Panel bonding method and panel combination component

A bonding method and technology of composite parts, which are applied in the direction of thin plate connection, connecting member, mechanical equipment, etc., to achieve the effect of strong bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

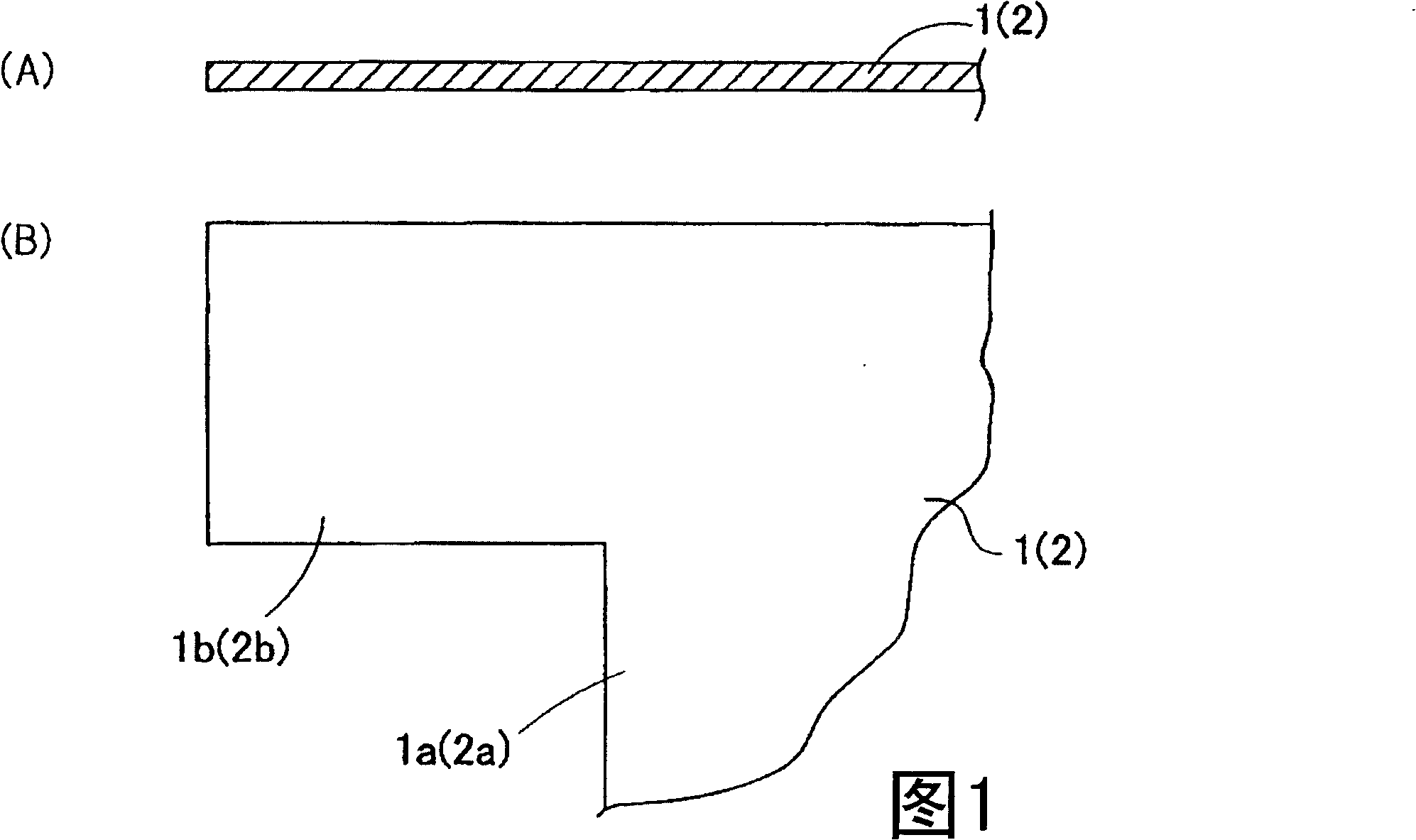

[0034] The plate joining method of the present invention will be described with reference to the accompanying drawings. here, as figure 1 As shown, two metal plates 1, 2 of the same shape in which protruding pieces 1b, 2b as curved pieces are integrally formed with the bases 1a, 2a are joined so that the bases 1a, 2a of the two overlap each other. Example to illustrate. For convenience of description, among the two metal plates, one plate 1 is referred to as a "first plate", and the other plate 2 is referred to as a "second plate".

