Copper-platinum alloy wire for connecting in semiconductor apparatus

A platinum alloy and semiconductor technology, which is applied in the field of copper-platinum alloy wire, can solve instability and other problems, and achieve the effect of preventing chip cracking and not improving dynamic strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] As Examples 1 to 30 and Comparative Examples 1 to 6, copper alloy thick wires each having a diameter of 5 mm were produced by melting alloys of the compositions shown in Table 1 and performing continuous casting.

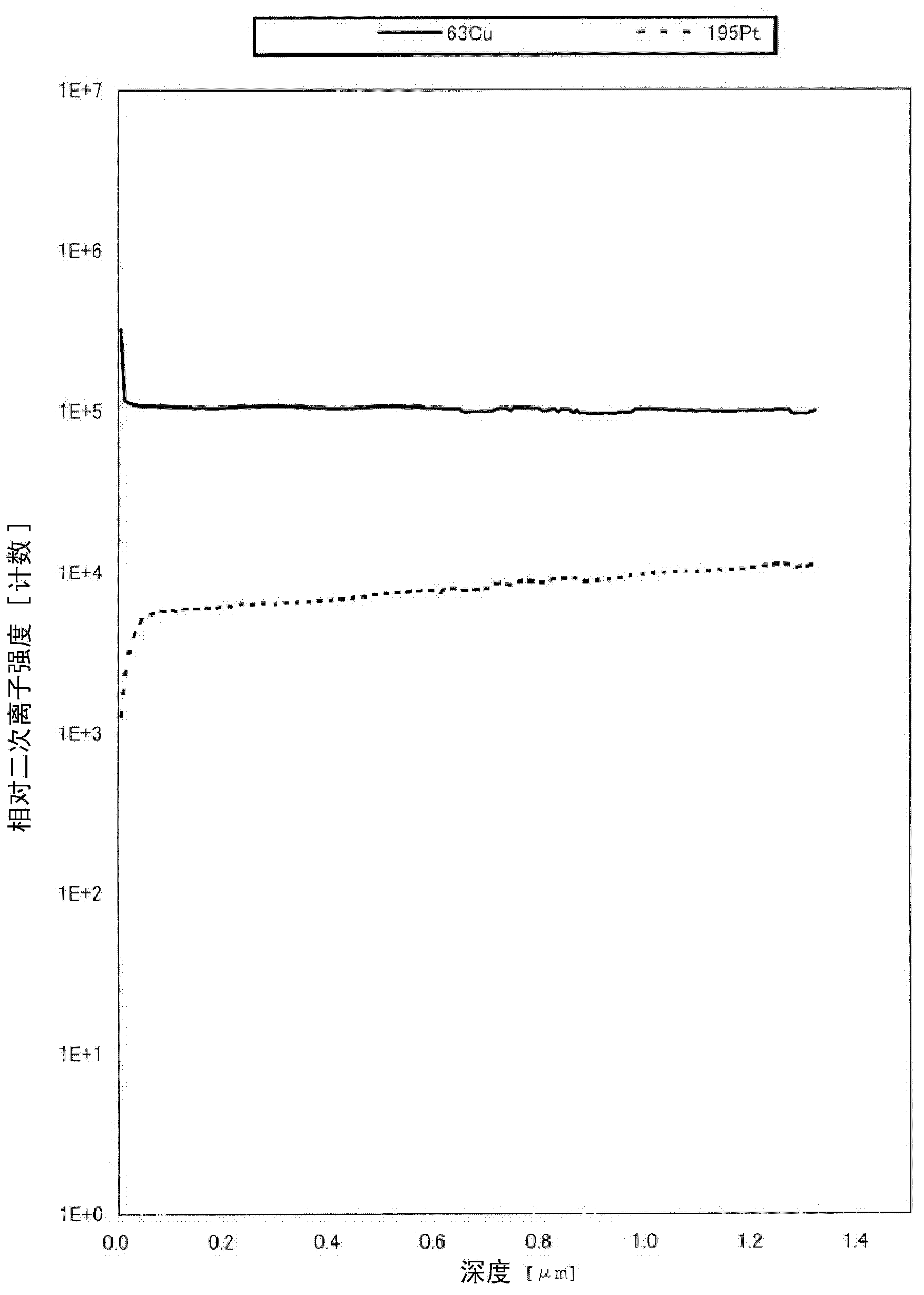

[0055] By the surface of the copper-platinum alloy thick wire of embodiment 1, measure platinum (Pt) and copper (Cu) by SIMS mass spectrometer respectively ( figure 1 ) and the concentration of oxygen (O). The horizontal axis of the graph represents the depth (μm) from the surface of the thick line, and the vertical axis represents the relative secondary ion intensity (log) of the depth.

