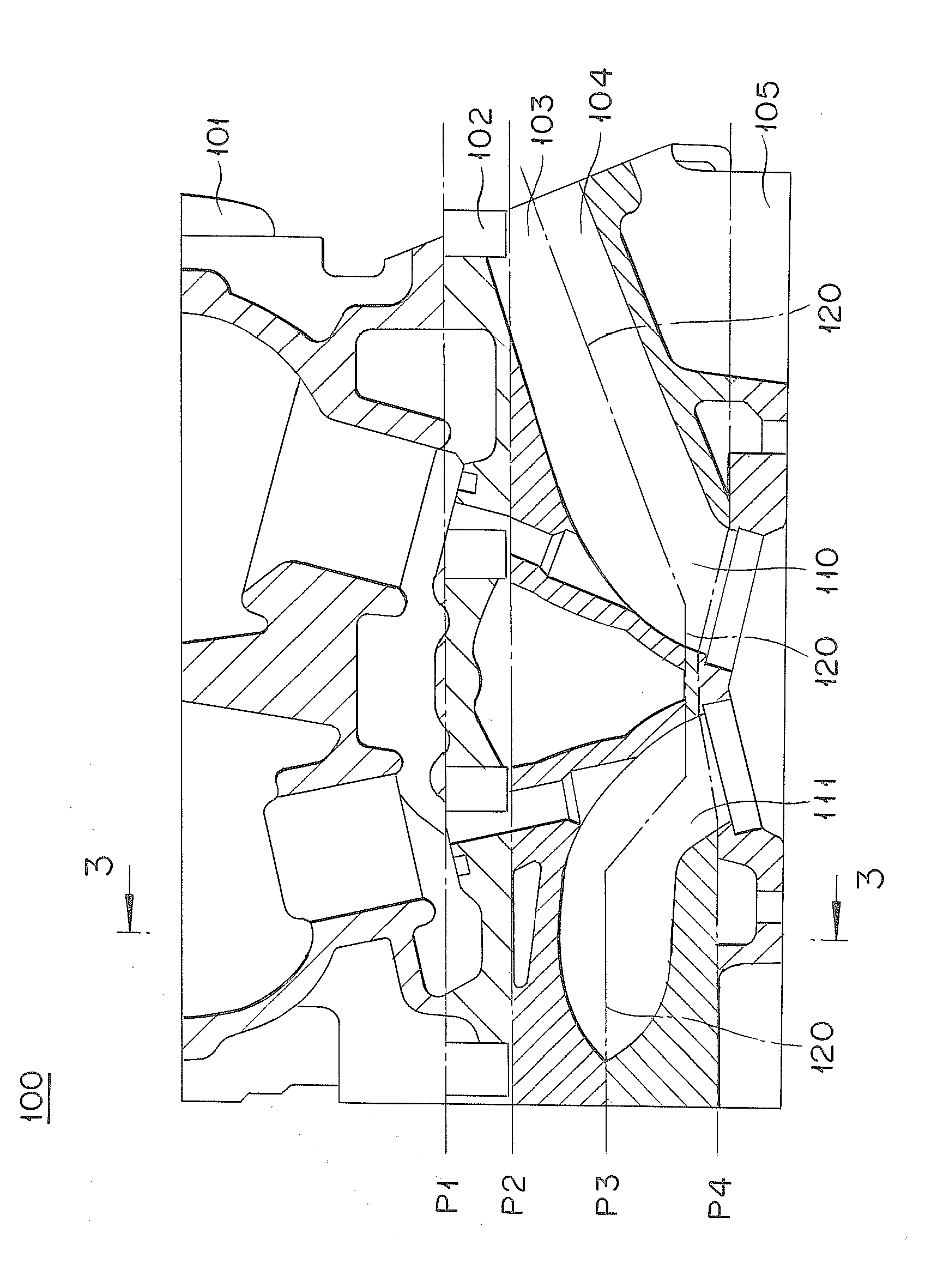

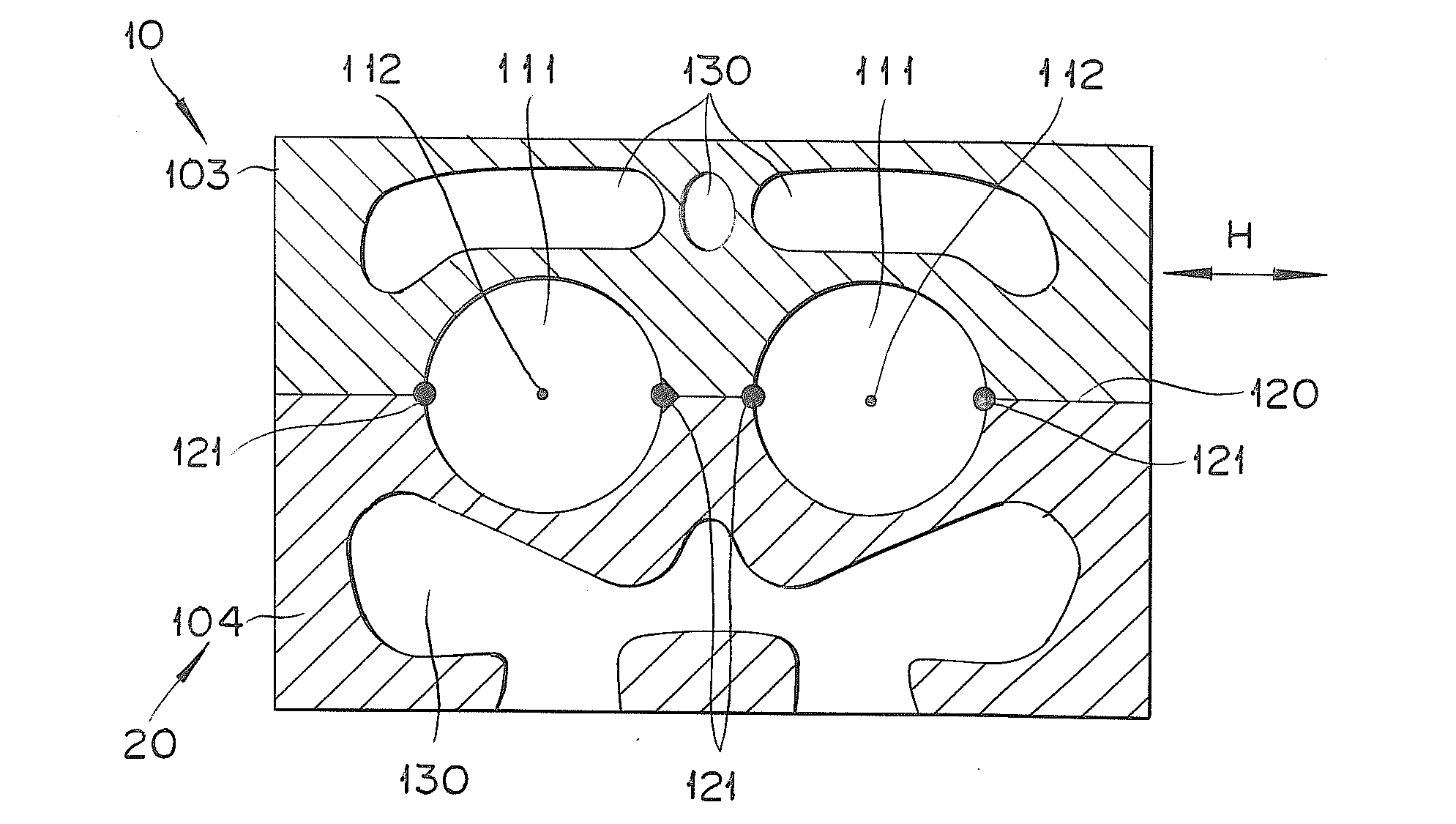

Provided is a bonding method for bonding a pair of members to be bonded (10, 20) that comprise a conductive material and have bonding surfaces which are not on identical flat surfaces, said bonding method including a bonding step in which the bonding surfaces (10a, 20a) of the members to be bonded to each other face each other, an electric current is passed from one of the members to be bonded to the other to perform resistance heating while the pair of members to be bonded are slid relative to each other, and the bonding surfaces are bonded to each other. Cut surfaces (120), which are for forming hollow passages (110, 111) and extend along the axes of the hollow passages, are set as the bonding surfaces which are not on identical flat surfaces.

Owner:NISSAN MOTOR CO LTD

Manufacturing method of electronic device package, electronic device package, and oscillator

InactiveCN102194712AWarpage suppressionImprove alignment accuracyImpedence networksSemiconductor/solid-state device detailsEngineeringAnodic bonding

Owner:SEIKO INSTR INC

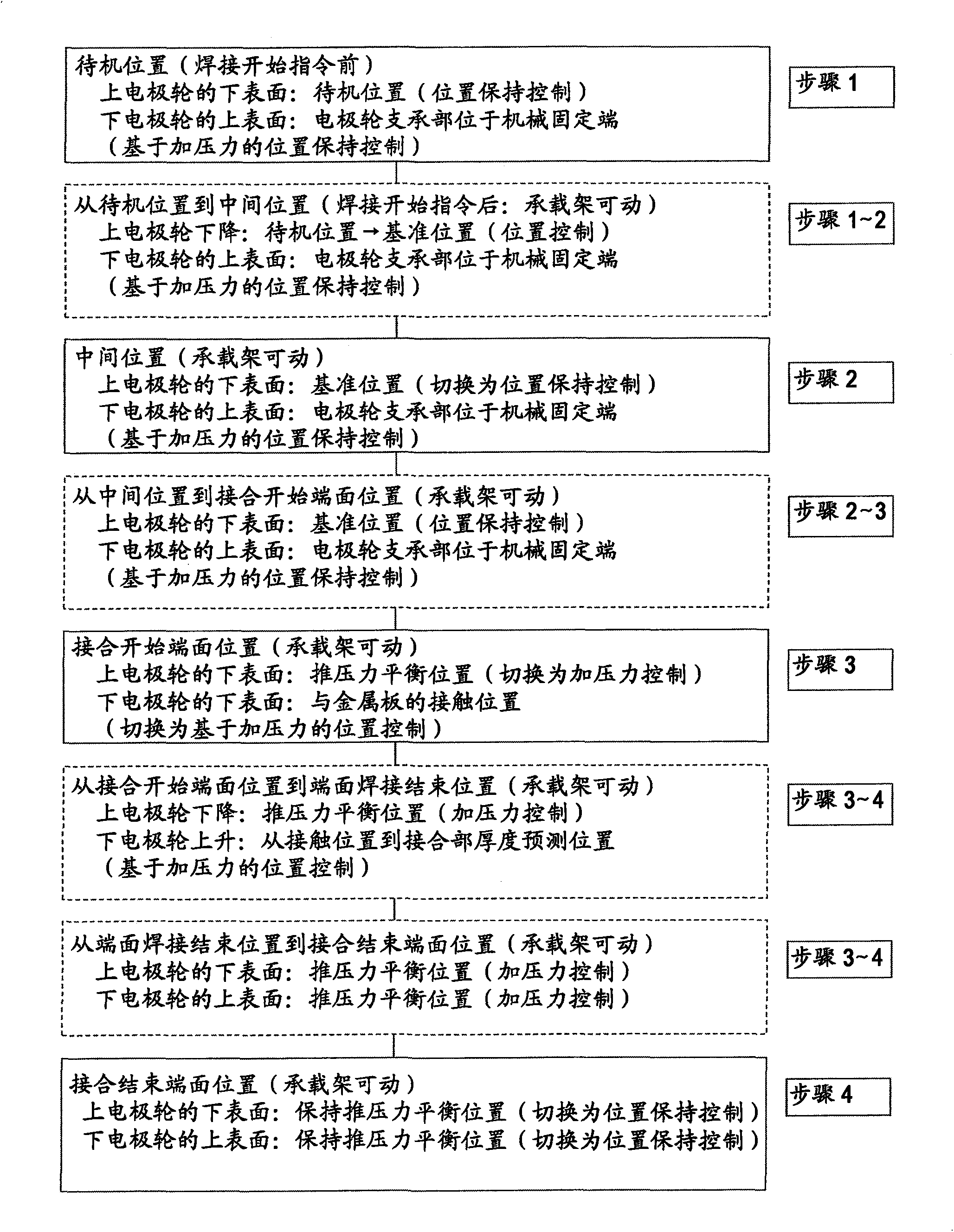

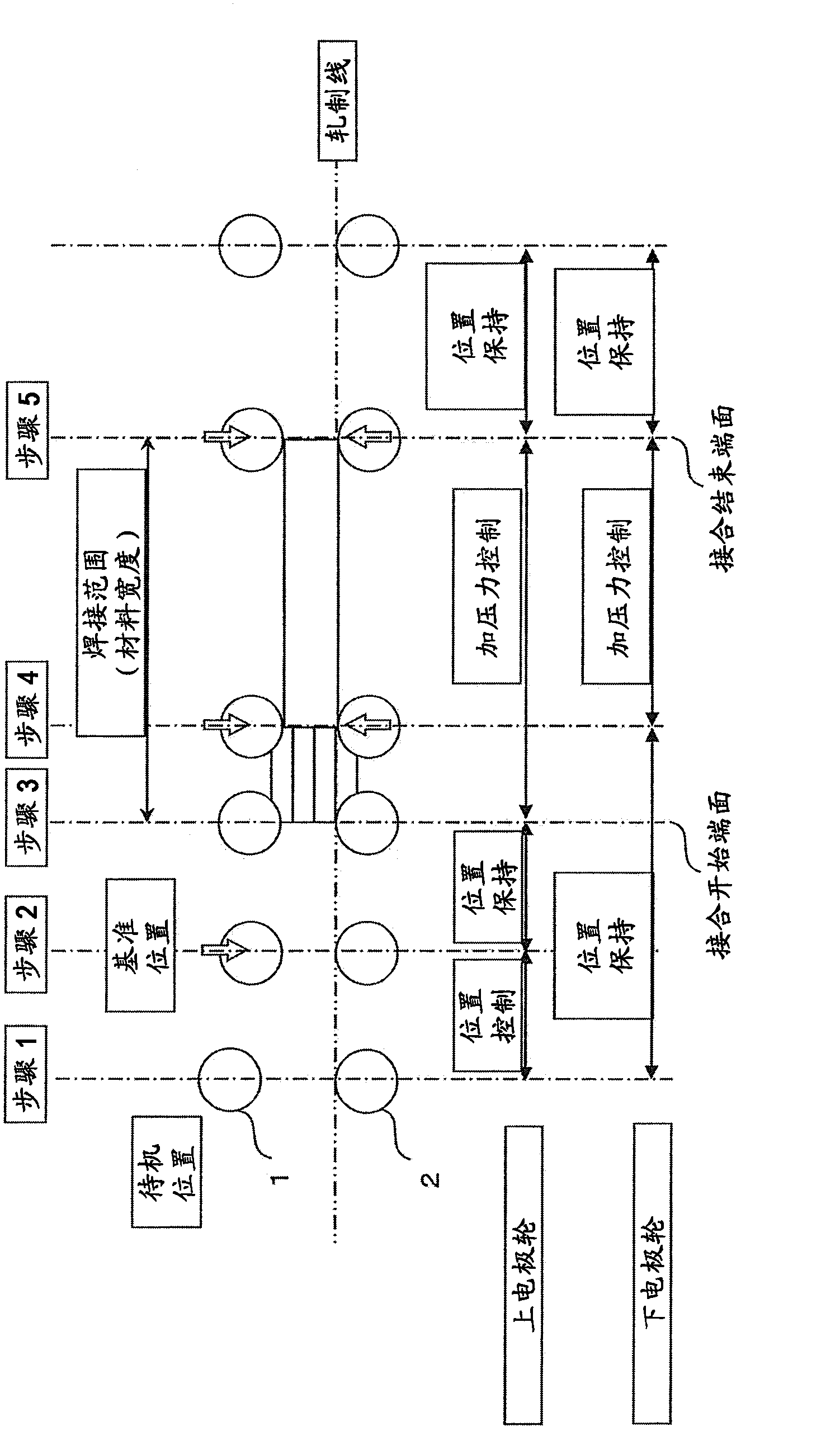

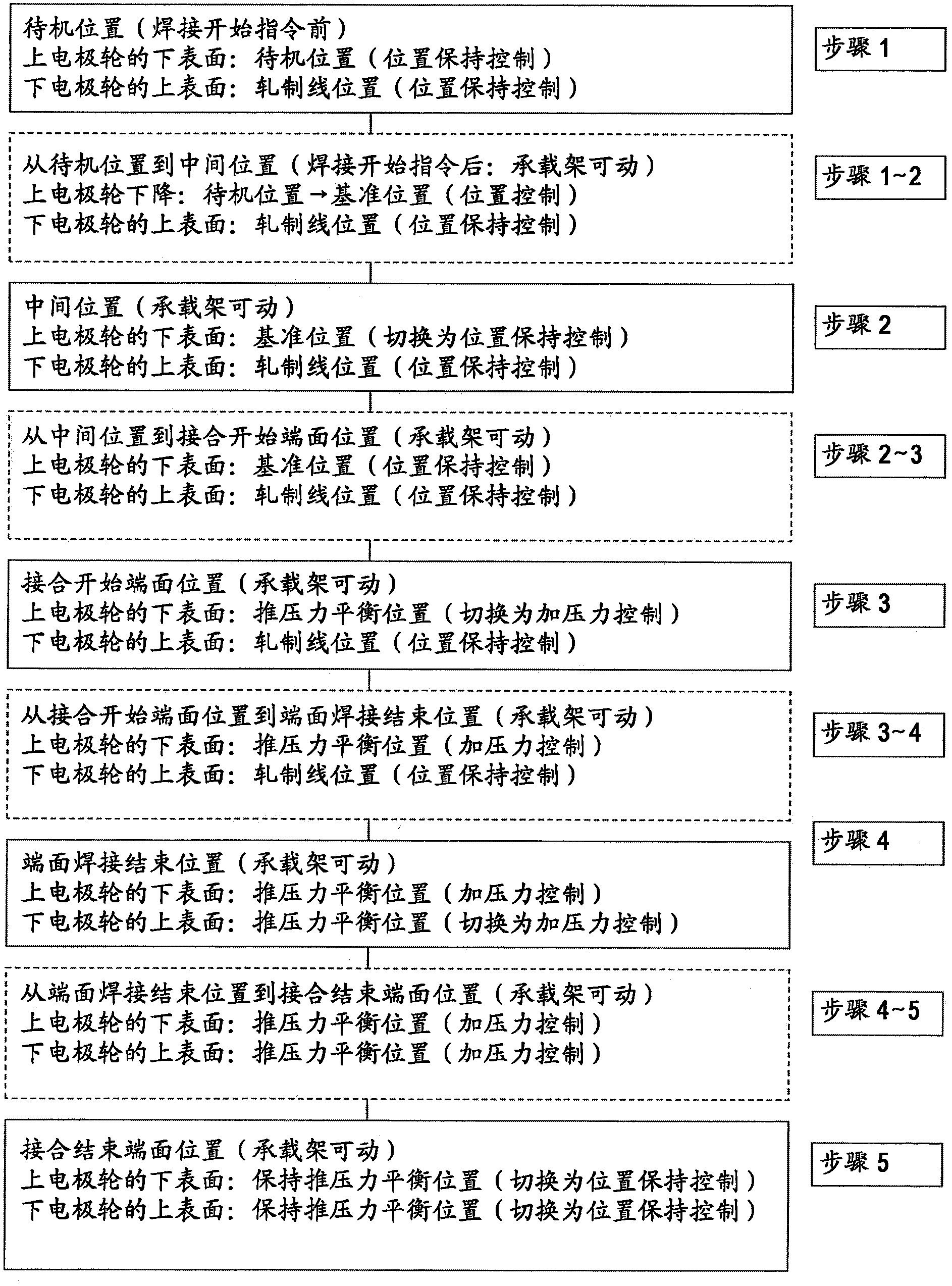

Mash seam welding method and device

ActiveCN103108719AIncreased pressure bearing shareIncrease the pressure differenceElectrode featuresWelding electric supplySeam weldingUltimate tensile strength

In order that in mash seam welding for metal plates with a thickness exceeding 2 mm, the joint strength is stabilized, the difference in the level of a joint part is reduced, high joint strength and reliability are ensured, and therefore metal plates with a thickness exceeding 4.5 mm can be also joined, two metal plates (5, 6) are grasped by first and second graspers (7, 8), respectively, ends of the two metal plates (5, 6) are overlapped , an overlap (L) therebetween is pressurized by a pair of upper and lower electrode wheels (1, 2) and continuously welded while a welding current is being passed to thereby join the two metal plates. While the overlap (L) is continuously welded while the welding current is being passed, welding pressure to be applied to the upper and lower electrode wheels (1, 2) is controlled such that upper and lower pressing forces acting on the overlap become equal.

