Efficient collecting agent for zinc separation of lead-zinc sulfide ore and zinc separation method of efficient collecting agent

A technology for sulfide ore and collector, applied in flotation, solid separation and other directions, can solve the problems of ore dressing production impact, low concentration of sulfur concentrate pulp, high lime unit consumption, saving labor costs, facilitating subsequent processing, reducing The effect of drug preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

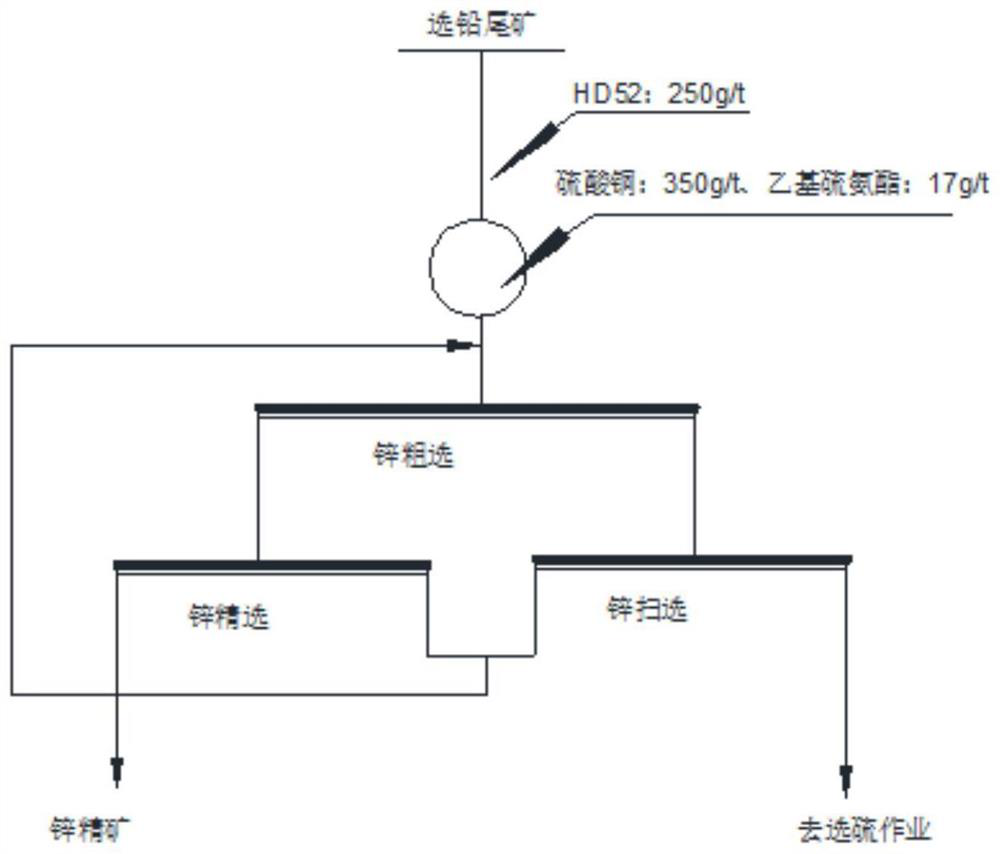

[0021] refer to figure 1 As shown, in the flotation of lead-zinc sulfide ore, the raw ore is ground and then the lead separation operation is carried out. After the lead separation, the tailings pulp has a mass concentration of 35-38% and a mineral particle size of -0.074mm in the pulp. 73-78%.

[0022] Add 200-300g / t pyrite inhibitor HD52 to the tailings slurry in the last scavenging flotation tank of lead selection to inhibit the floating of pyrite, and add it to the slurry mixing tank before zinc selection and roughing The dosage is 300-400g / t copper sulfate for activating sphalerite, adding 17-20g / t ethyl thiocarbamate for stirring and pulping, and then the slurry enters the zinc roughing flotation machine for zinc roughing.

[0023] The zinc roughing concentrate enters the zinc concentration 1 flotation machine for the first zinc concentration, the zinc concentration 1 concentrate enters the zinc concentration 2 flotation machine for the second zinc concentration, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com