Patents

Literature

61results about How to "Production process specification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Technique for separating mineral from weak magnetic separation iron tail sand

InactiveCN101219412AProduction process specificationLow costElectrostatic separationFlotationApatiteNon magnetic

The invention relates to a method used for separating minerals from weak magnetic iron tails, which is divided into six stages: primary sorting of strong magnetic minerals, separation of strong magnetic minerals, separation of weak magnetic minerals, separation of non-magnetic minerals, treatment of ore pulp water during the ore dressing process and treatment of finish tail sand. According to the magnetic susceptibility differences, specific gravitydifferences and floating differeces between minerals, magnetite, vanadium titano-magnetite, mixed ore of apatite and xenotime and hematite feldspar concentrate can be separated from the weak magnetic iron by using techniques of crude separation with a strong magnetic separator, refine separation with a weak magnetic separator, gravity separation, floatation, electric separation, etc. The method has advantages of standard production technique, low cost for industrialized production, great variety of separated minerals, stable quality and high separating efficiency, thereby having significant social and economic benefits.

Owner:冯云善

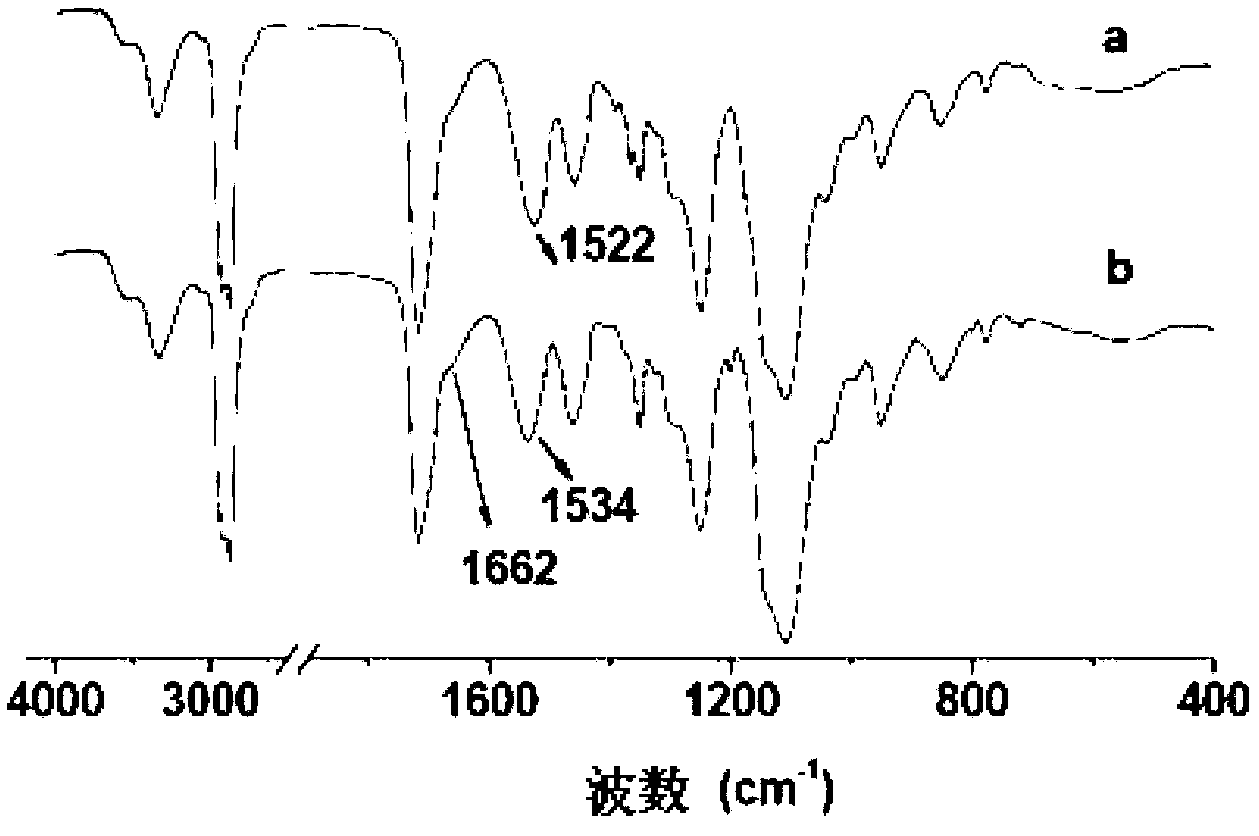

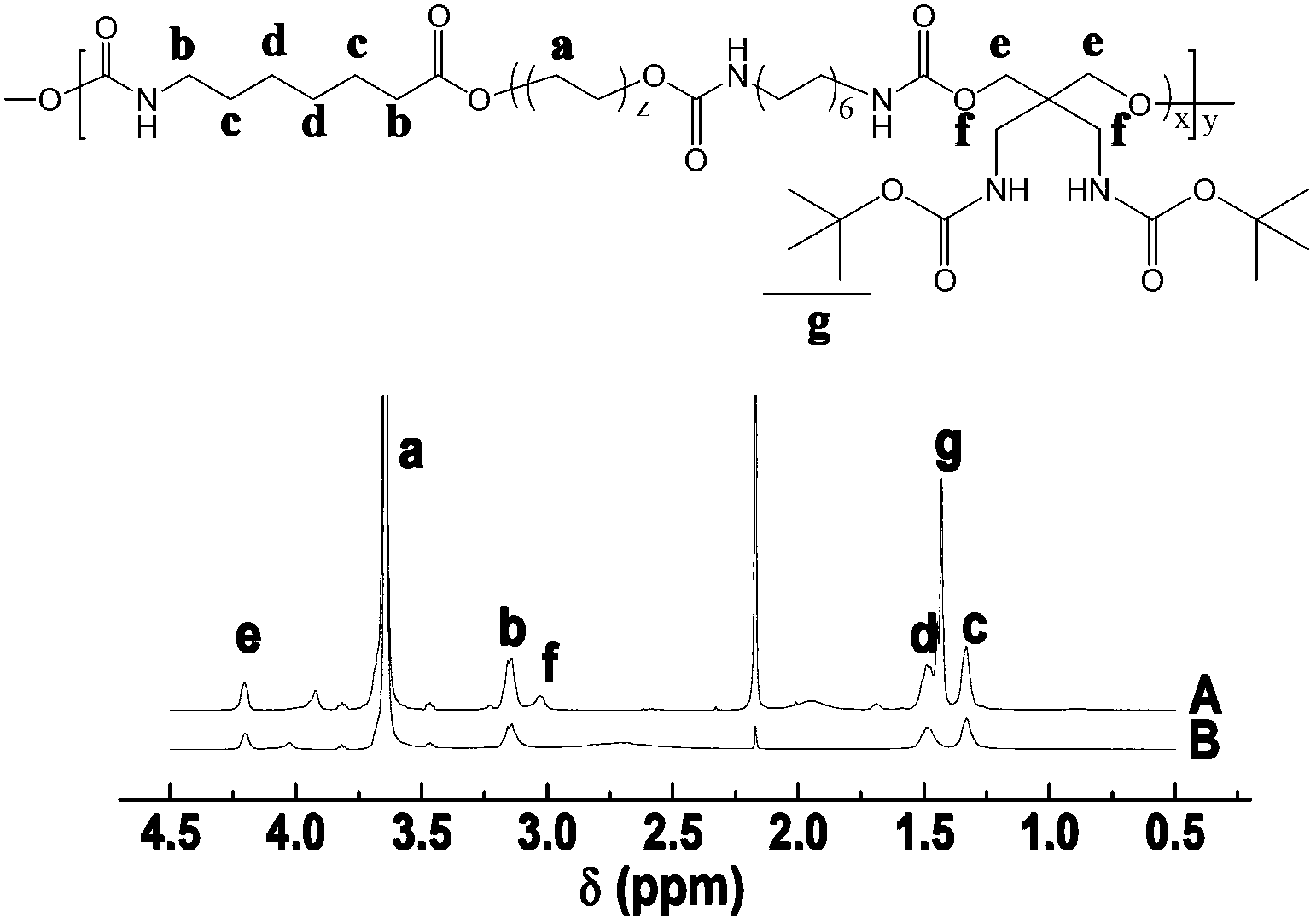

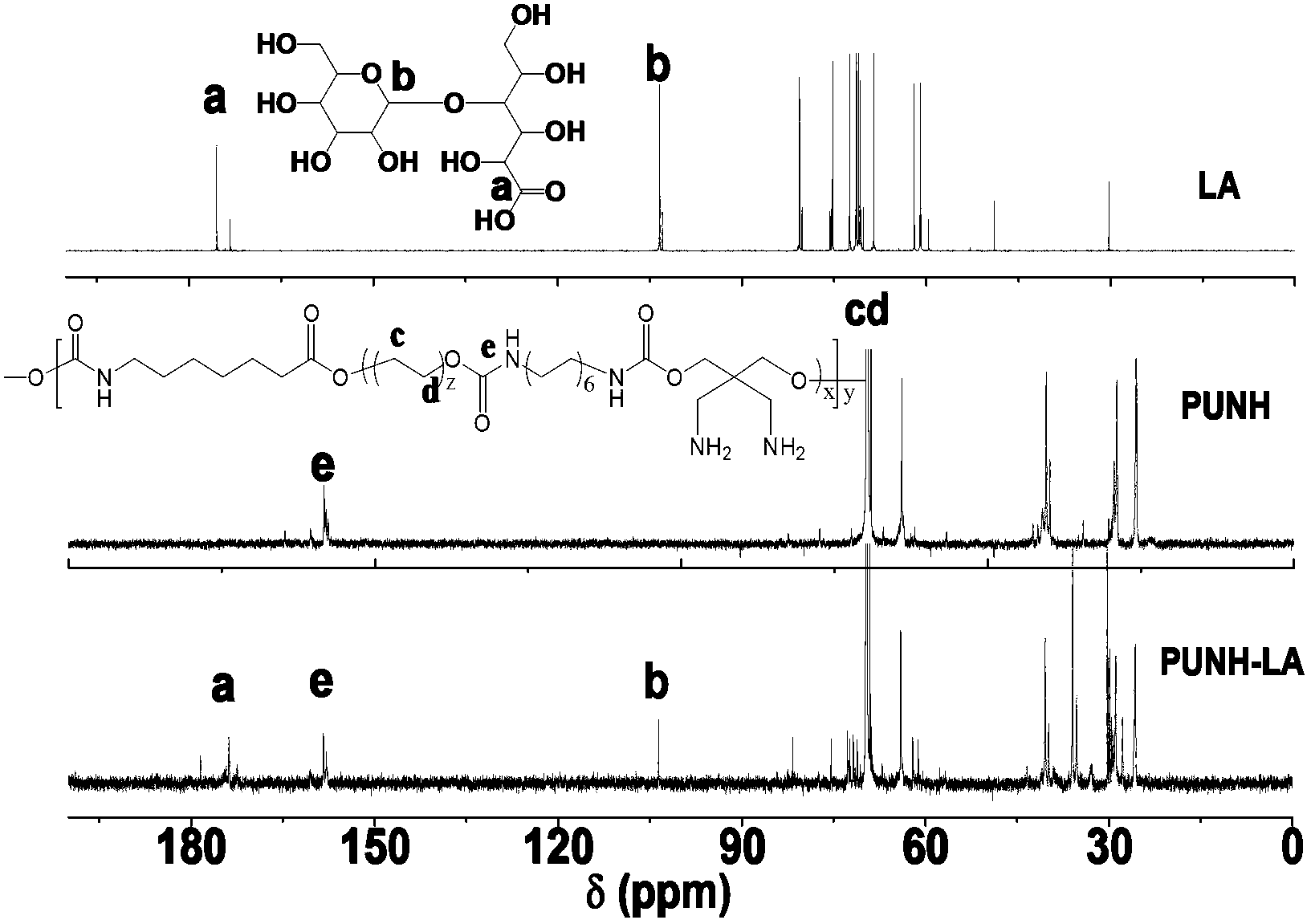

Biodegradable polyurethane with amino on side chain and preparation method and application thereof

InactiveCN103172819ARegular structureGood biocompatibility and biodegradabilityOrganic active ingredientsPharmaceutical non-active ingredientsIsocyanateFluorescence

The invention provides biodegradable polyurethane with an amino on the side chain and a preparation method and application thereof, belonging to the field of biomedical materials. Polyurethane is formed by a soft segment and a hard segment, wherein the soft segment is biodegradable polyester diol or biodegradable polyether diol; the hard segment is formed by aliphatic diisocyanate and a chain extender; and the hard segment is provided with the free or protected amino. The biodegradable polyurethane serves as a drug carrier, can wrap drug molecules to form drug carrying microspheres in the nanometer or micrometer scale and can be used for bonding drug molecules, fluorescent molecules and targeted molecules to prepare polyurethane bonded drugs, polyurethane fluorescent probes or polyurethane targeting carriers.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

