Patents

Literature

34results about How to "Stable grade" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

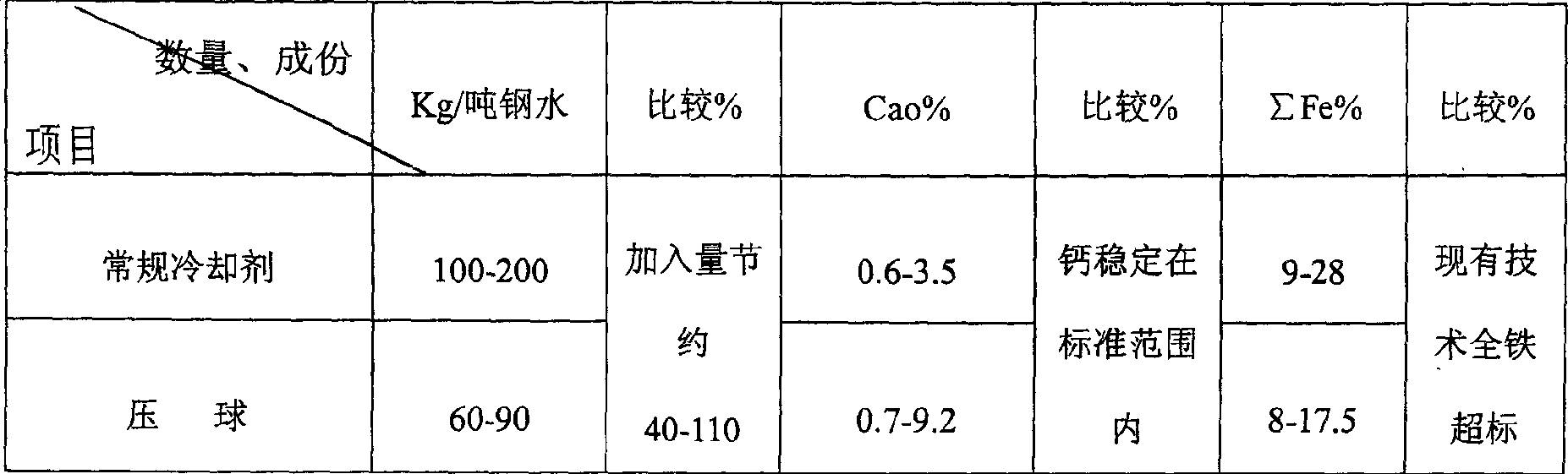

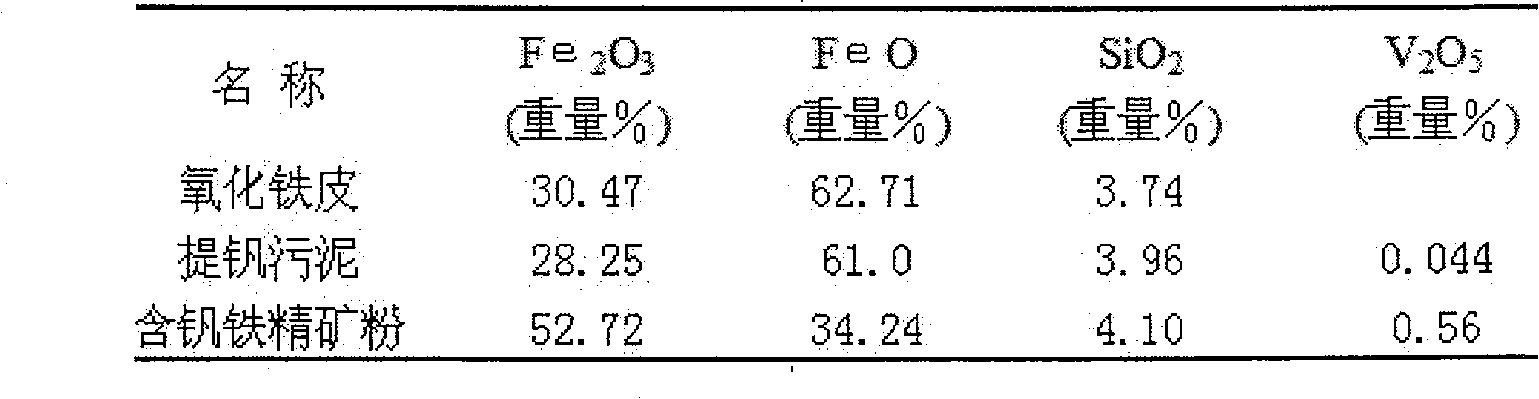

Molten iron vanadium-extracting calcium-controlling coolant and process therefor

The invention relates iron melt improving vanadium content and controlling calcium content cooling agent and the technology, specially relates the cooling agent of adjusting the proportion of cooling agent to stabilize calcium content in vanadium slag and the technology. The technology comprises the 56-60wt% iron scale, 30-40wt% iron concentrate powder containing vanadium, and 5-10wt% anchoring agent. The method stabilizes the calcium content and iron content in vanadium slag, and effectively solves the problems of great fluctuation of vanadium slag composition and superstandard calcium and iron. By controlling the thermoregulation material to meet the requirements of the improving vanadium temperature and calcium oxide content, the method improves the vanadium slag grade and extraction rate. The invention possesses the following characteristics: 1 shortening the converting time; 2 improving the vanadium slag grade and extraction rate, and stabilizing the calcium oxide content; 3 reducing the iron loss.

Owner:HEBEI LUANHE IND GROUP

Technique for separating mineral from weak magnetic separation iron tail sand

InactiveCN101219412AProduction process specificationLow costElectrostatic separationFlotationApatiteNon magnetic

The invention relates to a method used for separating minerals from weak magnetic iron tails, which is divided into six stages: primary sorting of strong magnetic minerals, separation of strong magnetic minerals, separation of weak magnetic minerals, separation of non-magnetic minerals, treatment of ore pulp water during the ore dressing process and treatment of finish tail sand. According to the magnetic susceptibility differences, specific gravitydifferences and floating differeces between minerals, magnetite, vanadium titano-magnetite, mixed ore of apatite and xenotime and hematite feldspar concentrate can be separated from the weak magnetic iron by using techniques of crude separation with a strong magnetic separator, refine separation with a weak magnetic separator, gravity separation, floatation, electric separation, etc. The method has advantages of standard production technique, low cost for industrialized production, great variety of separated minerals, stable quality and high separating efficiency, thereby having significant social and economic benefits.

Owner:冯云善

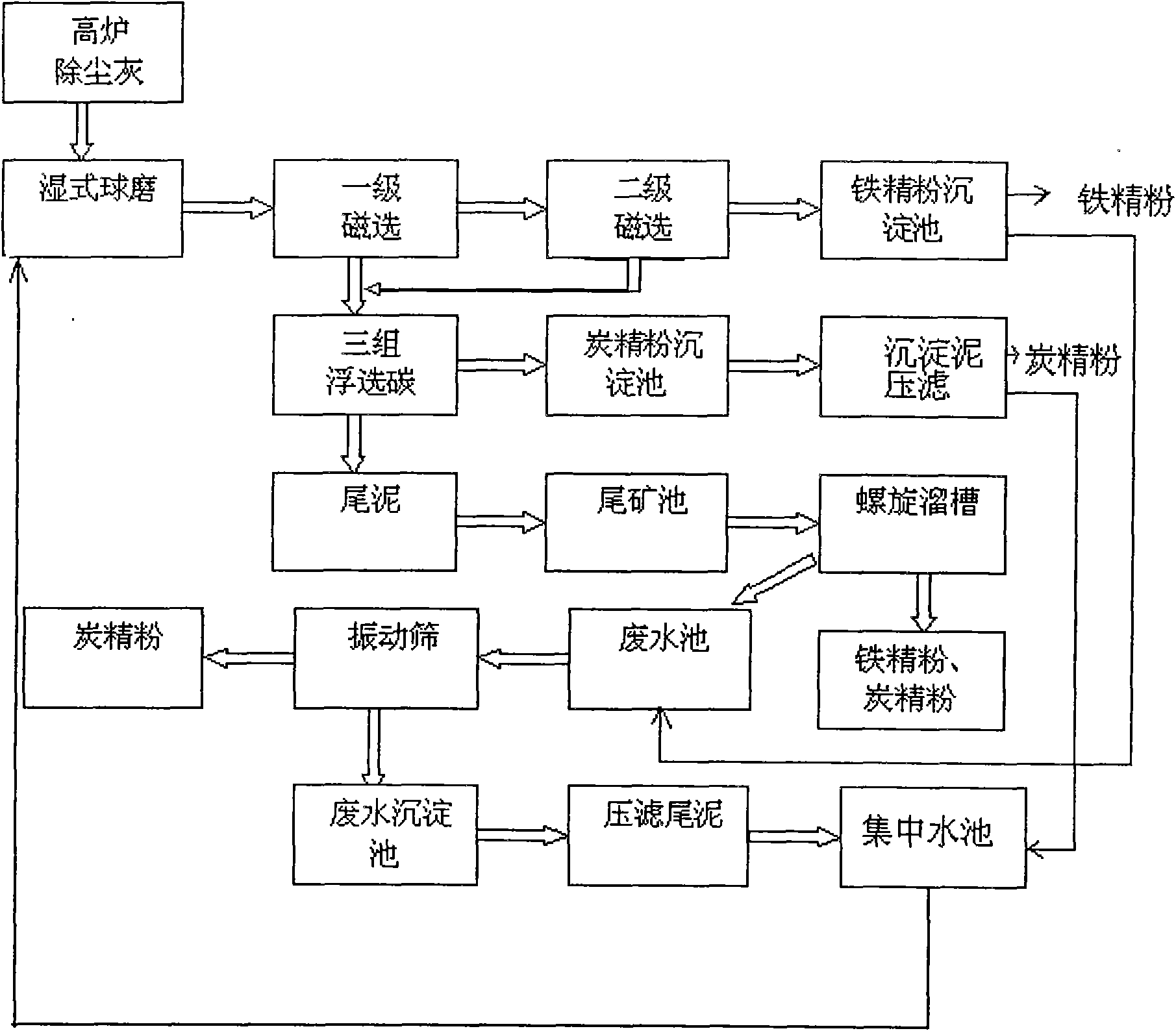

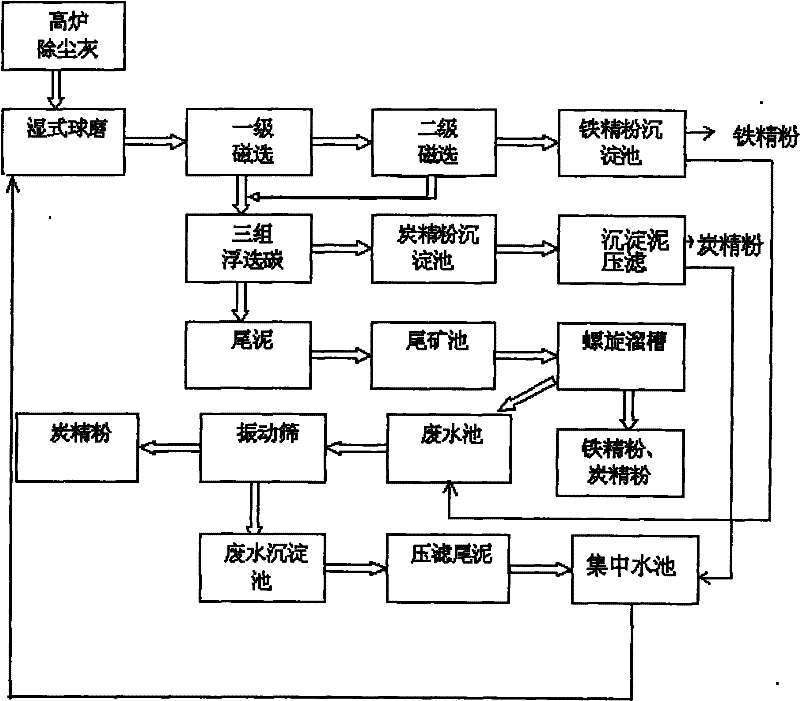

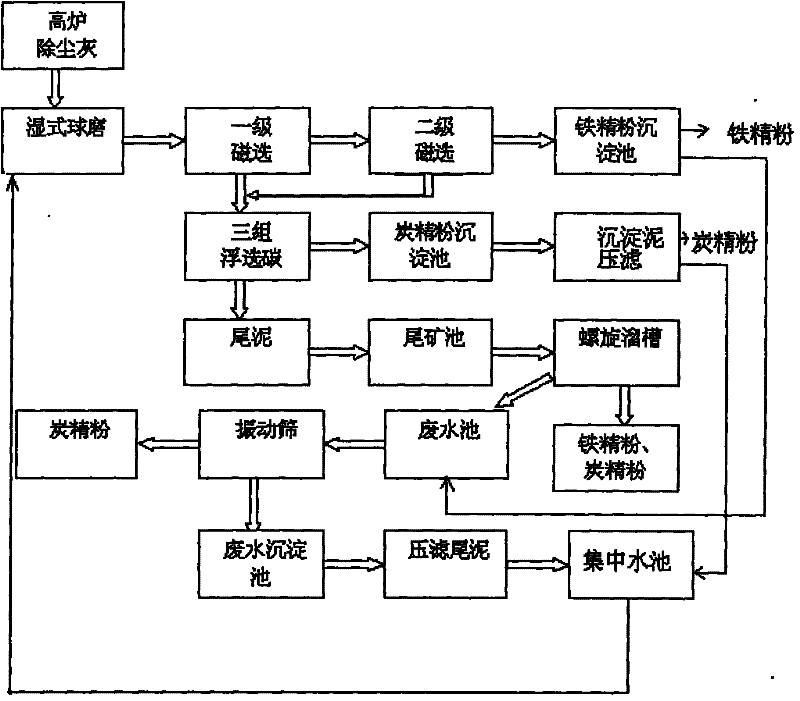

Comprehensive treatment method of blast furnace dedusting ash

InactiveCN101654717AReduce dosageLow costRecycling and recovery technologiesProcess efficiency improvementIonWaste treatment

The invention discloses a comprehensive treatment method of blast furnace dedusting ash, belonging to the technical field of the waste treatment. The method comprises the following steps: adding waterin blast furnace dedusting ash for mixing, performing secondary magnetic separation, performing flotation, in the tailings treatment using a spiral chute to separate iron refined powder and carbon refined powder, screening to recycle the carbon refined powder in the wastewater which is obtained in the step of spiral chute ion-removing and performing filter pressing to the obtained wastewater forrecycling. The method can greatly increase the selection yield and grade of the iron refined powder and carbon refined powder, can also avoid to produce new pollution, protect the environment and recycle waste material.

Owner:山东泰山焦化有限公司

Production method for as-cast high-performance ductile iron QT600-10 by precision-investment casting

ActiveCN105861917ALightweight design and developmentLightweight productivityFoundry mouldsFoundry coresInvestment castingDuctile iron

The invention provides a production method for as-cast high-performance ductile iron QT600-10 by precision-investment casting, wherein a matrix of the as-cast high-performance ductile iron QT600-10 is a mixture of ferrite and pearlite; the pearlite accounts for 35%-55%, the nodulizing grade ranges from grade I to grade II, and the size of graphite ranges from grade VI to grade VII; the material comprises the following final chemical components in percentage by mass: 3.3-3.6% of C, 2.8-3.0% of Si, 0.2-0.4% of Mn, less than or equal to 0.035% of P, less than or equal to 0.02% of S, 0.4-0.6% of Cu, 0.035-0.055% of Mg, 0.02-0.04% of RE and the balance Fe; and a dam type nodulizing treatment and three-time inoculation way is adopted. The produced as-cast high-performance ductile iron QT600-10 has tensile strength Rm greater than or equal to 600 MPa, and elongation after fracture A greater than or equal to 10%. By combining a precision-investment casting production way with a cooling way after shell casting, high-strength high-toughness ductile iron is produced by a precision-investment casting process, so that lightweight design development and production for car parts is realized by virtue of a near net-shape forming process.

