Composite inhibitor for reverse flotation of carbonate-containing iron ore as well as preparation method and application of composite inhibitor

A compound inhibitor and reverse flotation technology, applied in flotation, chemical instruments and methods, magnetic separation, etc., can solve the problems of unfavorable food security, poor selectivity of flotation reagents, easy sludge, etc., and reduce the consumption of grain resources. , Improve the flotation effect, enhance the hydrophilic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Prepare cornstarch and sodium alginate into an emulsion with a concentration of 50% according to the mass ratio of 0.5:1, then add it to a constant temperature hydrothermal reaction kettle and keep stirring, then add cornstarch and alginic acid Sodium hydroxide and 4% sodium chloride with a total mass of sodium of 8%, the reaction temperature is controlled at 60°C, and the reaction is carried out for 5 hours;

[0035] (2) After reacting for 5 hours, add polyacrylamide with 10% of the total mass of cornstarch and sodium alginate, adjust the reaction temperature to 85°C, continue to react for 4 hours to obtain a composite inhibitor, neutralize the composite inhibitor, wash and filter , dried and then prepared into an aqueous solution with a concentration of 8% for later use.

Embodiment 2

[0037] (1) Prepare cornstarch and sodium alginate into an emulsion with a concentration of 40% according to the mass ratio of 1:1, then add it to a constant temperature hydrothermal reaction kettle and stir continuously, then add cornstarch and alginic acid 5% sodium hydroxide and 3% sodium chloride of the total sodium mass, the reaction temperature is controlled at 50°C, and the reaction is 3h;

[0038] (2) After 3 hours of reaction, add polyacrylamide with 10% of the total mass of cornstarch and sodium alginate, adjust the reaction temperature to 80°C, and continue to react for 3 hours to obtain a composite inhibitor, neutralize the composite inhibitor, wash and filter , dried and then prepared into a 5% aqueous solution for later use.

Embodiment 3

[0055] A carbonate-containing iron ore mixed magnetic concentrate in Liaoning area was used as the flotation raw material. The particle size analysis result was -0.038mm, accounting for 89.62%. The TFe grade in the ore sample was 43.02%, and the SiO2 content was 50.68%. The salt mineral content is 6.86%.

[0056] The specific implementation steps are as follows:

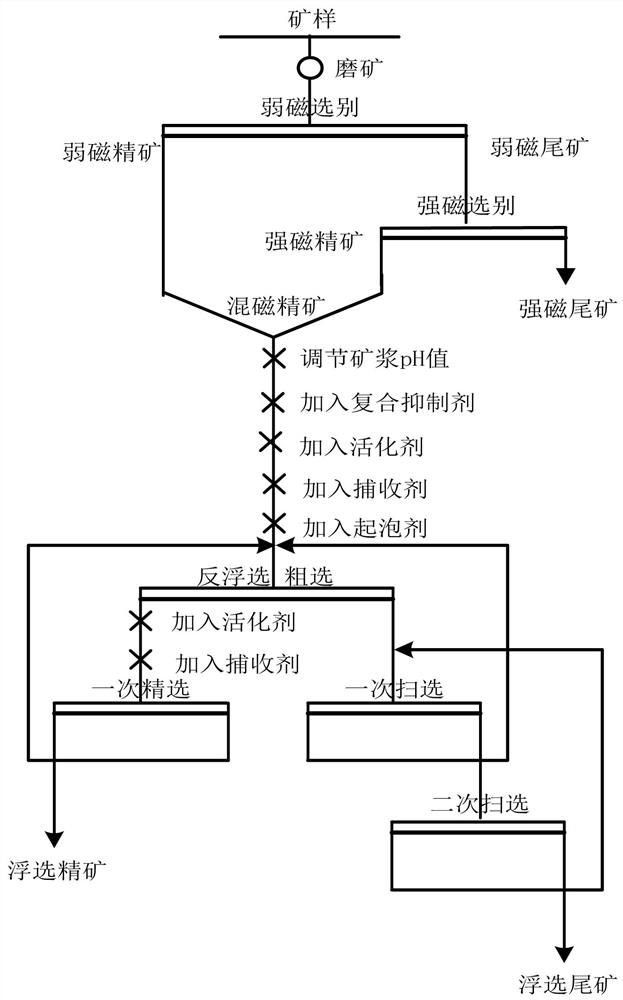

[0057] (1) Stir the obtained carbonate-containing iron ore mixed magnetic concentrate to adjust the slurry to a slurry with a mass concentration of 35%, and then add the slurry pH value regulator sodium hydroxide to adjust the slurry pH value 11.0, add compound inhibitors in sequence, the dosage of medicament is 600g / t, the dosage of gangue mineral activator lime is 600g / t, the dosage of collector sodium oleate is 500g / t, the dosage of No. 2 oil of foaming agent is 30g / t, adjust After slurrying for 3 minutes, carry out the reverse flotation roughing test, and the roughing time is 5 minutes;

[0058] (2) Carry out a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com