[0056] according to figure 1 , platinum (Pt) is absent on the surface layer, and up to 50 nm, platinum (Pt) has a lower relative secondary ionic strength than the solid solution matrix. In contrast, it is apparent that copper (Cu) has a significantly higher purity near the surface.

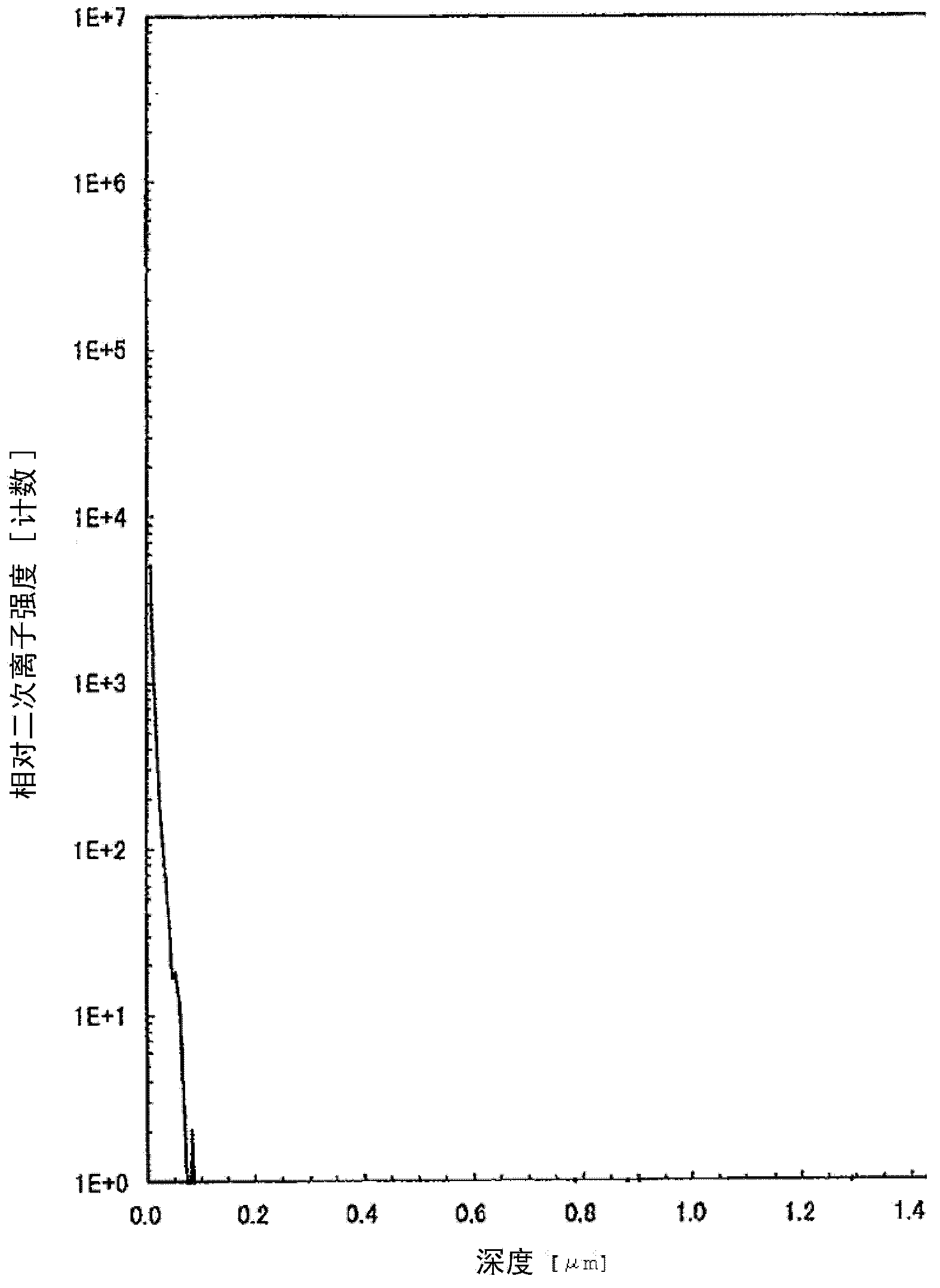

[0057] according to figure 2 , oxygen (O) decreases linearly from the surface layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com