A novel wearable supercapacitor fabric and its preparation method

A technology of supercapacitors and capacitors, applied in the manufacture of hybrid/electric double layer capacitors, fabrics, textiles, etc., can solve the problems of increasing the quality of supercapacitor units, increasing the quality of supercapacitor fabrics, reducing wearing comfort, etc., and achieving high energy density. , the effect of high operating voltage and high storage energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

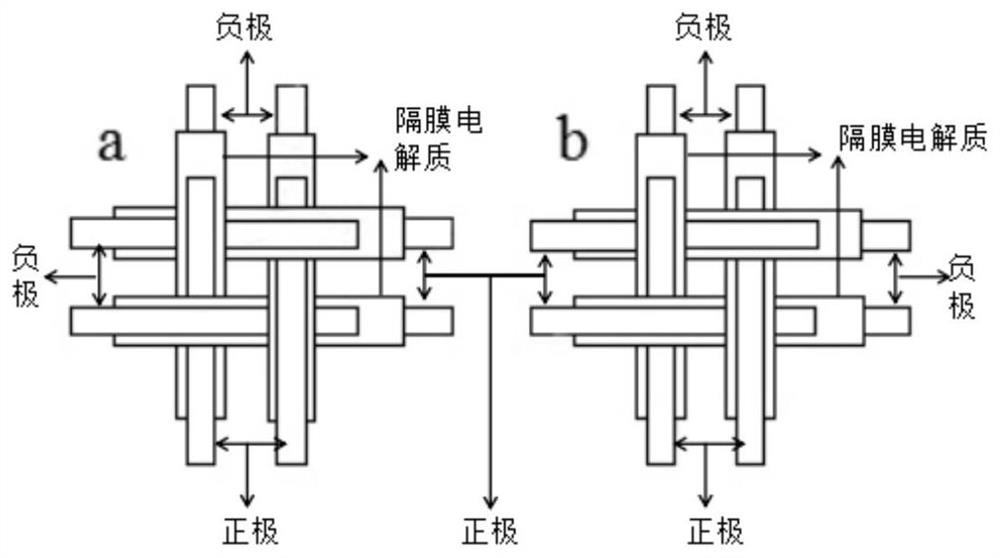

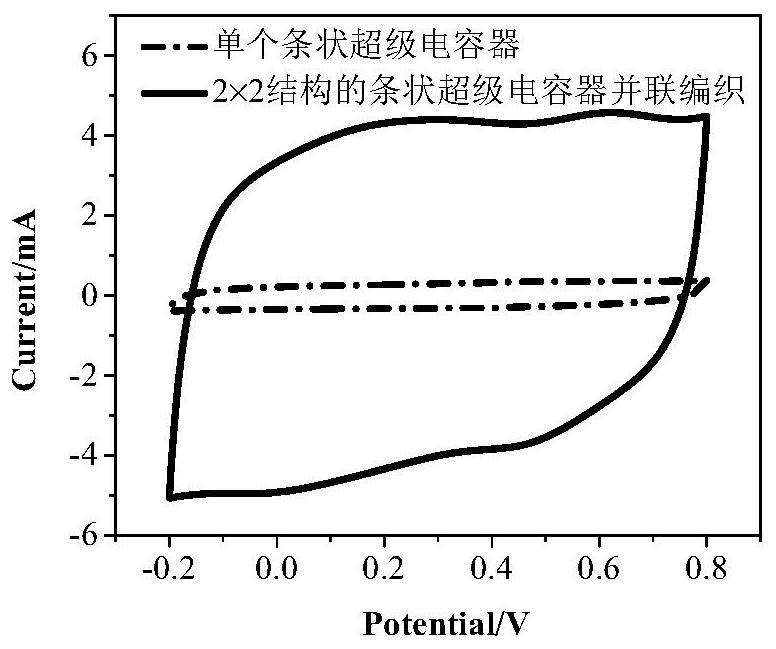

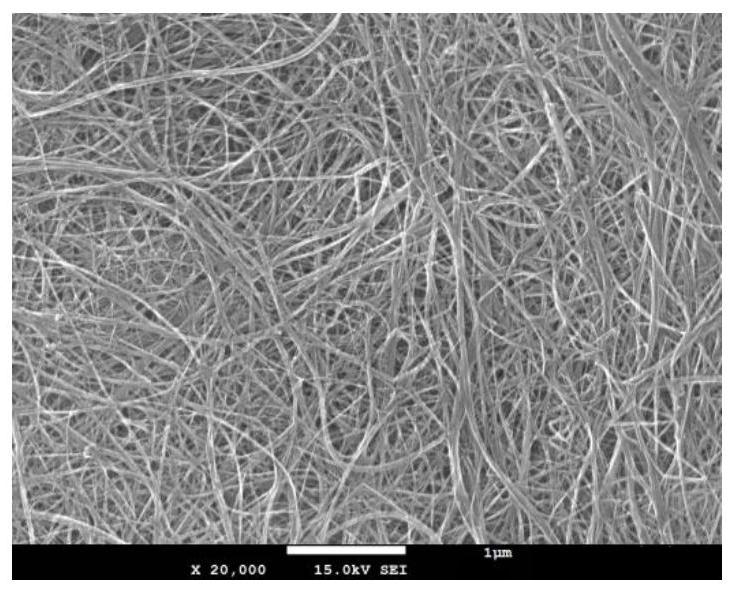

[0026] First, the strip-shaped CNT film electrodes were cleaned with concentrated nitric acid and dried for later use; then two pieces of CNT strip-shaped electrodes were adhered to the PVA-H 3 PO 4 The two sides of the solid electrolyte diaphragm are slightly compacted so that the electrodes and the diaphragm are in close contact with each other, so that a strip-shaped flexible all-solid supercapacitor is obtained. Four more strip-shaped supercapacitors were taken, and according to the design of the parallel structure, they were cross-woven into the required supercapacitor fabric for higher energy storage. The parallel weaving method described in this process is shown in the attached figure 1 For a, see the improvement effect on storage energy figure 2 , it can be seen that the increase of the covered area of the curve will increase the capacitance and thus the stored energy. The morphology of the CNT used is shown in image 3 .

Embodiment 2

[0028] First, the capacitive active material MnO was deposited by electrochemical deposition 2 Deposited on the CNT film after cleaning and drying with concentrated nitric acid to prepare flexible composite electrodes, and then assembled with PVA-KOH gel electrolyte diaphragm to form a strip-shaped all-solid supercapacitor. Six such strip-shaped supercapacitors were taken, and according to the design of the parallel structure, they were cross-woven into the required supercapacitor fabric for higher energy storage. See the woven supercapacitor fabric in kind Figure 4 .

Embodiment 3

[0030] First, polyaniline (PANI) was deposited onto the graphene film by electrochemical polymerization to prepare a flexible composite electrode, and then combined with PVA-H 2 SO4 The gel electrolyte separators are assembled together into a strip-shaped all-solid-state supercapacitor. 32 strip-shaped supercapacitors were taken, and according to the design of the series structure, they were cross-woven into the required supercapacitor fabric to obtain a higher operating voltage. Further, a layer of polyester tulle is laid on the upper and lower surfaces of the capacitor fabric, and the edges and insides of the two layers of tulle (corresponding to the intersections of each strip capacitor) are sewn together to reduce the wear and tear of the supercapacitor unit , cut off the direct contact with the wearer, and increase the service life of the supercapacitor fabric.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com