Reconsolidated bamboo and HDF composite floor production technology

A compound flooring and production process technology, applied in the field of heavy bamboo flooring, can solve problems such as weak controllability of the production process, unstable product quality, and inaccurate parameter setting, and achieve strong controllability of the production process and step parameter setting. Accurate determination and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

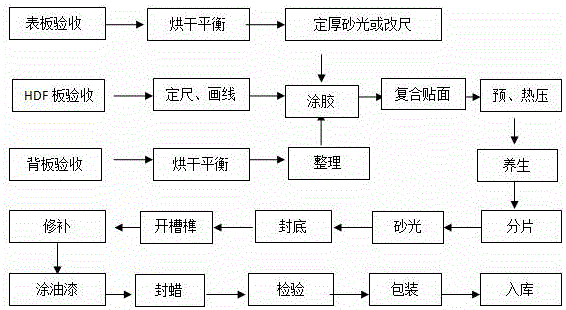

[0064] Such as figure 1 as shown, figure 1 It is a process flow chart of the production process of heavy bamboo HDF composite flooring.

[0065] Heavy bamboo HDF composite floor production technology of the present invention comprises the following steps:

[0066] Step 1: Prepare materials

[0067] 1.1 Surface plate: first dry and balance it, and after drying and balance, the moisture content reaches 6-7%; then it is sanded to the specified thickness and tolerance on both sides, and then sorted. Trimming or sawing as required by specification.

[0068] 1.2 HDF board: Determine the cutting board size of the HDF board according to the product specification and button type of the order, and determine the line spacing according to the produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com