Circuit board and thermal printing head using same

A thermal printing head, circuit substrate technology, applied in the direction of printed circuit, printed circuit manufacturing, printed circuit components, etc., can solve the problems of wire bonding strength (low tensile strength, reliability cannot be ensured, etc., without reducing the lead wire Effects of joint strength, reduction of unit consumption, and reduction of power costs for firing furnaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] In this example, 22K gold (composition: organic gold) was used as the low-purity gold layer, and 24K gold (composition: organic gold) was used as the high-purity gold layer to prepare and test three samples.

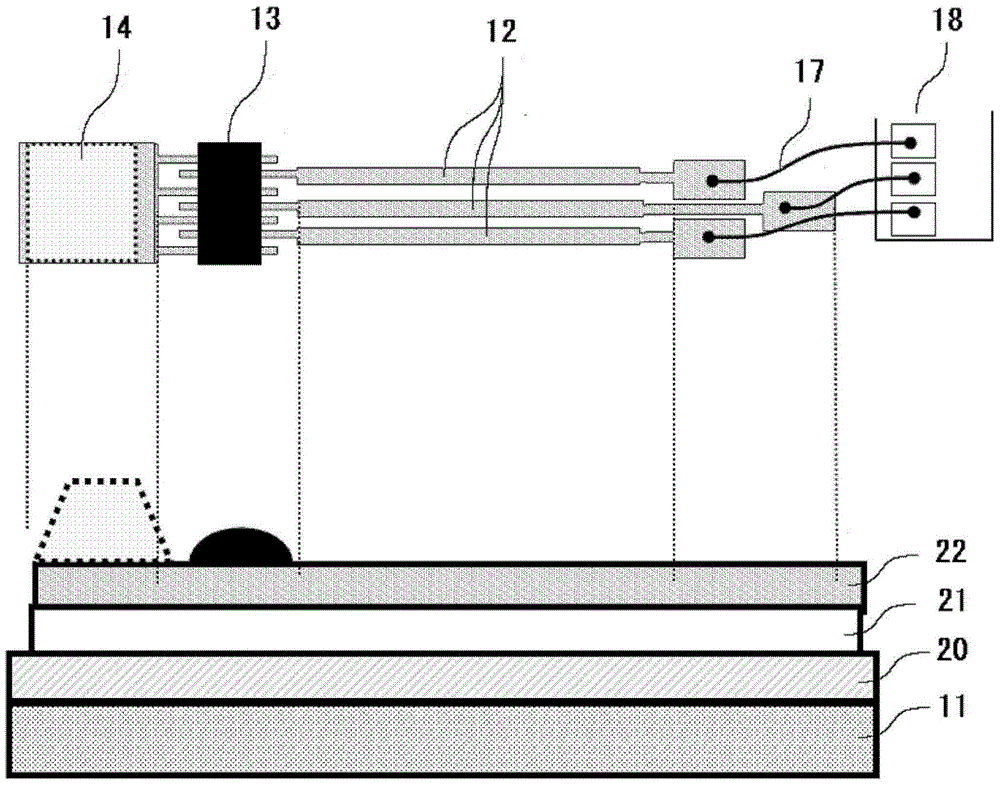

[0069] Make Figure 7 Sample of the configuration shown.

Embodiment 2

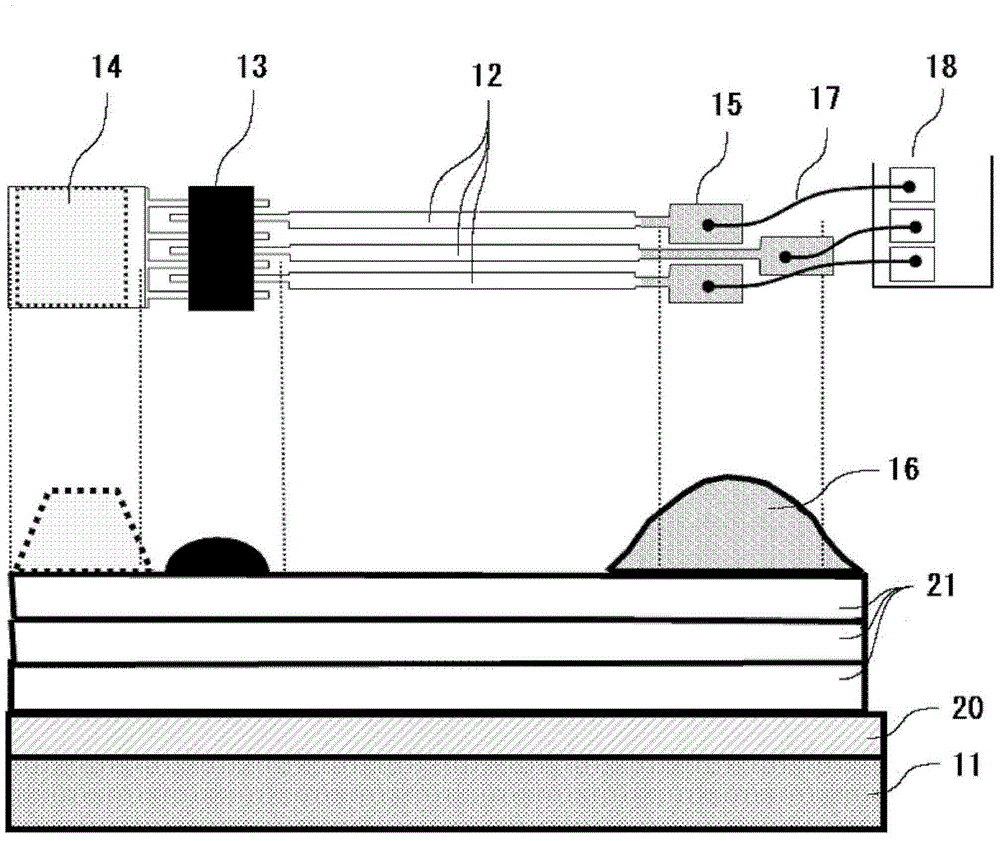

[0078] Comparing the hot spots through the above three samples ( figure 2 Of 13) Impulse resistance.

[0079] The test method is described below. Show the test results in Figure 4 .

[0080] Figure 4 Indicates at the wire bonding part ( figure 2 Of 15) with the common electrode ( figure 2 The correlation between the voltage when the pulse voltage is applied (pulse voltage) and the resistance value of the heating point between 14). From this test result, it is judged that it is not inferior to Comparative Example 1 (conventional) in pulse resistance.

Embodiment 3

[0082] With respect to the example of the present invention produced in Example 1, the wire bondability was evaluated. After the alloy lead was connected to the surface of the high-purity gold layer of Example 1, the tensile strength was measured and shown in Table 1. It can be seen that the tensile strength is stable even in a state where the wire bonding conditions vary in a wide range.

[0083] [Table 1]

[0084] Comparison of tensile strength of gold wire bonding part (N=30 wires)

[0085]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com