Owner:PRIMETALS TECHNOLOGIES JAPAN LTD

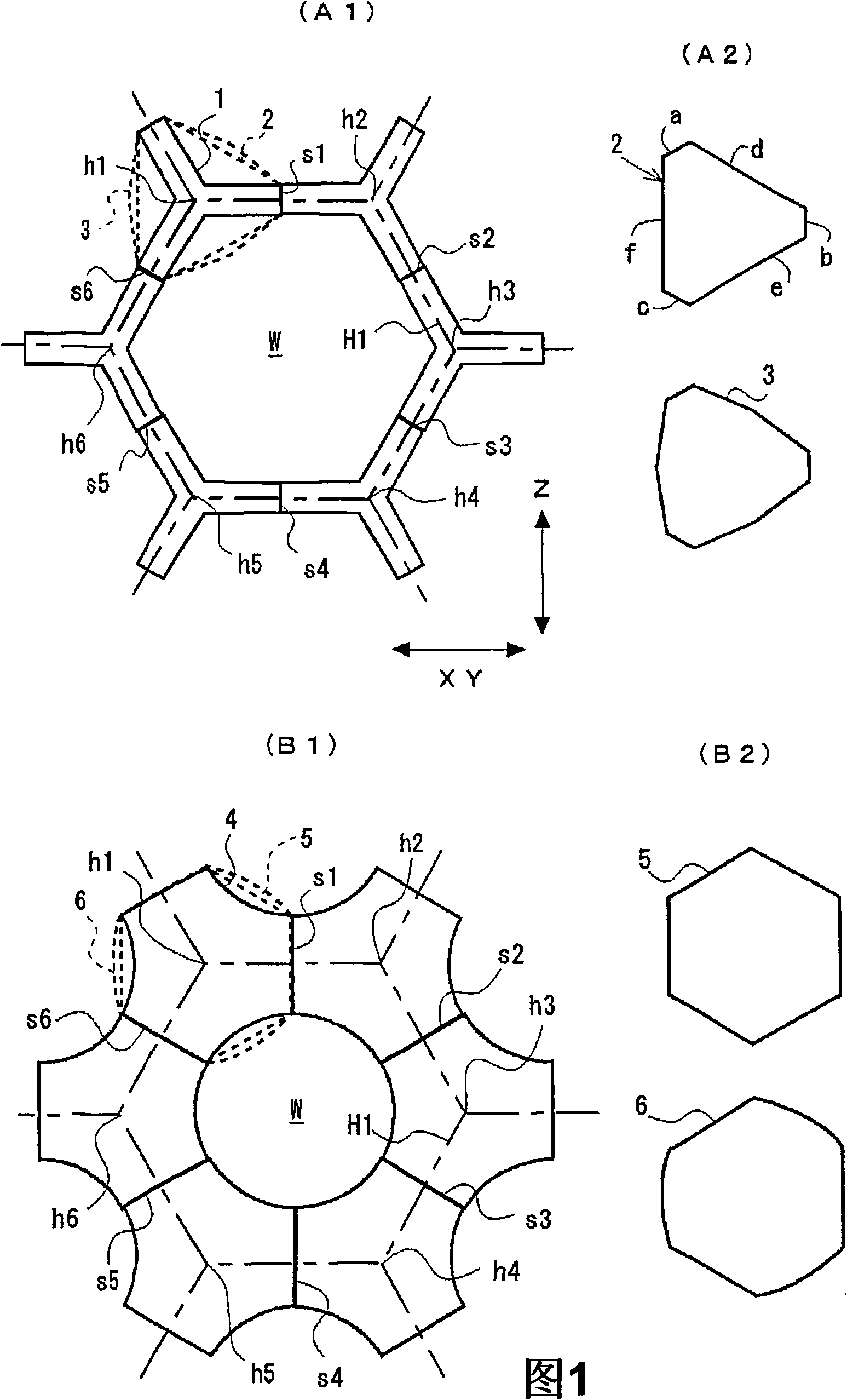

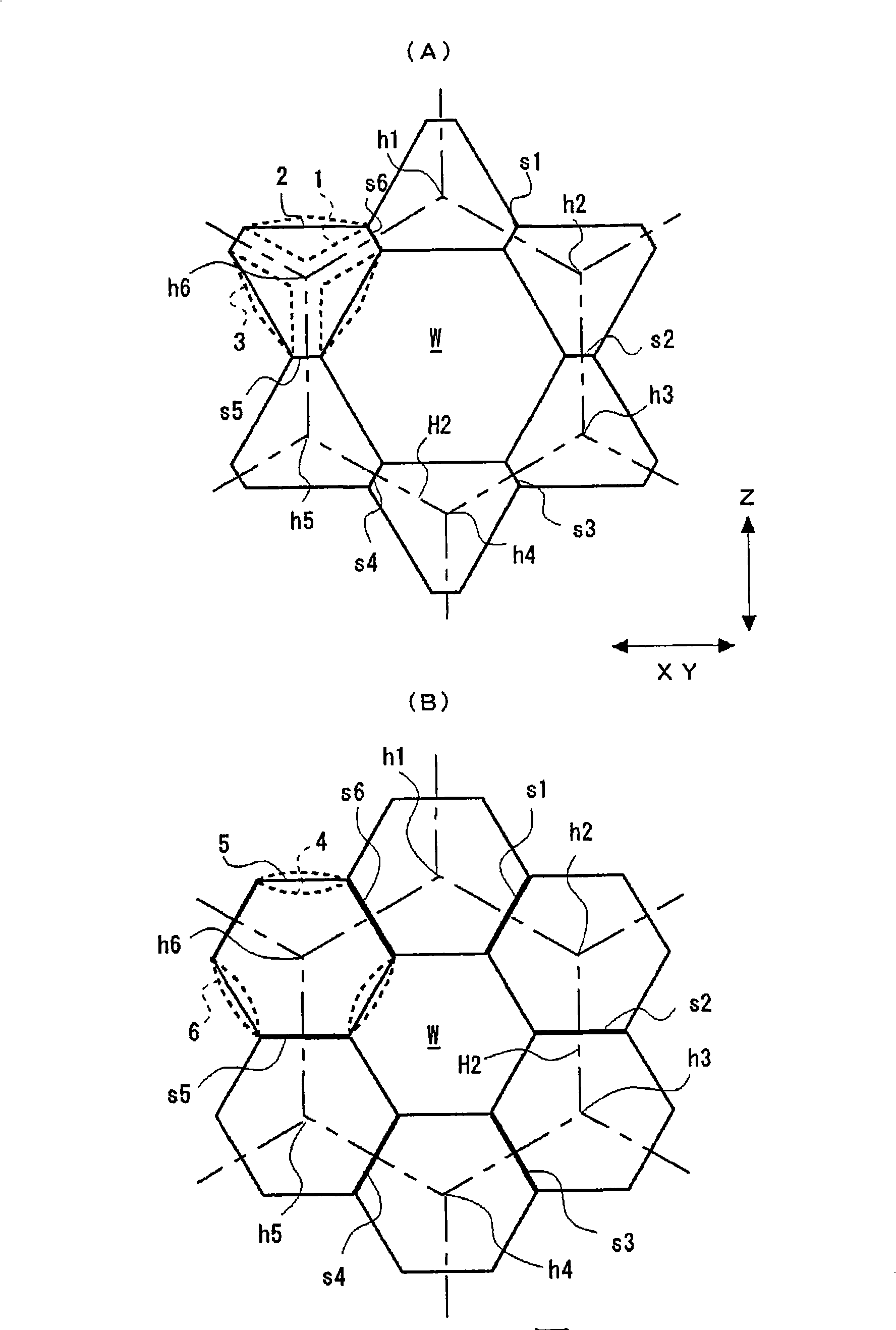

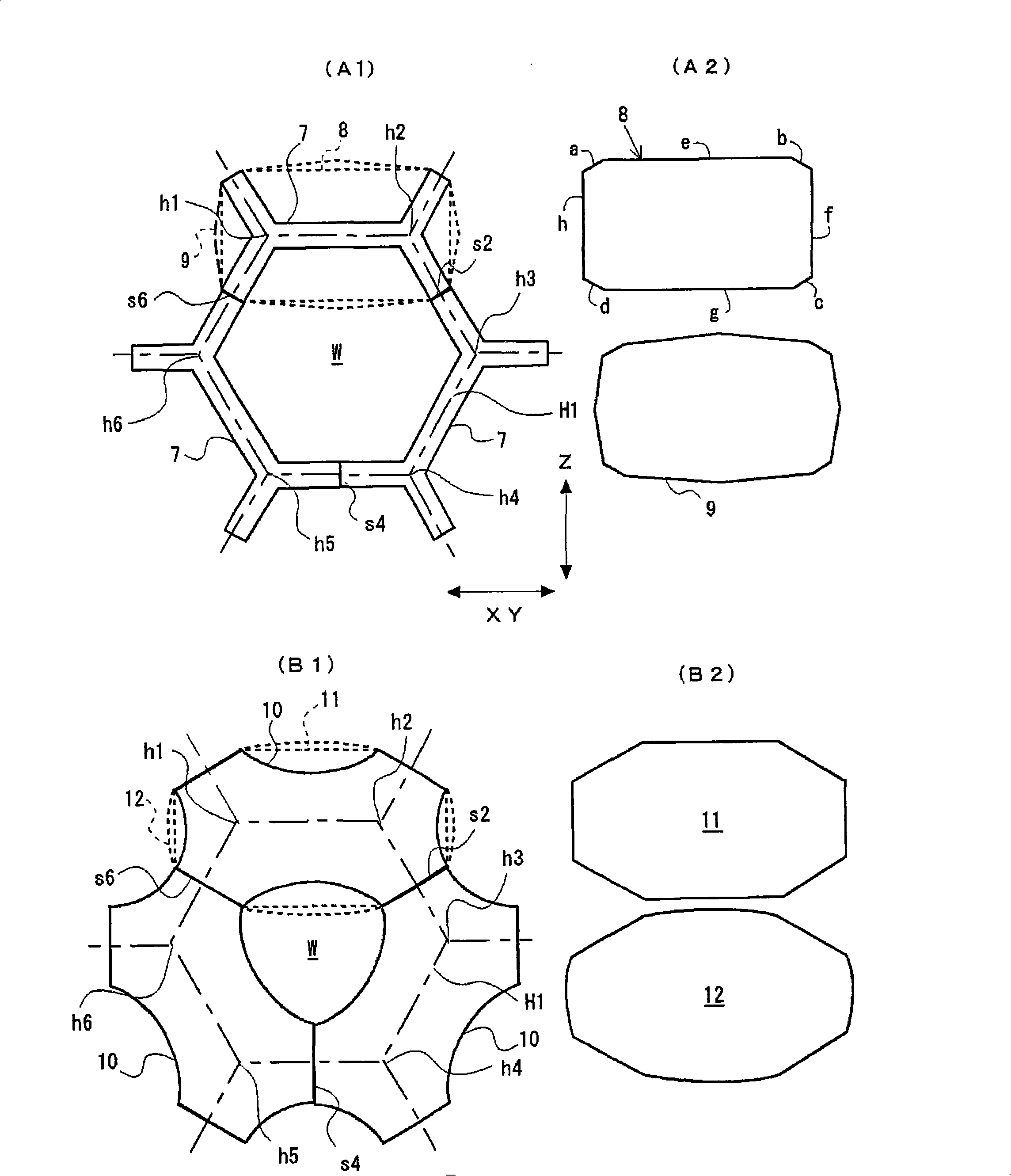

Construction structure body, structure unit, and method for the unit

InactiveCN101316972AValid conversionExtend your lifeExtraordinary structuresClassical mechanicsHoneycomb

The present invention provides a construction structure body having a honeycomb-shaped main frame that is raised and extends in a planar form, a structure unit for the construction structure body, and a method for unit. The construction structure body has the main frame formed by connecting structure units with each other, and an imaginary honeycomb shape is raised and planarly extends in the structure body. In a plan view, structure units (1, 2, 3, 4, 5, 6) are individually placed at positions including vertexes (h1, h2, h3, h4, h5. h6) of a hexagonal grid (H1, H2) as a unit grid of the imaginary honeycomb shape. The construction structure body has means for rigidly joining two structure units with joint surfaces of the two structure units faced to each other, where each of the joint surfaces are formed at a portion on the outer peripheral surface of each of the two adjacent structure units. Each of the rigidly joined surfaces (s1, s2, s3, s4, s5, s6) intersects with one of the sides of the hexagonal grid, an opening (W) is formed at the center of the hexagonal grid, and the opening (W) is surrounded by all the structure units placed on the grid.

