Two-stage fully-differential low-noise low-offset chopping operational amplifier

An operational amplifier and low-noise technology, which is applied in the field of two-stage fully differential low-noise and low-offset chopper operational amplifiers, can solve the problems of switching noise residual, complex circuit structure, and low chopping frequency, etc., and achieve low offset voltage and low noise , expand the output range, increase the effect of the bandwidth range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

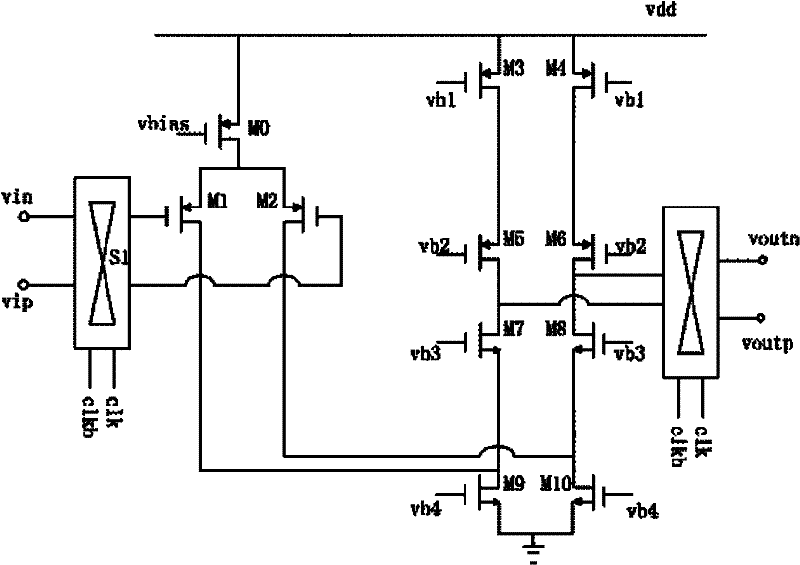

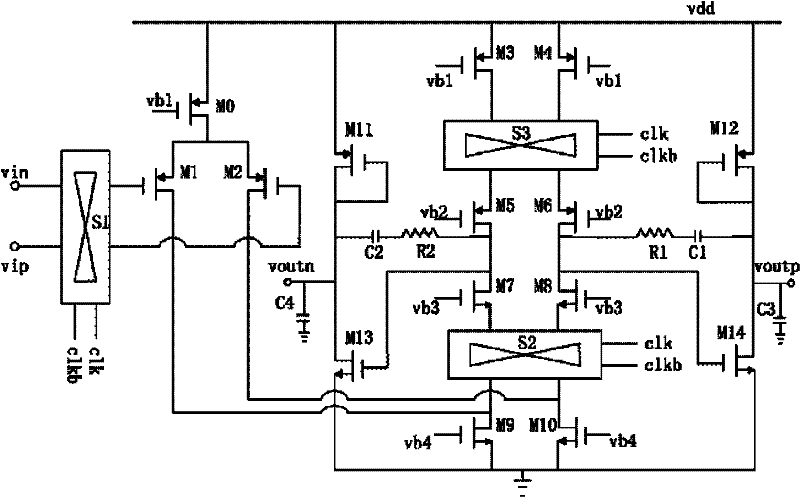

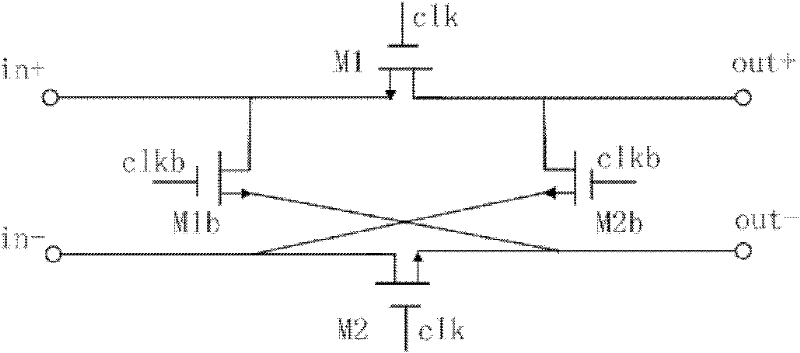

[0022] see figure 2 , the two-stage fully differential low-noise low-offset chopper operational amplifier of the embodiment of the present invention includes three choppers S1, S2, S3 and a two-stage folded cascode operational amplifier. see image 3 , choppers S1, S2, S3, composed of four NMOS transistors M1, M1b, M2, M2b controlled by two-way non-overlapping clocks, horizontal NMOS transistors M1, M2 and vertical NMOS transistors M1b, M2b are alternately turned on, similar to Because of the function of the multiplier, it multiplies the clock signal, that is, the chopping signal and the input signal, and completes the function of modulating the input signal to the frequency of the chopping signal.

[0023] The chopper S1 first modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com