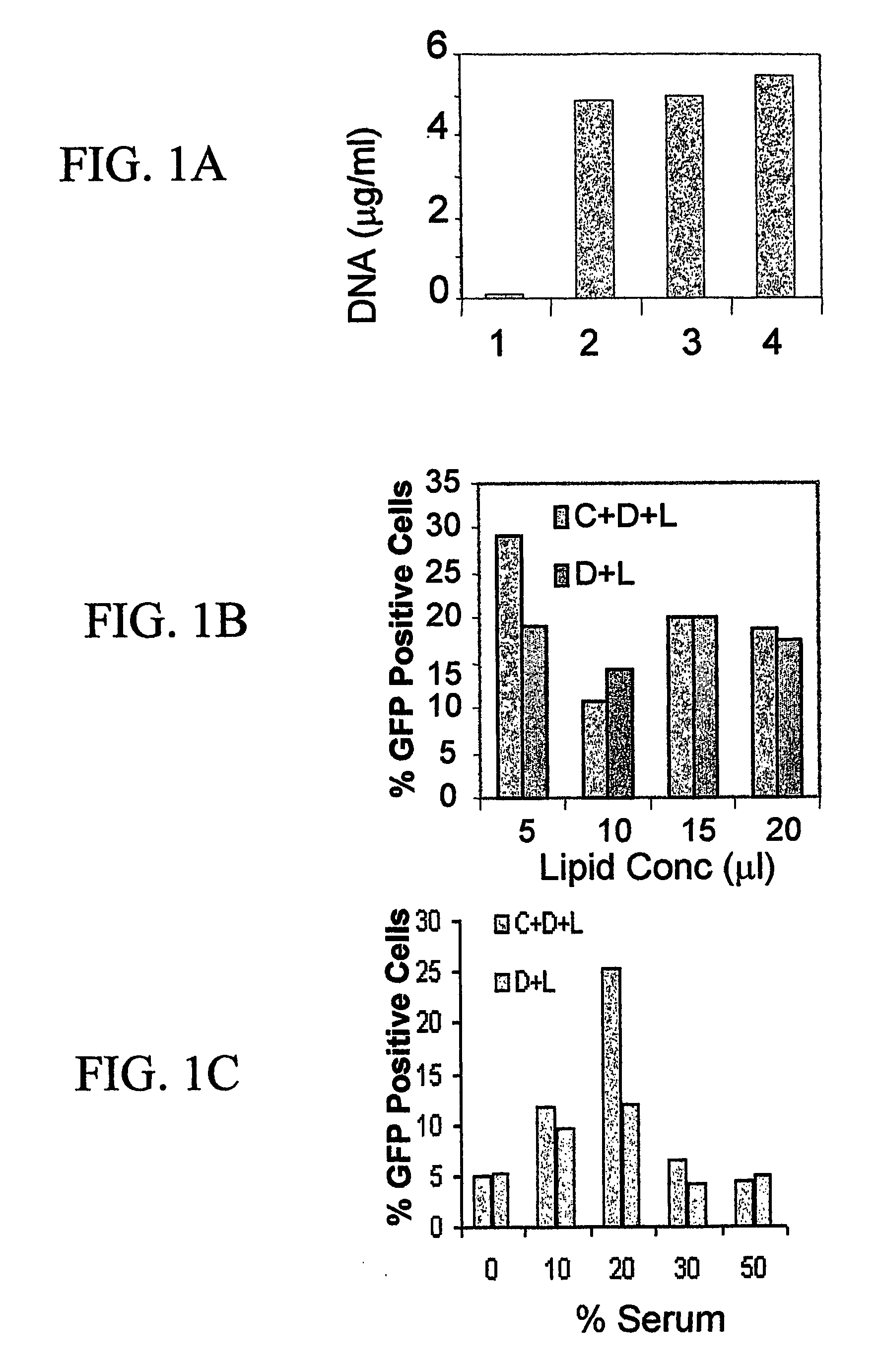

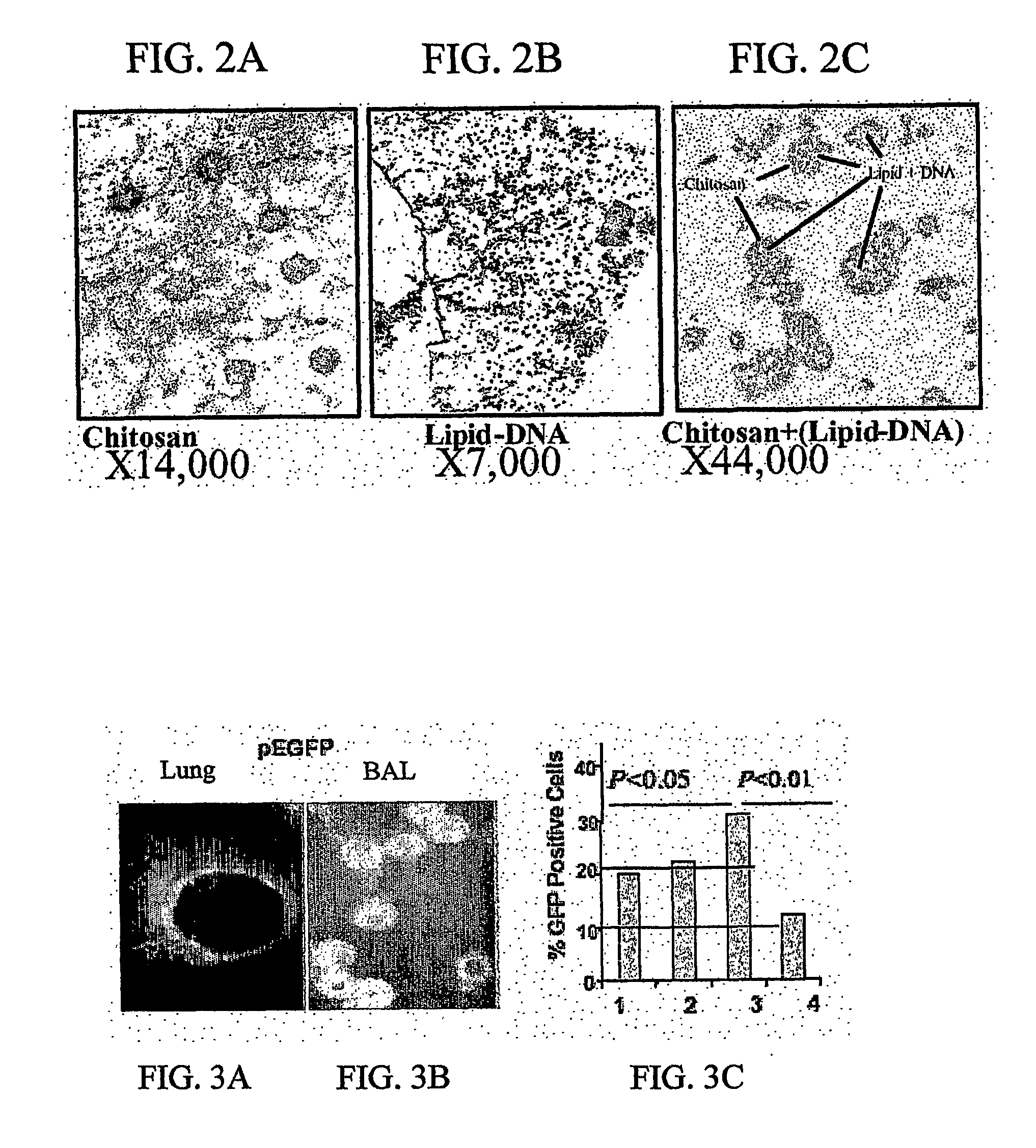

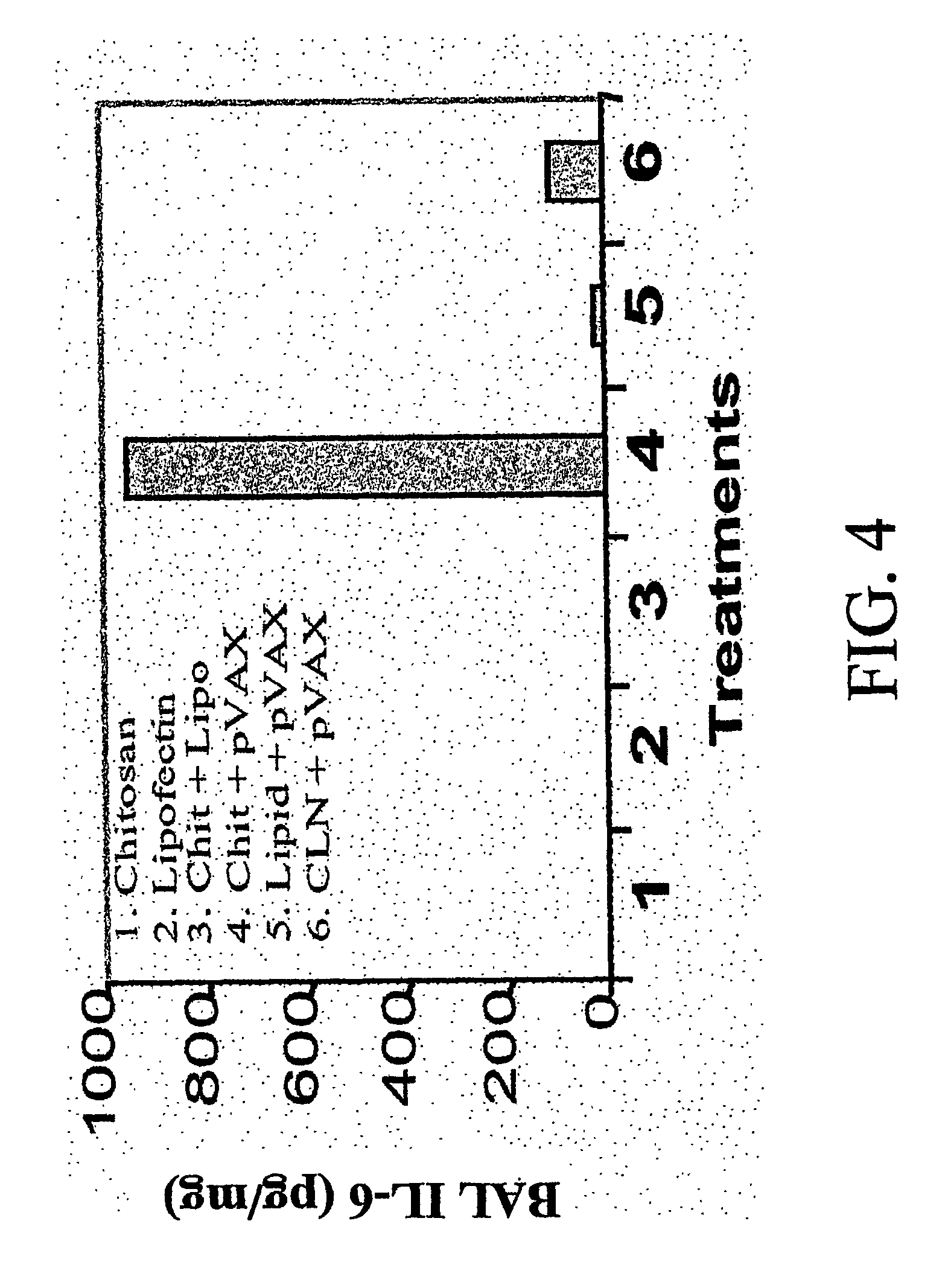

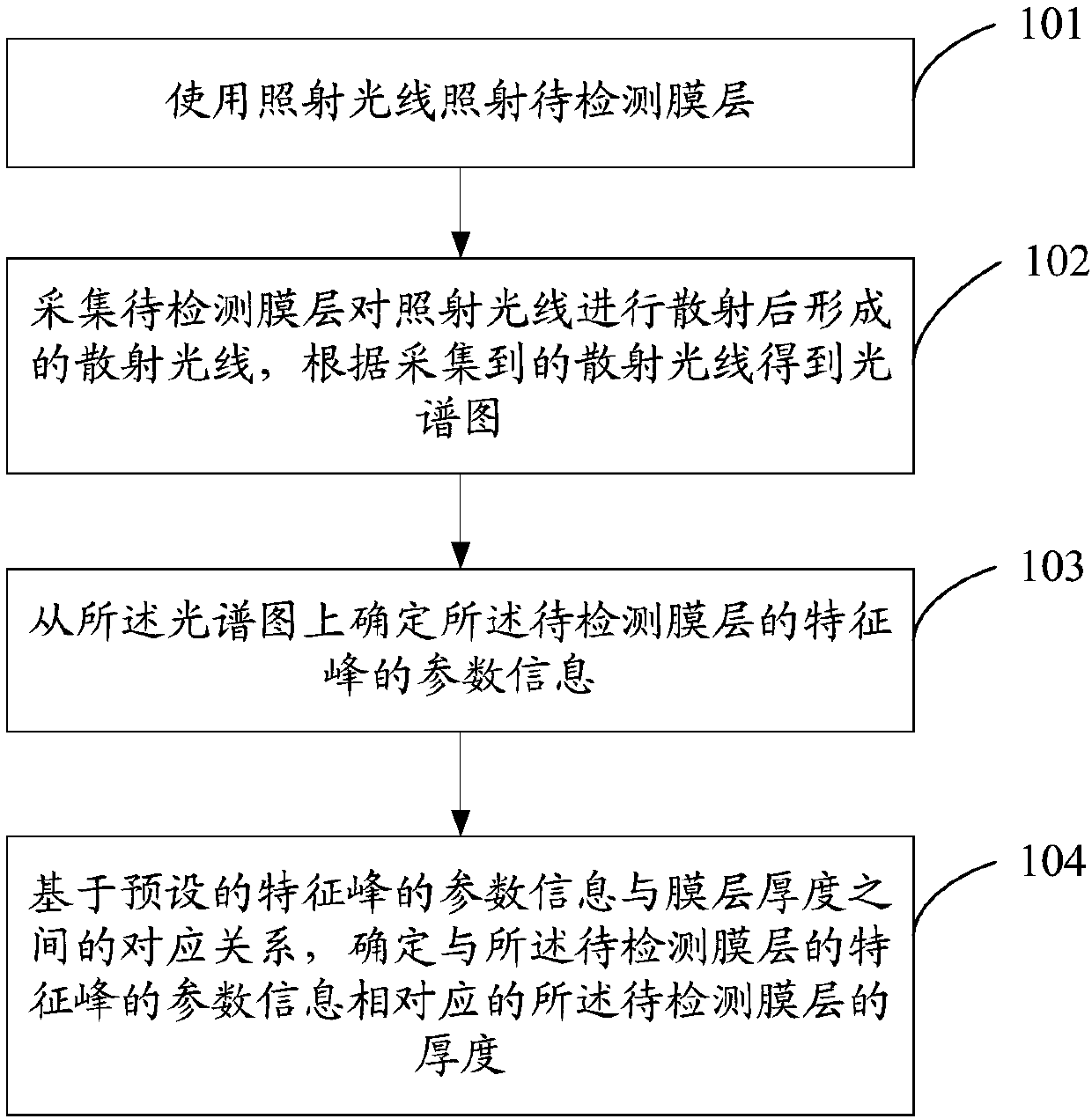

Chitosan-microparticles for ifn gene delivery

InactiveUS20070116767A1Enhancing interferon-gamma expressionProduction process specificationPowder deliveryBiocideGene deliveryDelivery vehicle

The present invention provides particles comprising chitosan, or a derivative thereof, useful as delivery vehicles for polynucleotides encoding polypeptides, compositions comprising such particles and a pharmaceutically acceptable carrier, and methods for delivering polynucleotides using such particles. Optionally, the particles of the invention further comprise a lipid component. The present invention further provides a method for enhancing interferon-gamma expression to regulate the production of cytokines secreted by T-helper type 2 (Th2) cells within a subject by administering an effective amount of a particle of the subject invention to the subject, wherein the particle comprises a polynucleotide encoding interferon-gamma.