Owner:SEKISUI CHEM CO LTD

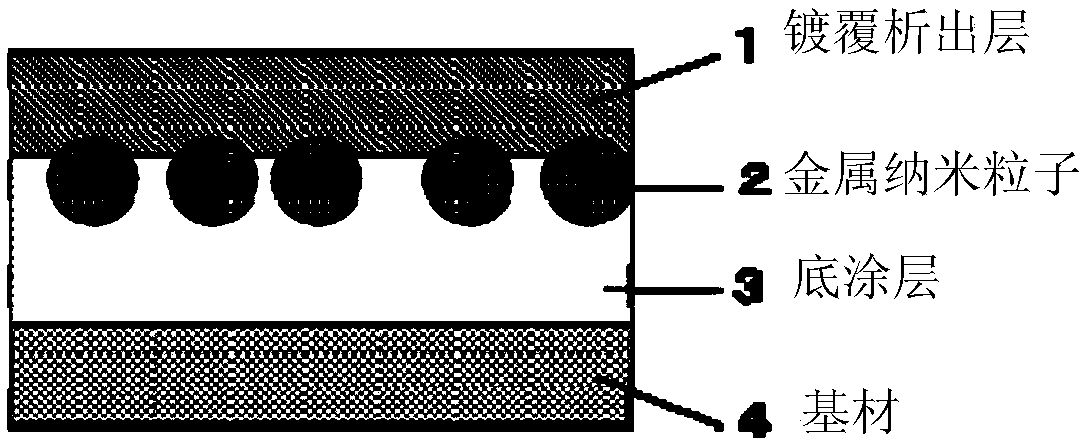

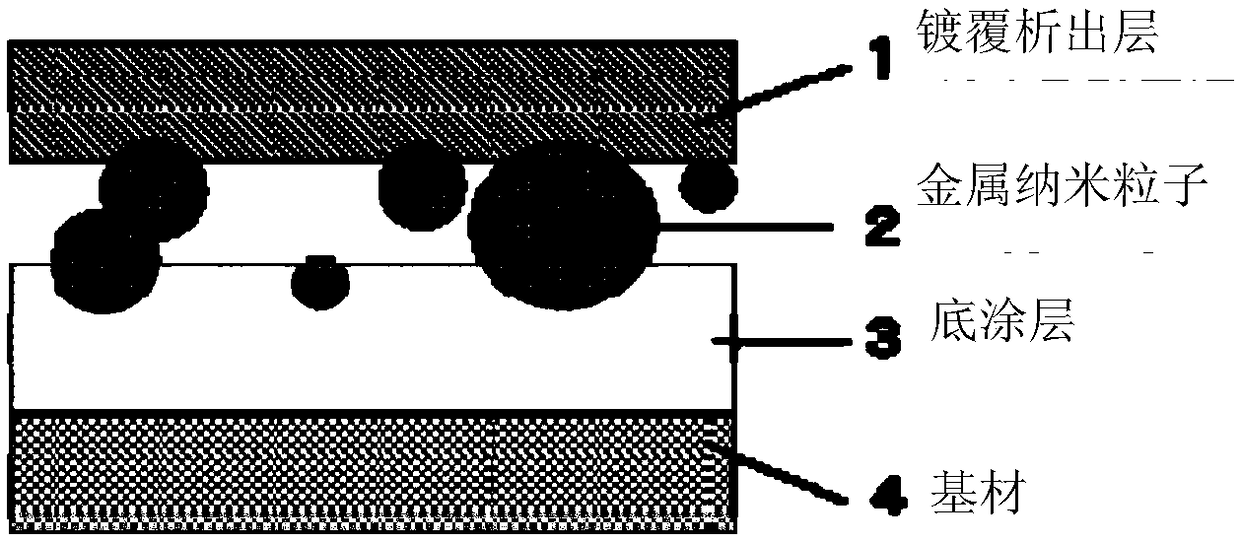

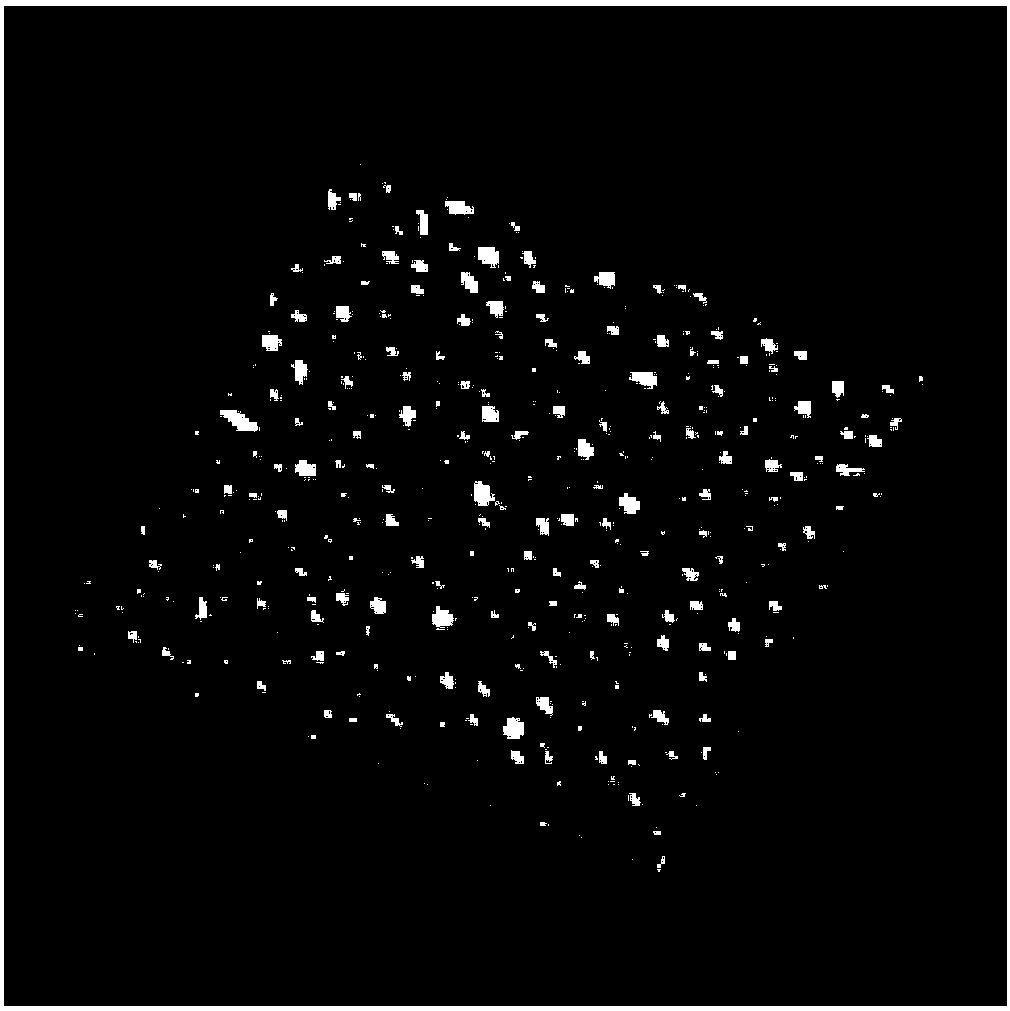

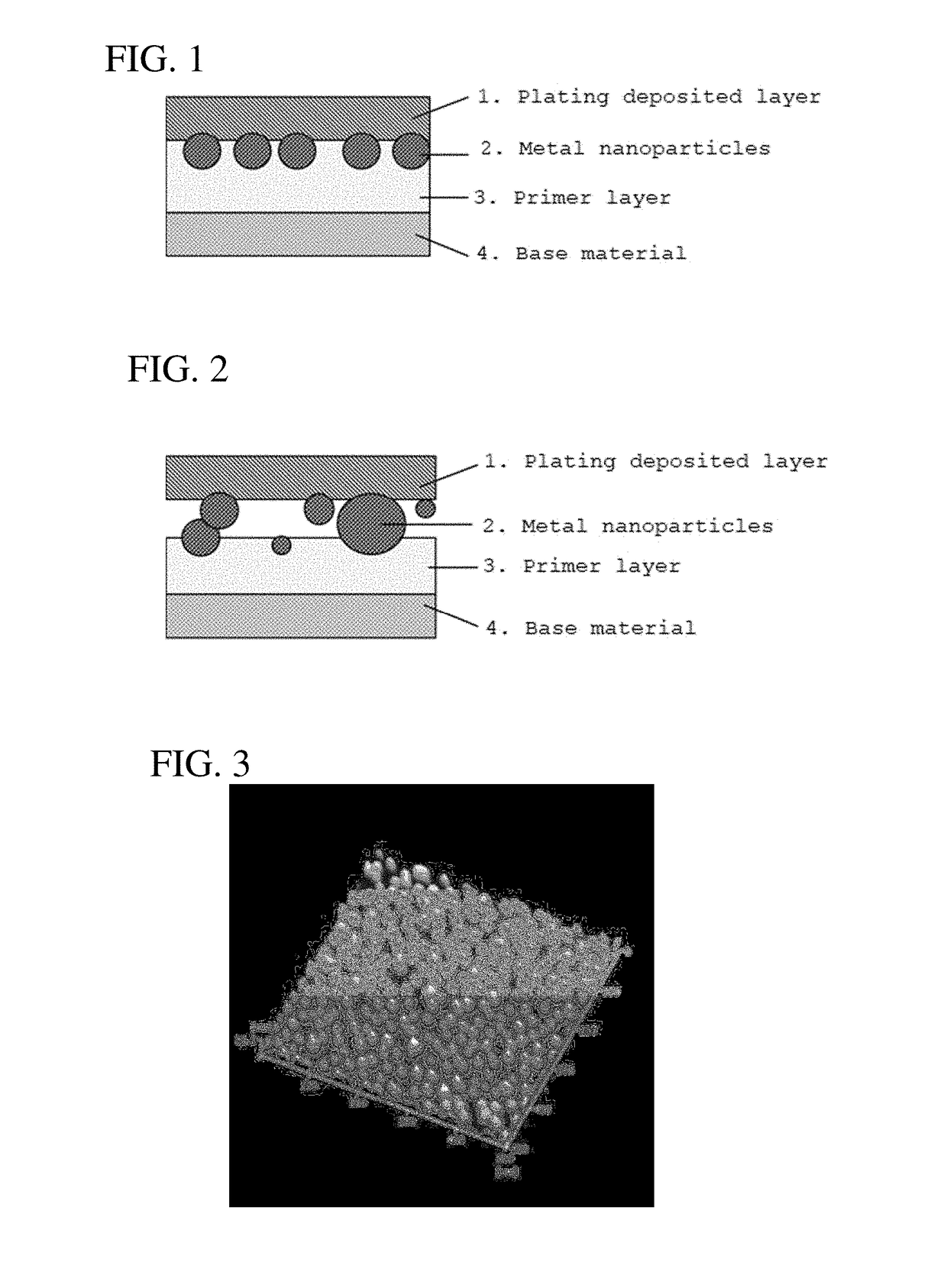

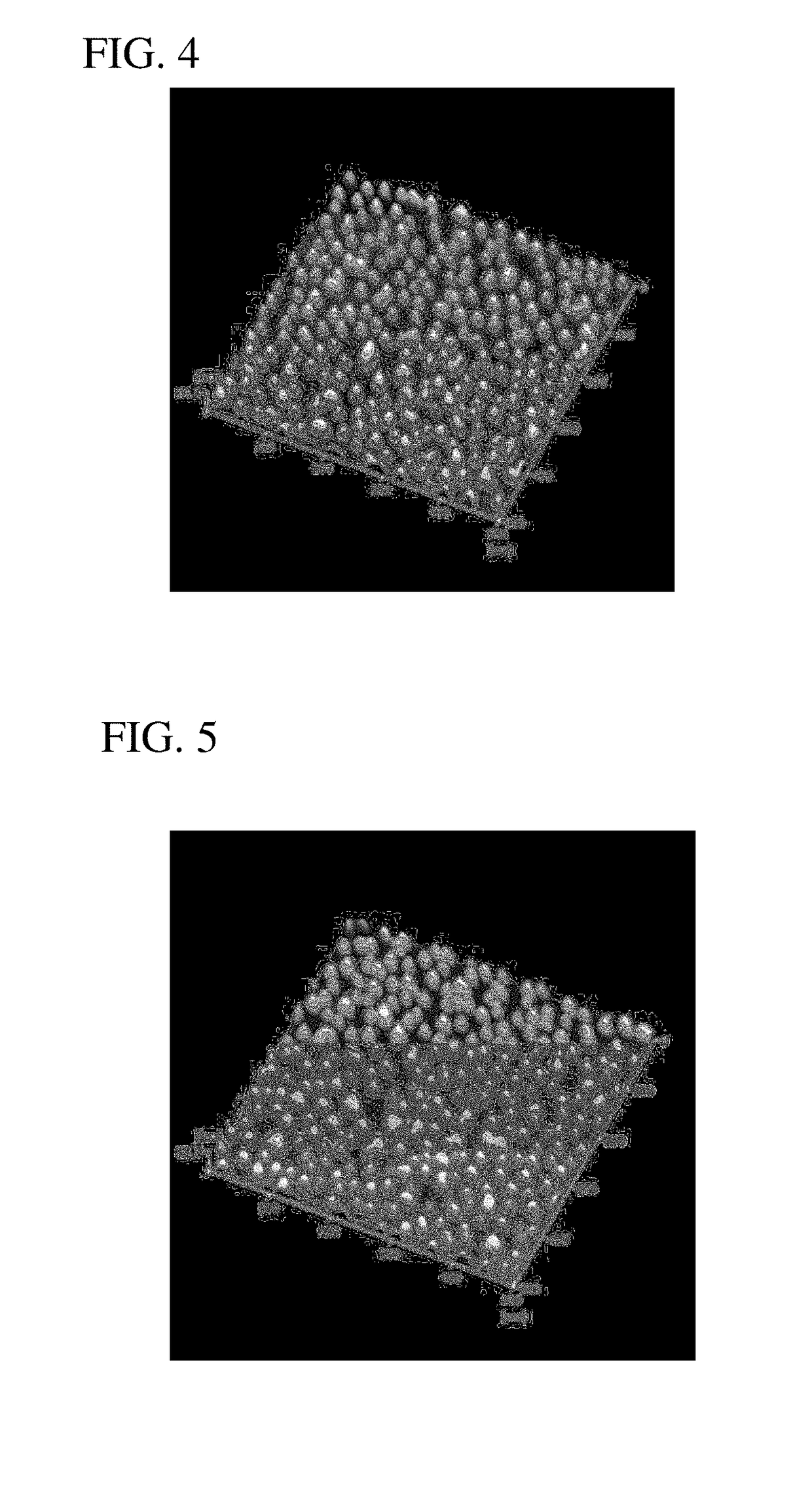

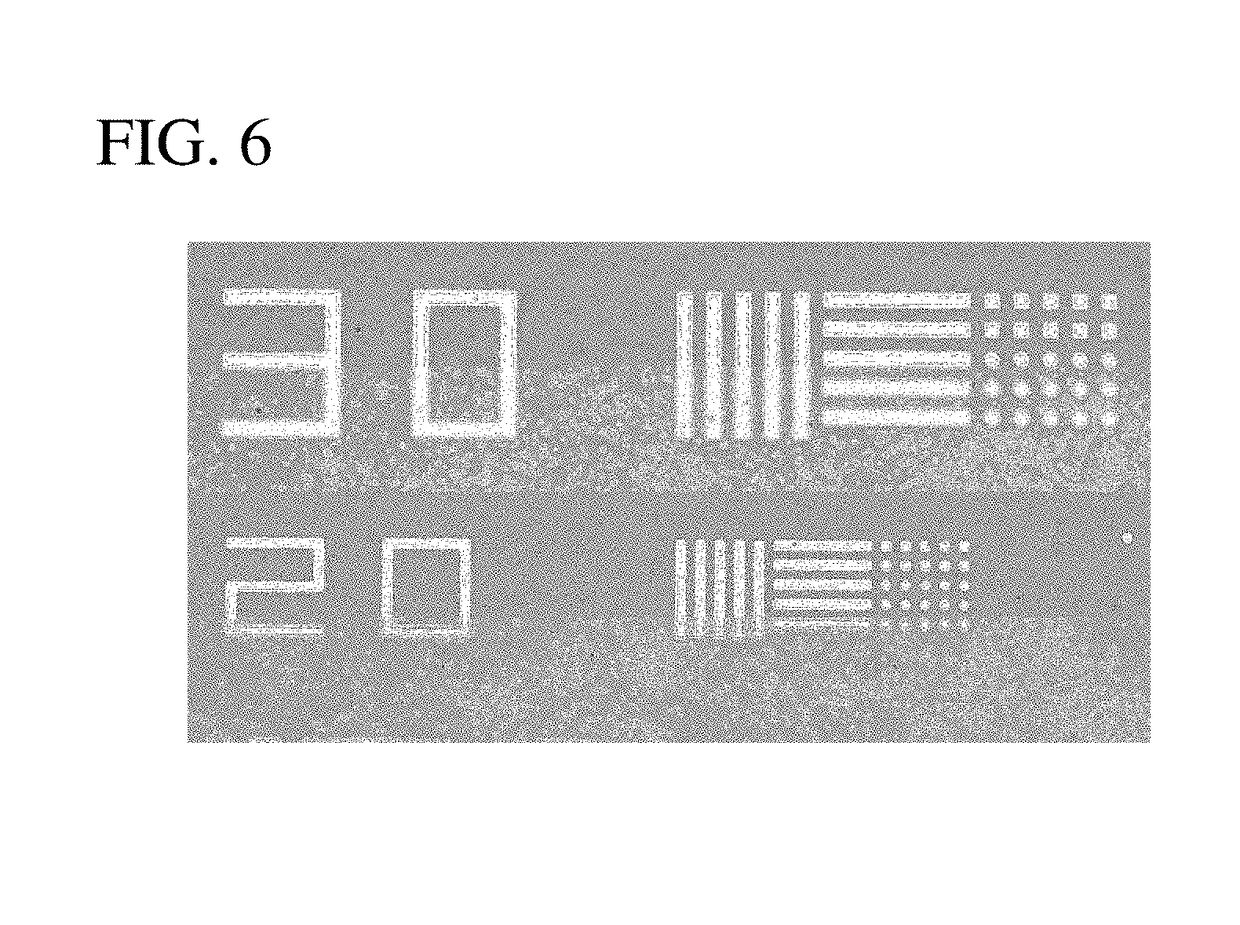

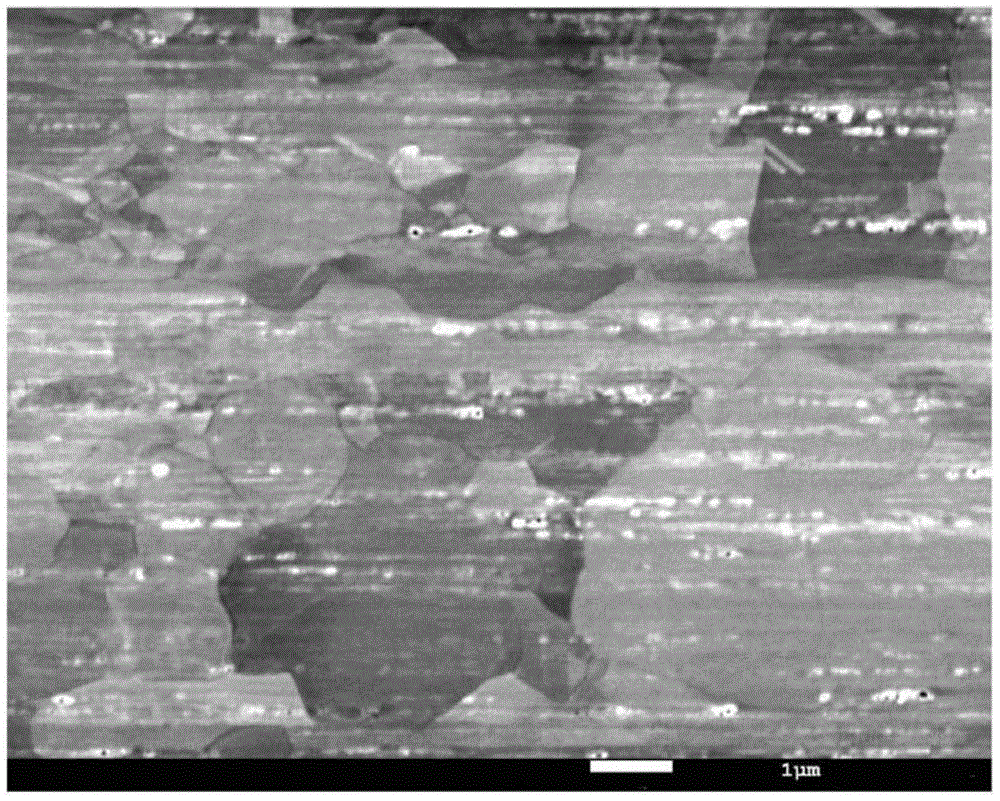

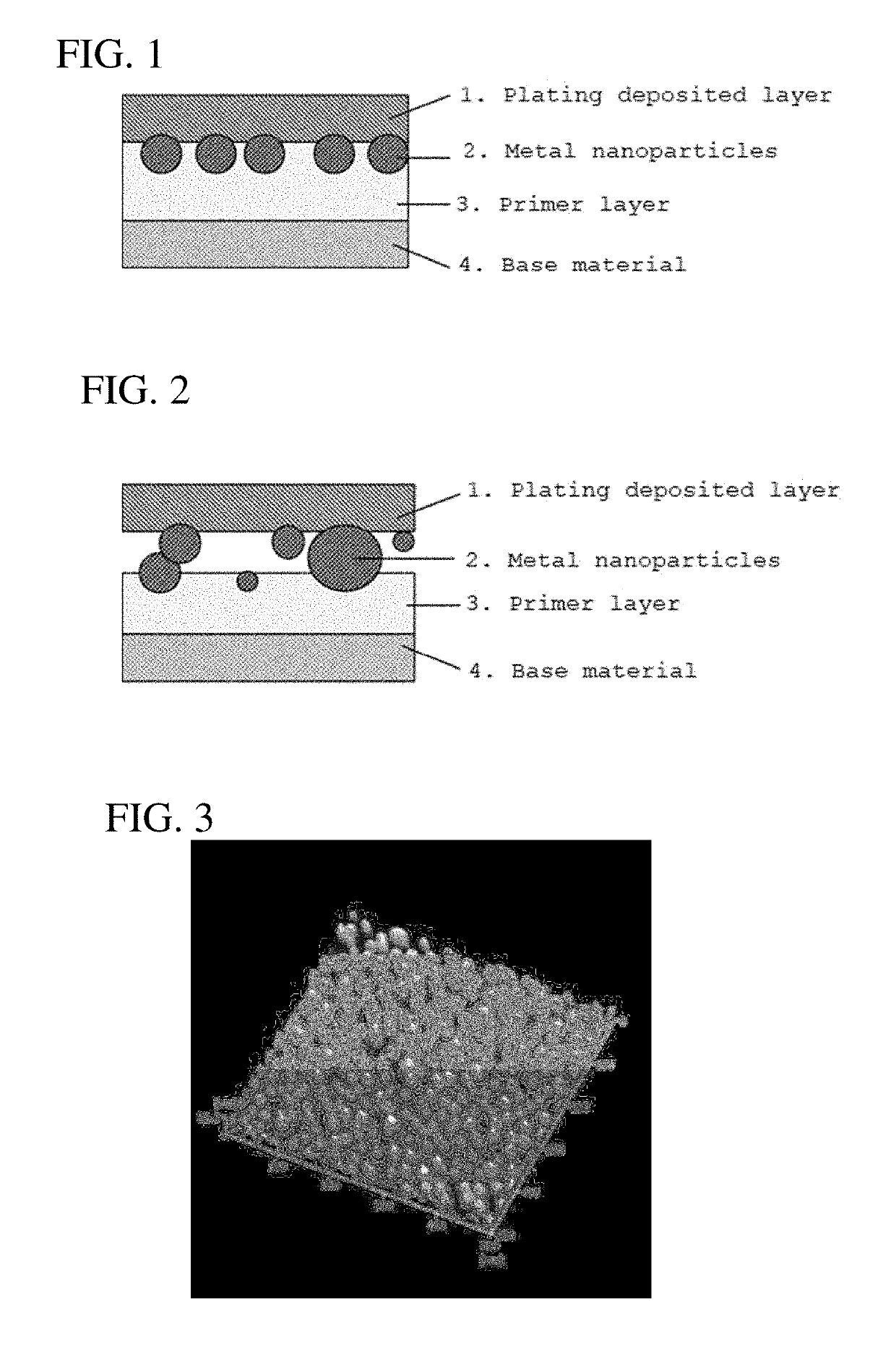

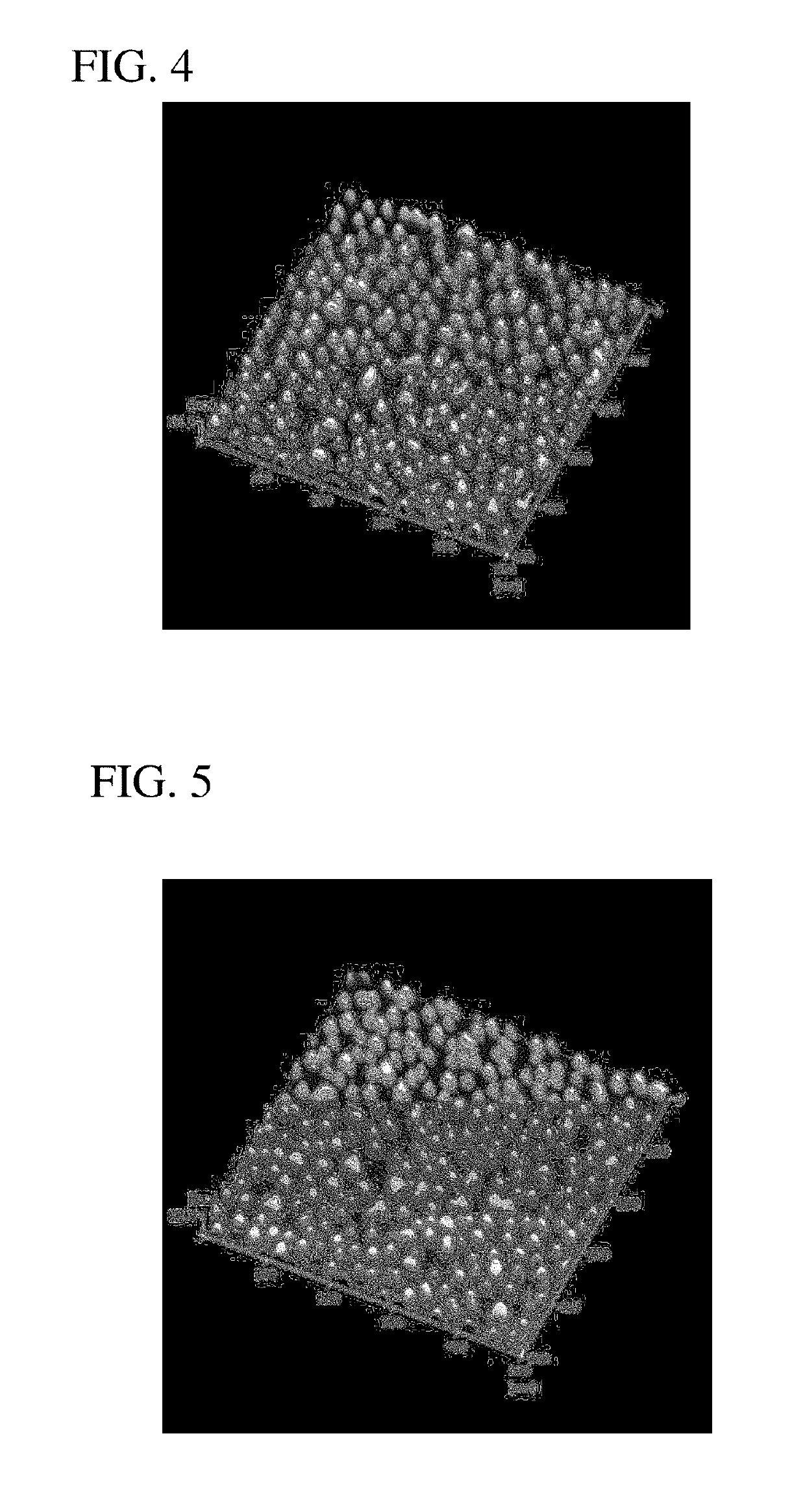

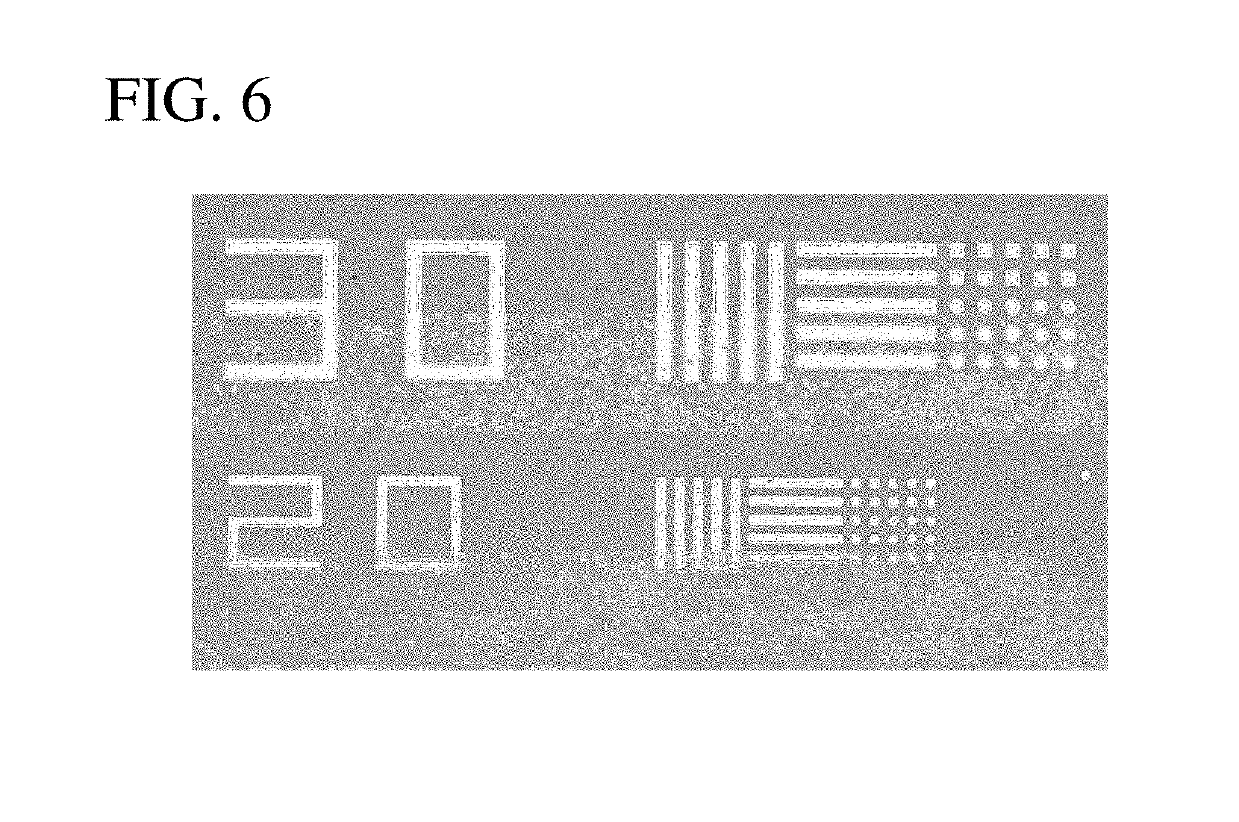

Metal film laminate structure

ActiveCN108291313AStable joint strengthImprove joint forcePrinted circuit aspectsLiquid/solution decomposition chemical coatingGlass transitionMetal nanoparticles

The present invention addresses the problem of the inability to form a uniform metal film due to weak adhesion of a deposition metal film making it impossible to obtain a uniform adhesive force, or due to partial aggregation of metal nanoparticles resulting in a decrease in the adsorption force of some of the metal nanoparticles with respect to a primer layer, and provides a metal film laminate structure in which metal nanoparticles of a catalyst layer are surrounded by a primer layer of which one end is bonded to a plating deposition layer. The metal film laminate structure of the present invention has a cross sectional structure in which three layers, namely a primer layer, a catalyst layer, and a plating deposition layer, are laminated on a base material, characterized in that the primer layer is a resin layer with a glass transition temperature (Tg) of 40 to 430DEG C, and the catalyst layer comprises a group of metal nanoparticles arranged in a planar fashion on the primer layer, wherein the group of metal nanoparticles comprises a metal of group IB or group VIIIB in the periodic table, and wherein the metal nanoparticles are surrounded by the primer layer, of which one end isbonded to the plating deposition layer.

Owner:EEJA LTD

Circuit board and thermal printing head using same

InactiveCN104105336AReduce usageNo reduction in joint strengthPrinted circuit manufacturePrintingElectrical conductorThermal printing

The present invention provides a printed circuit board which forms a gold conductor of a gold wire bonding part in a thinner way to reduce the number of manufacturing processes and material cost. In the printed circuit board produced by forming a conducting pattern on an insulating substrate by using gold-containing pasty fluid, a low-purity gold layer and a high-purity hold layer used for wire bonding thereabove are stacked on the board. And the present invention also provides a thermal printing head using the printed circuit board.