Owner:DONGFENG PRECISION CASTING CO LTD

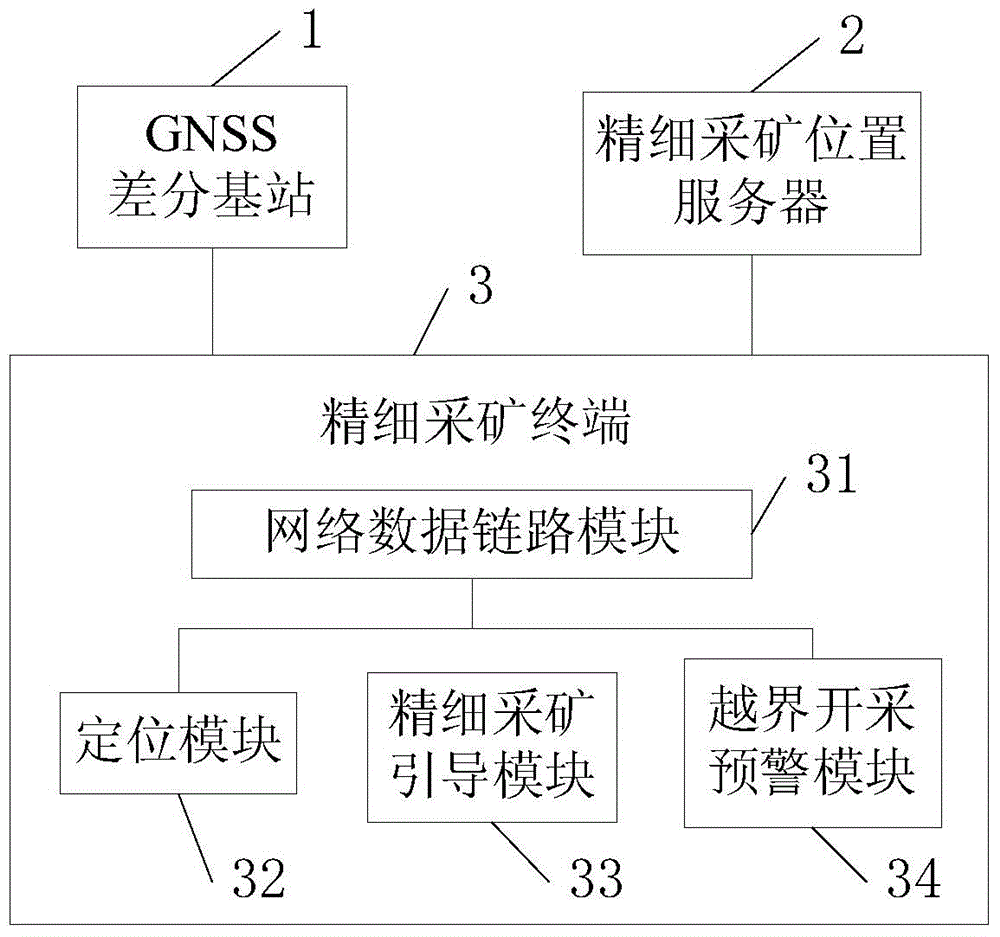

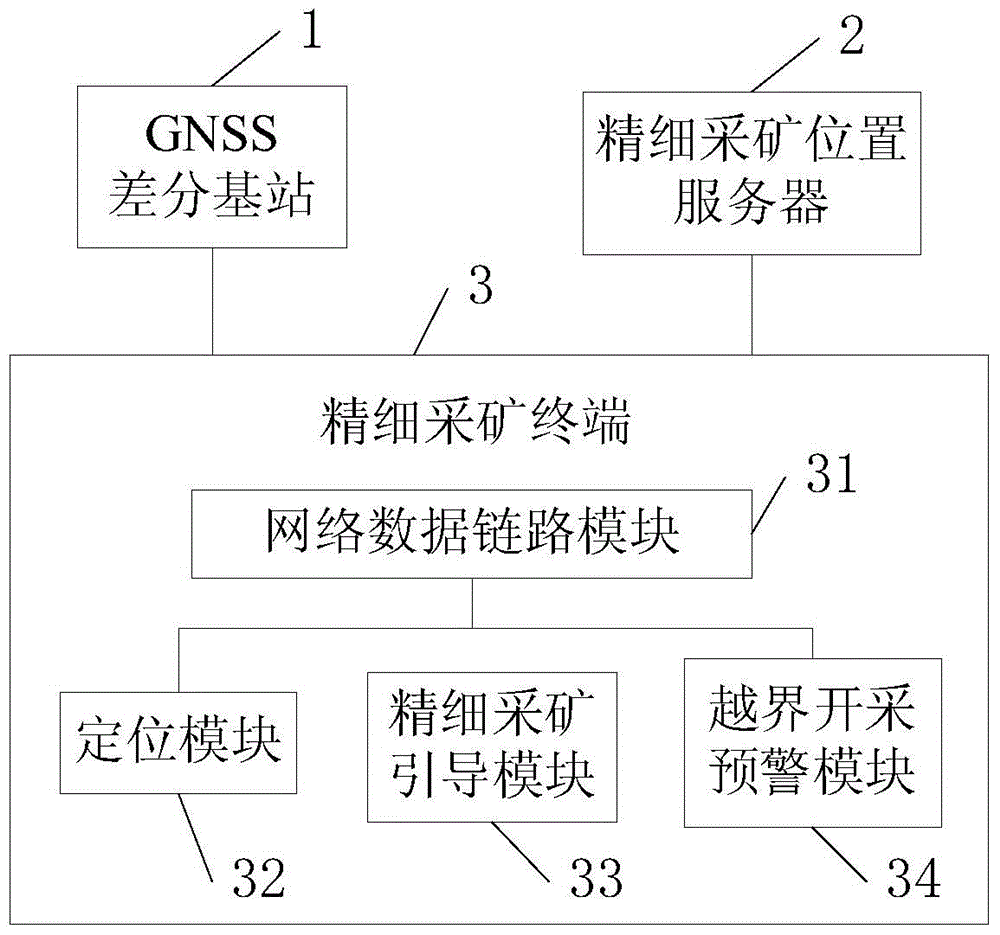

Surface mine fine mining system adopting GNSS (Global Navigation Satellite System) technology and surface mine fine mining method

ActiveCN104533528AIntuitive mine boundary positionPrevent leakageMining devicesUnderground miningComputer terminalMarine navigation

The invention provides a surface mine fine mining system adopting a GNSS (Global Navigation Satellite System) technology and a surface mine fine mining method. The surface mine fine mining system comprises at least one GNSS difference base station, a fine mining position server and a plurality of fine mining terminals, wherein the fine mining position server is internally provided with mine measurement data; and the fine mining terminals are used for calculating to obtain current positions of fine mining terminal scraper pans according to difference correction data provided by the GNSS difference base station and feeding back scraper pan position information to the fine mining position server. By utilizing the surface mine fine mining system, intuitive ore body thickness / depth / quality information is provided, accurate guidance is provided for mining operation of a digging operator, ore body condition is updated in real time, and the surface mine fine mining system also has the effect of early warning cross-border mining behaviors.