Owner:UNIV OF SOUTH FLORIDA

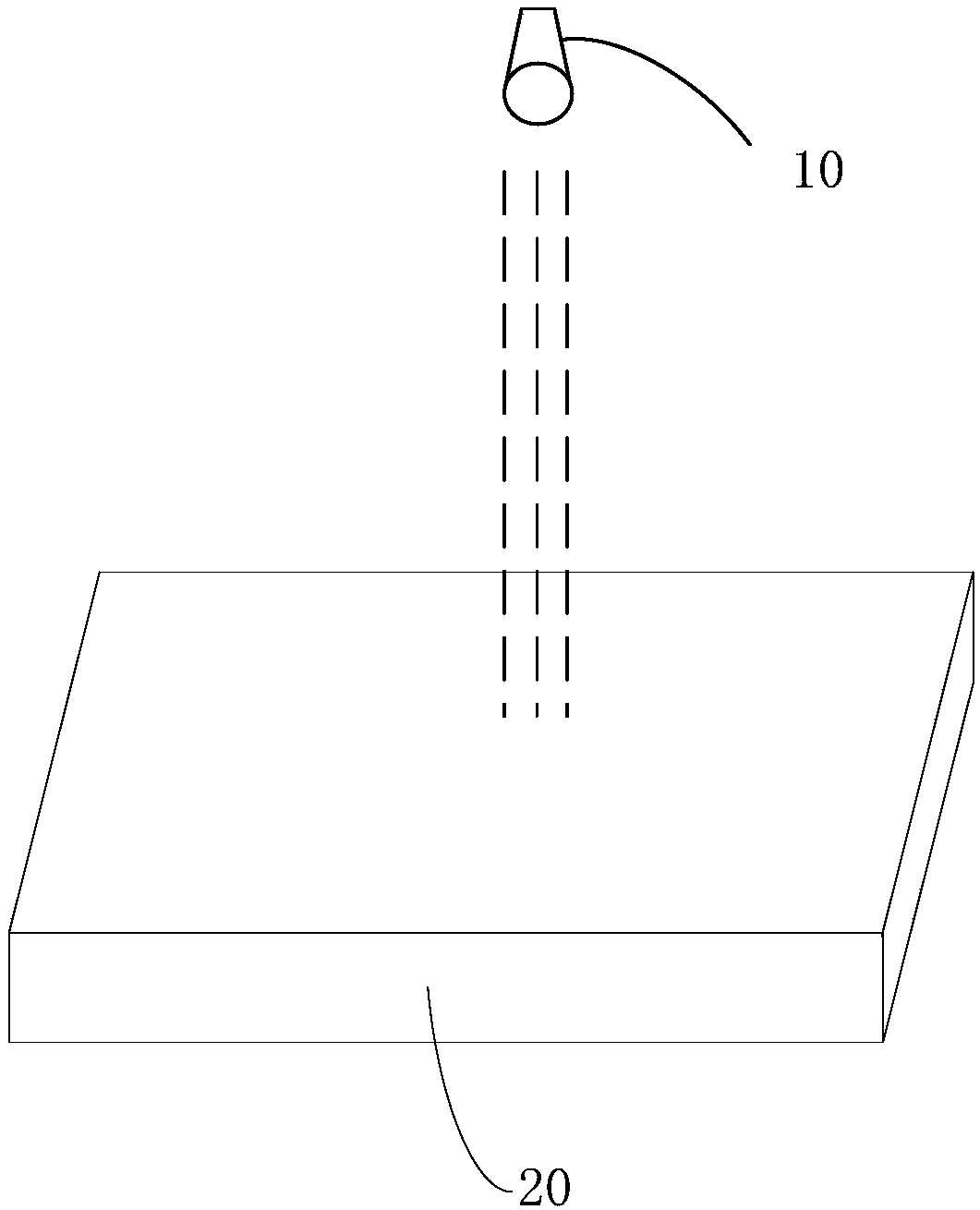

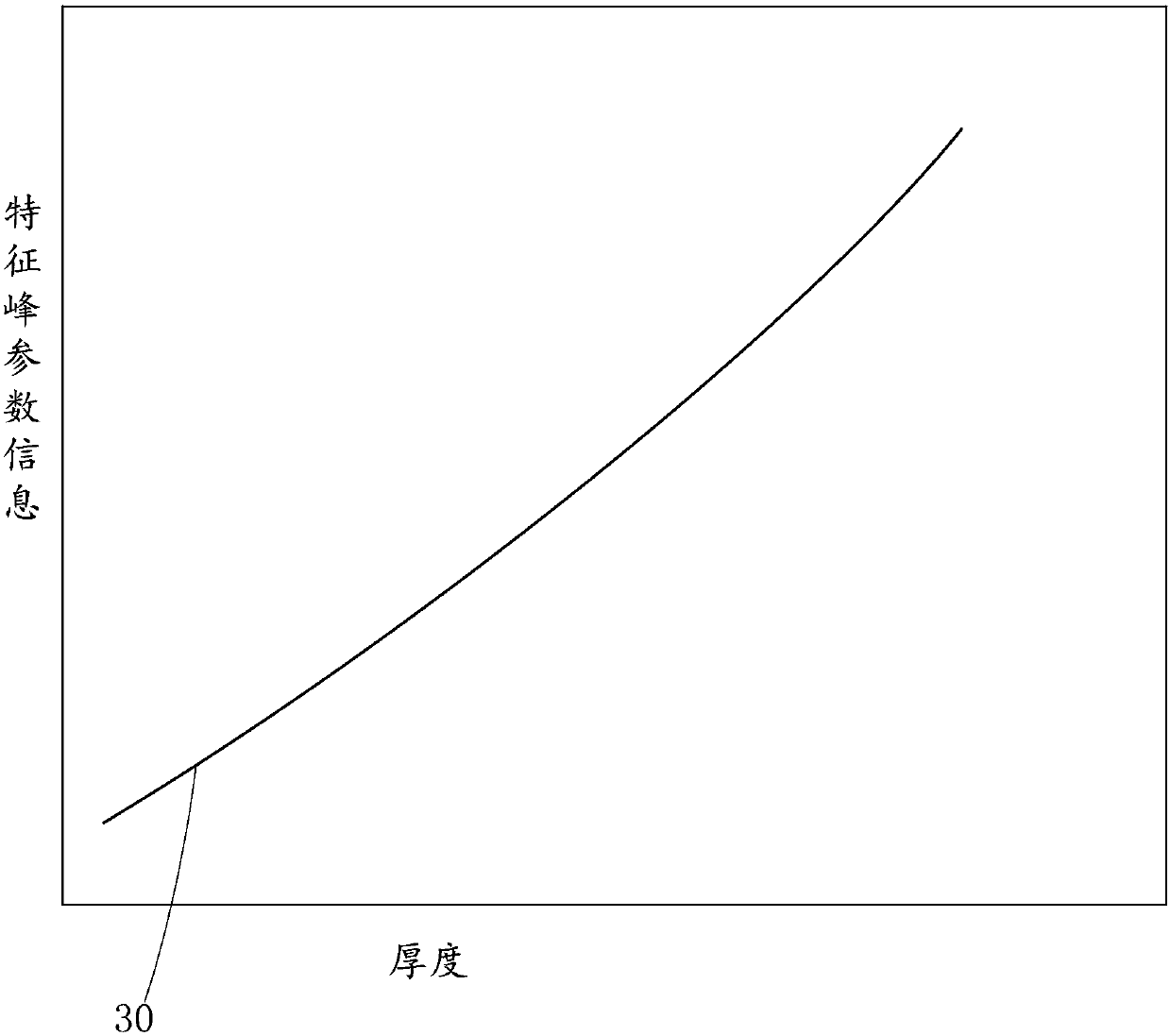

Detection method of film layer thickness

InactiveCN108050947AImplement automatic detectionUndetectableUsing optical meansLayer thicknessSpectrogram

The invention provides a detection method of film layer thickness. By using illuminating light to illuminate a film layer to be detected, scattering light formed by scattering the film layer to be detected is acquired, a spectrogram is obtained according to the acquired scattering light, parameter information of a characteristic peak of the film layer to be detected can be obtained from the spectrogram, and thus the thickness of the film layer to be detected is determined through the parameter information. In this way, the thickness of the film layer to be detected can be automatically detected, repeated manual detection and repeated adjustment are not needed, time and labor are saved, the detection method is convenient to operate, the production cost is lowered, the capacity is improved,and a production technology is normalized.

Owner:BOE TECH GRP CO LTD +1

Method for processing hot-stewed airing rabbit

InactiveCN102429250AChange the processing technologySuitable for mass productionFood preparationFermentationChemistry

The invention relates to a method for processing a hot-stewed airing rabbit. The method comprises the following steps of: inoculating auxiliary materials to an integral rabbit which is cooled and subjected to acid discharge, rolling and kneading under vacuum, salting and fermenting at low temperature, hanging, airing and fermenting in the shade, performing halogen cooking, drying, finishing, packaging, sterilizing, keeping temperature and inspecting, wherein the auxiliary materials consist of the following components in part by weight: 3 to 5 parts of fermentation agents, 3 to 4 parts of halogen materials and 4 to 5 parts of flavorings. In the method, the convention salting process is changed by utilizing a vacuum rolling and kneading technology, and the fermentation agents such as a probiotics growth promoter, a proenzyme activator and the like are added by utilizing a microbial fermentation technology; the integral rabbit is fermented twice and is flavored and subjected to the halogen cooking, a modernization processing process and the conventional sauce halogen process are combined, the conventional process for processing airing products is changed, the production period of the products is shortened, the integral production process is finished only for 22 to 26 hours, and the integral processing process can be programmed and standardized; and thus, method is suitable for large-scale batch production of factories.

Owner:青岛康大食品有限公司

Production method of quick frozen lotus rhizome product

ActiveCN1830305AFull of nutritionEasy to store and transportFood preservationFood preparationRhizomeLotus root

A process for preparing the quickly frozen stuffed double-layered lotus root slice includes such steps as slicing lotus root, preparing the stuffing from vegetables and meat, preparing paste from starch, filling stuffing between two lotus root slices, pre-steaming, coating paste, frying in hot oil, quick freezing and packing. It has unique taste and rich nutrients.