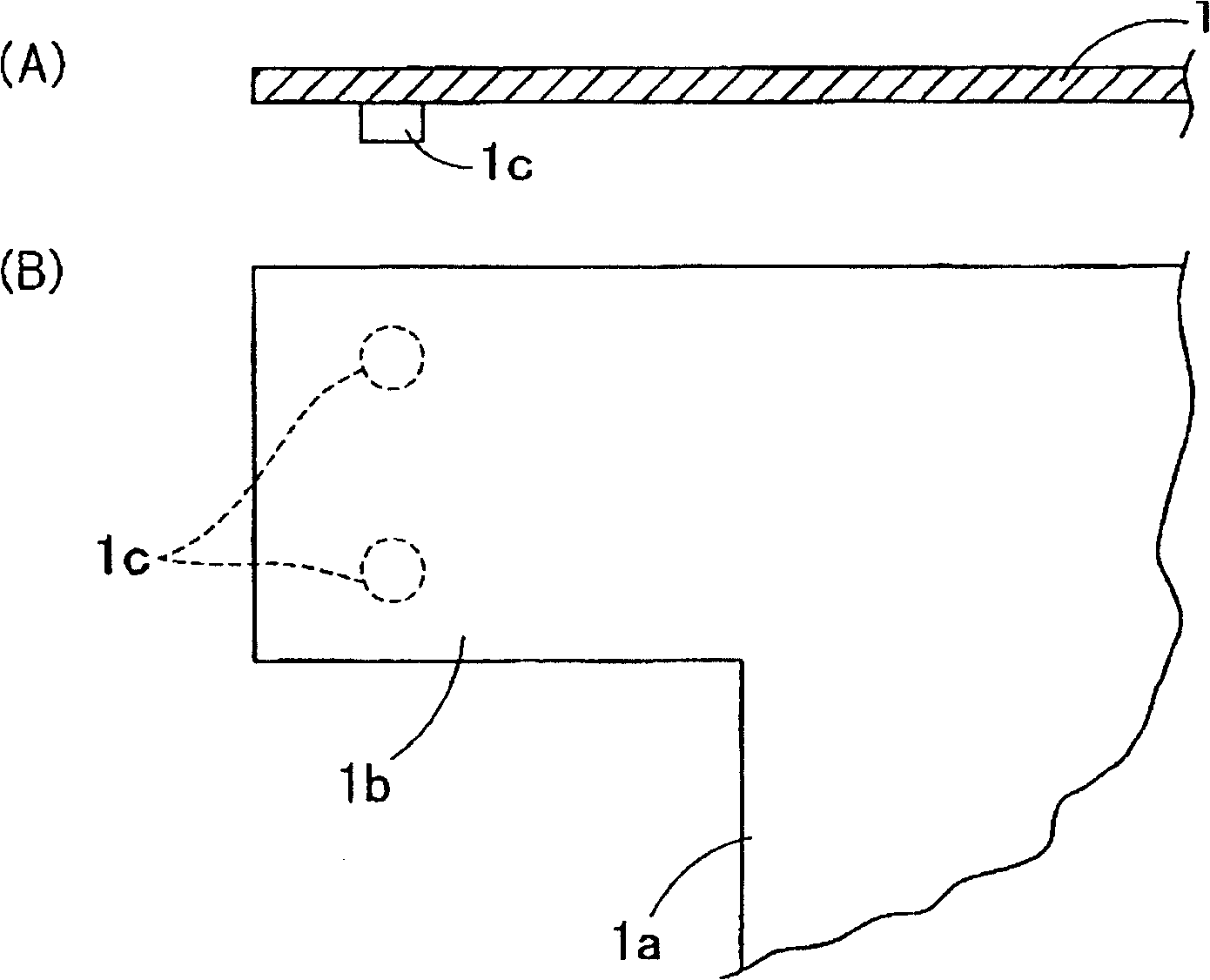

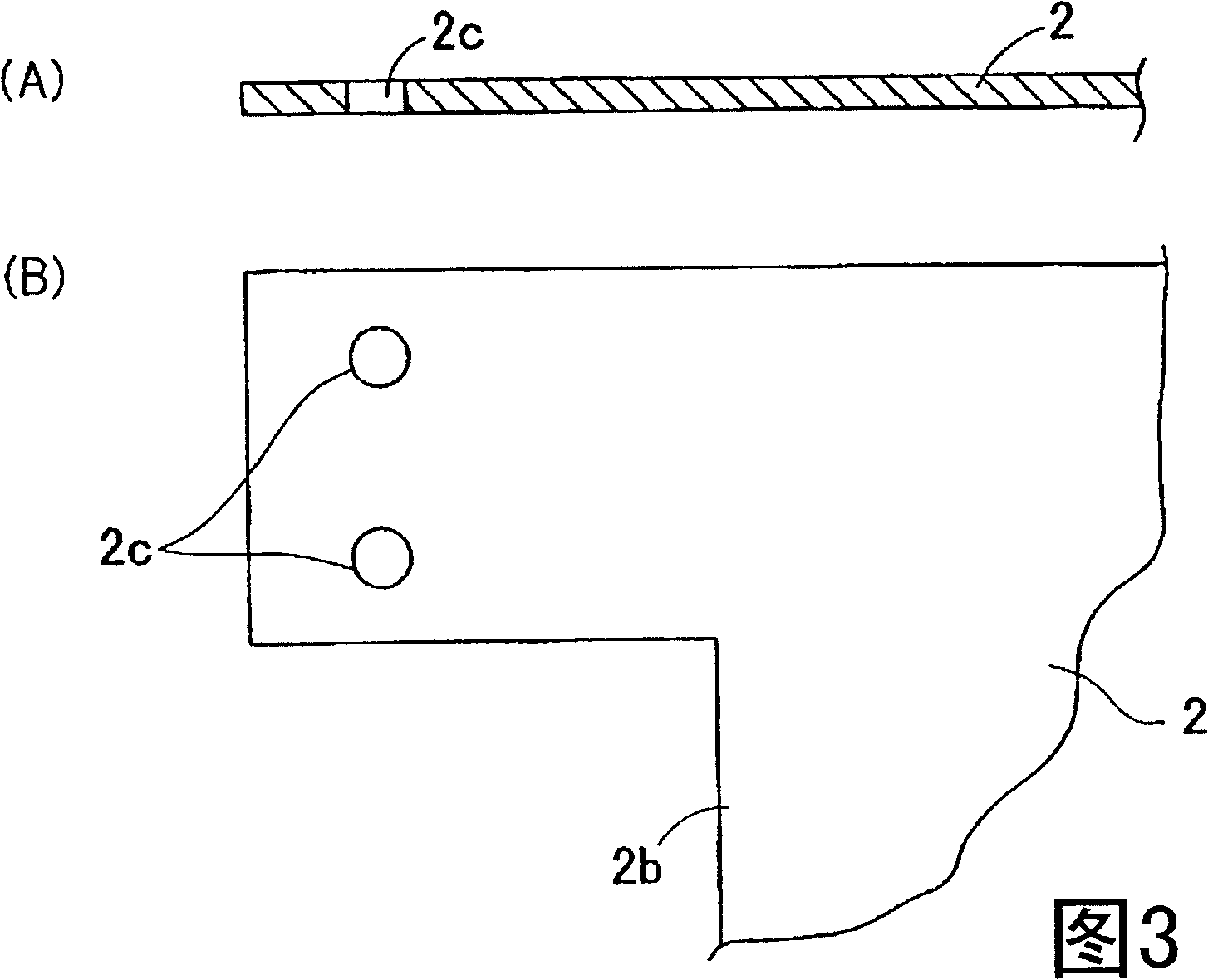

[0035] First, if figure 2 As shown, a dowel 1c is formed in the vicinity of the front end of the protruding piece 1b of the first board 1 . The dowel 1c may be formed by welding, or may be formed by press working. In the illustration, dowels 1c are formed at two positions equidistant from the edge of the protruding piece 1b. In addition, on the protruding piece 2b of the second board 2, such as image 3 As shown, an engaging hole 2c is for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com