Owner:AOI ELECTRONICS CO LTD

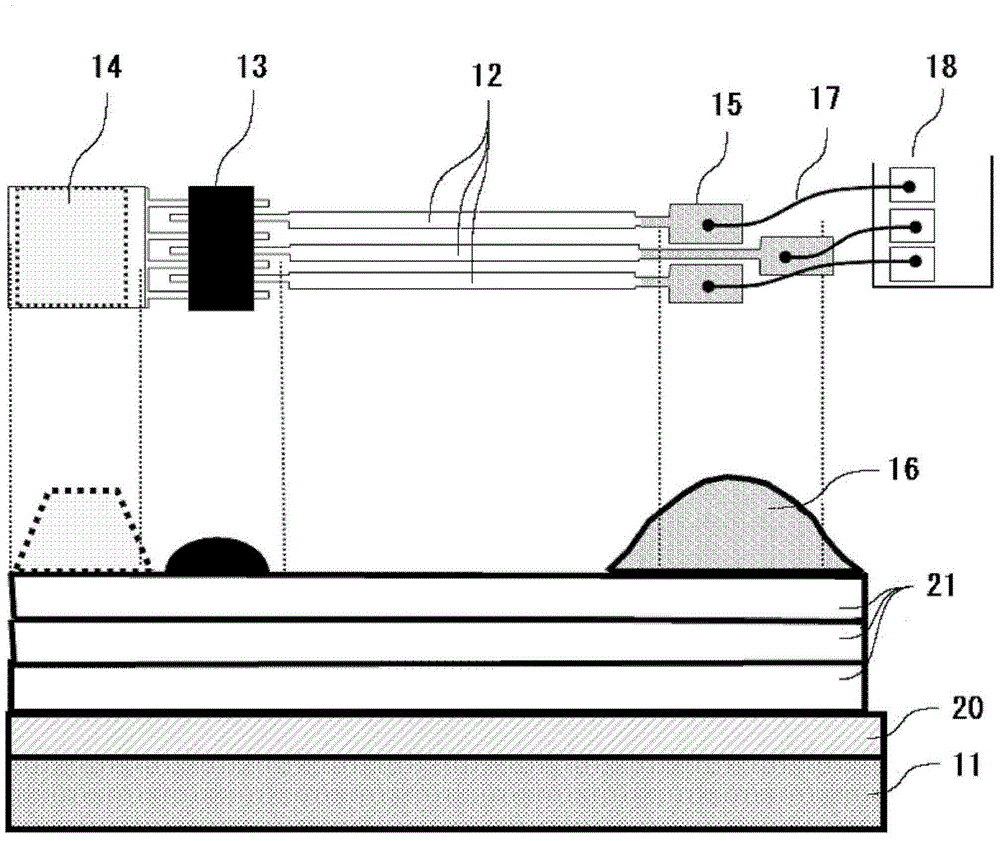

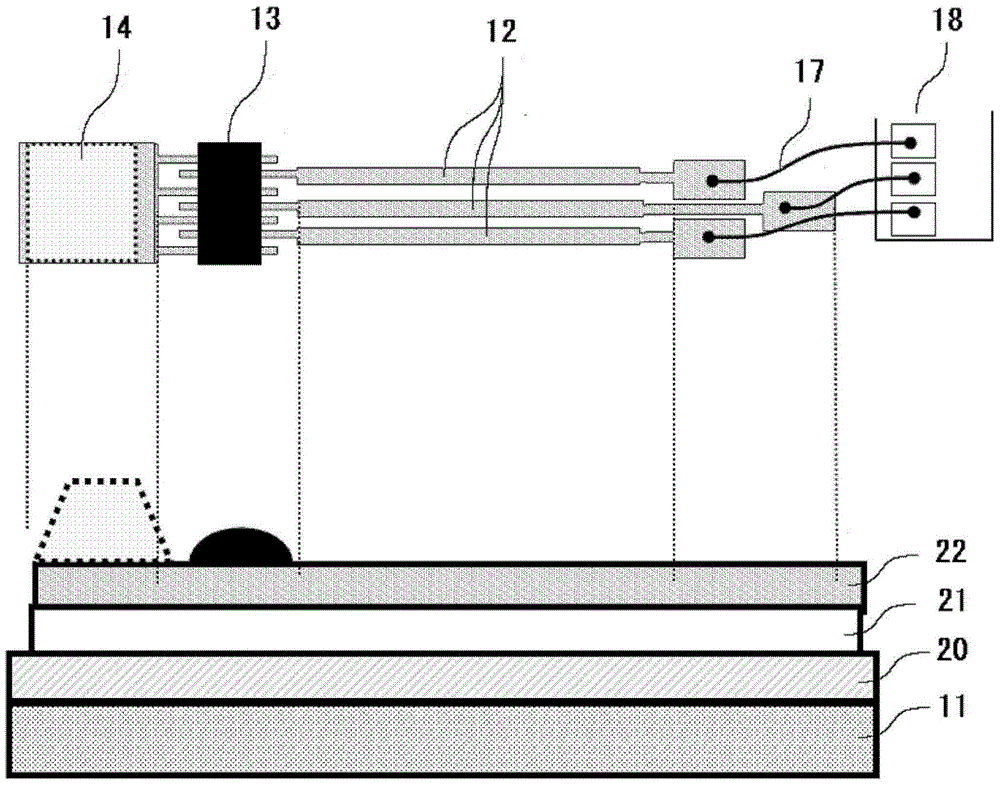

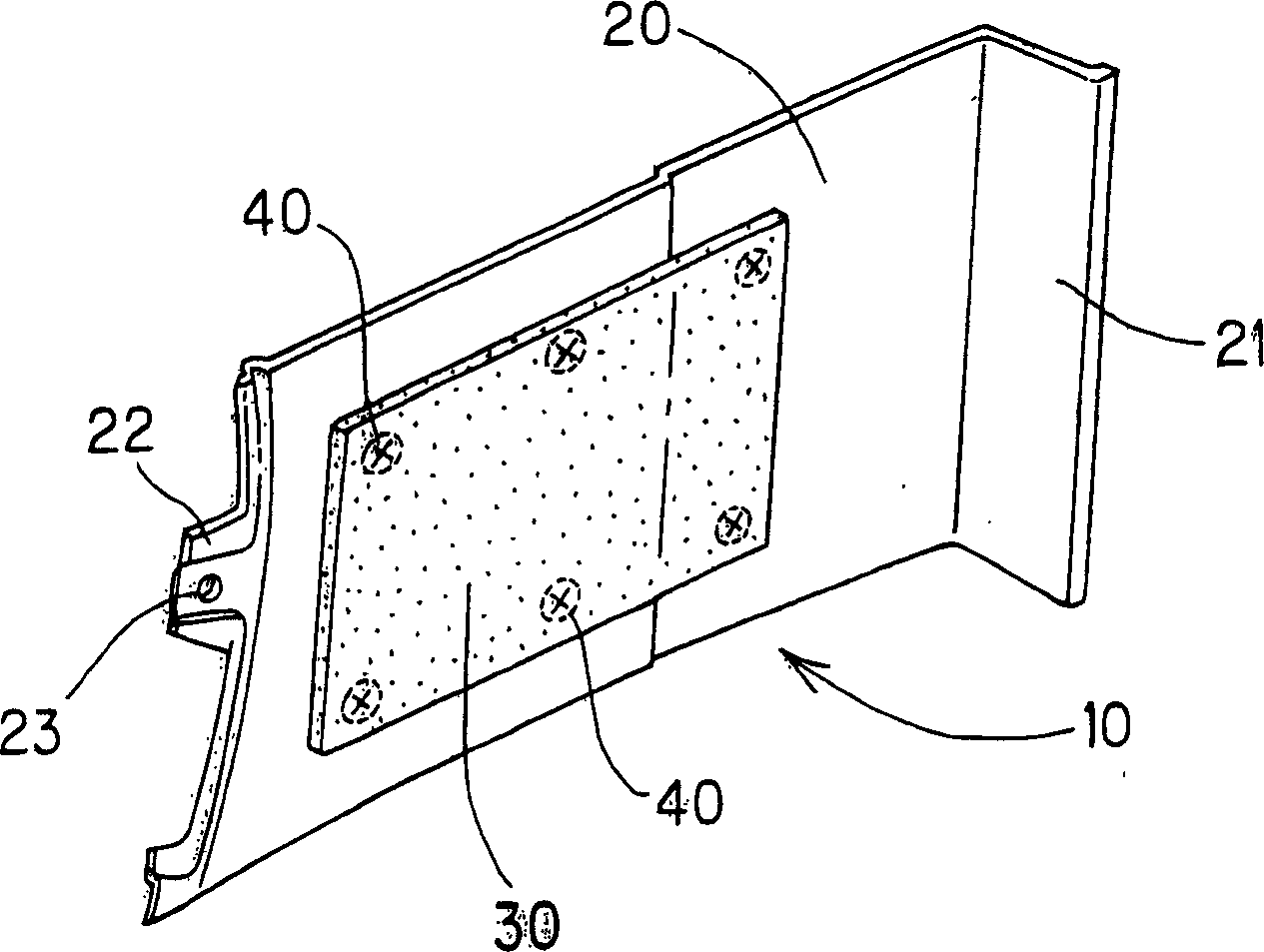

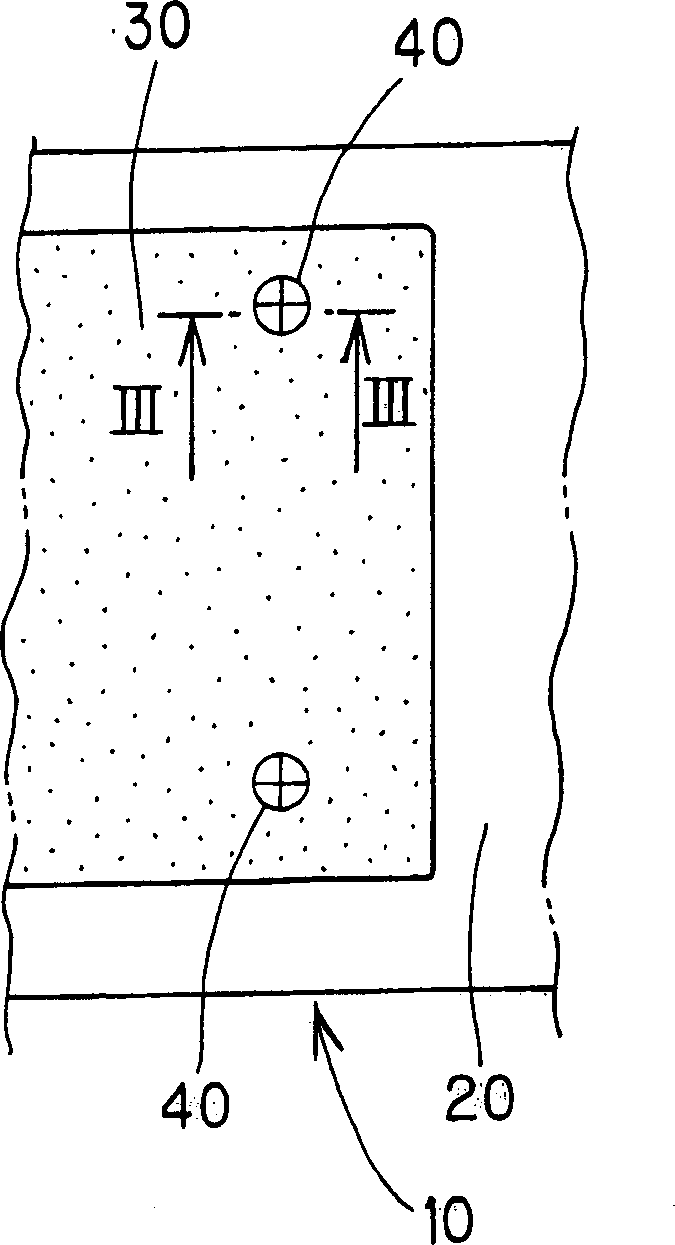

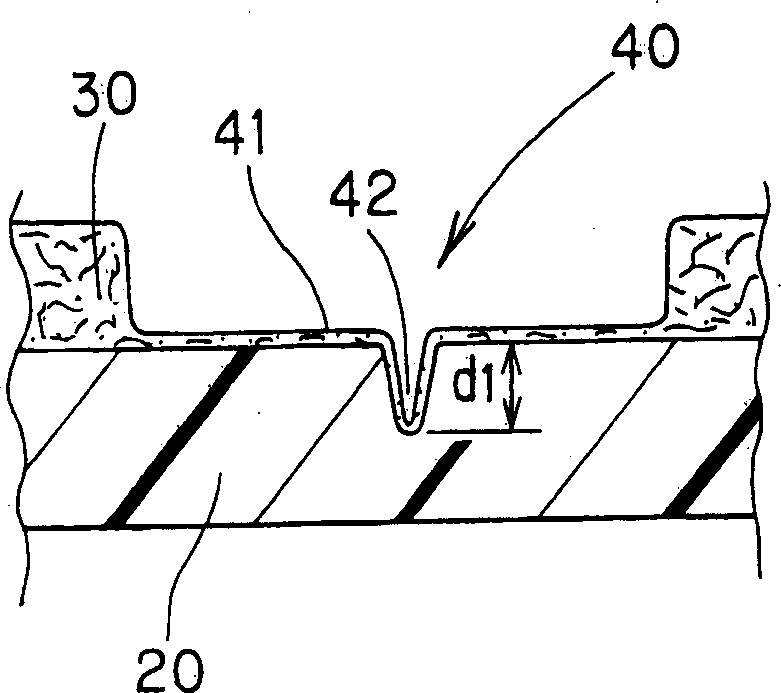

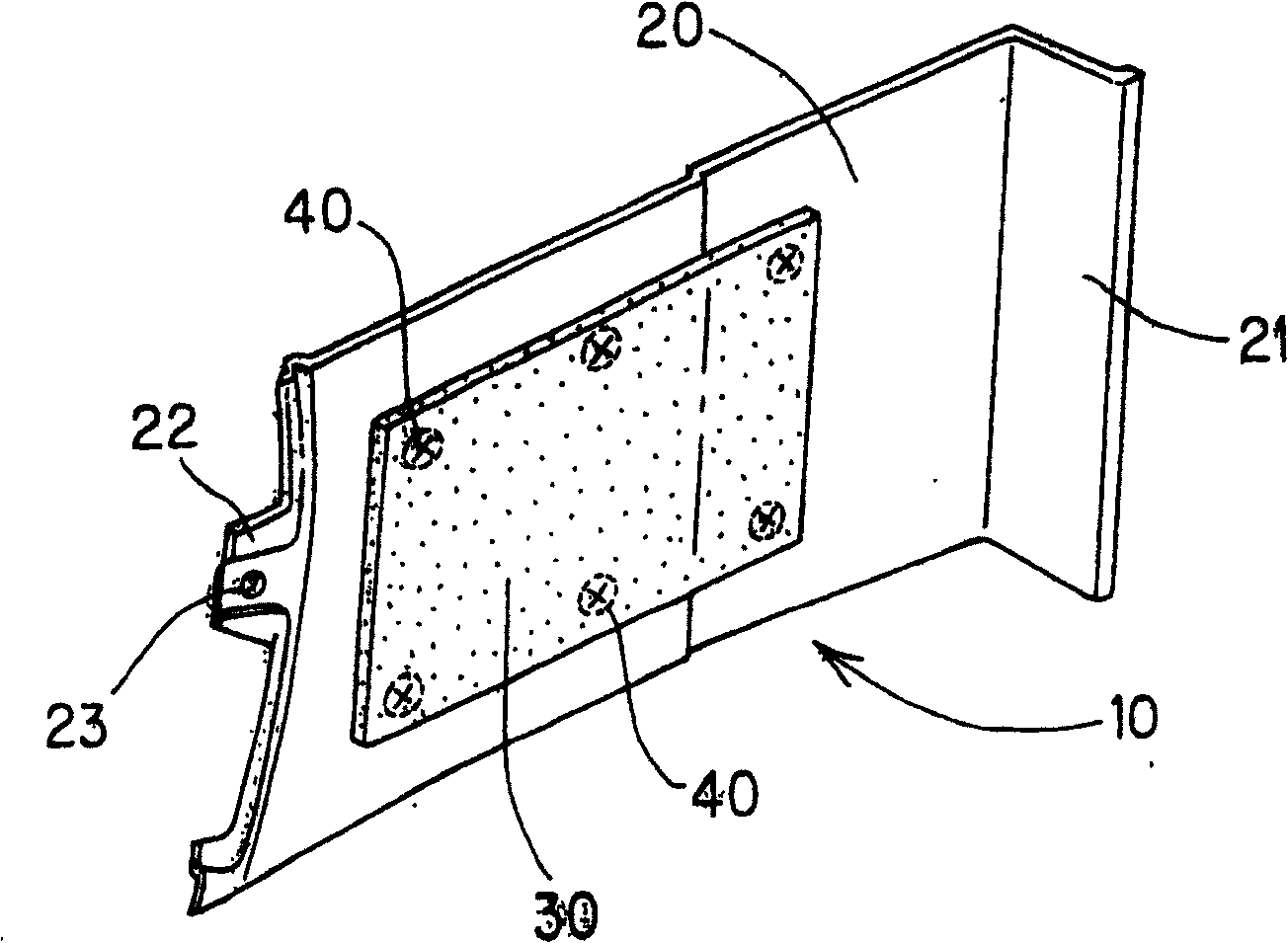

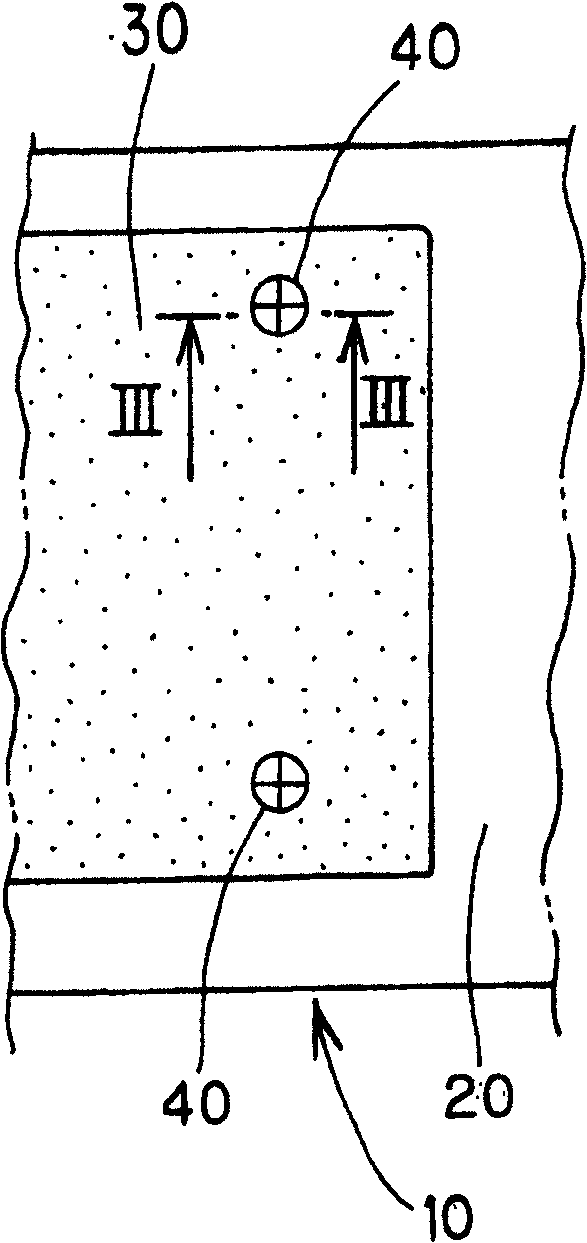

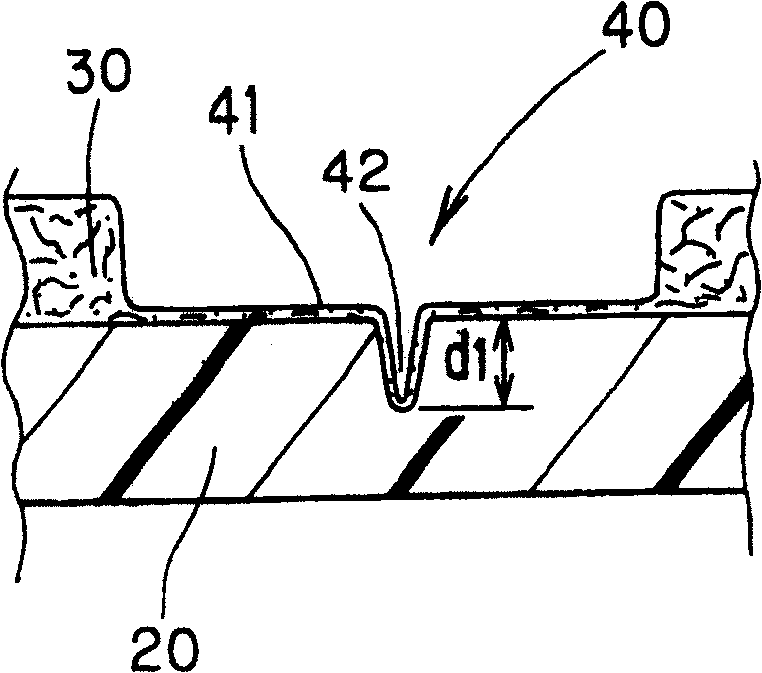

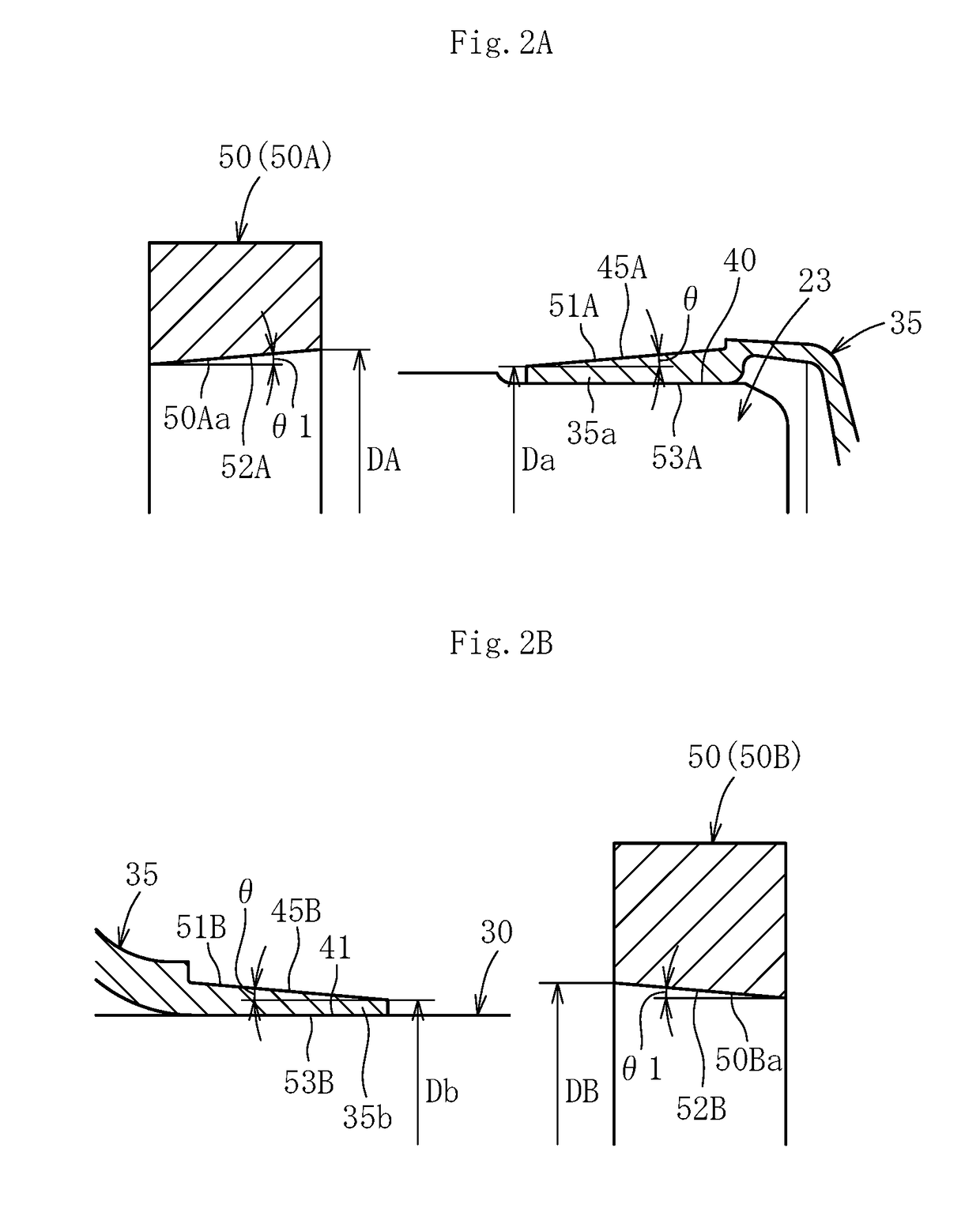

Fixing structure of fiber cover

InactiveCN1799833AStable joint strengthDeposition time shortenedSynthetic resin layered productsEngineeringNonwoven fabric

The invention relates to a fixing structure of fiber cover to integrate the cover fiber as non-woven cover and the resin molded product, which will not generate surface defects as convex-concave on the surface of resin molded product, and it can reduce the processing time and simplifying the processing device. Wherein, the decoration (10) on the side of luggage case is processed by melting the fiber cover as non-woven cover (30) and the inner surface of decoration (20). It uses the sharp convex rib (52) on the processing surface (51) of ultrasonic horn (50) to form the melting part (4) of non-woven cover (3) on the plane melting surface (41) to inserted into the V-shape groove (42) inside the resin molded product. The invention can simply inserted the fiber of non-woven cover (30) into resin molded product (20) to generate fixing effect and form the V-shape groove (42) of resin molded product in short time to improve the operation availability and appearance.

