Due to the properties of the DC power supply, the constant magnetic field coil only has the function of adsorption. After the concentrate

powder is absorbed, it does not have the ability to roll over. Therefore, the internal inclusions cannot be squeezed out. When the absorbed mineral

powder reaches a certain amount At this time, part of the ore

powder breaks away from the constraints of the magnetic field and falls into the washing drum. Since it does not have the functions of tumbling and scrubbing, the non-magnetic inclusions inside the

iron powder also fall into the washing drum, causing damage to the stable separation environment in the drum. Causes the output concentrate grade to be unstable

At the same time, the magnetic field along the cylinder wall to the center of the cylinder gradually decreases, making some areas in the cylinder a non-magnetic area and a weak magnetic area. For this area, when the

water flow is too large, it is impossible to use the magnetic field to absorb the fine-grained concentrate that rises with the

water flow. Therefore, the constant magnetic field coil has little effect in a stable sorting environment. When the

water flow or pulp volume fluctuates too much, it cannot play a decisive role in ore control, resulting in runaway

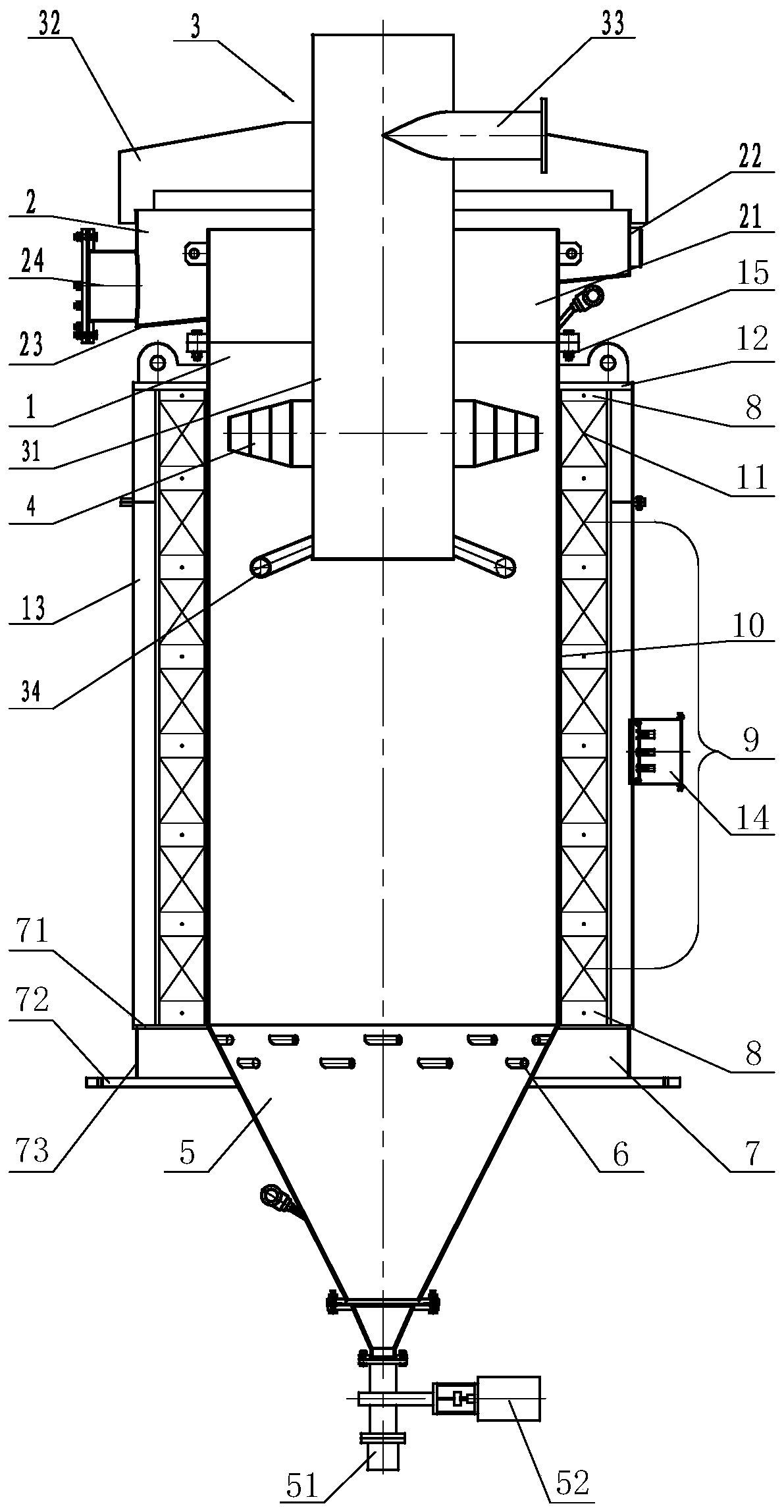

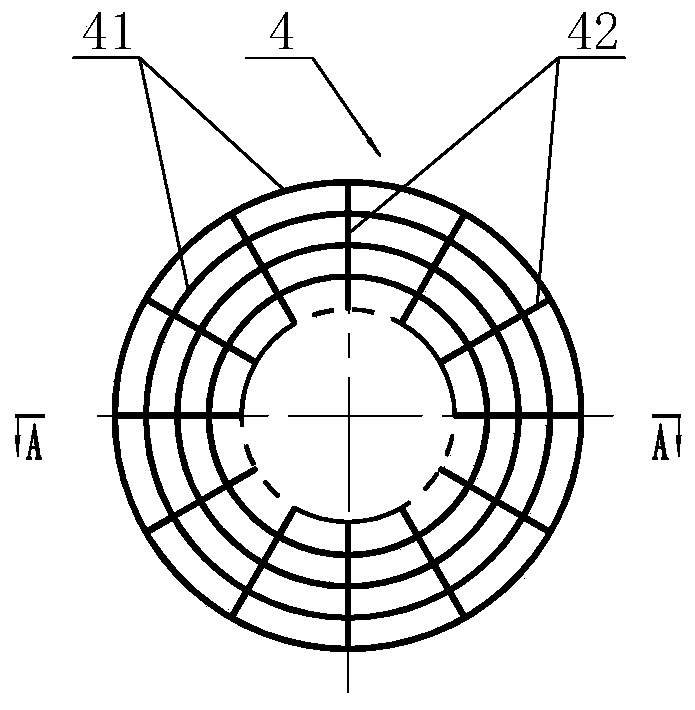

The lower end of the ore feeding

pipe is evenly distributed with ore distribution outlets along the circumferential direction. This method of ore distribution is to feed the ore in a way that coincides with the axis of the washing cylinder. The ore distribution mouth of the cloth flows into the rising water flow. Because the ore distribution mouth is far away from the inner cylinder wall, the magnetic field has a

weak binding force on the ore

slurry at this place. In this area, a

magnetic chain cannot be formed basically, and the magnetic rolling effect cannot be produced. And because the settlement distance is too long Therefore, unreasonable ore distribution position and method and too long feed

pipe cause too short settlement distance is one of the

key factors affecting the quality of concentrate

[0005] Secondly, the water inlets of the traditional electromagnetic

elutriation machine are evenly distributed on the horizontal circumference of the lower part of the washing cylinder, and holes are directly opened on the horizontal circumference, so that the water flow into the cylinder is in a disordered state, causing the concentrate that settles here to be disturbed again Breaking up will cause great damage to the enriched concentrate. Even if the enriched ore gathering coil with a constant magnetic field is installed at the lower part of the water inlet, it is difficult to adsorb the concentrate powder in the center of the washing cylinder, and it will not achieve good results. Enrichment