Owner:YANGZHOU TIANHE FOOD

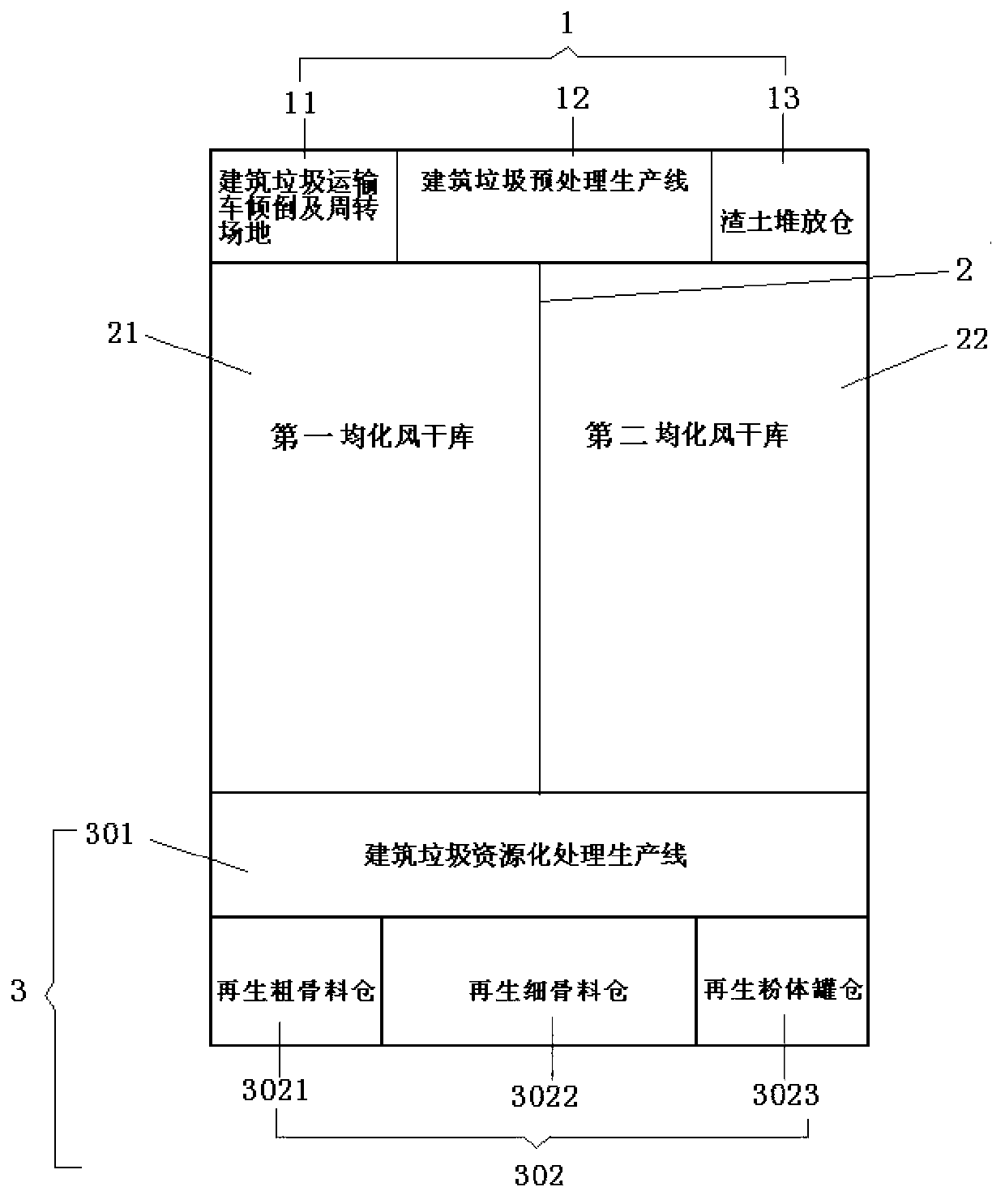

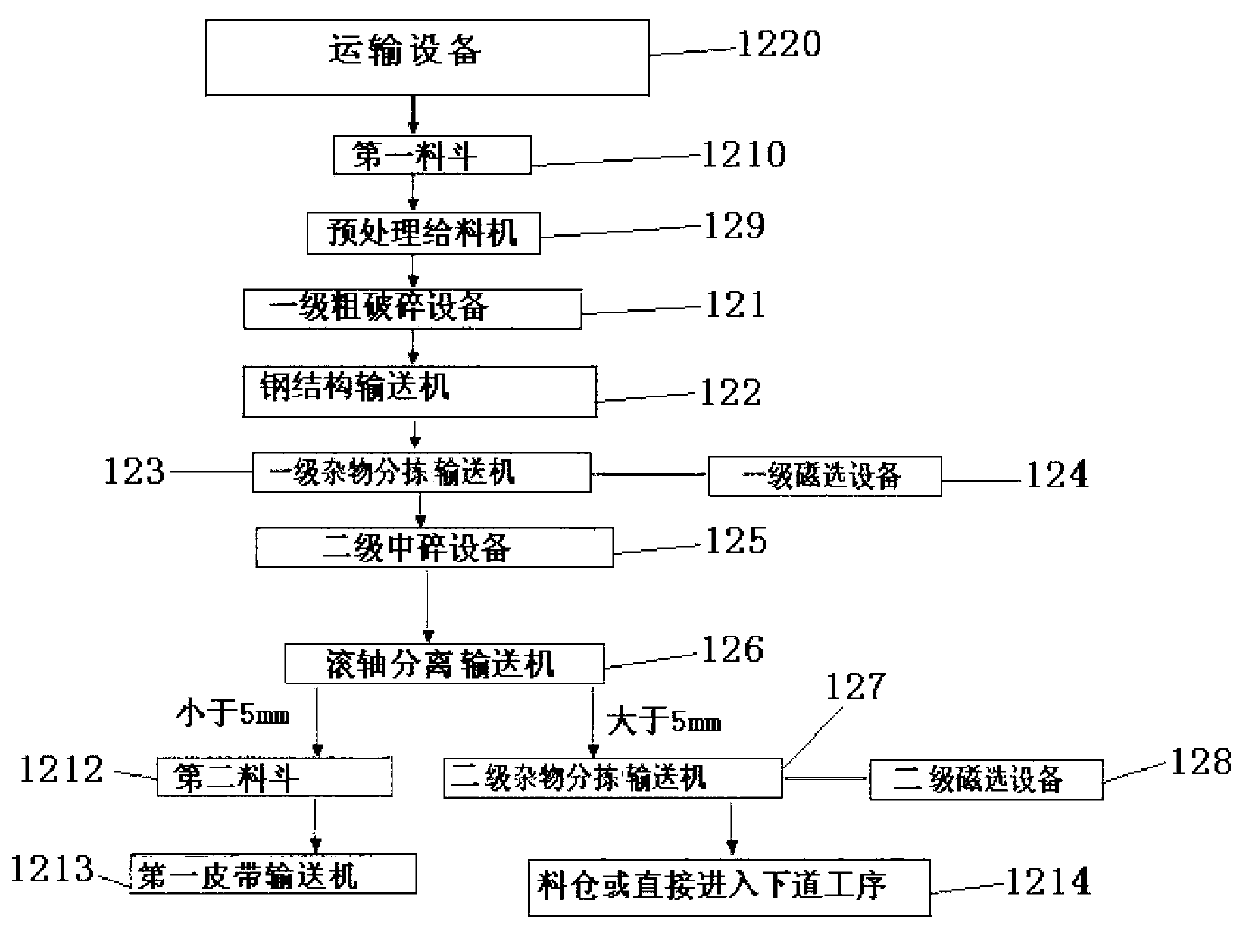

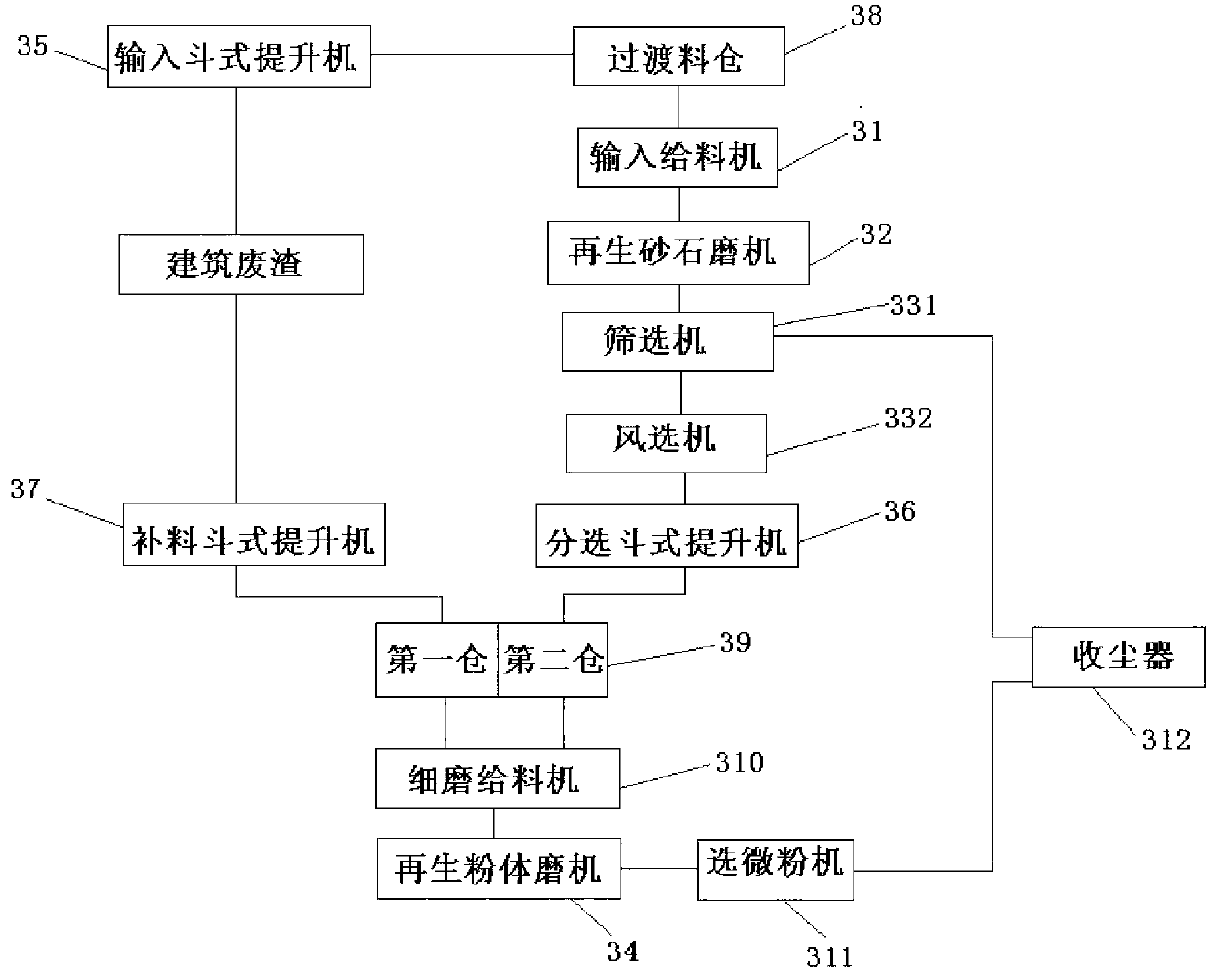

Factory type construction waste resourceful treatment system and technological process thereof

ActiveCN103128094AEasy to absorb waterIncrease moisture contentConstruction waste recoverySolid waste disposalLitterMaterials processing

The invention discloses a factory type construction waste resourceful treatment system and a technological process of the factory type construction waste resourceful treat system and belongs to the technical field of construction waste treatment. The factory type construction waste resourceful treatment system comprises a pretreatment unit, a homogenized drying unit and a recycled material processing production unit which are arranged in sequence. The layout of the technical scheme includes that no matter how the specification and the size of the components and the moisture content of the construction waste change, the normal production of three recycled materials of the construction waste resourceful treatment can not be influenced; and no matter how the three recycled materials of the construction waste resourceful treatment are adjusted, combined and changed, the normal production of the construction waste pretreatment can not be influenced. The processing and production of the recycled materials refer to breaking and grinding of the construction waste residue after harmless treatment, stripping of mishmash, homogenization and drying, the moisture content of the construction residue can be basically controlled below 6%, and therefore smooth production can be achieved.

Owner:SHANGHAI GUOTONG ENVIRONMENTAL PROTECTION EQUIP

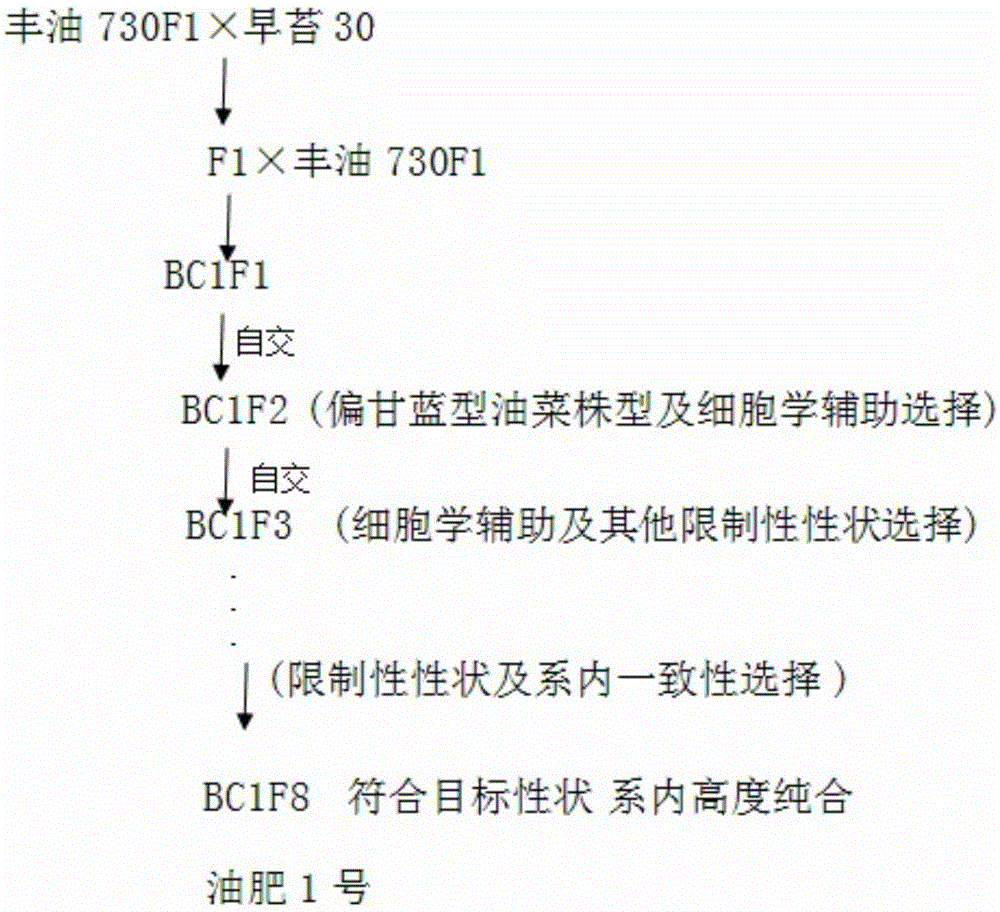

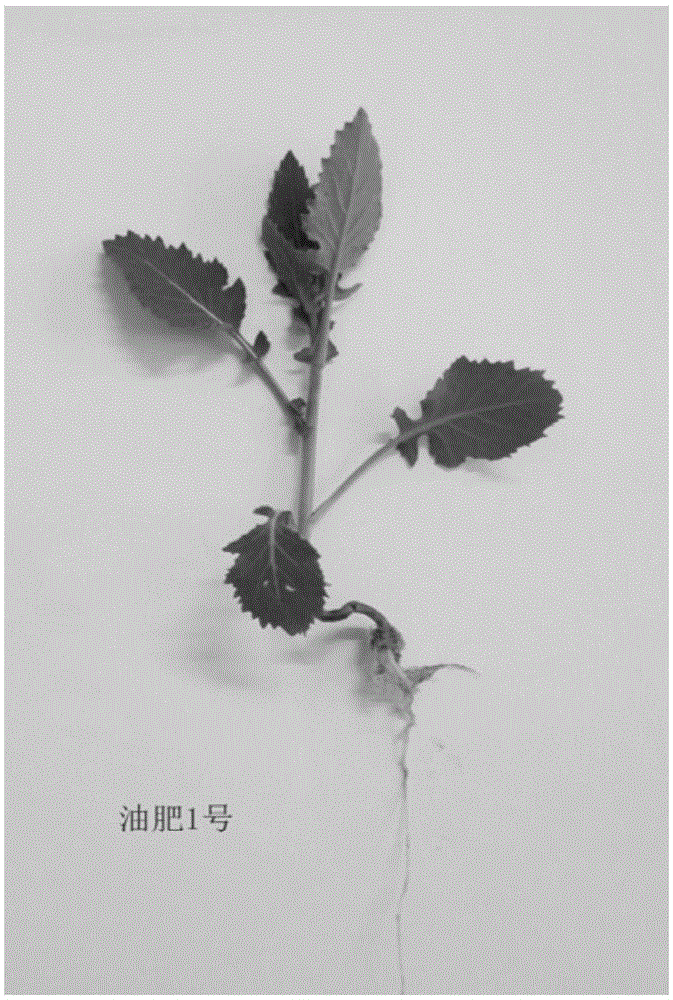

Breeding method of brassica napus capable of being specially adopted as green manure

The invention relates to a breeding method of brassica napus variety capable of being specially adopted as a green manure. The method comprises that brassica oleracea type hybrid brassica campestris is selected as the female parent and is subjected to interspecific hybridization with white brassica parachinensis to obtain a F1 generation hybrid species; the F1 generation hybrid species and the female parent are subjected to backcrossing to obtain BC1F1 seeds; the seeds are cultivated and are subjected to selfing to obtain BC1F2 seeds; the single plant having the chromosome number close to the brassica campestris female parent is selected to carry out selfing to obtain BC1F3 seeds; the single plant having the chromosome number n of 19 is further selected to carry out selfing to obtain BC1F4 seeds; and the BC1F4 seeds are subjected to subsequent multi-generation selfing, wherein the short growth period of the plant is adopted as the main limiting target character during the multi-generational selfing process and the consistent directional system selection in the line is performed until the brassica napus variety capable of being specially adopted as the green manure is obtained. With the breeding method of the present invention, the brassica napus variety capable of being specially adopted as the green manure and with characteristics of short growth period, strong adaptability, high biological yield and low seed production cost can be bred out.

Owner:湖南省作物研究所

Method for constructing food safety risk early warning system

The invention discloses a method for constructing a food safety risk early warning system. The method includes the following steps of developing software, conducting statistic analysis and detecting representative products. According to the method, a food safety dynamic risk management and dynamic supervision mode is established, accurate data support is supplied to relevant food organizations to conduct supervision, for food safety monitoring projects, response can be quickly made to various food hazards which constantly occur, corresponding effective measures are taken, life health safety of people is protected, indirect economic benefits are complementary, therefore, the food safety risks of enterprises are reduced, the fraction defective is reduced, production of distinctive agricultural products is standardized, and the method has very important economic and social benefits.

Owner:袁晓红 +1

Production process of buried gas PE pipe

The invention discloses a production process of a buried gas PE pipe, and the production process comprises the following steps: (1) compounding, to be more specific, selecting PE resin powder, a claynano composite material, a flame retardant, polyethylene wax, an antistatic agent, a low temperature resistant plasticizer and a coupling agent; (2) drying mixing, to be more specific, placing the selected raw materials in a dry mixer for drying and stirring to obtain a dry mixture; (3) extruding, to be more specific, and feeding the dry mixture into an extruder for extrusion; (4) cooling and setting, using a vacuum forming cooler to form and cool the extruded PE pipe under vacuum to obtain a PE base pipe; (5) preparing a wear-resistant layer; and (6) hot pressing, uniformly hot pressing the obtained wear-resistant layer and coating the outer surface of the prepared PE base pipe with the wear-resistant layer to obtain the finished PE pipe. The production process specification has low production cost and less waste, can ensure the quality of the produced product, can improve the impact resistance and wear resistance of the produced product, and increases the service life of the product.

Owner:四川省海维塑胶有限公司

Lees Chinese cabbage production technique

InactiveCN101530188AExtended shelf lifeProduction process specificationFood preparationFood processingVacuum packing

The invention relates to a food processing technique, especially a lees cabbage production technique, comprising the following steps: cleaning Chinese cabbage, blanching the Chinese cabbage in hot water, encasing the blanched Chinese cabbage into a container, uniformly scattering rice wine lees on the Chinese cabbage, capping and marinading, uncapping, detecting and vacuumizing. The food processing technique has features of norm production process and long product keeping time.

Owner:卢斌

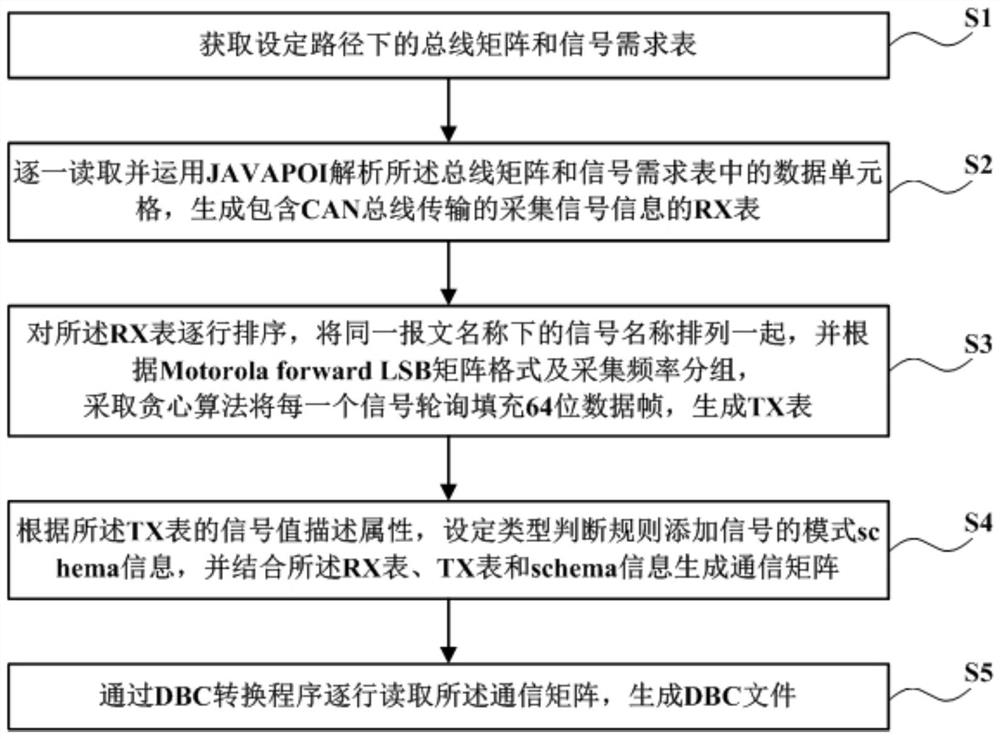

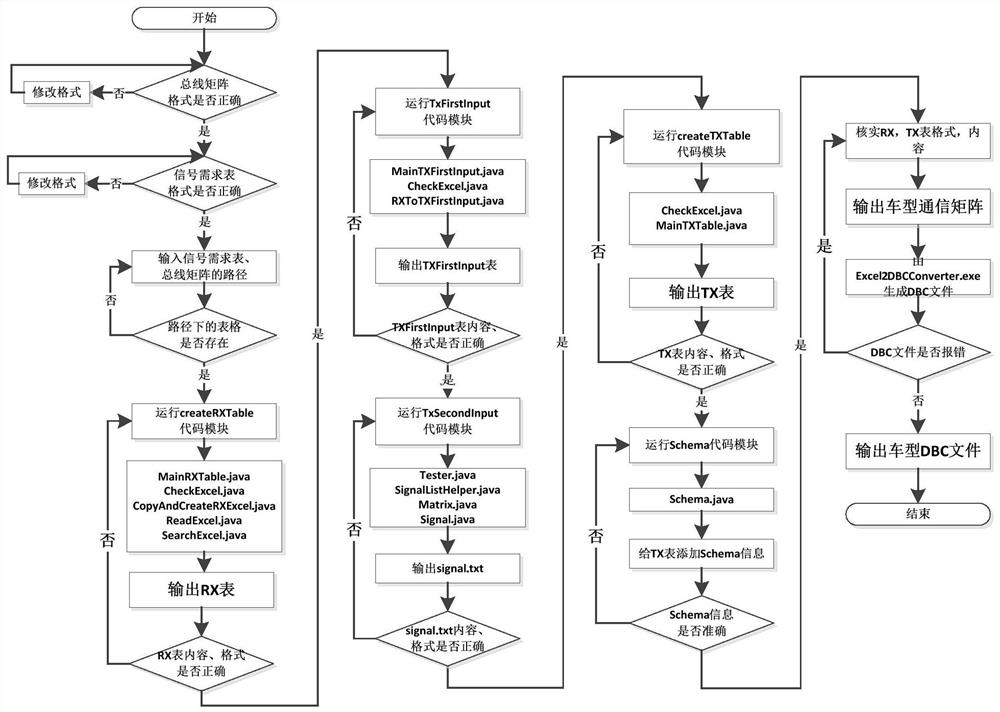

Vehicle data file generation method and device

PendingCN112347047AProduction process specificationReduce labor costsOther databases retrievalFile/folder operationsComputer hardwareDBc

