Double-head tenon joint tension test structure without additional bending moment

A technology of tensile test and additional bending moment, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of low efficiency, difficult processing, and the efficiency of additional bending moment test, so as to improve accuracy and eliminate The effect of additional bending moment and convenient design of loading scheme

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In the following, the technical scheme of a double-tenon tenon joint tensile test structure without additional bending moment of the present invention will be further explained in combination with the accompanying drawings and specific test cases.

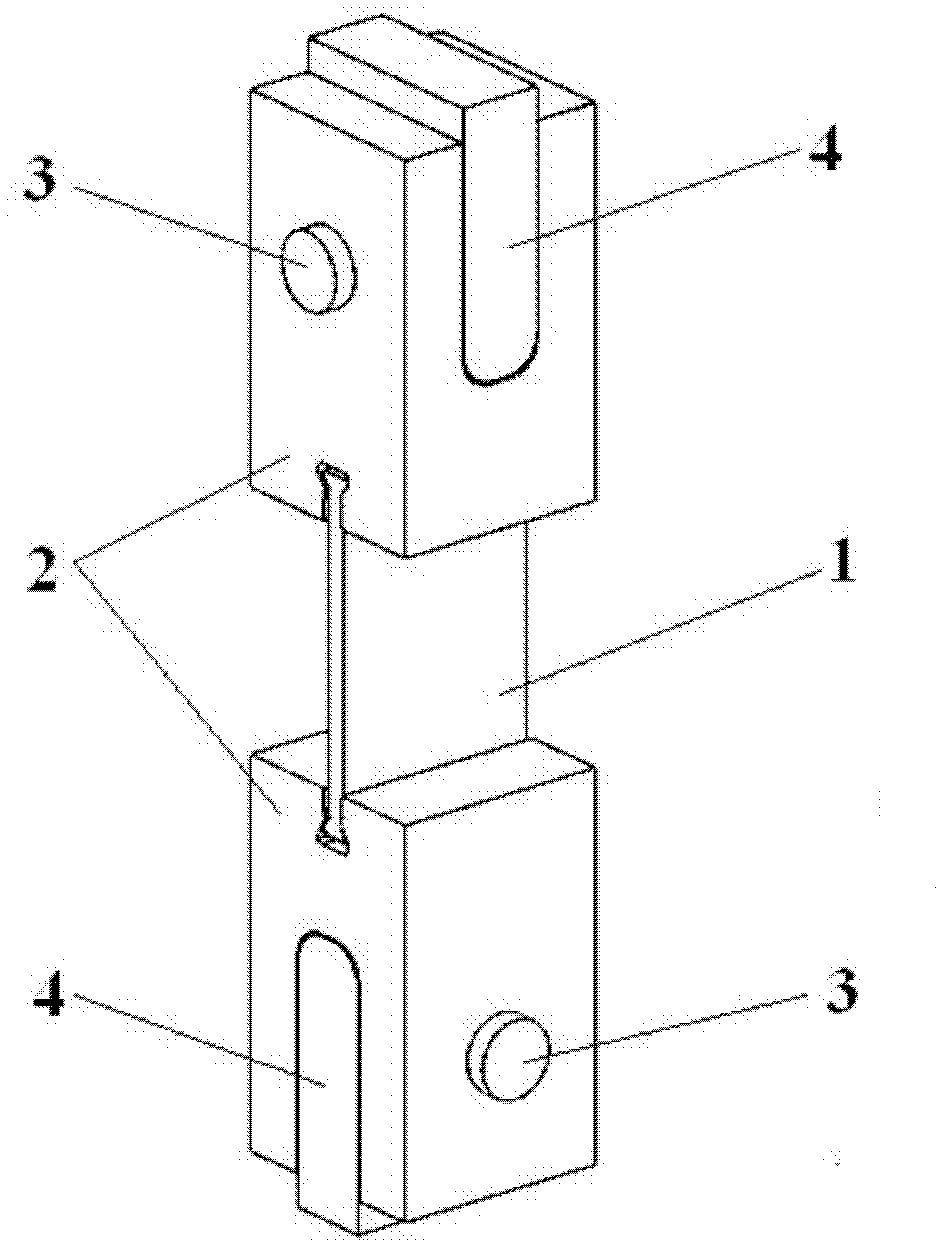

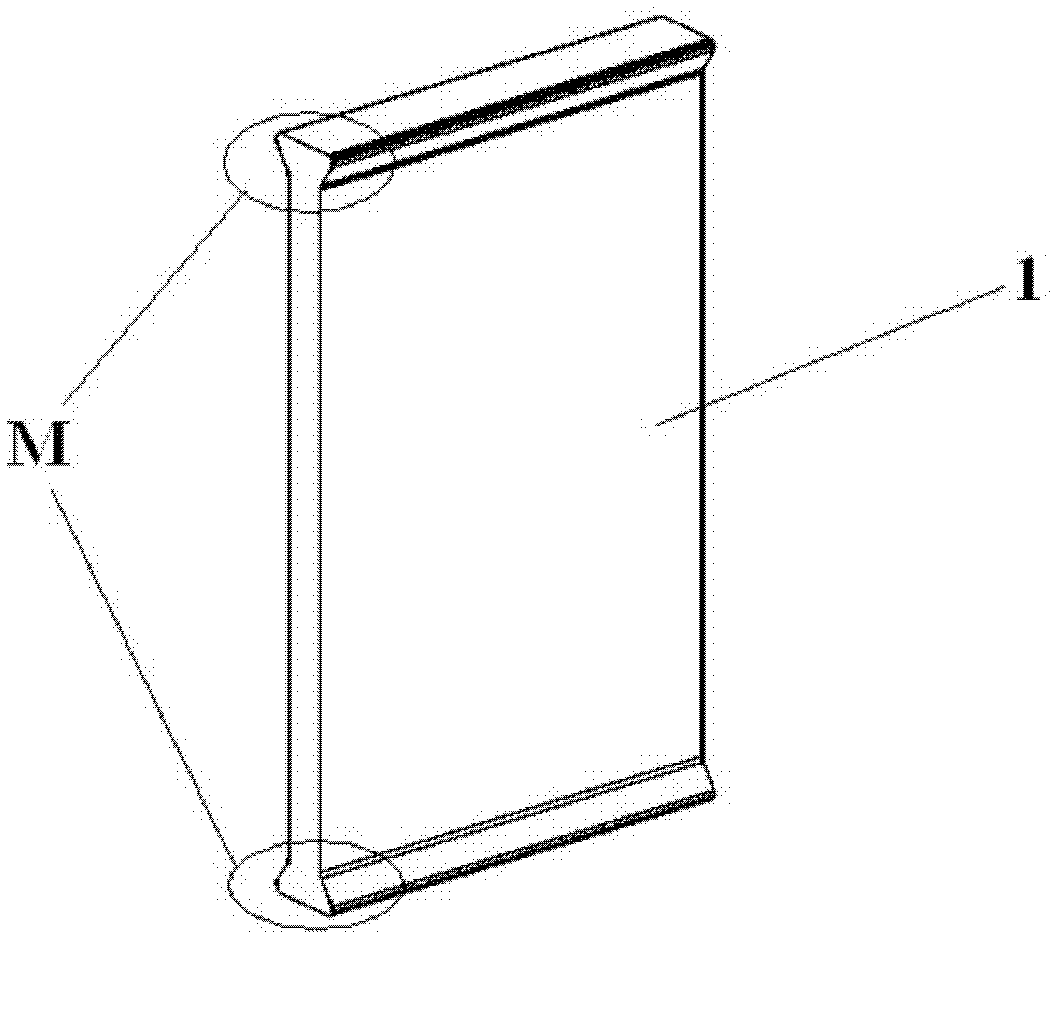

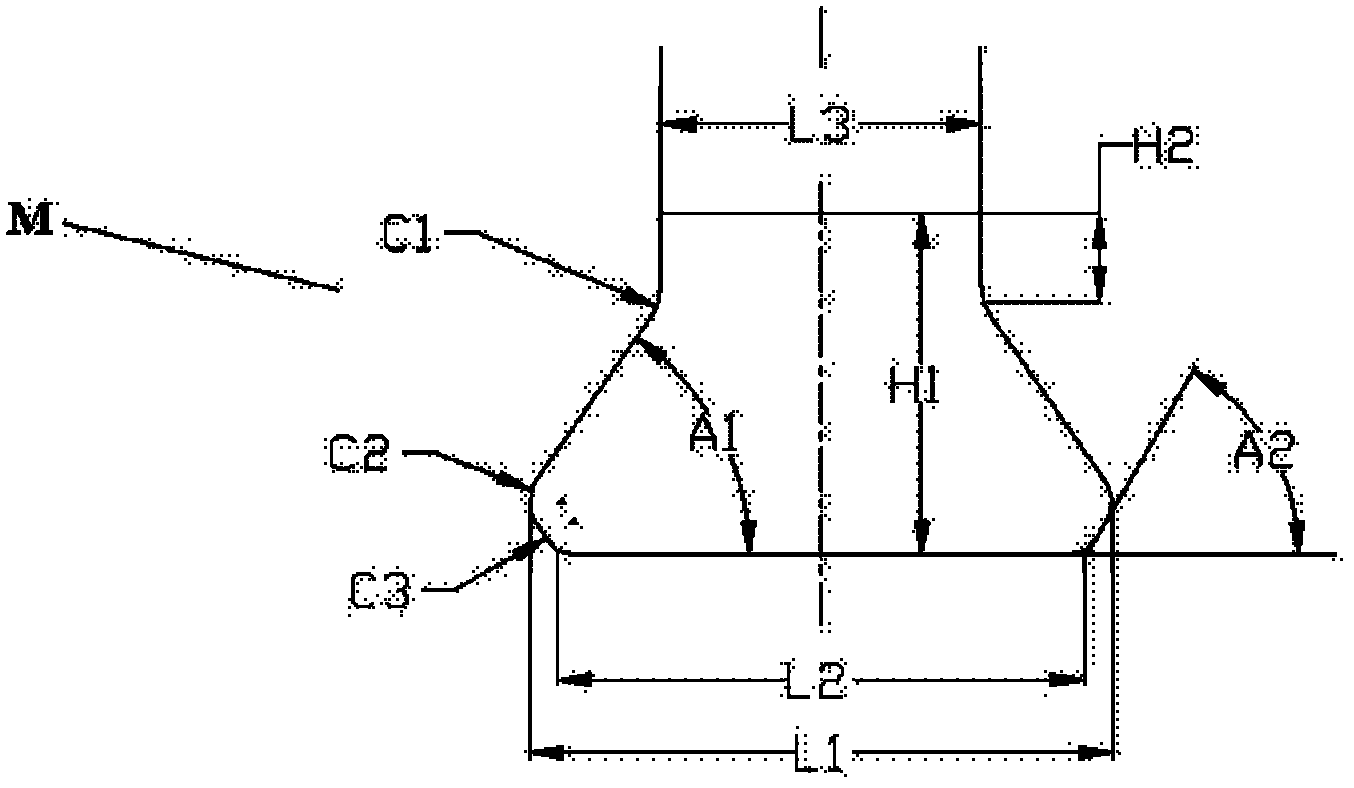

[0041] A new technical scheme adopted by the present invention to solve the problems of the prior art by a double-head tenon connection tensile test structure without additional bending moment is realized in this way: the test structure consists of a blade test piece 1, a fixture 2, a pin 3 and a Force piece 4 constitutes, such as figure 1 As shown, the positional connection relationship between them is: when the test is carried out, the tenon at both ends of the blade test piece 1 is clamped in the tenon groove of the fixture 2, and the fixture 2 is connected with the force-bearing parts 4 at both ends through the pin 3. The pins 3 are respectively perpendicular to the axis of the blade test piece 1 and distributed orthogon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com