Structure of surface-modified silver-palladium alloy wire

A surface modification, silver-palladium alloy technology, applied in semiconductor/solid-state device parts, semiconductor devices, electrical components, etc., can solve problems such as many restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

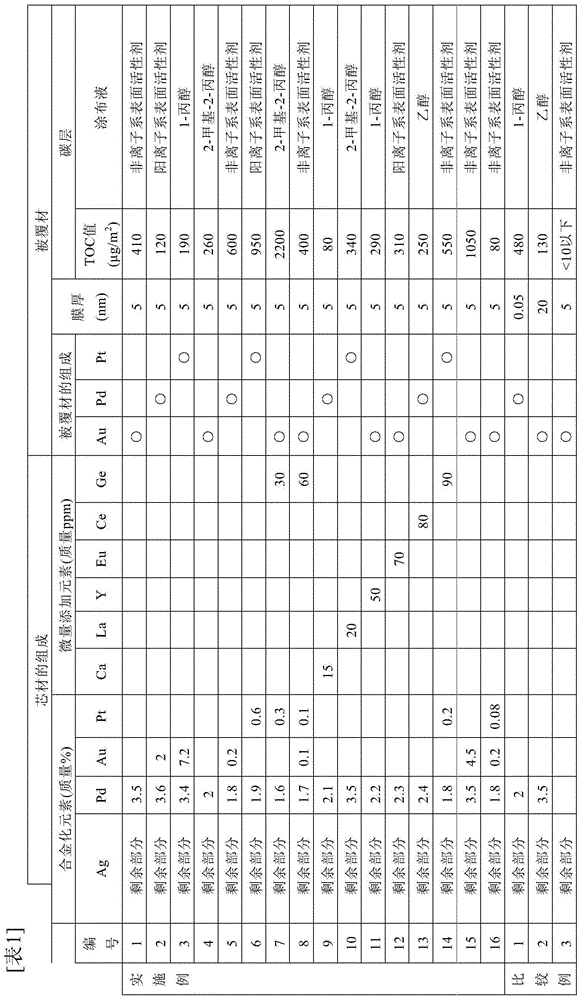

[0060] The silver-palladium alloy (silver (Ag), gold (Au) and copper (Cu) with a purity of 99.9999% by mass or more of the composition of the core material and the coating material in Table 1, and other palladium (Pd) and platinum (Pt) The alloying components of the alloys have a purity of 99.999% by mass or more), melt-casting uniformly, rolling while performing intermediate heat treatment (600°C×0.5 hours), and then drawing to obtain a thick wire (diameter 0.5mm) before coating the coating material.