Owner:CHINA NONFERROUS METAL CHANGSHA SURVEY & DESIGN INST CO LTD

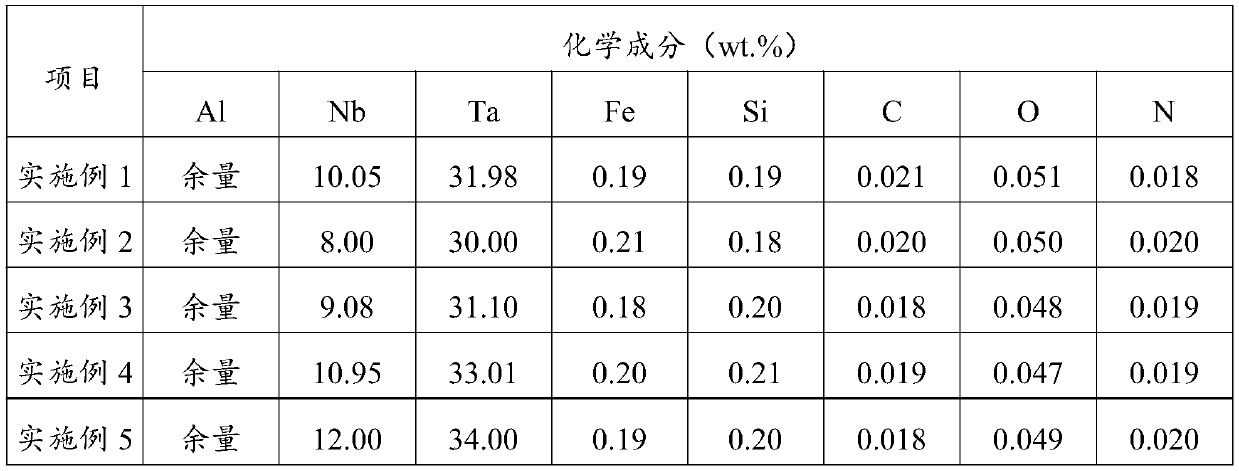

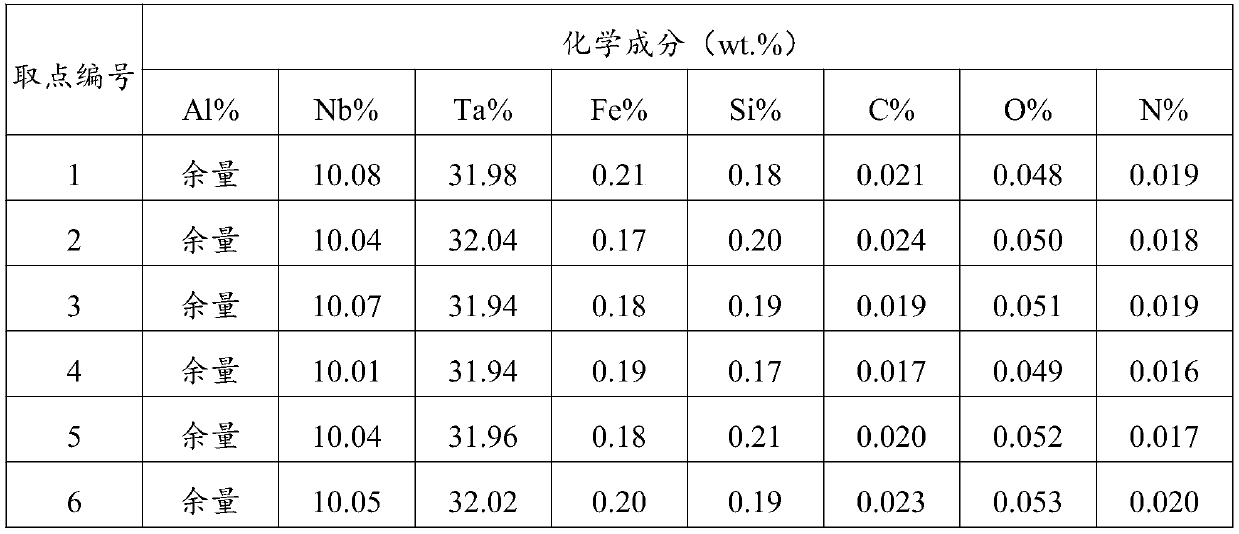

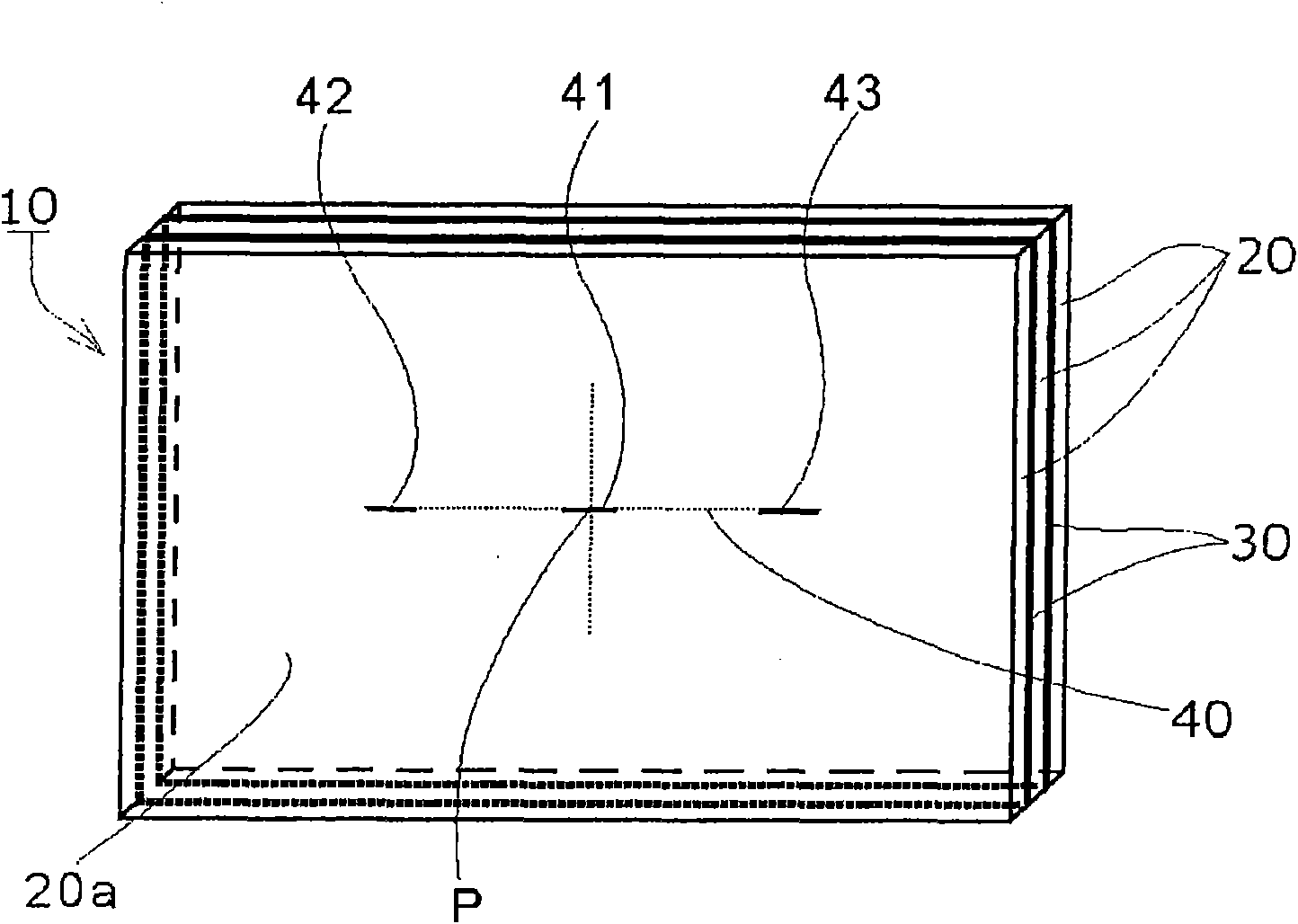

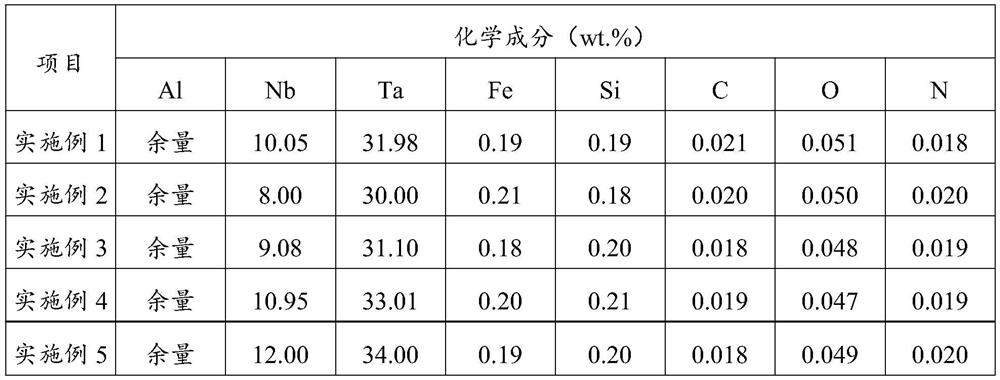

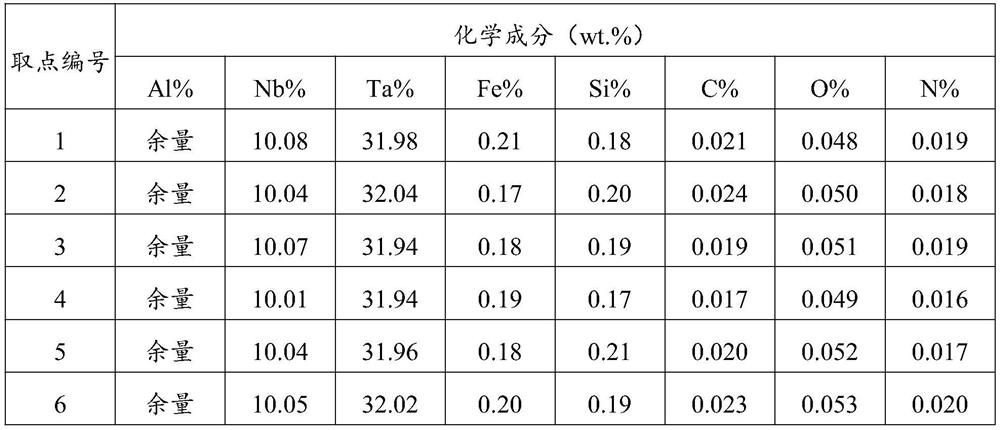

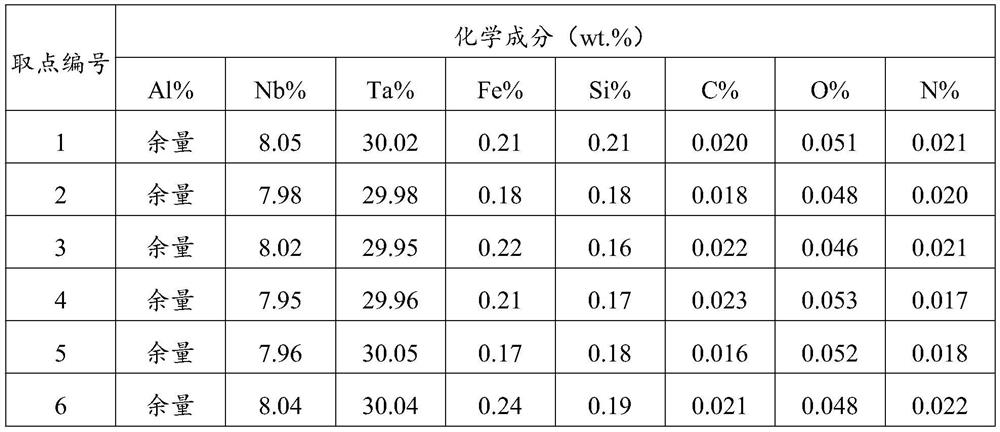

Aluminum-niobium-tantalum intermediate alloy and preparing method thereof

The invention provides an aluminum-niobium-tantalum intermediate alloy and a preparing method thereof and relates to the technical field of metal materials. The aluminum-niobium-tantalum intermediatealloy comprises, by mass, 8.0%-12.0% of Nb, 30.0%-34.0% of Ta and the balance Al. due to component and content control, the components of the aluminum-niobium-tantalum intermediate alloy are uniform,segregation is small, when the titanium alloy is smelted, titanium alloy component homogenization is facilitated, and component segregation is prevented. The preparing method of the aluminum-niobium-tantalum intermediate alloy is provided. The aluminum-niobium-tantalum intermediate alloy is prepared through a two-step method, namely the two steps of the thermit reaction and vacuum smelting are conducted. By means of the preparing method, homogenization stability of the components of the aluminum-niobium-tantalum intermediate alloy can be improved, the content of impurities of O, N and the likeis reduced, and the requirement for titanium alloy production can be better met.

Owner:CHENGDE TIANDA VANADIUM IND

Method for recovering titanium concentrate by strong magnet roughing and multistage spiral chute reselection and concentration

ActiveCN110918250AAvoid compromising tasteImprove equipment efficiencySolid separationSlagIron removal

The invention discloses a method for recovering a titanium concentrate by strong magnet roughing and multistage spiral chute reselection and concentration. The method comprises the following steps that: 1) a high-efficiency concentrator is adopted to concentrate the tailings pulp of low intensity magnetic separation iron in iron tailings in advance to obtain underflow ore pulp; 2) fine silt in theunderflow ore pulp is removed through a sloping plate concentrator to obtain an underflow; 3) coarse slags in the underflow are separated and removed through a high-efficiency linear screen, and thetailings subjected to slag separation can be collected; 4) according to a difference of the specific susceptibilities of the titanium concentrate and a magnetite, a 3000Gs semi-counter-current magnetic separator is selected to carry out iron removal on the tailings subjected to the slag separation in advance, a ferrotitanium intercalated intergrowth body is removed through weak magnetic iron removal, and strong magnetic separation is carried out through a vertical ring pulsating high gradient magnetic separator; and 5) a product obtained in 4) is subjected to multi-time roughing, scavenging and concentration sorting, a material splitting way of spiral chute sorting adopts three-stage annular ore separation device for material splitting, and a final spiral titanium concentrate is obtained through multi-stage spiral chute sorting.

Owner:会理秀水河矿业有限公司

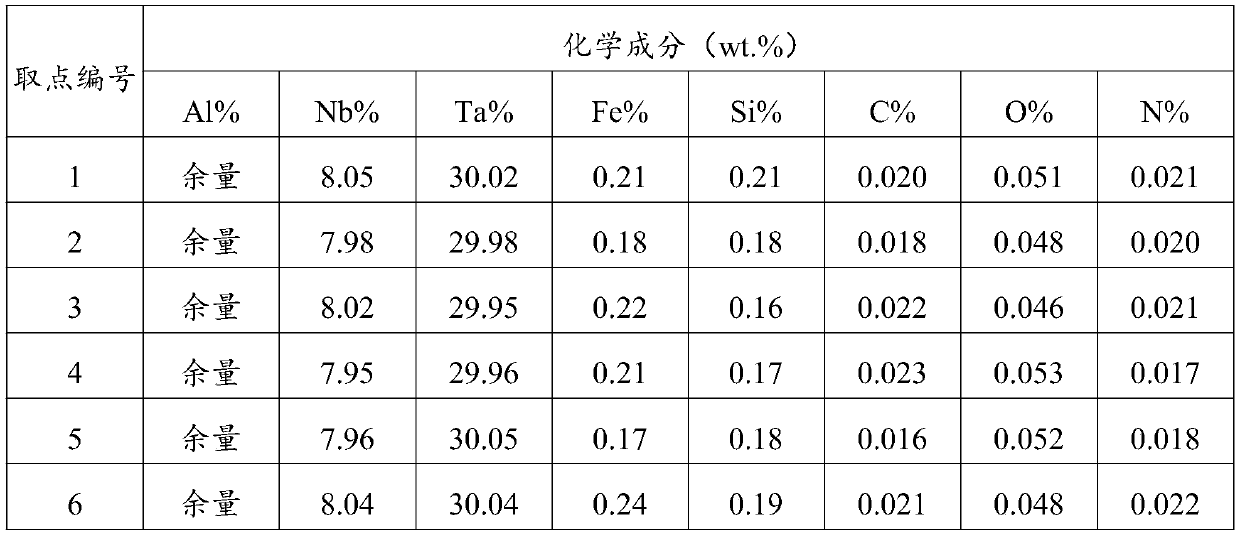

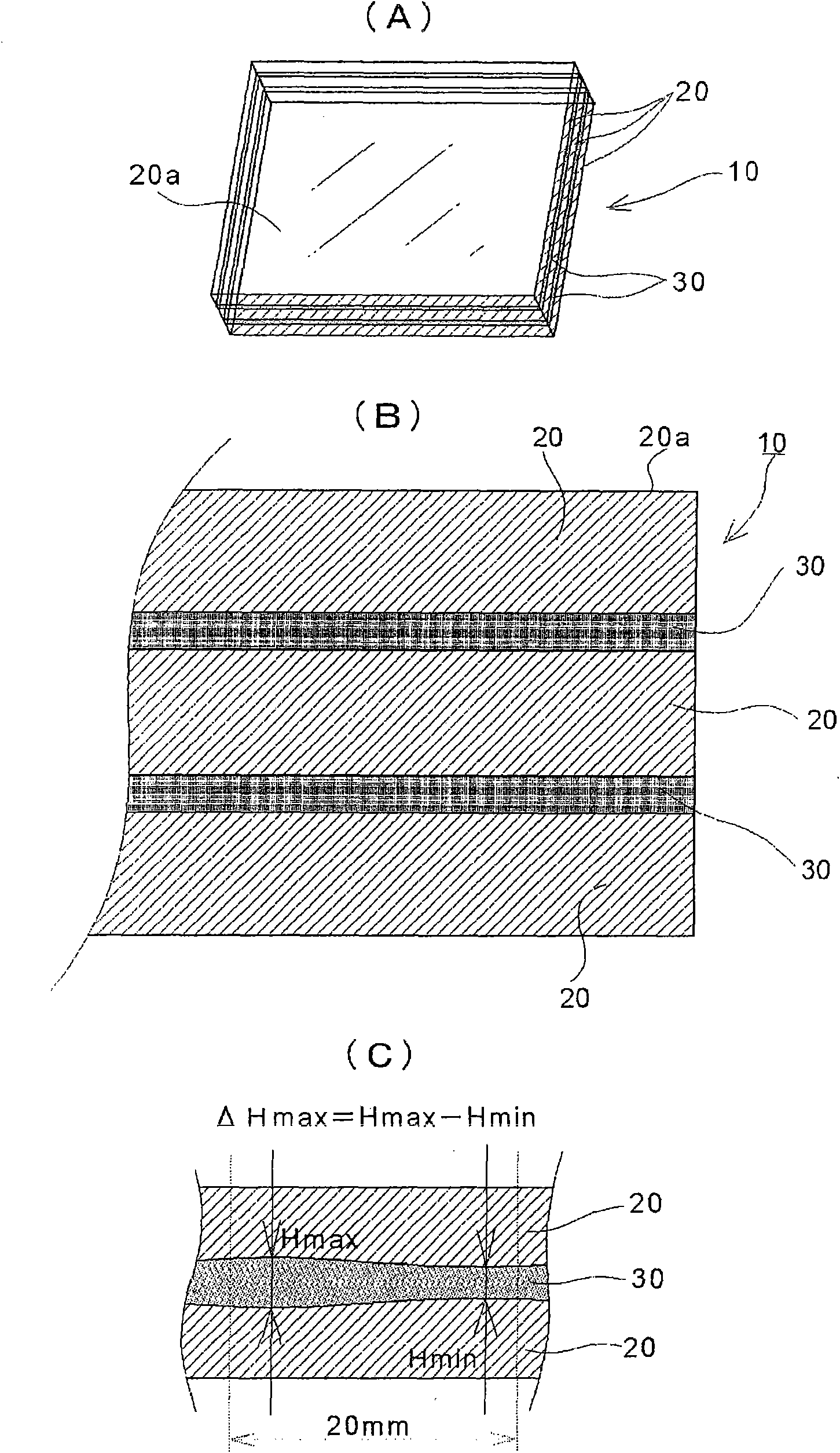

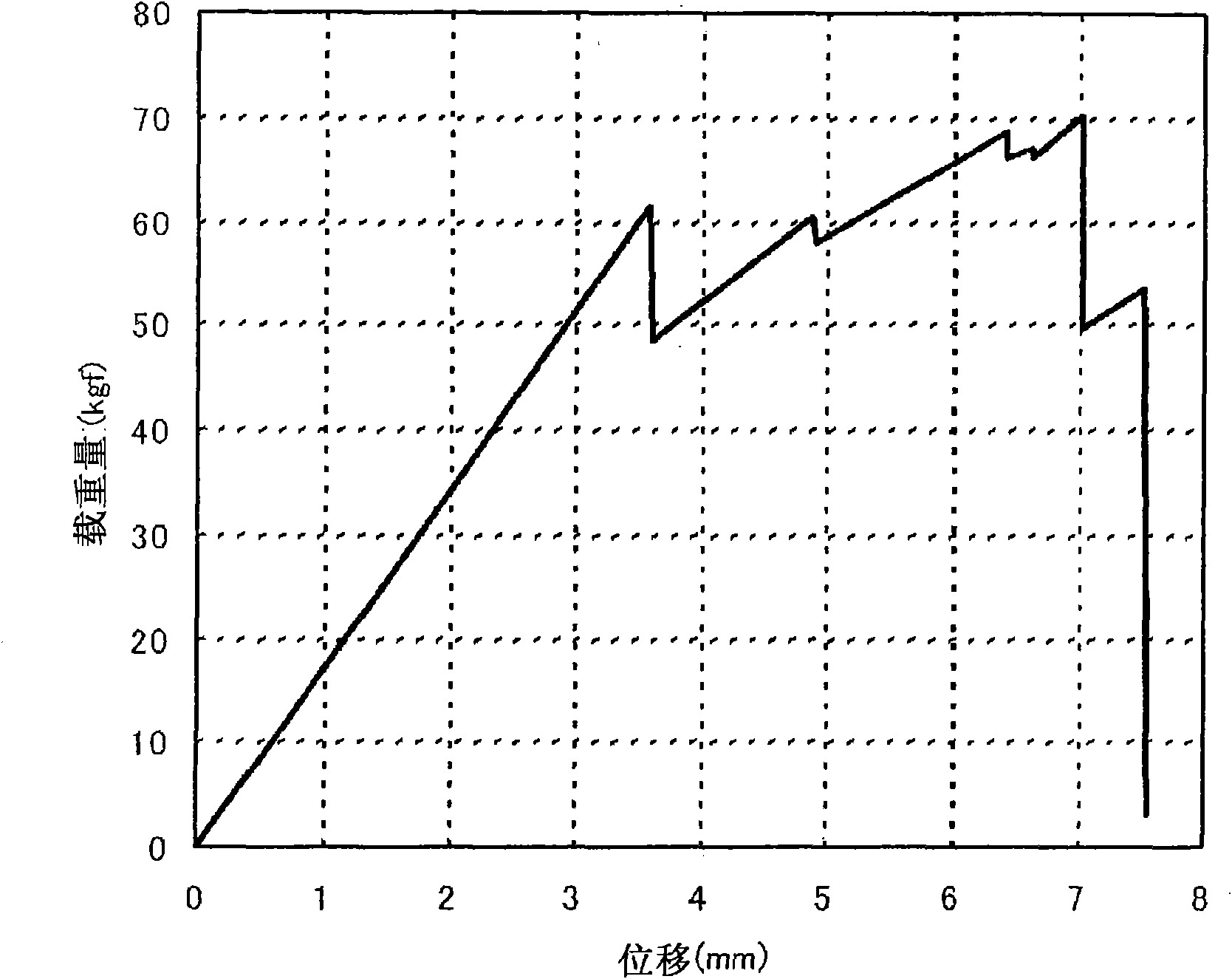

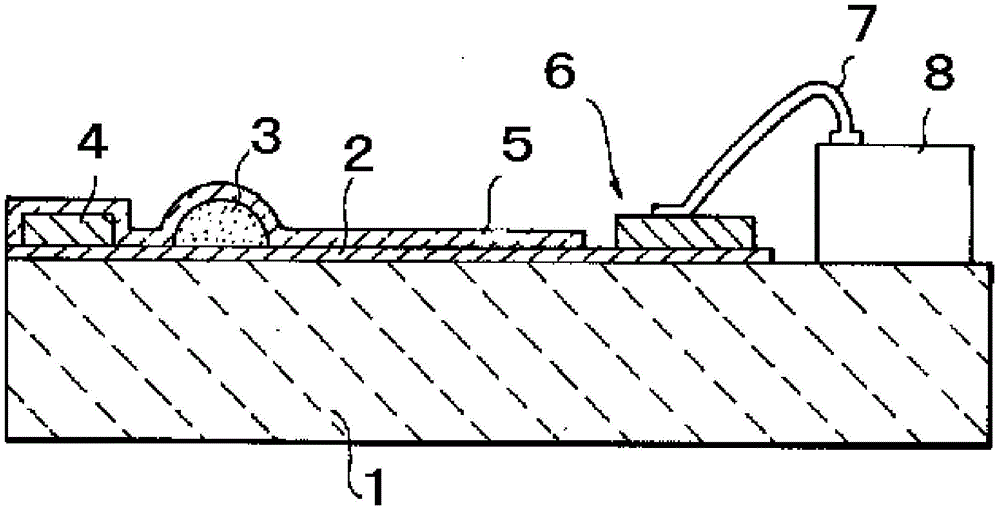

Sheet glass laminate structure and multiple sheet glass laminate structure

InactiveCN101516798AImpact resistantThermal shock resistantGlass/slag layered productsWoven fabricsEngineeringElectrical and Electronics engineering