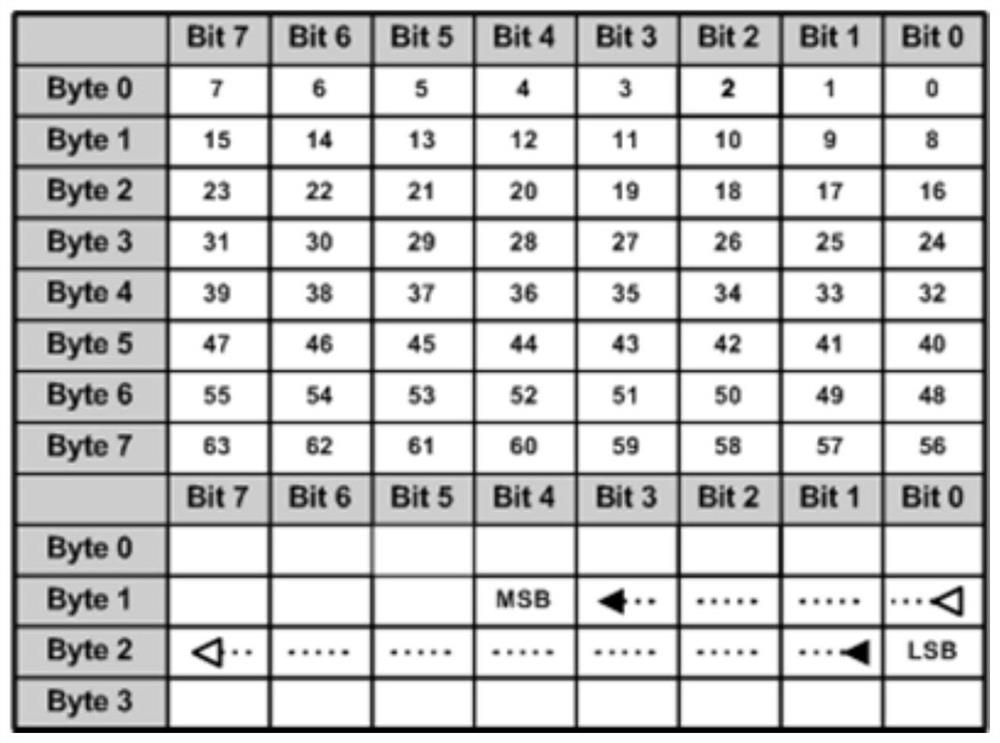

The invention discloses a vehicle data file generation method and device, and the method comprises the steps: obtaining a bus matrix and a signal demand table under a set path; reading and analyzing data cells in the bus matrix and the signal demand table one by one to generate an RX table; sorting the RX tables line by line, arranging the signal names under the same message name, grouping according to the Motorola format LSB matrix format and the acquisition frequency, and polling and filling each signal with 64-bit data frames by adopting a greedy algorithm to generate a TX table; accordingto the signal value description attribute of the TX table, setting a type judgment rule to add mode schema information of a signal, and generating a communication matrix in combination with the RX table, the TX table and the schema information; and reading the communication matrix line by line through a DBC conversion program to generate a DBC file. According to the invention, the manpower and time costs of engineers for manufacturing communication matrixes and DBCs are reduced, and great convenience is provided for signal acquisition of automobile big data and subsequent data analysis.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

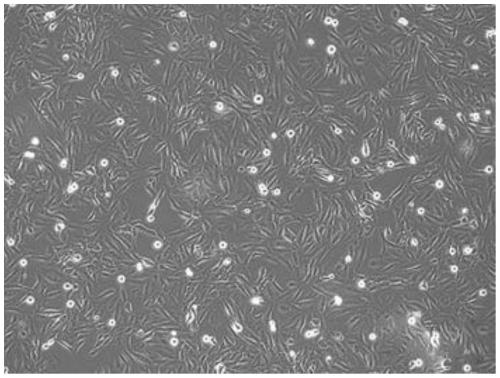

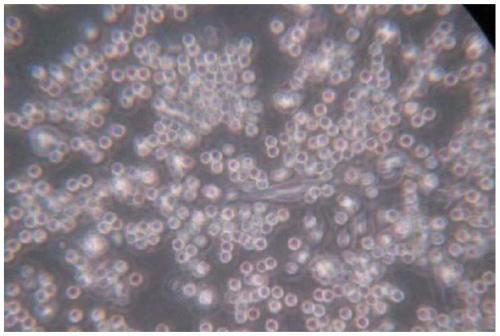

Method for directly culturing porcine reproductive and respiratory syndrome virus vaccine by using Marc-145 full-suspension cells

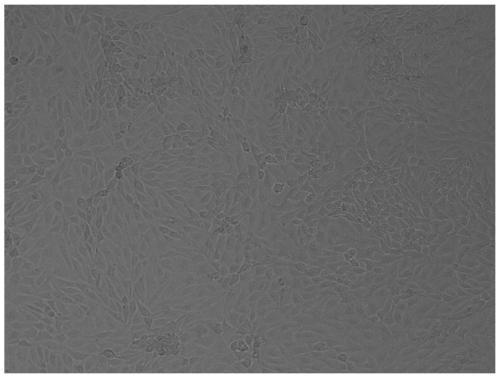

PendingCN110373379AProduction process specificationStandardized production specificationSsRNA viruses positive-senseViral antigen ingredientsViral VaccinePorcine reproductive and respiratory syndrome virus

The invention relates to the field of porcine reproductive and respiratory syndrome virus vaccine preparation, in particular to a method for directly culturing a porcine reproductive and respiratory syndrome virus vaccine by using Marc-145 full-suspension cells. The invention discloses a method for domesticating Marc-145 monolayer cells into suspension culture. Full-suspension culture of the Marc-145 cells in a culture medium is achieved, then a porcine reproductive and respiratory syndrome virus is directly inoculated into the Marc-145 suspension cells for culture, culture is enlarged by using a bioreactor, the cultured porcine reproductive and respiratory syndrome virus vaccine is stable in proliferation speed, and the virus content is larger than or equal to 108.5 TCID50; a virus liquidis obtained when the vaccine is cultured until the cytopathy reaches 80% or above, and the vaccine is obtained. According to the method, the porcine reproductive and respiratory syndrome virus is directly inoculated into the Marc-145 suspension cells for domestication and culture, and the stability, continuity and safety of the produced suspension virus are effectively improved; besides, the bioreactor is used for culture enlarging, the virus content of each 0.1 ml is larger than or equal to 108.5 TCID50, and the quality and yield of the porcine reproductive and respiratory syndrome vaccine are further improved.

Owner:BEIJING VBIOSCI INC +2

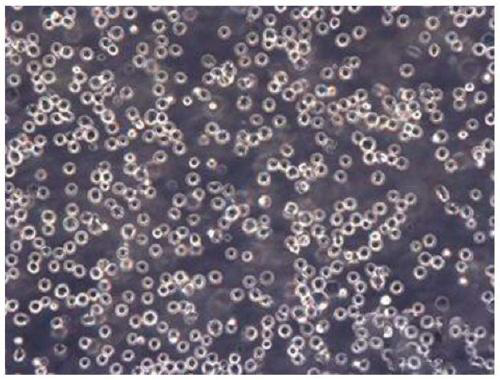

Method for fully suspended cell culture of avian influenza (H9) inactivated vaccine

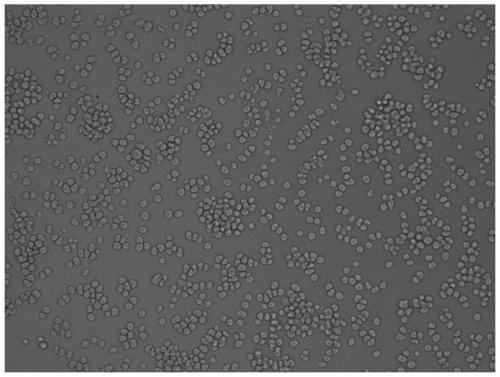

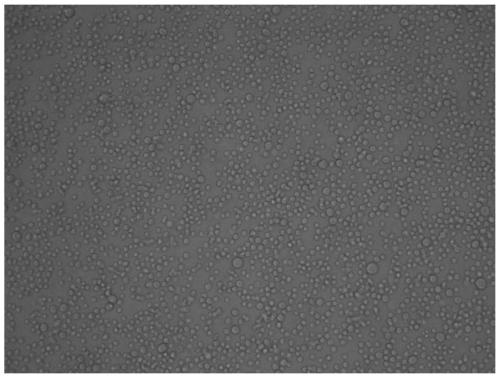

ActiveCN110237246AProduction process specificationStandardized production specificationSsRNA viruses negative-senseViral antigen ingredientsEmbryoBioreactor

The invention relates to a method for fully suspended cell culture of an avian influenza (H9) inactivated vaccine. The method comprises the following steps that MDCK monolayer cells are subjected to habituated culture, an avian influenza (H9) inactivated vaccine chick embryo virus is directly inoculated into MDCK suspension cells for culture, enlargement culture is carried out in a bioreactor, an harvested culture is cultured until the proliferation speed of the avian influenza (H9) inactivated vaccine is stable, and the virus content is greater than or equal to 108.5 EID50; when culture is carried out until the cytopathy reaches 80% or above, a virus solution is harvested, and the avian influenza (H9) inactivated vaccine is obtained. The chick embryo virus is directly inoculated into the MDCK suspension cells for habituated culture, which effectively increases the performance stability, continuity and safety of the produced suspended virus, the obtained suspended virus HA is greater than or equal to 1:4096; the virus content per 0.1 ml is greater than or equal to 109.5 EID50, and the virus content per 1 ml is greater than or equal to 109.5TCID50.

Owner:BEIJING VBIOSCI INC +2

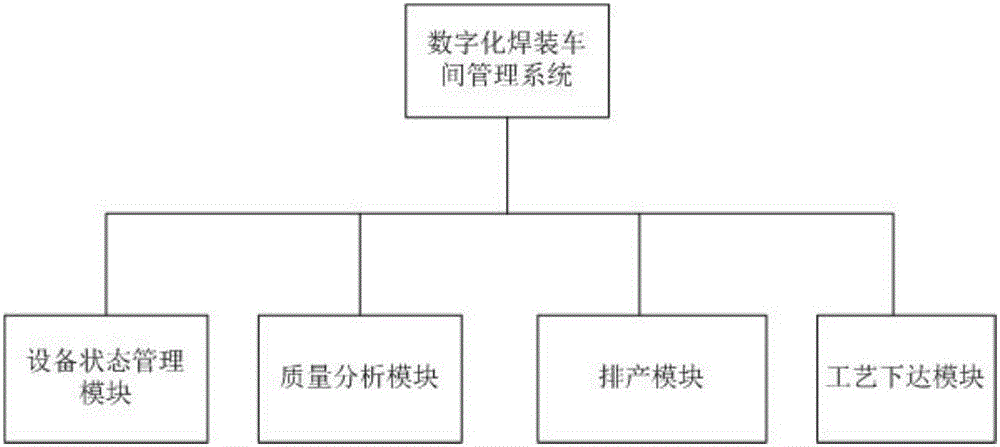

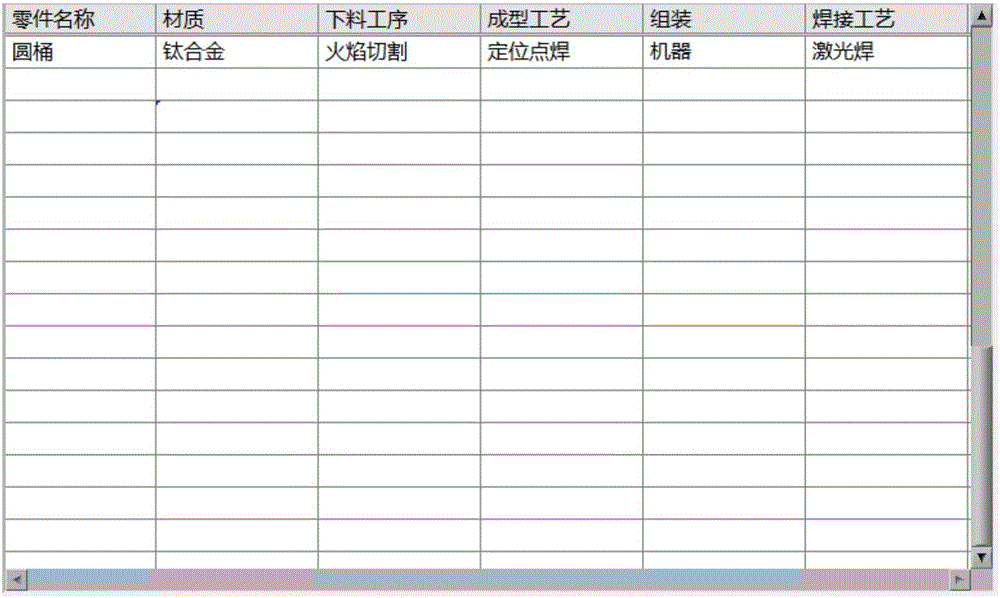

Management system for digital welding workshop

InactiveCN106563898AImprove practicalityIncrease productivityData processing applicationsWelding/cutting auxillary devicesProduction scheduleWork status

The invention discloses a management system for a digital welding workshop. The system comprises an equipment state management module, a quality analysis module, a production scheduling module and a technology assigning module; the quality analysis module analyzes the stability of welds and monitors defects of the welds; the equipment state management module acquires and displays the current working state and the historical working state of equipment; the production scheduling module sequences existing orders and determines the time when each task is conducted; and the technology assigning module assigns manually input technological parameters to the equipment through hardware circuits. Functions and the practicability of the quality analysis module are enriched, and the sequence of workpiece assembly processes is guided by the production scheduling module, so that the process of a processed product from a raw material to the final product is more reasonable and specific; and welding technology parameters are fixed by the technology assigning module, the non-standard operation of manual adjustment is avoided, the digital degree and the production efficiency of the workshop are improved, the production process of the workshop is standard and reasonable, and an administrator manages the workshop conveniently.

