Detection assembly line used for comprehensive performance testing of adjusting arm

A comprehensive performance and arm adjustment technology, which is applied in the direction of measuring devices, vehicle testing, machine/structural component testing, etc., can solve the problems of brake lining wear, brake drum and brake shoe brake clearance increase, Problems such as extended brake pedal travel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

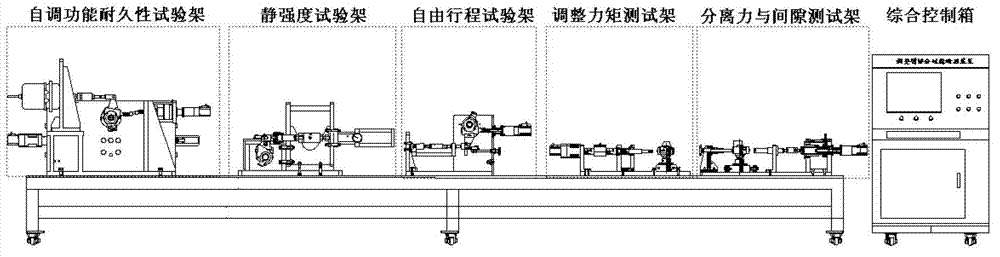

[0036] Such as figure 1 As shown, the self-adjusting function durability test frame, the static strength test frame, the free travel test frame, the adjustment moment test frame, and the separation force and gap test frame are fixed sequentially on the large support platform. Each test frame on the support seat is used to detect the test task of the specified item of the adjustment arm respectively. The integrated control box is placed on the right side of the support base, and the integrated control box and the support base communicate with the test device on the large support base through cables. The integrated control box is composed of PC, data acquisition system, motor drive system, signal conditioning system and other electrical auxiliary systems. The integrated control box is used to control the test tasks of each test frame on the support base, receive various test data, and judge whether the performance parameters of the adjusting arm are qualified.

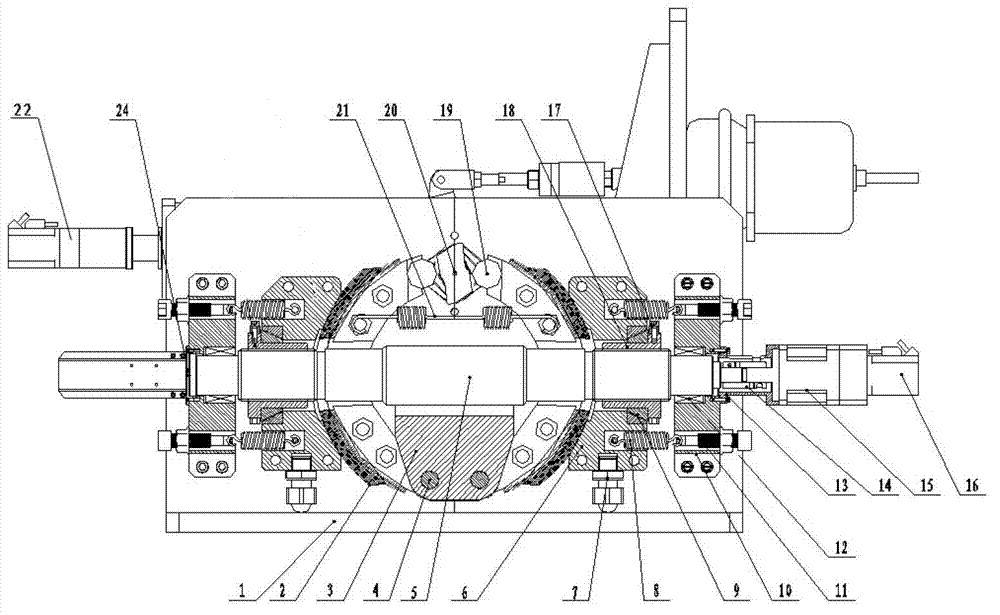

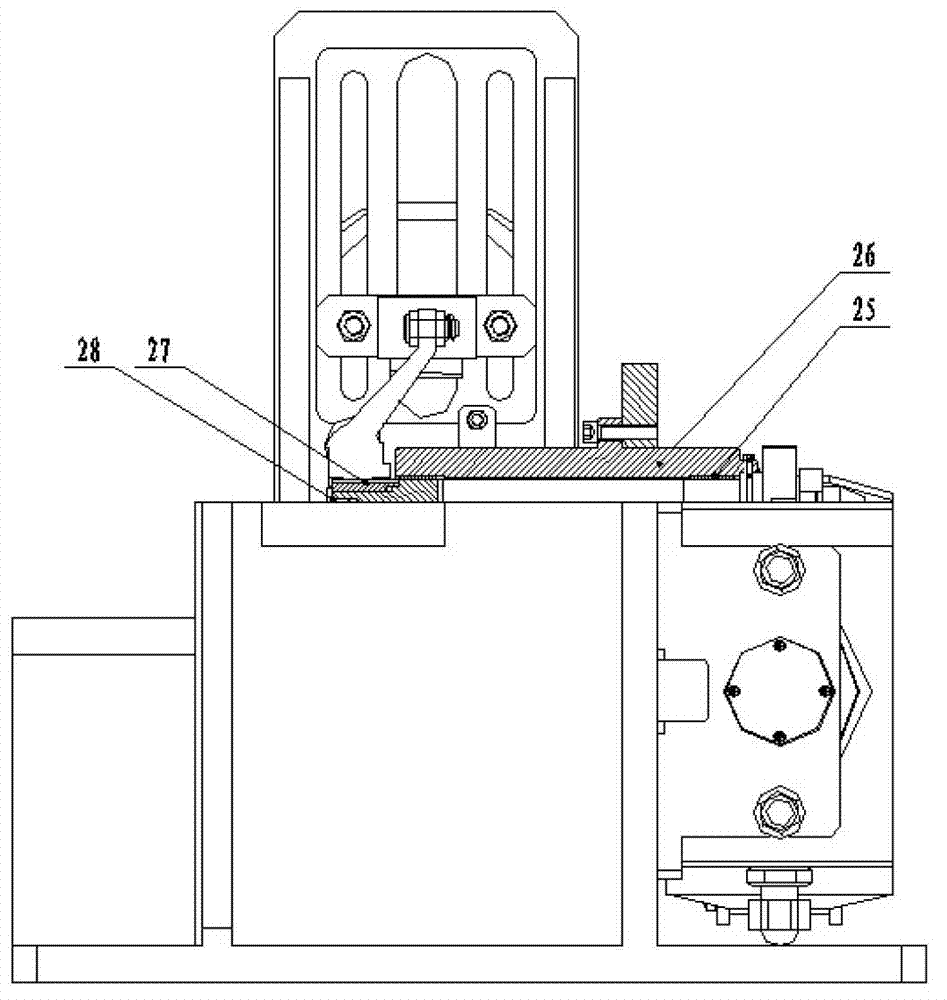

[0037] Such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com