The present invention provides a sheet glass laminate structure excellent in penetration resistance (bulletproof nature), crime prevention nature, heat shock resistance, translucency and airtightness. The sheet glass laminate structure (10) is produced by laminating at least three sheets of sheet glass (20) each having a sheet thickness of less than 1 mm with intermediate layers (30) interposed between them. When a central portion 20 mm in length including the middle point of a virtual line and opposite end portions respectively being 20 mm long from the opposite ends of the virtual line are set on the virtual line having a length equal to 50% of the maximum overall dimension of the translucent surface of the sheet glass (20) and extending in parallel with the direction of maximum overall dimension with the center of the translucent surface as its middle point, maximum variation DeltaHmax of the interval H between sheets of sheet glass opposing across the intermediate layer in connection with the central portion and the opposite end portions satisfies the following relation; 0[mu]m<DeltaHmax<20[mu]m.

Owner:NIPPON ELECTRIC GLASS CO LTD

Method for smelting and extracting zinc tailings by recovery method

InactiveCN102492851AReasonable useNo secondary pollutionProcess efficiency improvementMagnetic separationRecovery methodZinc

The invention belongs to the technical field of effective utilization of a waste resource, more specifically relates to a novel method for smelting and extracting zinc tailings by a recovery method. The novel method of the invention comprises the following steps: pretreating tailings, carrying out ball milling and magnetic separation on the tailings to obtain an enriched material with metallic iron grade of 40-50%, carrying out ball milling and the magnetic separation on the enriched material and reselecting to obtain a material product with the metallic iron grade greater than 80%, wherein, the tailings are subjected to at least two circles of ball milling and magnetic separation processes to obtain the enriched material. The product possesses high iron grade, and can be directly used as a reducing agent for producing titanium dioxide. According to the invention, useful elements in zinc tailings can be utilized in a reasonable mode by the recovery method, so that the added value of zinc tailings can be further enhanced, the value can reach the maximization, and the metallic iron can be effectively utilized; the traditional old technology that the material is returned to a blast furnace for making iron and carrying out multi-time reduction is changed, and the secondary pollution generated by reusing the waste resource can be reduced.

Owner:PANZHIHUA GANGCHENG GROUP

Copper-molybdenum separation electric potential flotation process

The invention discloses a copper-molybdenum separation electric potential flotation process. The copper-molybdenum separation electric potential flotation process comprises the steps of raw ore crushing, ore grinding, mixed flotation and separation flotation. In the separation flotation step, the ph value of pulp is kept at 10-11, and rougher flotation pulp electric potential is controlled to -510 mv to -530 mv; and then 180 ml / min of polyacrylamide modified matter is added as a copper inhibitor, the grade of separation rougher flotation foam molybdenum is controlled to 9%-12%, the copper grade is controlled to 11.2%-15%. Electric potential flotation is adopted, rougher flotation electric potential is controlled to be within a certain range, copper minerals can be restrained to the maximum, the foam grade of corresponding work is stabilized, a large amount of sodium bisulfide can be saved, the molybdenum recovery rate is increased, meanwhile, mutual containing in copper-molybdenum concentrate is lowered, and the effect is also very significant.

Owner:CHINA GOLD INNER MONGOLIA MINING

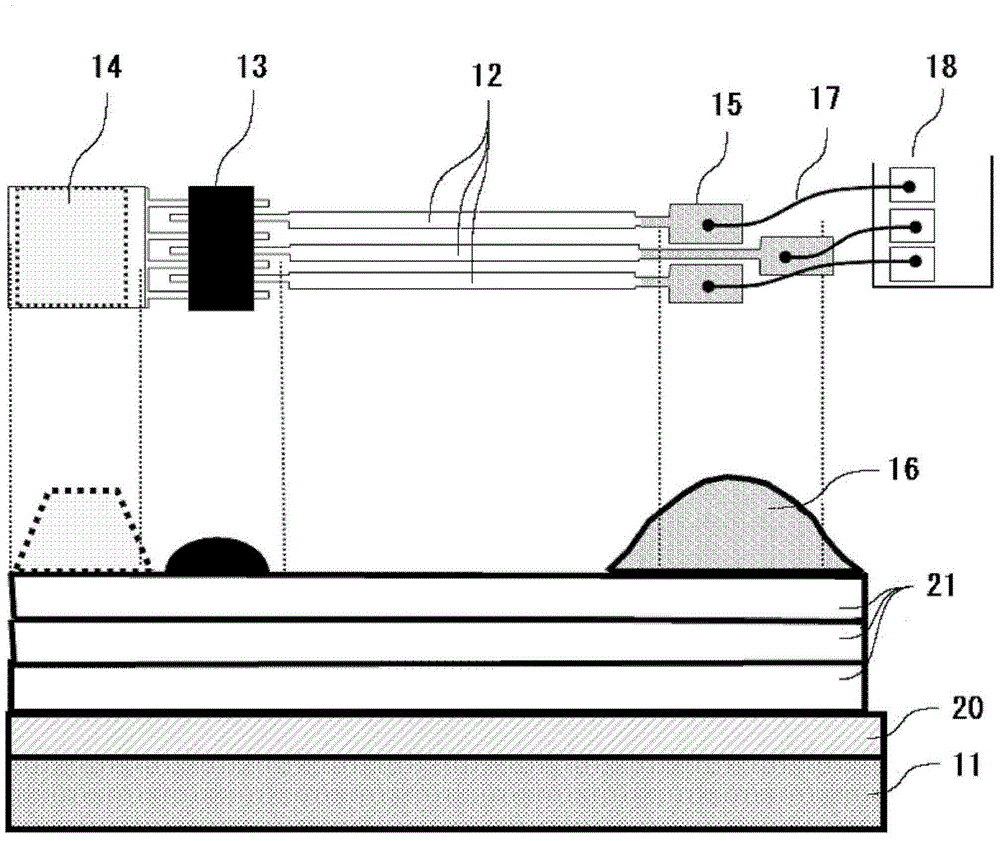

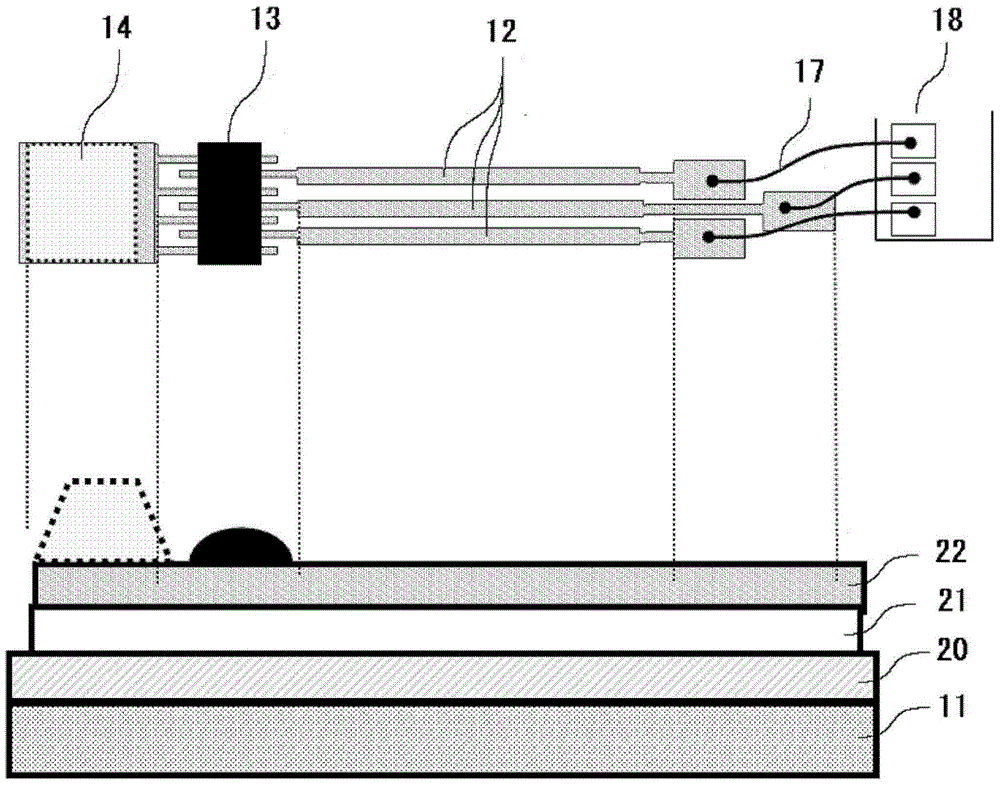

Circuit board and thermal printing head using same

InactiveCN104105336AReduce usageNo reduction in joint strengthPrinted circuit manufacturePrintingElectrical conductorThermal printing

The present invention provides a printed circuit board which forms a gold conductor of a gold wire bonding part in a thinner way to reduce the number of manufacturing processes and material cost. In the printed circuit board produced by forming a conducting pattern on an insulating substrate by using gold-containing pasty fluid, a low-purity gold layer and a high-purity hold layer used for wire bonding thereabove are stacked on the board. And the present invention also provides a thermal printing head using the printed circuit board.

Owner:AOI ELECTRONICS CO LTD

Method for smelting ferrovanadium through iron particles and steel scraps

The invention relates to a method for smelting ferrovanadium through iron particles and steel scraps, and belongs to the technical field of metallurgy. The method for smelting ferrovanadium through iron particles and steel scraps is adopted. The method includes the following steps of a, preparing a raw material and b, smelting. According to the step of preparing the raw material, vanadium oxide, aluminum particles, steel scraps and iron particles are mixed. According to the step of smelting, ignition smelting and standing are conducted, a furnace is removed after natural cooling is completed, and ferrovanadium is obtained. According to the method, the constitution of the ferrovanadium raw material is innovatively optimized, the consumption of steel scraps is reduced obviously, hence, the production cost of ferrovanadium is lowered, the production efficiency of enterprises can be improved, the production cost can be lowered, the alloy quality is improved, the enterprise competitiveness is enhanced, and a broad market prospect is achieved.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

Comprehensive treatment method of blast furnace dedusting ash

InactiveCN101654717BReduce dosageLow costRecycling and recovery technologiesProcess efficiency improvementWaste treatmentPollution

The invention discloses a comprehensive treatment method of blast furnace dedusting ash, belonging to the technical field of the waste treatment. The method comprises the following steps: adding water in blast furnace dedusting ash for mixing, performing secondary magnetic separation, performing flotation, in the tailings treatment using a spiral chute to separate iron refined powder and carbon refined powder, screening to recycle the carbon refined powder in the wastewater which is obtained in the step of spiral chute ion-removing and performing filter pressing to the obtained wastewater forrecycling. The method can greatly increase the selection yield and grade of the iron refined powder and carbon refined powder, can also avoid to produce new pollution, protect the environment and recycle waste material.

