Marsh gas production device combined of standardized mechanism unit containers

A biogas device and container technology, which is applied in the field of biogas production by standardized small-unit container combination devices, can solve the problems that have not been seen before, which is not conducive to popularizing biogas production technology, etc., achieves convenient production and use, increases standardized assembly content, and reduces production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

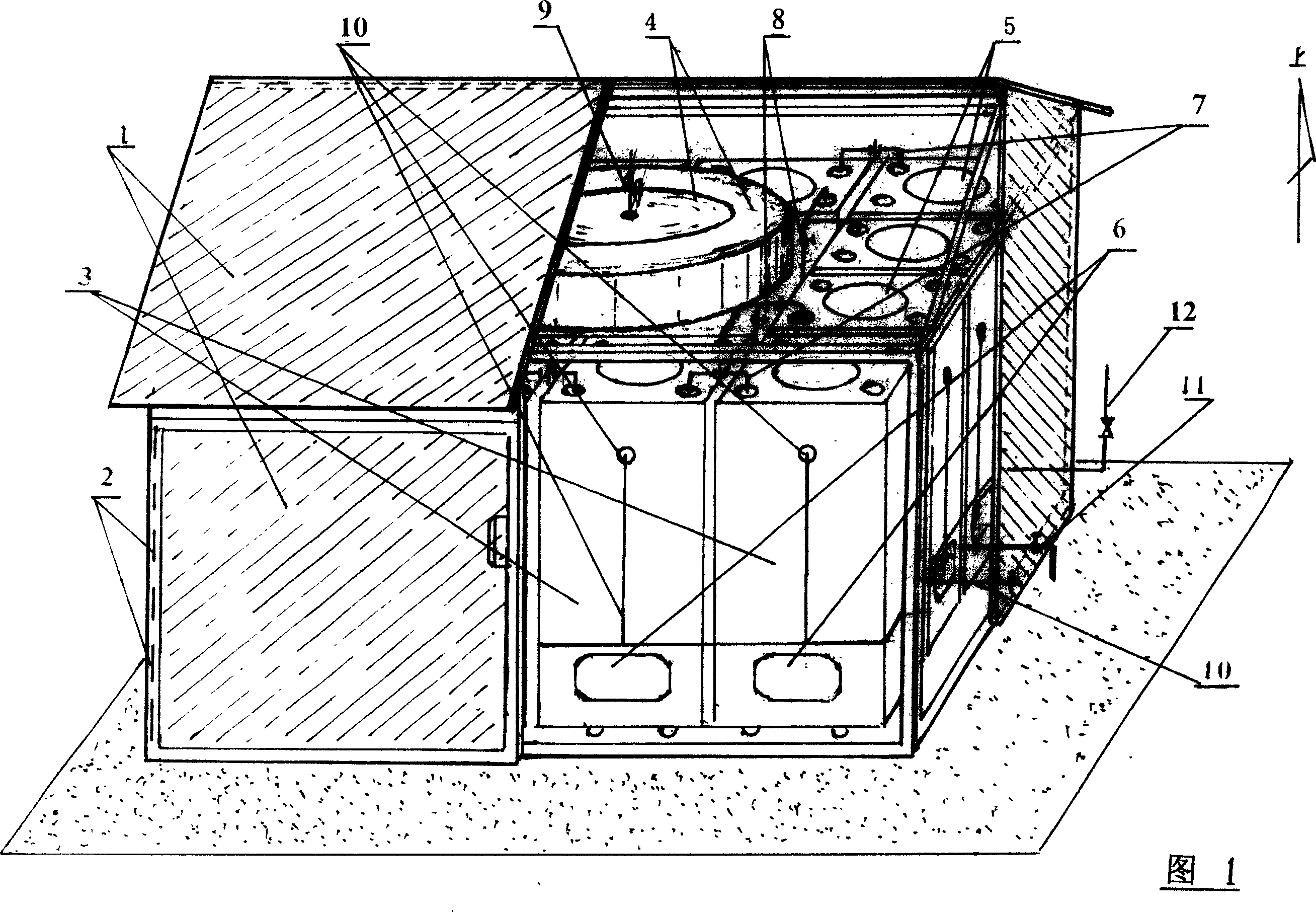

[0019] As can be seen from Fig. 1, the standardized overall assembly state of a group of devices 1-12 of the present invention: the standard unit container body 3 water-sealed gas collection tank 4 and the outer cover heat preservation room 1 are placed very compactly, occupying a small area and being convenient for management , showing the advantages of standardized assembly.