Owner:NANJING UNIV OF SCI & TECH

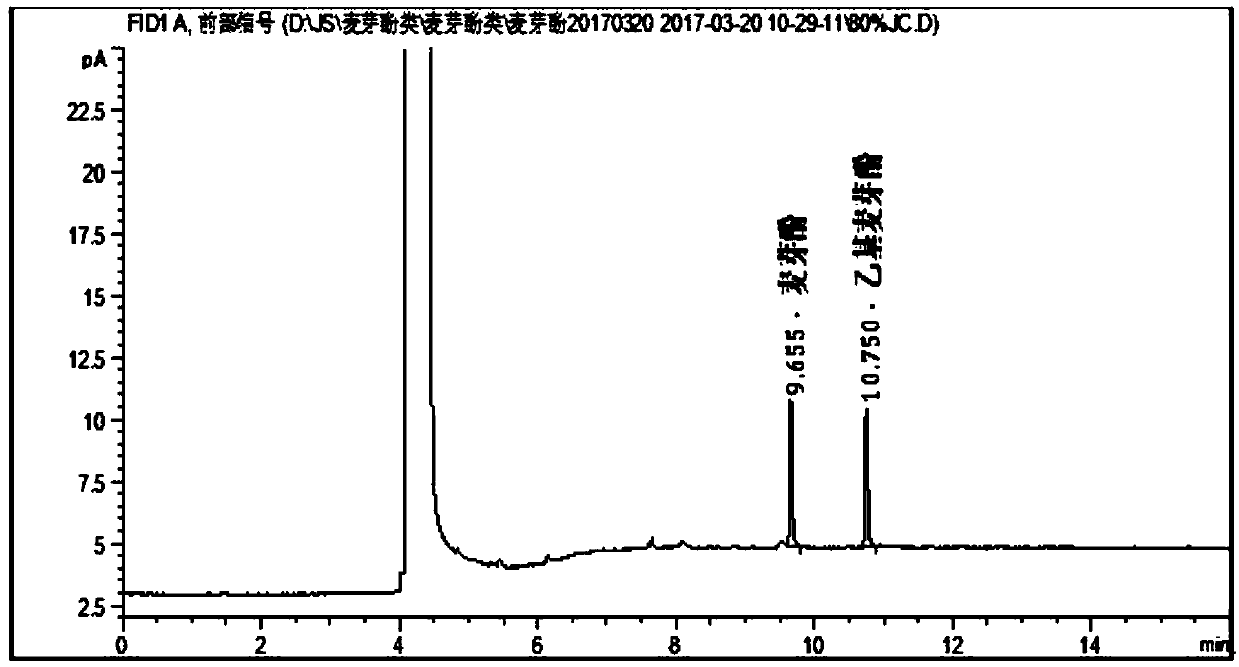

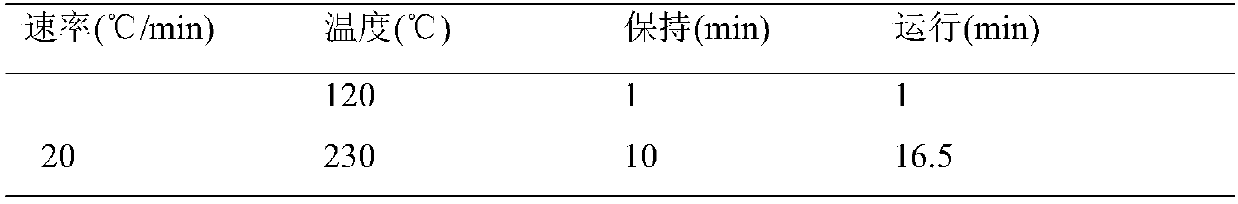

Method of simultaneously measuring maltol contents in edible vegetable oil by gas chromatography

ActiveCN109541050AProduction process specificationProtection of legal rightsComponent separationVegetable oilGas phase

The invention belongs to the technical field of vegetable oil composition measurement, and discloses a method of simultaneously measuring maltol contents in edible vegetable oil by gas chromatography.After a sample is spiral shaken with 80% methanol for 10 minutes and then frozen and centrifuged, maltol and ethyl maltol are measured simultaneously by gas chromatography. According to the result, the content of the maltol and the content of the ethyl maltol have a good linear relationship in a range of 0.5 to 30 mug / mL, and linear equations are: Y=1.0833X-0.2058, Y=1.3716X+0.0487, the maltol recovery rate measured in the method is 88.82%, RSD is 5.04%, and the ethyl maltol recovery rate is 86. 56% and RSD is 3.60%. The method disclosed in the invention can be used for detecting maltol and ethyl maltol illegal additives in the edible vegetable oil.

Owner:CHONGQING INST FOR FOOD & DRUG CONTROL

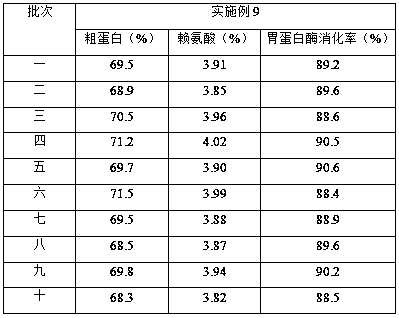

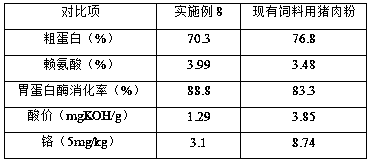

Full-automatic production process of pork powder for feeds

InactiveCN108125020AQuality assuranceGuaranteed reliabilityFatty-oils/fats refiningAnimal feeding stuffProduction lineCompound system

The invention discloses a full-automatic production process of pork powder for feeds. The production process comprises the following steps of: conveying raw fat as a raw material in batches into an automatic production line; sequentially performing crushing, performing vacuum-refining and performing filtering on the raw fat so as to obtain oil residues, and pressing the oil residues to obtain porkslices; crushing the pork slices in different batches, conveying the crushed pork slices into a compounding system of the automatic production line and performing compounding; and adding antioxidantsto the material finished products obtained by compounding, performing sterilization, and performing cooling so as to obtain the pork powder for feeds. The full-automatic production process disclosedby the invention cooperates with a modern automatic production line, and combines with a series of process steps such as performing crushing, performing vacuum refining, performing filtering, performing pressing, performing compounding, performing sterilization and the like on the raw fat as the raw material; and the full-automatic production process can be used for producing the pork powder for feeds, which is high in quality, stable in performance, safe and reliable, and is suitable for large-scale feed production enterprises.

Owner:四川省信瑞饲料科技有限公司

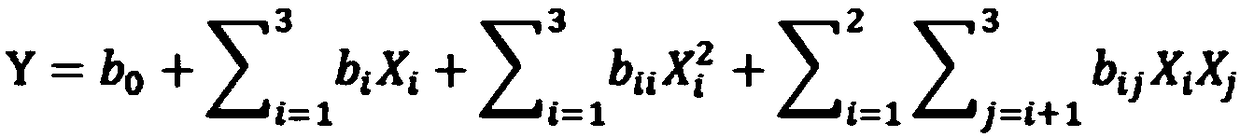

Method for preparing low-sodium nutritional salt substitute with liquid state fermentation technology

The invention relates to the technical field of food, in particular to a method for preparing a low-sodium nutritional salt substitute with multi-stain liquid state fermentation technology. The method comprises steps as follows: yeast strains, mushroom strains and Cordyceps millitaris strains are sequentially subjected for seed culture and fermentation tank culture after being activated, an obtained fermentation culture solution is subjected to enzymolysis with protease, centrifugal filtration and activated carbon decolorization, sodium chloride and potassium chloride are added for reduced pressure concentration and crystallization, and the low-sodium nutritional salt substitute is prepared. Raw materials required by the method are wide in source and low in cost, physical and chemical conditions are easy to control, the production cycle is short, the product is stable in quality and high in yield, requirements for preparation equipment and places are low, industrial production is facilitated, and the method is not limited by seasons. The prepared salt substitute is rich in nutrition and can prevent some common diseases, and the fresh taste is increased on the basis that saltiness is not decreased.

Owner:TIANJIN ZHONGYING HEALTH FOOD

Vinegar beverage with effects of refreshing and restoring consciousness and making method thereof

InactiveCN106360221AEnzyme richFull of nutritionFood ingredient as taste affecting agentFood ingredient as mouthfeel improving agentLimoniumLactarius

The invention relates to the technical field of foods and in particular to a vinegar beverage with effects of refreshing and restoring consciousness and a making method thereof. The vinegar beverage comprises the following raw materials in parts by weight: 20-30 parts of wheat, 10-20 parts of soybeans, 5-10 parts of peas, 5-15 parts of kelp, 5-10 parts of radish leaf, 5-10 parts of mandarin orange, 10-20 parts of lemon, 5-10 parts of pineapple and 30-50 parts of honey. The making method comprises the following steps: soaking the wheat, soybeans and peas, peeling the pineapple, mixing with the kelp, radish leaf, mandarin orange and lemon, crushing, grinding in a grinding machine, inoculating saccharomycetes, lactic acid bacteria and acetic bacteria, adding honey into the centrifugate for blending, filtering, sterilizing and filling, thereby obtaining the vinegar beverage with the effects of refreshing and restoring consciousness.

Owner:TIANJIN TIDAI MEDICINE SCI & TECH

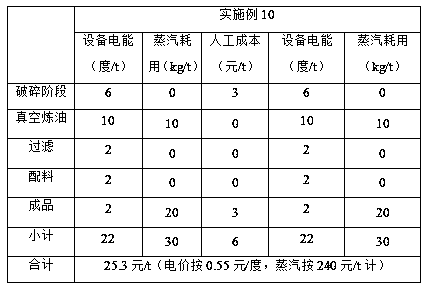

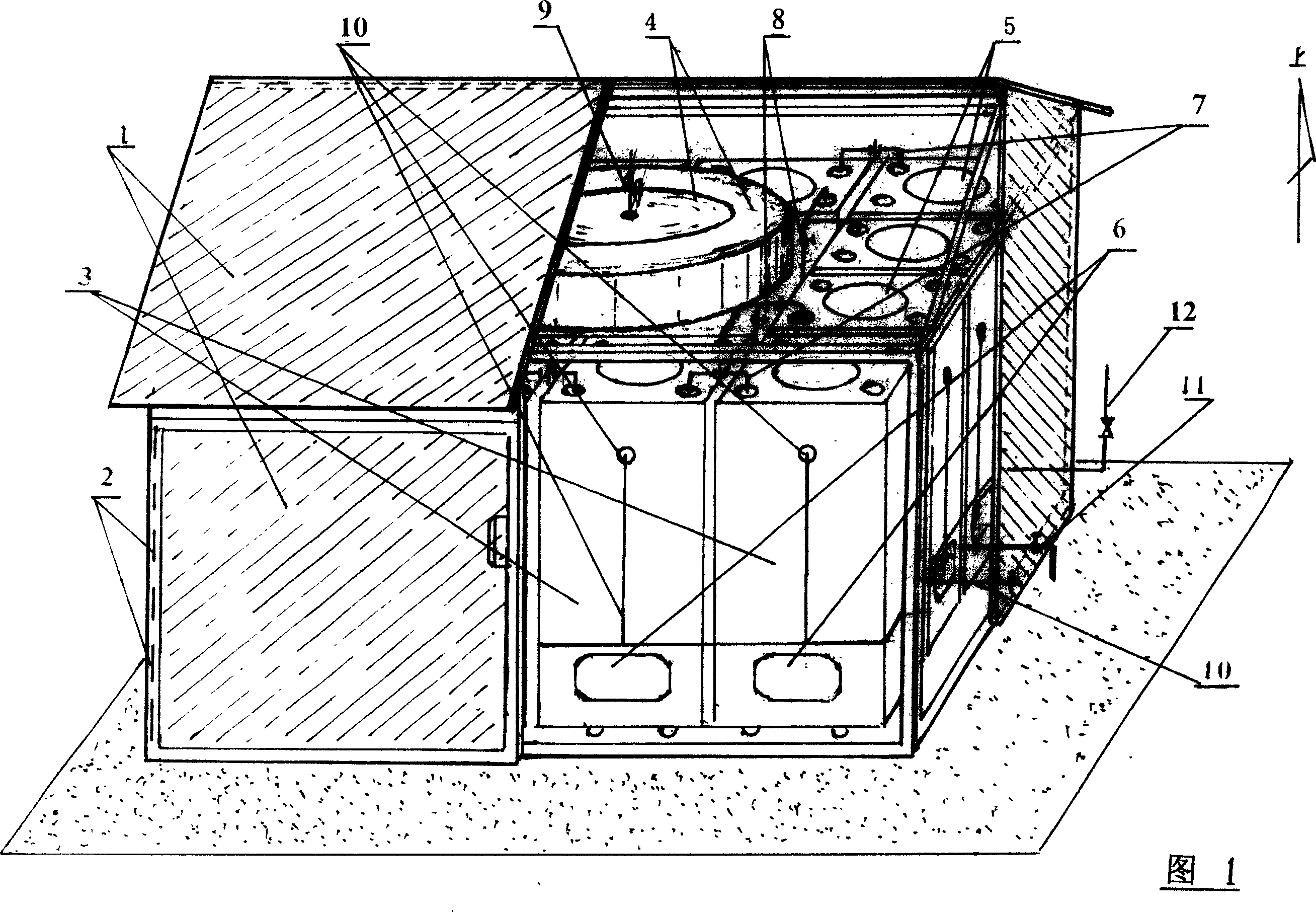

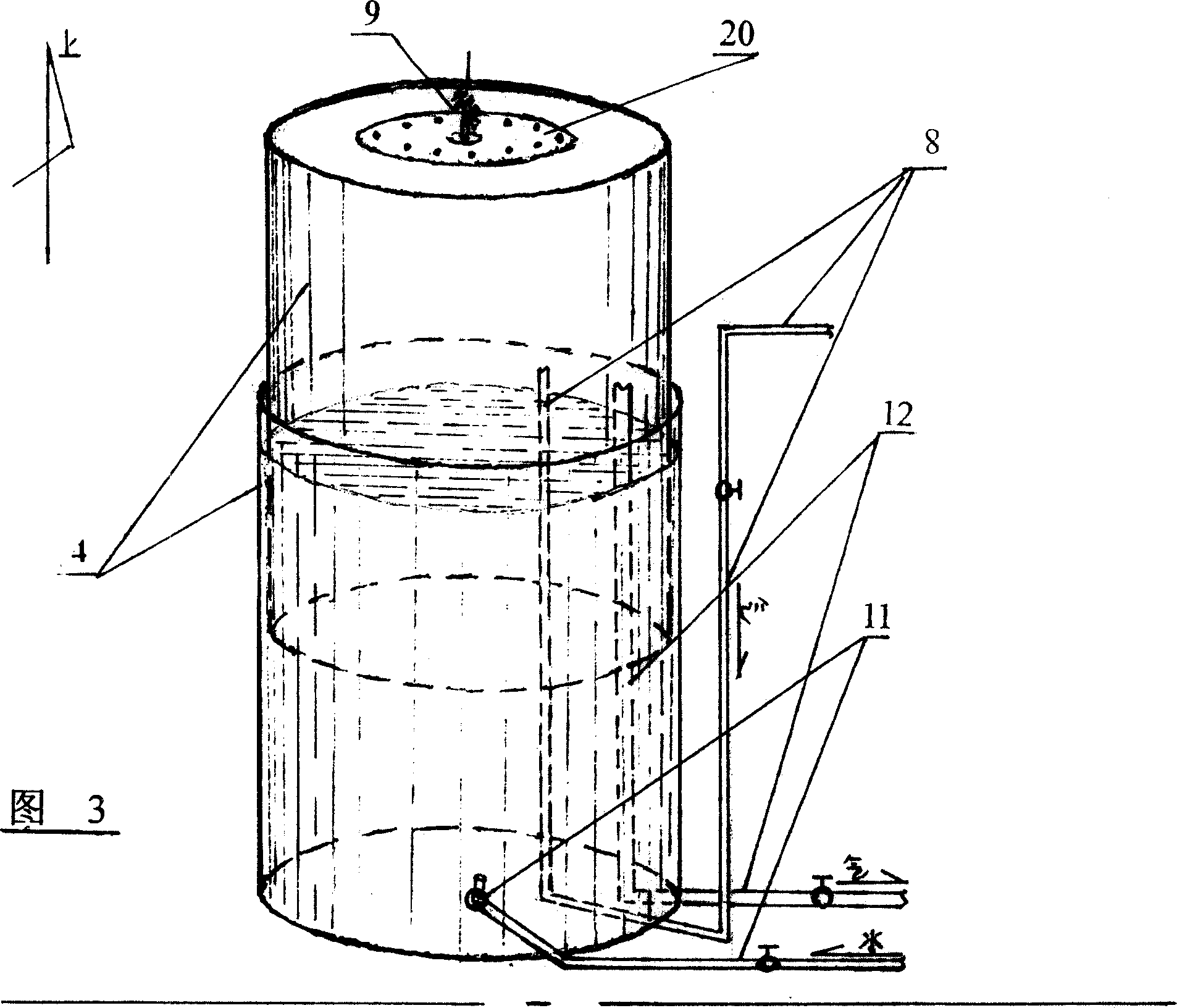

Marsh gas production device combined of standardized mechanism unit containers

InactiveCN101033447AIncrease production capacityEasy to useGas production bioreactorsBiogas productionProcess engineering