Owner:山东泰山焦化有限公司

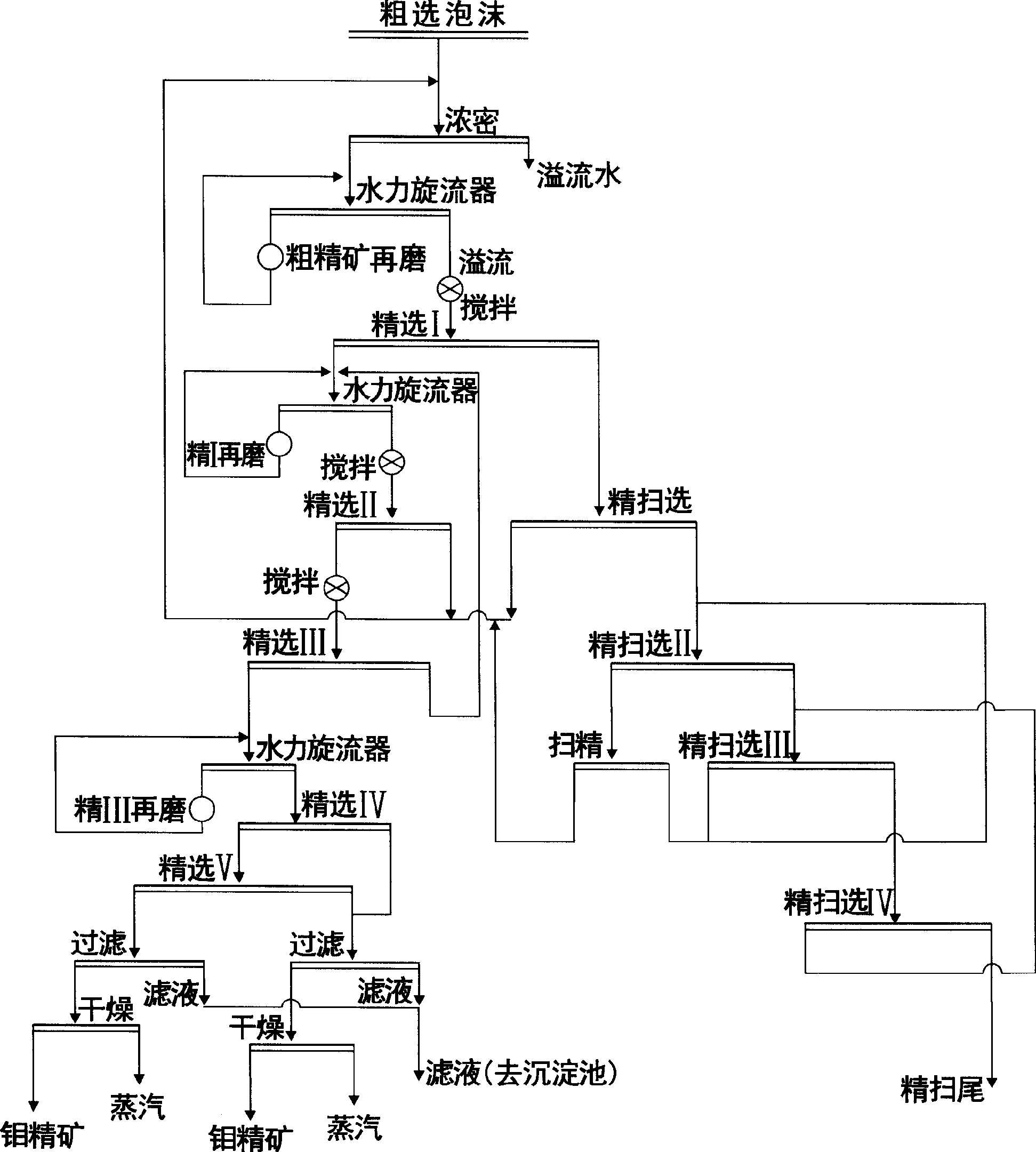

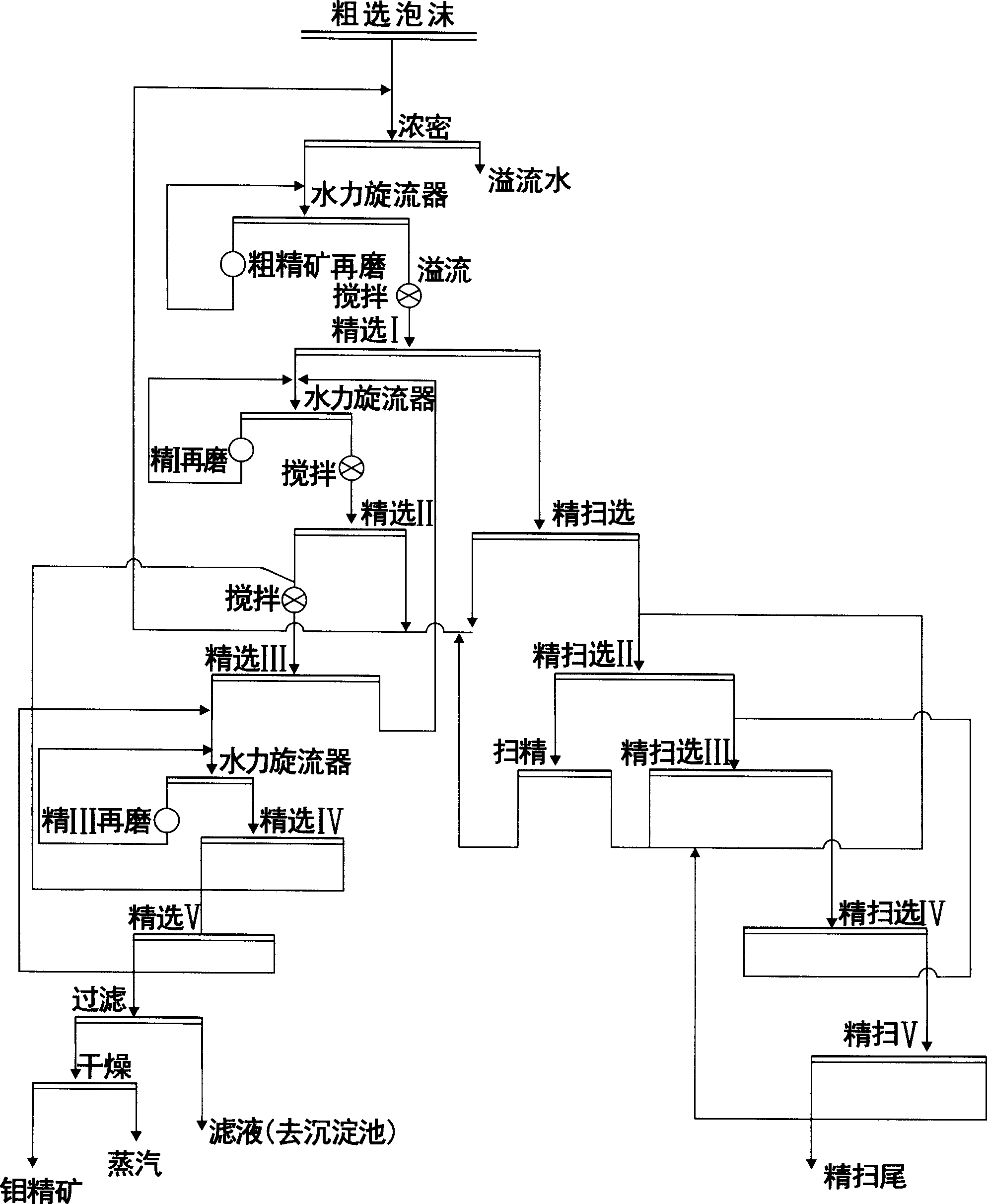

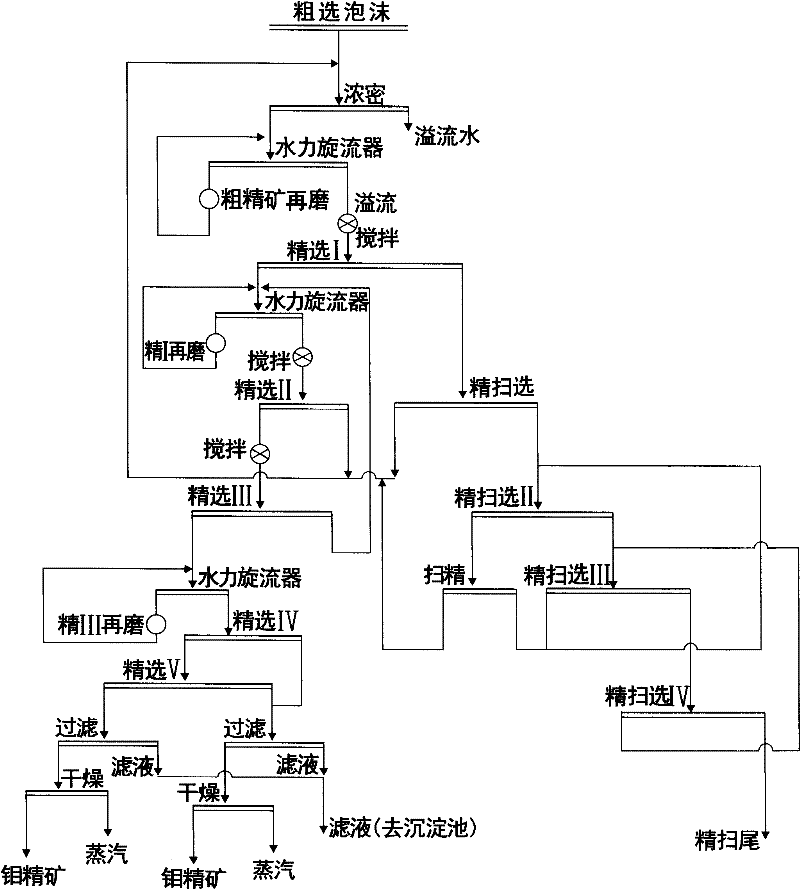

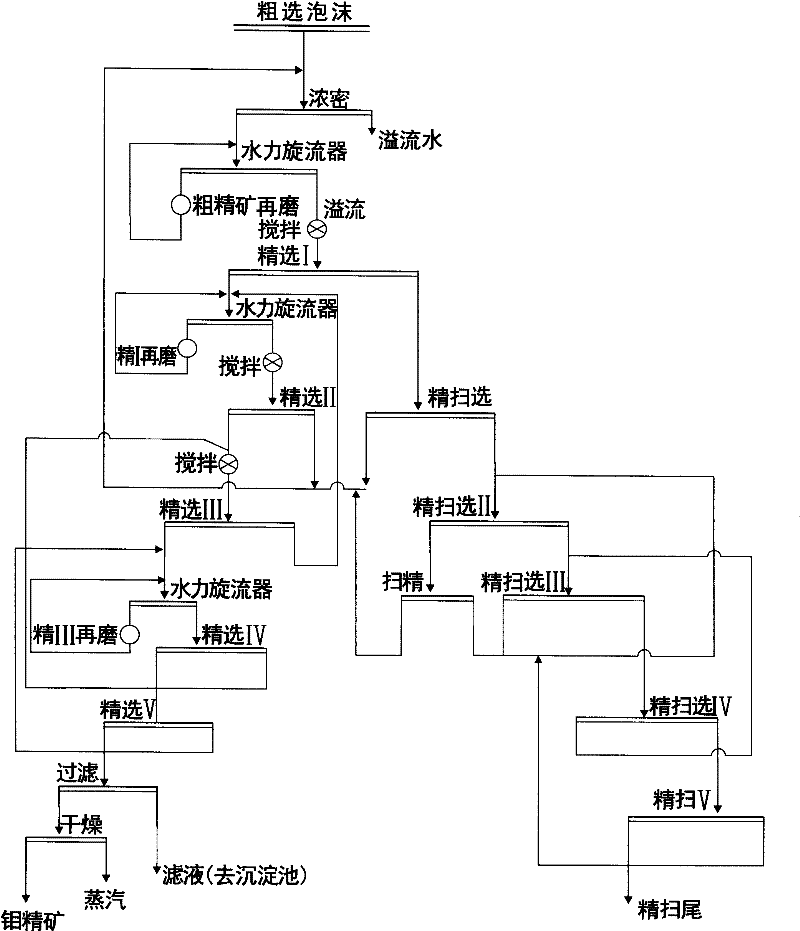

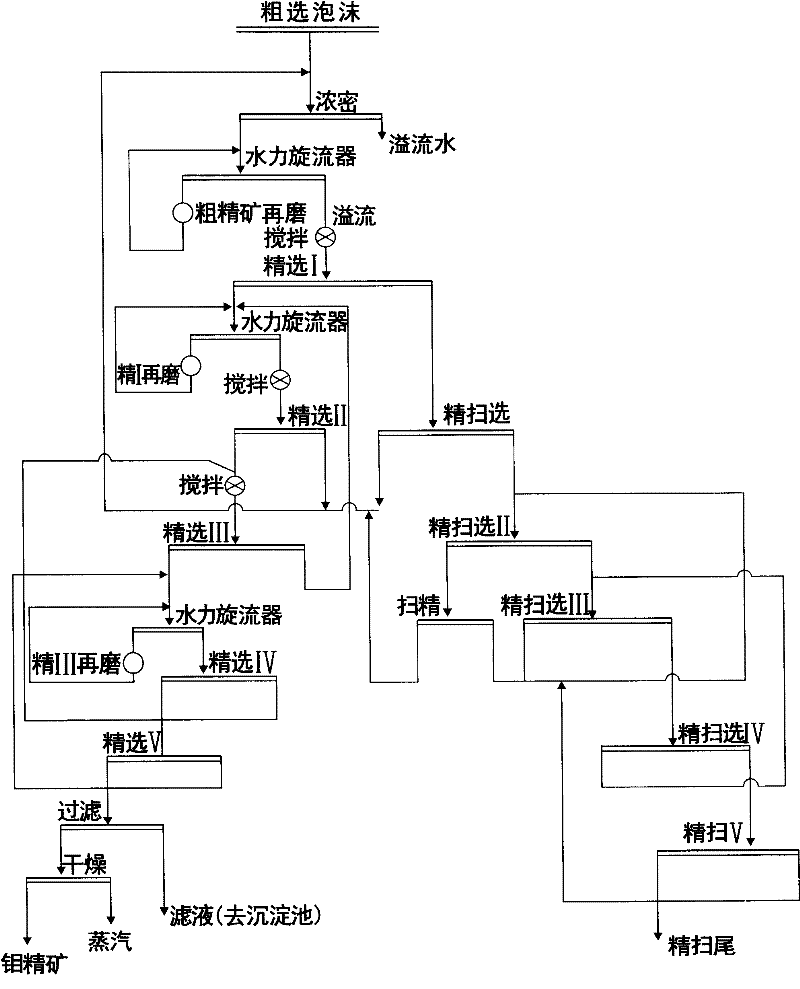

Method for improving ore grade of molybdenum concentrate with precise separating segment

The invention discloses a method for improving molybdenum concentrate grade by adopting a concentration stage. The invention comprises the technological process of the ore-feeding closed-circuit regrinding of a concentration I flotation column, a concentration II flotation column, and a concentration IV flotation column. The invention is characterized in that the concentration IV ore feeding, that is, concentration III foam enables pulp to overflow so as to enter the concentration IV flotation column after being classified by a hydrocyclone; a slurry pump is added on the tailings part of the concentration IV flotation column so as to enable the concentration IV tailings to return the concentration III flotation column, thereby forming a closed circuit; and concentration IV foam enters concentration V, the tailings of the concentration V and concentration III foam enters the concentration IV after being reground, and the foam of the concentration IV flotation column is directly regarded as final products. Therefore, the enrichment ratios of the concentration III, the concentration IV, and the concentration V pulp are increased, the flotation time is prolonged, and the grade of the final concentrates is improved significantly.

