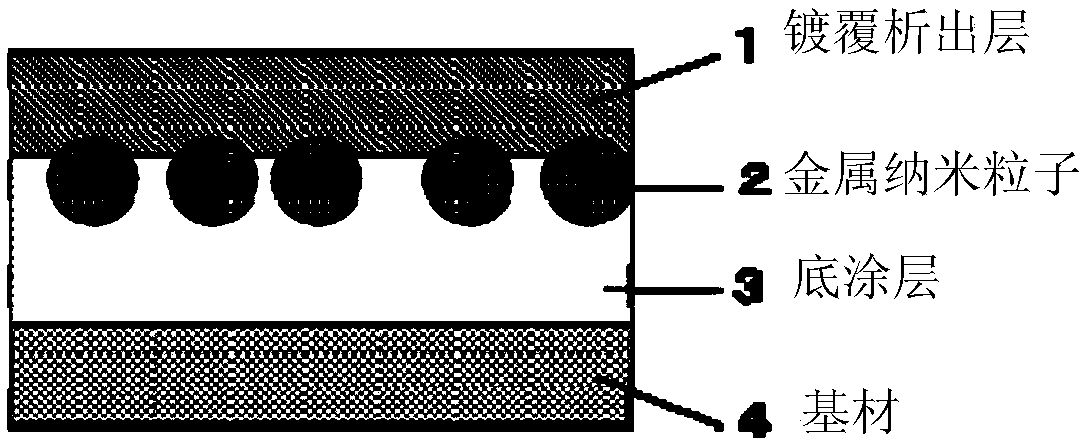

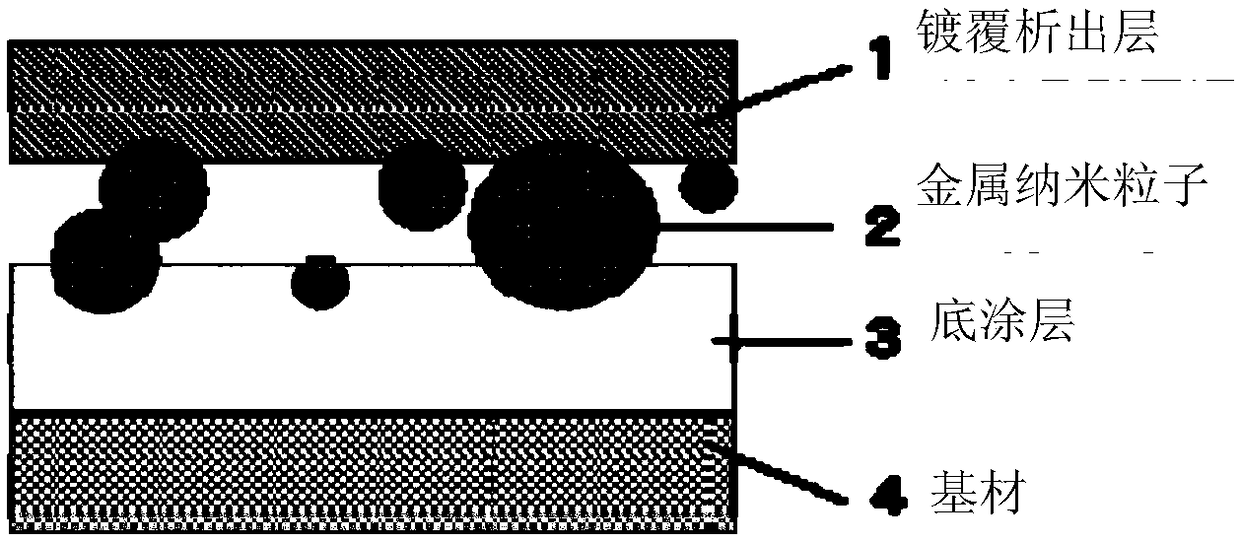

Metal film laminate structure

一种金属膜、构造的技术,应用在金属层状产品、金属材料涂层工艺、金属花纹材料等方向,能够解决底涂层表面凹凸变大、难金属纳米粒子群排列底涂层、无法得到密合力均匀电路等问题,达到简便层积构造的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] As the insulating base material A, glass (EAGLE XG manufactured by CORNING) was used. A polyester resin solution (glass transition temperature (measured value) 72°C) was used as the primer solution. The primer solution was applied to the insulating substrate A by a bar coating method and dried at 100°C for 5 minutes to form an undercoat layer having a thickness of 0.12 μm in terms of a dry film thickness.