Owner:KASAI KOGYO CO LTD

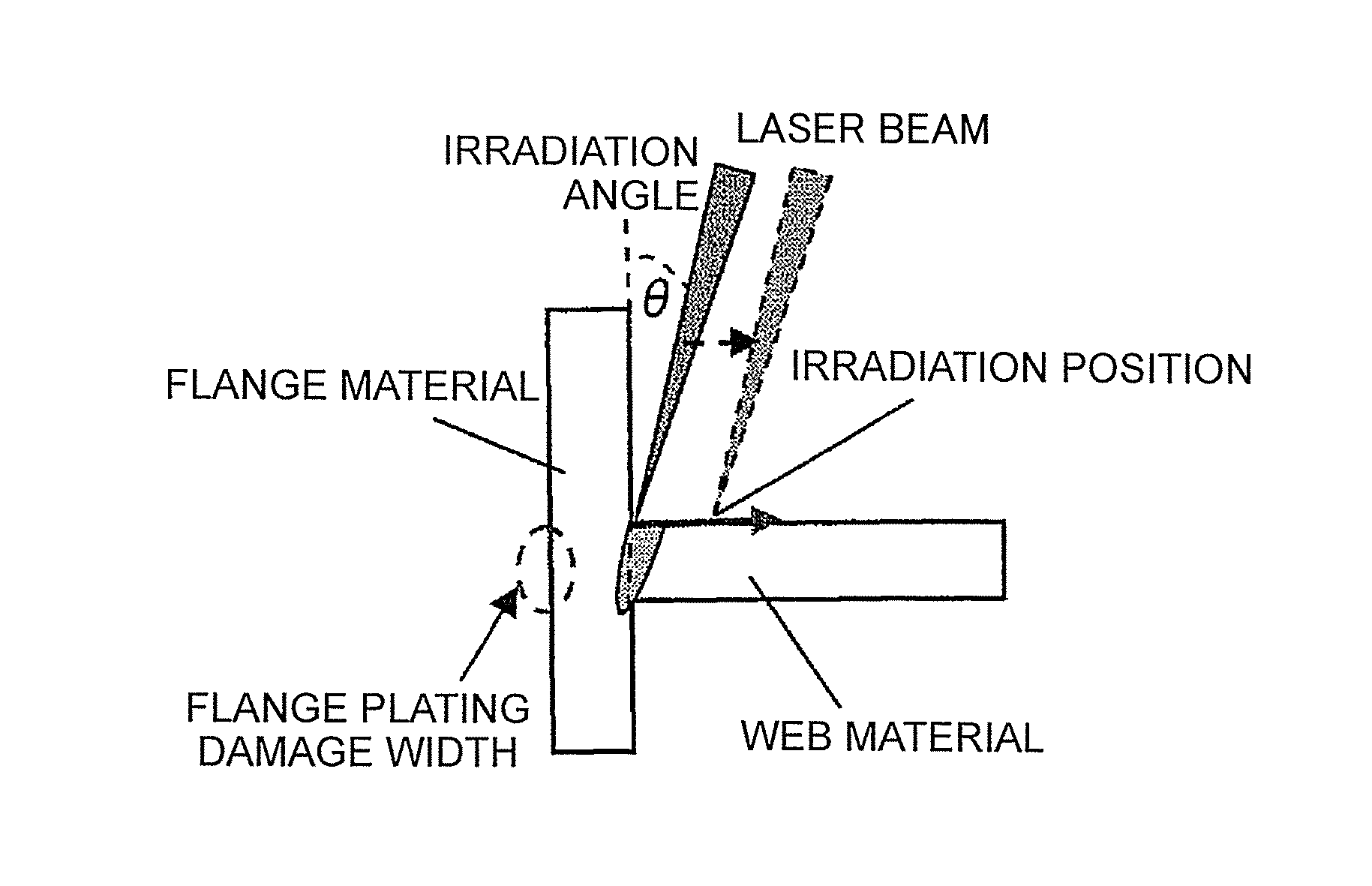

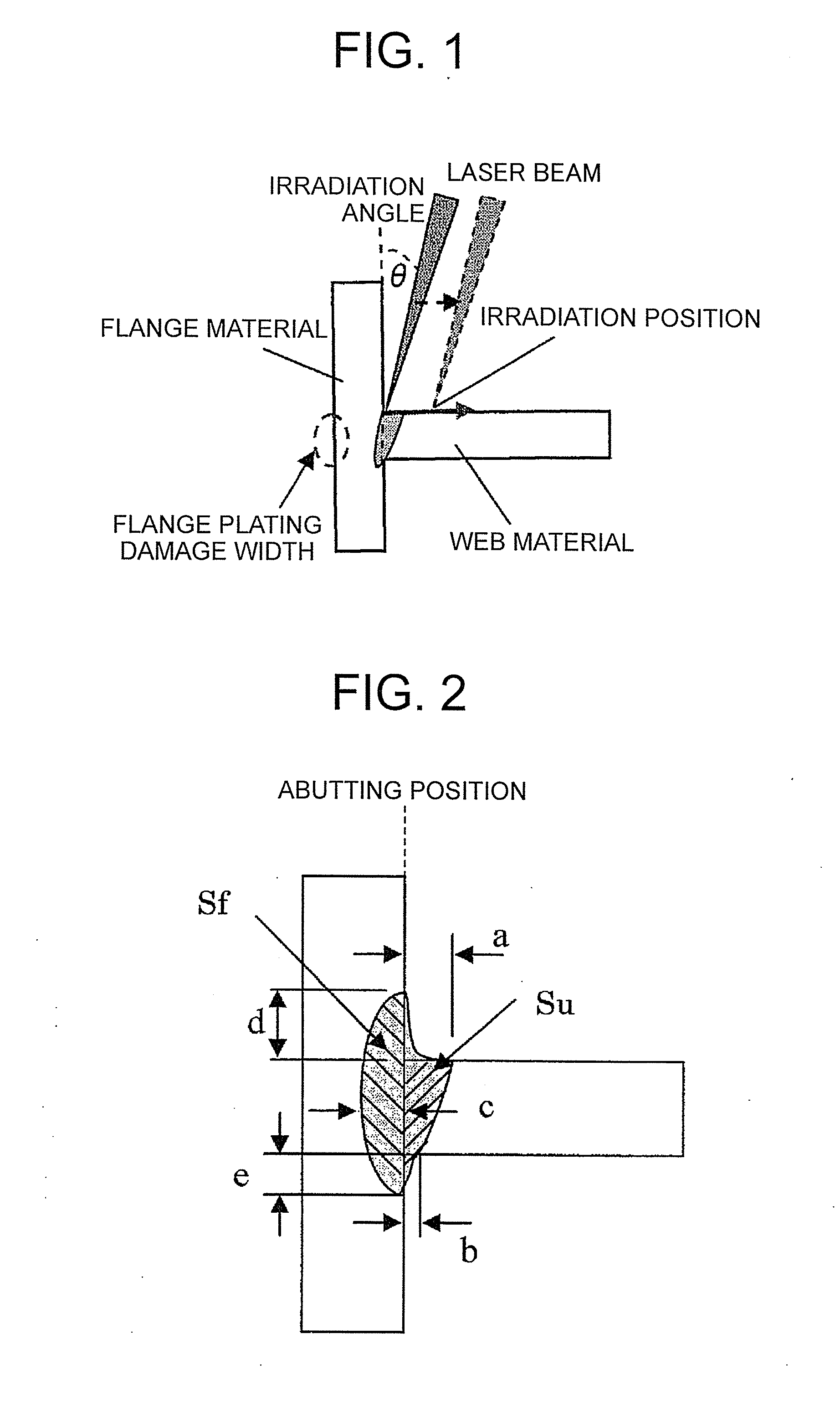

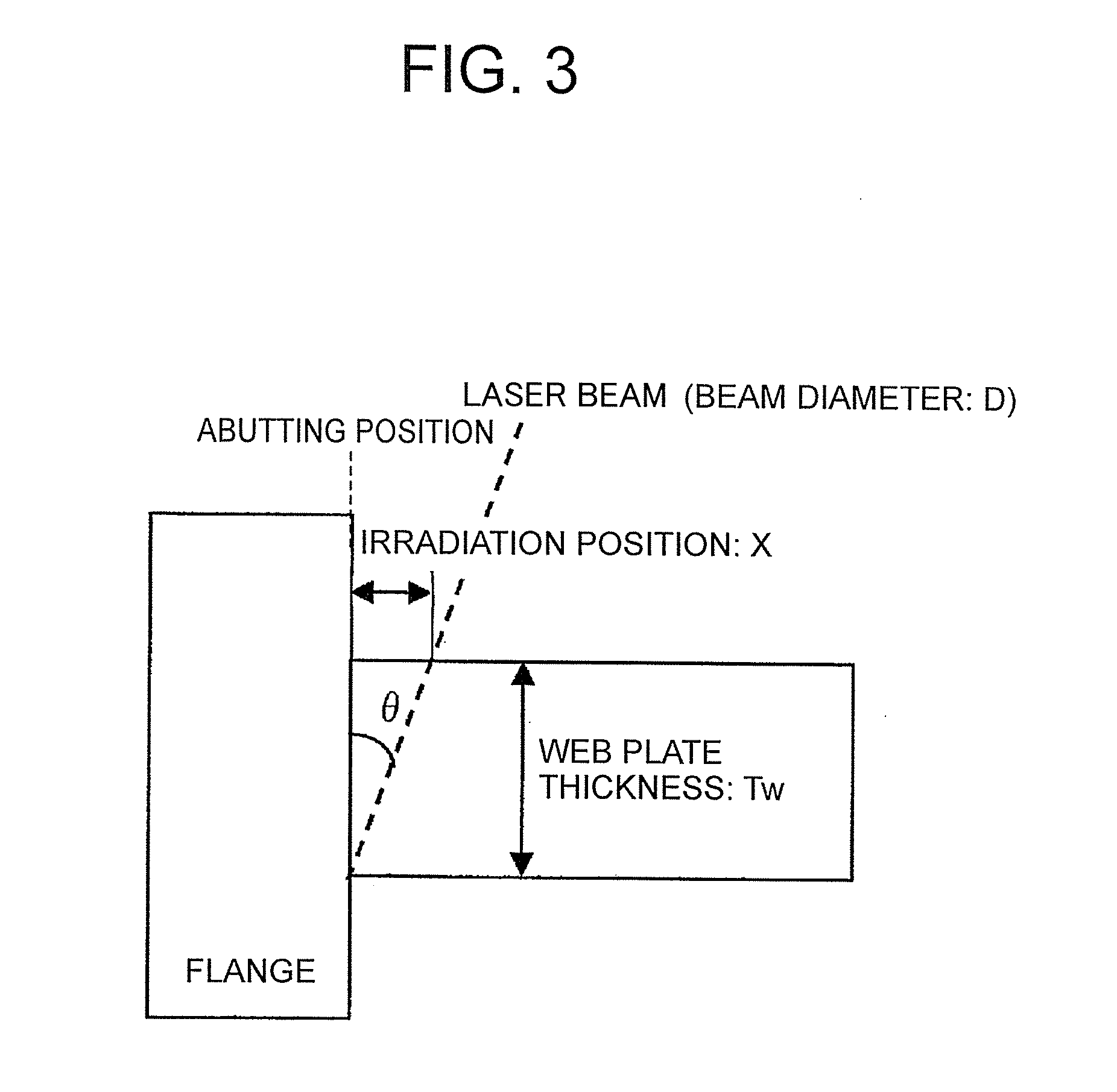

Laser welded shaped steel

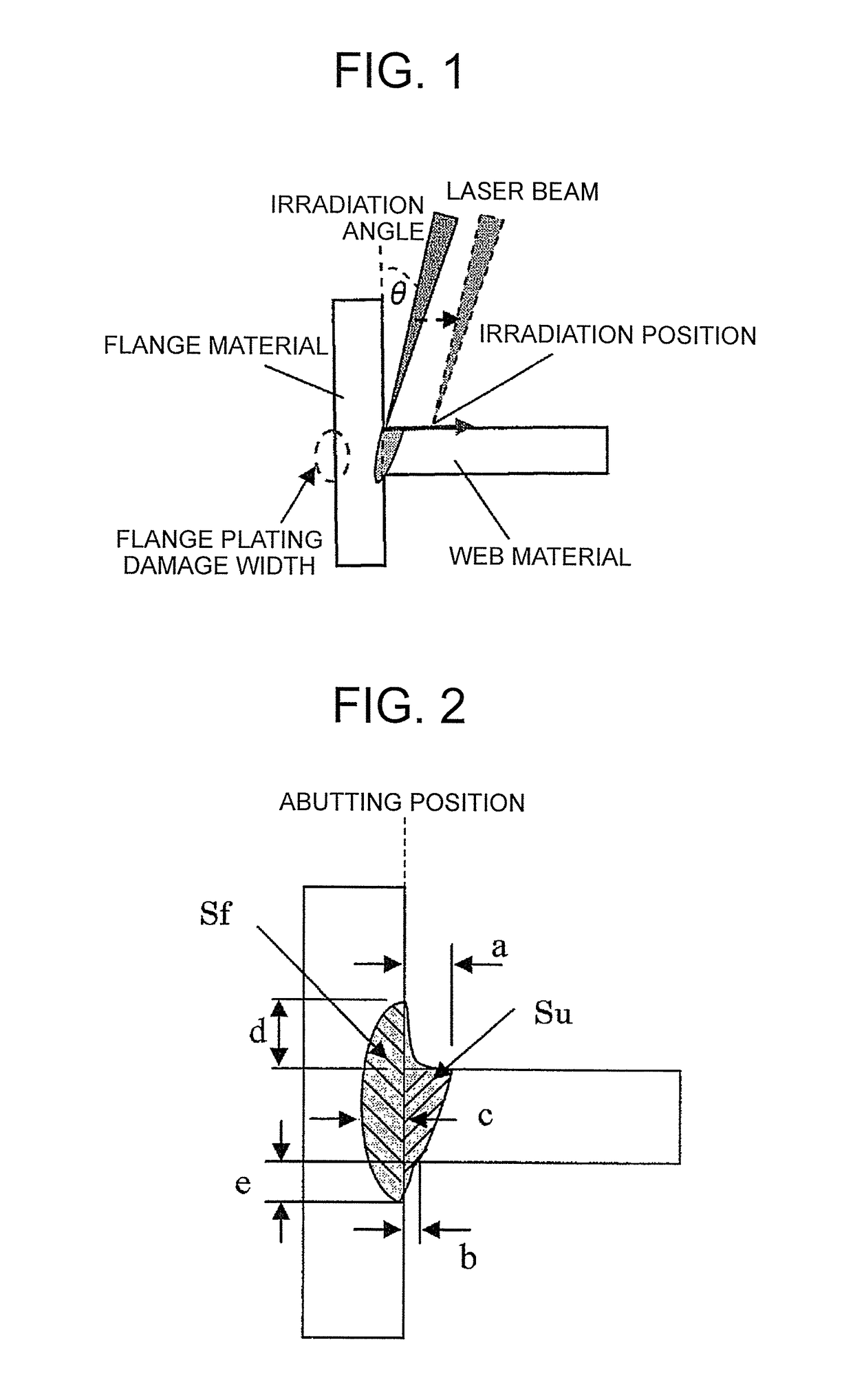

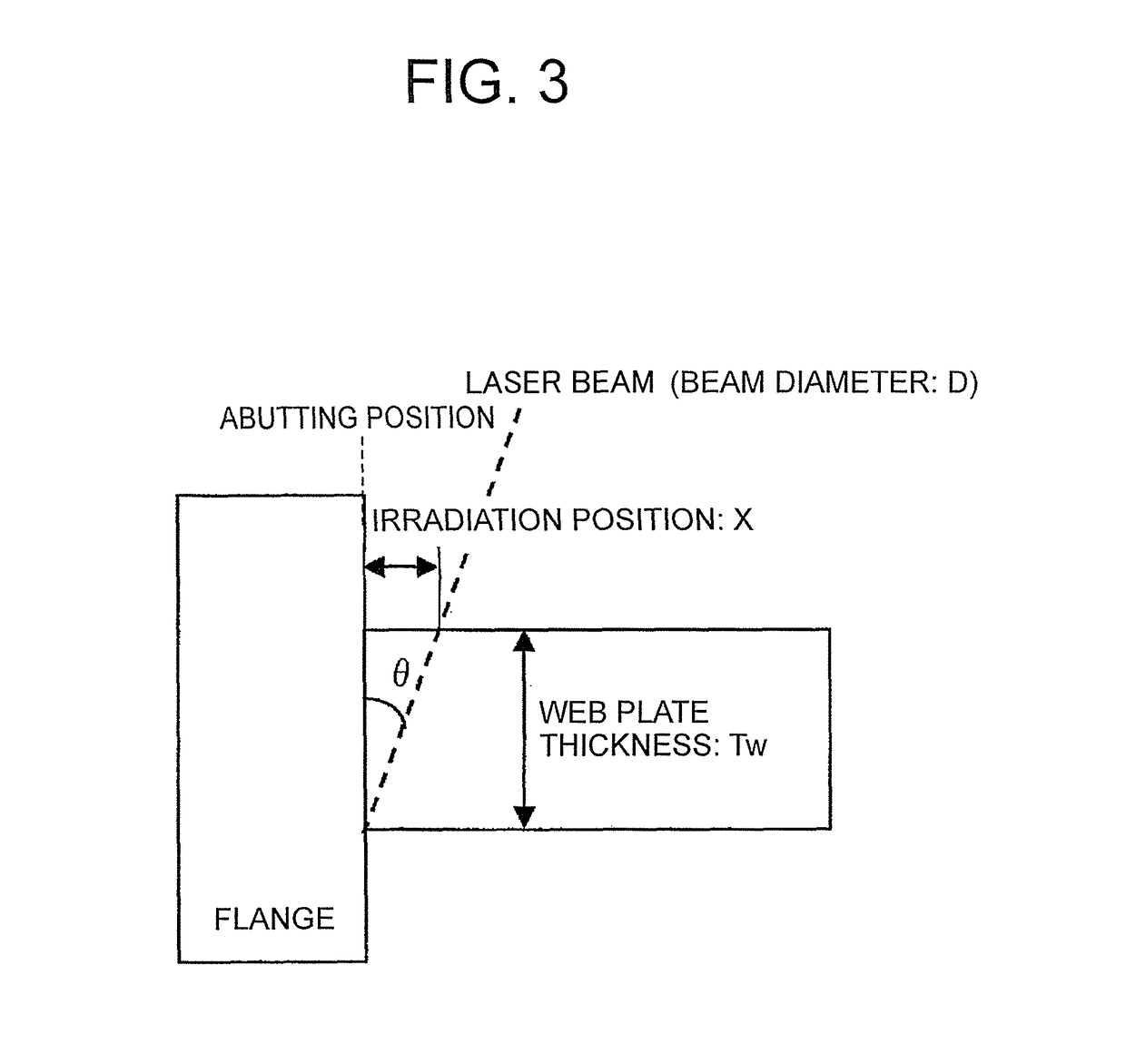

InactiveUS20150273630A1Stable joint strengthHigh strengthWelding/soldering/cutting articlesNon-disconnectible pipe-jointsMetallurgyLaser beams

A welded portion shape of a cross-section perpendicular to the shaped steel longitudinal direction is set to satisfy a>0 mm, b>0 mm, c≧0.14Tw, d≧0 mm, e≧0 mm, a+d≦2 mm and b+e≦2 mm; where a is a front melting width of the web material (on the laser beam irradiation side), b is a rear melting width of the web material (on the laser beam non-irradiation side), c is a maximum weld penetration depth, in a plate pressure direction, into the flange material, d is a front melting width of the flange material (on the laser beam irradiation side), e is a rear melting width of the flange material (on the laser beam non-irradiation side), and Tw is the plate thickness of the web material.

Owner:NISSHIN STEEL CO LTD

Laminate structure of metal coating

ActiveUS20190090357A1Stable joint strengthSimple structureInsulating substrate metal adhesion improvementPrinted circuit aspectsMetal coatingVitrification

A laminate structure of metal coating is laminated on a base material, and includes a primer layer, a catalyst layer and a plating deposited layer. The primer layer is a resin layer with a glass transition temperature (Tg) of 40 to 430° C. The catalyst layer is a metal nanoparticle group arranged in a plane on the primer layer, wherein the metal nanoparticle group is a metal in Group 11 or Groups 8, 9 and 10 in a periodic table, and the metal nanoparticles are surrounded by the primer layer. Ends of the metal nanoparticles are attached to the plating deposited layer.

Owner:EEJA LTD

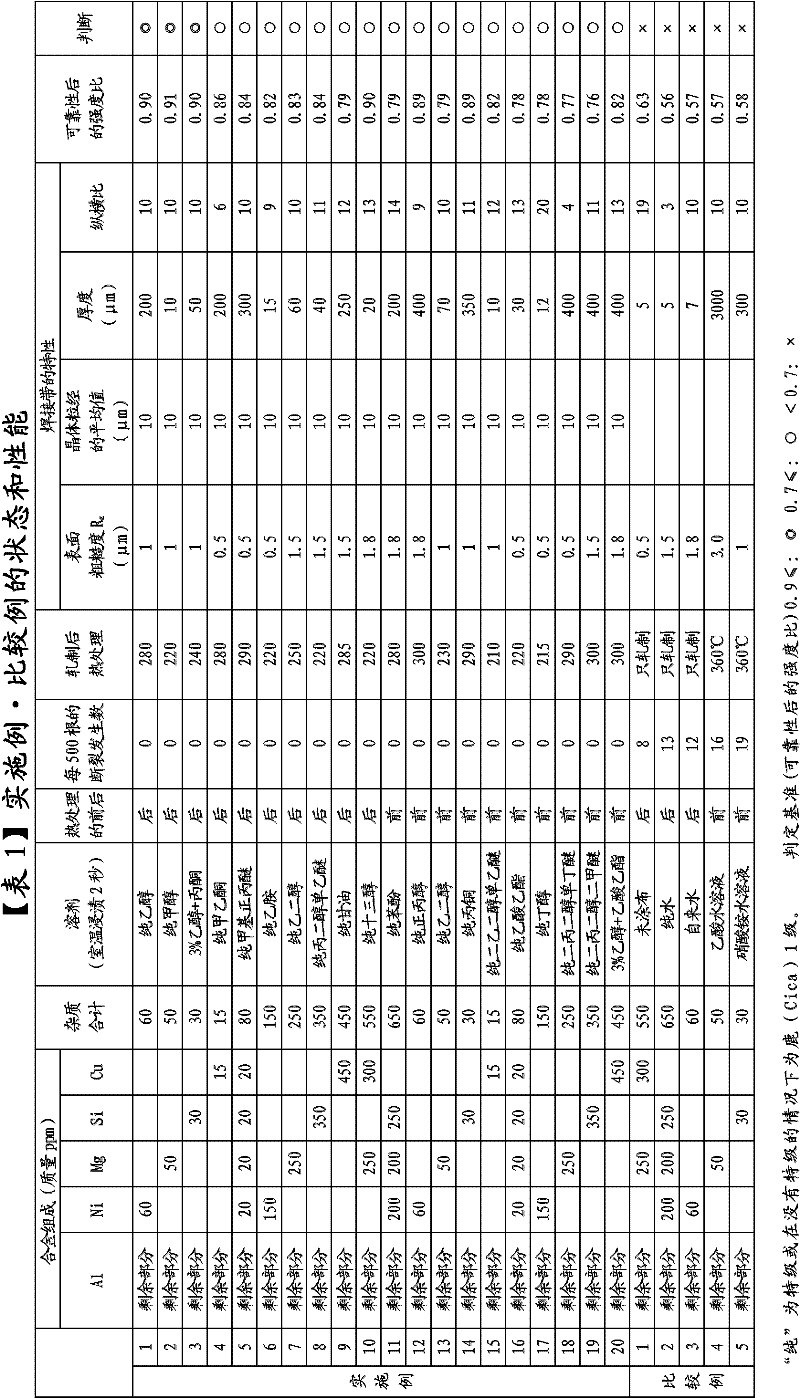

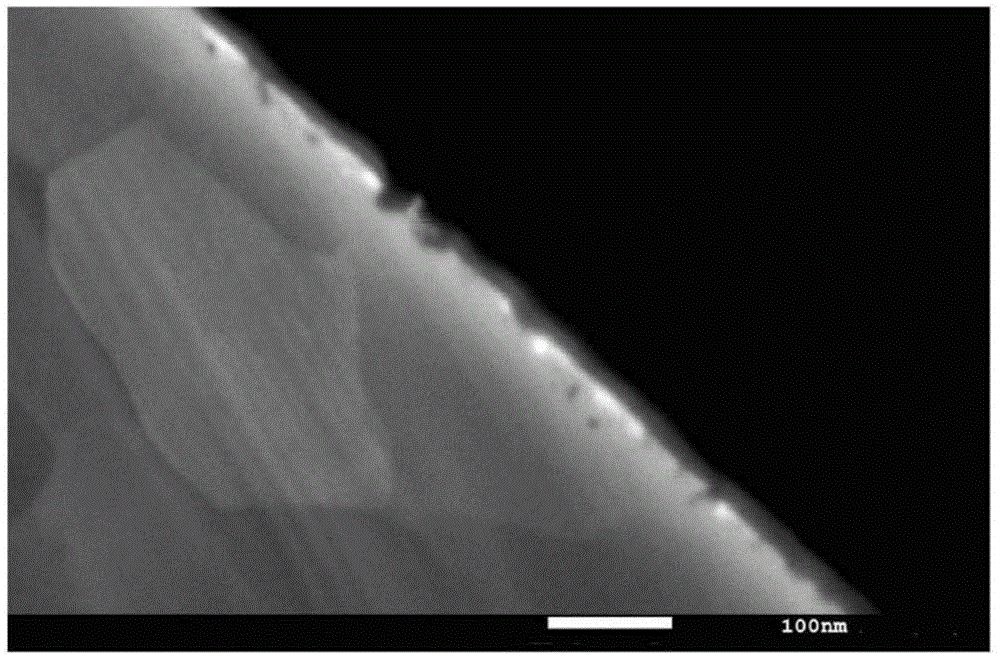

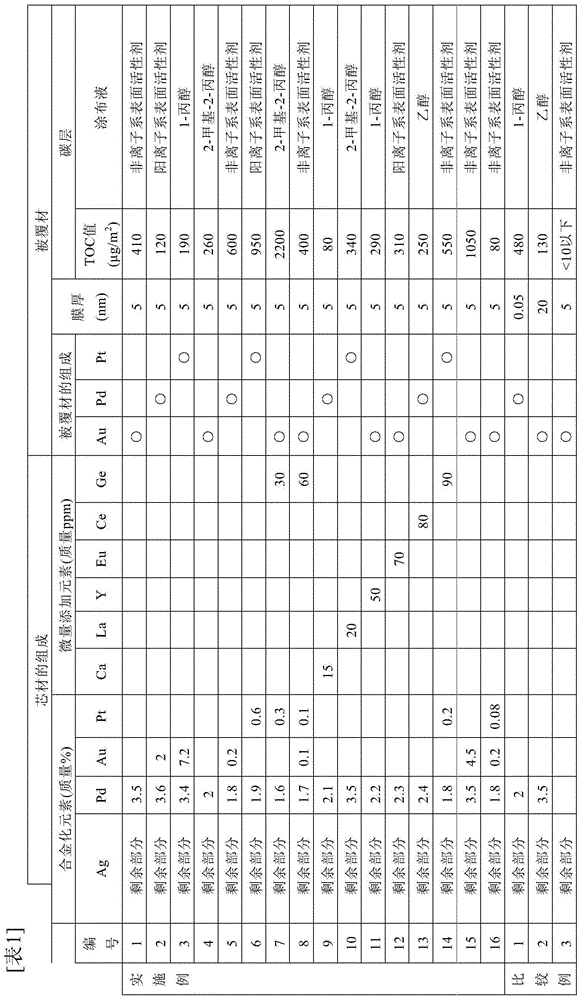

Aluminum ribbon for ultrasonic bonding

InactiveCN102549731AStable joint strengthStable arc formabilitySolid-state devicesSemiconductor/solid-state device manufacturingKetoneAlloy

[Problem] To provide a bonding ribbon which can be evenly bonded to the whole bonding surface every time even when used for bonding tens of thousands of times, thereby attaining stabler bond strength and which undergoes no breakage when looped. [Solution] The ribbon for ultrasonic bonding comprises an aluminum-based alloy having a purity of 99 mass% or higher, and has an ultrathin tape structure formed by multistage wiredrawing and subsequent rolling. The ribbon has a cross-section that has an average crystal grain diameter of 5-200 [mu]m, and has been mirror-finished to a surface roughness of Rz<=2 [mu]m. The ribbon has been treated by immersion in or with an atmosphere of a water-soluble hydrocarbon, alcohol, ketone, or ether solvent which has a higher vapor pressure than water.

Owner:TANAKA DENSHI KOGYO KK

Structure of surface-modified silver-palladium alloy wire

InactiveCN105321917AImprove bonding effectPrevent oxidationSemiconductor/solid-state device detailsSolid-state devicesAlloySilver-palladium alloy

The invention relates to a structure of a surface-modified silver-palladium alloy wire. The surface-modified silver-palladium alloy wire is composed of a core and a surface-modified layer. The core is made of Ag-Pd alloy or Ag-Pd-Au(Pt) alloy prepared from Ag and Au respectively with the purity being more than 99.99 mass% and Pd with the purity being more than 99.9 mass%, wherein the mass ratio of the Ag and Pd of the Ag-Pd alloy is 100:(1-5), and the mass ratio of the Ag, Pd and Au(or Pt)of the Ag-Pd-Au(Pt) alloy is 100:(1-5):(0.05-10). The surface-modified layer is composed of Ag, Pd and Pt respectively with the purity being more than 99.99 mass% and alloys thereof. The structure of the surface-modified silver-palladium alloy wire is characterized in that the wire surface and the grain boundary of the core form cross dark rings with the interval being 20-30 [mu]m in the long side direction of the wire, and the surface morphology of the surface-modified layer is embedded in uneven-sized longitudinal grooves of the core.

Owner:TANAKA DENSHI KOGYO KK

Resin member

ActiveCN105984124AStable thicknessStable joint strengthLayered productsThin material handlingContact pressureUltrasonic welding

The present invention provides a resin member capable of controlling a position and an amount of molten resin produced during the ultrasonic welding, and stabilizing the thickness of the interface so as to stabilize the bonding strength. A resin member contains a thermoplastic resin and is bonded to another resin member by ultrasonic welding. The resin member includes projections that are projected from a surface of a bonding target section of the resin member and melted by application of contact pressure during the ultrasonic welding. The projections include projections having different projection heights from the surface of the bonding target section.