Owner:CHINA MOLYBDENUM

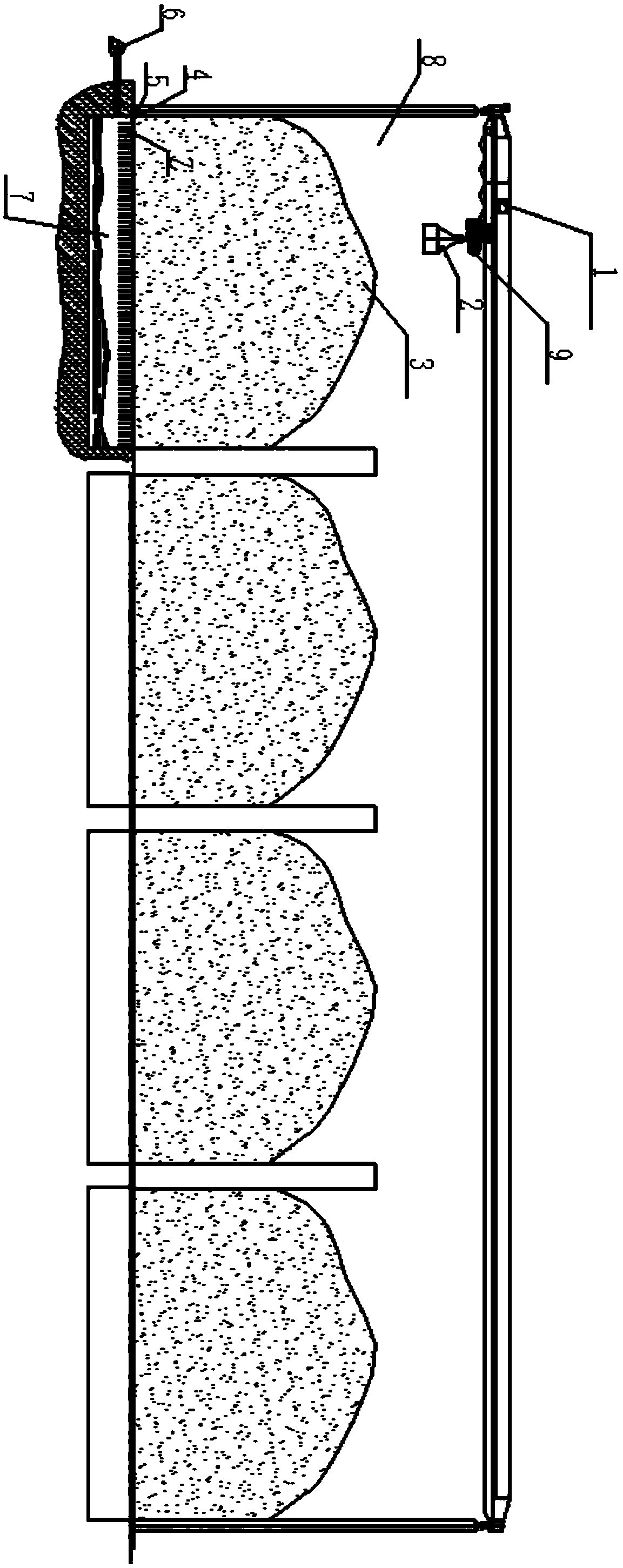

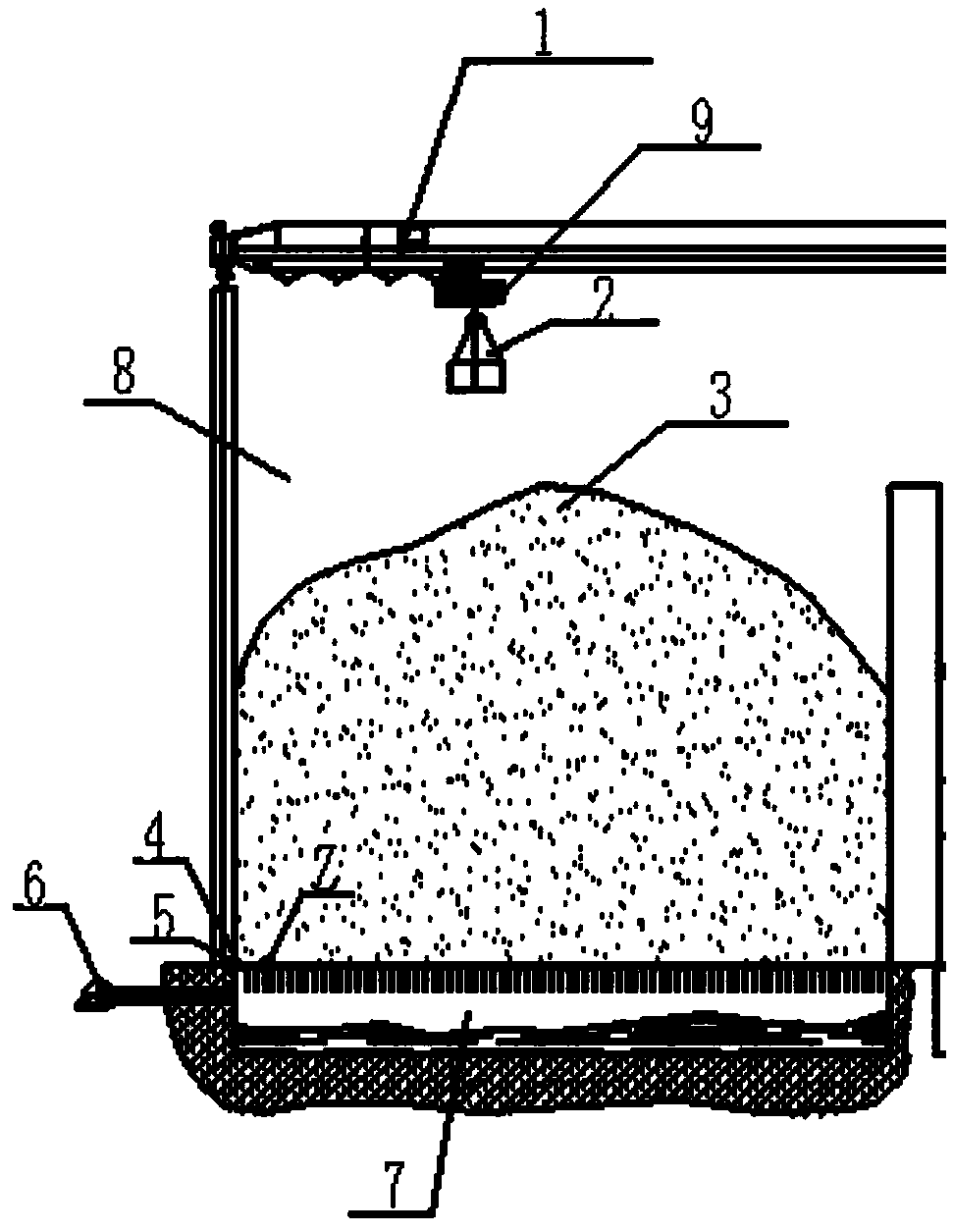

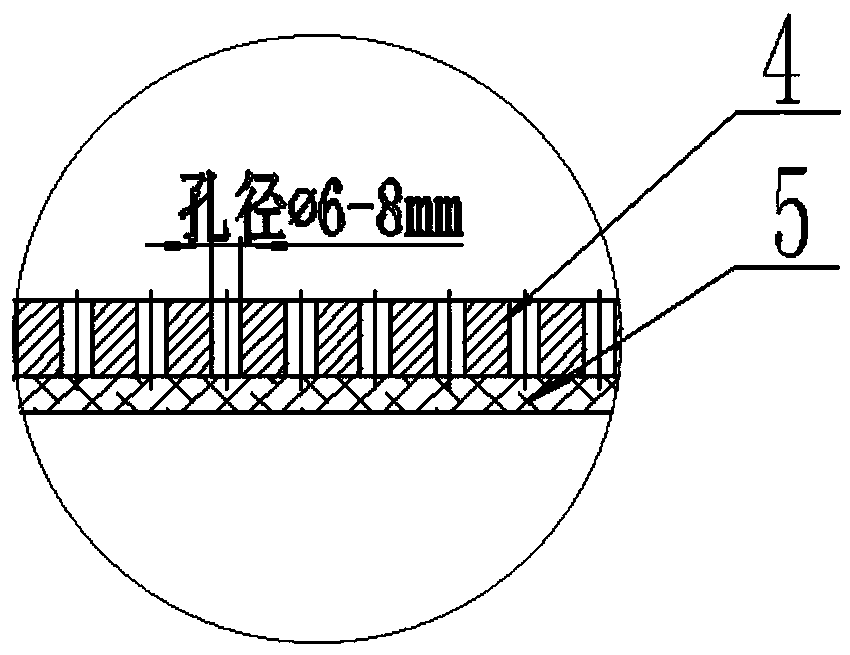

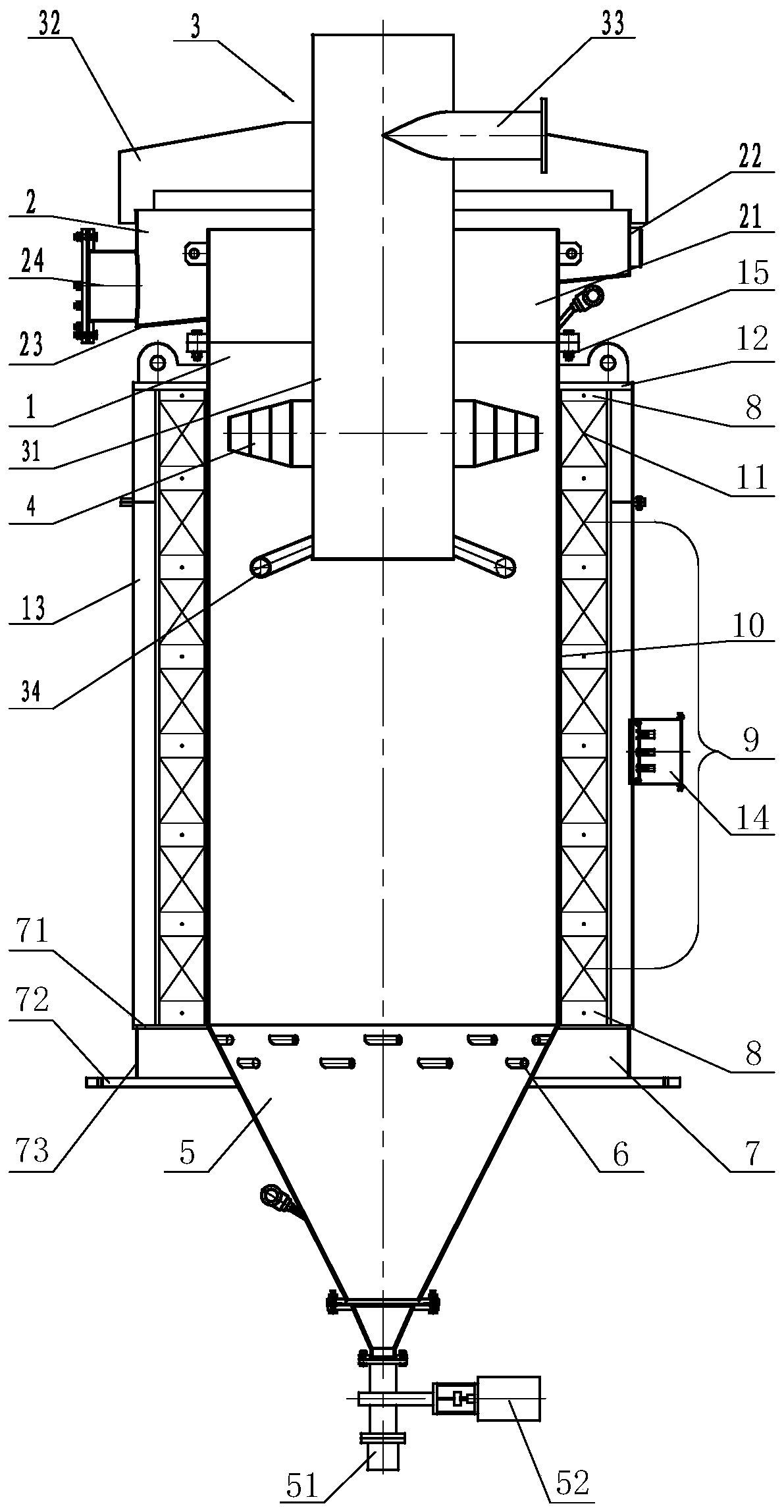

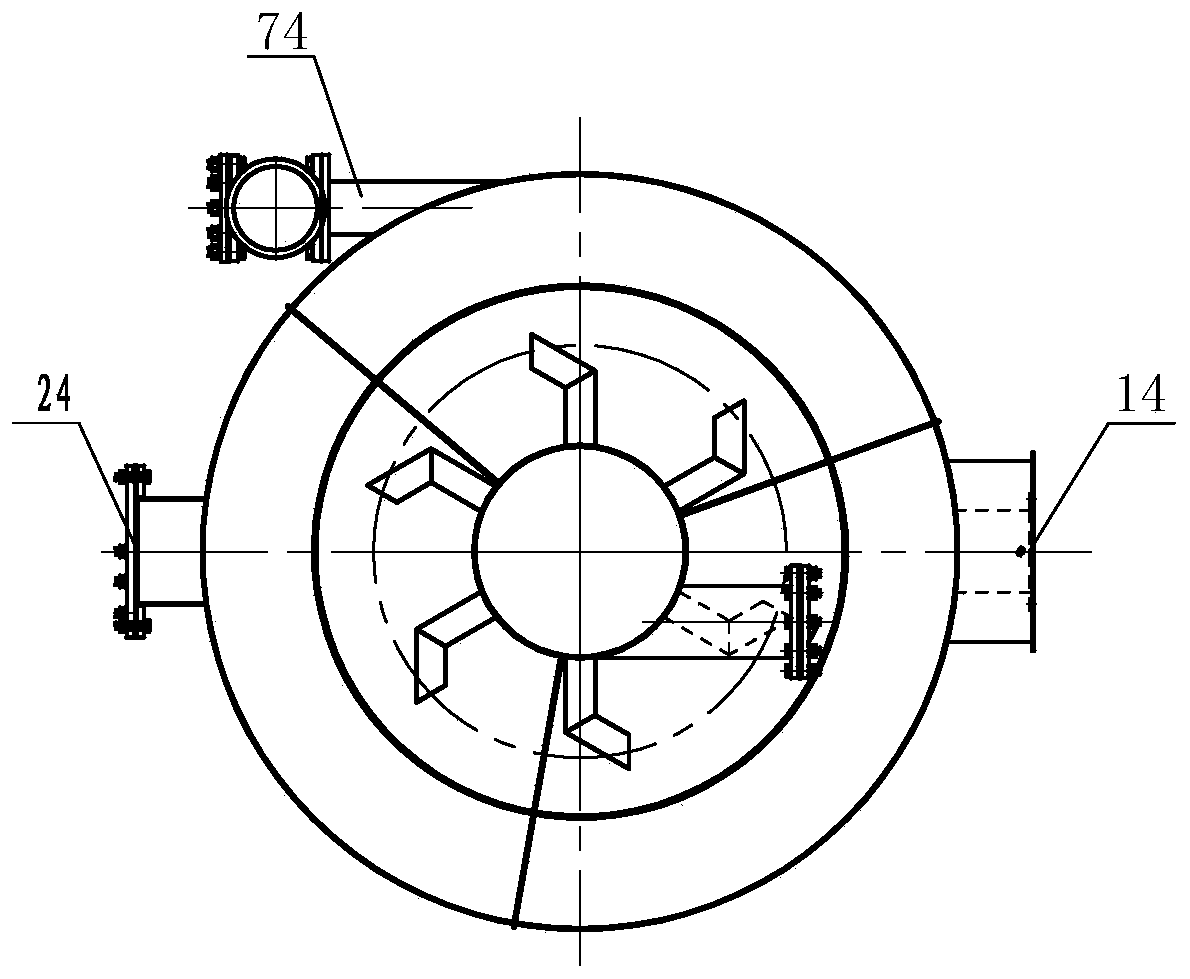

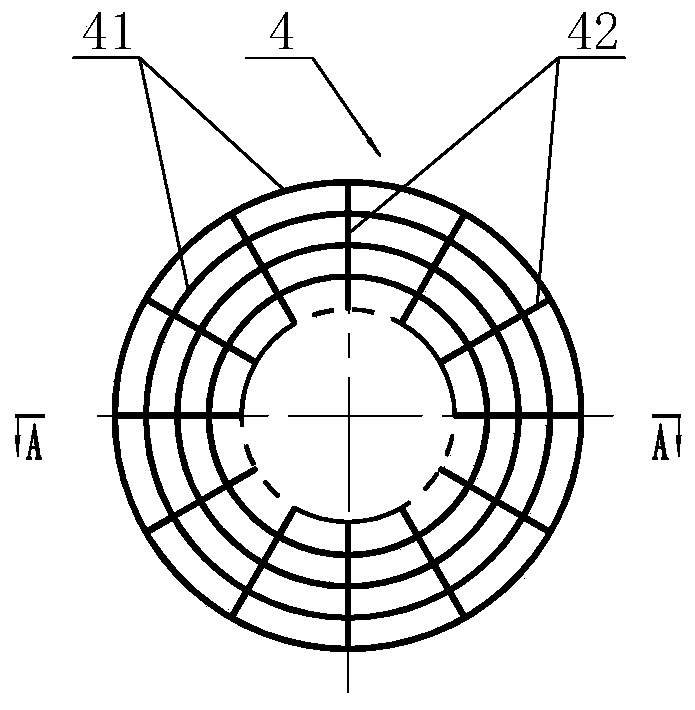

Homogenization and filtration equipment for chemical gypsum and homogenization and filtration method

PendingCN108654169AImprove filtration efficiencyGood product qualityTransportation and packagingCalcium/strontium/barium sulfatesGypsumWater collection

The invention discloses homogenization and filtration equipment for chemical gypsum. The homogenization and filtration equipment comprises at least one kiln duct, filtration water collection devices,filter layers and vacuum pumps, wherein the kiln ducts are arranged in parallel, the filtration water collection devices are located at the bottoms of the kiln ducts and communicate with the kiln ducts, the filter layers are located in the filtration water collection devices, and the vacuum pumps are connected to the filtration water collection devices; and each filter layer comprises an upper pore plate filter layer and a lower filter cloth filter layer. The invention further discloses a homogenization and filtration method. According to the equipment and the method, large-scale production ofthe high-moisture chemical gypsum can be realized, and the production energy consumption can be effectively reduced; and after the high-moisture chemical gypsum is subjected to homogenization and filtration, the quality (grade and adsorption water) of the chemical gypsum is more stable, the adsorbed water is effectively reduced by 50-60%, the filtering is uniform, the filtering effect is good, the filtering efficiency is high, the quality of filtered gypsum products is stable, the quality is improved, and meanwhile, the quality of downstream products is ensured.

