Comprehensive treatment method of blast furnace dedusting ash

A blast furnace dust removal and comprehensive treatment technology, which is applied in the field of waste treatment, can solve the problems of high cost and large amount of flotation reagents, and achieve the effects of improving recovery rate, reducing ironmaking cost, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

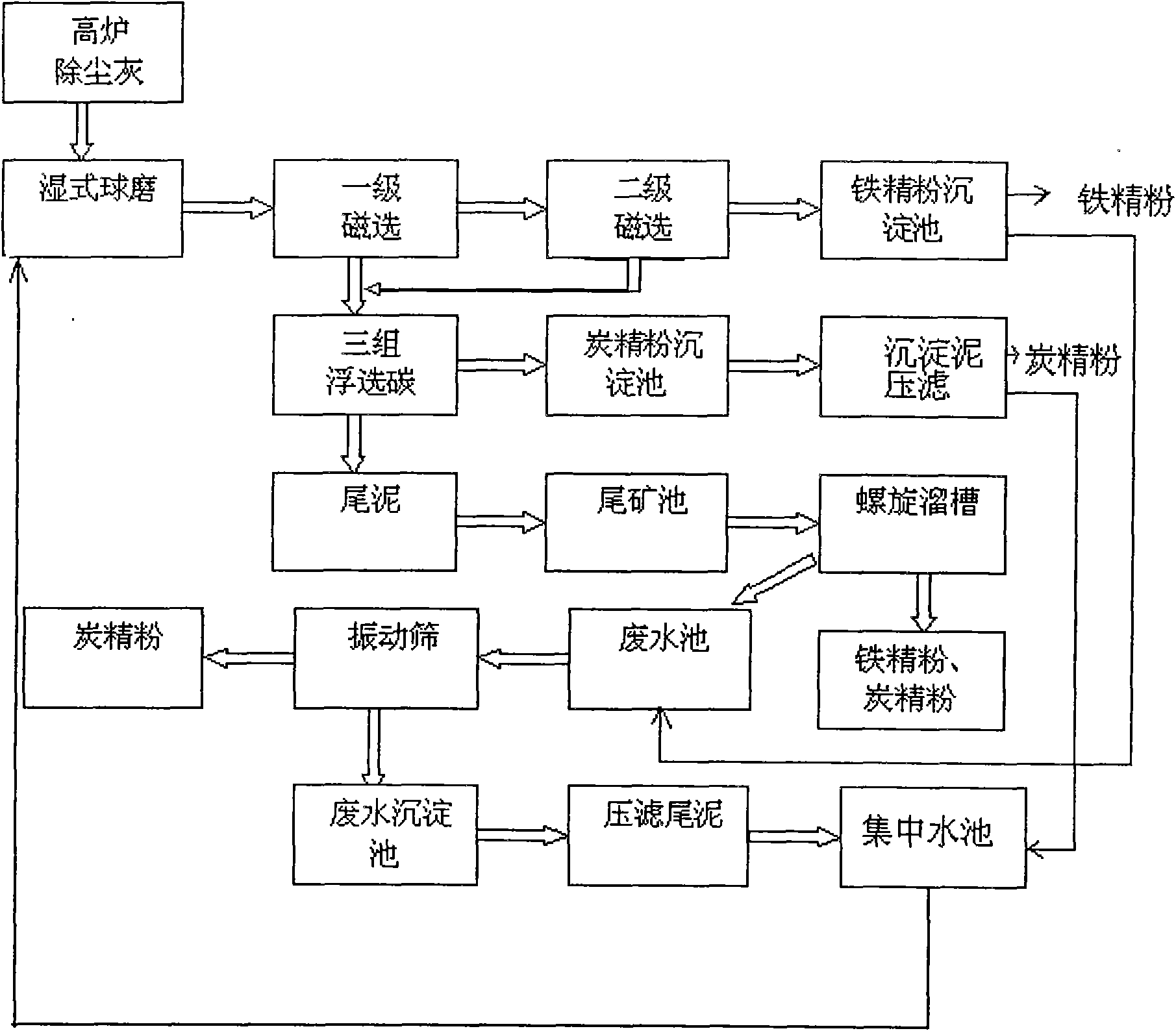

Image

Examples

Embodiment Construction

[0018] A comprehensive treatment method for blast furnace dust removal, comprising the following process steps:

[0019] (1) Blast furnace dust falls from the receiving bin through the pendulum feeder onto the belt of the belt conveyor. A water-adding hopper is provided at the end of the belt conveyor. After adding water to the blast furnace dust, (as long as the water and ash can Just flow) take water as the carrier and enter the wet ball mill in a spiral way for ball milling. (The wet ball mill can not only complete the slurry mixing function, but also grind the hard shell formed by the iron-containing material of the dust removal ash, coal powder, ash, and acid-base flux to improve the quality of the final product.) Blast furnace dust removal in the ball mill After being fully mixed and finely ground, it overflows the ball mill and enters the discharge chute.

[0020] (2) The blast furnace dedusting ash slurry after ball milling naturally flows into the first-stage magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com