Joint method, joint construction and assembly parts

A joining method and joining structure technology, which can be applied to corner joints/edge joints, etc., can solve problems such as the increase in the amount of metal materials used, and achieve the effects of ensuring joint strength, improving joint strength, and reducing processing time and workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

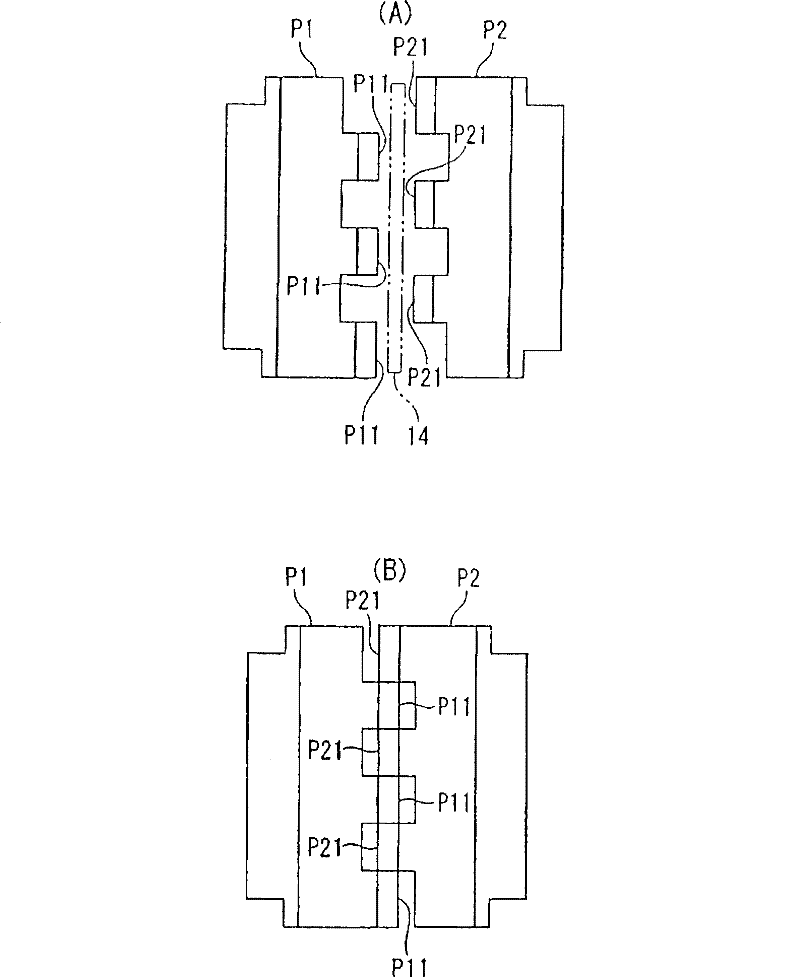

[0037] Hereinafter, various embodiments of the present invention will be described with reference to the drawings.