Owner:TAIAN JIEPU GYPSUM TECH

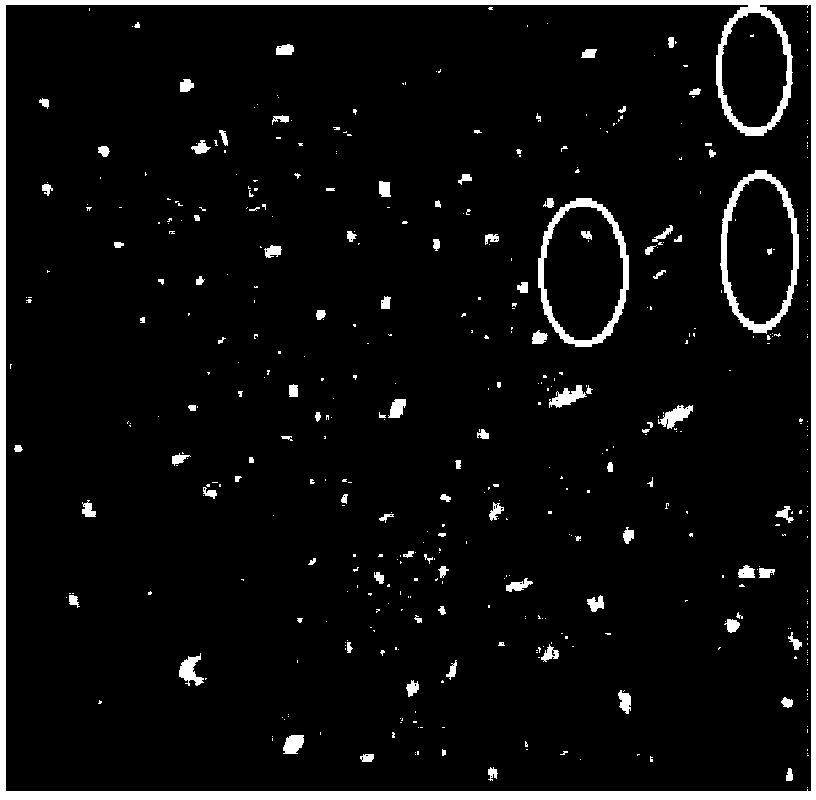

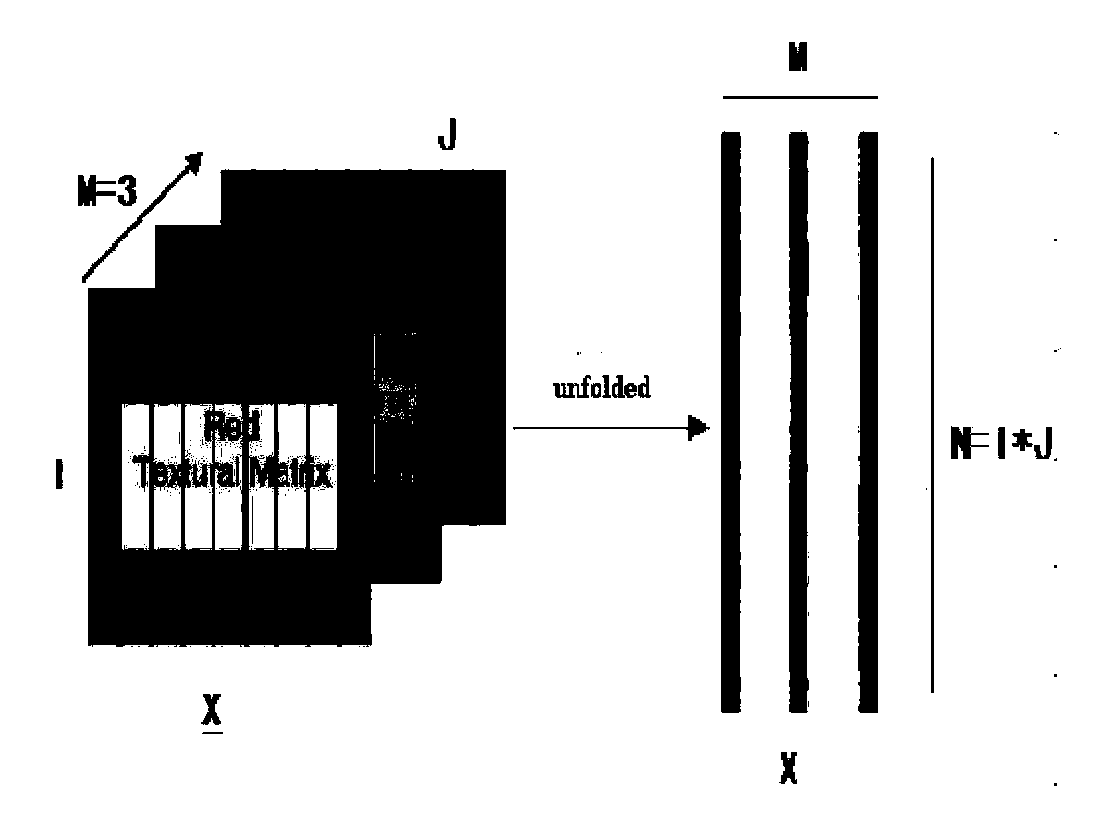

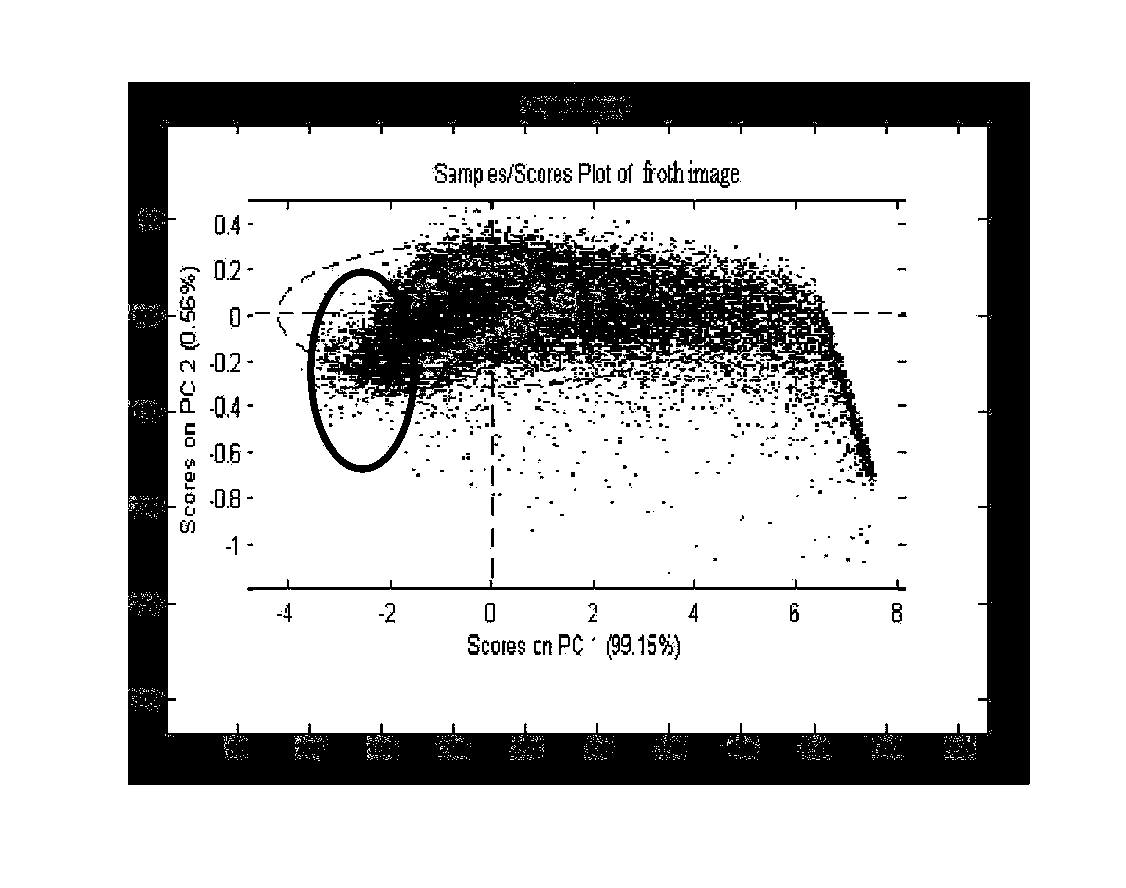

MPCA (Multiway Principal Component Analysis)-based measurement method for area of local region of copper flotation froth image

InactiveCN103454225APracticalReduce false positive rateColor/spectral properties measurementsSpectral signatureZone size

The invention discloses an MPCA (Multiway Principal Component Analysis)-based measurement method for the area of a local region of a copper flotation froth image. The method comprises the following steps: firstly, a three-dimensional RGB (Red, Green and Blue) image is expanded by MPCA to form two-dimensional image data and the two-dimensional image data is projected into an uncorrelated principal component space; then, a local black hydrated region in the image is marked in the principal component space; finally, a principal component image is reconstructed by a load vector, the relation between a principal component space score vector component value and a principal component image characteristic pixel value is used for determining the quantity and space positions of characteristic pixels in the principal component image, the marked local region is mapped to the principal component image and the size of the region is calculated and used as a spectral characteristic of the local region of the forth image. The MPCA-based measurement method for the area of the local region of the copper flotation froth image is applicable to a copper flotation production process and can be used for establishing a production working condition recognition model in a copper flotation process; the MPCA-based measurement method has important meanings of reducing the erroneous judgment rate of a working condition, improving the grade of copper concentrates and realizing the optimization of a copper flotation production and operation process.

Owner:CENT SOUTH UNIV

Vanadium-raising cooling agent, method for preparing same and use method

The invention relates to a vanadium extraction coolant and a preparation method and a use method thereof which belong to the field of metallurgy. The invention provides a novel vanadium extraction coolant and overcomes the defects of complex use of the existing coolant and the large operation difficulty of the existing vanadium extraction technique. The vanadium extraction coolant comprises 80 to 95 percent of the oxides of iron, 3 to 6 percent of SiO2, 0.1 to 0.6 percent of V2O5, 1 to 3 percent of MgCl2 and the rest is less inevitable unpurified elements; the total amount is 100 percent. The vanadium extraction coolant of the invention is collocated and pressed by adopting iron concentrate powder containing vanadium and ferric oxide (or vanadium extraction mud) with a bonding agent which not only has a simple preparation method, but also has high cooling intensity; besides, the using method is simple during the process of using the vanadium extraction; the vanadium extraction technique is more smooth; the quality of the vanadium slag and the quality of gun iron are more stable; the invention fully recycles the most resources of iron and vanadium in the coolant simultaneously when achieving the goals of ''removing vanadium and preserving carbon''.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

A kind of aluminum-niobium-tantalum master alloy and preparation method thereof

The invention provides an aluminum-niobium-tantalum intermediate alloy and a preparing method thereof and relates to the technical field of metal materials. The aluminum-niobium-tantalum intermediatealloy comprises, by mass, 8.0%-12.0% of Nb, 30.0%-34.0% of Ta and the balance Al. due to component and content control, the components of the aluminum-niobium-tantalum intermediate alloy are uniform,segregation is small, when the titanium alloy is smelted, titanium alloy component homogenization is facilitated, and component segregation is prevented. The preparing method of the aluminum-niobium-tantalum intermediate alloy is provided. The aluminum-niobium-tantalum intermediate alloy is prepared through a two-step method, namely the two steps of the thermit reaction and vacuum smelting are conducted. By means of the preparing method, homogenization stability of the components of the aluminum-niobium-tantalum intermediate alloy can be improved, the content of impurities of O, N and the likeis reduced, and the requirement for titanium alloy production can be better met.

Owner:CHENGDE TIANDA VANADIUM IND

A production method of as-cast high-performance nodular iron qt600‑10 by investment casting

ActiveCN105861917BImprove heat radiation environmentRun at willFoundry mouldsFoundry coresChemical compositionInvestment casting

The invention provides a production method for as-cast high-performance ductile iron QT600-10 by precision-investment casting, wherein a matrix of the as-cast high-performance ductile iron QT600-10 is a mixture of ferrite and pearlite; the pearlite accounts for 35%-55%, the nodulizing grade ranges from grade I to grade II, and the size of graphite ranges from grade VI to grade VII; the material comprises the following final chemical components in percentage by mass: 3.3-3.6% of C, 2.8-3.0% of Si, 0.2-0.4% of Mn, less than or equal to 0.035% of P, less than or equal to 0.02% of S, 0.4-0.6% of Cu, 0.035-0.055% of Mg, 0.02-0.04% of RE and the balance Fe; and a dam type nodulizing treatment and three-time inoculation way is adopted. The produced as-cast high-performance ductile iron QT600-10 has tensile strength Rm greater than or equal to 600 MPa, and elongation after fracture A greater than or equal to 10%. By combining a precision-investment casting production way with a cooling way after shell casting, high-strength high-toughness ductile iron is produced by a precision-investment casting process, so that lightweight design development and production for car parts is realized by virtue of a near net-shape forming process.

Owner:DONGFENG PRECISION CASTING CO LTD

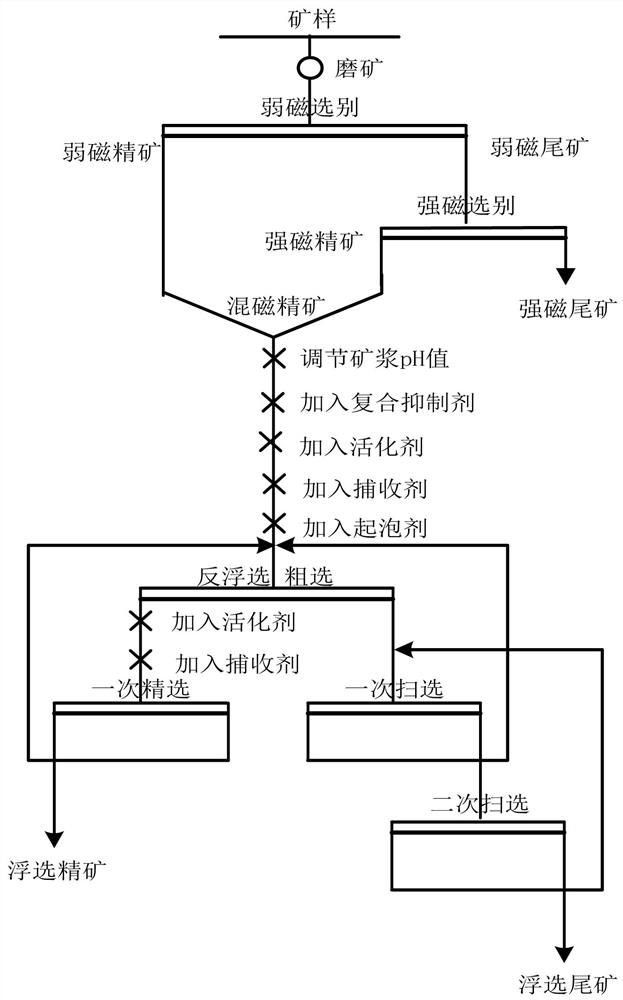

Composite inhibitor for reverse flotation of carbonate-containing iron ore as well as preparation method and application of composite inhibitor

ActiveCN113798065AImprove hydrophilicityReduce coverFlotationMagnetic separationFoaming agentMining engineering

The invention relates to a composite inhibitor for reverse flotation of carbonate-containing iron ore as well as a preparation method and application of the composite inhibitor. The preparation method is characterized by comprising the process steps of carrying out stirring and size mixing on carbonate-containing iron ore mixed magnetic concentrate, sequentially adding a composite inhibitor, an activating agent, a collecting agent and a foaming agent for stirring and size mixing, then feeding into a mechanical stirring type flotation machine, conducting reverse flotation roughing operation, and obtaining reverse flotation roughing concentrate and reverse flotation tailings; adding a certain amount of activating agent and collecting agent into the roughing concentrate, and then carrying out primary concentration to obtain reverse flotation final concentrate; and scavenging the roughing tailings twice, and obtaining final reverse flotation tailings. Compared with the prior art, the method has the advantages that by adding the composite inhibitor, the flotation effect is improved, the comprehensive iron ore concentrate grade is greater than 64%, the recovery rate is greater than 85%, and the recovery rate is increased by 3% or above under the condition that the grade is stable.