Owner:SUBARU CORP

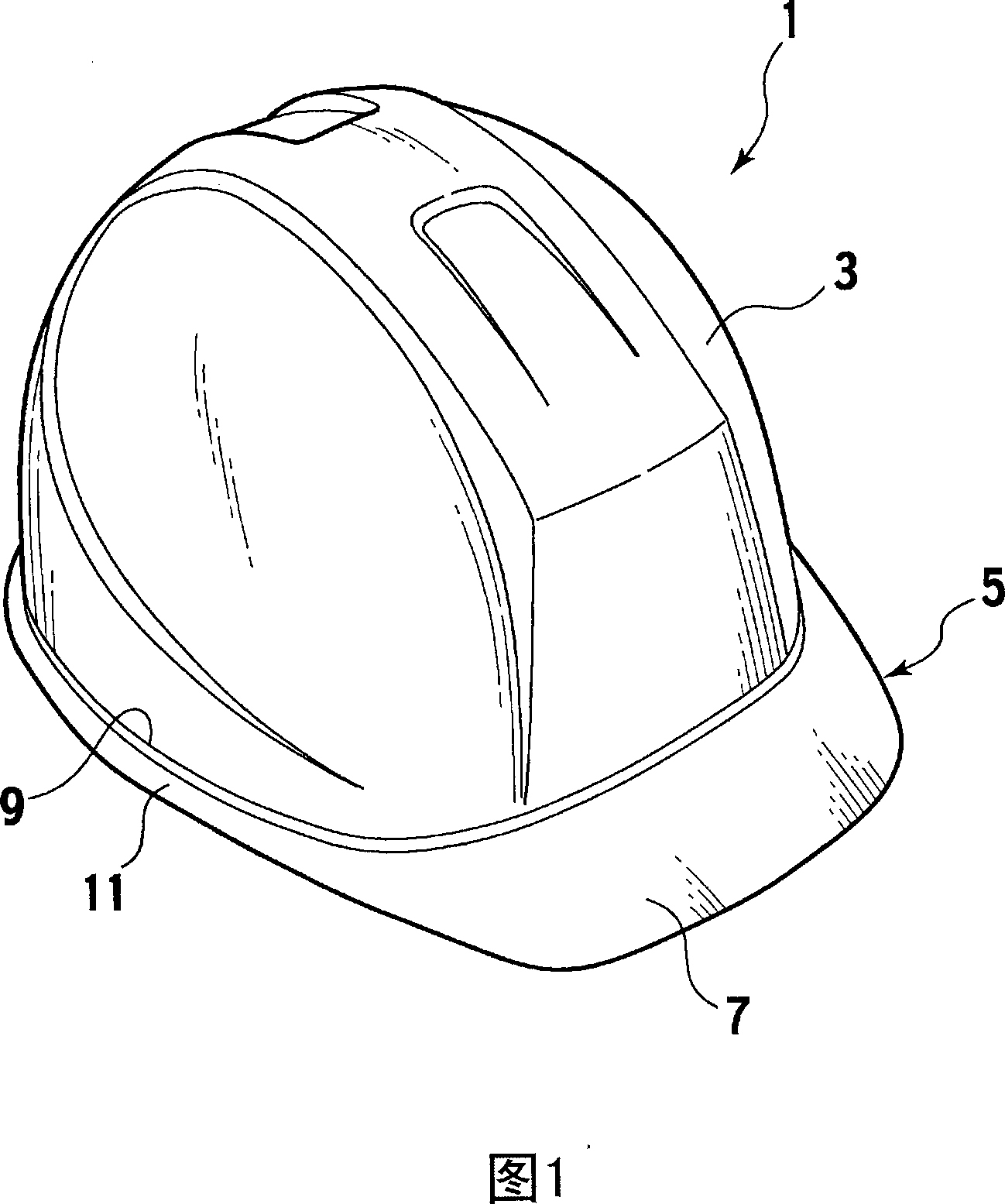

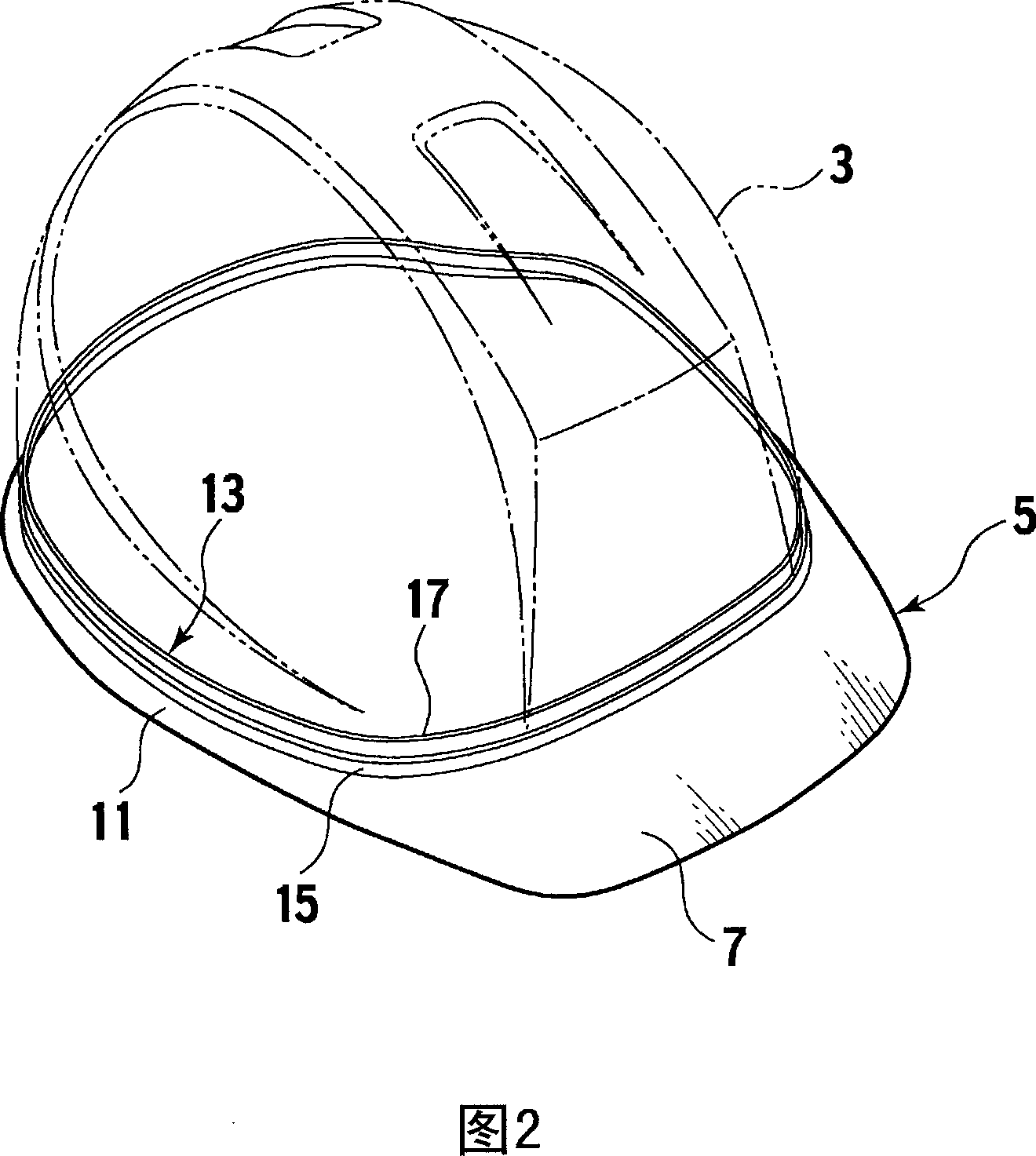

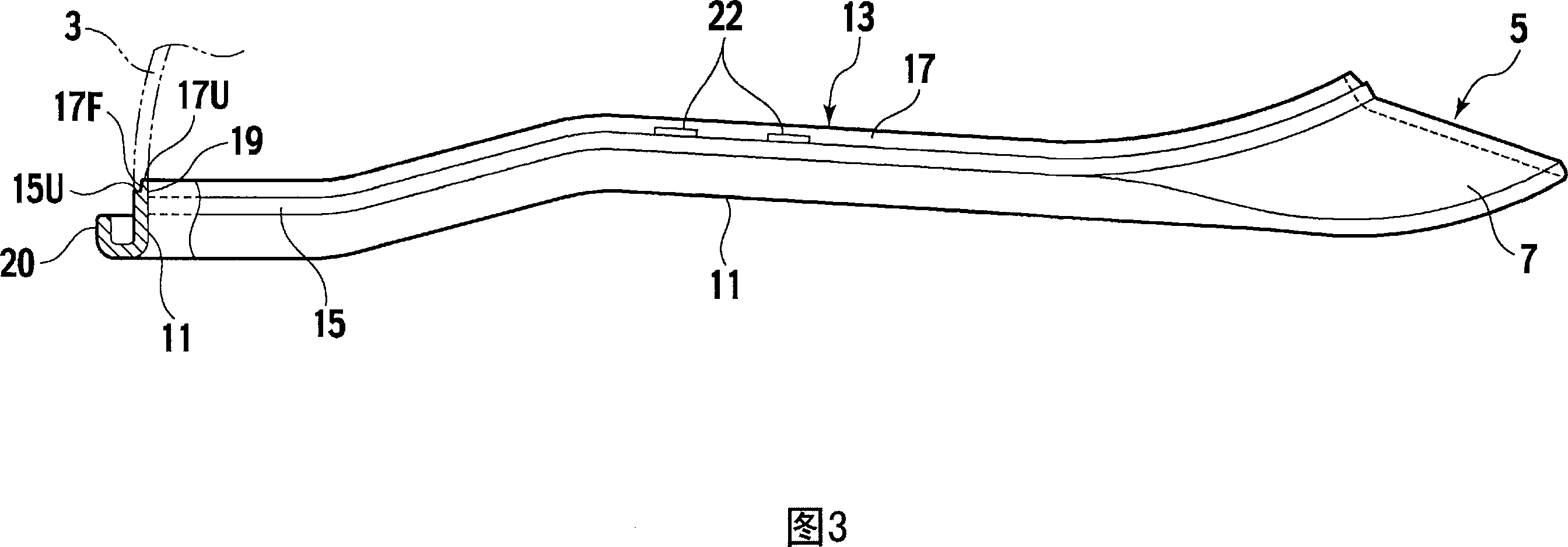

Helmet with visor

A helmet (1) with a visor formed by integrally joining the preliminarily injection-molded visor (5) to a cap body (3), wherein an opening end edge part (9) formed on the cap body is joined to the outer side of a joining wall part (17) formed on the visor (5), and the joining wall part (17) is held by the opening end edge part (9) and a tongue-shaped part (31) formed on the inside of the cap body (3). The joined faces of the visor (5) and the cap body (3) are joined to each other by fusing, an intruding engagement part intruded in a through hole (22) formed in the joining wall part (17) is formed at the opening end edge part of the cap body (3), and the joined parts of the visor and the cap body are formed in annular shapes.

Owner:MIDORI ANZEN

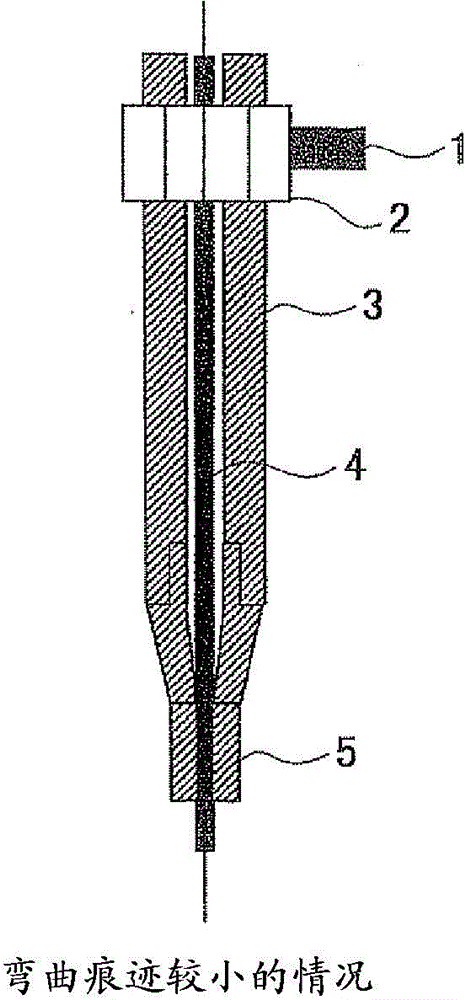

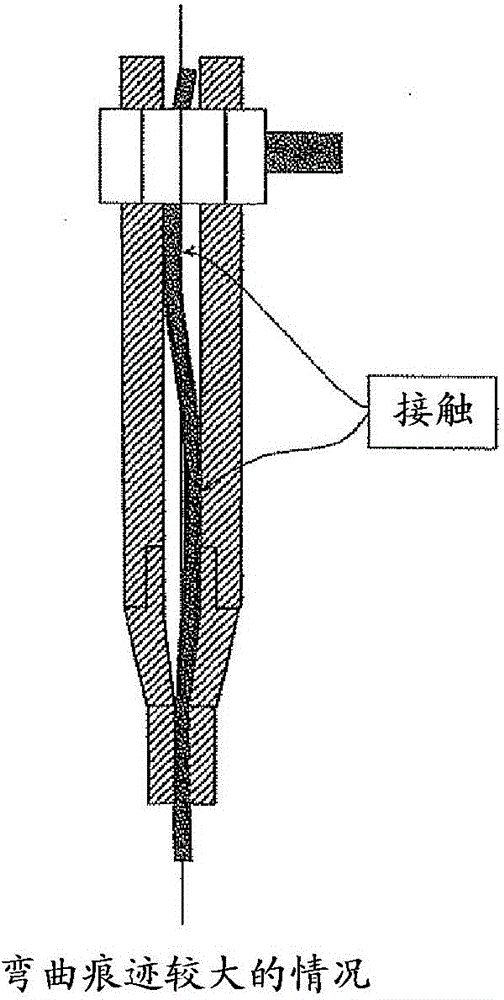

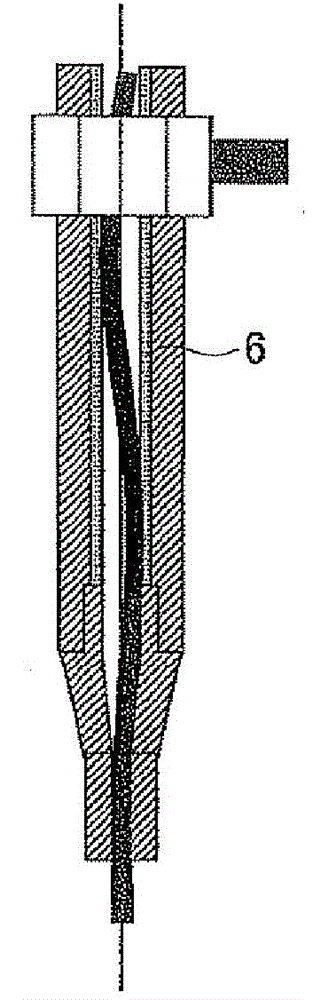

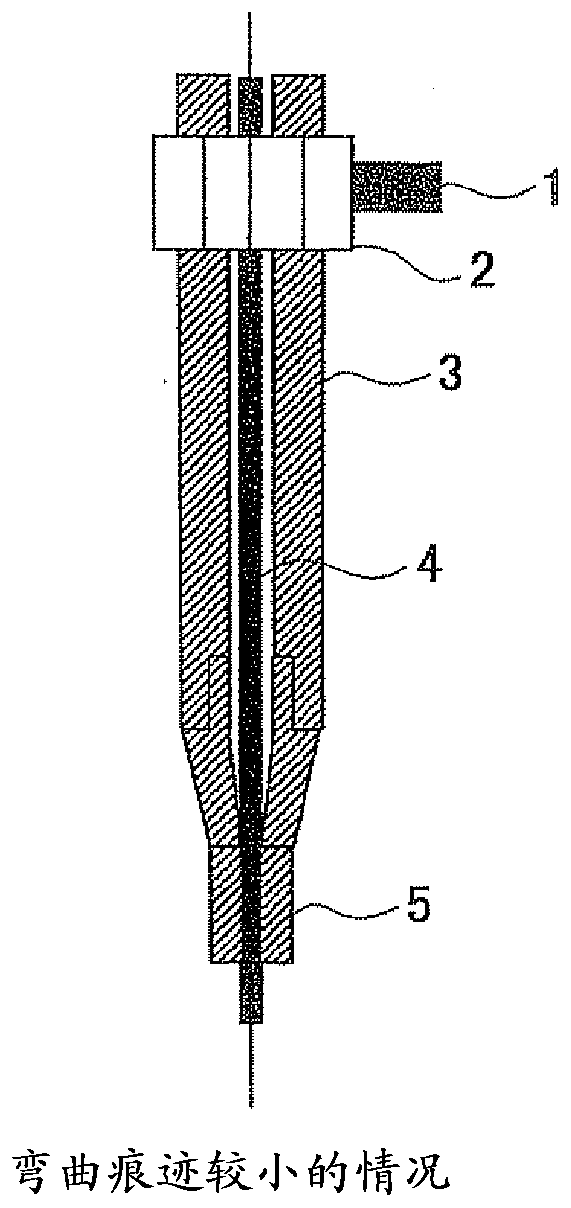

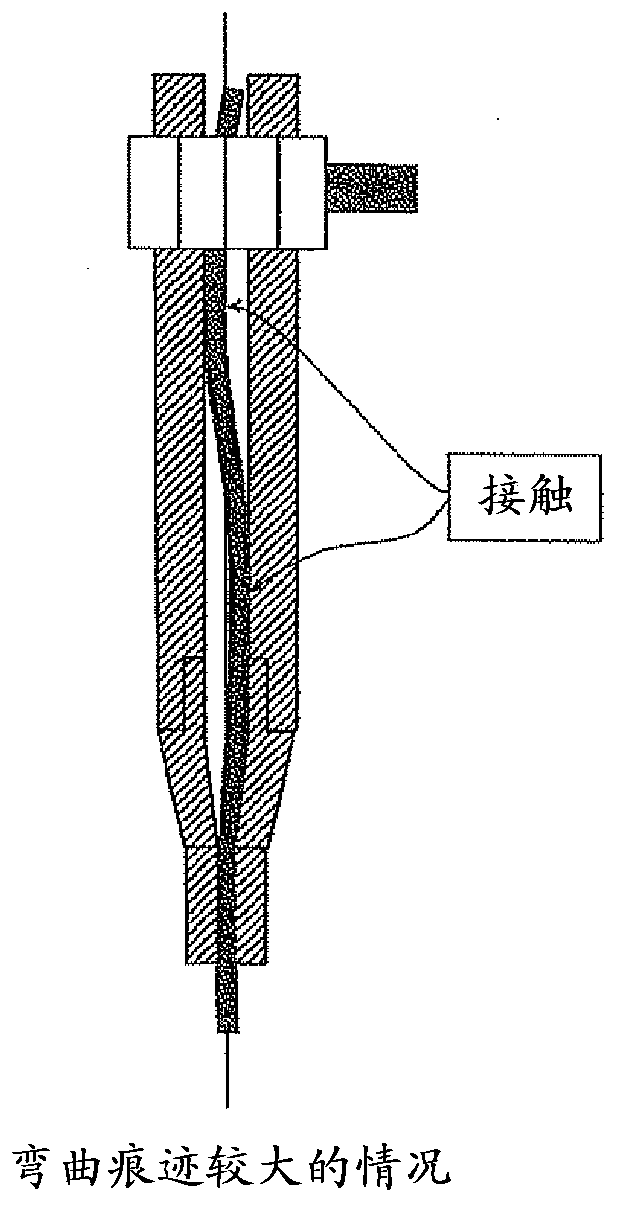

Welding torch for first electrode for multi-electrode submerged arc welding and welding method using same

InactiveCN104159694AGood effectImprove qualityNon-shielding electrode holdersElectrode accessoriesConductor CoilWelding torch

The present invention provides a welding technique for multi-electrode submerged arc welding that is stable even if a small-diameter wire is used with a first electrode, in particular if welding is being carried out under welding conditions where the wire feed speed increases or if there is considerable kinked winding, even after correction, with a flux cored wire. A welding torch for a first electrode for multi-electrode submerged arc welding and a method for multi-electrode submerged arc welding using the same are characterized by comprising a means for insulating, from an electrode wire, a tubular electric conductor that is arranged between a power supply chip and a connecting part of a power supply cable.

Owner:JFE STEEL CORP

Laser welded shaped steel

InactiveUS10144091B2Reduce the amount requiredHigh shape accuracyWelding/soldering/cutting articlesLaser beam welding apparatusPlate pressureMetallurgy

A welded portion shape of a cross-section perpendicular to the shaped steel longitudinal direction is set to satisfy a>0 mm, b>0 mm, c≥0.14 Tw, d≥0 mm, e≥0 mm, a+d≤2 mm and b+e≤2 mm; where a is a front melting width of the web material (on the laser beam irradiation side), b is a rear melting width of the web material (on the laser beam non-irradiation side), c is a maximum weld penetration depth, in a plate pressure direction, into the flange material, d is a front melting width of the flange material (on the laser beam irradiation side), e is a rear melting width of the flange material (on the laser beam non-irradiation side), and Tw is the plate thickness of the web material.

Owner:NISSHIN STEEL CO LTD

Fixing structure of fiber cover surface and sound absorbing component for vehicle

InactiveCN100457449CStable joint strengthDeposition time shortenedSynthetic resin layered productsEngineeringNonwoven fabric

The invention relates to a fixing structure of fiber cover to integrate the cover fiber as non-woven cover and the resin molded product, which will not generate surface defects as convex-concave on the surface of resin molded product, and it can reduce the processing time and simplifying the processing device. Wherein, the decoration (10) on the side of luggage case is processed by melting the fiber cover as non-woven cover (30) and the inner surface of decoration (20). It uses the sharp convex rib (52) on the processing surface (51) of ultrasonic horn (50) to form the melting part (4) of non-woven cover (3) on the plane melting surface (41) to inserted into the V-shape groove (42) inside the resin molded product. The invention can simply inserted the fiber of non-woven cover (30) into resin molded product (20) to generate fixing effect and form the V-shape groove (42) of resin molded product in short time to improve the operation availability and appearance.

Owner:KASAI KOGYO CO LTD

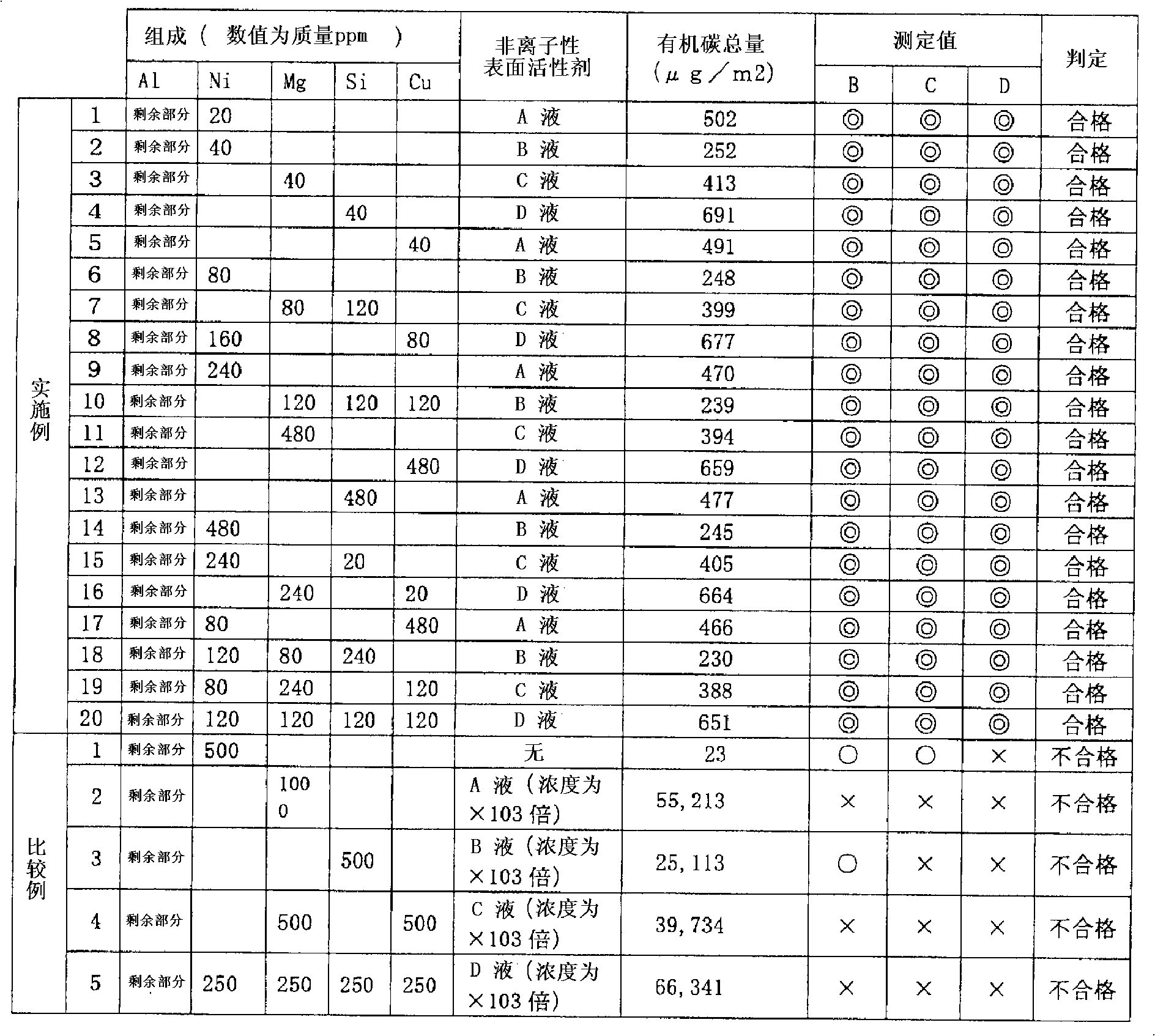

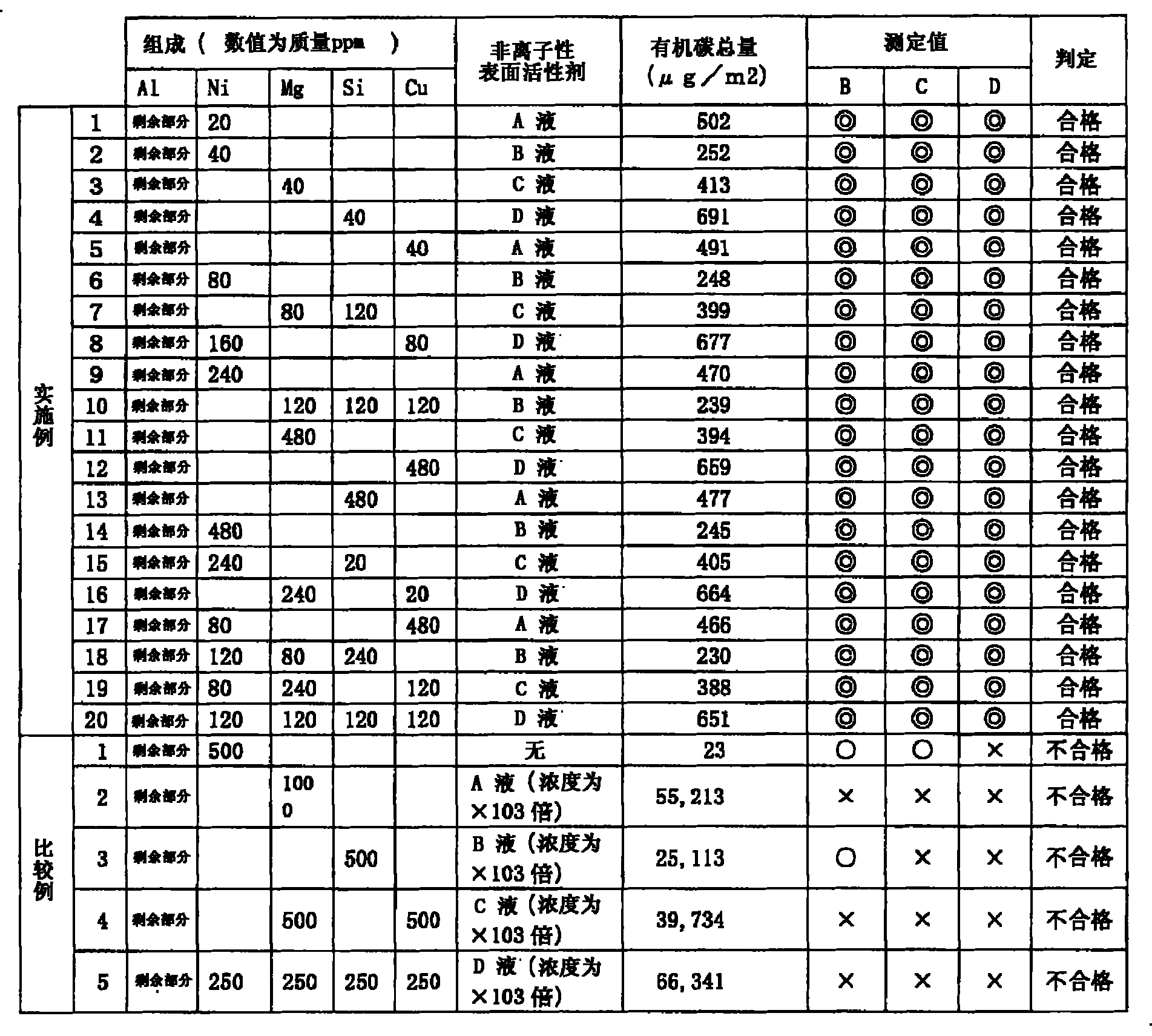

Aluminum ribbon for ultrasonic bonding

InactiveCN102326242AAvoid pollutionPrevent getting involvedSolid-state devicesSemiconductor/solid-state device manufacturingAlloyVaporization

Provided is an aluminum ribbon for ultrasonic bonding which, even when used for bonding tens of thousands of times, can retain high bond strength and a certain level of bond strength. The aluminum ribbon for ultrasonic bonding comprises aluminum metal or an aluminum-based alloy, the aluminum having a purity of 99.99 mass% or higher. The aluminum ribbon has a nonionic surfactant having a molecular weight of 500 or less, the surfactant having been deposited through vaporization to dryness on a mirror surface of the ribbon in an amount of 100-1,000 [mu]g / m2 in terms of total organic-carbon amount.

