Ore-matching method of selecting phosphorus ore to raw ore

A technology for raw ore and phosphate ore, applied in the field of ore blending of phosphate ore selected as raw ore, can solve the problems of inability to accurately know the average grade of ore and the detection error of raw ore grade, so as to reduce energy consumption, reduce transportation costs and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

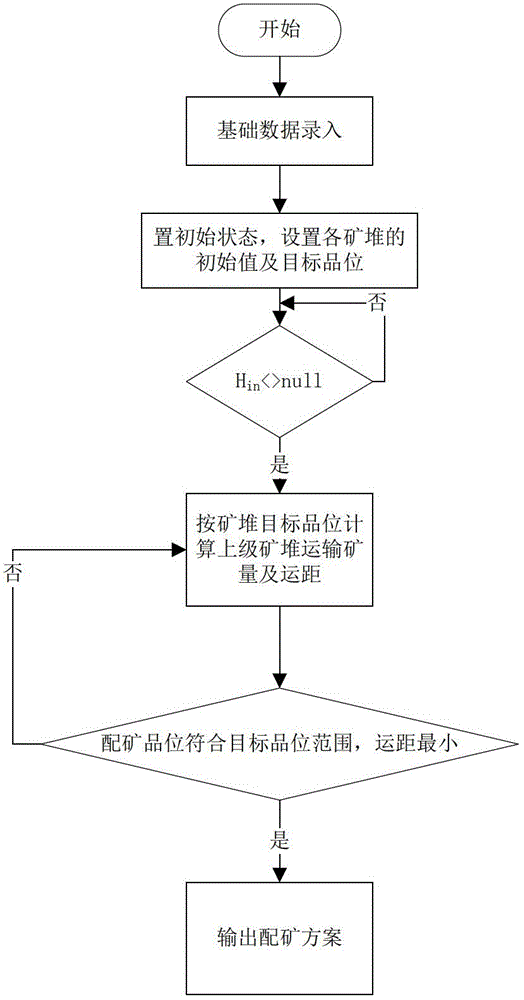

[0022] A method for mixing phosphate rock into raw ore, comprising the following steps:

[0023] 1) Data collection;

[0024] 2) Determine the ore blending target of each production link, so that in the process of formulating ore blending, the raw ore grade that each production link should reach;

[0025] 3) Build a model;

[0026] 4) Output raw ore blending plan;

[0027] The model described is:

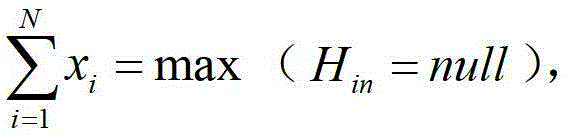

[0028] Σ i = 1 N x i = max ( H in = null ) , i=1...N. Objective function (1)

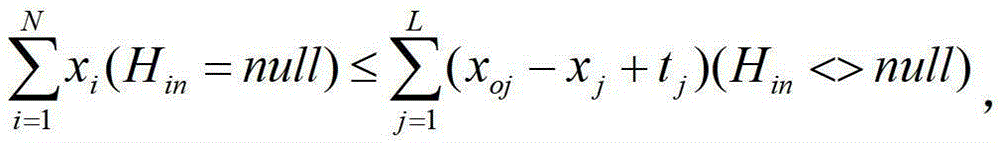

[0029] Σ i = 1 N x i ( H in = ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com