Owner:ANSTEEL GRP MINING CO LTD

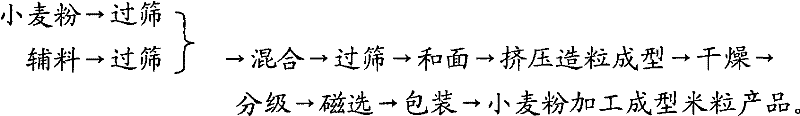

Product of rice grains formed by processing wheat flour and processing method thereof

Owner:HUBEI BAIDIAN IND

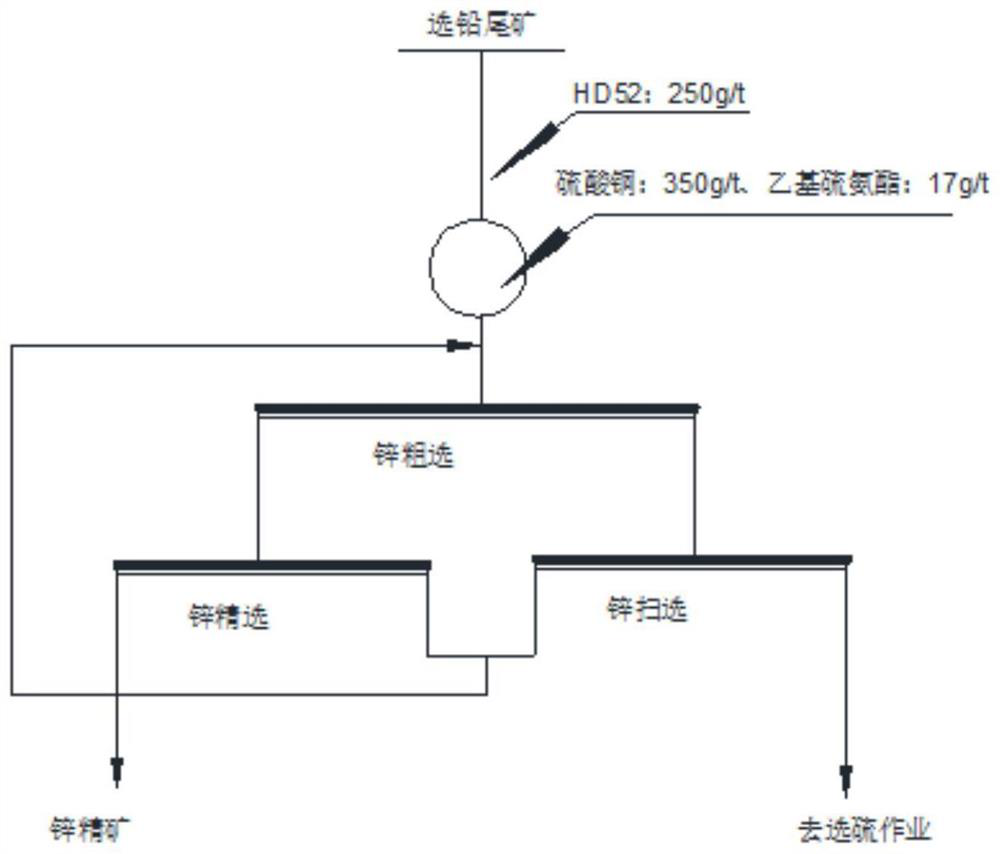

Efficient collecting agent for zinc separation of lead-zinc sulfide ore and zinc separation method of efficient collecting agent

The invention discloses an efficient collecting agent for zinc separation of lead-zinc sulfide ore. The efficient collecting agent for zinc separation is ethyl thionocarbamate. The invention further discloses a method for separating zinc from the lead-zinc sulfide ore. The method comprises the following steps that in flotation of the lead-zinc sulfide ore, raw ore is ground, and then lead separation operation is conducted; a pyrite inhibitor HD52 is firstly added into tailing pulp of the last scavenging of lead flotation; then, copper sulfate is added into the slurry mixing and stirring barrel before zinc selection and roughing, and ethyl thionocarbamate is added for stirring and size mixing; and then the ore pulp enters a zinc roughing flotation machine for zinc roughing. According to the method, ethyl thionocarbamate is adopted as a zinc collecting agent in flotation of the lead-zinc sulfide ore, so that the sphalerite and the pyrite can be separated by adopting ethyl thionocarbamate with good selectivity to the sphalerite as the collecting agent of the sphalerite under the condition of a natural PH value.

Owner:SHUI KOU SHAN NONFERROUS METALS LTD

Method for improving ore grade of molybdenum concentrate with precise separating segment

The invention discloses a method for improving molybdenum concentrate grade by adopting a concentration stage. The invention comprises the technological process of the ore-feeding closed-circuit regrinding of a concentration I flotation column, a concentration II flotation column, and a concentration IV flotation column. The invention is characterized in that the concentration IV ore feeding, that is, concentration III foam enables pulp to overflow so as to enter the concentration IV flotation column after being classified by a hydrocyclone; a slurry pump is added on the tailings part of the concentration IV flotation column so as to enable the concentration IV tailings to return the concentration III flotation column, thereby forming a closed circuit; and concentration IV foam enters concentration V, the tailings of the concentration V and concentration III foam enters the concentration IV after being reground, and the foam of the concentration IV flotation column is directly regarded as final products. Therefore, the enrichment ratios of the concentration III, the concentration IV, and the concentration V pulp are increased, the flotation time is prolonged, and the grade of the final concentrates is improved significantly.

Owner:CHINA MOLYBDENUM

A kind of by-product high-purity vanadium-nitrogen alloy production process

ActiveCN114182133BHigh purityHigh nitrogen contentAmmonia compoundsCalcium silicateAmmonium metavanadate

Owner:江西林力高新材料有限公司

A Method of Extracting Flotation Foam Motion Feature Based on r-k Algorithm

Owner:云南华迅达智能科技有限公司

A kind of preparation method of vanadium nitrogen alloy

The invention relates to a preparation method of a vanadium-nitrogen alloy and belongs to the technical field of vanadium-nitrogen alloys. The method comprises the following steps: 1) a vanadium-nitrogen compound is smashed and uniformly mixed with a reducing agent, a nitrogen increasing agent and a catalyst in proportion, and the substances are stirred for 1.5-3 h; a binder and water are mixed uniformly in proportion; the two mixtures are mixed uniformly for standby application; 2) the finally obtained mixture in step 1) is pressed for the first time and subjected to second pressing forming under pressure higher than the first pressing pressure, a formed pressed product is naturally air-dried; 3) the pressed product air-dried in step 2) is subjected to drying, reduction, carbonization nitriding and nitrification sintering, and the vanadium-nitrogen alloy is obtained. Stirring time after raw materials are mixed with water can be shortened effectively, the binder is dissolved completelyand plays the binding role sufficiently, one-time pelletizing rate is increased, initial strength of pellets is improved, and curing effect is improved; surface quality and grade of vanadium-nitrogenare improved.

Owner:山东济钢泰航合金有限公司

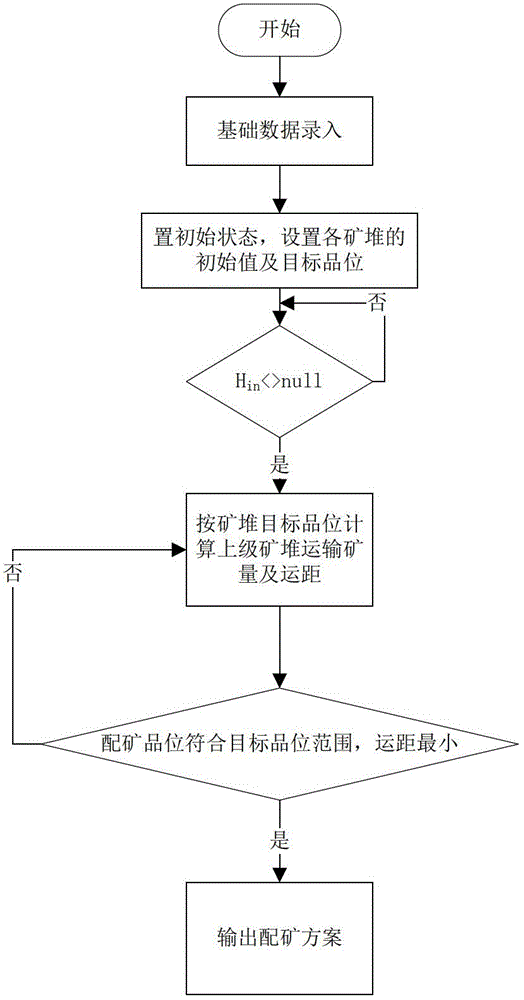

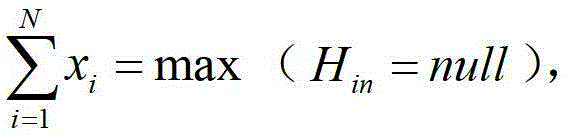

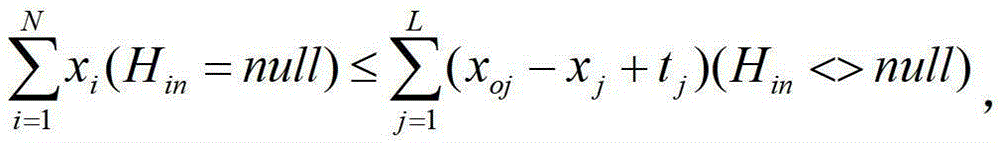

Ore-matching method of selecting phosphorus ore to raw ore

InactiveCN103157547BStable production processReduce shipping costsSolid separationData acquisitionPhosphorite

The invention relates to an ore-matching method of selecting phosphorus ore to raw ore. The method comprises the following steps: 1) data are collected; 2) an ore-matching target of each production ring is ensured to ensure that in the ore-matching process, each production process achieves the raw ore grade; 3) a model is built; and 4) an ore-matching scheme of the raw ore is output. An effective ore-matching method is provided. Due to the adoption of three grades of ore-matching modules, namely, ore-matching of the raw ore in a collecting field, ore-matching of an ore heap in a selected dressing plant heap and ore-matching of a concentrate store, the effect of errors to average grade calculation of the ore is gradually corrected and detected, and meanwhile haul distances are calculated, transportation cost is greatly reduced, and the stable ore grade has important significance in stabling production technology of the ore dressing plant, reducing energy consumption and improving production efficiency.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Low frequency AC electromagnetic washing machine

PendingCN109746117ARaise the gradeAvoid being thrown toMagnetic separationMagnetic separatorThree-phase

The invention discloses a low frequency AC electromagnetic washing machine. The low frequency AC electromagnetic washing machine comprises a washing cylinder, a concentrated ore cone cylinder, an overflow device, an ore feed device, a water supply device, and a magnetic separator, wherein the magnetic separator comprises an ore gathering magnetic field coil sleeved at the peripheral top of the washing cylinder and a plurality of traveling wave magnetic field coils below the or gathering magnetic field coil, the ore gathering magnetic field coil is connected with single-phase low frequency AC,the traveling wave magnetic field coils are connected with a three-phase low frequency AC, a wiring manner of the traveling wave magnetic field coils is 'Y' shape or 'delta' shape, frequency of the lower frequency AC is lower than 50Hz, an induction magnetic ring is arranged in a position in the washing cylinder corresponding to the ore gathering magnetic field coil, an overflow inner cylinder andthe washing cylinder are identical in diameter, an ore outlet of the ore feed device is in the middle between the first traveling wave magnetic field coil and the second traveling wave magnetic fieldcoil and is in the middle of a distance between the inner wall of the washing cylinder and the outer wall of an ore feed tube, and the water supply device is arranged on the concentrated ore cone cylinder below the washing cylinder. The low frequency AC electromagnetic washing machine produces high quality concentrated ore, has good sorting effect and can be widely used.

Owner:SHANDONG HUATE MAGNET TECH

Surface mine fine mining system and mining method using gnss technology

ActiveCN104533528BIntuitive mine boundary positionPrevent leakageMining devicesUnderground miningComputer terminalMarine navigation

The invention provides a surface mine fine mining system adopting a GNSS (Global Navigation Satellite System) technology and a surface mine fine mining method. The surface mine fine mining system comprises at least one GNSS difference base station, a fine mining position server and a plurality of fine mining terminals, wherein the fine mining position server is internally provided with mine measurement data; and the fine mining terminals are used for calculating to obtain current positions of fine mining terminal scraper pans according to difference correction data provided by the GNSS difference base station and feeding back scraper pan position information to the fine mining position server. By utilizing the surface mine fine mining system, intuitive ore body thickness / depth / quality information is provided, accurate guidance is provided for mining operation of a digging operator, ore body condition is updated in real time, and the surface mine fine mining system also has the effect of early warning cross-border mining behaviors.

Owner:CHINA NONFERROUS METAL CHANGSHA SURVEY & DESIGN INST CO LTD

A method for recovering ilmenite concentrate by strong magnetic roughing and multi-stage spiral chute gravity separation

The invention discloses a method for selecting and recovering titanium concentrate by using strong magnetic roughing and multi-stage spiral chute gravity separation. The method includes the following steps: 1) Using a high-efficiency thickener to separate iron from iron tailings by weak magnetic separation 2) The fine mud in the underflow slurry is removed by an inclined plate thickener to obtain the underflow; 3) The coarse slag in the underflow is separated by a high-efficiency linear sieve to collect the separated slag 4) According to the difference in specific magnetic susceptibility coefficient between titanium concentrate and magnetite, a 3000Gs semi-countercurrent magnetic separator is selected to pre-remove the tailings after separation of slag; and then remove iron and titanium by weak magnetic iron removal Mixed conjoined organisms, and then carry out strong magnetic separation through a vertical ring pulsating high-gradient magnetic separator; 5) The product obtained in step 4) is subjected to multiple roughing, sweeping and selective selection by a spiral chute, and the separation by the spiral chute The material method adopts a three-stage annular separator to divide the material, and the final spiral titanium concentrate is obtained after being separated by a multi-stage spiral chute.

Owner:会理秀水河矿业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com