Owner:TANAKA DENSHI KOGYO KK

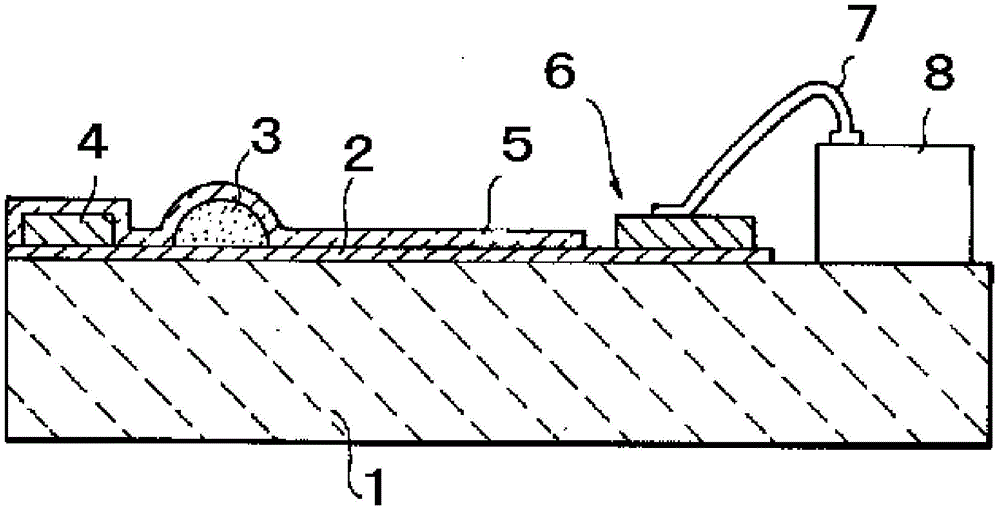

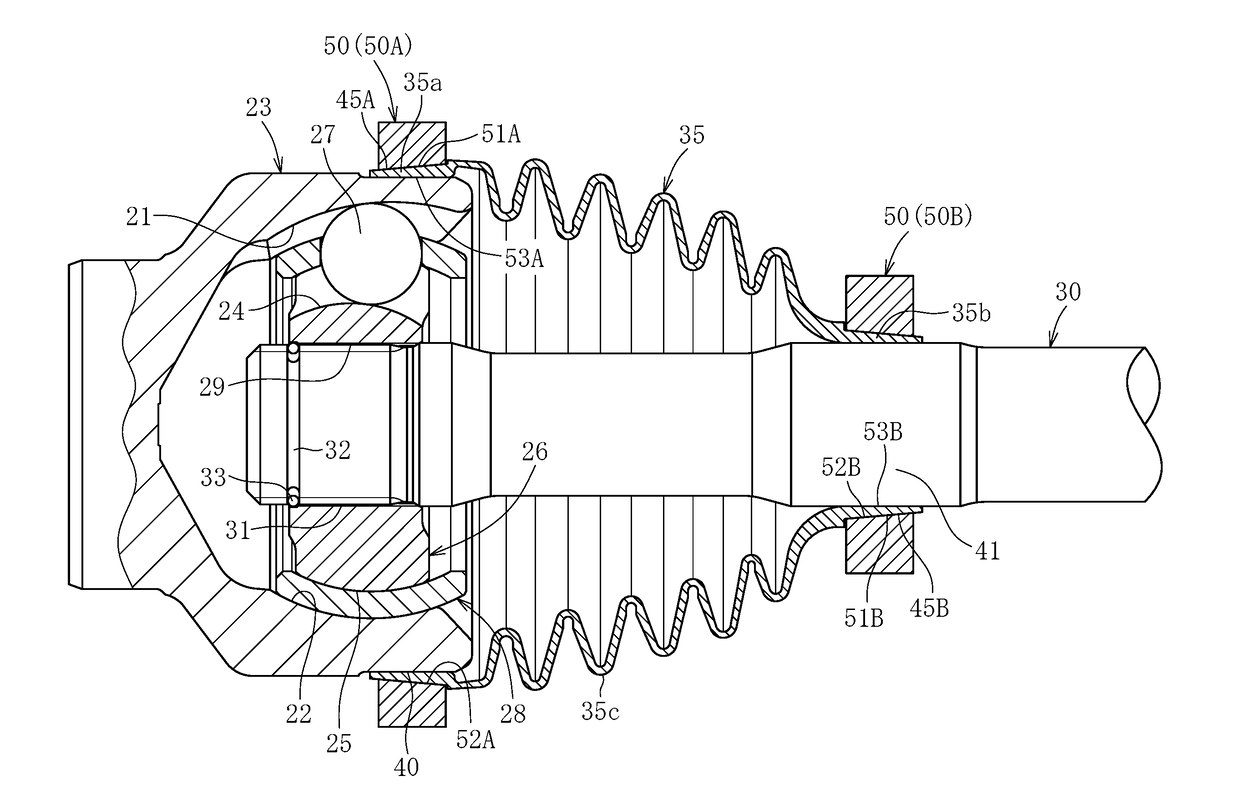

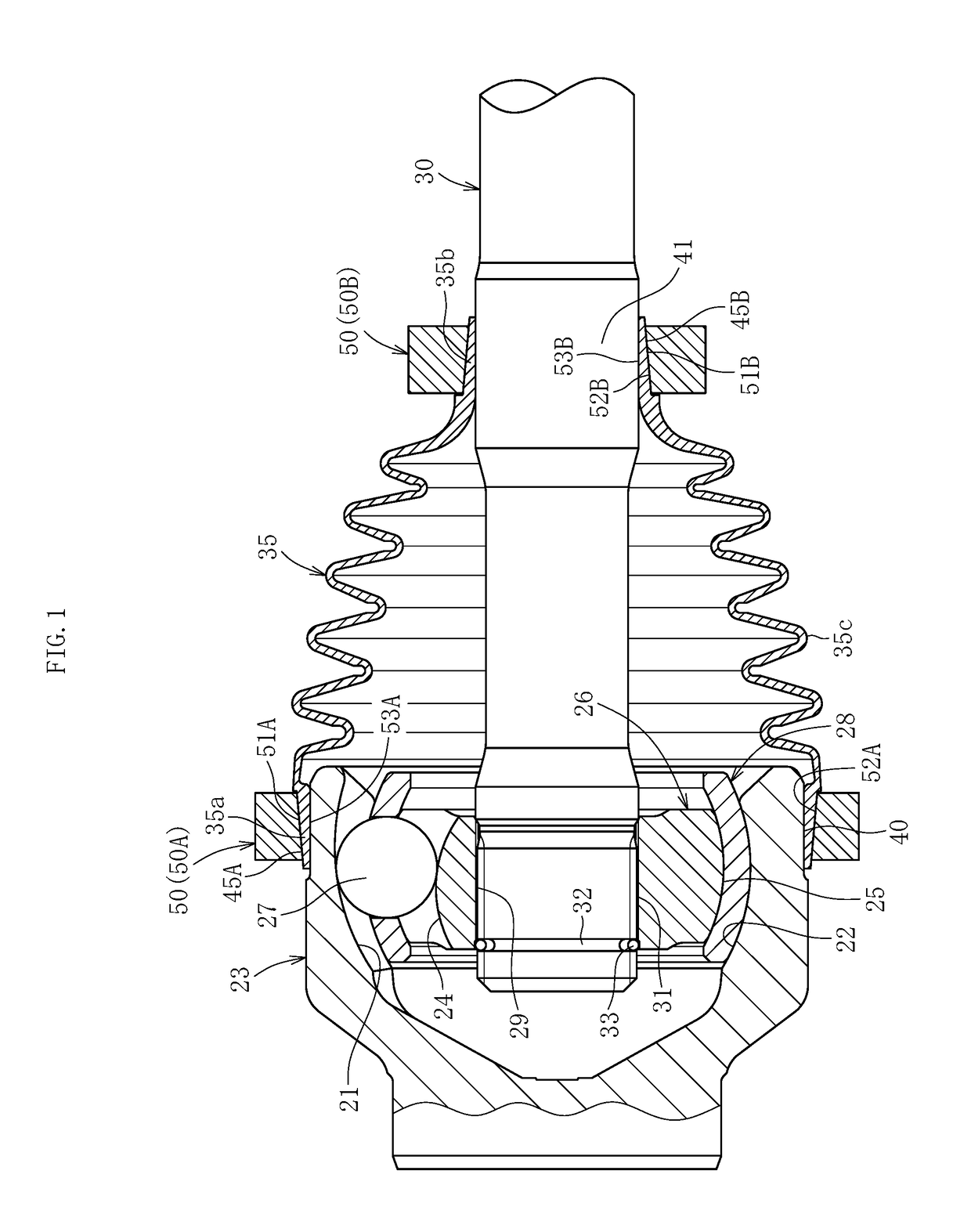

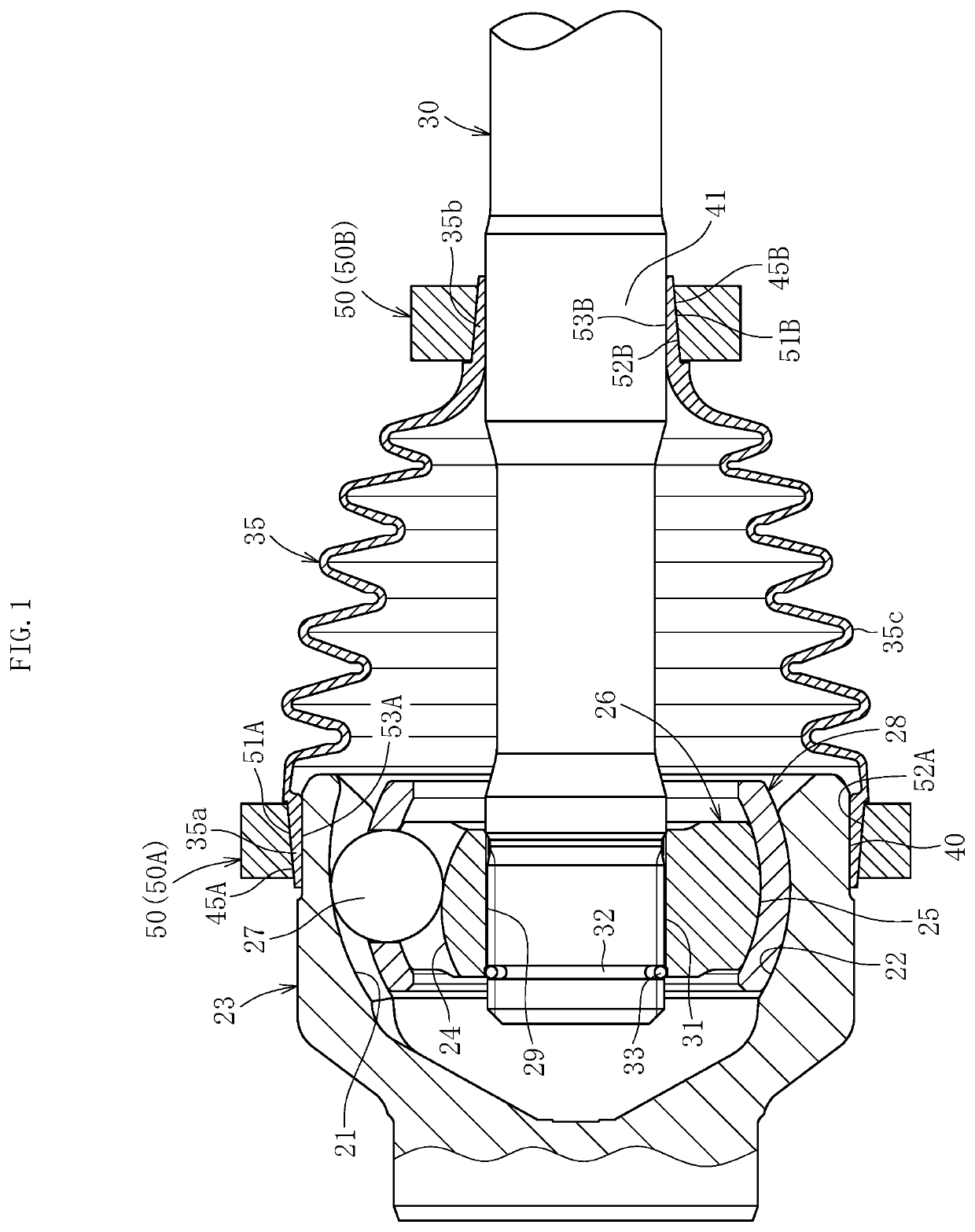

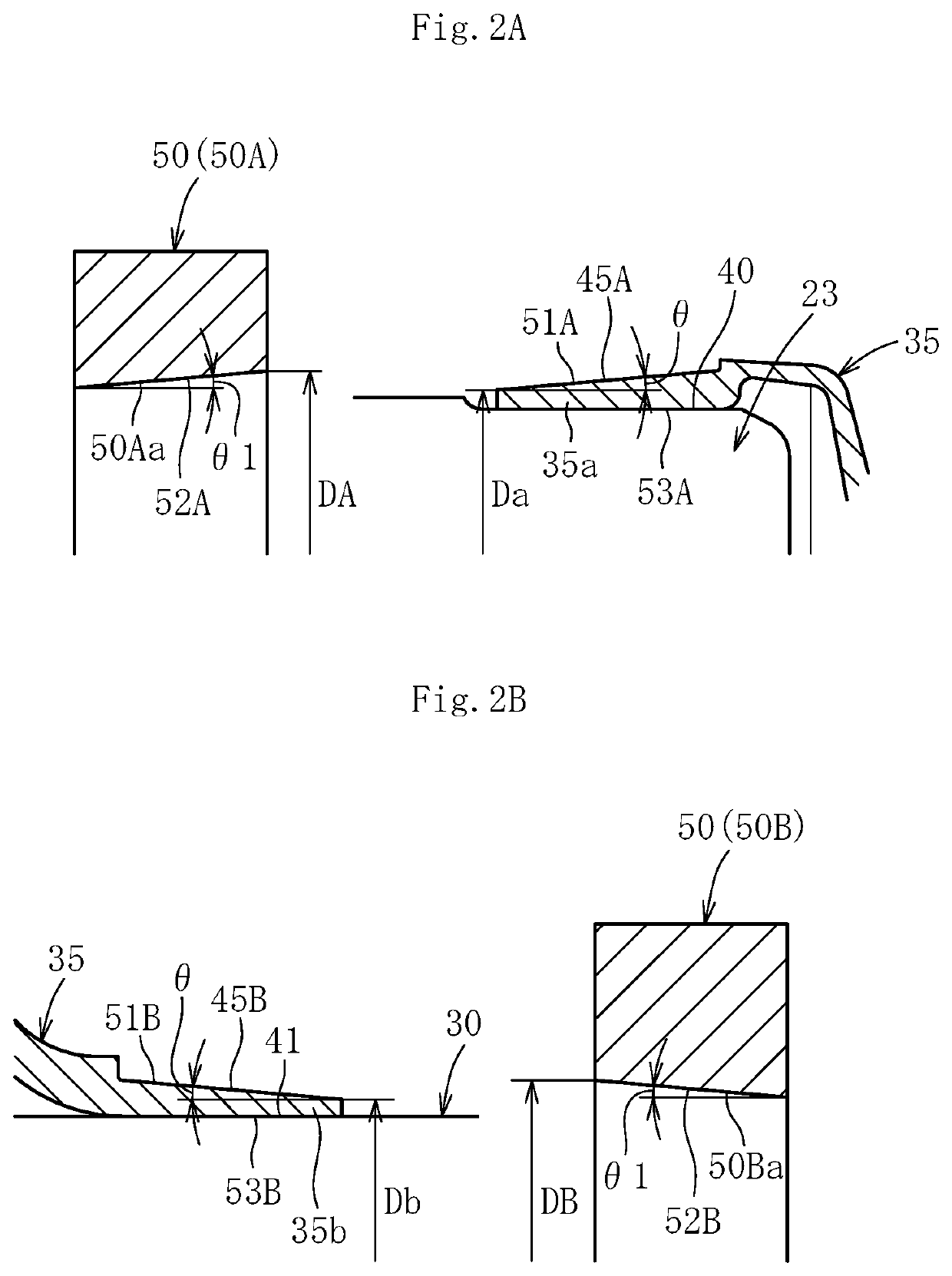

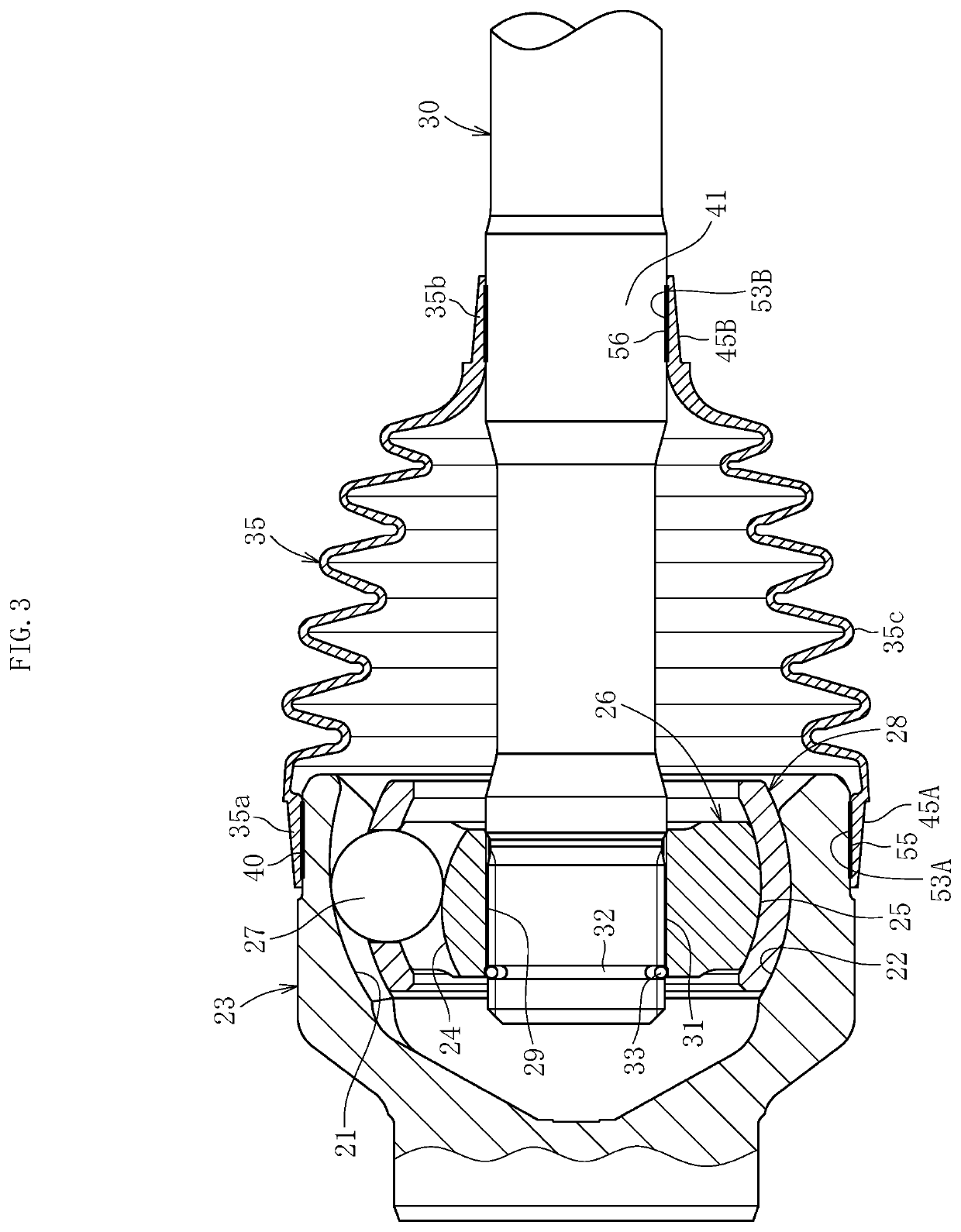

Boot attachment method and constant velocity universal joint

ActiveUS20180045251A1Reduce size and weightCost reductionEngine sealsYielding couplingConstant-velocity jointConstant velocity

Provided is a boot mounting method for a constant velocity universal joint in which a boot end portion is mounted and fixed to a mating member made of metal. After the boot end portion is fitted over a receiving surface being a radially outer surface of the mating member, a high-frequency induction heating coil having a ring shape is fitted over the boot end portion. Only a top portion of the receiving surface of the mating member is heated by high-frequency induction through application of a high-frequency current to the high-frequency induction heating coil. With this action, a mounting surface being a radially inner surface of the boot end portion and the receiving surface being the radially outer surface of the mating member are integrally joined to each other.