This invention relates to a methane producing device composed of containers of standardized mechanical units composed of a unitized square column methane container, assembling parts on it, a conventional water sealed pressure gas-collecting tank and a corresponding heat-preservation room characterizing that the container and the assembling parts are designed according to standardization and produced mechanically suitable for standardized production and use.

Owner:孙正维

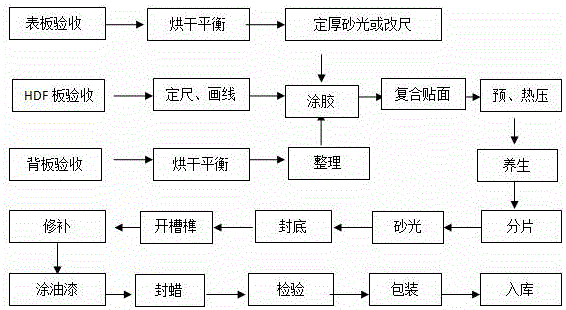

Reconsolidated bamboo and HDF composite floor production technology

ActiveCN105922423AIncrease productionOptimize process flowOther plywood/veneer working apparatusDovetailed workWaxControllability

The invention relates to a reconsolidated bamboo and HDF composite floor production technology. The reconsolidated bamboo and HDF composite floor production technology includes the steps of preparing, veneer combining, curing, splitting, sanding, putty bottom sealing and repairing, chase mortise forming, repairing, paint applying, wax sealing, inspecting, packaging and warehouse entering. The reconsolidated bamboo and HDF composite floor production technology is suitable for producing various reconsolidated bamboo and HDF composite floors with different face veneers and backboards. Existing technological processes are greatly improved, detailed production technology parameters and work requirements are specified in each step of the production technology, the whole production technology is complete, detailed and precise, the parameters of each step are set accurately, the production work is standard, the production process is high in controllability, and therefore the production efficiency is high, the yield is high and the product quality is stable.

Owner:FUJIAN JUYI BAMBOO & WOOD IND CO LTD

Healthy substitute sugar and method for preparing healthy substitute sugar through liquid state fermentation technology

The invention relates to the technical field of food, in particular to healthy substitute sugar and a method for preparing healthy substitute sugar through a liquid state fermentation technology.The healthy substitute sugar comprises, by mass, 40-90% of L- arabinose, 10-60% of fructose, 0-10% of xylose and 0-10% of glucose.The preparation method comprises the steps of preparation of corn bran enzymatic hydrolysate and jerusalem artichoke juice; culture of strains; fermentation and culture; centrifugal filtration, decoloration and vacuum concentration, so that the substitute sugar is obtained.Syrup of the substitute sugar is subjected to centrifugal separation and spray drying, and the substitute sugar can be made into substitute powdered sugar.The obtained healthy substitute sugar is applicable to people who are forbidden from eating cane sugar and people who love sweet food but are worried about that sweet food affects health.The required raw materials are wide in source and low in price, the physicochemical condition is easy to control, the production cycle is short, the healthy substitute sugar is stable in quality and high in yield, it is convenient to conduct industrialized production, and the preparation method is not controlled by seasons.

Owner:AMOY FOOD LTD

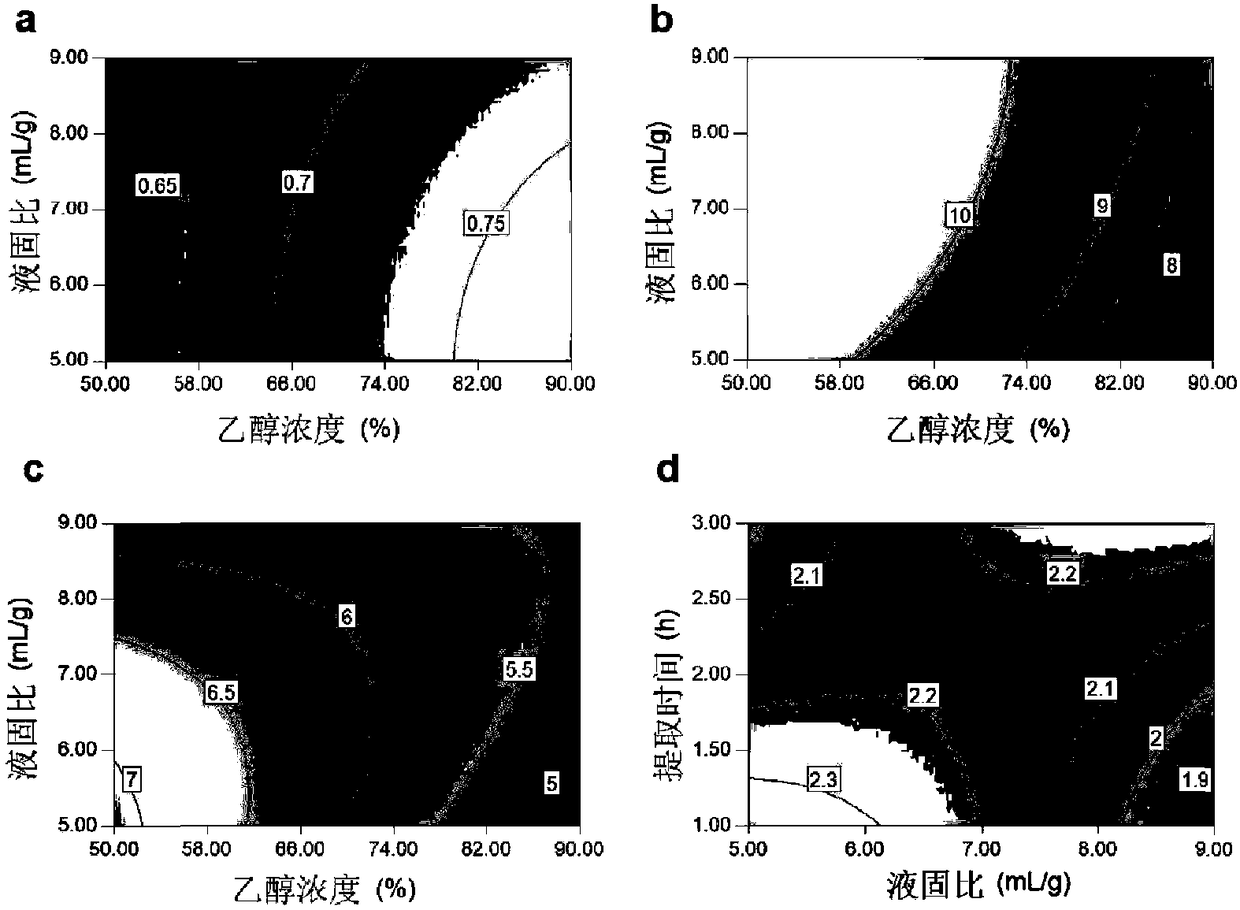

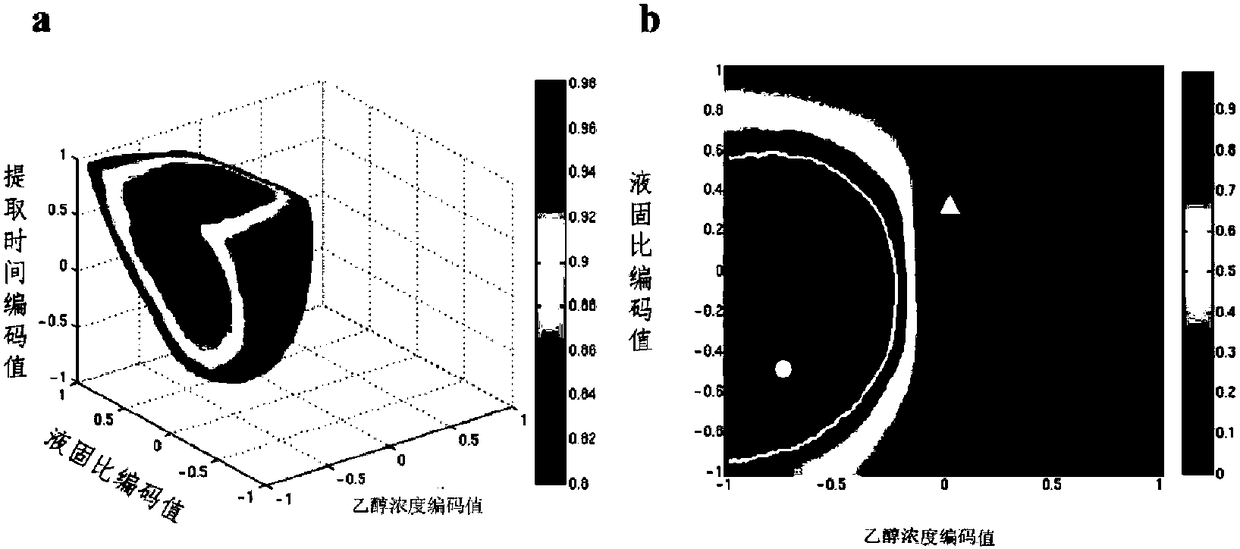

Ginkgo leaf extract and extraction method thereof

InactiveCN108272833AImprove drug efficacyControl ratioGinkgophyta medical ingredientsBlood disorderPharmacyReflux extraction

The invention belongs to the technical field of pharmacies, relates to a traditional Chinese medicine raw material extract and an extraction method thereof, particularly relates to a ginkgo leaf extract and an extraction method thereof. The extraction method for the extract comprises the following steps: smashing dried ginkgo leaves with a smashing machine; and performing reflux extraction on thesmashed ginkgo leaves by ethanol to obtain the ginkgo leaf extract. By adopting the extraction method, the effective component content is controlled effectively, the medicinal effect of the medicine is improved.

Owner:ZHEJIANG WANBANG PHARMA

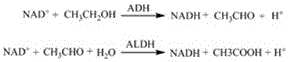

Preparation method of antialcoholism product

InactiveCN106387917AImprove metabolismHarm mitigationMicroorganism based processesOxidoreductasesL-ArabinoseAlcohol dehydrogenase

The invention relates to the technical field of foods, in particular to a preparation method of an antialcoholism product. The antialcoholism product comprises alcohol dehydrogenase and aldehyde dehydrogenase obtained through crushing saccharomyces cerevisiae cells, as well as L-arabinose obtained through fermentation of corn husk enzymatic hydrolysate. The product prepared by the method disclosed by the invention can be made into a product in any forms accepted by bromatology and health-care food science, and the made antialcoholism product has obvious effect of neutralizing the effect of alcoholic drinks.

Owner:TIANJIN TIDAI MEDICINE SCI & TECH

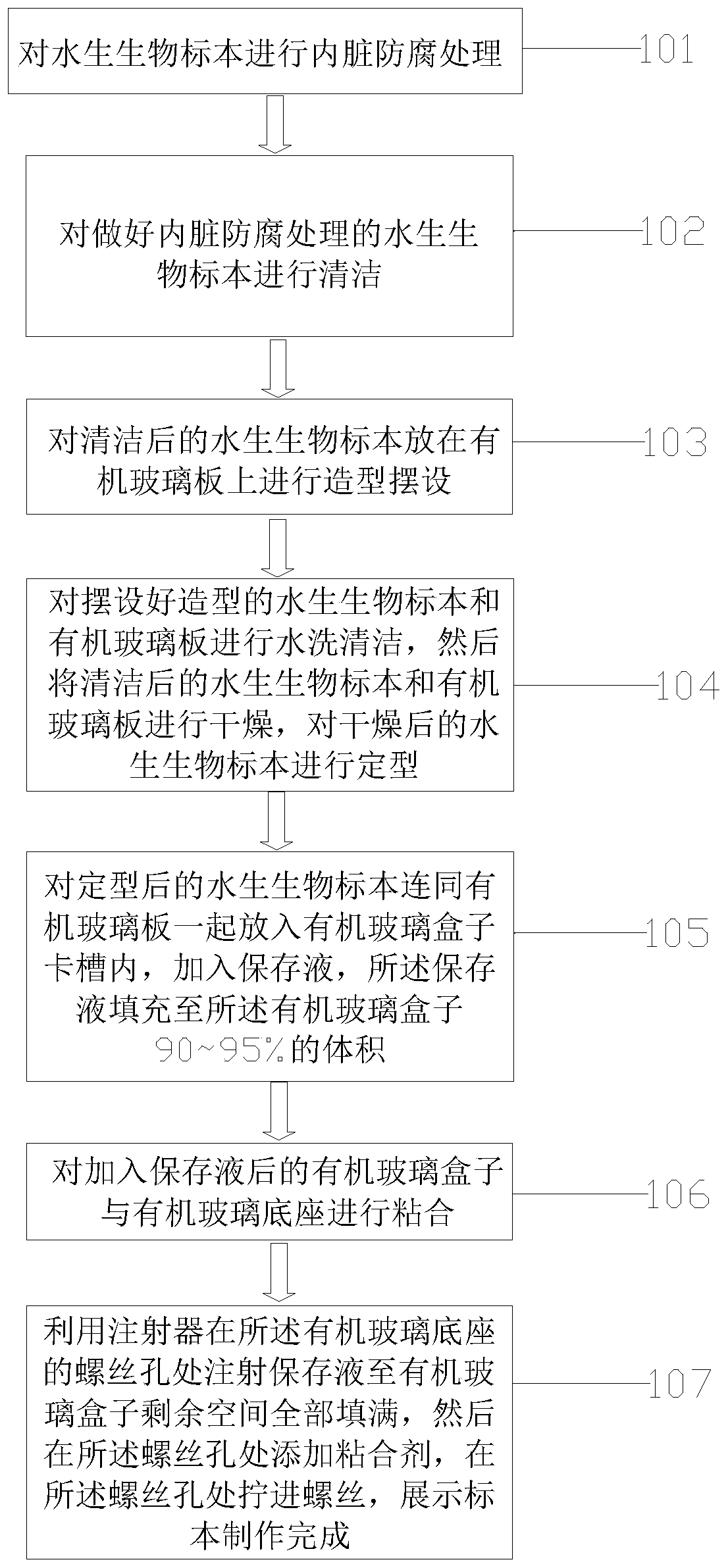

Preparation method for aquatic biological display specimen

InactiveCN110637807AComplete external formStable and not deformedDead animal preservationEducational modelsAdhesiveOrganic glass

A preparation method for an aquatic biological display specimen is characterized by comprising the following steps: performing visceral antiseptic treatment on an aquatic biological specimen; cleaningthe aquatic biological specimen subjected to visceral antiseptic treatment; placing the soaked aquatic biological specimen on an organic glass plate, and performing modelling; cleaning the modelled aquatic biological specimen and the organic glass plate by using water, and drying and shaping the cleaned aquatic biological specimen and the organic glass plate; putting the shaped aquatic biologicalspecimen together with the organic glass plate into a clamping groove of an organic glass box, and adding a preservation solution until 90-95% of the volume of the organic glass box is filled; bonding the organic glass box with the added preservation solution and an organic glass base; and injecting a preservation solution through screw holes of the organic glass base into the organic glass box by using a syringe until the remaining space is filled, adding an adhesive at the screw holes, and screwing screws to complete preparation of the display specimen to obtain the neat and completely-displayed specimen.

