Homogenization and filtration equipment for chemical gypsum and homogenization and filtration method

A filtration equipment and chemical gypsum technology, applied in chemical instruments and methods, chemical/physical processes, filtration and separation, etc., can solve the problems of difficult to improve quality, corrosion and energy consumption, large equipment investment, etc., to achieve stable product quality and reduce production. Energy consumption, good filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

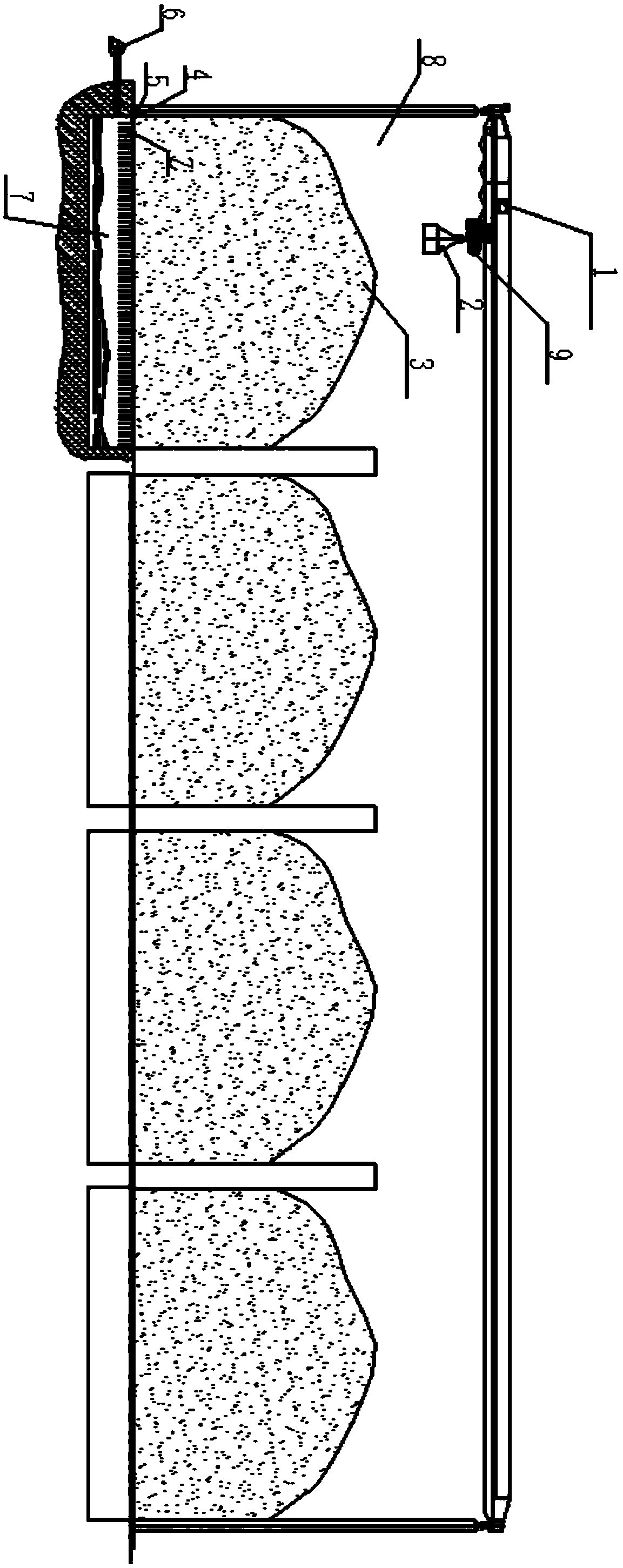

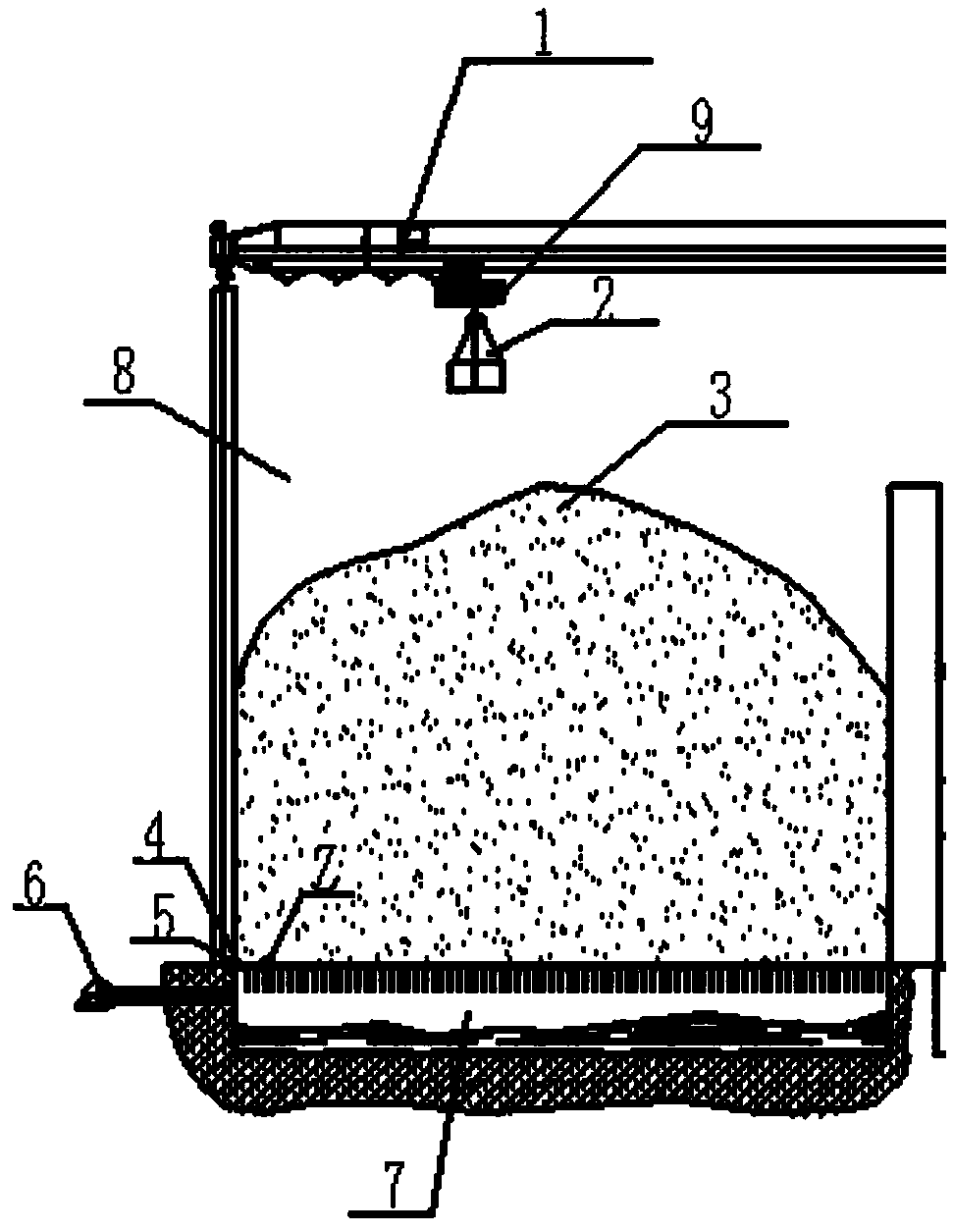

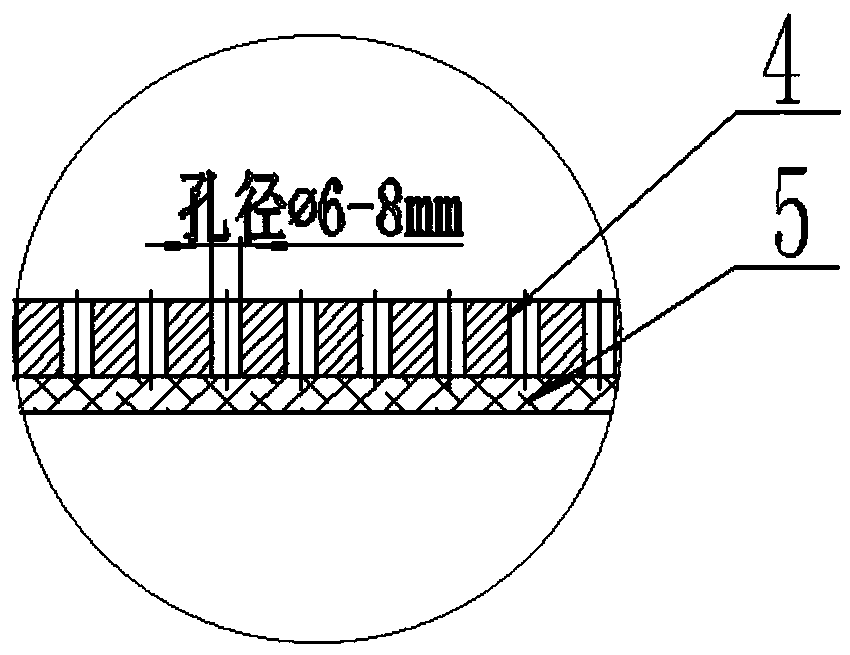

[0031] Example 1, such as Figure 1-4 As shown, the present embodiment provides a homogenizing and filtering equipment for chemical gypsum, including four kilns 8 in a row, and a water filtration collection device connected to the bottom of each kiln passage 8, which is located in the water filtration collection device The filter layer and the vacuum pump 6 connected with the filtered water collection device; the filter layer includes an upper orifice filter layer 4 and a lower filter cloth filter layer 5.

[0032] The above-mentioned device is a filtering device for gypsum; the gypsum is added to the stacking area in the kiln 8 from the inlet and outlet passages, and the gypsum is filtered through the orifice filter layer 4 and the filter cloth filter layer 5 in the water filtration collection device at the bottom of the kiln 8 in sequence. The primary filtration realized by the plate filter layer 4, the secondary filtration realized by the filter cloth filter layer 5, the fi...

Embodiment 2

[0039] Embodiment 2, the present embodiment provides a homogenizing filtration method of chemical gypsum homogenizing filtration equipment, comprising the following steps:

[0040] 1) Feeding: gypsum is evenly added to the stacking area in the kiln from the inlet and outlet channels;

[0041] 2) Filtration: Gypsum is filtered sequentially through the orifice filter layer and filter cloth filter layer in the filter water tank at the bottom of the kiln, and the filtered water flows into the sump through the collection box for collection; Cloth filter layer for secondary filtration, high filtration efficiency, good product quality;

[0042] 3) Homogenized discharge: The filtered gypsum grabs the materials in the kiln at multiple points through the grab hopper on the top of the kiln according to the set program sequence, and enters the storage hopper of the production line to discharge, so as to realize the homogenization of the material; after the discharge is completed, continue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com