Owner:NTN CORP

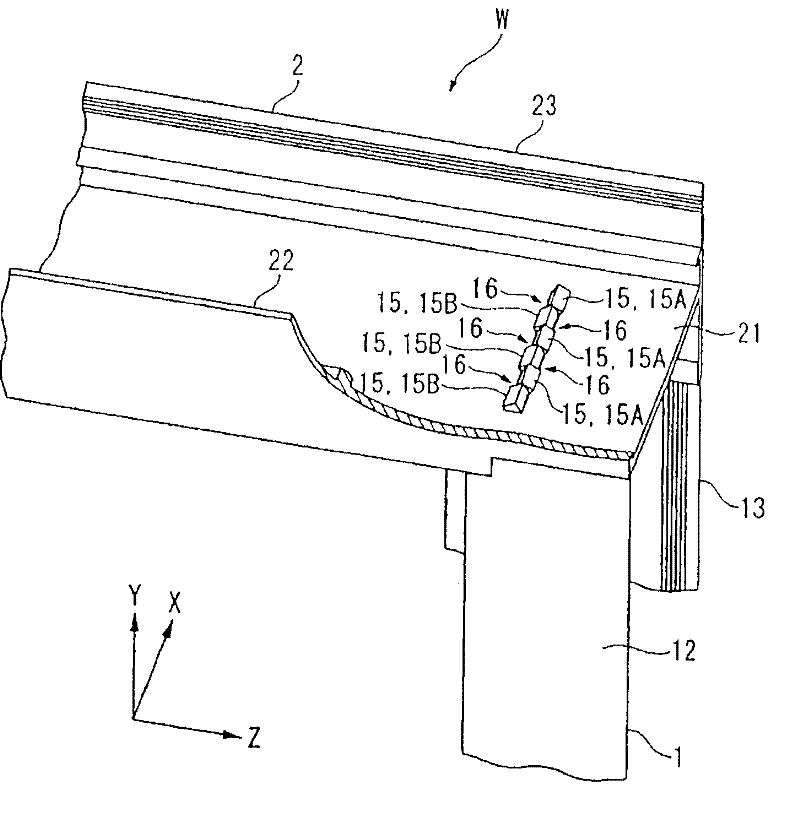

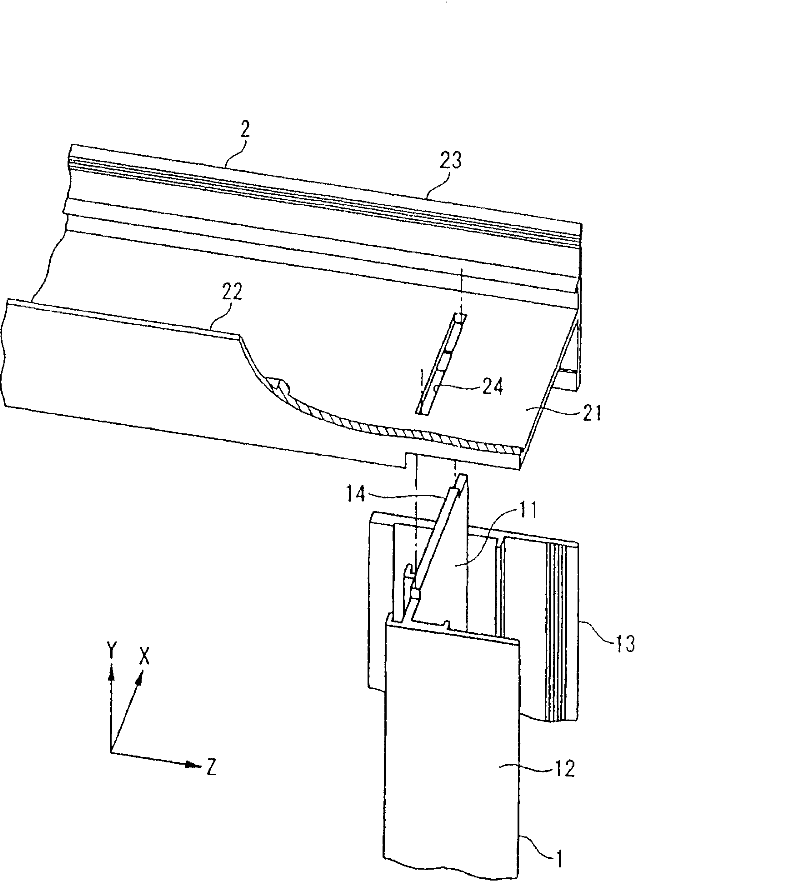

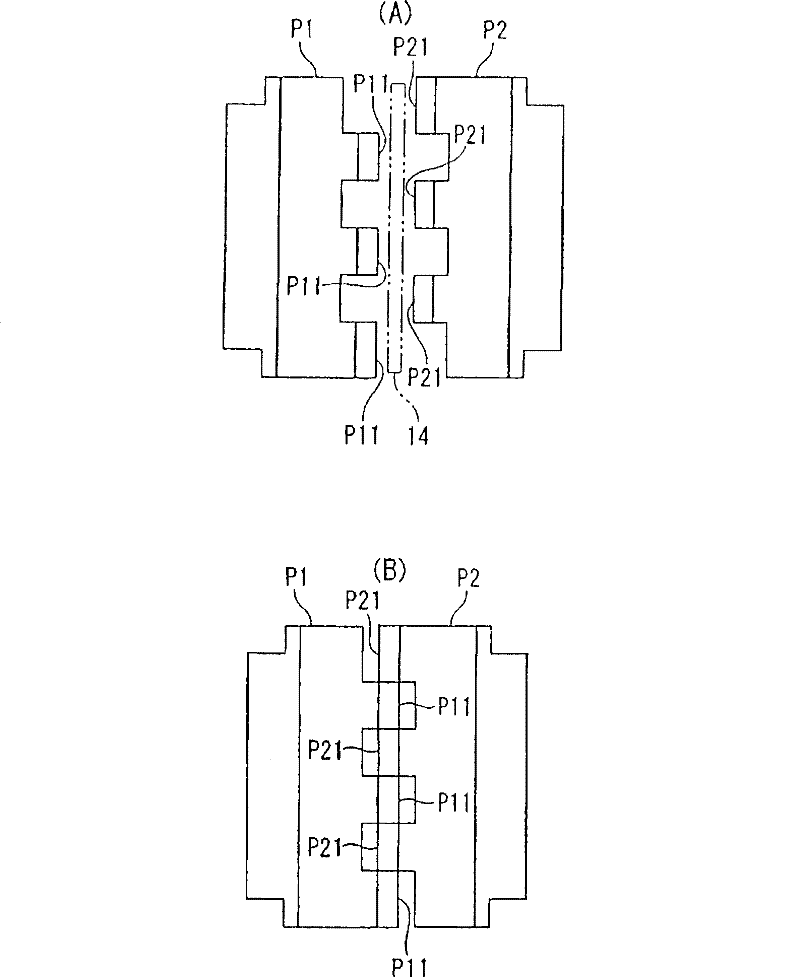

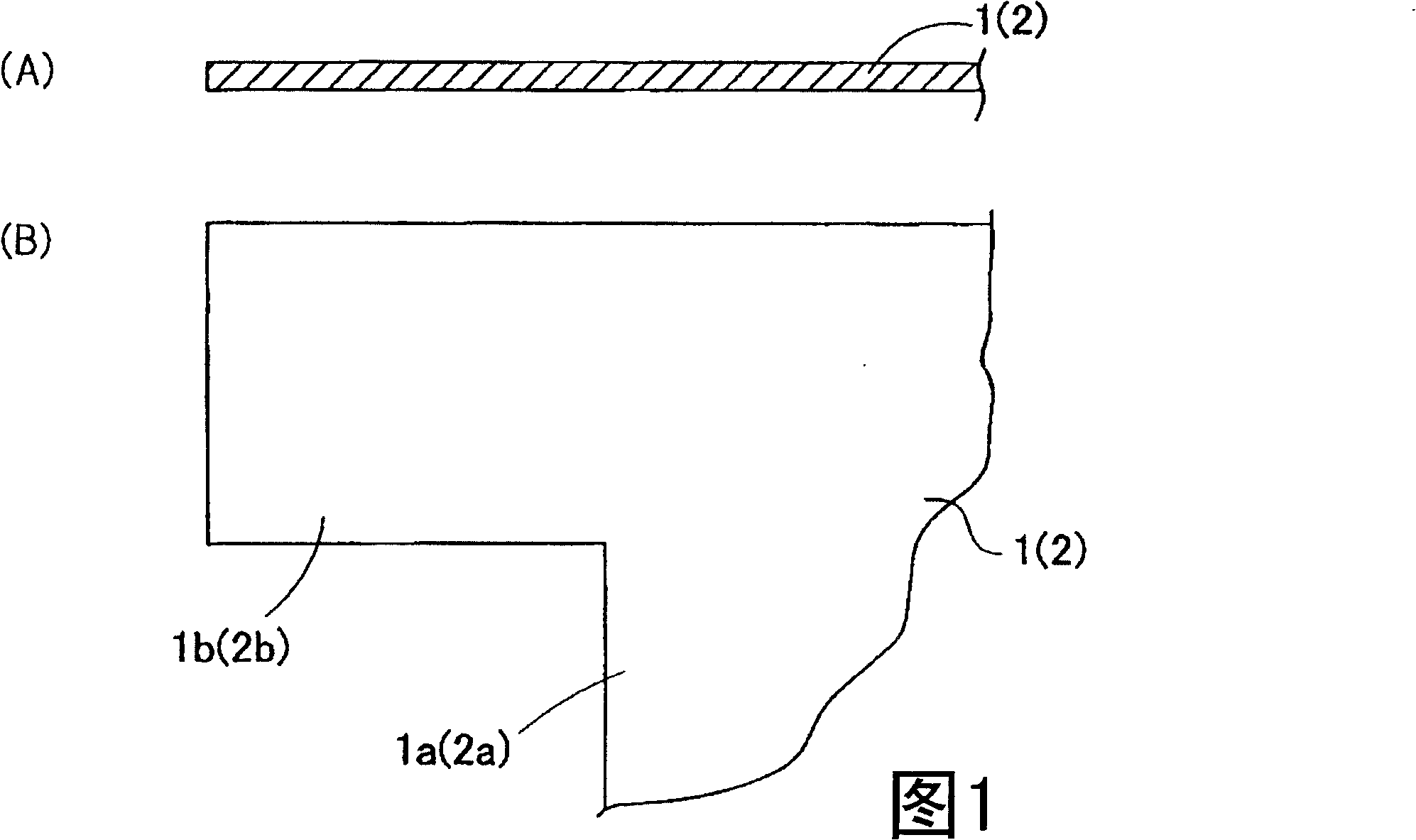

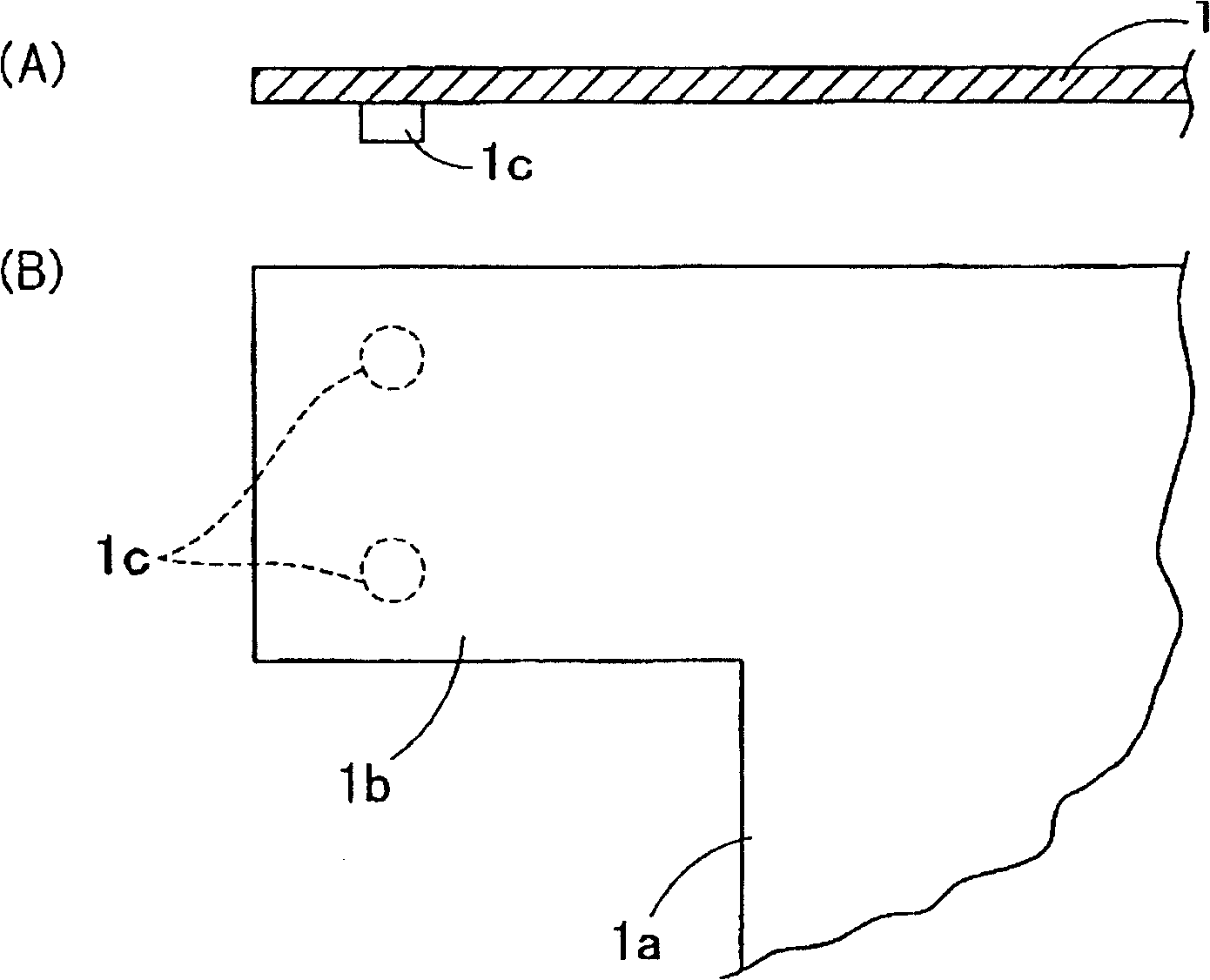

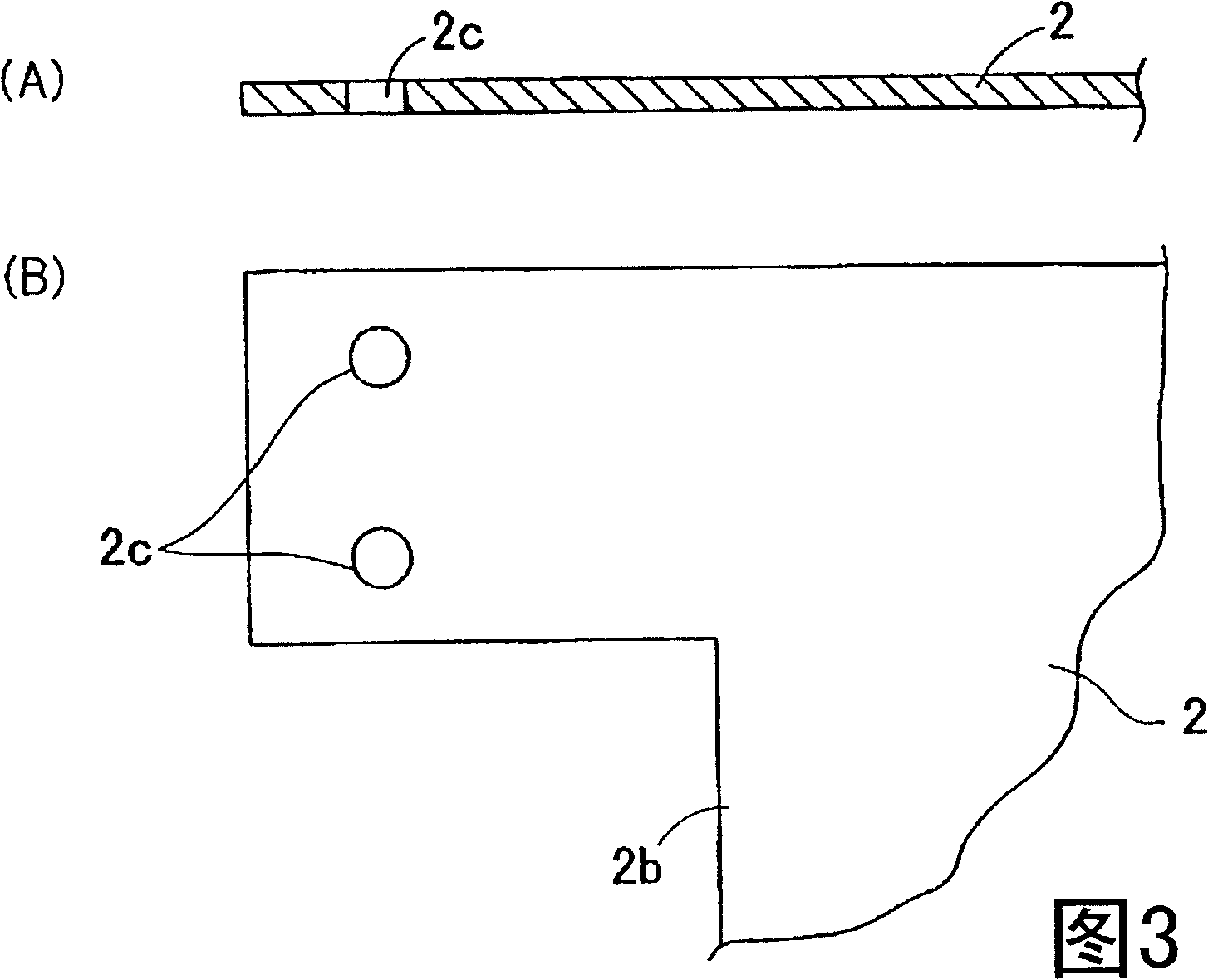

Joint method, joint construction and assembly parts

ActiveCN101397881BAvoid warpingImprove machining accuracyCorner/edge jointsJoint componentUltimate tensile strength

The present invention provides a jointing method, a jointing structure and an assembly part, which can reduce processing time and work capacity, and at the same time increase the processing accuracy of jointing part. The upper frames (1) which are taken as one pair of jointed components are formed with plate shaped projections. The longitudinal frames (2) which are taken as the other pair of jointed components are formed with inserting through holes. Through clamping the front end of the projection which traverses the inserting hole and cutting thereby dividing the projection to a plurality of projection parts (15), and at the same time deforming the adjacent projection parts (15A, 15B) to a reverse direction, the processing time and work capacity can be reduced without beforehand forminga plurality of projection pars or inserting through holes. Furthermore, through cutting the front end of projection and deforming the projection, the processing homogeneity can be realized for increasing the processing accuracy of jointing part and ensuring stable jointing strength.

Owner:YKK AP INC

Laminate structure of metal coating

ActiveUS10306774B2Stable joint strengthSimple structureInsulating substrate metal adhesion improvementPrinted circuit aspectsVitrificationMetal coating

A laminate structure of metal coating is laminated on a base material, and includes a primer layer, a catalyst layer and a plating deposited layer. The primer layer is a resin layer with a glass transition temperature (Tg) of 40 to 430° C. The catalyst layer is a metal nanoparticle group arranged in a plane on the primer layer, wherein the metal nanoparticle group is a metal in Group 11 or Groups 8, 9 and 10 in a periodic table, and the metal nanoparticles are surrounded by the primer layer. Ends of the metal nanoparticles are attached to the plating deposited layer.

Owner:EEJA LTD

Aluminum ribbon for ultrasonic bonding

InactiveCN102326242BAvoid pollutionPrevent getting involvedSolid-state devicesSemiconductor/solid-state device manufacturingAlloyAluminum metal

[Issues to be Solved] To provide an aluminum ribbon for ultrasonic bonding, is able to realize the high bonding strength and is able to maintain defined level of bonding strength, during several ten thousand bonding cycles. [Means to be Solved] An aluminum ribbon for ultrasonic bonding is consisted aluminum metal or aluminum based alloy, the purity of aluminum is more than 99.99 wt %, and total amount of organic carbon non-ionic surfactant less than 500 molecular weight vaporized and adhered is 100-1,000 μg / m2 on the mirror finished bright surface of aluminum ribbon.

Owner:TANAKA DENSHI KOGYO KK

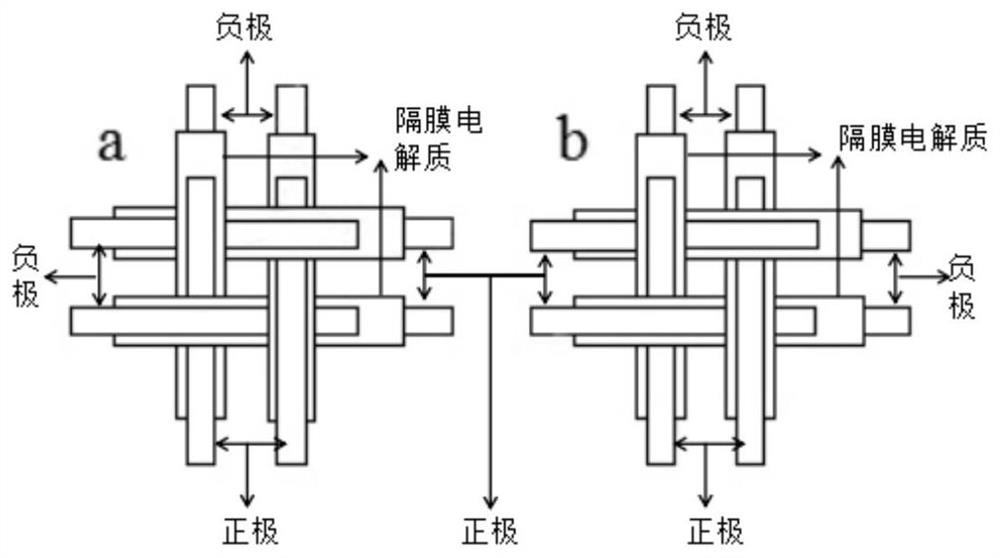

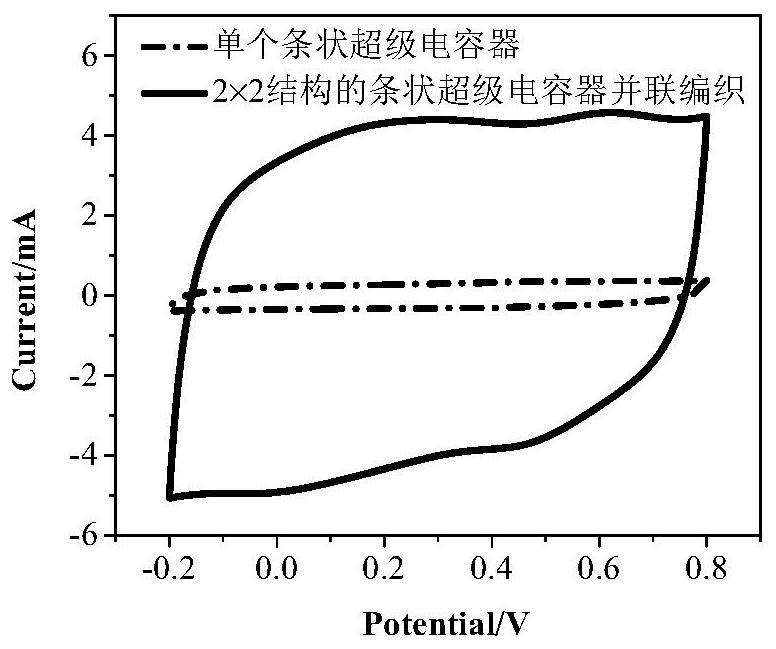

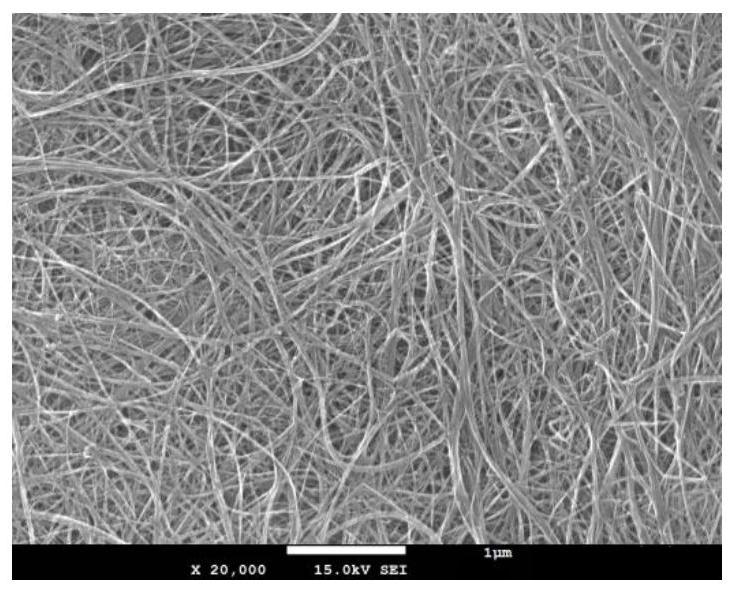

A novel wearable supercapacitor fabric and its preparation method

ActiveCN110172771BStable joint strengthStable structureWoven fabricsHybrid/EDL manufactureEngineeringMaterials science

The invention discloses a novel wearable supercapacitor fabric and a preparation method thereof, belonging to the technical field of energy storage. In this invention, a strip-shaped all-solid-state supercapacitor is first prepared by using a flexible film as an electrode material, and then a supercapacitor fabric composed of a plurality of strip-shaped capacitor units combined in a certain way is obtained by weaving. The outstanding feature of this fabric is that the electrodes of different capacitor units are connected to each other at the intersection, so that the capacitor units are connected in series or parallel, so that higher storage energy or higher operating voltage can be obtained for different capacitor units. Occasion wear. The invention skillfully utilizes the series-parallel connection theory of supercapacitors and the traditional cross weaving technology, avoids the introduction of insulating layers between capacitor units, and realizes the preparation of a new type of wearable supercapacitor fabric, which has broad application prospects.

Owner:安徽飞象山科技发展有限公司

Copper-platinum alloy wires for connections in semiconductor devices

ActiveCN103295993BStrong jointStable joint strengthSemiconductor/solid-state device detailsSolid-state devicesAir atmosphereDynamic strength

PROBLEM TO BE SOLVED: To improve second bondability as well as prevent breakage of a chip in ball bonding and improve looping property in a copper fine wire for ball bonding.SOLUTION: An ultra thin layer of copper not containing platinum due to segregation is formed in a process of forming a single wire by continuous casting from a molten copper platinum alloy containing high purity copper (Cu), 0.1 to 2.0 mass% of platinum (Pt), 1 to 10 mass ppm of sulfur (S), 10 to 150 mass of oxygen (O) and if necessary 1 to 5 mass ppm of phosphorus (P) as nonmetallic elements, and is oxidized in the air atmosphere to form an oxide film having 6 to 2 nm on a wire surface layer after wire drawing. Uniform oxide film improves second bondability as a bonding wire having a Vickers hardness of 77 to 105 Hv, prevents aluminum splash by preventing dynamic strength at ball bonding by a matrix additive element, and maintains static strength without generating leaning.

Owner:TANAKA DENSHI KOGYO KK

Welding torch for first electrode for multi-electrode submerged arc welding and welding method using same

InactiveCN110076432AGood effectImprove qualityNon-shielding electrode holdersElectrode accessoriesConductor CoilWelding torch

The present invention provides a welding technique for multi-electrode submerged arc welding that is stable even if a small-diameter wire is used with a first electrode, in particular if welding is being carried out under welding conditions where the wire feed speed increases or if there is considerable kinked winding, even after correction, with a flux cored wire. A welding torch for a first electrode for multi-electrode submerged arc welding and a method for multi-electrode submerged arc welding using the same are characterized by comprising a means for insulating, from an electrode wire, atubular electric conductor that is arranged between a power supply chip and a connecting part of a power supply cable.

Owner:JFE STEEL CORP

Boot attachment method and constant velocity universal joint

ActiveUS10907692B2Reduce weight and sizeStable joint strengthEngine sealsYielding couplingUniversal jointEngineering

Provided is a boot mounting method for a constant velocity universal joint in which a boot end portion is mounted and fixed to a mating member made of metal. After the boot end portion is fitted over a receiving surface being a radially outer surface of the mating member, a high-frequency induction heating coil having a ring shape is fitted over the boot end portion. Only a top portion of the receiving surface of the mating member is heated by high-frequency induction through application of a high-frequency current to the high-frequency induction heating coil. With this action, a mounting surface being a radially inner surface of the boot end portion and the receiving surface being the radially outer surface of the mating member are integrally joined to each other.

Owner:NTN CORP

Panel bonding method and panel combination component

InactiveCN100999005BNo position shiftStable joint strengthSheet joiningAcute angleClassical mechanics

The aim of the invention is to provide a method for connecting two pieces of sheets, including: a step of forming a bending piece by bending a end part of a first sheet from one of the two sheets made of metal to a sharp angle relatively to a base part of the first sheet; a step of forming a bending piece by bending a end part of a second sheet from the other one of the two sheets made of metal to form an opening of the end relative to a base part of the second sheet, which opening is shorter than a maximum distance between the bending piece and the base part of the first sheet; a step of connecting the first and the second sheets, due to elastic recovery of the bending piece of the first sheet, by inserting the bending piece and the opposite base part of the first sheet into the bending piece and the opposite base part of the second sheet via the opening, and bending the bending piece of the first sheet to a further sharp angle.

Owner:MURATA MASCH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com