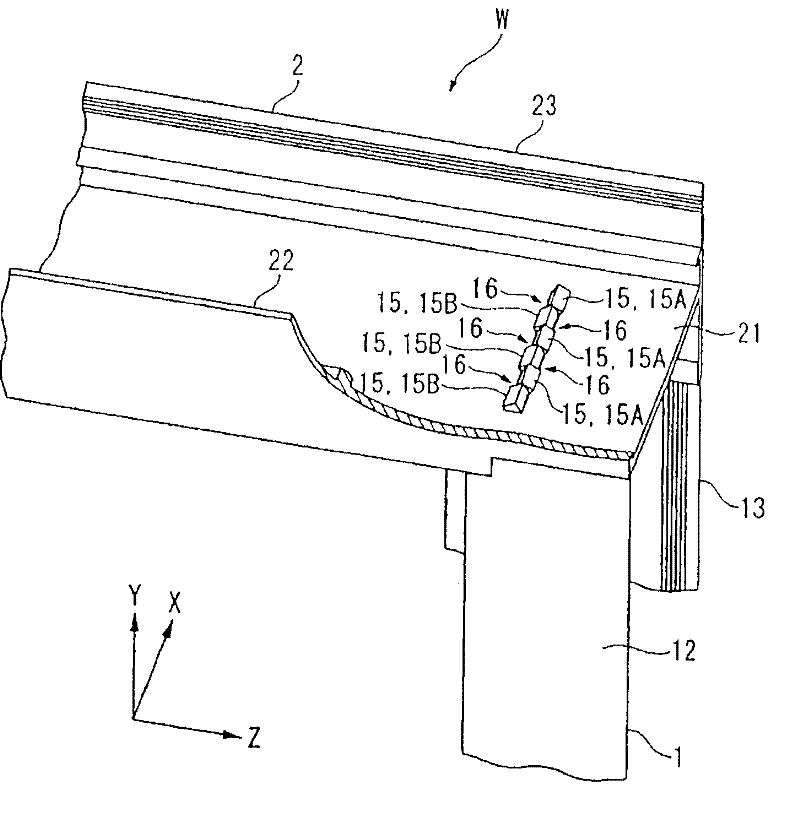

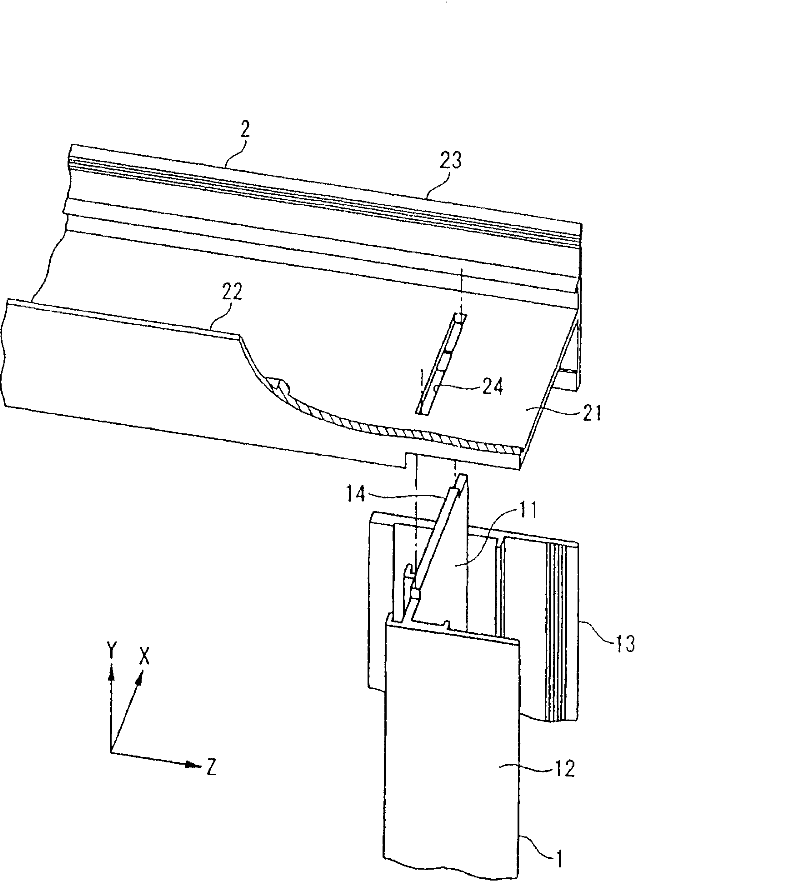

[0038] figure 1 It is a perspective view showing main parts of a window frame W constituting the fitting according to the present invention. figure 2 It is a perspective view showing the state before the window frame W is assembled into a frame.

[0039] exist figure 1 , figure 2 Among them, the window frame W as a frame body is configured to be installed on the outer wall of a building, etc., to support a sliding door or a fixed plate (not shown) inside to form a sash window, and the upper frame and the lower frame of the aluminum profile And the surrounding frames of the left and right vertical frames are combined and constituted.

[0040] Among them in figure 1 , figure 2 In , as an example, among the upper frame, the lower frame, and the left and right vertical frames, one end of the upper frame 1 as one member to be joined and the upper end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com