Method and system for automatically stopping pump at overtime moment of injection molding machine

An injection molding machine and automatic stop technology, applied in the field of automatic control, can solve the problems of abnormal machine wear and energy waste, and achieve the effect of improving the service life of the machine, saving energy and preventing accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

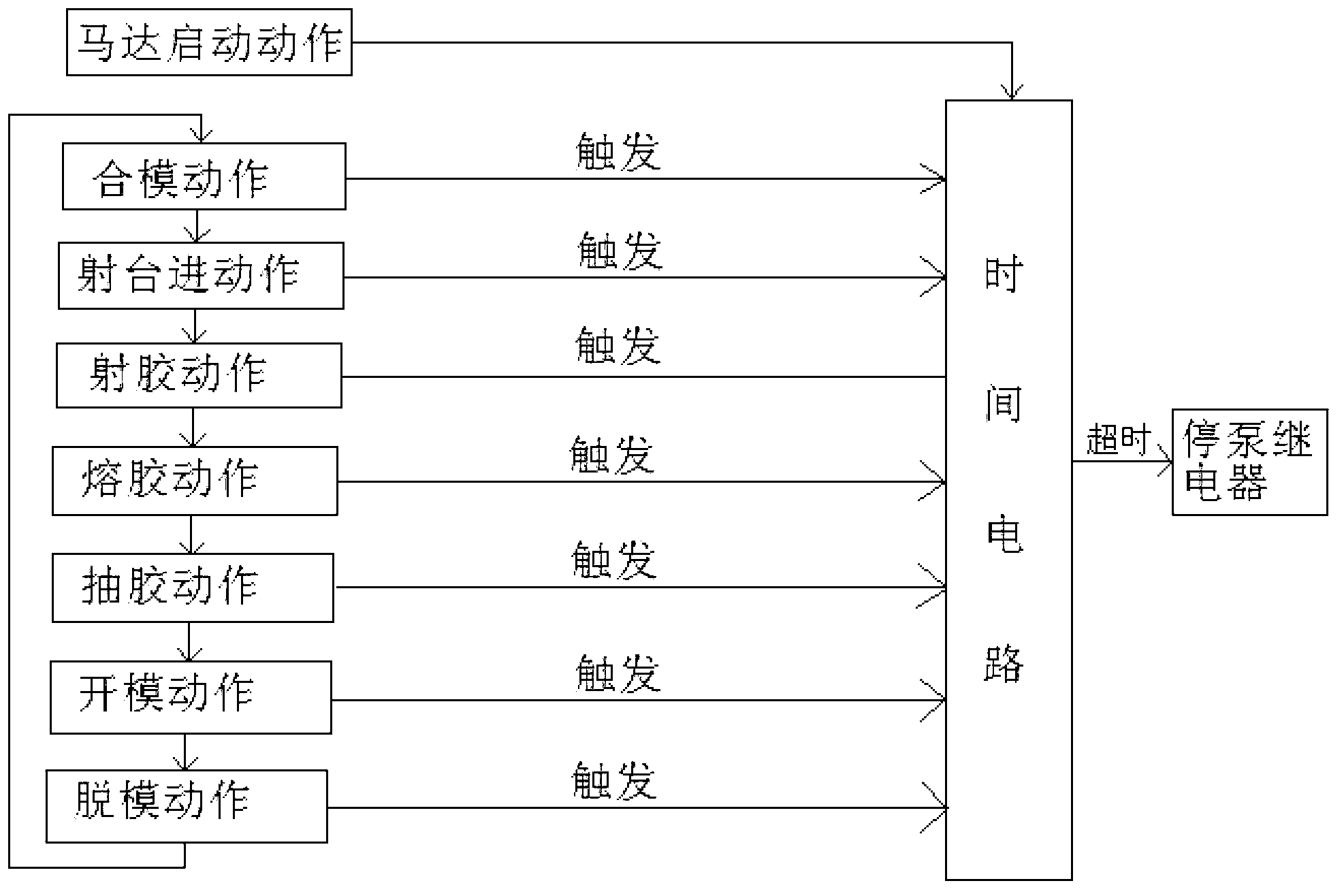

[0026] The embodiment provides a system for automatically stopping the pump of the injection molding machine over time, including a time circuit and a pump stop relay.

[0027] The time circuit includes a timing circuit and a time relay, the time relay is connected to each action module of the injection molding machine circulation system through a trigger, receives the signal of the trigger, and transmits the signal to the timing circuit connected thereto, the The timing circuit is reset and timed; the timing circuit is connected to the pump stop relay, and transmits a timeout signal to the pump stop relay to control the pump stop relay to work.

[0028] In addition, the time circuit also includes an external dial switch connected to the timing circuit. The external dial switch controls three gears, which are 5 minutes, 10 minutes and 15 minutes. The gear switch sets the timing circuit threshold.

[0029] The pump stop relay is a normally closed output relay, that is, when th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com