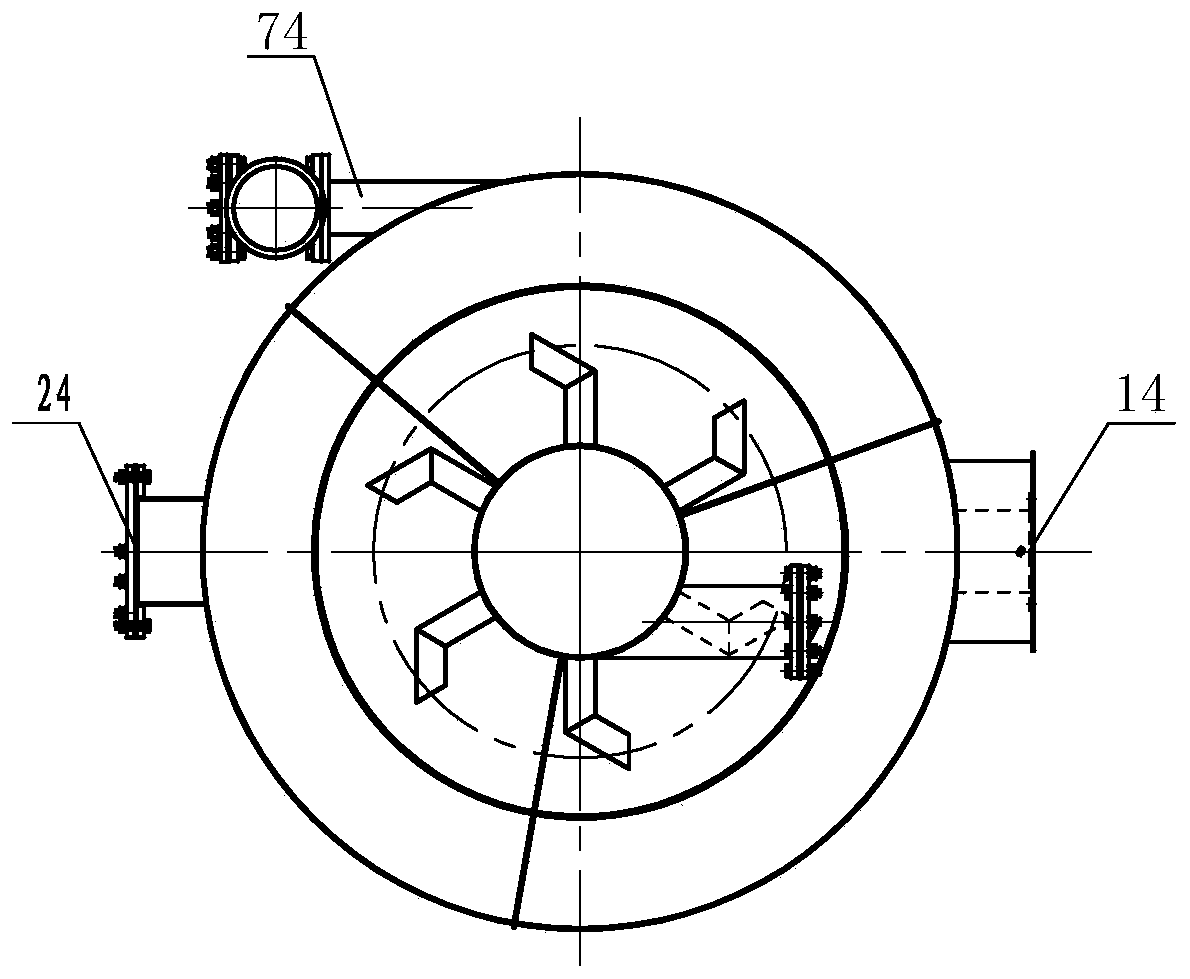

Therefore, it is inappropriate to set the water inlet at this position and the way of setting the water inlet; some manufacturers set the water inlet in the horizontal area of the fourth and fifth coils, and connect the

water pipe from the outside of the washing tube to the inside of the tube perpendicular to the At the axis of the washing cylinder, connect a water inlet

pipe that coincides with the axis of the washing cylinder to the horizontal area of the fourth and fifth coils, block the top of the water inlet pipe, and distribute water distribution pipes horizontally on the upper circumference of the water inlet pipe. A number of water outlets are evenly distributed on the same side of each water distribution pipe, so that the water flow is in an upward spiral state. Since the grade of the concentrate has reached the ideal state when it enters this area, it is the key stage of enrichment and accumulation. After the upward spiral Disturbance of water flow breaks up the preliminarily enriched concentrate powder again, which is not conducive to ore gathering

Moreover, in this area, the law of progressively improving

water quality conditions from top to bottom in the water distribution and destruction cylinder shows that the

water quality in the

water supply area is the best, followed by the lower area, and the top area is the worst. The problem of recontamination

[0006] Moreover, the power supply of the traditional electromagnetic

elutriation machine adopts DC excitation, and alternately energizes through the

thyristor, so that an alternating pulsating magnetic field is generated between the coils. For example, when coils 1, 3, and 5 are energized at the same time, the concentrate powder located here forms Magnetic linkage, the concentrate powder in a fixed magnetic field only forms a magnetic linkage, and the concentrate particles are relatively immovable, so it is impossible to scrub and precipitate the non-magnetic inclusions inside. When the power is turned off, the magnetic linkage disappears, and the concentrate powder continues to sink A part of the fine

ore concentrate powder is discharged into the

tailings with the rising water flow and the medium and fine-grained non-magnetic substances without magnetic field adsorption.

When coils 2, 4, and 6 are energized, the fine ore powder rotates 180° from the state in the previous magnetic field cycle to form a

flux linkage again. The energization intervals of the two sets of coils are different due to the different sorting environments, and the approximate range is 1 Between -6 seconds, while the magnetic rolling effect is realized repeatedly, the interval non-magnetic

window period also causes a large amount of fine

ore concentrate powder to be thrown into the

tailings, resulting in a waste of a lot of resources

Due to the difference in ore properties, the emphases of ore dressing are different, and the elutriation machine must have a large magnetic field adjustment range and matching tumbling times and scrubbing functions. However, the traditional DC electromagnetic elutriation machine The adjustment range of the magnetic field is narrow, it does not have the function of scrubbing, and it cannot meet the ore separation requirements with huge differences, resulting in the

beneficiation indicators failing to meet

customer requirements Login to View More

Login to View More  Login to View More

Login to View More