Preparation method of antialcoholism product

A product and inoculum technology, applied in microorganism-based methods, biochemical equipment and methods, functions of food ingredients, etc., can solve problems such as high cost and reduce cost, achieve less retention, improve metabolism, and sweetness. Moderate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1) Strain cultivation: Inoculate Saccharomyces cerevisiae strains into a fermenter with strain medium, the liquid volume is 10%, the inoculum volume is 7%, the air volume is 1:0.6, pH 7, and the rotation speed is 200 rpm / min. The culture temperature was 28 ℃, cultured for 16 h, and the strain culture solution was obtained;

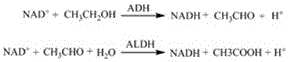

[0038] 2) Centrifuge the strain culture solution prepared in step 1), discard the supernatant to obtain a precipitate, wash twice with 0.066 mol / L disodium hydrogen phosphate buffer, keep the bacterial cells, add 5% 50 mM Tris -Cl (pH 8.0), 0.2 % 1 mM EDTA, 2 % 100 mM NaCl buffer solution, use Constant high-pressure cell disruptor to disrupt cells to obtain a solution containing alcohol dehydrogenase and acetaldehyde dehydrogenase;

[0039] 3) Preparation of corn husk enzymatic hydrolysis solution: After crushing corn husks, pass through a 60-mesh sieve, add purified water at a weight ratio of 1:8, adjust the pH value to 6.0, and stir at 120 rpm / min...

Embodiment 2

[0051] 1) Strain cultivation: Inoculate Saccharomyces cerevisiae strains into a fermenter with strain medium, the liquid volume is 10%, the inoculum volume is 7%, the air volume is 1:0.6, pH 7, and the rotation speed is 200 rpm / min. The culture temperature was 30 ℃, cultured for 16 h, and the strain culture solution was obtained;

[0052] 2) Centrifuge the strain culture solution prepared in step 1), discard the supernatant to obtain a precipitate, wash with 0.066 mol / L disodium hydrogen phosphate buffer 3 times, keep the bacterial cells, add 5% 50 mM Tris -Cl (pH 8.0), 0.2 % 1 mM EDTA, 2 % 100 mM NaCl buffer solution, use Constant high-pressure cell disruptor to disrupt cells to obtain a solution containing alcohol dehydrogenase and acetaldehyde dehydrogenase;

[0053] 3) Preparation of corn husk enzymatic hydrolysis solution: After crushing corn husks, pass through a 60-mesh sieve, add purified water at a weight ratio of 1:3, adjust the pH value to 5.0, and stir at 50 rpm / mi...

Embodiment 3

[0065] 1) Strain cultivation: Inoculate Saccharomyces cerevisiae strains into a fermenter with strain medium, the liquid volume is 10%, the inoculum volume is 7%, the air volume is 1:0.6, pH 7, and the rotation speed is 200 rpm / min. The culture temperature was 29 ℃, cultured for 16 h, and the strain culture solution was obtained;

[0066] 2) Centrifuge the strain culture solution prepared in step 1), discard the supernatant to obtain a precipitate, wash twice with 0.066 mol / L disodium hydrogen phosphate buffer, keep the bacterial cells, add 5% 50 mM Tris -Cl (pH 8.0), 0.2 % 1 mM EDTA, 2 % 100 mM NaCl buffer solution, use a constant high-pressure cell disruptor to disrupt cells to obtain a solution containing alcohol dehydrogenase and acetaldehyde dehydrogenase;

[0067] 3) Preparation of corn husk enzymatic hydrolysis solution: After crushing corn husks, pass through a 60-mesh sieve, add purified water at a weight ratio of 1:12, adjust the pH value to 5.5, stir at 80 rpm / min, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com