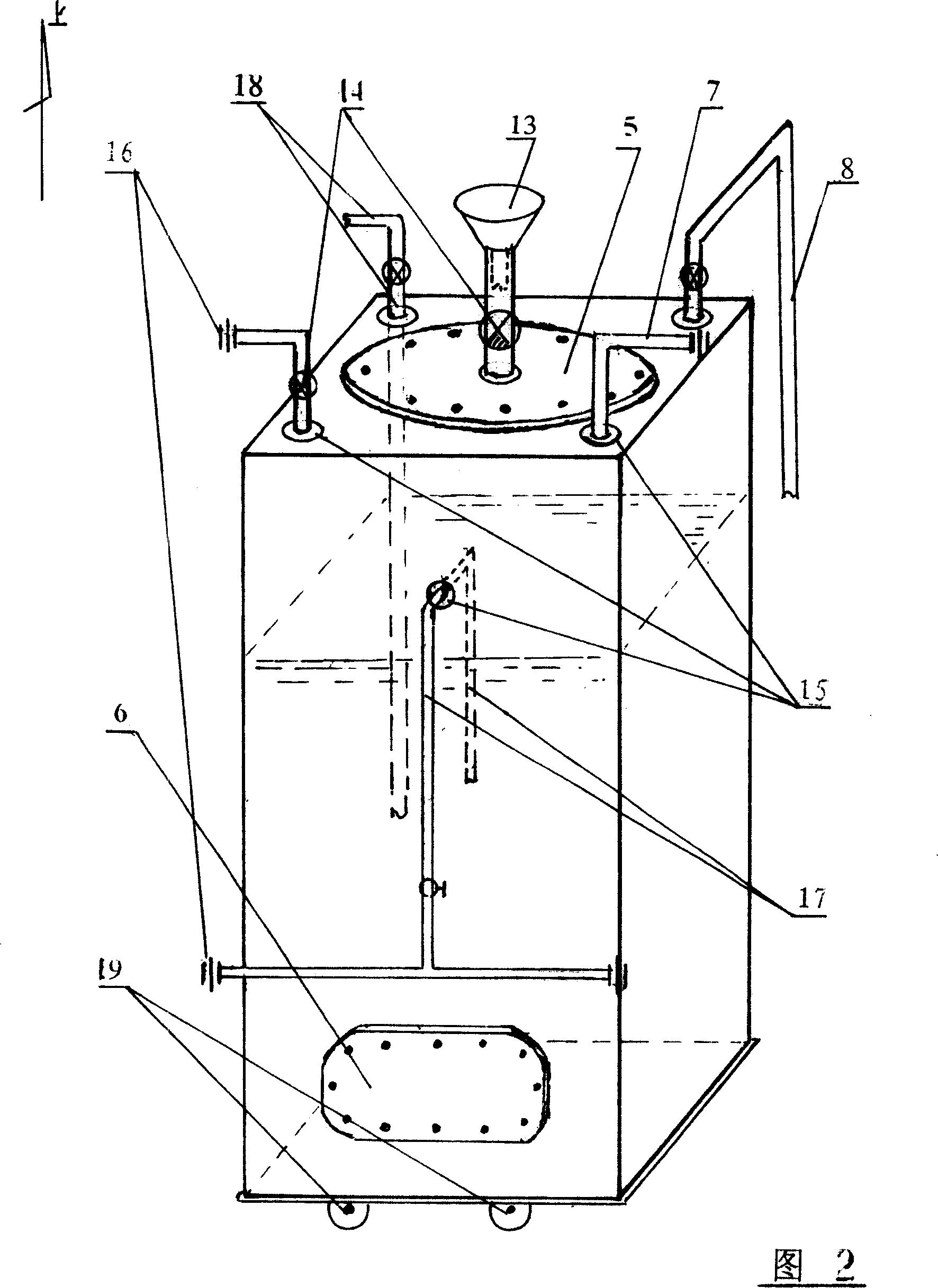

[0020] As can be seen from Fig. 2: the circular feeding inlet flange plugging 5 center on the unitized container 3 leaves the feeding funnel pipe 13, the rectangular discharge flange cover 6 that the container wall bottom is provided with and the top that is provided with The liquid outlet siphon pipeline 17, the pneumatic control pipe 18 on the top surface of the container, the connection holes 15 of the pressure-sealed pipe fittings, the valve 14 and the joint 16 in the pipeline, and the small wheel trailer 19 at the bottom of the container, most of these components are common Standardized parts.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com