Owner:惠州市渔业研究推广中心

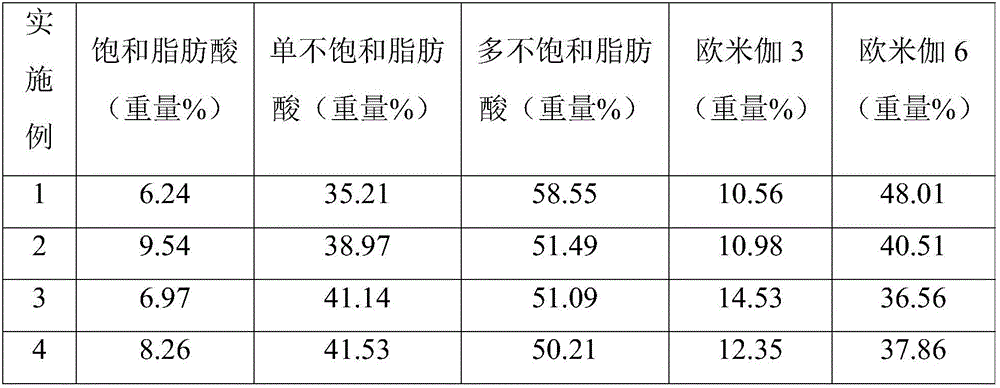

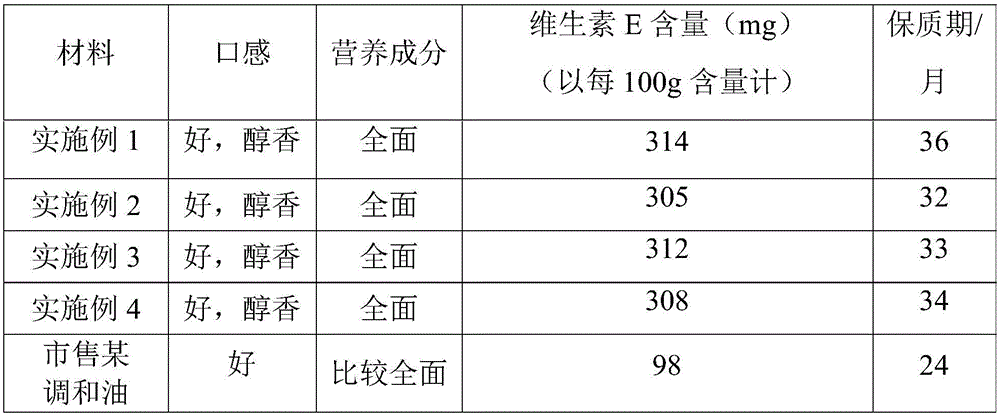

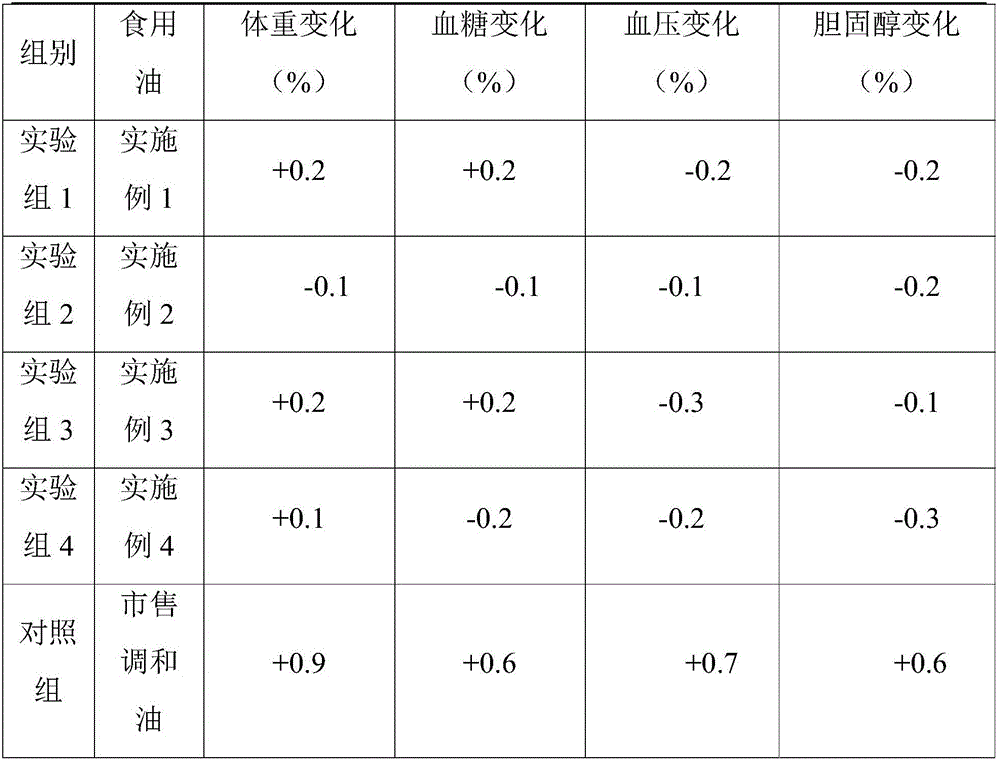

Functional blend oil and preparation method thereof

InactiveCN106615231AImprove antioxidant capacityPromote blood circulationEdible oils/fatsOMEGA-3 POLYUNSATURATED FATTY ACIDSAntioxidant

The invention relates to the technical field of food, in particular to functional blend oil and a preparation method thereof. The functional blend oil is prepared from raw materials including flaxseeds, sesames, sunflower seeds, purple perilla, cinnamon and rosemaries. In the functional blend oil, saturated fatty acid accounts for 3 to 12 percent; monounsaturated fatty acid accounts for 35 to 44 percent; polyunsaturated fatty acid accounts for 44 to 62 percent; Omega 3 polyunsaturated fatty acid accounts for 9 to 15 percent; Omega 6 polyunsaturated fatty acid accounts for 29 to 53 percent. The prepared functional blend oil has mellow smell and is lower in cost; the additional addition of ingredients of antioxidants, preservatives and the like is not needed; the effects of preventing chronic diseases such as cardiovascular diseases, cancer diseases and diabetes are achieved.

Owner:天津百利食品股份有限公司

Three-dimensional filigree enamel manufacturing method

InactiveCN109664665AImprove visual effectsImprove shockAdditive manufacturing apparatusDecorative surface effectsGraphicsData needs

The invention belongs to the field of artware manufacturing, and relates to a three-dimensional filigree enamel manufacturing method. The three-dimensional filigree enamel manufacturing method comprises the following steps: 1) a drawing is designed; 2) a three-dimensional master plate is manufactured according to a drawing, and data is acquired to obtain data needed by 3D printing; or modeling data is obtained according to the drawing, and the modeling is performed on a computer; 3) a mold body is manufactured through 3D printing; and filigree areas or pattern edge lines are reserved on the mold body to form recess areas to be blued; and 4) the filigree operation is performed on the filigree parts of the mold body to form recess places; the recess areas formed by the pattern edge lines orthe recess places formed by the filigree operation are blued; and then, sand is fixed. The three-dimensional filigree enamel manufacturing method has the effects of high three-dimensional feeling ofproducts, improvement of the visual effect, improvement of the product grade, standardization of the artware manufacturing flow, reduction of influence on the product effect by human factors and realization of the batch production.

Owner:兰州北方文化影视传媒有限公司

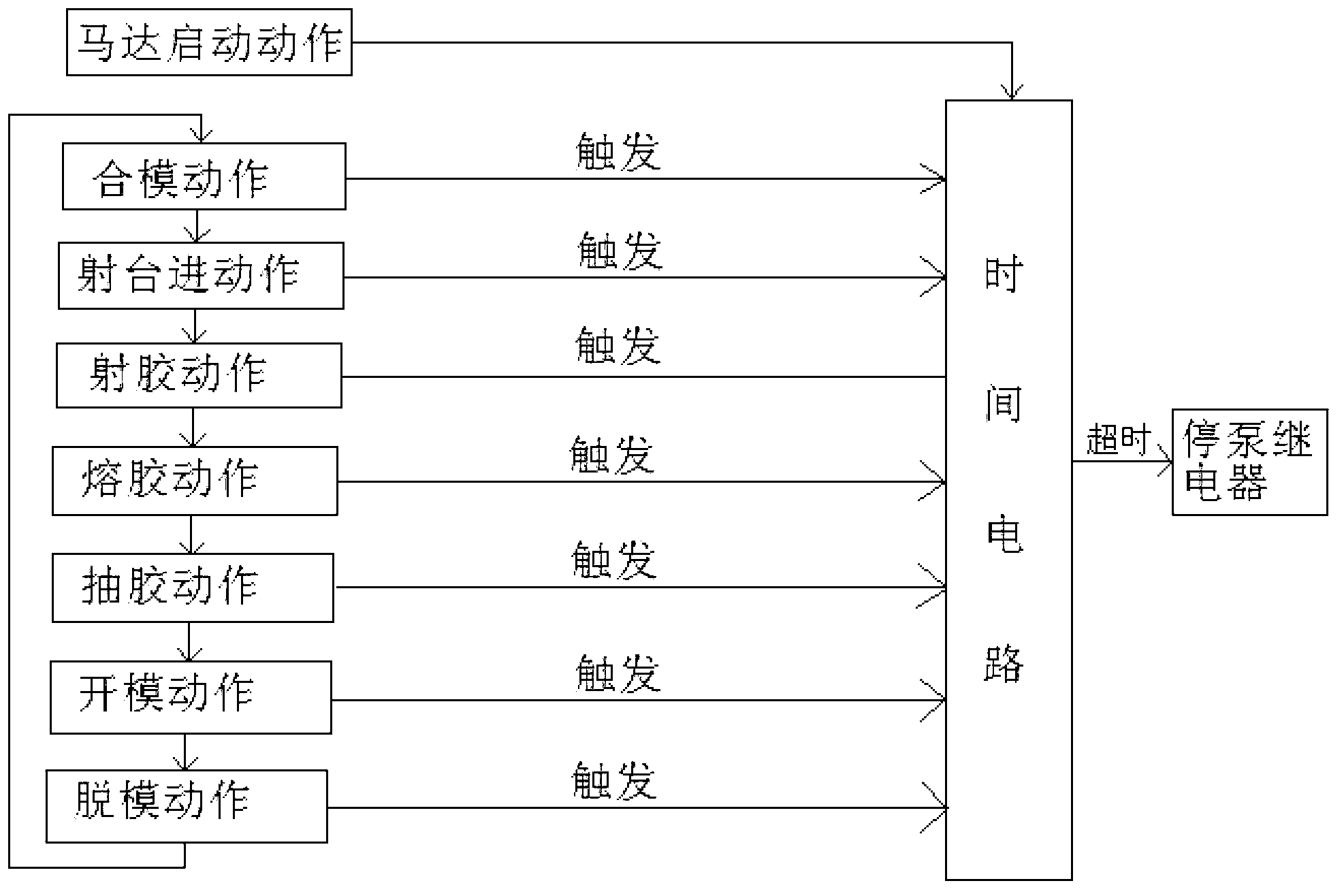

Method and system for automatically stopping pump at overtime moment of injection molding machine

The invention discloses a method for automatically stopping a pump at an overtime moment of an injection molding machine. The method comprises the steps of (1) when a motor is started to work, inputting positive voltage to a time circuit; starting to time by the time circuit; if a signal of the next step is received, executing step (2) when the signal of the next step is received; if the signal of the next step is not received, outputting a positive voltage signal to a pump stopping relay by the time circuit through a time relay; and powering off the injection molding machine by the pump stopping relay and emergently stopping the signal to stop the motor; and (2) sequentially and circularly executing a die assembly movement, an injection platform feeding movement, a glue injection movement, a glue smelting movement, a glue extracting movement, a die opening movement and a die removing movement; when each movement is started, triggering the time circuit by a trigger and zeroing time; and repeatedly timing by a method which is the same as that the step (1). When the system is in failure, the pump can be stopped in time, so that the energy source is saved and the service life of the machine is prolonged.

Owner:NANJING HUAGE ELECTRONICS & AUTOMOBILE PLASTIC IND

Plastic reinforcing cap for detonating cap

The invention relates to the manufacturing field of explosive materials and providing a plastic reinforcing cap for a detonating cap. The plastic reinforcing cap is used for solving the problems that the existing plastic reinforcing cap is deformed and cracked under high pressure, easy to chap under an extreme environment and melt and block a flash hole when the eruption of the first fire composition of the detonating cap is delayed, and easy to tear and smash during explosion. The plastic reinforcing cap can be suitable for detonating cap shells made from various materials, is convenient for static electricity guiding and further reducing the frictional force between the reinforcing cap and the inner wall of the tube, and easy to popularize and use.

Owner:SICHUAN YIBIN WEILI CHEM CO LED

Preparation method for water-free Chuanminshen violaceum-flavor pot-stewed chicken wing

The invention especially relates to a preparation method for a water-free Chuanminshen violaceum-flavor pot-stewed chicken wing, belonging to the technical field of food. The preparation method comprises the following steps: unfreezing a frozen chicken wing and smearing a mixture of salt, cooking wine and Chuanminshen violaceum powder onto the surface of the chicken wing for pickling; and putting edible oil into a wok, adding the pickled chicken wing, carrying out turning and stirring, covering the cover of the wok for heating, then putting the heated chicken wing into a stewing pot, adding flavorings, carrying out hermetic heating, taking the processed chicken wing out for cooling in the air and then carrying out packaging so as to obtain the pot-stewed chicken wing. The pot-stewed chicken wing prepared in the invention has good taste, low caloric value, rich nutrients and no toxic and side effect, and is convenient to purchase and eat and applicable to any occasions and any population; since no water is added, the nutritional components of the chicken wing are retained and prevented from loss; and the preparation method is simplified, saves water resources and heat energy and reduces cost.

Owner:TIANJIN TIDAI MEDICINE SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com