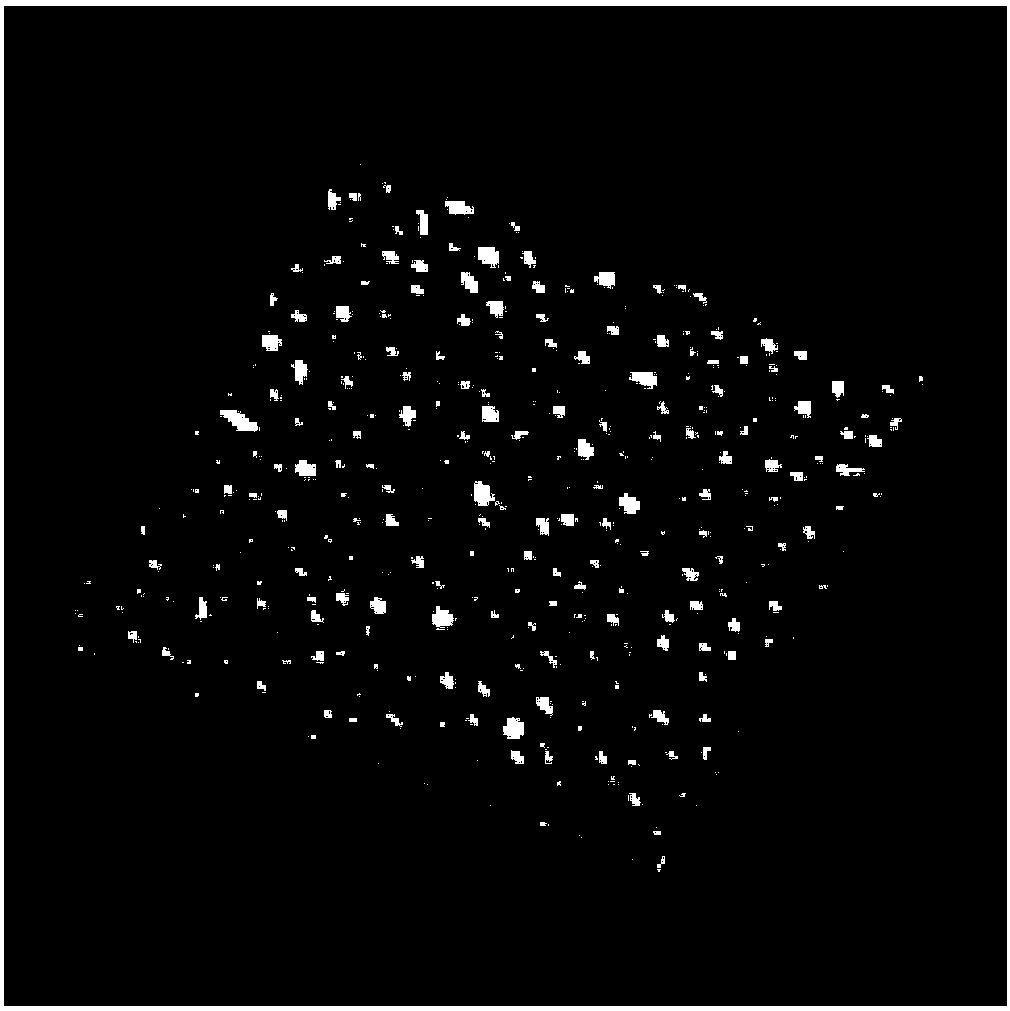

[0067] The insulating substrate A provided with the primer layer is immersed in colloidal spherical gold (Au) nanoparticles (0.1g / L as Au) containing an average particle diameter of 20nm (variation coefficient CV=0.15) After 10 minutes in the aqueous solution of ), wash with pure water. As a result, nanoparticles with an average particle diameter of 20 nm were obtained with an average adsorption density of 273 particles / 0.25 μm 2 The substrate of the catalyst layer adsorbed on the primer layer ( image 3 ). The surface shape was observed using a scanning probe microsc...

Embodiment 2

[0074] As the insulating base material B, a polyester film (Lumirror S10 manufactured by Toray Co., Ltd.) was used. As the primer solution, a polyester resin solution containing an amine group (glass transition temperature 80°C) was used. The primer solution was applied on the insulating substrate B by a bar coating method and dried at 100° C. for 5 minutes to form an undercoat layer with a thickness of 0.07 μm in terms of a dry film thickness.

[0075] Next, the substrate was irradiated with light of a wavelength of 300 nm or less from a distance of 10 mm with an ultraviolet lamp light source device (Model 312 manufactured by Technovision, Inc.) for 30 seconds. Between the light source and the substrate, a quartz mask with a shading pattern formed of chromium is placed. As a result, the amine group on the primer irradiated with ultraviolet rays disappears.

[0076] The insulating substrate B treated in this way is immersed in colloidal spherical gold (Au) nanoparticles (0.1g / L a...

Embodiment 3

[0080] As the insulating substrate C, a polyimide film (UPILEX 50SGA manufactured by Ube Industries Co., Ltd.) was used. The primer solution was an olefin resin solution (glass transition temperature 130°C). The primer solution was applied on the insulating substrate B by a spin coating method and dried at 150° C. for 15 minutes to form a primer layer having a thickness of 0.3 μm in terms of dry film thickness.

[0081] The insulating substrate C provided with the primer layer is immersed in spherical palladium (Pd) nanoparticles (0.3g / L as Pd) dispersed in a colloidal shape with an average particle diameter of 3nm (variation coefficient CV=0.40) ) And polyethyleneimine (average molecular weight 10,000) 0.01 g / L in an aqueous solution for 10 minutes to obtain a substrate on which a palladium (Pd) nanoparticle catalyst layer adsorbed on the primer layer was formed.

[0082] Next, the substrate was immersed in an electroless palladium (Pd) plating solution (LECTROLESS Pd2000S manufa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com