Implantable blood pump adopting driven suspension bearing

A suspension bearing and implantable technology, applied in suction devices and other directions, can solve the problems of complex mechanical structure, complicated control method and large volume of magnetic suspension blood pump, and achieve reduced energy input, less bearing wear and less heat generation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

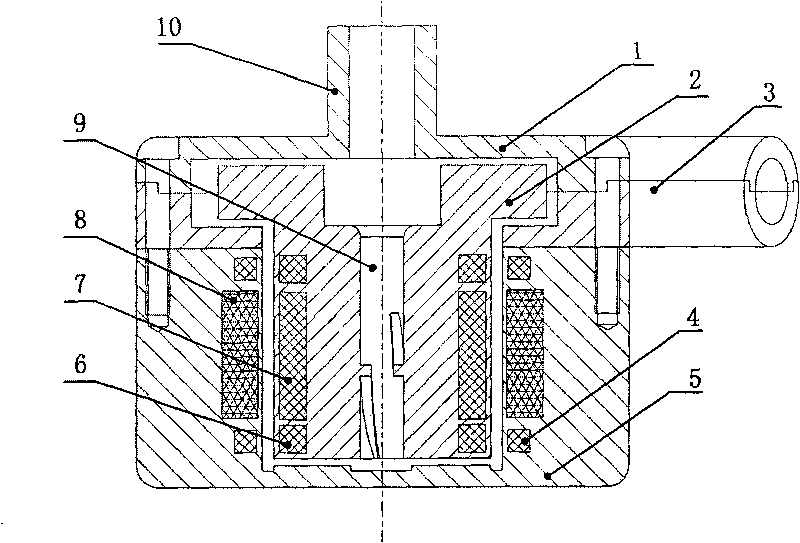

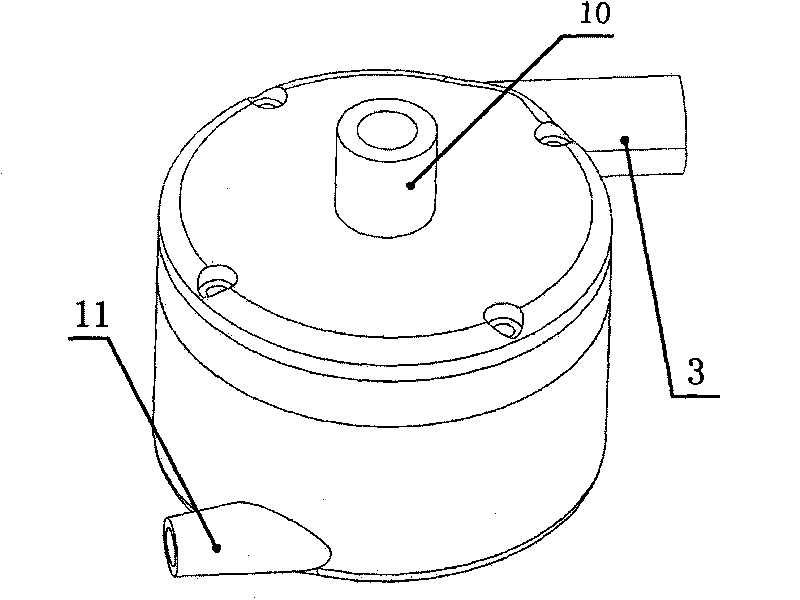

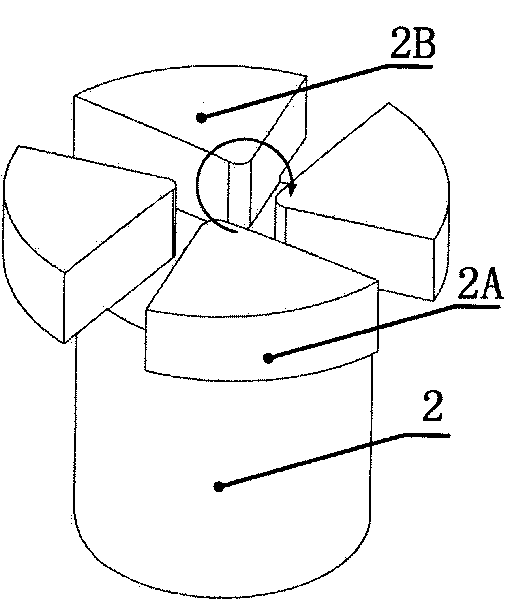

[0027] Such as figure 1 As shown, the present invention comprises pump upper case 1 and pump lower case 5, T-shaped rotor 2, suspension permanent magnet outer ring 4 and suspension permanent magnet inner ring 6, driving permanent magnet magnetic ring 7 and Drive the electromagnetic coil 8; insert the T-shaped rotor 2 with a drainage groove in the inner hole between the pump upper shell 1 and the pump lower shell 5, and the big end of the T-shaped rotor 2 is 4, 6 or 8 blades with an angle The impeller is composed of a driving electromagnetic coil 8 embedded around the inner wall of the pump lower casing 5, a floating permanent magnet outer ring 4 is embedded symmetrically up and down on the driving electromagnetic coil 8 of the inner wall of the pump lower casing 5, and a driving permanent magnet is embedded around the outer ring of the T-shaped rotor 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com