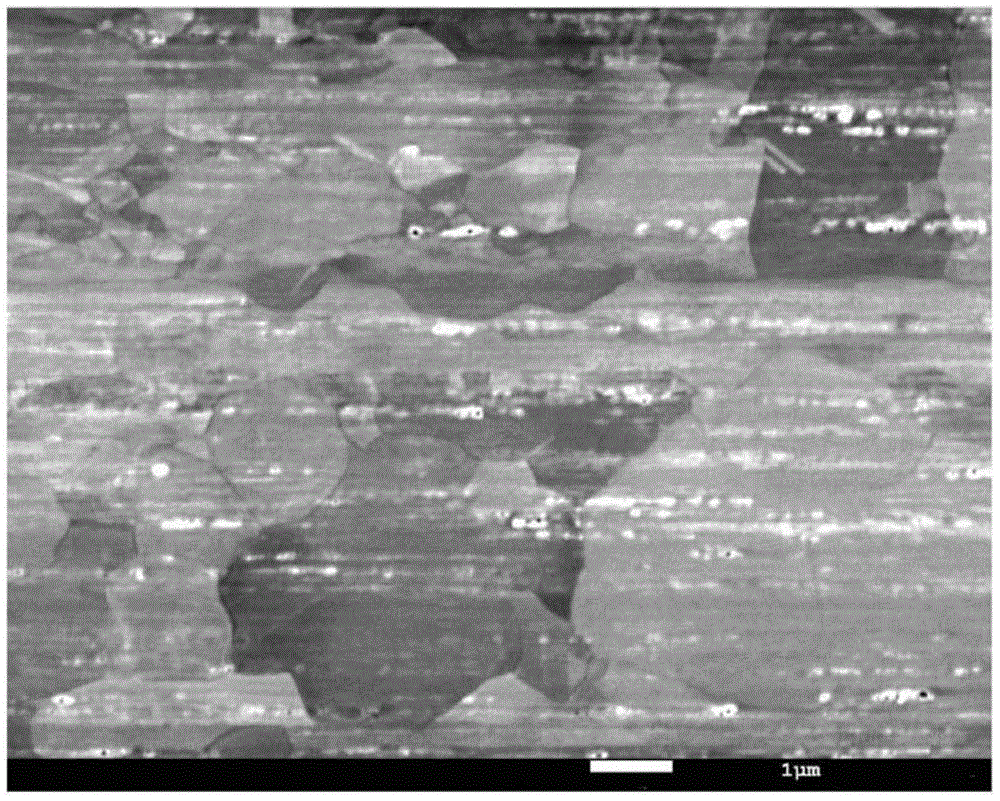

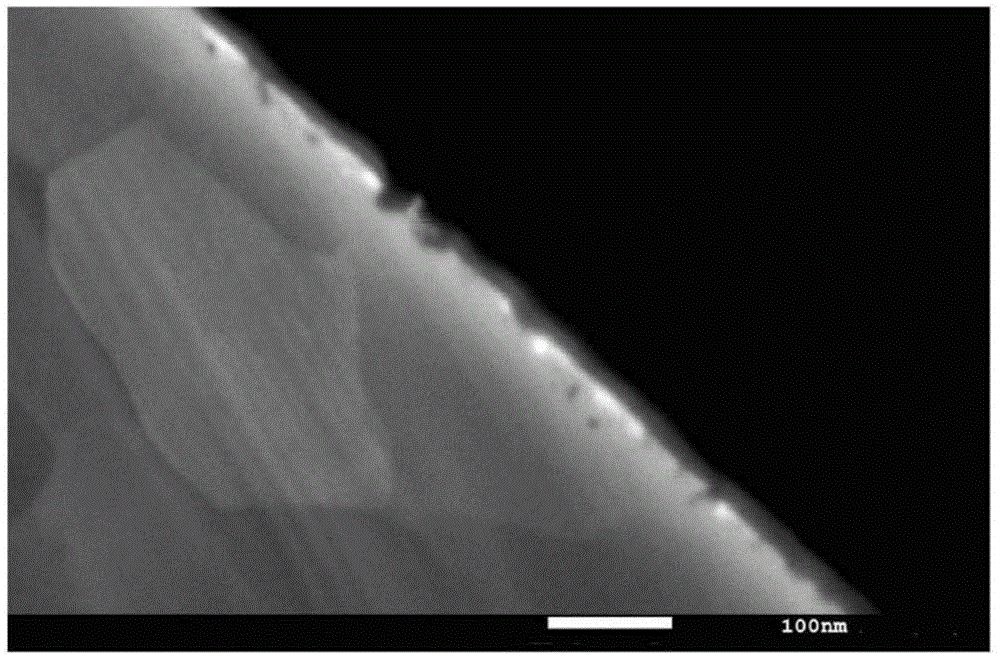

[0061] A core material composed of an Ag-3.5% by mass Pd alloy shown in No. 1 in Table 1 was drawn to a diameter of 0.5 mm, and the outer circumference of the thick wire was coated with gold (Au) at a thickness of about 0.1 μm. Thereafter, the wire was continuously drawn using a diamond die in a wet method to finally obtain a wire for ultrasonic bonding with a diameter of 15 μm. The structure of the plane obtained by observing the appearance of the line with a scanning electron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com